Hydrological Effects of Prefabricated Permeable Pavements on Parking Lots

Abstract

:1. Introduction

2. Materials and Methods

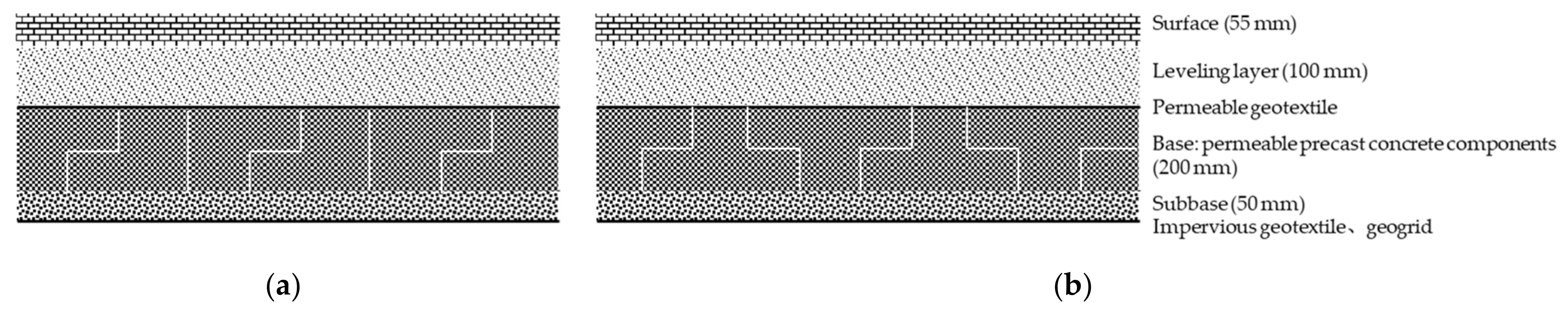

2.1. Structure of Fabricated Permeable Pavement

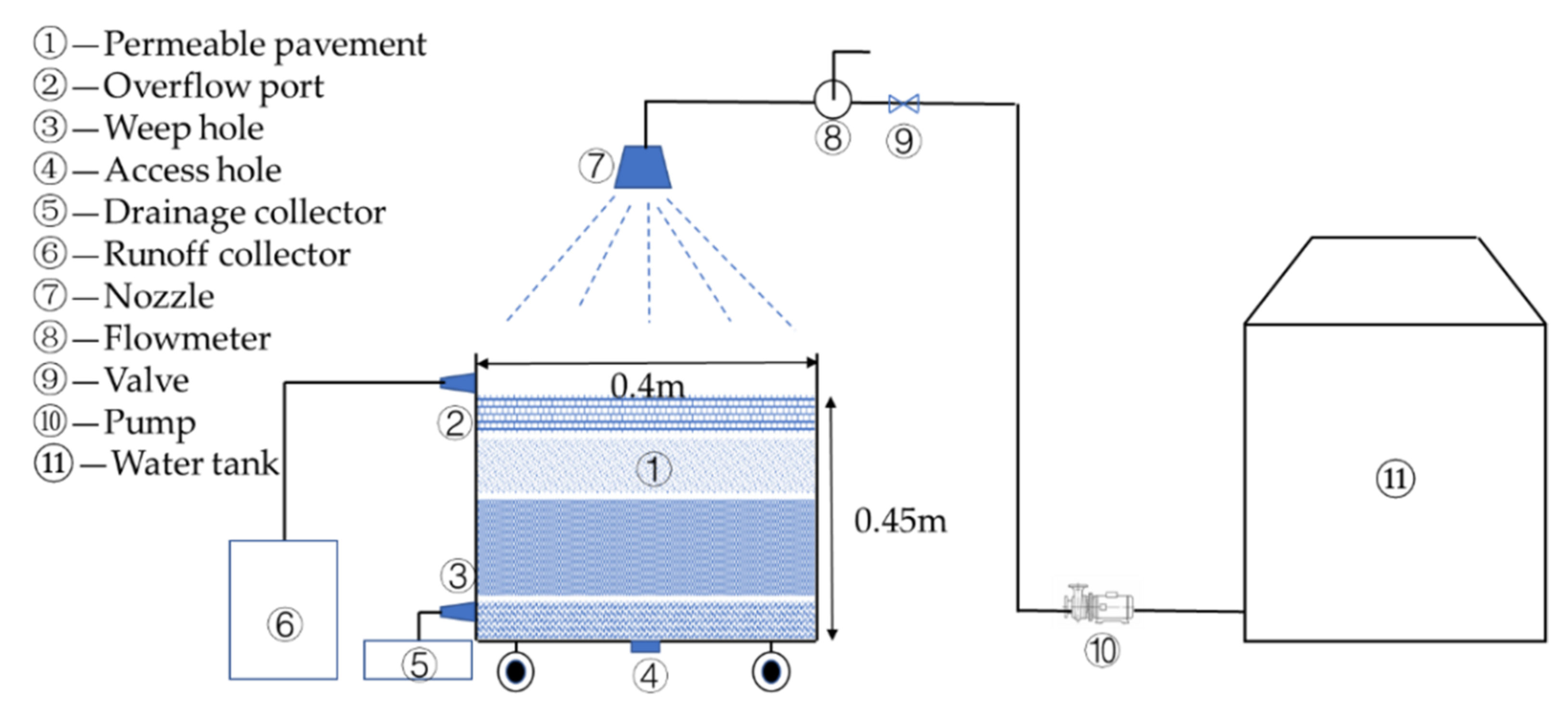

2.2. Experimental Set-Up

2.3. Experimental Scheme

2.4. Experimental Procedure

- Enough tap water was stored in the bucket to guarantee at least one experiment.

- The pump was opened and the opening of the valve was adjusted according to the reading of the flowmeter to ensure that the rainfall intensity reached the set value.

- The surface of the permeable pavement structure was observed, and the time was recorded by a stopwatch when overflow occurred.

- After the rain, the pump and valve were closed, and the amount of rainwater overflow was measured.

- The drainage outlet at the bottom of the device was kept open and the rainwater accumulated in the permeable pavement was approximately emptied.

- The mobile water tank pump was stopped for the rainfall interval before the next experiments.

