Development of Novel Microcomposite Materials from Coal Fly Ash and Incense Sticks Ash Waste and Their Application for Remediation of Malachite Green Dye from Aqueous Solutions

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Collection and Processing of Incense Sticks Ash

2.2.2. Fly Ash Collection

2.2.3. Preparation of ISA-CFA Alkali-Activated Sintered Product

2.2.4. Dye Removal Study by Batch Adsorption Method

2.2.5. Leaching of Al, Si, Mg, and Na from ICCa Adsorbent in Aqueous Solution

3. Characterization of ISA and Alkali-Activated ISA Samples

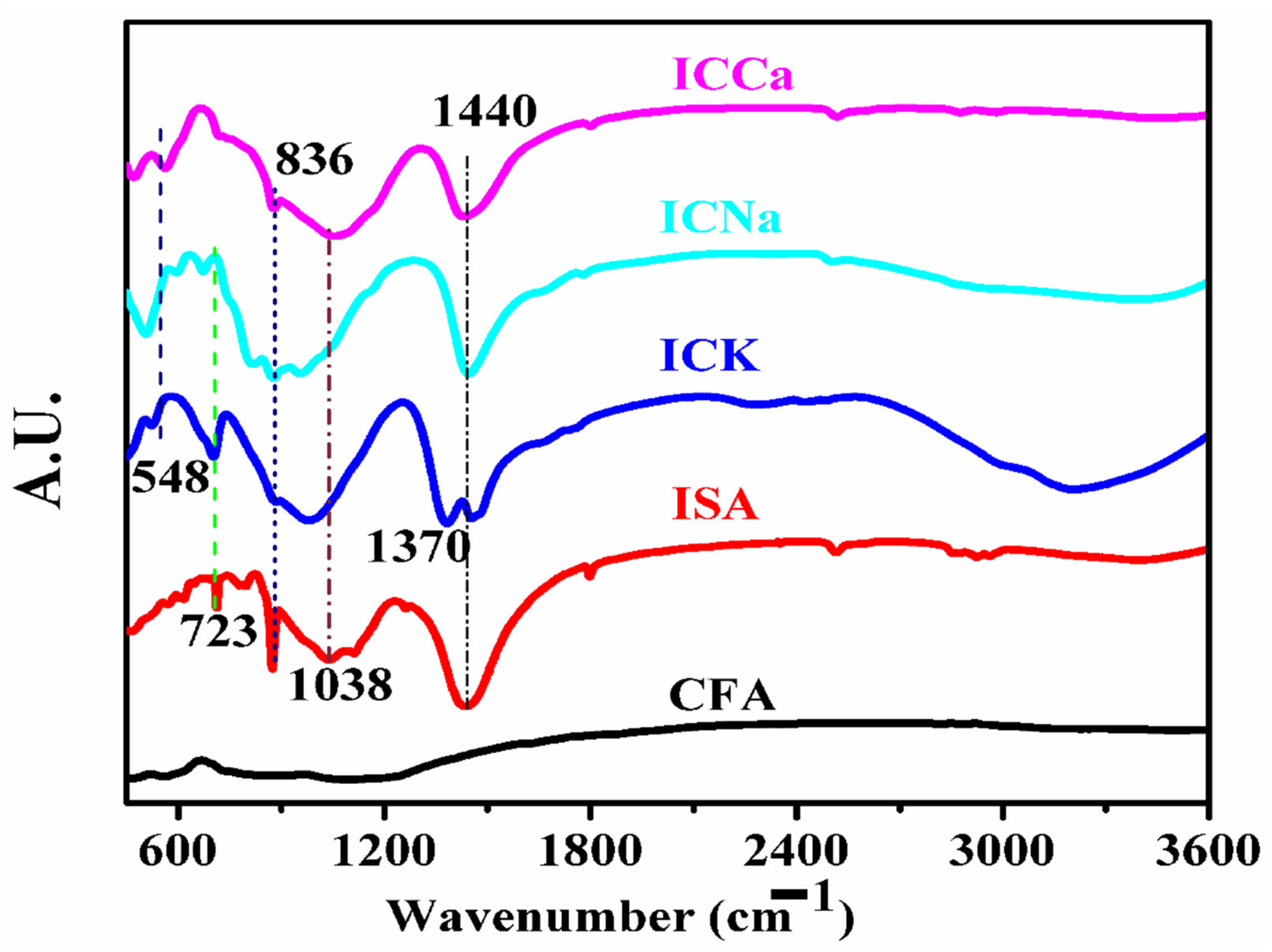

3.1. FTIR Measurement

3.2. XRD Analysis

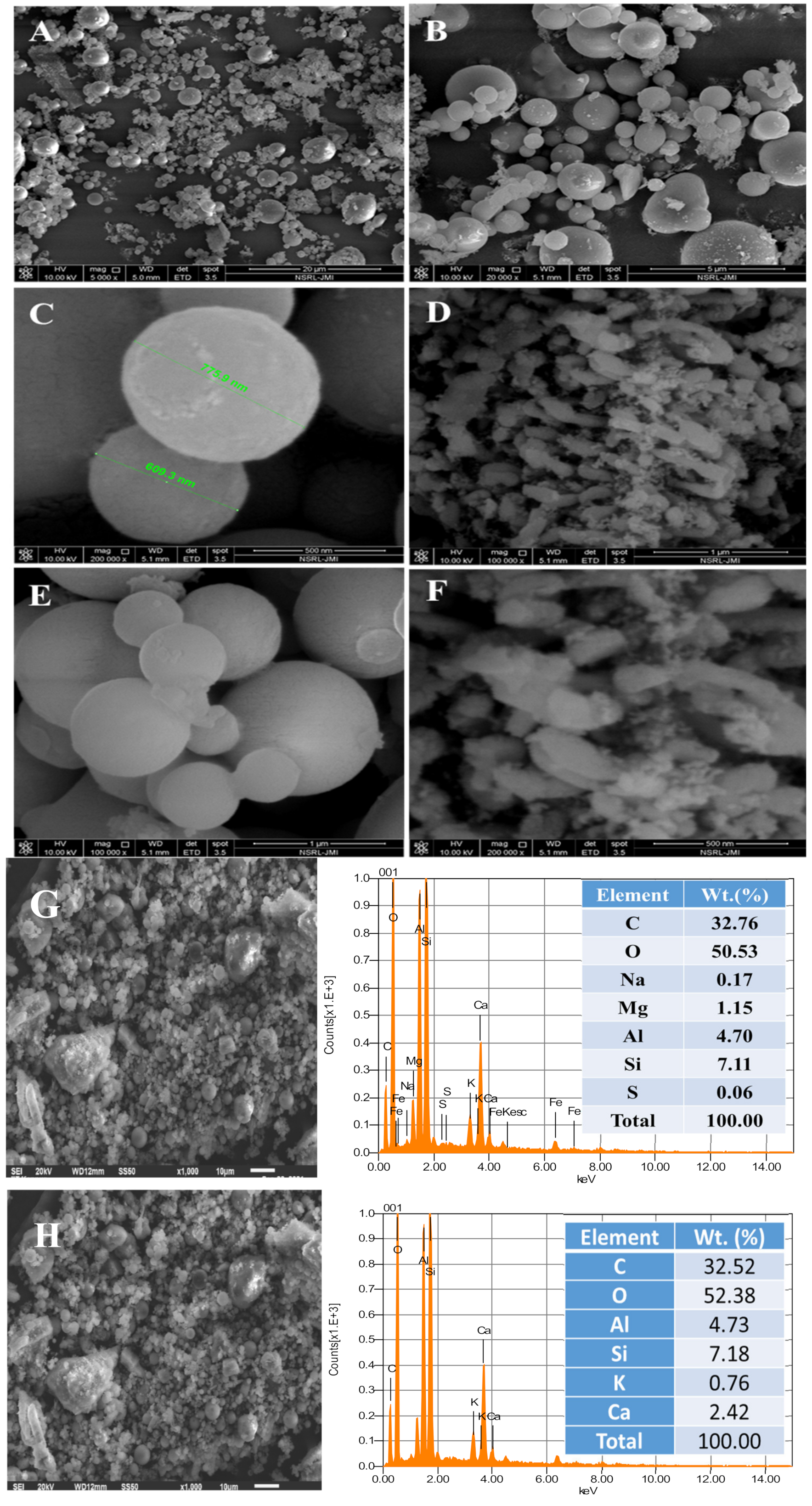

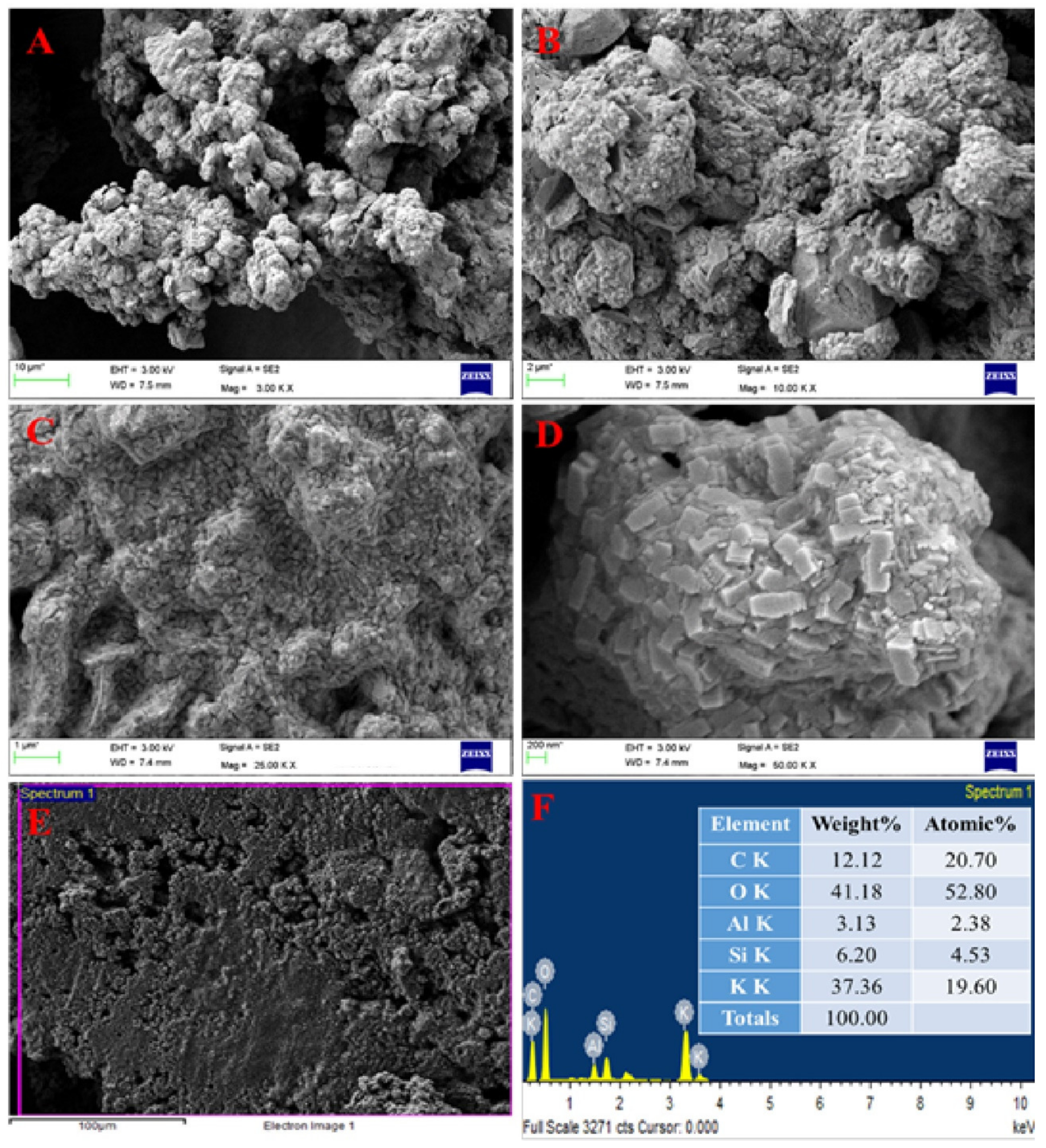

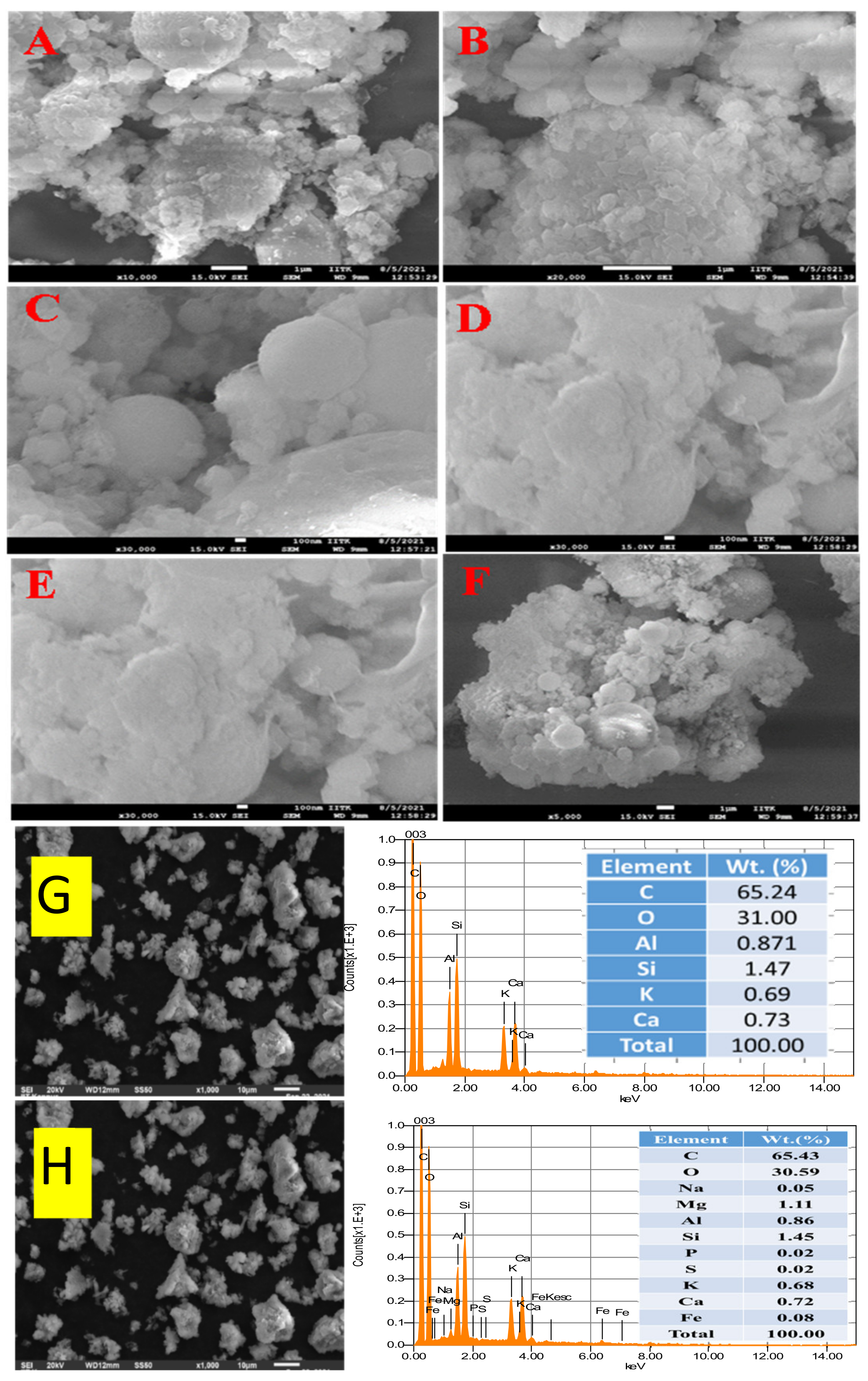

3.3. FESEM

3.4. Electron Dispersive X-ray (EDX)/(EDS)

4. Results and Discussion

4.1. FTIR for Microstructure Analysis

4.2. XRD Analysis of Samples for Phase Identification

4.3. FESEM Analysis for Morphological Properties

CFA-ISA

5. Dye Remediation Study by the Adsorbents

MG Removal by ISA:CFA as an Adsorbent

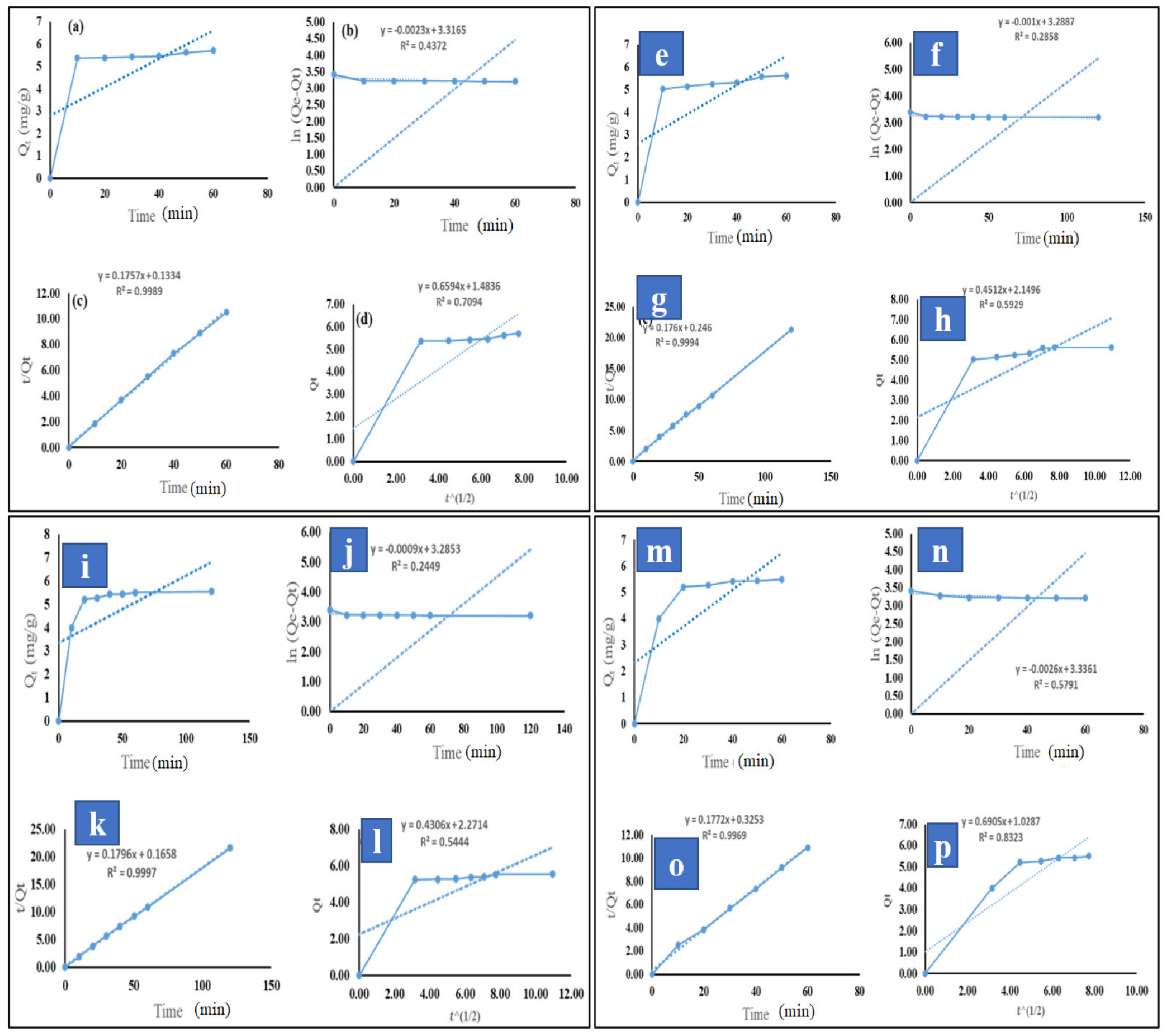

6. Kinetic Study of Malachite Green Removal by the Adsorbents

7. Effect on the Development as an Adsorbent for Wastewater Treatment

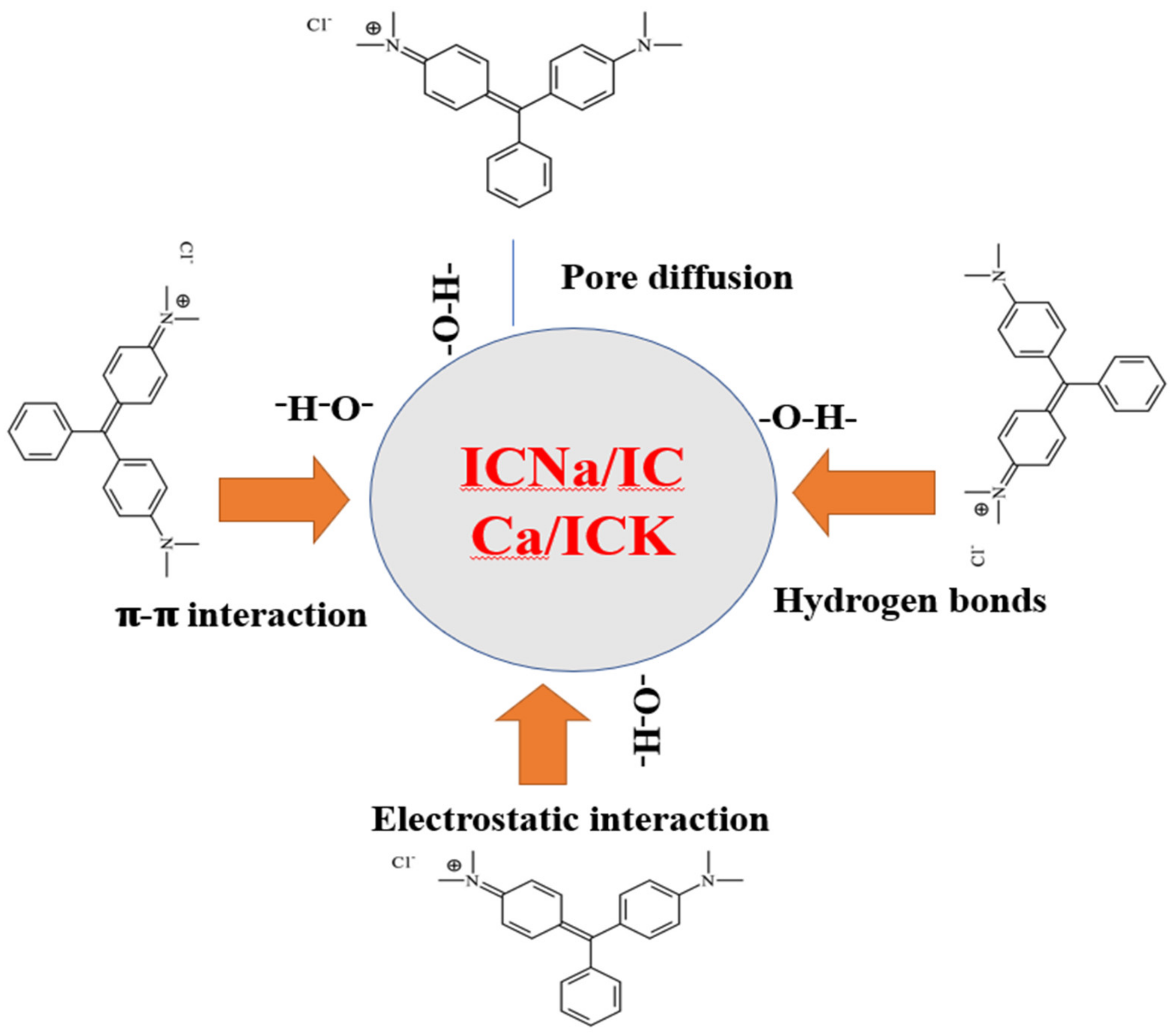

Adsorption Mechanism of Malachite Green by Adsorbents

8. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Debnath, N.K.; Acharya, V.; Jangu, S.; Singh, P.; Majhi, M.R.; Singh, V.K. Characterization of fly ash solid-waste for low-cost insulation refractory bricks. Mater. Today Proc. 2021, 47, 1598–1600. [Google Scholar] [CrossRef]

- Malav, L.C.; Yadav, K.K.; Gupta, N.; Kumar, S.; Sharma, G.K.; Krishnan, S.; Rezania, S.; Kamyab, H.; Pham, Q.B.; Yadav, S.; et al. A review on municipal solid waste as a renewable source for waste-to-energy project in India: Current practices, challenges, and future opportunities. J. Clean Prod. 2020, 277, 123227. [Google Scholar] [CrossRef]

- Alharthi, M.; Hanif, I.; Alamoudi, H. Impact of environmental pollution on human health and financial status of households in MENA countries: Future of using renewable energy to eliminate the environmental pollution. Renew. Energy 2022, 190, 338–346. [Google Scholar] [CrossRef]

- Yadav, V.K.; Yadav, K.K.; Alam, J.; Cabral-Pinto, M.; Gnanamoorthy, G.; Alhoshan, M.; Kamyab, H.; Hamid, A.A.; Ali, F.A.A.; Shukla, A.K. Transformation of hazardous sacred incense sticks ash waste into less toxic product by sequential approach prior to their disposal into the water bodies. Environ. Sci. Pollut. Res. 2021, 1–13. [Google Scholar] [CrossRef]

- Rafieizonooz, M.; Khankhaje, E.; Rezania, S. Assessment of environmental and chemical properties of coal ashes including fly ash and bottom ash, and coal ash concrete. J. Build. Eng. 2022, 49, 104040. [Google Scholar] [CrossRef]

