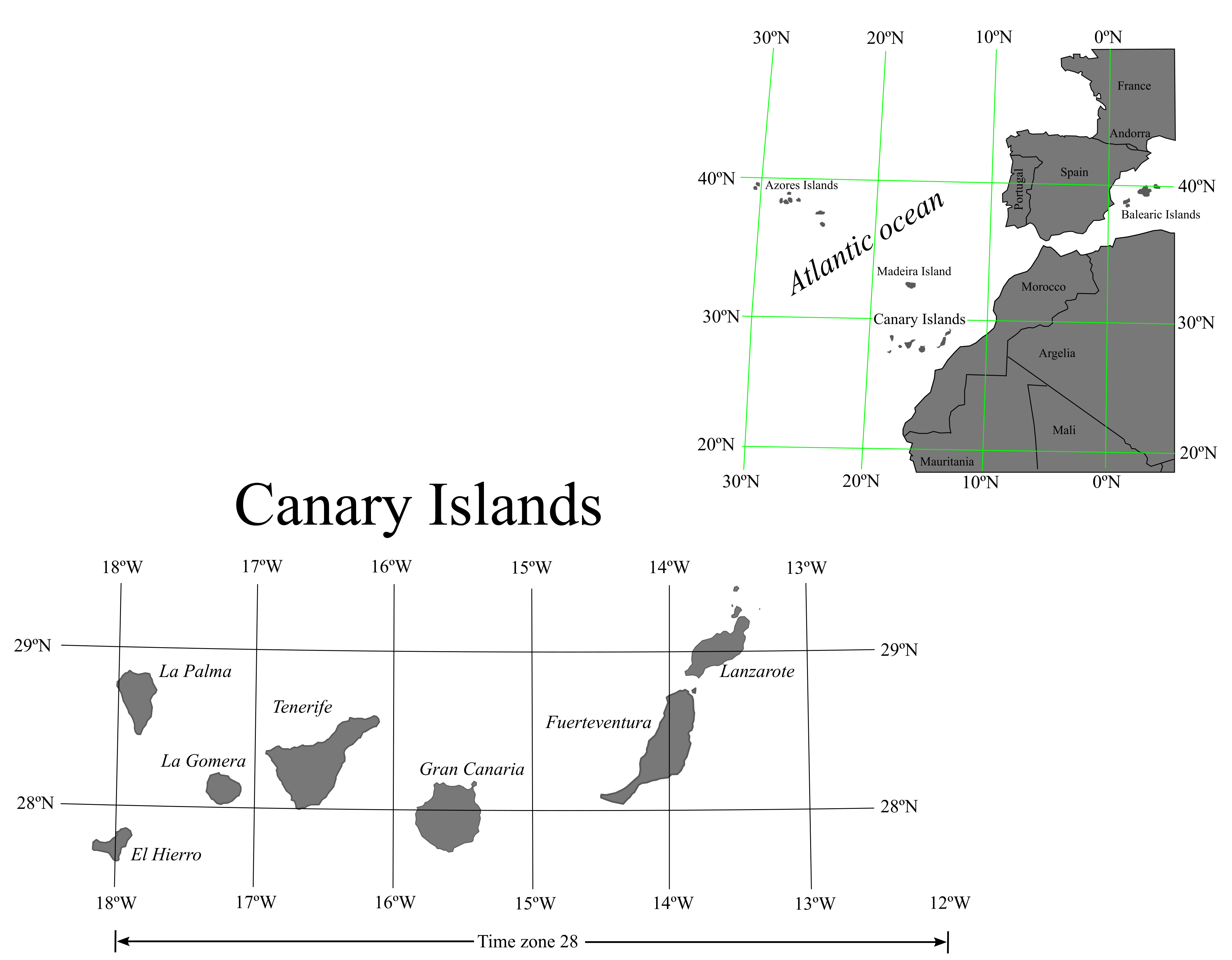

Experience of Application of Natural Treatment Systems for Wastewater (NTSW) in Livestock Farms in Canary Islands

