1. Introduction

Water mills have a history of almost two millennia as a source of energy, particularly in Europe [

1]. Prior to inventing the first water mill, prehistoric people invented hand-driven grindstones (

Figure 1) used mainly for flour production from grains. During historical times, the original hand-driven grindstones were followed by heavier millstones driven by human and, later, animal power. Thereafter, during the Hellenistic and Roman periods, the two major components of the mill were invented: the water wheel itself and the gearing that powered the water wheel.

The first documented use of water mills was in the 1st century BC, and the technology spread quite quickly across the known world. Commercial mills were in use in Roman times in England, where the existence of more than 6000 water mills late in the 11th century was reported in the Doomsday Book [

2]. By the 16th century, water was the most important source of power in Britain and Europe. The number of water mills probably peaked at more than 20,000 in Europe by the 19th century.

As has already been mentioned, the first appearance of water mills dates back to the end of the Hellenistic period, when the energy generated by humans and animals to rotate the millstones was replaced by that of water. With this innovation, people were able to grind large quantities of cereal seeds and cover the needs of cities in the developing world [

3]. The water mills powered by water were mentioned for the first time by Strabon (64 BC–19 AD), who called them

ydraletas [

3]. In addition, it was mentioned that the oldest known water mill was owned by the King Mithridates of Pontus (132–63 BC) in Cabeira.

A water mill is a construction that uses the power of water to turn a wheel or turbine for the mechanical process, such as milling for flour, lumber sawing, or textile production facilities, as well as metal shaping, such as grinding, rolling, or wire drawing, and by using the potential and kinetic energy of water flow, the water mill could rotate a large water wheel.

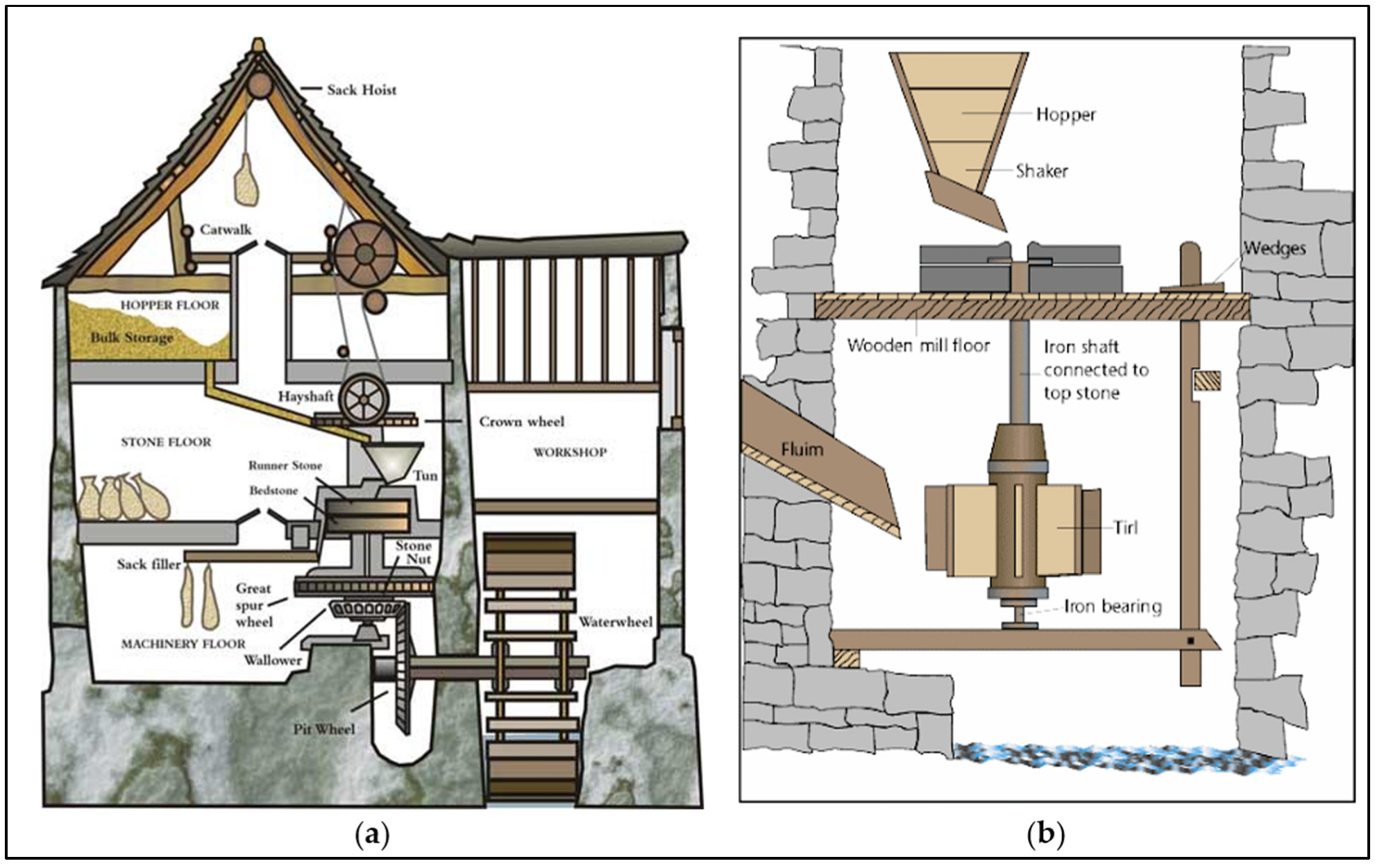

There are two basic types of water mills: (a) one powered by a vertical water wheel via a gearing mechanism and (b) the other equipped with a horizontal water wheel without a gearing mechanism. The water mill is the first work machine, which was first named neromichani (i.e., water engine), constructed by man for the use of natural, mild, and renewable energy source.

When the first use of a wind mill occurred is unknown although drawings of a water pumping by a wind mill from Persia (current day Iran) exist. This design had vertical sails made of bundles of reeds or wood attached to a central vertical shaft. In practice, in Asia, the water mills fully appeared around the end of the 5th century BC in Persia. The water mill was adopted and expanded by the Romans and was widely spread in the Byzantine Empire and during the Middle Ages in both main types (

Figure 2a,b) according to the position of the water wheel: vertical (Vitruvian), which requires a right-angle gear, and horizontal (Greek or Norse), in which the rotating millstones were attached directly to the same axis [

3], as indicated before. The raw materials used in ancient Greece used to be sandstones or volcanic rocks. There were many locations, e.g., Nisyros, Milos, Santorini, etc., where millstones were quarried and exported to other areas [

3].

The horizontal mill originated in the Near East and showed a very simple mechanical system: The horizontal water wheel is directly connected to the load through a vertical shaft, supported by an axial bearing cooled by the waterpower. This wheel is suitable for mills in rivers with low flow rates and high water velocity due to its height. The average rotational velocity ranges from 15 to 20 rpm.

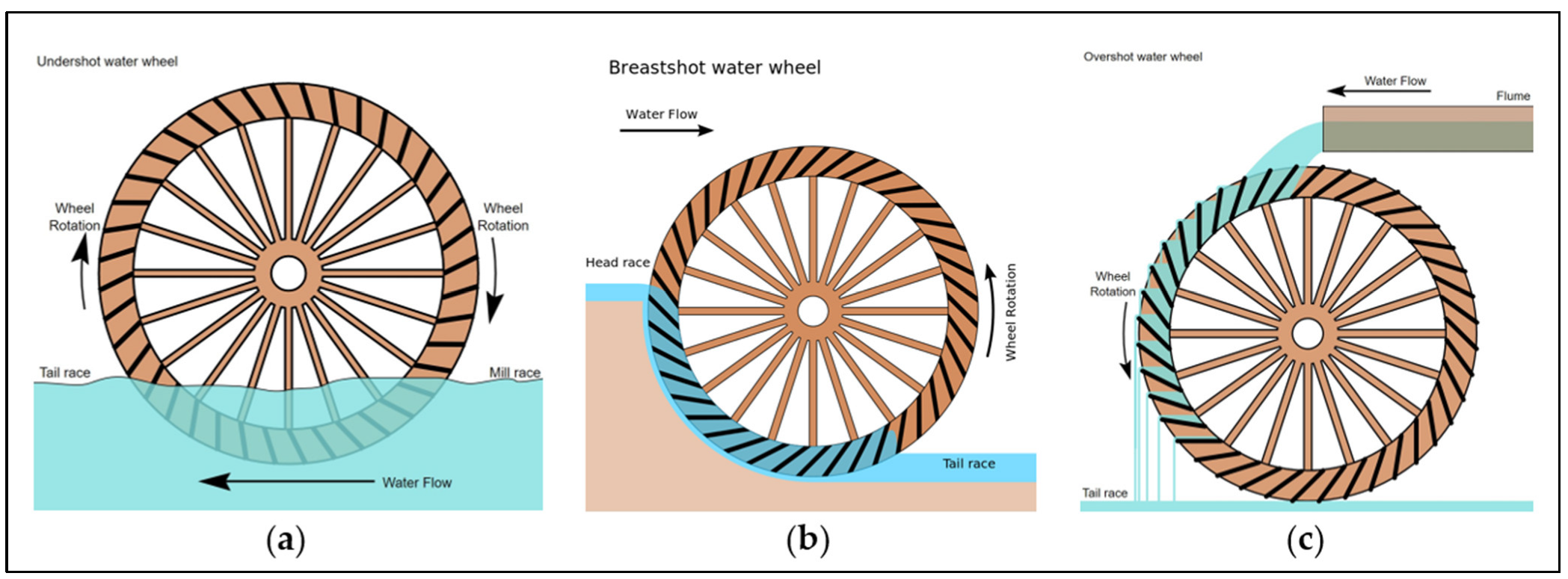

The mill type powered by vertical water wheels could be further divided into undershot (

Figure 3a), breastshot (

Figure 3b), and overshot (

Figure 3c) depending on the way in which water is supplied. The Vitruvian mill does not need a millrace, dam, or chute. However, the overshot wheel, which required these structures, appeared by the 5th century in Greece. It is possible that the improvement in the Vitruvian mill may have arisen by borrowing the idea of the millrace and chute from the primitive vertical mill. From the last half of the 5th century onwards, the application of the Vitruvian mill became general in Rome and throughout the later Empire, whence it appears to have spread northwards into Germany, probably as a result of the barbarian conquest of Rome. Ultimately, its use spread from there to northern France and England [

4].