- Kozáková, Ľ.; Bakalár, T.; Zeleňák, M.; Praščáková, M. Solidification of MSWI fly-ash with regard to hazardous metals leaching. Acta Montan. Slovaca 2013, 18, 129–139. [Google Scholar]

- Sun, X.; Li, J.; Zhao, X.; Zhu, B.; Zhang, G. A Review on the Management of Municipal Solid Waste Fly Ash in American. Procedia Environ. Sci. 2016, 31, 535–540. [Google Scholar] [CrossRef] [Green Version]

- Roy, D.; Tarafdar, A. Solid Waste Management and Landfill in High-Income Countries. In Circular Economy in Municipal Solid Waste Landfilling: Biomining & Leachate Treatment: Sustainable Solid Waste Management: Waste to Wealth; Pathak, P., Palani, S.G., Eds.; Springer International Publishing: Cham, Switzerland, 2022; pp. 1–23. [Google Scholar] [CrossRef]

- Yadav, V.K.; Kumar, P.; Kalasariya, H.; Choudhary, N.; Singh, B.; Gnanamoorthy, G.; Gupta, N.; Khan, S.H.; Khayal, A. The current scenario of Indian incense sticks market and their impact on the Indian economy. Ind. J. Pure Appl. Biosci. 2020, 8, 627–636. [Google Scholar] [CrossRef]

- Adewuyi, Y.G. Recent Advances in Fly-Ash-Based Geopolymers: Potential on the Utilization for Sustainable Environmental Remediation. ACS Omega 2021, 6, 15532–15542. [Google Scholar] [CrossRef]

- Khan, M.A.; Memon, S.A.; Farooq, F.; Javed, M.F.; Aslam, F.; Alyousef, R. Compressive Strength of Fly-Ash-Based Geopolymer Concrete by Gene Expression Programming and Random Forest. Adv. Civ. Eng. 2021, 2021, 6618407. [Google Scholar] [CrossRef]