2.5. Data Processing and Analysis

3. Results and Discussion

3.1. Hydrological Effect of Permeable Pavement under Different Rainfall Intensities

3.1.1. Initial Runoff Time

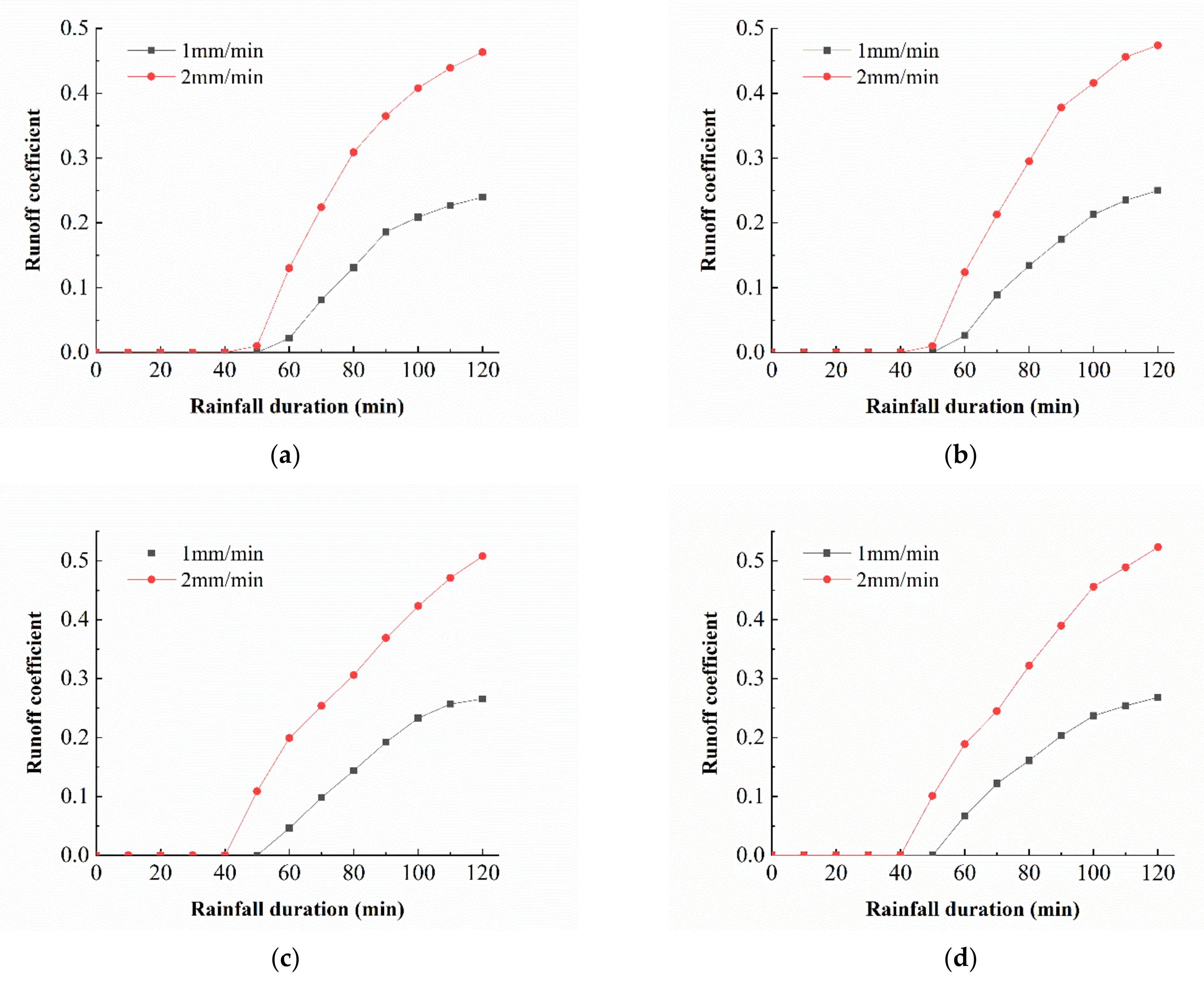