Abstract

:1. Introduction

2. Materials and Methods

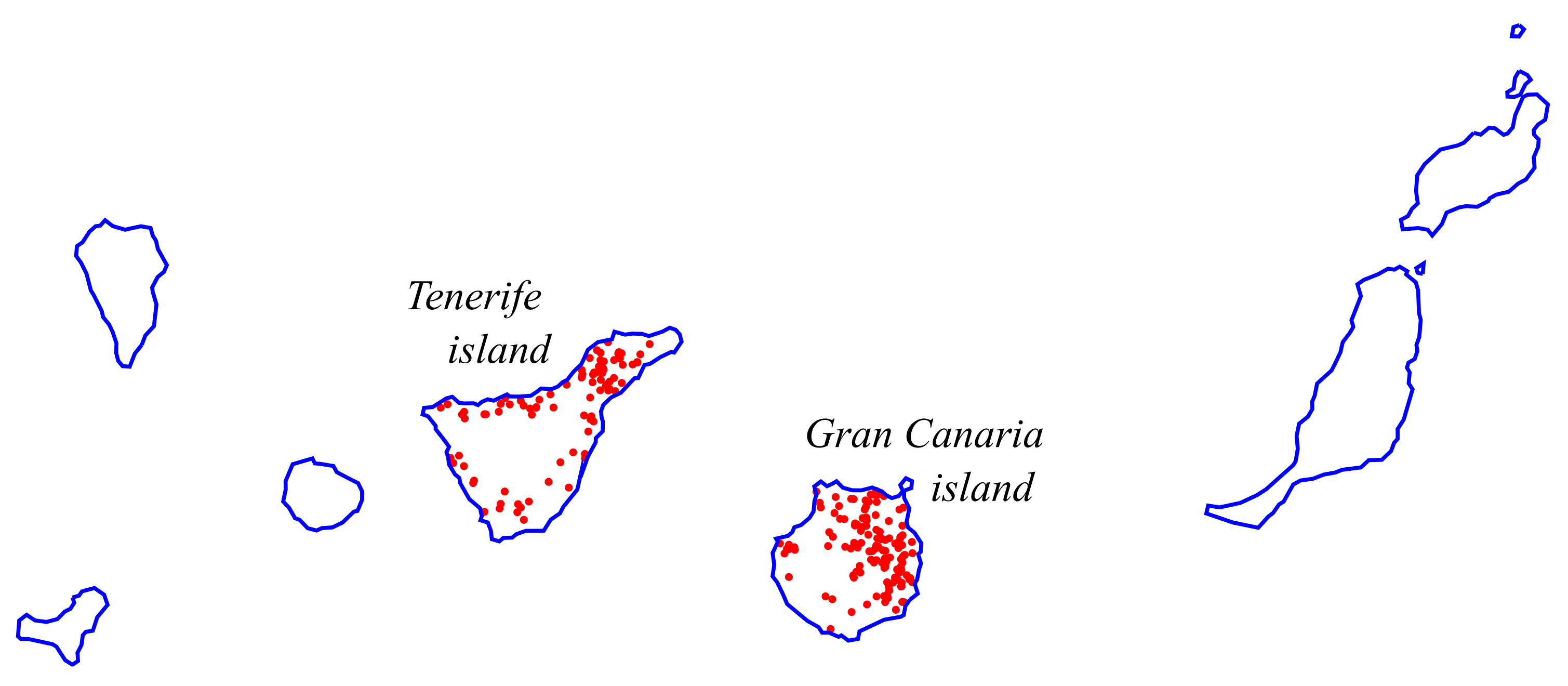

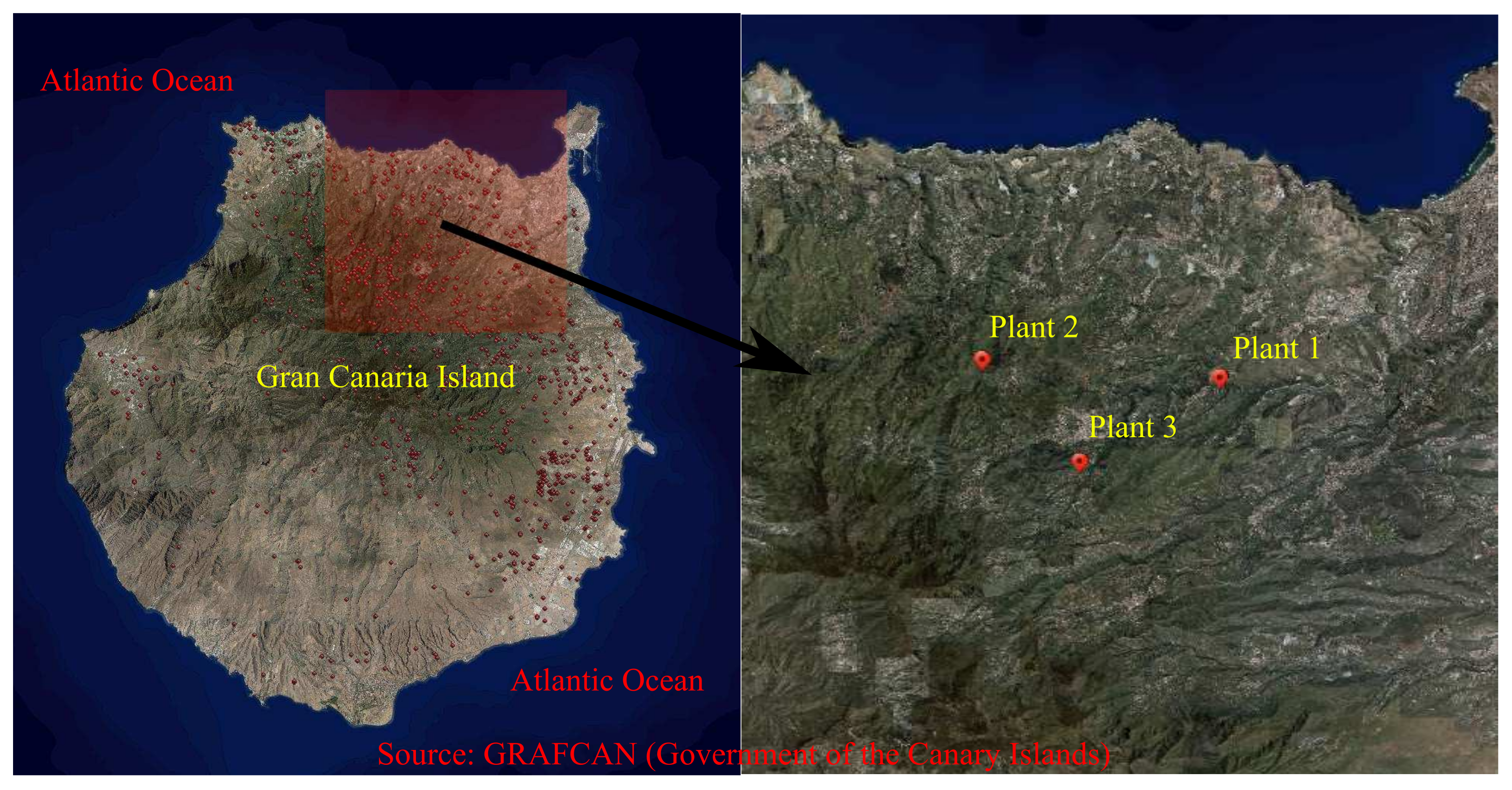

2.1. Pilot Plants Features

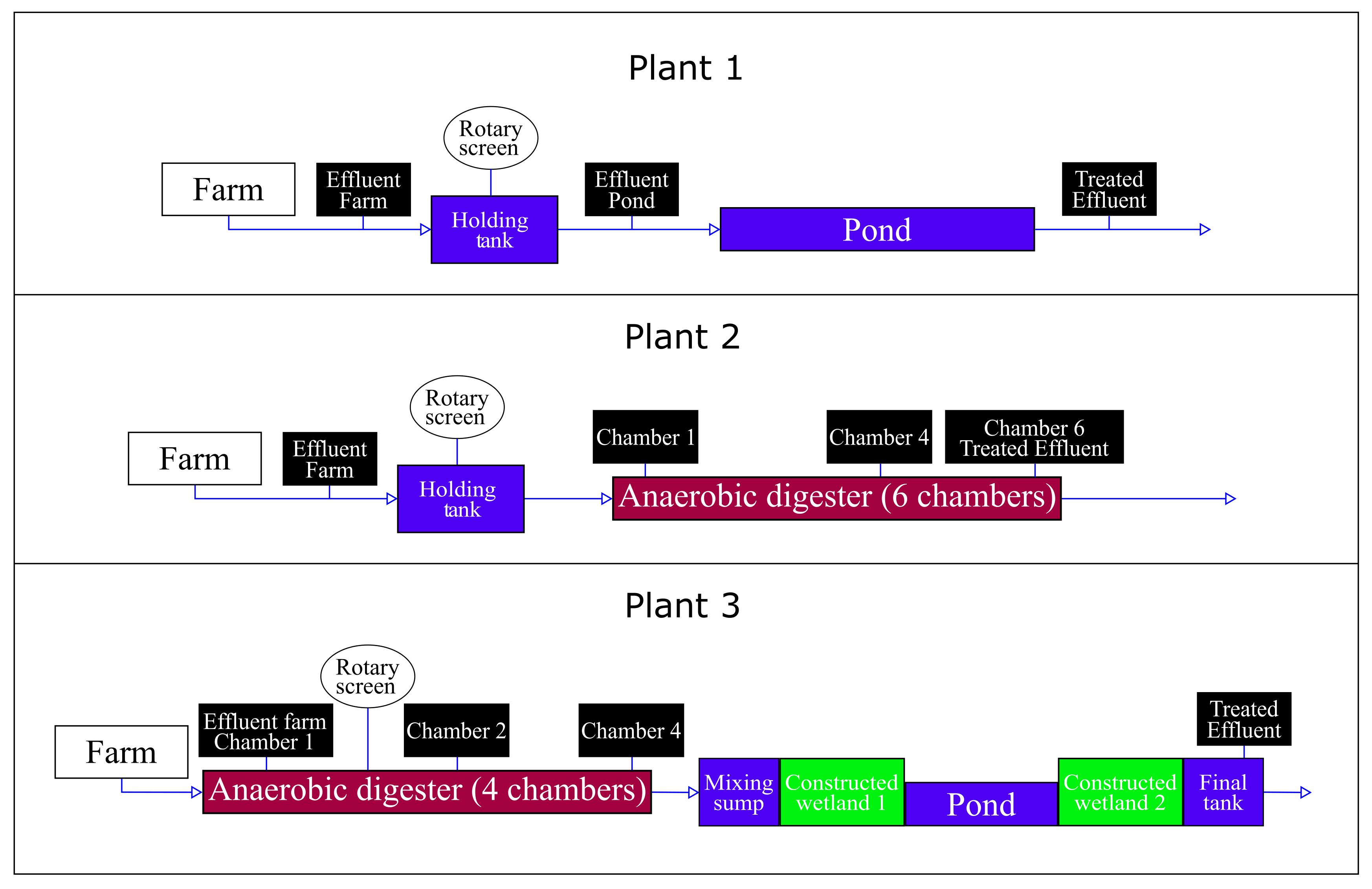

- Plant 1. Farm located at 450 m of altitude (UTM coordinates x: 450,052.41 m, y: 3,105,359.68 m), with 1600 animals. The effluent from the farm (13.60 m/day) is discharged to a holding tank, which has been fitted with a 10 micron rotary screen and it is deposited in a pond of , and 1100 m of effective capacity. The depth is 1.5 m. Figure 5 displays a photograph of Plant 1, with a detail of the pond. The total hydraulic retention time is 80 days.