- Hwang, S.; Yeon, J.H. Fly Ash-Added, Seawater-Mixed Pervious Concrete: Compressive Strength, Permeability, and Phosphorus Removal. Materials 2022, 15, 1407. [Google Scholar] [CrossRef] [PubMed]

- Yadav, V.K.; Suriyaprabha, R.; Inwati, G.K.; Gupta, N.; Singh, B.; Lal, C.; Kumar, P.; Godha, M.; Kalasariya, H. A Noble and Economical Method for the Synthesis of Low Cost Zeolites From Coal Fly Ash Waste. Adv. Mater. Process. Technol. 2021, 1–19. [Google Scholar] [CrossRef]

- Yatsenko, E.A.; Goltsman, B.M.; Trofimov, S.V.; Kurdashov, V.M.; Novikov, Y.V.; Smoliy, V.A.; Ryabova, A.V.; Klimova, L.V. Improving the Properties of Porous Geopolymers Based on TPP Ash and Slag Waste by Adjusting Their Chemical Composition. Materials 2022, 15, 2587. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Khalili, N. Fly-Ash-Modified Calcium-Based Sorbents Tailored to CO2 Capture. Ind. Eng. Chem. Res. 2017, 56, 1888–1894. [Google Scholar] [CrossRef]

- Yadav, V.K.; Yadav, K.K.; Tirth, V.; Jangid, A.; Gnanamoorthy, G.; Choudhary, N.; Islam, S.; Gupta, N.; Son, C.T.; Jeon, B.H. Recent advances in methods for recovery of cenospheres from fly ash and their emerging applications in ceramics, composites, polymers and environmental cleanup. Crystals 2021, 11, 1067. [Google Scholar] [CrossRef]