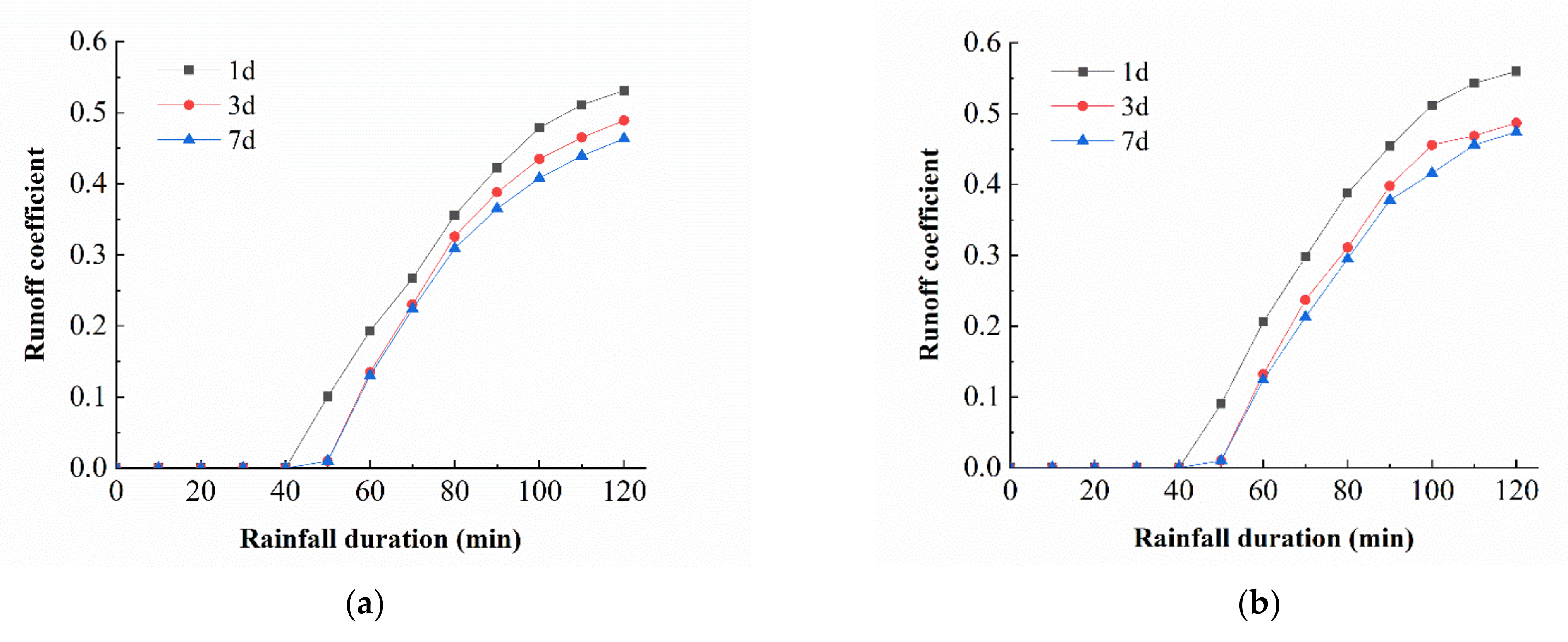

3.1.2. Runoff Coefficient

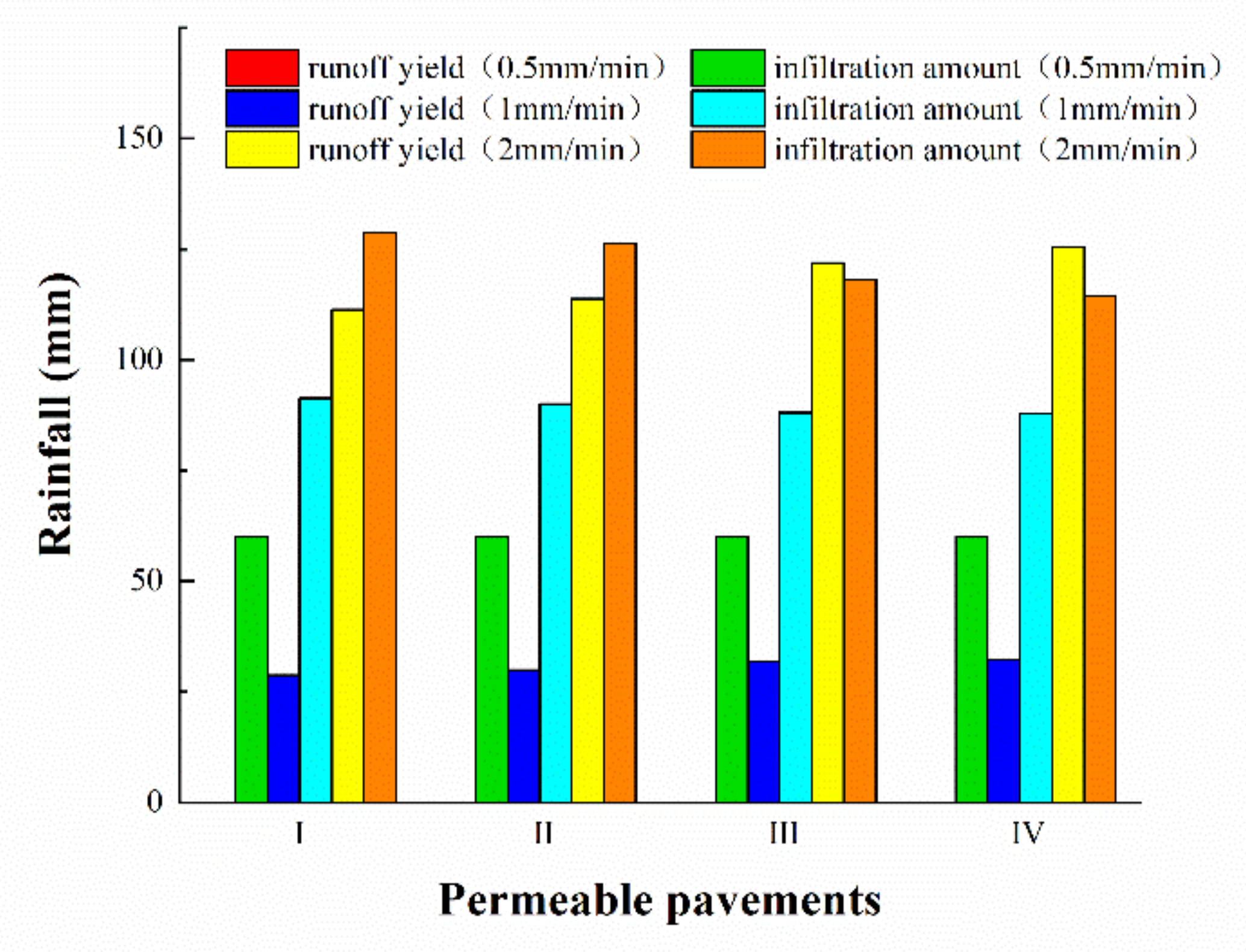

3.1.3. Runoff Control Rate

3.2. Hydrological Effects under Different Rainfall Intervals