Water mills are known to have appeared at roughly around the same time in several different regions. The horizontal mill appeared almost simultaneously in the Middle East, Mediterranean Basin, and China between 100 BC and 100 AD. The vertical mill also appeared at roughly around the same time in the Middle East, Mediterranean Basin, and China [

5]. When and where the water wheel originated remains unclear, with various hypotheses regarding its origins.

Water mills are usually built beside streams, rivers, or qanats (an underground hydro-technology to extract water using gravity) used for water supply. Very often, these facilities were improved by the provision of mill races and weirs to help overcome the problems of different seasonal water levels. Many of the weirs seen on rivers today were originally built to help control and keep constant water levels for mills.

The process of ensuring the sustainability of water mill structures and the related restoration techniques will have positive socio-economic impacts [

6]; they will revitalize local villages and economies; encourage the retrofitting of heritage buildings to new uses in rural areas also for promoting socio-economic revitalization in a local level; contribute to the preservation of traditional crafts and activities, thus ensuring the continuation of traditional knowledge as well as stability in rural communities; and contribute to a return in the art of building traditional structures while also maintaining the heritage of rural and vernacular structures.

The scope of this review is not an exhaustive presentation of what is known today on the historical development and use of water mills worldwide. Rather, some characteristic examples of water mills that chronologically and geographically extend from prehistoric to modern times and to the regions with a long history are presented. Such cases of water mill technologies, which are presented, are not widely known among engineers, historians, and archaeologists. These may be relevant for the use of water for energy production and conservation even in present times.

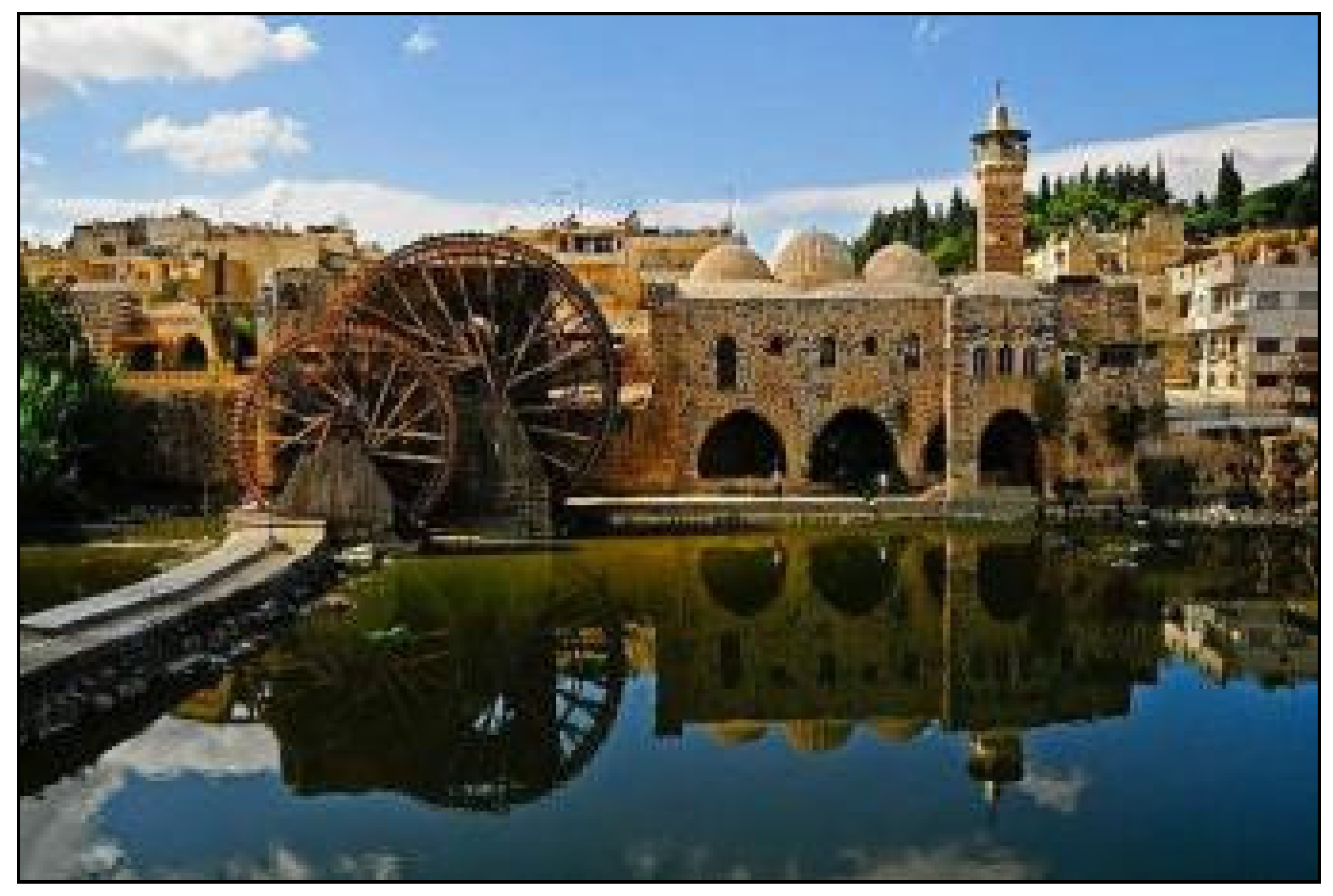

5. Ancient Persia/Iran

In Persia/Iran, in order to power the water mills, apart from rivers, springs’ and qanats’ flowing water was used. The water-mill system in ancient Iran was usually based on 5 to 6 m head between upstream and downstream of the facility, and a tower was used to canalize the water downwards.

Apparently, this generated pressure higher than usual, which hindered the proper functioning of the classical wheel.

The towers at those sites were funnel-shaped, with a decreasing cross-section as water descended each level. An example of such towers can be found in Kashan (currently Iran), where the structure has a diameter of 2.5 m at the top and 1.2 m at the bottom. This tower led to a narrow channel equipped with a wooden weir, which was operated from inside the mill to open or shut the water flow. As mentioned, the difference in the height of water at the upstream channel and at the outlet was about 5 to 6 m. When the milling stopped, the tower would be emptied, and the flow would be diverted to the back of the mill.

The grains were stored in a small chamber located above the millstone. A wooden hopper on the floor of the chamber conducted the grains to the sole in the middle of the millstone.

5.1. Downstream and Upstream Canals and Wooden Turbine

When water passes through the turbine, it enters the downstream channel and is returned to the river. The channel was often covered by bricks and lime mortar. A wooden by-pass weir was located next to the main channel and before the tower’s inlet. It was connected to the downstream channel and diverted the water flow from the mill when it was at rest. However, some mills had only a single channel.

The turbine consisted of a wooden axle with a gradually increasing diameter from top to bottom. The extremities of this axle were generally made of iron. Its lower end was attached to a stone, which acted as the turbine’s support. The upper end was fixed to the upper millstone and rotated when the turbine was in operation. The lower end had a number of grooves where the wooden blades were inserted. These blades measured 40 to 60 cm in length. Their free ends were connected to each other. The blades have a moderate slope with respect to the main axle.

5.2. Millstones

The diameter of the millstones depended on the volume and the head of the available water. For example, the millstones of Feen Spring and Gar-Gar Weir had a diameter of 1.6 m, whereas at Amir Weir, it is about 1.3 m. The lower millstone was heavy and fixed, but the upper one, which was attached to the axle of the turbine, was generally lighter in comparison and could rotate. A hole around the axle in the middle of the upper stone led the grains to the space between the two stones. These stones were not completely horizontal and were positioned with a moderate slope. This simple technique caused the flour to pour down from the highest point and was collected in a shallow hole. The miller would then collect the flour in bags and deliver it to the respective owners [

27].

5.3. Some of the Most Famous Iranian Water Mills

Until 1960, there were more than 300 water mills in operation, but now, only a handful remain. The main features of part of those historic mills in Iran are described here.

