Research on Descaling Characteristics and Simulation Calculation of a Coaxial High-Frequency Electronic Descaling Device

Abstract

1. Introduction

2. Experimental Principle and Experimental System

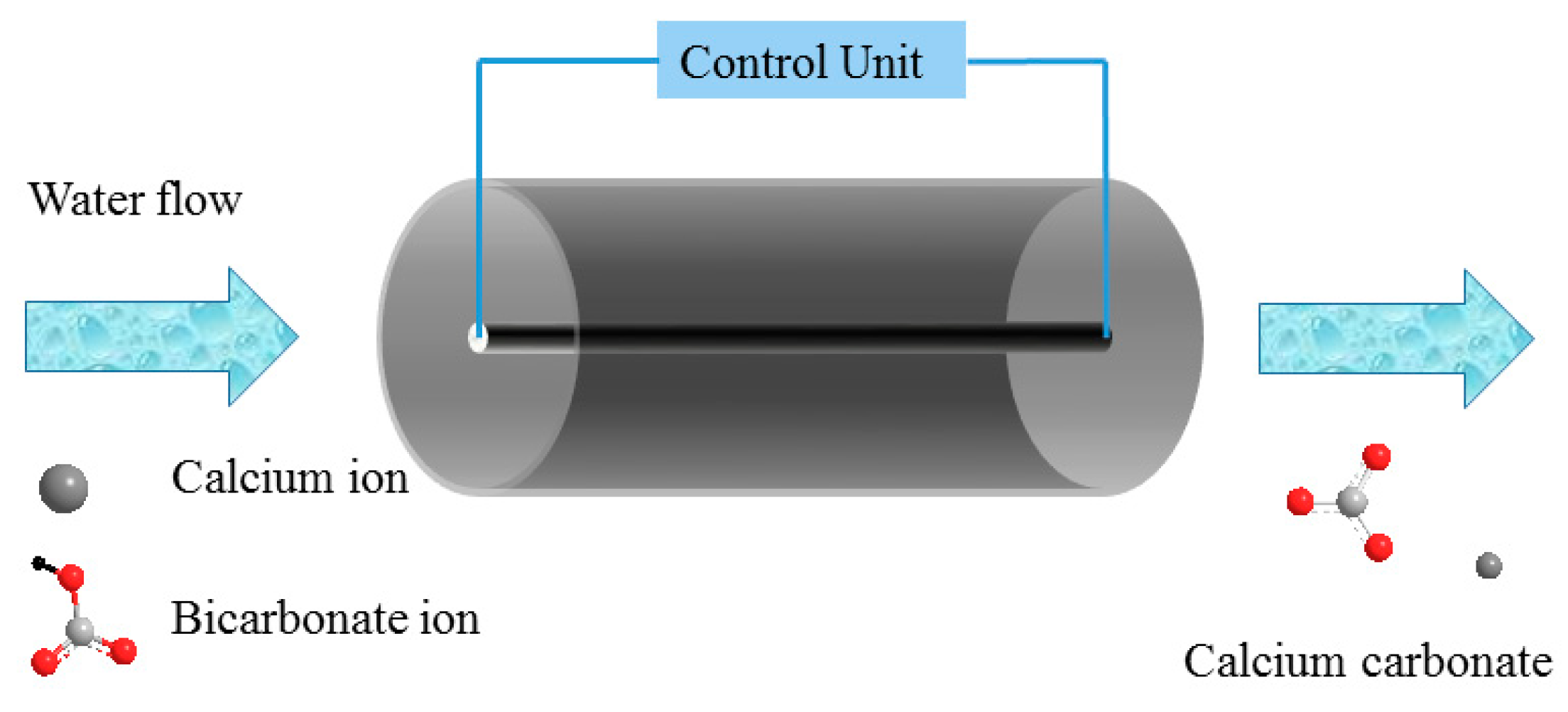

2.1. Mechanism of a High-Frequency Electronic Descaling Device

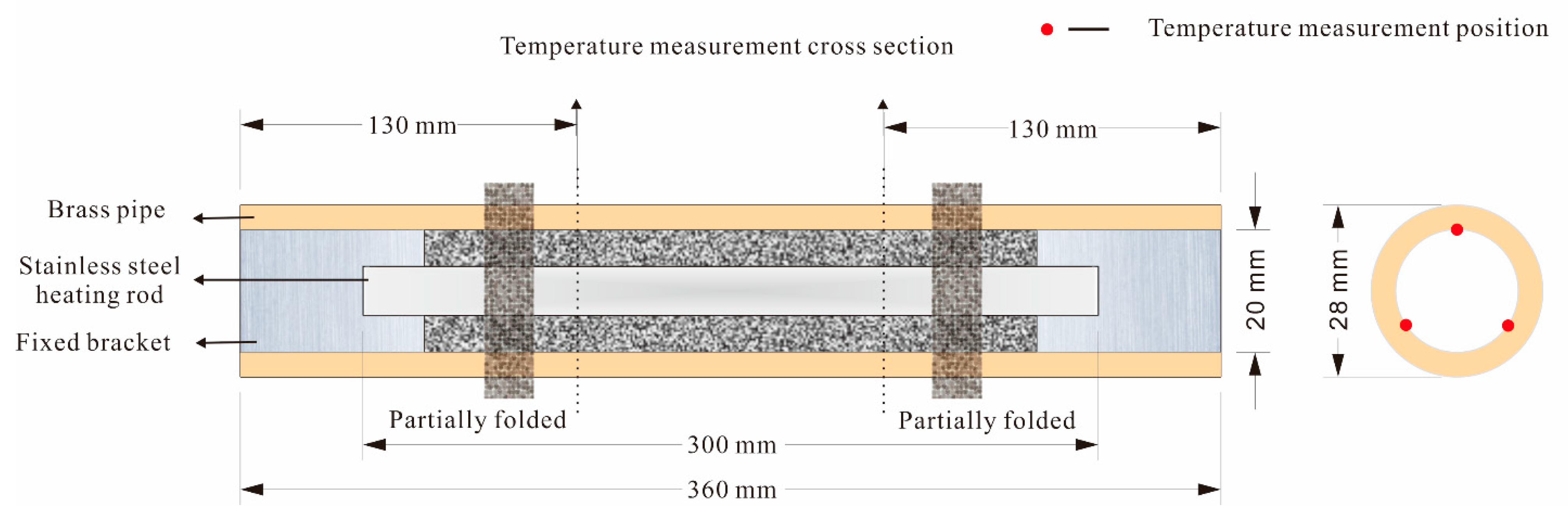

2.2. Experimental System

2.3. Experimental Principle

3. Experimental Results and Discussion