3.2.1. Initial Runoff Time

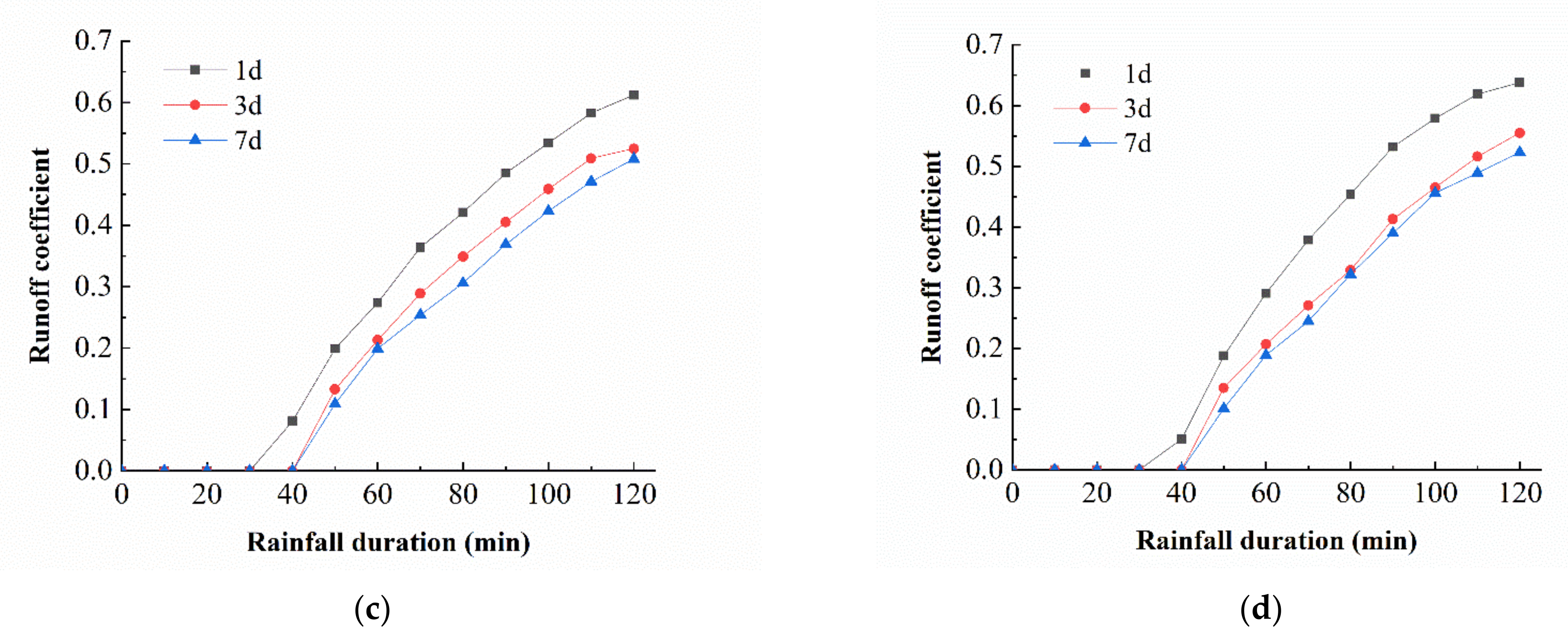

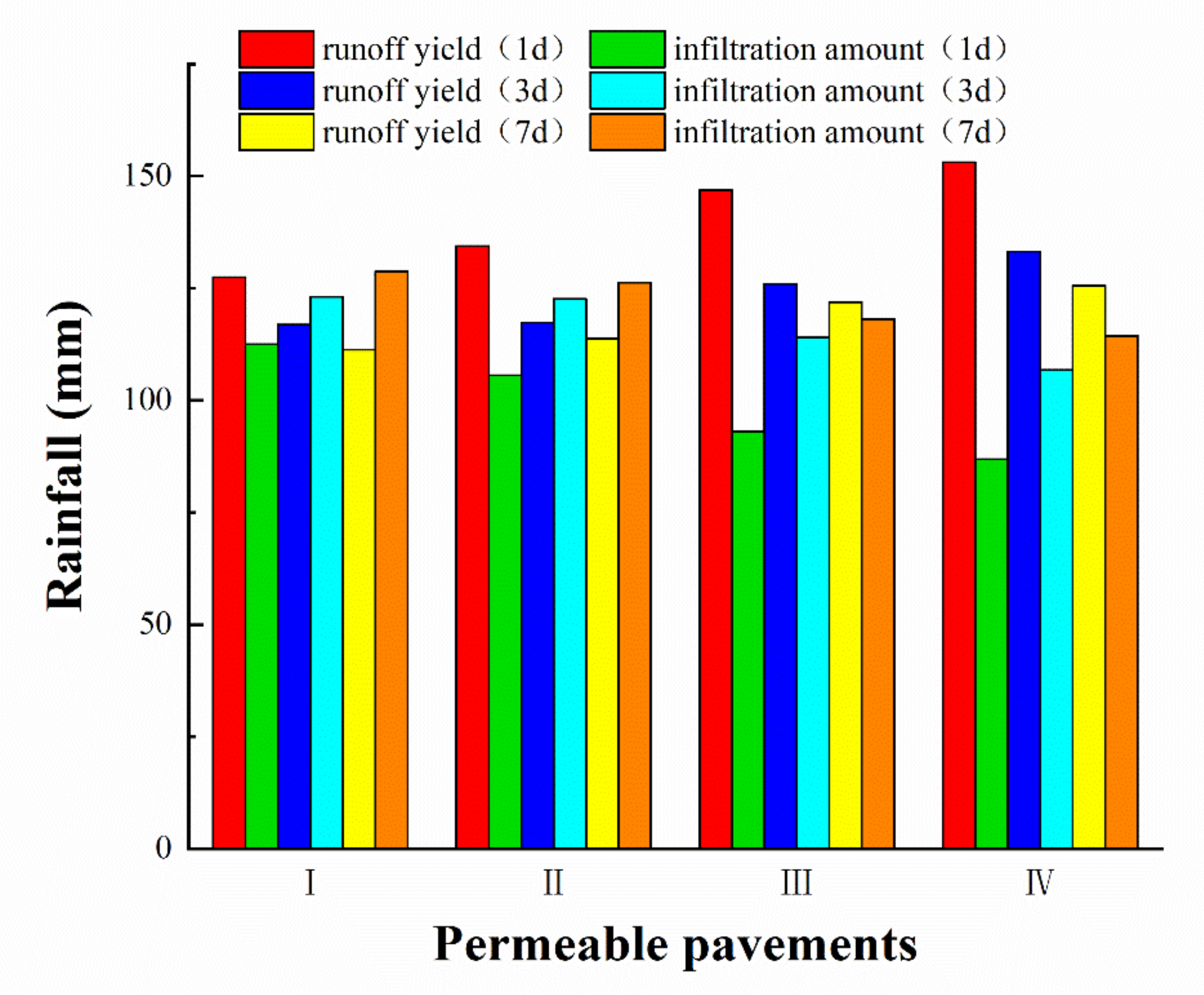

3.2.2. Runoff Coefficient

3.2.3. Runoff Control Rate

4. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hu, M.C.; Zhang, X.Q.; Siu, Y.L.; Li, Y.; Tanaka, K.; Yang, H.; Xu, Y.P. Flood Mitigation by Permeable Pavements in Chinese Sponge City Construction. Water 2018, 10, 172. [Google Scholar] [CrossRef] [Green Version]