5.3.1. Dezful Mills

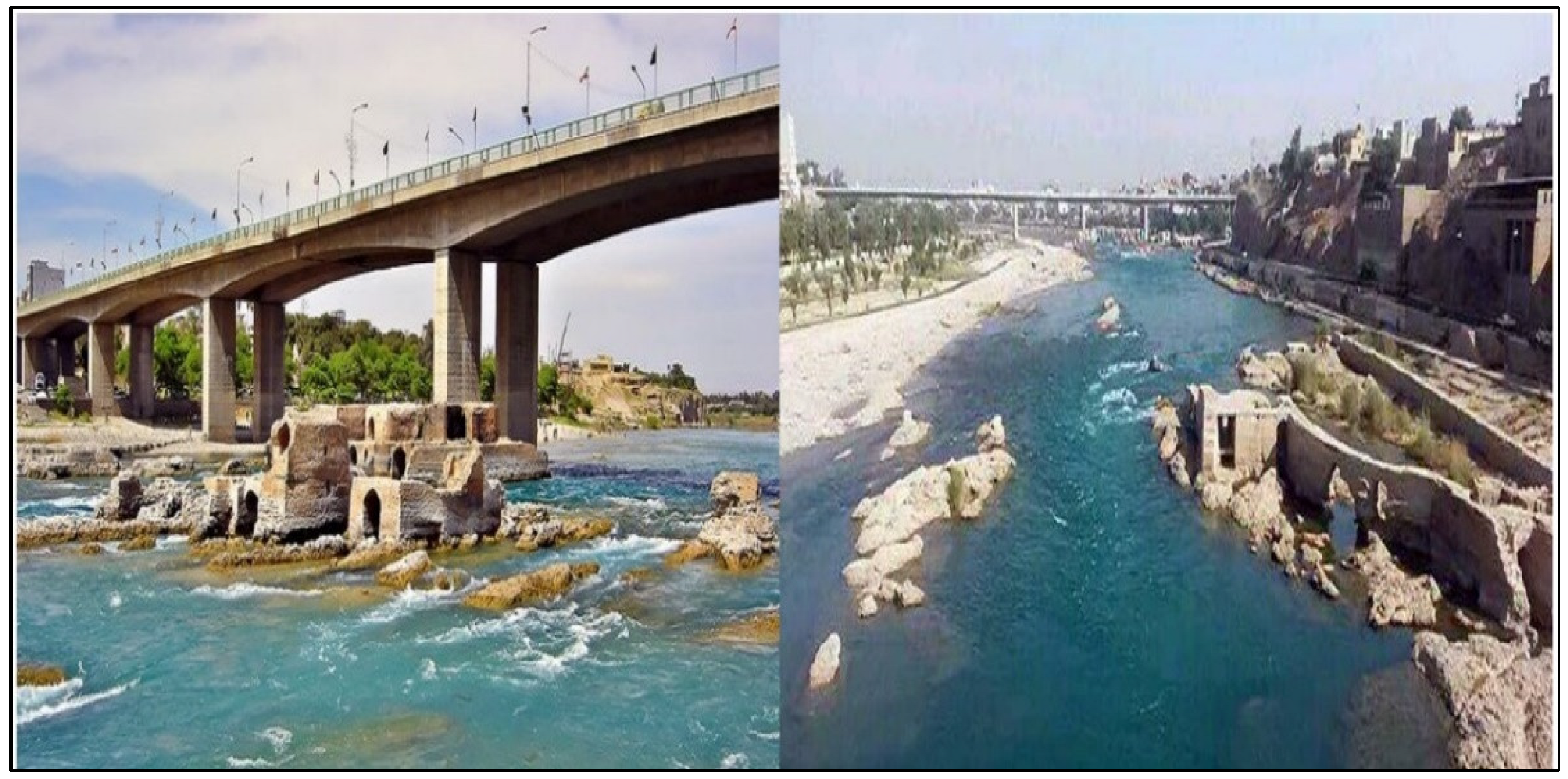

In Iran, Dezful (the fortified bridge) city has a history that dates back to the Sasanian era. The bridge that gives name to the city dates back to 300 AD. The first water mill of the city was built at the same time as the construction of the bridge (

Figure 7), but afterwards, additional ones (50 to 60) were built according to the increasing needs of the city. The river is adequate to build water mills and is ship-like structured due to the powerful and continuous flow of water [

28].

Many of these mills were active until the very beginning of the second Pahlavi era (around the 1950s). The building of the mills was in relation to the water demand for agricultural products (turmeric, gypsum, juniper oil, and sugar) and flour (milling and grinding the wheat) and was somewhat in relation to the management of flows through an upper dam.

As partly stated, the initial structures and bridge date back to the Sassanid (226–651), Safavid (1501–1736), and Qajar (1794–1925) dynasties—mainly the two last ones.

The problem arose on how to put together mills in a way that, in the past, was a barrier to direct the water to the desired locations. This is an advanced Sasanian system that cuts off the first part of the river. These structures are called bridges or trunks, which in addition to linking the western and eastern parts of the river at the time required, allow controlling the river level, which is useful to supply water to town or for high or low agricultural crops.

There are also floating mills in the area. Part of the mills in the middle of the channel used to operate during the whole year, while others, located close to the riverbanks, only operated when the river had flooded enough.

A number of bridges connected the water mills, which were also connected to each other and to the river bank, allowing the people to carry their wheat, barley, or other grains by horse or other cattle to the mill in exchange for flour. However, as the paths leading to the mills were too narrow to allow the animals to pass through, they had to be attached near the dykes, and laborers carried the packs of grains for the rest of the way [

28].

In the human art book [

29], Roman Greishman introduced the system as the oldest irrigation system in the ancient world, dating from about 1400 to 1500 years, which confirms the new developments of this era. In addition, in the middle of the river, one of the openings has a huge arch that resembles the Sassanid porches, and given the interest of the Sassanid kings, it can be considered as the remaining Sardar or Mohtashmi position in the past. These structures are huge bridges, which later became mills with changes in parts. Due to the length of time, changes have occurred due to floods and human factors. The last changes can be seen in the Safavid times with the evolution of the production of bricks and changing its dimensions by 18.5 × 18.5 × 3.5 cm.

Within the mills, the stone has two pieces with a fixed lower part and a rotating upper wheel using the force generated by the river flow. In each mill, five workers had different responsibilities: two for carrying wheat to the mules and into the mill, another one for collecting the flour, and the remnant two were responsible for the mill during the day and the night. In the past, during the seasons when the volume of water in the river was reduced, for the rise of water level and diversion to the mills, people used to place wicker baskets filled with stones together to form a diversion dam. The mills are made with a ship-like structure. The purpose of this kind of architecture was to regulate or intensify the water pressure.

These mills were privately owned and referred to as Levine mills. The number of mills in the Safavid period, as indicated, was about 50 to 60, a number of which were destroyed by seasonal floods. Dezful’s water mills are located at different parts along the Dez River. Some are at a distance of about 800 m away from the Dezful Regulatory Dam and to the south of the Dez Beach Resort, some under the Dezful new bridge (second), while others are situated along the old bridge of this city [

29].

Additionally, there have been suggestions that the Tiberian prayer wheel was the inspiration for the water mills and wind mills in Persia. Although this may be a possibility, the provenance of the prayer wheel is questionable. The next available chronological reference to the water mill dates back to the 7th century AD, but the actual text appeared at least 200 years later [

18]. The story has been recorded by several writers in more than one version. The first mention is by Ali al-Tabari (834–927 AD).

The ancient Iranians had developed the skills of tapping on the water’s hidden power to rotate the water mill’s stones. The roof of a water mill was usually a dome, with light and air entering through a door. The roof’s geometry gave this place a solemn atmosphere, combined with the geometrical patterns of the decorated courtyard and the prevailing poetic atmosphere, in which only the sound of water flowing from the mill shaft onto the rotating paddles could be heard. The pleasant features of the old mill-lord (according to traditional and religious beliefs, he alone could mill the grains and produce flour with God’s blessing) provided a quiet and charming atmosphere at the water mill.