- Plant 2. Farm located at 540 m above sea level (UTM coordinates x: 443,504.65 m, y: 3,105,955 m), with 1100 animals. The effluent (6.40 m/day) is conveyed in the retention tank. In the holding tank (capacity 40 m, and retention time 4–6 days), it will be stored the manure until it is sieved. At the top of the half-closed closed digester is a 100-micron mesh rotary screen. The dimensions of the rectangular half-buried digester are 17.50 m × 6.50 m × 3.50 m and an effective height of 1.70 m. It is constituted by six rectangular chambers of dimensions 3.00 m × 3.00 m, being of all them equal and intercommunicated by siphon, with an effective capacity unit of 22.90 m each, and 132.60 m of total volume. By the type of flow, it is possible to assimilate it to the operation of a cascade digester. Figure 6 displays a photograph of Plant 2, with a detail of the rotary screen, and the anaerobic digesters. The is 25 days.

- Plant 3. Farm located at 700 m of altitude (UTM coordinates x: 446,164 m, y: 3,102,557.64 m 282.83 N, 1532.87 W), with 1400 animals. Effluent (8.70 m/day) is collected in a reception tank with a capacity of 10 m, then it is taken to the chamber 1 of an anaerobic digester. In the chamber 1, the slurry is stored until it is pumped to the 100 micron rotary screen on top of the anaerobic digester. The rectangular anaerobic digester consists of four equal and interconnected rectangular chambers with an effective capacity of 103.00 m in total and of 10 days. At the exit of the digester, the waste past to the first of the constructed wetlands with subsurface vertical flow constituted by a cubicle with rectangular form, this volume is filled by stones of varied granulometry, being the free volume 22.95 m and a about of 4 days. In the subsurface constructed wetland several types of plants are developed that degrade the organic matter. It has two vertical ventilation tubes. The passage of the water to be treated is performed below the surface throughout the lateral contact area with the pond. Slurry from flows into a pond of ratio, and 90 m of effective capacity. The depth will be 1.5 m. The residence time is 10 days.The pond is surrounded by constructed wetlands, this has allowed us to experiment with a pond of inferior capacity and on the plant 1. The , at the outlet of the effluent, has an identical design to the previous one. The installation has a recirculation circuit that allows recirculating of all or part of the liquid that exists in the lagoon to a control pool that is connected to the homogenization tank. At the end of , it is the final tank of dimensions of 10.50 m of capacity. The stabilized effluent percolates from the wetland to the final tank. Figure 6 displays a photograph of Plant 3, with a detail of the pond, and the constructed wetlands. The is 28 days.

- Each chamber of the digesters and ponds were initially filled with clean water.

- No external resources have been added, such as bacteria cultures, sewage sludge, etc., leaving only the slurry to rest so that the native bacterial flora develops its performance.

2.2. Parameters and Samples

- During the first half of the year, the samples were taken four times a month, equally spaced in time.

- In the second half of the year, the samples were taken twice a month, equally spaced in time.

- After the first year, samples were taken on a monthly basis.