- Kumar, P.; Singh, N. Influence of recycled concrete aggregates and Coal Bottom Ash on various properties of high volume fly ash-self compacting concrete. J. Build. Eng. 2020, 32, 101491. [Google Scholar] [CrossRef]

- Iyer, R.S.; Scott, J.A. Power station fly ash—A review of value-added utilization outside of the construction industry. Resour. Conserv. Recycl. 2001, 31, 217–228. [Google Scholar] [CrossRef]

- Ściubidło, A.; Majchrzak-Kucęba, I. Exhaust gas purification process using fly ash-based sorbents. Fuel 2019, 258, 116126. [Google Scholar] [CrossRef]

- Gadore, V.; Ahmaruzzaman, M.D. Fly ash–based nanocomposites: A potential material for effective photocatalytic degradation/elimination of emerging organic pollutants from aqueous stream. Environ. Sci. Pollut. Res. 2021, 28, 46910–46933. [Google Scholar] [CrossRef]

- Yadav, V.K.; Inwati, G.K.; Ali, D.; Gnanamoorthy, G.; Bera, S.P.; Khan, S.H.; Choudhary, N.; Kumar, G.; Chaurasia, T.P.; Basnet, A. Remediation of Azure A Dye from Aqueous Solution by Using Surface-Modified Coal Fly Ash Extracted Ferrospheres by Mineral Acids and Toxicity Assessment. Adsorpt. Sci. Technol. 2022, 2022, 7012889. [Google Scholar] [CrossRef]

- Yadav, V.K.; Malik, P.; Tirth, V.; Khan, S.H.; Yadav, K.K.; Islam, S.; Choudhary, N.; Inwati, G.K.; Arabi, A.; Kim, D.-H. Health and Environmental Risks of Incense Smoke: Mechanistic Insights and Cumulative Evidence. J. Inflamm. Res. 2022, 15, 2665. [Google Scholar] [CrossRef] [PubMed]

- Yadav, V.K.; Singh, B.; Choudhary, N. Characterization of Indian incense stick powders for their physical, chemical and mineralogical properties. World J. Environ. Biosci. 2020, 9, 39–43. [Google Scholar]

- Yadav, V.K.; Choudhary, N.; Heena Khan, S.; Khayal, A.; Ravi, R.K.; Kumar, P.; Modi, S.; Gnanamoorthy, G. Incense and Incense Sticks: Types, Components, Origin and Their Religious Beliefs and Importance among Different Religions. J. Bio. Innov. 2020, 9, 1420–1439. [Google Scholar] [CrossRef]

- Yadav, V.K.; Yadav, K.K.; Gnanamoorthy, G.; Choudhary, N.; Khan, S.H.; Gupta, N.; Kamyab, H.; Bach, Q.-V. A novel synthesis and characterization of polyhedral shaped amorphous iron oxide nanoparticles from incense sticks ash waste. Environ. Technol. Innov. 2020, 20, 101089. [Google Scholar] [CrossRef]

- Yadav, V.K.; Gnanamoorthy, G.; Ali, D.; Bera, S.P.; Roy, A.; Kumar, G.; Choudhary, N.; Kalasariya, H.; Basnet, A. Cytotoxicity, Removal of Congo Red Dye in Aqueous Solution Using Synthesized Amorphous Iron Oxide Nanoparticles from Incense Sticks Ash Waste. J. Nanomater. 2022, 2022, 1–12. [Google Scholar] [CrossRef]

- Yadav, V.K.; Yadav, K.K.; Gacem, A.; Gnanamoorthy, G.; Ali, I.H.; Khan, S.H.; Jeon, B.-H.; Kamyab, H.; Inwati, G.K.; Choudhary, N. A novel approach for the synthesis of vaterite and calcite from incense sticks ash waste and their potential for remediation of dyes from aqueous solution. Sustain. Chem. Pharm. 2022, 29, 100756. [Google Scholar] [CrossRef]

- Šulc, R.; Šídlová, M.; Formáček, P.; Snop, R.; Škvára, F.; Polonská, A. A Study of Physicochemical Properties of Stockpile and Ponded Coal Ash. Materials 2022, 15, 3653. [Google Scholar] [CrossRef]

- Jain, S.N.; Tamboli, S.R.; Sutar, D.S.; Mawal, V.N.; Shaikh, A.A.; Prajapati, A.A. Incense stick ash as a novel and sustainable adsorbent for sequestration of Victoria Blue from aqueous phase. Sustain. Chem. Pharm. 2020, 15, 100199. [Google Scholar] [CrossRef]

- Yadav, V.K.; Choudhary, N.; Tirth, V.; Kalasariya, H.; Gnanamoorthy, G.; Algahtani, A.; Yadav, K.K.; Soni, S.; Islam, S.; Yadav, S. A short review on the utilization of incense sticks ash as an emerging and overlooked material for the synthesis of zeolites. Crystals 2021, 11, 1255. [Google Scholar] [CrossRef]

- Yaseen, D.A.; Scholz, M. Textile dye wastewater characteristics and constituents of synthetic effluents: A critical review. Int. J. Environ. Sci. Technol. 2019, 16, 1193–1226. [Google Scholar] [CrossRef] [Green Version]

- Maheshwari, K.; Agrawal, M.; Gupta, A.B. Dye Pollution in Water and Wastewater. In Novel Materials for Dye-Containing Wastewater Treatment; Muthu, S.S., Khadir, A., Eds.; Springer: Singapore, 2021; pp. 1–25. [Google Scholar] [CrossRef]

- Patel, H.; Yadav, V.K.; Yadav, K.K.; Choudhary, N.; Kalasariya, H.; Alam, M.M.; Gacem, A.; Amanullah, M.; Ibrahium, H.A.; Park, J.-W.; et al. A Recent and Systemic Approach towards Microbial Biodegradation of Dyes from Textile Industries. Water 2022, 14, 3163. [Google Scholar] [CrossRef]

- Pare, B.; Barde, V.S.; Solanki, V.S.; Agarwal, N.; Yadav, V.K.; Alam, M.M.; Gacem, A.; Alsufyani, T.; Khedher, N.; Park, J.W.; et al. Green Synthesis and Characterization of LED-Irradiation-Responsive Nano ZnO Catalyst and Photocatalytic Mineralization of Malachite Green Dye. Water 2022, 14, 3221. [Google Scholar] [CrossRef]

- Patel, Y.; Chhaya, U.; Rudakiya, D.M.; Joshi, S. Biological Decolorization and Degradation of Synthetic Dyes: A Green Step Toward Sustainable Environment. In Microbial Rejuvenation of Polluted Environment; Panpatte, D.G., Jhala, Y.K., Eds.; Springer: Singapore, 2021; Volume 2, pp. 77–110. [Google Scholar] [CrossRef]

- Gnanamoorthy, G.; Yadav, V.K.; Ali, D.; Ramar, K.; Ali, H.; Narayanan, V. New designing (NH4) 2SiP4O13 nanowires and effective photocatalytic degradation of Malachite Green. Chem. Phys. Lett. 2022, 803, 139817. [Google Scholar] [CrossRef]

- Argumedo-Delira, R.; Gómez-Martínez, M.J.; Uribe-Kaffure, R. Trichoderma biomass as an alternative for removal of congo red and malachite green industrial dyes. Appl. Sci. 2021, 11, 448. [Google Scholar] [CrossRef]