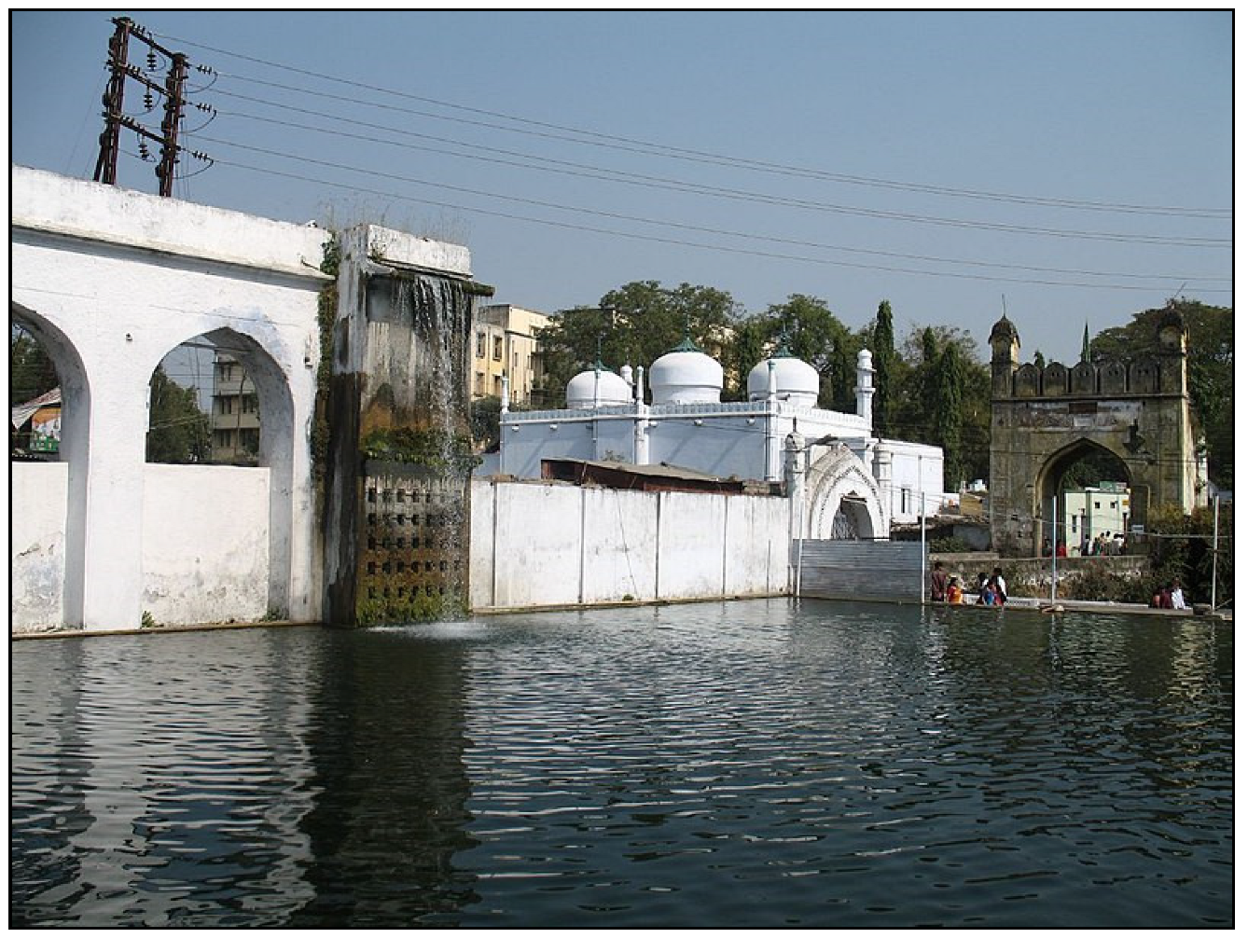

5.3.2. Gar-Gar and Amir Mills

Usually, the water mills in Iran were powered by river currents, springs, or qanats, but the Gar-Gar and Amir water mills were also powered by reservoir water. The Feen-garden’s water mill in Kashan was fed by a spring, whereas the Du-Sangi water mill of Mohammad Abbad in Meibod, the ancient water mill of Ashkezar, at a distance of 15 km from Yazd; and the two-hundred-year-old Taft water mills were all powered by the neighboring qanats. These mills were connected to water by canals. A conduit just before the mill shaft acted as a bypass when the mill was not in operation.

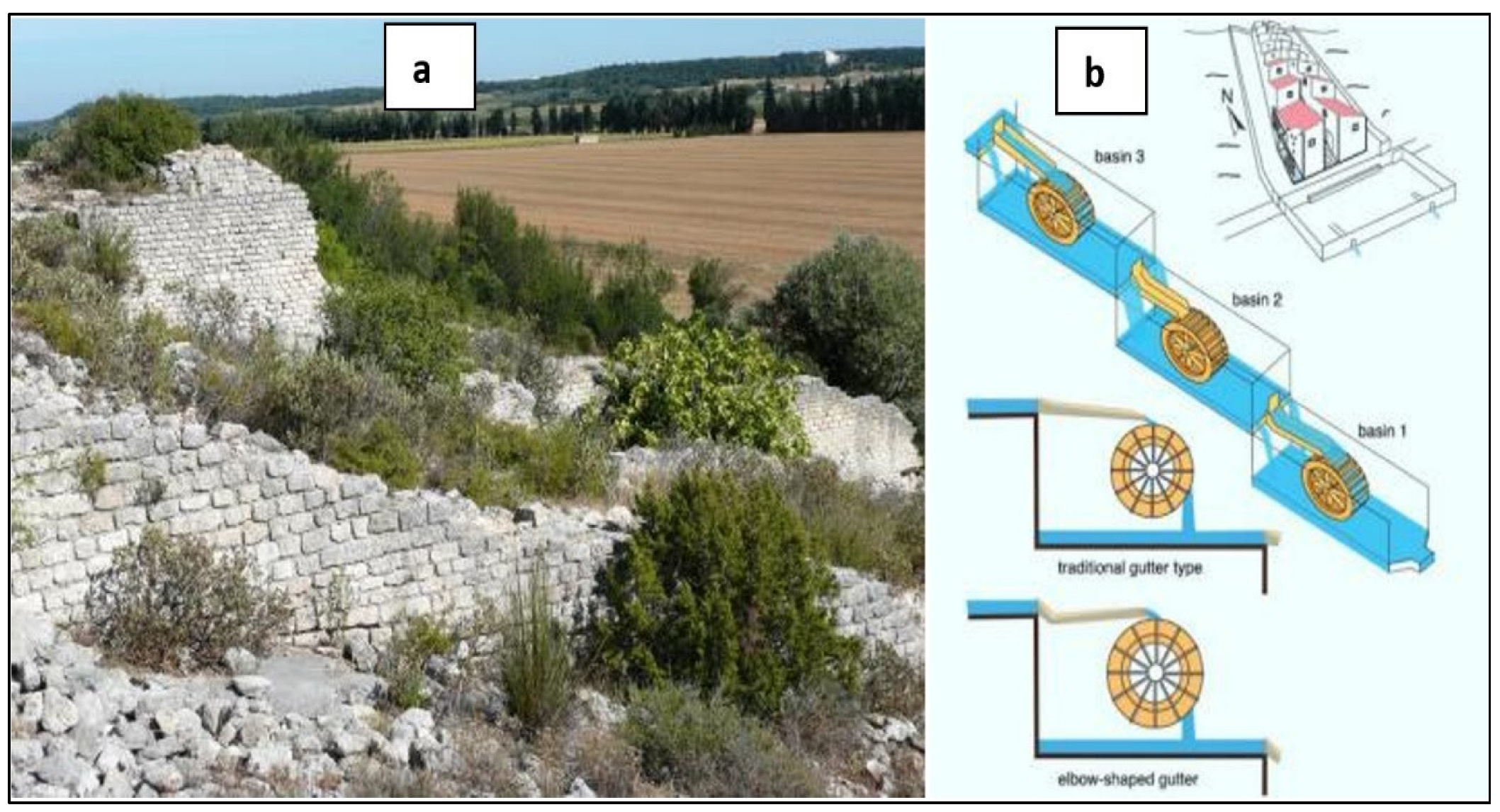

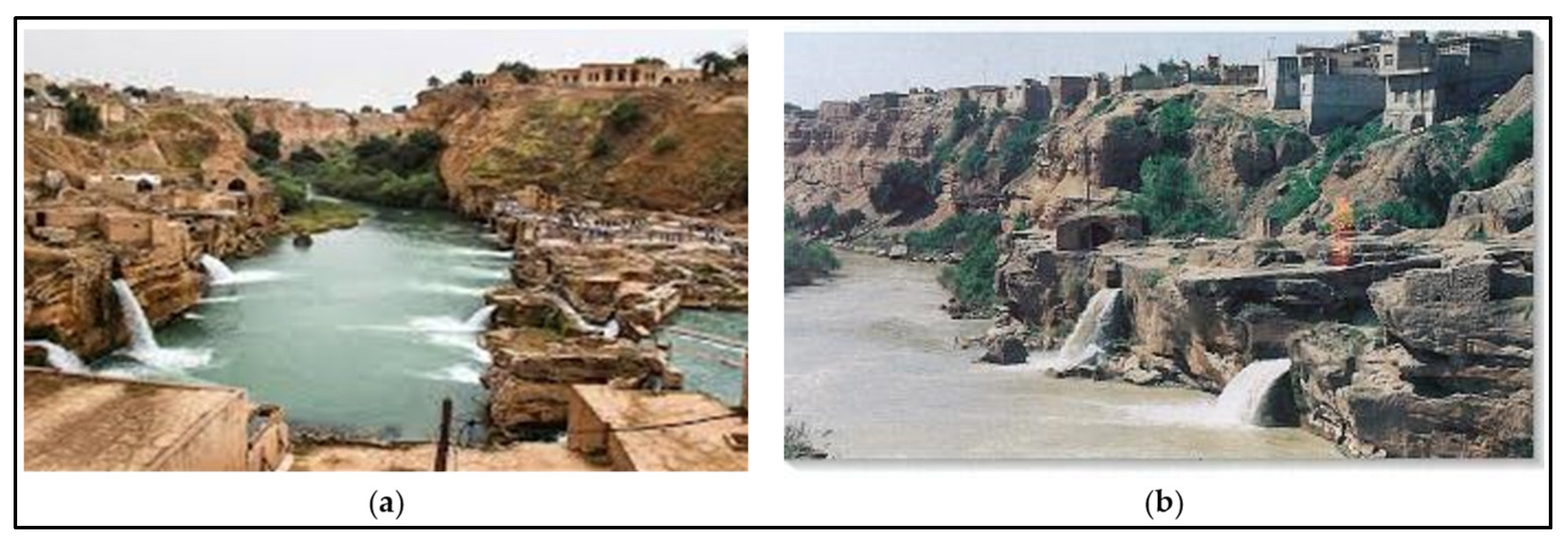

The 1700-year-old Shushtar’s mills complex valued by United Nations Educational, Scientific, and Cultural Organization (UNESCO) as mankind’s heritage is a symbol of Iranian art of exploiting water potential. A canal diverts the excess flood water of the Gar-Gar River in the area (Province of Khoozestan) from the north and east side of the Gar-Gar bridge weir south of the array of mills and finally back to the river. The Gar-Gar Mills complex is situated south of the bridge–weir. Wells related to the water reservoir, water supply network, water control gates, and the space required for spinning the millstones were dug out of natural rocks on either side of the riverbank [

30].

Until half a century ago, a total of 40 mills located behind the Gar-Gar weir produced the flour supplied to Shushtar and the surrounding towns. Then, the sites of three mills were allocated to three power-generation plants to meet the power requirements of Shushtar citizens. After the closure of the mills and the old power plants not so long ago, the water circulation in this complex remained uncontrollable [

30]. Currently, water is let into most of the obliterated outlets of the obsolete mills, splashing out of the rocks and creating a remarkable scene (

Figure 8).