3. Results and Discussions

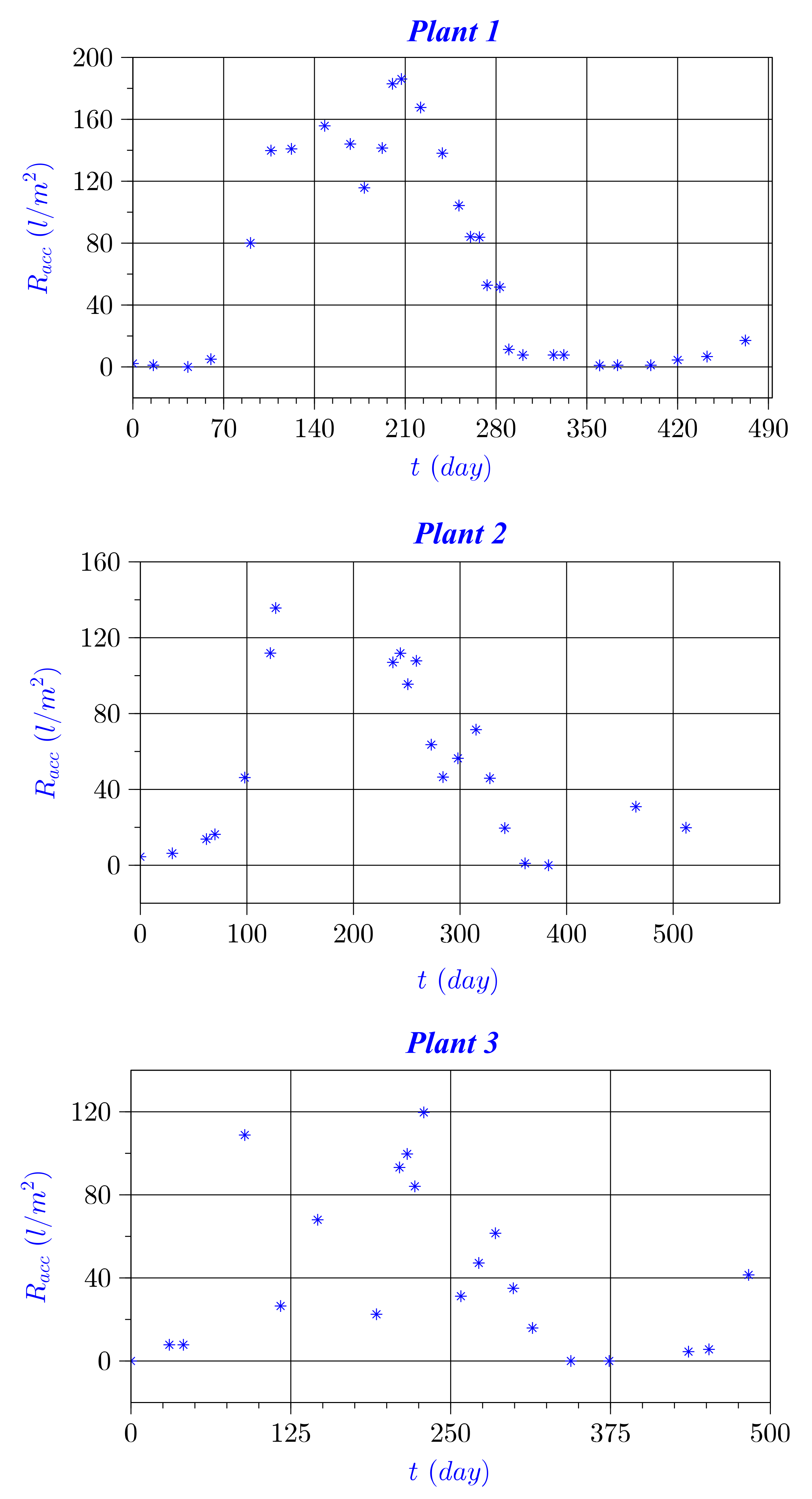

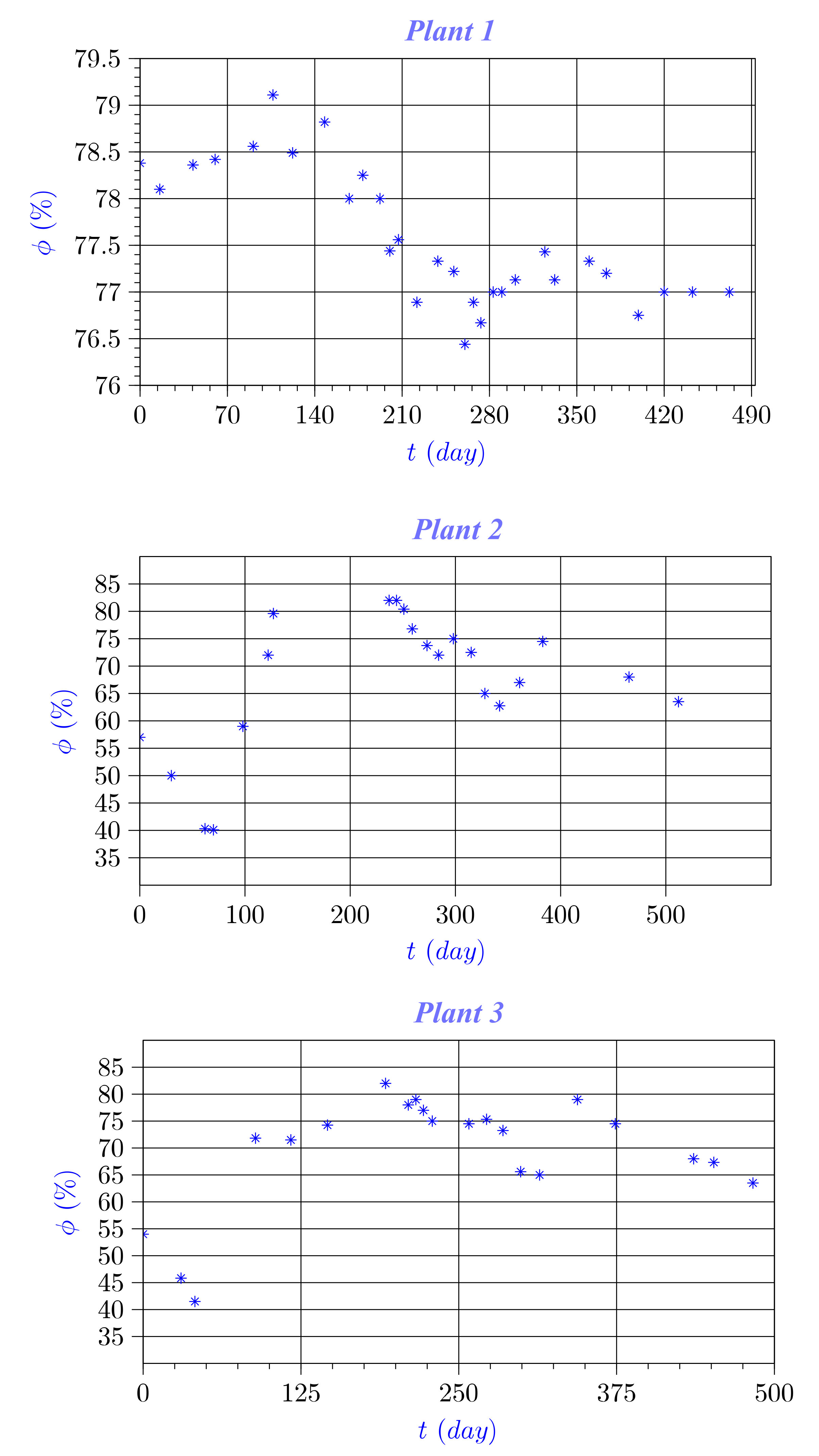

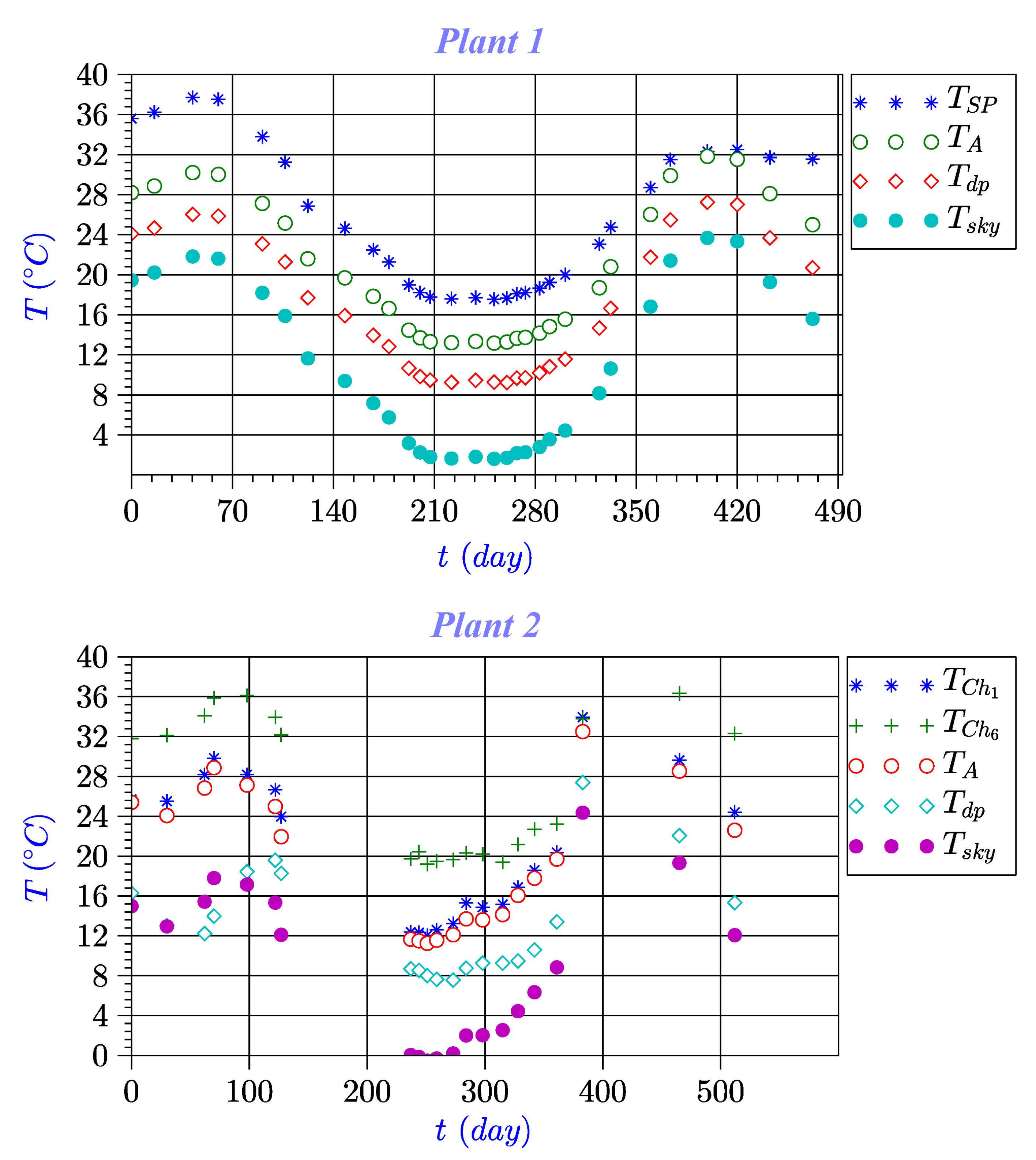

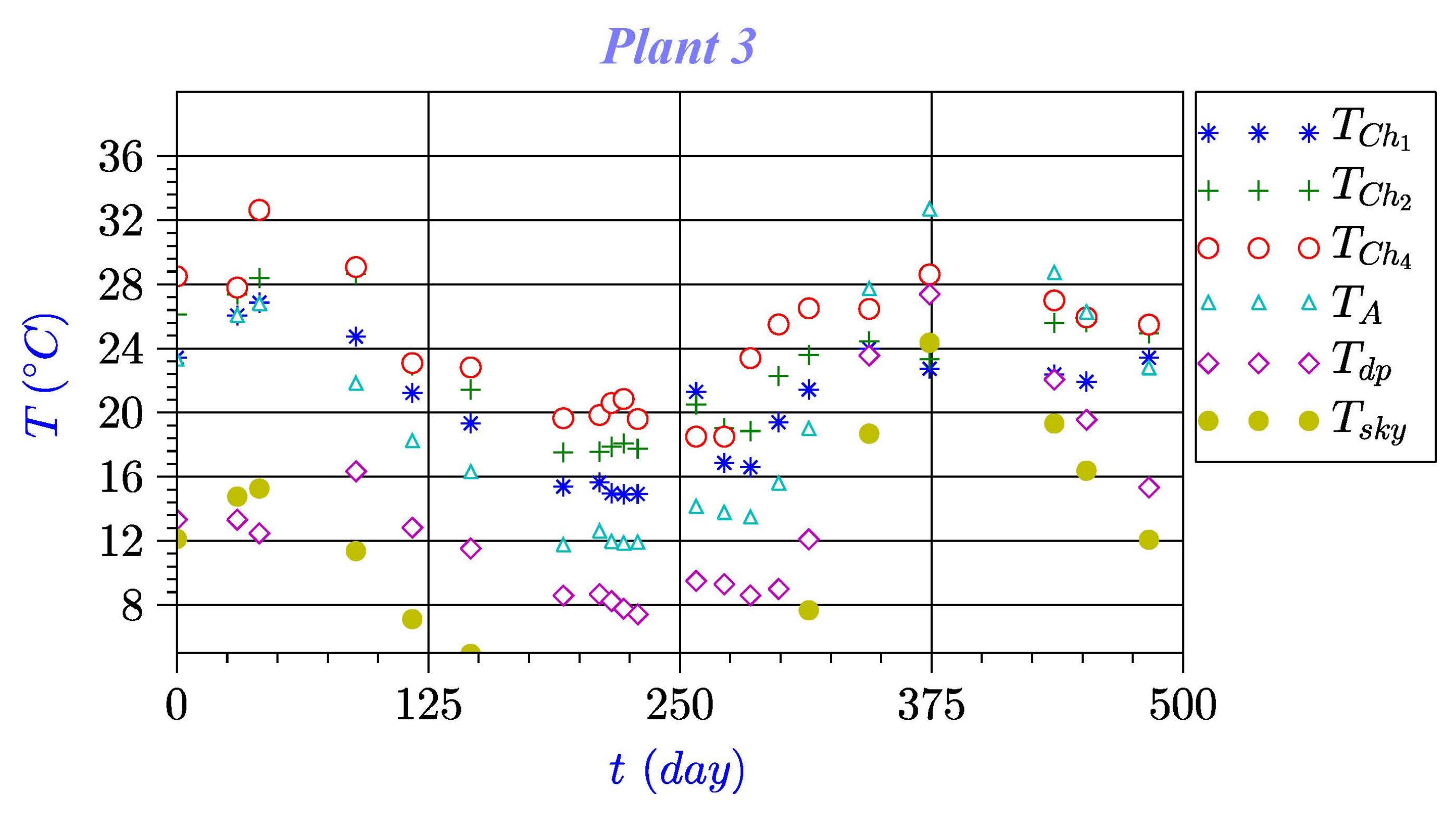

3.1. Atmospheric Conditions

3.2. Temporal Evolution of the Analyzed Variables

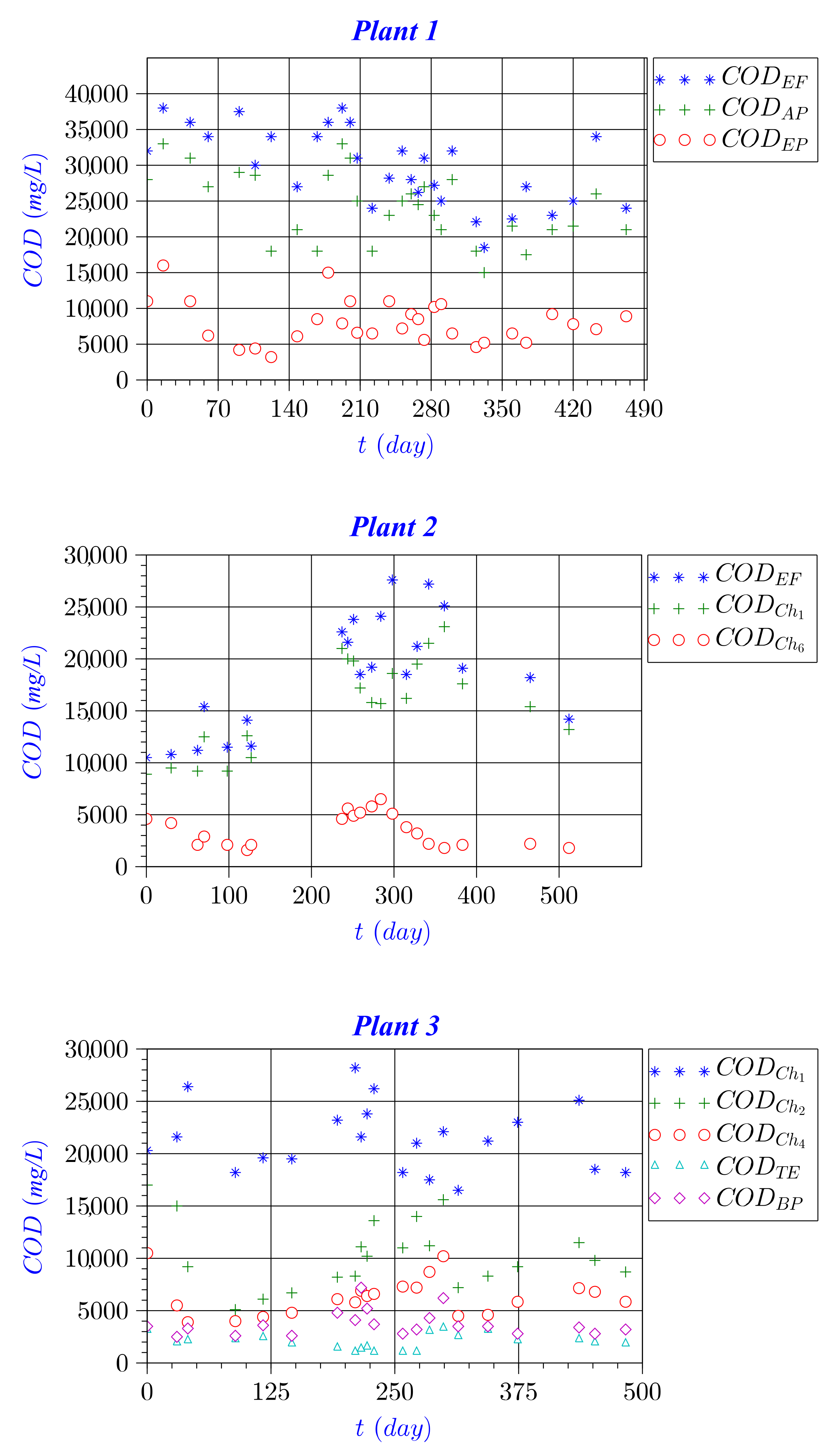

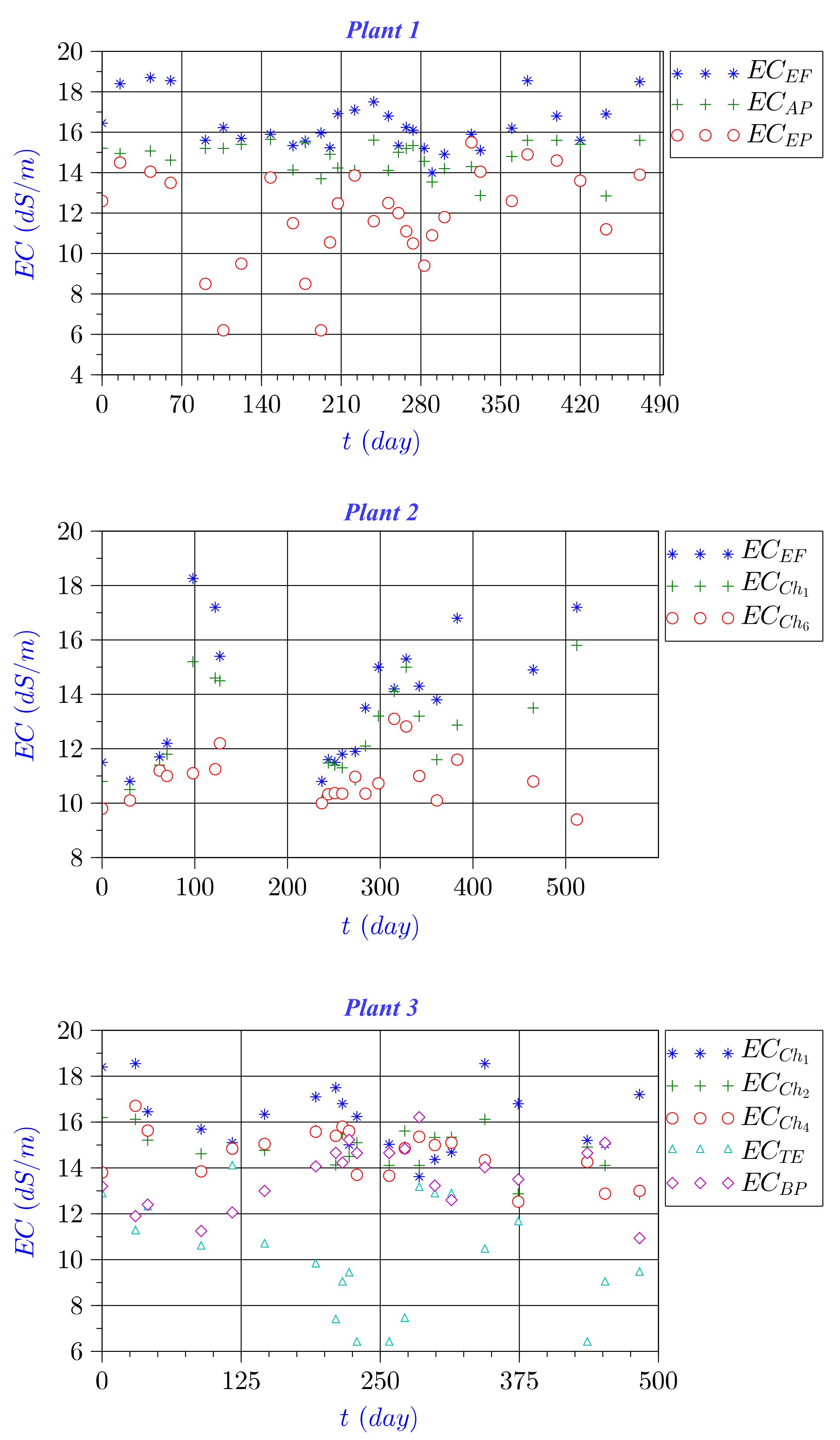

- The curves of variables, which are labeled , for plants 1 and 2, and subindex , for plant 3, represent the discharge in the pilot plants of the pools and intermediate tanks that each of the livestock farms have in their pens.

- The curves of variables, which its label has the subindex , for plant 1, and subindex , for plant 2, and subindex , for plant 3, represent the initial point of the system.

- An finally, the curves of variables, which its label has the subindex , for plants 1 and 3, and subindex , for plant 2, represent the effluent treated of the plants.

3.3. Correlations

3.4. Performance

4. Conclussions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| Chemical oxigen demand | |

| Effluent farm | |

| of Effluent pond | |

| of Treated Effluent | |

| of chamber number i | |

| at bottom of pond | |

| Percentage ratio of the removal efficiency of Chemical oxigen demand | |

| of the global plant | |

| at the screen | |

| at the digester | |

| at the effluent pond | |

| Electrical conductivity | |

| Effluent farm | |

| at Effluent pond | |

| of the treated effluent | |

| at chamber number i | |

| at bottom of pond | |

| Percentage ratio of the removal efficiency of electrical conductivity | |

| of the global plant | |

| of the pond | |

| of the screen | |

| of the digesters | |

| Hydraulic retention time | |

| Global Hydraulic retention time for the plant | |

| Natural treatment system for wastewater | |