- Zhu, Z.; Chen, X. Evaluating the Effect of Low Impact Development Practices on Urban Flooding Under Different Rainfall Intensities. Water 2017, 9, 548. [Google Scholar] [CrossRef]

- Martins Vaz, I.C.; Ghisi, E.; Thives, L.P. Stormwater Harvested from Permeable Pavements as a Means to Save Potable Water in Buildings. Water 2021, 13, 1896. [Google Scholar] [CrossRef]

- Kumar, A.; Taxak, A.K.; Mishra, S.; Pandey, R. Long Term Trend Analysis and Suitability of Water Quality of Himalayan Hills of Uttrakhand, India. Environ. Technol. Innov. 2021, 22, 101405. [Google Scholar] [CrossRef]

- Collins, A.K.; Hunt, W.F.; Hathaway, J.M. Hydrologic Comparison of Four Types of Permeable Pavement and Standard Asphalt in Eastern North Carolina. J. Hydrol. Eng. 2008, 13, 1146–1157. [Google Scholar] [CrossRef]

- Yang, F.K.; Fu, D.F.; Liu, S.; Zevenbergen, C.; Singh, R.P. Hydrologic and Pollutant Removal Performance of Media Layers in Bioretention. Water 2020, 12, 921. [Google Scholar] [CrossRef] [Green Version]

- Ding, N. Study on Parking Standard for Construction Projects in Harbin. Master’s Thesis, Chang’an University, Xi’an, China, May 2019. [Google Scholar]

- Nguyen, T.H.; Ahn, J. Numerical Study on the Hydrologic Characteristic of Permeable Friction Course Pavement. Water 2021, 13, 843. [Google Scholar] [CrossRef]

- Kumar, K.; Kozak, J.; Hundal, L.; Cox, A.; Zhang, H.; Granato, T. In-situ Infiltration Performance of Different Permeable Pavements in a Employee Used Parking Lot—A Four-year Study. J. Environ. Manag. 2016, 167, 8–14. [Google Scholar] [CrossRef]

- Pratt, C.J.; Mantle, J.D.G.; Schofield, P.A. Urban Stormwater Reduction and Quality Improvement through the Use of Permeable Pavements. Water Sci. Technol. 1989, 21, 769–778. [Google Scholar] [CrossRef]

- Hunt, B.; Stevens, S.; Mayes, D. Permeable Pavements Use and Research at Two Sites in Eastern North Carolina. In Proceedings of the 9th International Conference on Urban Drainage, Global Solutions for Urban Drainage, ASCE, Portland, OR, USA, 8–13 September 2002. [Google Scholar]

- Brattebo, B.O.; Booth, D.B. Long-term Stormwater Quantity and Quality Performance of Permeable Pavement Systems. Water Res. 2003, 37, 4369–4376. [Google Scholar] [CrossRef]

- Bean, E.Z.; Hunt, W.F.; Bidelspach, D.A. Field Survey of Permeable Pavement Surface Infiltration Rates. J. Irrig. Drain. Eng. 2007, 133, 247–255. [Google Scholar] [CrossRef]

- Wang, J.L.; Wang, X.M.; Zhang, A.; Zhang, Y. Review on Permeable Pavement Systems Based on the Concept of “Sponge City” Runoff Management Performances of Permeable Pavements: A Review. Environ. Eng. 2015, 33, 1–4. (In Chinese) [Google Scholar]

- Wei, S.; Wu, L.P.; Li, J. Discussion on the Application of Water Permeable Brick in the Construction of Sponge City. China Water Wastewater 2017, 33, 1–5. [Google Scholar]

- Li, Z.Z.; Dong, M.J.; Wong, T.; Wang, J.B.; Kumar, A.J.; Singh, R.P. Objectives and Indexes for Implementation of Sponge Cities—A Case Study of Changzhou City, China. Water 2019, 11, 81. [Google Scholar] [CrossRef] [Green Version]

- Li, M.Y.; Zhang, S.H.; Wang, Y.J.; Wang, Y.Q. Runoff Management Performances of Permeable Pavements: A Review. Environ. Sci. Technol. 2018, 41, 105–112. [Google Scholar]

- Cheng, Y.-Y.; Lo, S.-L.; Ho, C.-C.; Lin, J.-Y.; Yu, S.L. Field Testing of Porous Pavement Performance on Runoff and Temperature Control in Taipei City. Water 2019, 11, 2635. [Google Scholar] [CrossRef] [Green Version]