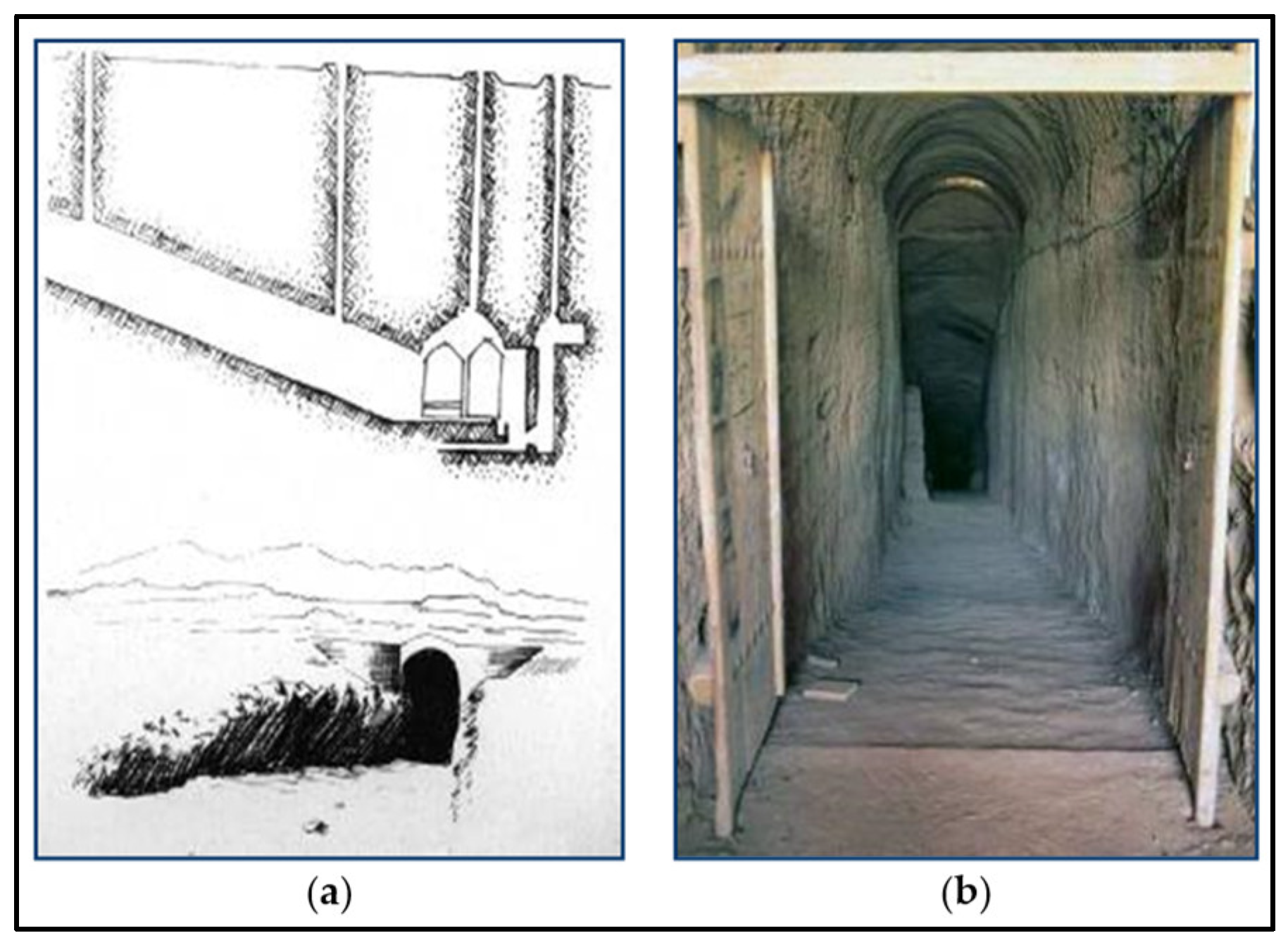

The Double Stone Water Mill of Mohammad Abbad in Meybod, Iran, is an amazing and unique hydraulic structure. It was built at a depth of 40 m on a qanat gallery to grind grains. This 150-year-old water-driven structure met all the flour needs of the neighboring oases. It had a high vestibule to allow pack animals, even camels, to move back and forth with ease, and the lateral stables were large enough to accommodate the cows, donkeys or camels used to carry the produced flour. The mill is situated in a remote and deserted area at a distance of about 8 km from the Mohammad Abbad village, 50 km away from Yazd (

Figure 9).

5.3.3. Ashkezar and Taft mills

Other famous water mills are an ancient water mill named Ashkezar located 15 km away from the city of Yazd, and a 200-year-old water mill named Taft. Both water mills have been supported by the neighboring qanats and are still producing flour (

Figure 10).

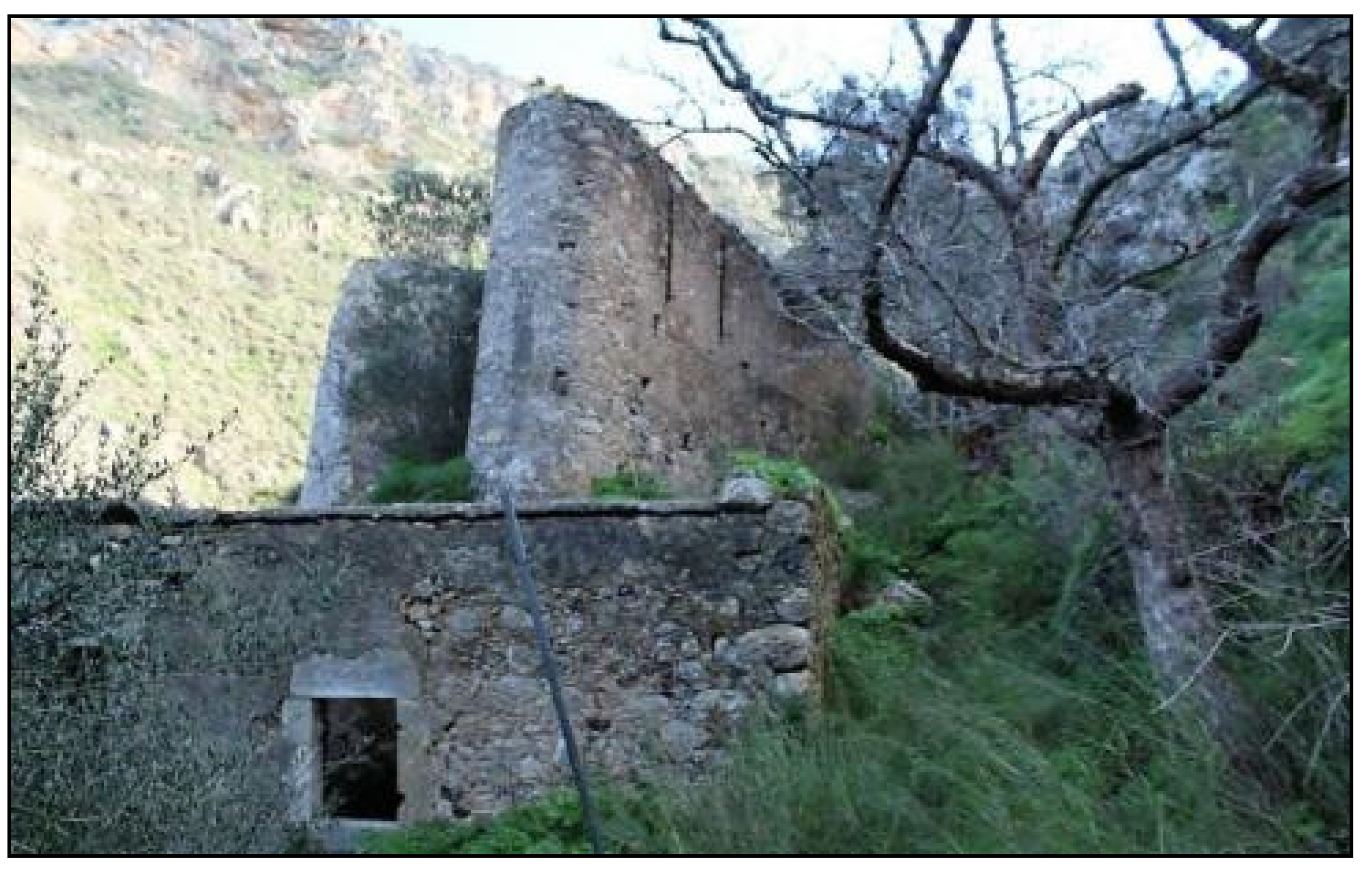

8. Venetian Crete (1205–1669 AD)

The first mills appeared in Crete after the medieval period, during the Venetian occupation (

ca 1205–1669 AD) and before the industrial era. The conquerors were seeking the island’s livelihood and more ease in dealing with sieges from enemy fleets [

34]. Thus, in the villages crossed by rivers or streams, and if the conditions allowed, they built water mills, and new settlements were created around those mills. Later on, those mills were built by Cretans who learned the miller profession, gradually creating their own water mills, and thus prospered. Along with them, the economy of the whole settlement developed, at least until the Turkish occupation, when the conqueror kept the management of the water mills. Much later, in the late 19th century, with the bourgeois-industrial revolution, rural water mills were abandoned because it was impossible to compete with the mills created near urban centers [

34,

35,

36,

37,

38,

39].