| Number of bristles | |

| Total number of animals | |

| Measure of the concentration of protons in a solution | |

| at effluent farm | |

| at the surface pond | |

| at the digester | |

| at chamber number i | |

| of the global plant | |

| Average of the global plant | |

| Average of the digester | |

| Average at the surface pond | |

| Average at effluent farm | |

| Effluent flow rate | |

| Accumulated rainfall | |

| Average accumulated rainfall | |

| Subsurface flow constructed wetland | |

| Temperature surface pond | |

| Ambient temperature | |

| Indoor temperature chamber number i | |

| Average temperature surface pond | |

| Average ambient temperature | |

| Average digester temperature | |

| Reception tank volume | |

| Anaerobic digester volume | |

| SSFCW volume | |

| Pond volume | |

| Relative humidity | |

| Average relative humidity |

Appendix A. Samples for the Plants

| Plant 1 | Plant 2 | Plant 3 | ||||||

|---|---|---|---|---|---|---|---|---|

| Monthly day | Time (day) | Sample | Monthly day | Time (day) | Sample | Monthly day | Time (day) | Sample |

| June 27 | 0 | 1 | June 4 | 0 | 1 | July 4 | 0 | 1 |

| July 13 | 16 | 2 | July 4 | 30 | 2 | August 3 | 30 | 2 |

| July 30 | 43 | 3 | August 6 | 62 | 3 | August 14 | 41 | 3 |

| August 18 | 61 | 4 | August 14 | 70 | 4 | October 2 | 89 | 4 |

| September 18 | 92 | 5 | September 12 | 98 | 5 | October 30 | 117 | 5 |

| October 4 | 108 | 6 | October 6 | 122 | 6 | Nobember 29 | 146 | 6 |

| October 10 | 124 | 7 | October 11 | 127 | 7 | January 14 | 192 | 7 |

| November 16 | 150 | 8 | January 31 | 237 | 8 | February 2 | 210 | 8 |

| December 7 | 170 | 9 | February 7 | 244 | 9 | February 8 | 216 | 9 |

| December 18 | 181 | 10 | February 14 | 251 | 10 | February 13 | 222 | 10 |