- Caponi, N.; Collazzo, G.C.; Jahn, S.L.; Dotto, G.L.; Mazutti, M.A.; Foletto, E.L. Use of Brazilian kaolin as a potential low-cost adsorbent for the removal of malachite green from colored effluents. Mater. Res. 2017, 20, 14–22. [Google Scholar] [CrossRef] [Green Version]

- Igwegbe, C.A.; Ighalo, J.O.; Onyechi, K.K.; Onukwuli, O.D. Adsorption of Congo red and malachite green using H3PO4 and NaCl-modified activated carbon from rubber (Hevea brasiliensis) seed shells. Sustain. Water Resour. Manag. 2021, 7, 63. [Google Scholar] [CrossRef]

- Gupta, N.; Yadav, V.K.; Yadav, K.K.; Alwetaishi, M.; Gnanamoorthy, G.; Singh, B.; Jeon, B.-H.; Cabral-Pinto, M.M.S.; Choudhary, N.; Ali, D. Recovery of iron nanominerals from sacred incense sticks ash waste collected from temples by wet and dry magnetic separation method. Environ. Technol. Innov. 2022, 25, 102150. [Google Scholar] [CrossRef]

- Yadav, V.K.; Gnanamoorthy, G.; Yadav, K.K.; Ali, I.H.; Bagabas, A.A.; Choudhary, N.; Yadav, S.; Suriyaprabha, R.; Islam, S.; Modi, S. Utilization of Incense Stick Ash in Hydrometallurgy Methods for Extracting Oxides of Fe, Al, Si, and Ca. Materials 2022, 15, 1879. [Google Scholar] [CrossRef]

- Singh, D.; Yadav, V.K.; Ali, D.; Soni, S.; Kumar, G.; Dawane, V.; Chaurasia, T.P. Isolation and Characterization of Siderophores Producing Chemolithotrophic Bacteria from the Coal Samples of the Aluminum Industry. Geomicrobiol. J. 2022, 1–7. [Google Scholar] [CrossRef]

- Li, Y.J.; Yeung, J.W.T.; Leung, T.P.I.; Lau, A.P.S.; Chan, C.K. Characterization of organic particles from incense burning using an aerodyne high-resolution time-of-flight aerosol mass spectrometer. Aerosol Sci. Technol. 2012, 46, 654–665. [Google Scholar] [CrossRef]

- Chancey, R.T.; Stutzman, P.; Juenger, M.C.G.; Fowler, D.W. Comprehensive phase characterization of crystalline and amorphous phases of a Class F fly ash. Cem. Concr. Res. 2010, 40, 146–156. [Google Scholar] [CrossRef]

- Yadav, V.K.; Gnanamoorthy, G.; Cabral-Pinto, M.M.S.; Alam, J.; Ahamed, M.; Gupta, N.; Singh, B.; Choudhary, N.; Inwati, G.K.; Yadav, K.K. Variations and similarities in structural, chemical, and elemental properties on the ashes derived from the coal due to their combustion in open and controlled manner. Environ. Sci. Pollut. Res. 2021, 28, 32609–32625. [Google Scholar] [CrossRef] [PubMed]

- Balapour, M.; Khaneghahi, M.H.; Garboczi, E.J.; Hsuan, Y.G.; Hun, D.E.; Farnam, Y. Off-spec fly ash-based lightweight aggregate properties and their influence on the fresh, mechanical, and hydration properties of lightweight concrete: A comparative study. Constr. Build. Mater. 2022, 342, 128013. [Google Scholar] [CrossRef]

- Balapour, M.; Thway, T.; Rao, R.; Moser, N.; Garboczi, E.J.; Hsuan, Y.G.; Farnam, Y. A thermodynamics-guided framework to design lightweight aggregate from waste coal combustion fly ash. Resour. Conserv. Recycl. 2022, 178, 106050. [Google Scholar] [CrossRef]

- Wen, S.; Buyukada, M.; Evrendilek, F.; Liu, J. Uncertainty and sensitivity analyses of co-combustion/pyrolysis of textile dyeing sludge and incense sticks: Regression and machine-learning models. Renew. Energy 2020, 151, 463–474. [Google Scholar] [CrossRef]

- Hoang, N.; Ngoc, L. Characterization of Geopolymer-based Materials Synthesized from Fly Ash and Rice Husk Ash. Available Online WwwJsaerCom. J. Sci. Eng. Res. 2018, 270, 270–277. [Google Scholar]

- Lo, F.-C.; Lee, M.-G.; Lo, S.L. Effect of coal ash and rice husk ash partial replacement in ordinary Portland cement on pervious concrete. Constr. Build. Mater. 2021, 286, 122947. [Google Scholar] [CrossRef]

- Gupta, V.K.; Sharma, S. Removal of Zinc from Aqueous Solutions Using Bagasse Fly Ash—A Low Cost Adsorbent. Ind. Eng. Chem. Res. 2003, 42, 6619–6624. [Google Scholar] [CrossRef]

- Patil, C.; Manjunath, M.; Hosamane, S.; Bandekar, S.; Athani, R. Pozzolonic activity and strength activity index of bagasse ash and fly ash blended cement mortar. Mater. Today Proc. 2021, 42, 1456–1461. [Google Scholar] [CrossRef]

- Murukutti, M.K.; Jena, H. Synthesis of nano-crystalline zeolite-A and zeolite-X from Indian coal fly ash, its characterization and performance evaluation for the removal of Cs+ and Sr2+ from simulated nuclear waste. J. Hazardous Mater. 2022, 423, 127085. [Google Scholar] [CrossRef]

- Li, L.; Wei, X.-Y.; Liu, G.-H.; Li, Z.; Li, J.-H.; Liu, F.-J.; Kong, Q.-Q.; Fan, Z.-C.; Zong, Z.-M.; Bai, H.-C. Selective catalytic hydroconversion of organic waster oil to cyclanes over a coal fly ash-derived zeolite-supported nickel catalyst: Waster to energy. Fuel 2022, 316, 123185. [Google Scholar] [CrossRef]

- Roulia, M.; Koukouza, K.; Stamatakis, M.; Vasilatos, C. Fly-ash derived Na-P1, natural zeolite tuffs and diatomite in motor oil retention. Clean. Mater. 2022, 4, 100063. [Google Scholar] [CrossRef]

- Inada, M.; Eguchi, Y.; Enomoto, N.; Hojo, J. Synthesis of zeolite from coal fly ashes with different silica–alumina composition. Fuel 2004, 84, 299–304. [Google Scholar] [CrossRef]

- Lim, J.M.; Park, J.; Park, J.T.; Bae, S. Preparation of quasi-solid-state electrolytes using a coal fly ash derived zeolite-X and -A for dye-sensitized solar cells. J. Ind. Eng. Chem. 2019, 71, 378–386. [Google Scholar] [CrossRef]

- Yadav, V.K.; Choudhary, N.; Ali, D.; Kumar, G.; Gnanamoorthy, G.; Khan, A.U.; Kumar, P.; Hari Kumar, S.; Tizazu, B.Z. Determination of Adsorption of Methylene Blue Dye by Incense Stick Ash Waste and Its Toxicity on RTG-2 Cells. Adsorpt. Sci. Technol. 2022, 2022, 1–10. [Google Scholar] [CrossRef]

- Parvaiz, M.R.; Mohanty, S.; Nayak, S.K.; Mahanwar, P.A. Effect of surface modification of fly ash on the mechanical, thermal, electrical and morphological properties of polyetheretherketone composites. Mater. Sci. Eng. A 2011, 528, 4277–4286. [Google Scholar] [CrossRef]