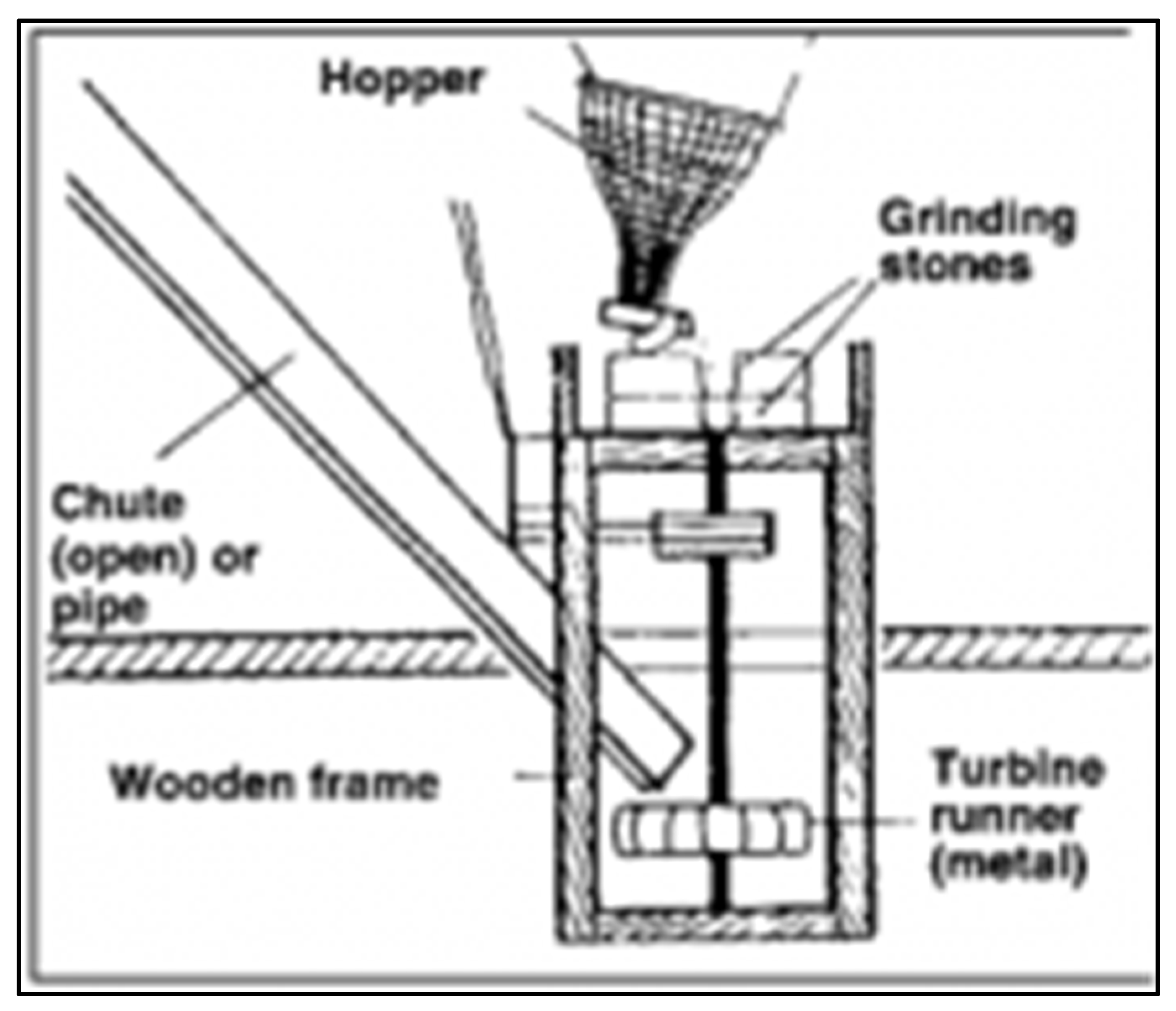

The Cretan water mill is shown in

Scheme 1 and

Figure 13. Water from a spring on a hillside or mainly from a stream is led by gravity to a pipeline with a slight slope to the top of a tower. Battye [

40] not absurdly likened it to a chimney. From the base of the water tower, a nozzle (i.e., in the form of a jet) strikes what can be explained as a water turbine in such a way that it has axial and tangential velocity components.

In the prefecture of Chania in the region of Crete, 1400 mills were accounted. The Venetian-type mills are of special architectural interest because they were built near villages and near the sea and belong to the “Greek” type, with a horizontal impeller and usually with three pairs of millstones [

37,

38].

Unfortunately, today, it is very difficult to even suspect where most water mills were located. Even if you see them, it is not easy to imagine that these ruins that are now lost behind reeds and other wild weeds were water mills, which gave life to the place. There are hundreds of such ruins of water mills in Crete, mainly of Venetian type: they were sources of life.

11. Present Times

In the 16th century, some major changes in the water mills in the Iberian Peninsula appeared. This new version was called “regolfo” and represented an engineering advancement [

42,

43,

44]. The engineering explanation indicates that the innovation was in terms of introducing closed vessels where water spins, and thus, a vortex is generated and an impeller (named “

rodete”) rotated. Those improvements were forerunners of the present turbines. If compared with other older models, such as open-wheel “

rodezno” horizontal mills, the performance improved if the water source was constant and with high flow. There are many remnants of this type of Spanish mill, such as the one located in the southeast of Spain, near the village of Relleu, Alacant province (

Figure 17) [

45].

Another example in Spain dates from the early 18th century. The place is Alcalá (Madrid province, Spain), where 30 penstock mills were installed on the streams and springs of the area. There are still traces of 19 mills, which remain today. Nevertheless, and unfortunately, only seven are in a good state of preservation. The other five are nearly ruined, while from the other seven, unrecognizable vestiges remain. It is especially interesting in the case of the mill called “La Mina” because it is built fully underground. Due to the presence of big subterranean flows under the village, the mill is fueled by groundwater. This is the only example of an underground mill known in Spain.

In Spain, many mills have an additional small building used as the miller’s residence and sometimes attached to the principal building and sometimes separated from it and built on higher ground for protection against river floods. Some mills have towers crowned with battlements perhaps due to a defensive character but sometimes interpreted as an ostentatious and ornamental value [

44].

One of the examples of water mills in the present time is the Forno mill near Torino, Italy, built in 1874. In 1946, the productive apparatus was enlarged and the original millstones replaced. The production stopped in 2011. Nowadays, Forno mill is under consideration for possible inclusion in a proposal for an Eco-Museum.

Poland is one of the countries in which many water mills can still be found. In river valleys throughout Poland, facilities can still be found that use hydropower; many of these are nowadays industrial monuments. This group also includes water mills, which not only testify to the use of rivers as sources of power and showcase ancient technologies but also gives insights into the life of the people who used to live around them. Water mills appeared in Poland in the late 11th and early 12th centuries and became widespread in the 13th century [

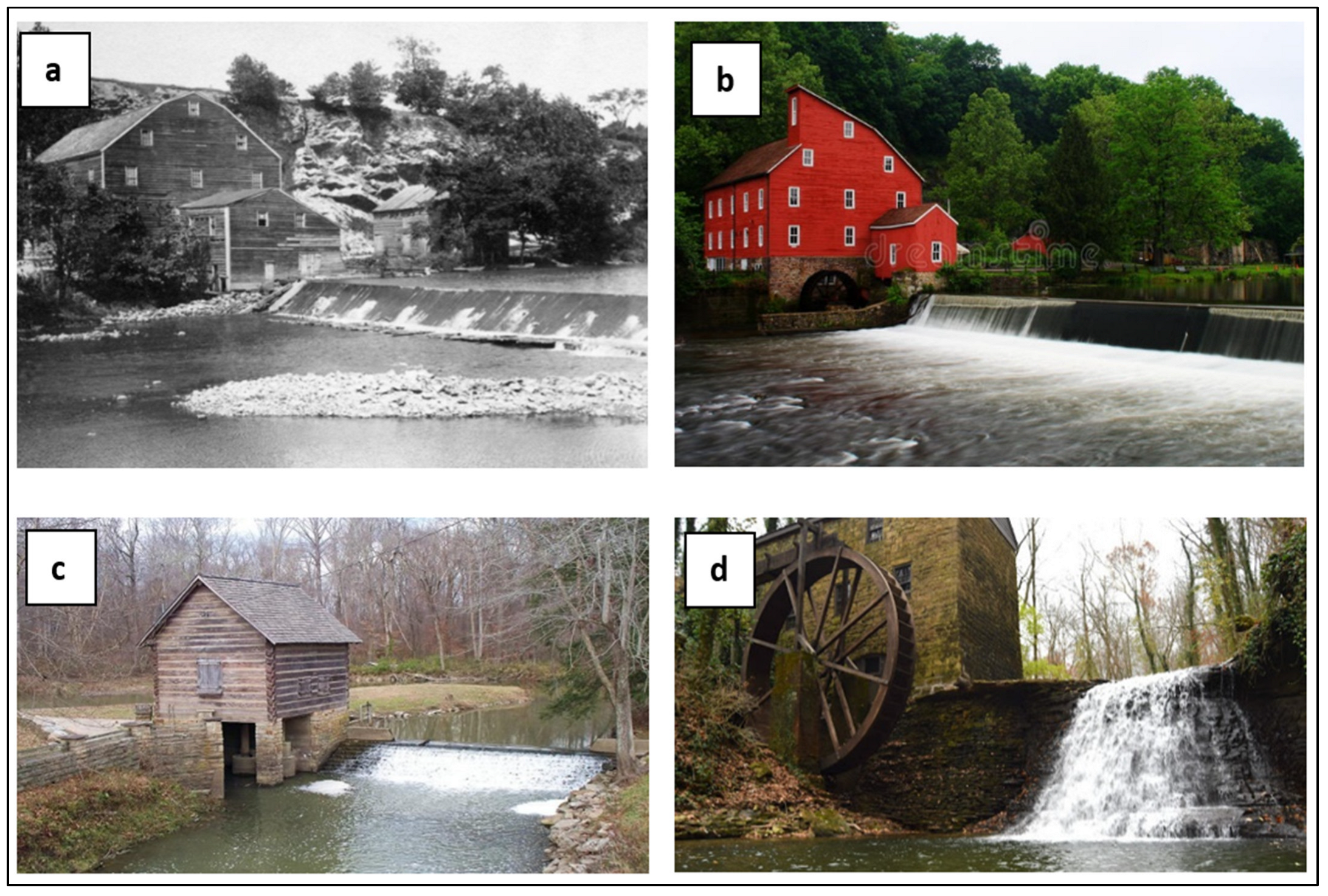

46]. In Poland, 10,500 water mills operated in the late 18th century. Almost 80% of the water mills were in rural areas. Some of the contemporary water mills in Poland are shown in