- Park, J.; Park, J.; Cheon, J.; Lee, J.; Shin, H. Analysis of Infiltrating Water Characteristics of Permeable Pavements in a Parking Lot at Full Scale. Water 2020, 12, 2081. [Google Scholar] [CrossRef]

- Ghisi, E.; Belotto, T.; Thives, L.P. The Use of Permeable Interlocking Concrete Pavement to Filter Stormwater for Non-Potable Uses in Buildings. Water 2020, 12, 2045. [Google Scholar] [CrossRef]

- Zhu, X.J.; Liu, J.; Wu, W. Application of Slotted Permeable Pavement in the Construction of Sponge City: Taking Zhenjiang as an Example. China Water Wastewater 2017, 33, 1–4. [Google Scholar]

- Li, J.; Zhang, Y.; Liu, G.; Peng, X.H. Preparation and Performance Evaluation of an Innovative Pervious Concrete Pavement. Constr. Build. Mater. 2017, 138, 479–485. [Google Scholar] [CrossRef]

- Braswell, A.S.; Winston, R.J.; Hunt, W.F. Hydrologic and Water Quality Performance of Permeable Pavement with Internal Water Storage over a Clay Soil in Durham, North Carolina. J. Environ. Manag. 2018, 224, 277–287. [Google Scholar] [CrossRef]

- Lin, W.; Kim, I.T.; Kim, H.; Cho, Y.H. Water Runoff Characteristics in Porous Block Pavements Using an Accelerated Pavement Tester. J. Hydrol. Eng. 2014, 19, 04014012. [Google Scholar] [CrossRef]

- Walter, E.; Sieglen, J.; Langsdorff, H.V. Interlocking Concrete Block Pavements at Howland Hook Marine Terminal. In Proceedings of the Ports Conference 2004, Houston, TX, USA, 23–26 May 2004; pp. 1–10. [Google Scholar]

- Yang, Y.J. An Assembled Permeable Sidewalk Base Block. Patent No. 201721177033.9, 13 September 2017. [Google Scholar]

- Yang, H.; Chen, H.M.; Huang, X. An Ecological Permeable Pavement. Patent No. 201910336928.X, 23 April 2019. [Google Scholar]

- Bateni, N.; Lai, S.H.; Putuhena, F.J.; Mah, D.Y.S.; Mannan, M.A.; Chin, R.J. Hydrological Performances on the Modified Permeable Pavement with Precast Hollow Cylinder Micro detention Pond Structure. KSCE J. Civ. Eng. 2019, 23, 3951–3960. [Google Scholar] [CrossRef]

- Liu, W.; Feng, Q.; Chen, W.; Ravinesh, C.D. Stormwater Runoff and Pollution Retention Performances of Permeable Pavements and the Effects of Structural Factors. Environ. Sci. Pollut. Res. 2020, 27, 30831–30843. [Google Scholar] [CrossRef]

- Zhang, S.H.; Chen, J.G.; Zhao, F.; Hou, L.Z. Experimental Study on Pavement Structure of Pervious Bricks Based on Infiltration and Runoff Generation Analysis. Adv. Sci. Technol. Water Resour. 2011, 31, 39–42. [Google Scholar]

- Alyaseri, I.; Zhou, J.P. Stormwater Volume Reduction in Combined Sewer Using Permeable Pavement: City of St. Louis. J. Environ. Eng. 2016, 142, 04016002. [Google Scholar] [CrossRef]

- USEPA (United States Environmental Protection Agency). Porous Asphalt Pavements; United States Environmental Protection Agency: Washington, WA, USA, 2009.

- Zhao, F.; Chen, J.G.; Zhang, S.H.; Su, D.B.; Gong, Y.A. Study of Rainfall-Runoff Model at Permeable Pavement. Water Wastewater Eng. 2010, 46, 154–159. [Google Scholar]

- Shafique, M.; Kim, R.; Kyung-Ho, K. Rainfall Runoff Mitigation by Retrofitted Permeable Pavements in an Urban Area. Sustainability 2018, 10, 1231. [Google Scholar] [CrossRef] [Green Version]

- Antunes, L.N.; Sydney, C.; Ghisi, E.; Phoenix, V.R.; Thives, L.P.; White, C.; Garcia, E.S.H. Reduction of Environmental Impacts Due to Using Permeable Pavements to Harvest Stormwater. Water 2020, 12, 2840. [Google Scholar] [CrossRef]

- Alam, T.; Mahmoud, A.; Jones, K.D.; Bezares-Cruz, J.C. A Comparison of Three Types of Permeable Pavements for Urban Runoff Mitigation in the Semi-Arid South Texas, USA. Water 2019, 11, 1992. [Google Scholar] [CrossRef] [Green Version]