- Du, X.; Huang, Z.; Ding, Y.; Xu, W.; Zhang, M.; Wei, L.; Yang, H. Feasibility Study of Grinding Circulating Fluidized Bed Ash as Cement Admixture. Materials 2022, 15, 5610. [Google Scholar] [CrossRef]

- Yadav, V.K.; Fulekar, M.H. Advances in methods for recovery of ferrous, alumina, and silica nanoparticles from fly ash waste. Ceramics 2020, 3, 384–420. [Google Scholar] [CrossRef]

- Yadav, V.K.; Fulekar, M.H. Green synthesis and characterization of amorphous silica nanoparticles from fly ash. Mater. Today Proc. 2019, 18, 4351–4359. [Google Scholar] [CrossRef]

- Yadav, V.K.; Saxena, P.; Lal, C.; Gnanamoorthy, G.; Choudhary, N.; Singh, B.; Tavker, N.; Kalasariya, H.; Kumar, P. Synthesis and Characterization of Mullites From Silicoaluminous Fly Ash Waste. Int. J. Appl. Nanotechnol. Res. 2020, 5, 10–25. [Google Scholar] [CrossRef]

- Kiefer, J.; Stärk, A.; Kiefer, A.L.; Glade, H. Infrared Spectroscopic Analysis of the Inorganic Deposits from Water in Domestic and Technical Heat Exchangers. Energies 2018, 11, 798. [Google Scholar] [CrossRef] [Green Version]

- Yadav, V.K.; Gacem, A.; Choudhary, N.; Rai, A.; Kumar, P.; Yadav, K.K.; Abbas, M.; Khedher, N.B.; Awwad, N.S.; Barik, D.; et al. Status of Coal-Based Thermal Power Plants, Coal Fly Ash Production, Utilization in India and Their Emerging Applications. Minerals 2022, 12, 1503. [Google Scholar] [CrossRef]

- See, S.W.; Balasubramanian, R.; Man Joshi, U. Physical characteristics of nanoparticles emitted from incense smoke. Sci. Technol. Adv. Mater. 2007, 8, 25–32. [Google Scholar] [CrossRef] [Green Version]

- Lin, T.-C.; Krishnaswamy, G.; Chi, D.S. Incense smoke: Clinical, structural and molecular effects on airway disease. Clin. Mol. Allergy 2008, 6, 3. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jilla, A.; Kura, B. Particulate Matter and Carbon Monoxide Emission Factors from Incense Burning. Environ. Pollut. Clim. Change 2017, 1, 1–7. [Google Scholar] [CrossRef]

- Goel, A.; Wathore, R.; Chakraborty, T.; Agrawal, M. Characteristics of exposure to particles due to incense burning inside temples in Kanpur, India. Aerosol Air Qual. Res. 2017, 17, 608–615. [Google Scholar] [CrossRef] [Green Version]

- Lee, S.C.; Wang, B. Characteristics of emissions of air pollutants from burning of incense in a large environmental chamber. Atmos. Environ. 2004, 38, 941–951. [Google Scholar] [CrossRef]

- Wen, S.; Yan, Y.; Liu, J.; Buyukada, M.; Evrendilek, F. Pyrolysis performance, kinetic, thermodynamic, product and joint optimization analyses of incense sticks in N2 and CO2 atmospheres. Renew. Energy 2019, 141, 814–827. [Google Scholar] [CrossRef]

- Peterson, J.R.; Rochelle, G.T. Aqueous reaction of fly ash and calcium hydroxide to produce calcium silicate absorbent for flue gas desulfurization. Environ. Sci. Technol. 1988, 22, 1299–1304. [Google Scholar] [CrossRef]

- Gupta, N.; Yadav, V.K.; Gacem, A.; Al-Dossari, M.; Yadav, K.K.; Abd El-Gawaad, N.S.; Ben Khedher, N.; Choudhary, N.; Kumar, P.; Cavalu, S. Deleterious Effect of Air Pollution on Human Microbial Community and Bacterial Flora: A Short Review. Int. J. Environ. Res. Public Health 2022, 19, 15494. [Google Scholar] [CrossRef]

- Das, D.; Rout, P.K. Synthesis, Characterization and Properties of Fly Ash Based Geopolymer Materials. J. Mater. Eng. Perform. 2021, 30, 3213–3231. [Google Scholar] [CrossRef]

- Miricioiu, M.G.; Niculescu, V.-C. Fly Ash, from Recycling to Potential Raw Material for Mesoporous Silica Synthesis. Nanomaterials 2020, 10, 474. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yadav, V.K.; Choudhary, N.; Ali, D.; Gnanamoorthy, G.; Inwati, G.K.; Almarzoug, M.H.A.; Kumar, G.; Khan, S.H.; Solanki, M.B. Experimental and computational approaches for the structural study of novel Ca-rich zeolites from incense stick ash and their application for wastewater treatment. Adsorpt. Sci. Technol. 2021, 2021, 1–12. [Google Scholar] [CrossRef]

- Choudhary, N.; Yadav, V.K.; Malik, P.; Khan, S.H.; Inwati, G.K.; Suriyaprabha, R.; Singh, B.; Yadav, A.K.; Ravi, R.K. Recovery of natural nanostructured minerals: Ferrospheres, plerospheres, cenospheres, and carbonaceous particles from fly ash. In Handbook of Research on Emerging Developments and Environmental Impacts of Ecological Chemistry; IGI Global: Hershey, PA, USA, 2020; pp. 450–470. [Google Scholar]

- Sunjidmaa, D.; Batdemberel, G.; Takibai, S. A Study of Ferrospheres in the Coal Fly Ash. Open J. Appl. Sci. 2019, 9, 10–16. [Google Scholar] [CrossRef] [Green Version]

- Sharonova, O.M.; Anshits, N.N.; Fedorchak, M.A.; Zhizhaev, A.M.; Anshits, A.G. Characterization of Ferrospheres Recovered from High-Calcium Fly Ash. Energy Fuels 2015, 29, 5404–5414. [Google Scholar] [CrossRef]

- Xue, Q.F.; Lu, S.G. Microstructure of ferrospheres in fly ashes: SEM, EDX and ESEM analysis. J. Zhejiang Univ. Sci. A 2008, 9, 1595–1600. [Google Scholar] [CrossRef]

- Anshits, N.N.; Fedorchak, M.A.; Zhizhaev, A.M.; Sharonova, O.M.; Anshits, A.G. Composition and Structure of Block-Type Ferrospheres Isolated from Calcium-Rich Power Plant Ash. Inorg. Mater. 2018, 54, 187–194. [Google Scholar] [CrossRef]

- Shende, D.Z.; Wasewar, K.L.; Wadatkar, S.S. Target-Specific Applications of Fly Ash Cenosphere as Smart Material. In Handbook of Nanomaterials and Nanocomposites for Energy and Environmental Applications; Kharissova, O.V., Martínez, L.M.T., Kharisov, B.I., Eds.; Springer International Publishing: Cham, Switzerland, 2020; pp. 1–22. [Google Scholar] [CrossRef]

- Yeung, K.-W.; Tang, C.-Y.; Hu, R.; Lam, C.-H.; Law, W.-C.; Tsui, G.C.-P.; Zhao, X.; Chung, J.K.-H. Fabrication of ceramic bioscaffolds from fly ash cenosphere by susceptor-assisted microwave sintering. J. Eur. Ceram. Soc. 2022, 42, 4410–4419. [Google Scholar] [CrossRef]