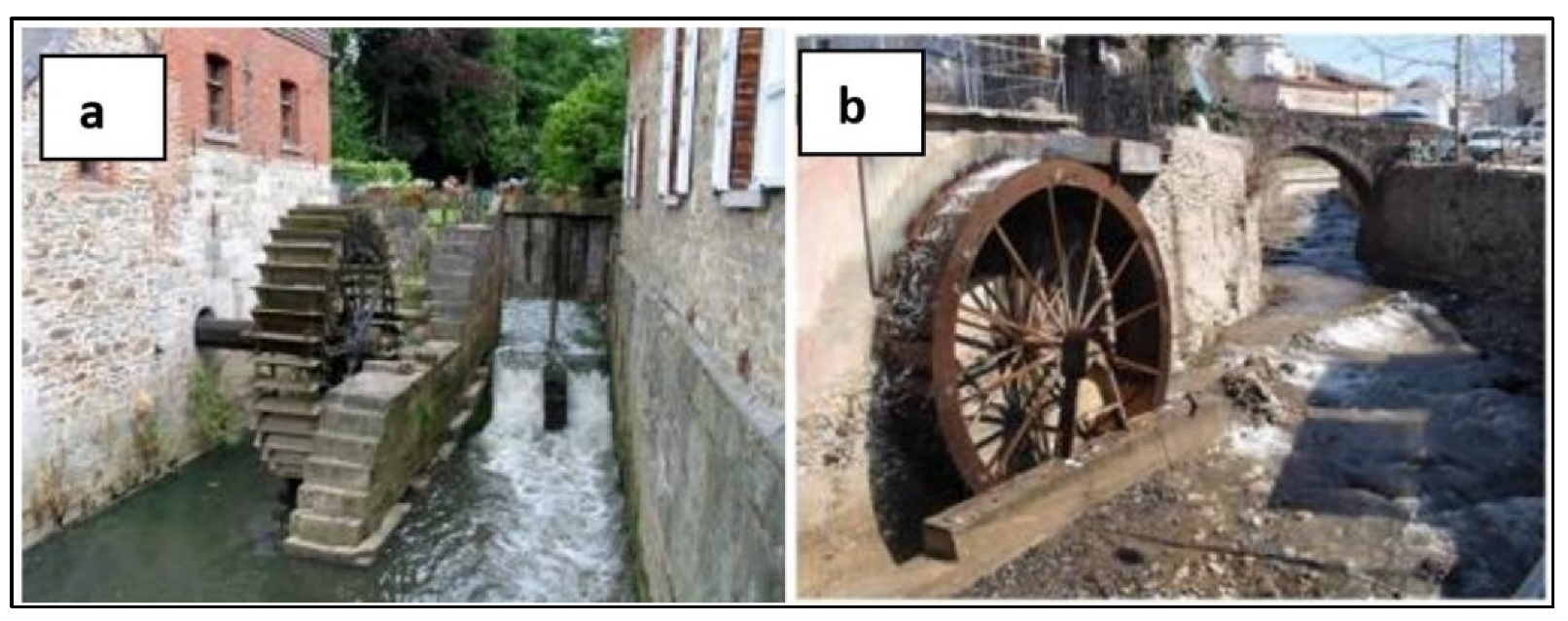

Figure 18.

In the U.S., there are many water mills that belong to the present time, e.g., water mills can be seen in the commonwealth of Kentucky, where most of the farms are small and have the potential to develop water mills or retrieve the old ones either for agricultural purposes or for the tourism industry. The Red Water mill in New Jersey is one of the most famous American water mills. It was built by Ralph Hunt in 1810 in order to process wool. The mill was expanded during 1828–1834 for grinding feed and flour as well as by preparing and selling chestnut wood for rails. In the 20th century, the mill was still in operation, with three elevators and one crusher. In this century, the Red Water mill houses a large portion of the Red Water Mill Museum [

47]. Two examples of water mills in Kentucky are Wolf Pen Branch and McHargues water mills. McHargues water mill was built (rebuilt) in 1812 (1939), on the banks of Lynn Camp Creek, in Knox County, KY. It was the first water-powered grist and sawmill in southeastern Kentucky. The McHargues’ water mill area became an attraction environment, particularly in summer and fall, when horse swapping, fishing, and children’s games took place there [

48]. The Wolf Pen Branch water mill was built in 1870 and is located in Jefferson County, Louisville. Its water wheel has been repaired, replaced, and restored several times over the water mill’s history. However, the mill itself has needed very few upgrades over the decades. New roofing and windows have been the main upgrades made to the mill, as its stone body and frame remain strongly stable. The water mill was added to the National Register of Historic places in 1978 and is now protected by a conservation easement co-held by River Fields and the Kentucky Heritage Council [

49]. It is worth mentioning that, in Kentucky, there are several rivers (e.g., Kentucky River, Mississippi River, etc.) that allow farmers to reuse or develop water mills.

Figure 19 shows some American water mills.

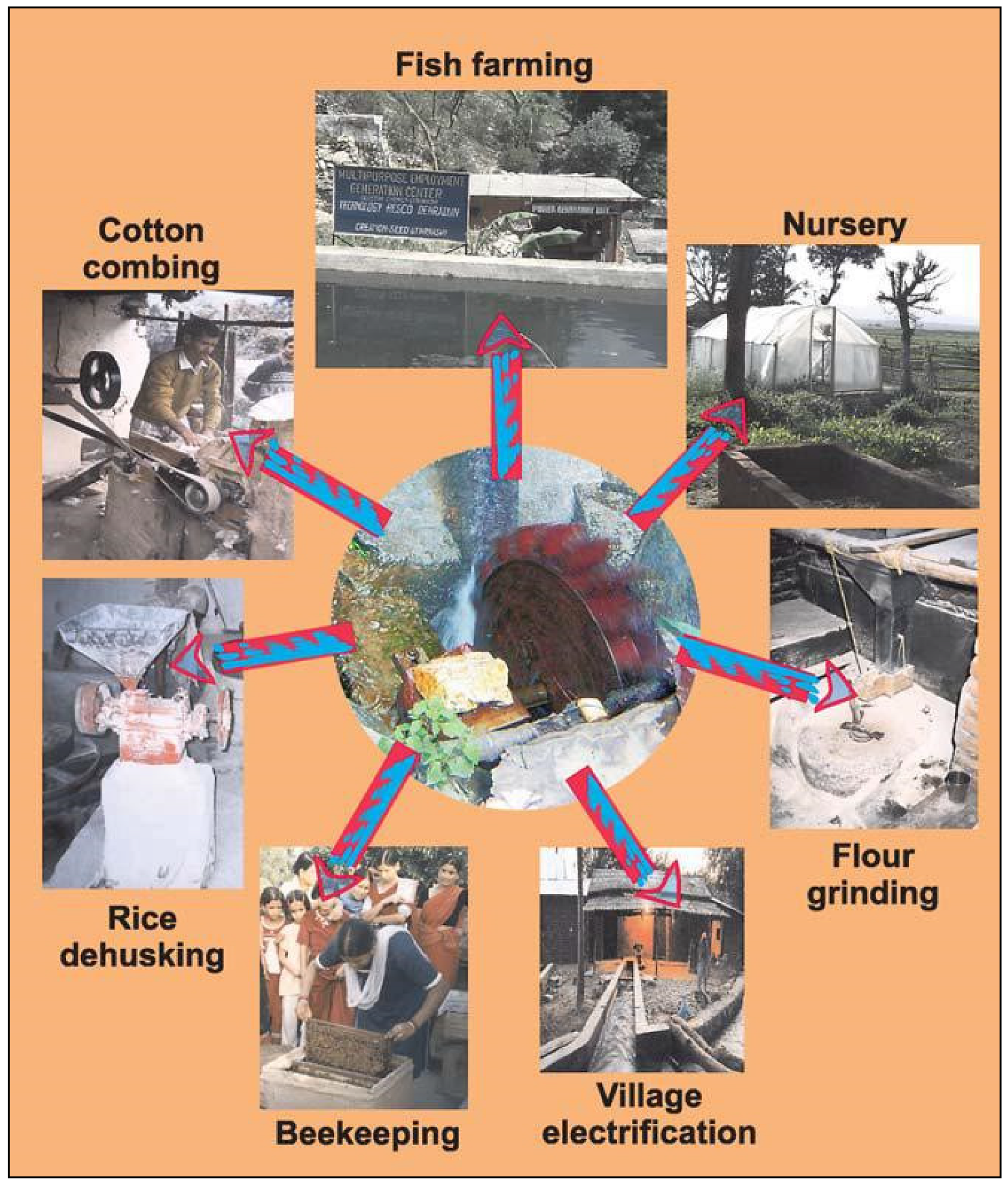

Water mills are still widely used for processing grain in developing countries, particularly in rural areas, villages, and small farms. In India, around 200,000 devices are still in operation for different purposes [

50]. Most of them are still of the traditional style, but some have been upgraded by replacing wooden parts with better-designed metal ones to improve efficiency. In Uttarakhand, India, around 30,000 to 40,000 water mills are nowadays in operation [

51]. In India, a specific type of water mills (i.e., “

gharat") is used by the Himalayan people for their small farms. Now, it has been modified to empower several machines simultaneously. Unfortunately, the government is not making any effort to popularize it. The “

gharat" can be developed as an excellent alternative energy source for hill villages and far-flung areas of the Himalayan region [

52]. In India, different traditional water mills have been improved to enhance their efficiency, and their operational capacity has also increased (

Figure 20). They have been used as cereals grinder, oil expeller, paddy huller, and sawmill and to produce electricity (coupled with electric generators) [

33].