| January 2 | 195 | 11 | February 22 | 259 | 11 | February 20 | 229 | 11 |

| January 10 | 203 | 12 | March 6 | 273 | 12 | March 19 | 258 | 12 |

| January 17 | 210 | 13 | March 17 | 284 | 13 | April 3 | 272 | 13 |

| February 3 | 225 | 14 | March 31 | 298 | 14 | April 16 | 285 | 14 |

| February 20 | 242 | 15 | April 17 | 315 | 15 | April 30 | 299 | 15 |

| March 3 | 255 | 16 | April 30 | 328 | 16 | May 15 | 314 | 16 |

| March 12 | 264 | 17 | May 14 | 342 | 17 | June 15 | 344 | 17 |

| March 19 | 271 | 18 | June 3 | 361 | 18 | July 15 | 374 | 18 |

| March 25 | 277 | 19 | June 25 | 383 | 19 | September 17 | 436 | 19 |

| April 5 | 287 | 20 | September 17 | 465 | 20 | October 3 | 452 | 20 |

| April 12 | 294 | 21 | November 4 | 512 | 21 | Nobember 4 | 483 | 21 |

| April 23 | 305 | 22 | ||||||

| May 17 | 329 | 23 | ||||||

| May 25 | 337 | 24 | ||||||

| June 23 | 365 | 25 | ||||||

| July 7 | 379 | 26 | ||||||

| August 03 | 405 | 27 | ||||||

| August 24 | 426 | 28 | ||||||

| September 17 | 449 | 29 | ||||||

| October 18 | 479 | 30 | ||||||

Appendix B. Rainfall, Relative Humidity and pH Results

References and Note

- Gearheart, R.A. Use of Constructed Wetlands to Treat Domestic Wastewater, City of Arcata, California. Water Sci. Technol. 1992, 26, 1625–1637. [Google Scholar] [CrossRef]

- Yoon, C.G.; Kim, S.B.; Kwun, T.Y.; Jung, K.W. Development of natural and ecological wastewater treatment system for decentralized community in Korea. Paddy Water Environ. 2008, 6, 221–227. [Google Scholar] [CrossRef]

- Vera-Pena, L.; Martel-Rodriguez, G.; Armas-Estevez, A.; Toscon, A. DEPURANAT Gestion sostenible del agua residual en los entornos rurales. Rincones Del Atl. 2005, 3, 1–4. [Google Scholar]

- Ayaz, S.C.; Akca, L. Treatment of wastewater by natural systems. Environ. Int. 2001, 26, 189–195. [Google Scholar] [CrossRef]