- Yoriya, S.; Tepsri, P. Crystal growth on cenospheres from high-calcium fly ash. Crystals 2021, 11, 919. [Google Scholar] [CrossRef]

- Scaccia, S.; Vanga, G.; Gattia, D.M.; Stendardo, S. Preparation of CaO-based sorbent from coal fly ash cenospheres for calcium looping process. J. Alloys Compd. 2019, 801, 123–129. [Google Scholar] [CrossRef]

- Nakonieczny, D.S.; Antonowicz, M.; Heim, T.; Swinarew, A.S.; Nuckowski, P.; Matus, K.; Lemanowicz, M. Cenospheres-Reinforced PA-12 Composite: Preparation, Physicochemical Properties, and Soaking Tests. Polymers 2022, 14, 2332. [Google Scholar] [CrossRef] [PubMed]

- Cheng, Z.; An, J.; Li, F.; Lu, Y.; Li, S. Effect of fly ash cenospheres on properties of multi-walled carbon nanotubes and polyvinyl alcohol fibers reinforced geopolymer composites. Ceram. Int. 2022, 48, 18956–18971. [Google Scholar] [CrossRef]

- Bijekar, S.; Padariya, H.D.; Yadav, V.K.; Gacem, A.; Hasan, M.A.; Awwad, N.S.; Yadav, K.K.; Islam, S.; Park, S.; Jeon, B.-H. The State of the Art and Emerging Trends in the Wastewater Treatment in Developing Nations. Water 2022, 14, 2537. [Google Scholar] [CrossRef]

- Musyoka, N.M.; Petrik, L.F.; Balfour, G.; Gitari, W.M.; Hums, E. Synthesis of hydroxy sodalite from coal fly ash using waste industrial brine solution. J. Environ. Sci. Health Part A 2011, 46, 1699–1707. [Google Scholar] [CrossRef] [PubMed]

- De Gennaro, B.; Aprea, P.; Liguori, B.; Galzerano, B.; Peluso, A.; Caputo, D. Zeolite-rich composite materials for environmental remediation: Arsenic removal from water. Appl. Sci. 2020, 10, 6938. [Google Scholar] [CrossRef]

- Karakaya, M.Ç.; Karakaya, N.; Yavuz, F. Geology and Conditions of Formation of the Zeolite-Bearing Deposits Southeast of Ankara (Central Turkey). Clays Clay Min. 2015, 63, 85–109. [Google Scholar] [CrossRef]

- Kumar Inwati, G.; Kumar, P.; Roos, W.D.; Swart, H.C. Thermally induced structural metamorphosis of ZnO:Rb nanostructures for antibacterial impacts. Colloids Surf B Biointerfaces 2020, 188, 110821. [Google Scholar] [CrossRef]

- Kumar, P.; Inwati, G.K.; Mathpal, M.C.; Ghosh, S.; Roos, W.D.; Swart, H.C. Defects induced enhancement of antifungal activities of Zn doped CuO nanostructures. Appl. Surf. Sci. 2021, 560, 150026. [Google Scholar] [CrossRef]

- Inwati, G.K.; Kumar, P.; Roos, W.D.; Swart, H.C.; Singh, M. UV-irradiation effects on tuning LSPR of Cu/Ag nanoclusters in ion exchanged glass matrix and its thermodynamic behaviour. J. Alloys Compd. 2020, 823, 153820. [Google Scholar] [CrossRef]

- Astuti, W.; Chafidz, A.; Wahyuni, E.T.; Prasetya, A.; Bendiyasa, I.M.; Abasaeed, A.E. Methyl violet dye removal using coal fly ash (CFA) as a dual sites adsorbent. J. Environ. Chem. Eng. 2019, 7, 103262. [Google Scholar] [CrossRef]

- Balarak, D.; Zafariyan, M.; Igwegbe, C.A.; Onyechi, K.K.; Ighalo, J.O. Adsorption of Acid Blue 92 Dye from Aqueous Solutions by Single-Walled Carbon Nanotubes: Isothermal, Kinetic, and Thermodynamic Studies. Environ. Process. 2021, 8, 869–888. [Google Scholar] [CrossRef]

- Balarak, D.; Raju, R.; Igwegbe, C.A.; Ighalo, J.O. Ultimate Eradication of Acid Orange 7 from Contaminated Liquid via Synthesized Mesoporous Goethite. J. Turk. Chem. Soc. Sect. B Chem. Eng. 2021, 4, 13–26. [Google Scholar]

| Kinetic | Parameter | Values | |||

|---|---|---|---|---|---|

| ISA:CFA | ICNa | ICCa | ICK | ||

| Pseudo-First order | Qe (mg/g) | 27.56 | 26.78 | 26.71 | 28.1 |

| k1 (min−1) | 0.159 × 10−7 | 6.94 × 10−7 | 0.625 × 106 | 1.80 × 10−6 | |

| R2 | 0.437 | 0.285 | 0.2449 | 0.5791 | |

| Pseudo-Second order | Qe (mg/g) | 5.69 | 5.68 | 5.56 | 5.64 |

| k2 (g/mg·min) | 0.2314 | 0.125 | 0.194 | 0.0965 | |

| R2 | 0.998 | 0.994 | 0.9997 | 0.9969 | |

| Intra Particle diffusion | kid (mg/g·min3/2) | 0.6594 | 0.4512 | 0.4306 | 0.6905 |

| C (mg/g) | 1.4836 | 2.1496 | 2.2714 | 1.028 | |

| R2 | 0.7094 | 0.592 | 0.5444 | 0.832 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yadav, V.K.; Singh, B.; Gacem, A.; Yadav, K.K.; Gnanamoorthy, G.; Alsufyani, T.; Hussein, H.S.; Awwad, N.S.; Verma, R.; Inwati, G.K.; et al. Development of Novel Microcomposite Materials from Coal Fly Ash and Incense Sticks Ash Waste and Their Application for Remediation of Malachite Green Dye from Aqueous Solutions. Water 2022, 14, 3871. https://doi.org/10.3390/w14233871

Yadav VK, Singh B, Gacem A, Yadav KK, Gnanamoorthy G, Alsufyani T, Hussein HS, Awwad NS, Verma R, Inwati GK, et al. Development of Novel Microcomposite Materials from Coal Fly Ash and Incense Sticks Ash Waste and Their Application for Remediation of Malachite Green Dye from Aqueous Solutions. Water. 2022; 14(23):3871. https://doi.org/10.3390/w14233871

Chicago/Turabian StyleYadav, Virendra Kumar, Bijendra Singh, Amel Gacem, Krishna Kumar Yadav, Govindhan Gnanamoorthy, Taghreed Alsufyani, Hany S. Hussein, Nasser S. Awwad, Rajesh Verma, Gajendra Kumar Inwati, and et al. 2022. "Development of Novel Microcomposite Materials from Coal Fly Ash and Incense Sticks Ash Waste and Their Application for Remediation of Malachite Green Dye from Aqueous Solutions" Water 14, no. 23: 3871. https://doi.org/10.3390/w14233871

APA StyleYadav, V. K., Singh, B., Gacem, A., Yadav, K. K., Gnanamoorthy, G., Alsufyani, T., Hussein, H. S., Awwad, N. S., Verma, R., Inwati, G. K., Swain, K., & Choudhary, N. (2022). Development of Novel Microcomposite Materials from Coal Fly Ash and Incense Sticks Ash Waste and Their Application for Remediation of Malachite Green Dye from Aqueous Solutions. Water, 14(23), 3871. https://doi.org/10.3390/w14233871