- Li, H.Y.; Li, Z.F.; Zhang, X.R.; Li, Z.R.; Liu, D.Q.; Li, T.H.; Zhang, Z.Y. The Effect of Different Surface Materials on Runoff Quality in Permeable Pavements Systems. Environ. Sci. Pollut. Res. 2017, 24, 21103–21110. [Google Scholar] [CrossRef]

- Tirpak, R.A.; Winston, R.J.; Simpson, I.M.; Dorsey, J.D.; Grimm, A.G.; Pieschek, R.L.; Petrovskis, E.A.; Carpenter, D.D. Hydrologic Impacts of Retrofitted Low Impact Development in a Commercial Parking Lot. J. Hydrol. 2021, 592, 125773. [Google Scholar] [CrossRef]

- Daniel, J.; Nora, S.; Susanne, C.; Ignacio, A. Coupling GIS with Stormwater Modelling for the Location Prioritization and Hydrological Simulation of Permeable Pavements in Urban Catchments. Water 2016, 8, 451. [Google Scholar]

- Tirpak, R.A.; Winston, R.J.; Feliciano, M.; Dorsey, J.D.; Epps, T.H. Impacts of Permeable Interlocking Concrete Pavement on the Runoff Hydrograph: Volume Reduction, Peak Flow Mitigation and Extension of Lag Times. Hydrol. Process 2021, 35, e14167. [Google Scholar] [CrossRef]

- Kumar, A.; Pinto, M.C.; Candeias, C.; Dinis, P.A. Baseline Maps of Potentially Toxic Elements in the Soils of Garhwal Himalayas, India: Assessment of their Eco-environmental and Human Health Risks. Land Degrad. Dev. 2021, 9, 3984. [Google Scholar] [CrossRef]

- Kumar, A.; Jigyasu, D.K.; Kumar, A.; Subrahmanyam, G.; Mondal, R.; Shabnam, A.A.; Cabral-Pinto, M.M.S.; Malyan, S.K.; Chaturvedi, A.K.; Gupta, D.K.; et al. Nickel in Terrestrial Biota: Comprehensive Review on Contamination, Toxicity, Tolerance and its Remediation Approaches. Chemosphere 2021, 10, 1016. [Google Scholar] [CrossRef]

| Type | Surface | Leveling Layer | Base | Subbase |

|---|---|---|---|---|

| I | Water permeable brick | Natural sand-gravel | Type a | Natural graded crushed stone |

| II | Type b | |||

| III | Medium sand | Type a | ||

| IV | Type b |

| Rainfall Intensity (mm/min) | Initial Runoff Time (min) | |||

|---|---|---|---|---|

| Type I | Type II | Type III | Type IV | |

| 0.5 | 0 | 0 | 0 | 0 |

| 1 | 58 | 58 | 54 | 53 |

| 2 | 51 | 49 | 43 | 42 |

| Rainfall Intensity (mm/min) | Runoff Control Rate (%) | |||

|---|---|---|---|---|

| Type I | Type II | Type III | Type IV | |

| 0.5 | 100 | 100 | 100 | 100 |

| 1 | 76.0 | 75.0 | 73.4 | 73.2 |

| 2 | 53.6 | 52.6 | 49.2 | 47.7 |

| Rainfall Interval (d) | Initial Runoff Duration (min) | |||

|---|---|---|---|---|

| Type I | Type II | Type III | Type IV | |

| 1 | 47 | 46 | 38 | 36 |

| 3 | 50 | 50 | 41 | 40 |

| 7 | 51 | 49 | 43 | 42 |

| Rainfall Interval (d) | Runoff Control Rate (%) | |||

|---|---|---|---|---|

| Type I | Type II | Type III | Type IV | |

| 1 | 46.9 | 44.0 | 38.8 | 36.2 |

| 3 | 51.3 | 51.1 | 47.5 | 44.5 |

| 7 | 53.6 | 52.6 | 49.2 | 47.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dai, K.; Liu, W.; Shui, X.; Fu, D.; Zevenbergen, C.; Singh, R.P. Hydrological Effects of Prefabricated Permeable Pavements on Parking Lots. Water 2022, 14, 45. https://doi.org/10.3390/w14010045

Dai K, Liu W, Shui X, Fu D, Zevenbergen C, Singh RP. Hydrological Effects of Prefabricated Permeable Pavements on Parking Lots. Water. 2022; 14(1):45. https://doi.org/10.3390/w14010045

Chicago/Turabian StyleDai, Kechang, Weixing Liu, Xiaotian Shui, Dafang Fu, Chris Zevenbergen, and Rajendra Prasad Singh. 2022. "Hydrological Effects of Prefabricated Permeable Pavements on Parking Lots" Water 14, no. 1: 45. https://doi.org/10.3390/w14010045

APA StyleDai, K., Liu, W., Shui, X., Fu, D., Zevenbergen, C., & Singh, R. P. (2022). Hydrological Effects of Prefabricated Permeable Pavements on Parking Lots. Water, 14(1), 45. https://doi.org/10.3390/w14010045