- Ayaz, S.; Akca, I. Treatment of wastewater by constructed wetland in small settlements. Water Sci. Technol. 2000, 41, 69–72. [Google Scholar] [CrossRef]

- Belmont, M.A.; Cantellano, E.; Thompson, S.; Williamson, M.; Sánchez, A.; Metcalfe, C.D. Treatment of domestic wastewater in a pilot-scale natural treatment system in central Mexico. Ecol. Eng. 2004, 23, 299–311. [Google Scholar] [CrossRef]

- Vera, L.; Martel, G.; Marquez, M. Two years monitoring of the natural system for wastewater reclamation in Santa Lucia, Gran Canaria Island. Ecol. Eng. 2013, 50, 21–30. [Google Scholar] [CrossRef]

- Mendieta, C.; Lopez, C.; Perez, S. Evaluacion de sistemas de tratamiento no-convencional para efluentes procedentes de explotaciones ganaderas. In Proceedings of the I Simposio Iberoamericano de Ingeniería de Residuos—REDISA, Castellón, Spain, 23–24 July 2008; Volume 1, p. 7. [Google Scholar]

- Caballero-Lajarin, A.; Faz, A.; Lobera, J. Constructed wetland application to remove the pollution of waste water from pig farms. In Proceedings of the 5th International Conference on Land Degradation, Valenzano, Italy, 18–22 September 2008; Volume 1, p. 9. [Google Scholar]

- Crites, R.; Middlebrooks, E.J.; Bastian, R. Natural Wastewater Treatment Systems, 2nd ed.; CRC Press Taylor and Francis Group: Boca Raton, FL, USA, 2014; Volume 1. [Google Scholar]

- Gachango, F.G.; Pedersen, S.M.; Kjaergaard, C. Cost-Effectiveness Analysis of Surface Flow Constructed Wetlands (SFCW) for Nutrient Reduction in Drainage Discharge from Agricultural Fields in Denmark. Environ. Manag. 2015, 56, 1478–1486. [Google Scholar] [CrossRef]

- Mannino, I.; Franco, D.; Piccioni, E.; Favero, L.; Mattiuzzo, E.; Zanetto, G. A Cost-Effectiveness Analysis of Seminatural Wetlands and Activated Sludge Wastewater-Treatment Systems. Environ. Manag. 2008, 41, 118–129. [Google Scholar] [CrossRef] [Green Version]

- Hjorth, M.; Christensen, K.V.; Christensen, M.L.; Sommer, S.G. Solid—Liquid separation of animal slurry in theory and practice. A review. Agron. Sustain. Dev. 2010, 30, 153–180. [Google Scholar] [CrossRef] [Green Version]

- Goberment, C.I. Plan Integral de Residuos de Canarias. Decreto 161/2001, 2001. An optional note.

- U.S. Environmental Protection Agency. Manual: Constructed Wetlands Treatment of Municipal Wastewaters; U.S. Environmental Protection Agency: Cincinnati, OH, USA, 2000. [Google Scholar]

- Castillo, P.; Collado, R. Eliminacion de nitrogeno en sistemas naturales de depuracion de aguas residuales: Analisis comparativo. Retema Rev. Tec. Medio Ambiente 1996, 2, 49–55. [Google Scholar]

- Qadiri, R.Z.Z.; Gani, K.M.; Zaid, A.; Aalam, T.; Kazmi, A.A.; Khalil, N. Comparative evaluation of the macrophytes in the constructed wetlands for the treatment of combined wastewater (greywater and septic tank effluent) in a sub-tropical region. Environ. Challenges 2021, 5, 100265. [Google Scholar] [CrossRef]

- Yu, Q.; Duan, X.; Gu, Y.; Li, J.; Zhang, X.; Chen, C.; Zhao, D. Increasing chemical oxygen demand and nitrogen removal efficiencies of surface-flow constructed wetlands in macrophyte-dominant seasons by adding artificial macrophytes. Bioresour. Technol. 2022, 348, 126755. [Google Scholar] [CrossRef]

- Ji, B.; Zhao, Y.; Li, Q.; Yang, Y.; Wei, T.; Tang, C.; Zhang, J.; Ruan, W.; Tai, Y. Interrelation between macrophytes roots and cathode in constructed wetland-microbial fuel cells: Further evidence. Sci. Total Environ. 2022, 838, 156071. [Google Scholar] [CrossRef]

- Kataki, S.; Chatterjee, S.; Vairale, M.G.; Dwivedi, S.K.; Gupta, D.K. Constructed wetland, an eco-technology for wastewater treatment: A review on types of wastewater treated and components of the technology (macrophyte, biolfilm and substrate). J. Environ. Manag. 2021, 283, 111986. [Google Scholar] [CrossRef]

- Brix, H. Do macrophytes play a role in constructed treatment wetlands? Water Sci. Technol. 1997, 35, 11–17. [Google Scholar] [CrossRef]

- Brito-Espino, S.; Ramos-Martín, A.; Pérez-Báez, S.O.; Mendieta-Pino, C.; Leon-Zerpa, F. A Framework Based on Finite Element Method (FEM) for Modelling and Assessing the Affection of the Local Thermal Weather Factors on the Performance of Anaerobic Lagoons for the Natural Treatment of Swine Wastewater. Water 2021, 13, 882. [Google Scholar] [CrossRef]

- Walton, G.N. Thermal Analysis Research Program Reference Manual; National Bureau of Standards: Gaithersburg, MD, USA, 1983. [Google Scholar]

- Suresh, A.; Choi, H.; Oh, D.; Moon, O. Prediction of the nutrients value and biochemical characteristics of swine slurry by measurement of EC – Electrical conductivity. Bioresour. Technol. 2009, 100, 4683–4689. [Google Scholar] [CrossRef]

- Suresh, A.; Choi, H.L. Estimation of nutrients and organic matter in Korean swine slurry using multiple regression analysis of physical and chemical properties. Bioresour. Technol. 2011, 102, 8848–8859. [Google Scholar] [CrossRef]

- Moral, R.; Perez-Murcia, M.D.; Perez-Espinosa, A.; Moreno-Caselles, J.; Paredes, C. Estimation of nutrient values of pig slurries in Southeast Spain using easily determined properties. Waste Manag. 2005, 25, 719–725. [Google Scholar] [CrossRef]

- Antezana, W.; de Blas Beorlegui, J.C.; Rebollar, P.G.; Rodriguez, C.; Beccaccia, A.; Ferrer, P.; Cerisuelo, A.; Moset, V.; Estelles, F.; Lopez, M.C.; et al. Composition, potential emissions and agricultural value of pig slurry from Spanish commercial farms. Nutr. Cycl. Agroecosyst. 2016, 104, 159–173. [Google Scholar] [CrossRef] [Green Version]

- Moral, R.; Perez-Murcia, M.; Perez-Espinosa, A.; Moreno-Caselles, J.; Paredes, C.; Rufete, B. Salinity, organic content, micronutrients and heavy metals in pig slurries from South-eastern Spain. Waste Manag. 2008, 28, 367–371. [Google Scholar] [CrossRef]

- Ngwabie, N.M.; Chungong, B.N.; Yengong, F.L. Characterisation of pig manure for methane emission modelling in Sub-Saharan Africa. Biosyst. Eng. 2018, 170, 31–38. [Google Scholar] [CrossRef]

- Sharma, R.; Malaviya, P. Constructed wetlands for textile wastewater remediation: A review on concept, pollutant removal mechanisms, and integrated technologies for efficiency enhancement. Chemosphere 2022, 290, 133358. [Google Scholar] [CrossRef]

- Wdowczyk, A.; Szymańska-Pulikowska, A.; Gałka, B. Removal of selected pollutants from landfill leachate in constructed wetlands with different filling. Bioresour. Technol. 2022, 353, 127136. [Google Scholar] [CrossRef]