In Karnataka, India, farmers have designed water mills to generate electricity for their small farms. They have conceptualized the water mills based on their own knowledge. They operate the water mills in the canal near their small farms shown in

Figure 21 [

53].

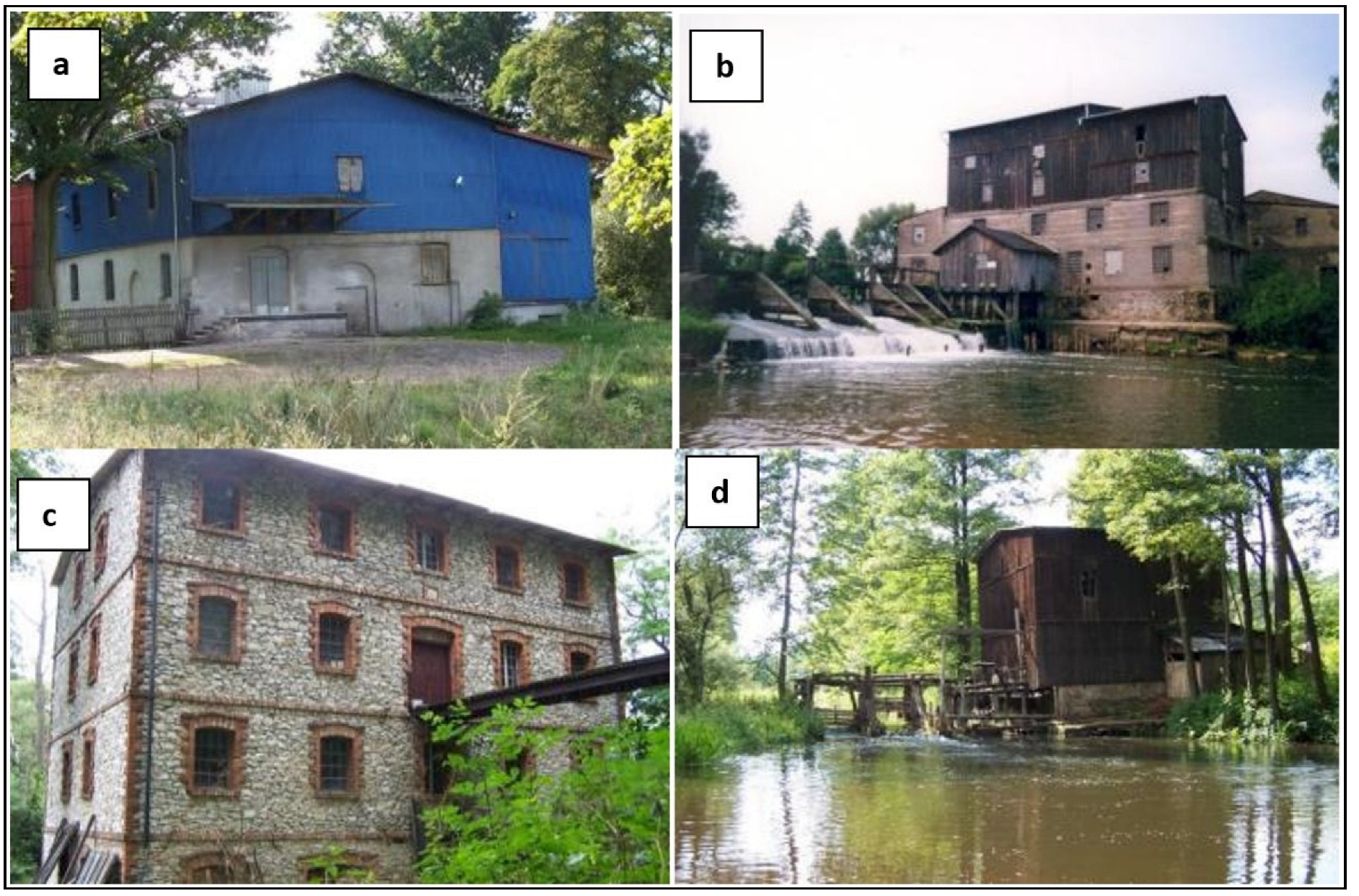

13. Discussion and Conclusions

The history of water mills indicates that they have had different beginnings, stories, and ends. Some of them have demonstrated good quality and performances. However, for centuries, great fluctuations in the form and flows of water bodies occurred in the immediate vicinity of water mills with undershot and overshot water wheels and, finally, mills driven by water turbines. Some of them could be maintained for decades or centuries and are still in use today (

Figure 22a). However, usually, an abandoned cultural landscape results from the cessation of economic activities. In this stage, partial denaturalization of modified ecosystem components occurs along with the destruction or degradation of technical components since attempts to keep the water mills useable are made only sporadically (

Figure 22b). In addition, the destroyed milling facilities, which can be considered because of their characteristic cultural components, include buildings, hydraulic structures, overgrown troughs of mill ponds, and vanishing mill races (

Figure 22c). On the other hand, revitalization transforms ponds into recreational facilities, and water mill buildings are used as cultural centers, museums, dining facilities, or hotels, among others (

Figure 22d).

According to Hognogia et al. [

55], mills in general and water mills more specifically are strongly associated with the rural areas and their transformations over centuries. Another parameter related to water mills’ evolution concerns the deterioration of some components of the mill-related industrial heritage. On the other hand, having a new role as an element of cultural heritage leads to their functional necrosis.

Centuries of development and use of water mills combine tradition and remarkable technological progress. At the same time, the basic idea of converting the power of natural resources into forms of energy that are more usable for humans has been preserved in a long tradition. Today, many water mills are beautiful cultural and historical monuments in their simplicity. Modern technologies for harnessing waterpower are certainly more efficient and environmentally friendly than earlier plants, but they continue the tradition of decentralized energy generation through the sustainable use of local resources [

25].

Müller and Kauppert [

57] revealed that Britain’s 20,000 out-of-use water mills could, in many cases, be brought back to life as micro-hydro stations generating up to 1000 MW of electricity. Both overshot and undershot water wheels are cheaper to build, install, and maintain. Their efficiency lacks behind modern low-head turbines, but they can operate with a head as low as 0.5 m, which allows operation in a wide range of flow conditions. The authors reported that hydraulic screws—Archimedean screws working in reverse (

Figure 23)—have also proved very efficient and durable low-head generators.

Many low-head hydropower sites with power ratings of 1–100 kW exist in most industrialized countries. Most of this hydropower potential remains unused since existing turbine technology is too expensive for these small applications. Very simple energy converters, namely the water wheel and the hydraulic screw [

57], are alternative technologies for this class of hydropower plants.

Then, those water-related devices in their two most “modern” forms and the hydraulic screw offer cost-effective and efficient solutions for the exploitation of small hydropower sites. The water wheel and hydraulic screw have efficiencies of up to 80% and a broad performance range so that energy can be generated without additional control mechanisms. Both can cope with small debris, so trash racks and cleaning machines are not usually required. The prices for water wheels can be estimated as 3000–3500 USD/kW (overshot) and 6700–7500 USD/kW (undershot), that is, 33–66% lower than comparable Kaplan turbine facilities. These very simple machines could also be employed in developing countries where they could be manufactured locally. Research and development potential still exist for both “turbines” despite their application since antiquity [

57].

Nowadays, water mills equipped with turbines are an important source of renewable, decentralized energy and thus support the transition into a carbon-neutral future. On the other hand, water mills are challenged by requirements of environmental flow and ecological continuity, e.g., during the implementation of the European Water Framework Directive. Often, water mills cannot fulfil flow requirements in the main rivers without compromising their function or economic viability. Ecological improvements can be made by installing structures for fish migration, but small mills fear their economic end, as energy-production facilities are the main source of income for many of them. The conflicts between natural protection and renewable energy generation have led to protests from owners of small hydropower plants (

Figure 24).

This review shows that communities respond quickly to new income-generating opportunities and readily adopt new activities generating economic benefits. A good example is the use of surplus water for multipurpose activities, such as nursery cultivation, fisheries, and apiculture near water mills. This integrated agriculture-related technology model has empowered local communities to manage and make sustainable use of local resources, thus reducing the risk of migration to seek income-generating opportunities for their small farms (

Figure 25). Impact assessment studies demonstrate that simple upgrading of water mills has impacts on both the water miller, who can sustain and improve a declining business, and the end-user, who saves time and money.

Optimization of water mills’ benefits is not only important for sustainable/regenerative development but is also cost-efficient, particularly for small farms. Quaranta et al. [

59] showed this optimization, based on improving water wheels and installation of Turgo turbines, will generate an income of UAD 20,000 and USD 83,000, respectively, in 20 years (

Table 1).

The force of the water was and can be used to produce mechanical power for centuries. There are many lessons that we can learn by studying water mills. Historical investigation helps us to understand the history behind their structures and the reasons for building them. In addition, we can learn how people have lived through the centuries and how they have adapted themselves to food and water supply problems as well as energy resources. In remote villages in low-income regions around the world, hydropower can be utilized for water pumping, agro-, and food processing.

The advantage of ancient water technologies is to deal with future environmental challenges and water crises to meet sustainable/regenerative development goals. Indeed, what sustainable development is to traditional economic development, regenerative development is to sustainable development [

60]. The potential of reusing water mills as an example of agricultural technologies, if rediscovered, conserved, and enhanced, will play a crucial role in the regenerative development of small farms and smallholder farmers. The next step is to protect them as the Society for the Preservation of Old Mills (SPOOM) to keep them for our next generations as examples of industrial heritage that reveal the evolution of hydraulic power technology as well as the societies’ cultural structure and lifestyle since the early ages [

61,

62,

63,

64,

65].

_S._Voudouris.png)