- Wang, Y.; Li, Q.; Zhang, W.; Wang, S.; Peng, H. Pollutants removal efficiency assessment of constructed subsurface flow wetlands in lakes with numerical models. J. Hydrol. 2021, 598, 126289. [Google Scholar] [CrossRef]

- Yellezuome, D.; Zhu, X.; Wang, Z.; Liu, R. Mitigation of ammonia inhibition in anaerobic digestion of nitrogen-rich substrates for biogas production by ammonia stripping: A review. Renew. Sustain. Energy Rev. 2022, 157, 112043. [Google Scholar] [CrossRef]

- Tsapekos, P.; Kovalovszki, A.; Alvarado-Morales, M.; Rudatis, A.; Kougias, P.G.; Angelidaki, I. Anaerobic co-digestion of macroalgal biomass with cattle manure under high salinity conditions. J. Environ. Chem. Eng. 2021, 9, 105406. [Google Scholar] [CrossRef]

- Xie, Z.; Zou, H.; Zheng, Y.; Fu, S.F. Improving anaerobic digestion of corn straw by using solid-state urea pretreatment. Chemosphere 2022, 293, 133559. [Google Scholar] [CrossRef]

- Vera, L.; Martel, G.; Marquez, M. First year performance of a new constructed wetland on the island of Gran Canaria: A case study. In Proceedings of the 12th International Conference on Wetland Systems for Water Pollution Control, Venice, Italy, 4–8 October 2010; Volume 1, p. 7. [Google Scholar]

- Knight, R.L.; Payne, V.W.; Borer, R.E.; Clarke, R.A.; Pries, J.H. Constructed wetlands for livestock wastewater management. Ecol. Eng. 2000, 15, 41–55. [Google Scholar] [CrossRef]

- Becares, E.; Alvarez, J.; Garcia-Gonzalez, M. Caracterizacion de purines de cerdo y eficacias de tratamiento en Espana Central. Innovacion y Tecnologia Agroalimentaria 2008, 4, 65–75. [Google Scholar]

- Choi, E.; Kim, D.; Eum, Y.; Yun, Z.; Min, K.S. Full-Scale Experience for Nitrogen Removal from Piggery Waste. Water Environ. Res. 2005, 77, 381–389. [Google Scholar] [CrossRef]

- Dias, T.; Fragoso, R.; Duarte, E. Anaerobic co-digestion of dairy cattle manure and pear waste. Bioresour. Technol. 2014, 164, 420–423. [Google Scholar] [CrossRef]

- Ferreira, L. Anaerobic co-digestion of pig manure with fruti wastes. Process development for the recycling in decentralised farm scale plants. In Proceedings of the 12th Ramiran International Conference, Aarhus, Denmark, 11–13 September 2006; Volume 1, p. 7. [Google Scholar]

- Deng, L.; Cai, C.; Chen, Z. The treatment of pig slurry by a full-scale Anaerobic-Adding Raw Wastewater-Intermittent Aeration Process. Biosyst. Eng. 2007, 98, 327–334. [Google Scholar] [CrossRef]

- Fugère, R.; Mameri, N.; Gallot, J.E.; Comeau, Y. Treatment of pig farm effluents by ultrafiltration. J. Membr. Sci. 2005, 255, 225–231. [Google Scholar] [CrossRef]

- Juteau, P.; Tremblay, D.; Ould-Moulaye, C.B.; Bisaillon, J.G.; Beaudet, R. Swine waste treatment by self-heating aerobic thermophilic bioreactors. Water Res. 2004, 38, 539–546. [Google Scholar] [CrossRef]

- Kalyuzhnyi, S.; Sklyar, V.; Epov, A.; Arkhipchenko, I.; Barboulina, I.; Orlova, O.; Kovalev, A.; Nozhevnikova, A.; Klapwijk, A. Sustainable treatment and reuse of diluted pig manure streams in Russia. Appl. Biochem. Biotechnol. 2003, 109, 77–94. [Google Scholar] [CrossRef]

- Yi, Y.S.; Kim, S.; An, S.; Choi, S.; Choi, E.; Yun, Z. Gas analysis reveals novel aerobic deammonification in thermophilic aerobic digestion. Water Sci. Technol. 2003, 47, 131–138. [Google Scholar] [CrossRef]

- Gonzalez-Fernandez, C.; Nieto-Diez, P.P.; Leon-Cofreces, C.; Garcia-Encina, P.A. Solids and nutrients removals from the liquid fraction of swine slurry through screening and flocculation treatment and influence of these processes on anaerobic biodegradability. Bioresour. Technol. 2008, 99, 6233–6239. [Google Scholar] [CrossRef]

| Plant | |||||||

|---|---|---|---|---|---|---|---|

| 1 | 45,600 | − | − | ||||

| 2 | 29,000 | − | − | ||||

| 3 | 50,000 | ||||||

| Plant | |||||||

| 1 | 1115 | 750 | 81 | ||||

| 2 | 172 | 180 | 25 | ||||

| 3 | 250 | 140 | 27 | ||||

| Plant 1 | |

| R | Correlation |

| Plant 2 | |

| R | Correlation |

| Plant 3 | |

| R | Correlation |

| Plant | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1 | − | − | ||||||

| 2 | − | − | ||||||

| 3 | ||||||||

| Plant | ||||||||

| 1 | − | − | ||||||

| 2 | − | − | ||||||

| 3 | ||||||||

| Plant | ||||||||

| 1 | − | − | − | − | ||||

| 2 | − | − | − | − | ||||

| 3 | − | − |

| Plant | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1 | − | − | |||||||

| 2 | − | − | |||||||

| 3 |

| Treatment | References | |||

|---|---|---|---|---|

| Anoxic-aerobic | 54 | [39] | ||

| Anerobic-anoxic-aerobic | 48 | [39] | ||

| Anaerobic | 14 | [40] | ||

| Codigestion anaerobic | [41] | |||

| Anoxic-aerobic | 13 | [38] | ||

| Anoxic-aerobic | 13 | [38] | ||

| Activated Slugge | 10 | [38] | ||

| NTSW Domestic | 20 | [6] | ||

| NTSW Domestic | 28 | [4] | ||

| NTSW Domestic | 30 | [7] | ||

| NTSW Livestock | 25 | [37] | ||

| SBR and MBR technology | [47] | |||

| Anaerobic-Biofilters | 6 | [45] | ||

| Aerobic termofilic | 3 | [46] | ||

| Anaerobic-SBR | [42] | |||

| MBR technology | 1 | [43] | ||

| Aerobic termofilic | 3 | [44] | ||

| NTSW Plant 1 | 81 | This work | ||

| NTSW Plant 2 | 25 | This work | ||

| NTSW Plant 3 | 28 | This work | ||

| SBR | 6 | [39] | ||

| SBR and MBR technology | 8 | [47] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mendieta-Pino, C.A.; Garcia-Ramirez, T.; Ramos-Martin, A.; Perez-Baez, S.O. Experience of Application of Natural Treatment Systems for Wastewater (NTSW) in Livestock Farms in Canary Islands. Water 2022, 14, 2279. https://doi.org/10.3390/w14142279

Mendieta-Pino CA, Garcia-Ramirez T, Ramos-Martin A, Perez-Baez SO. Experience of Application of Natural Treatment Systems for Wastewater (NTSW) in Livestock Farms in Canary Islands. Water. 2022; 14(14):2279. https://doi.org/10.3390/w14142279

Chicago/Turabian StyleMendieta-Pino, Carlos A., Tania Garcia-Ramirez, Alejandro Ramos-Martin, and Sebastian O. Perez-Baez. 2022. "Experience of Application of Natural Treatment Systems for Wastewater (NTSW) in Livestock Farms in Canary Islands" Water 14, no. 14: 2279. https://doi.org/10.3390/w14142279

APA StyleMendieta-Pino, C. A., Garcia-Ramirez, T., Ramos-Martin, A., & Perez-Baez, S. O. (2022). Experience of Application of Natural Treatment Systems for Wastewater (NTSW) in Livestock Farms in Canary Islands. Water, 14(14), 2279. https://doi.org/10.3390/w14142279