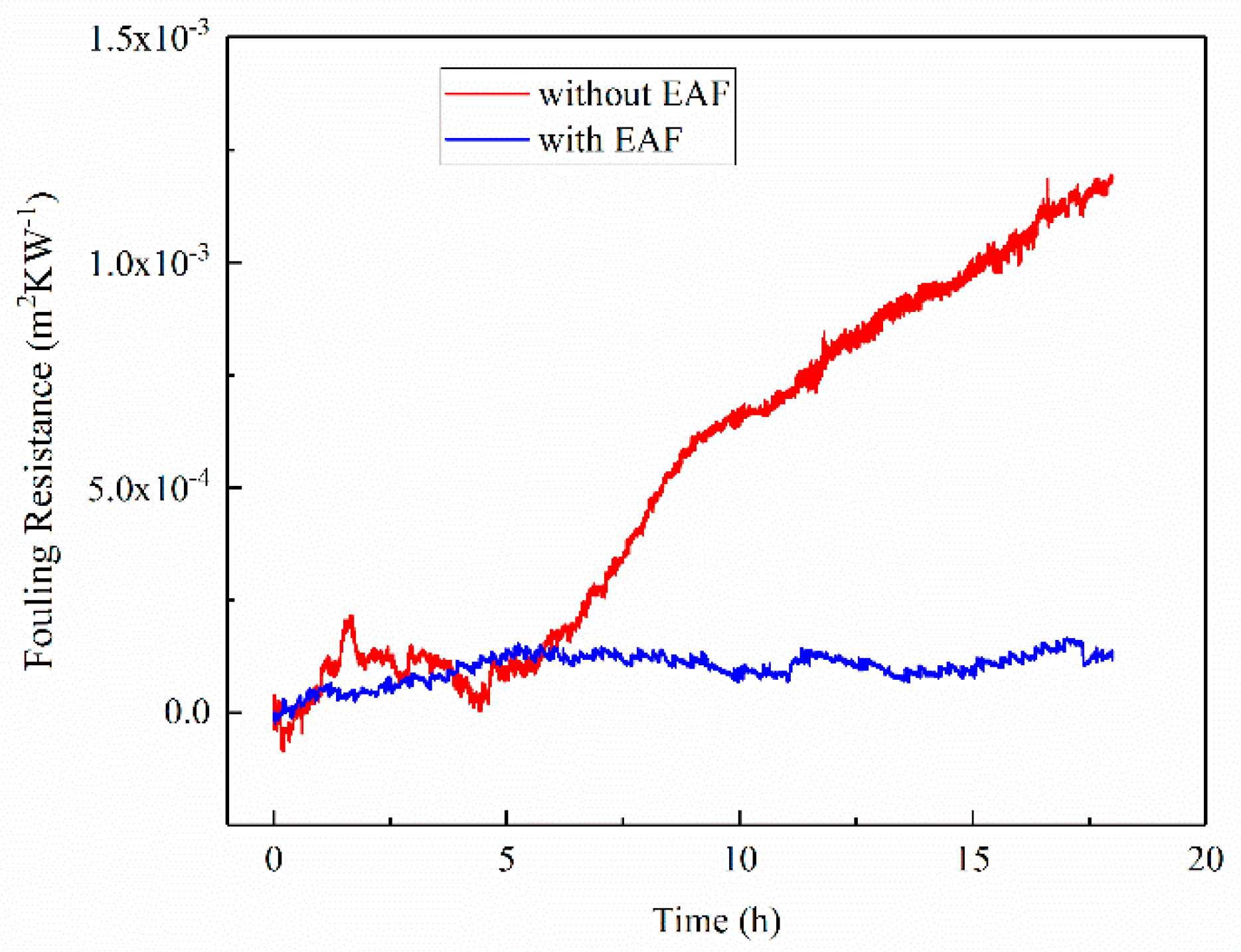

3.1. Results and Discussion of Fouling Resistance

3.2. Results and Discussion of Microscopic Morphology of Scale Samples

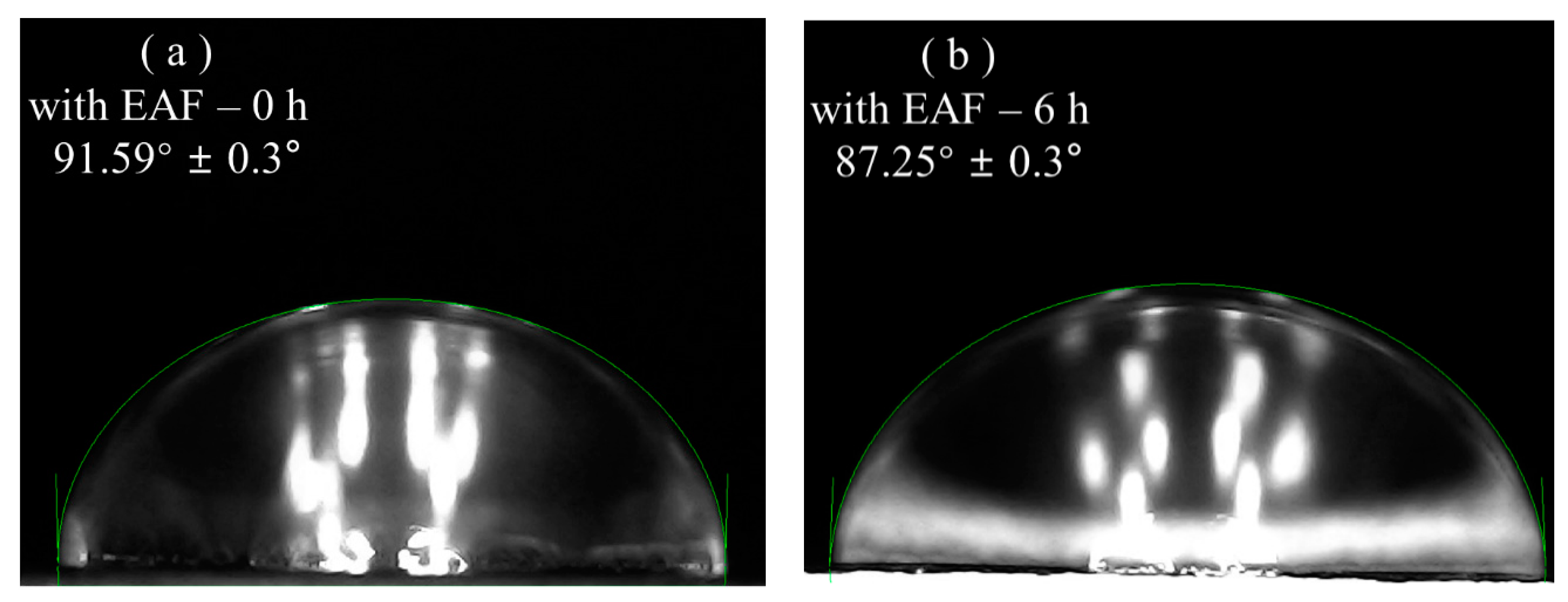

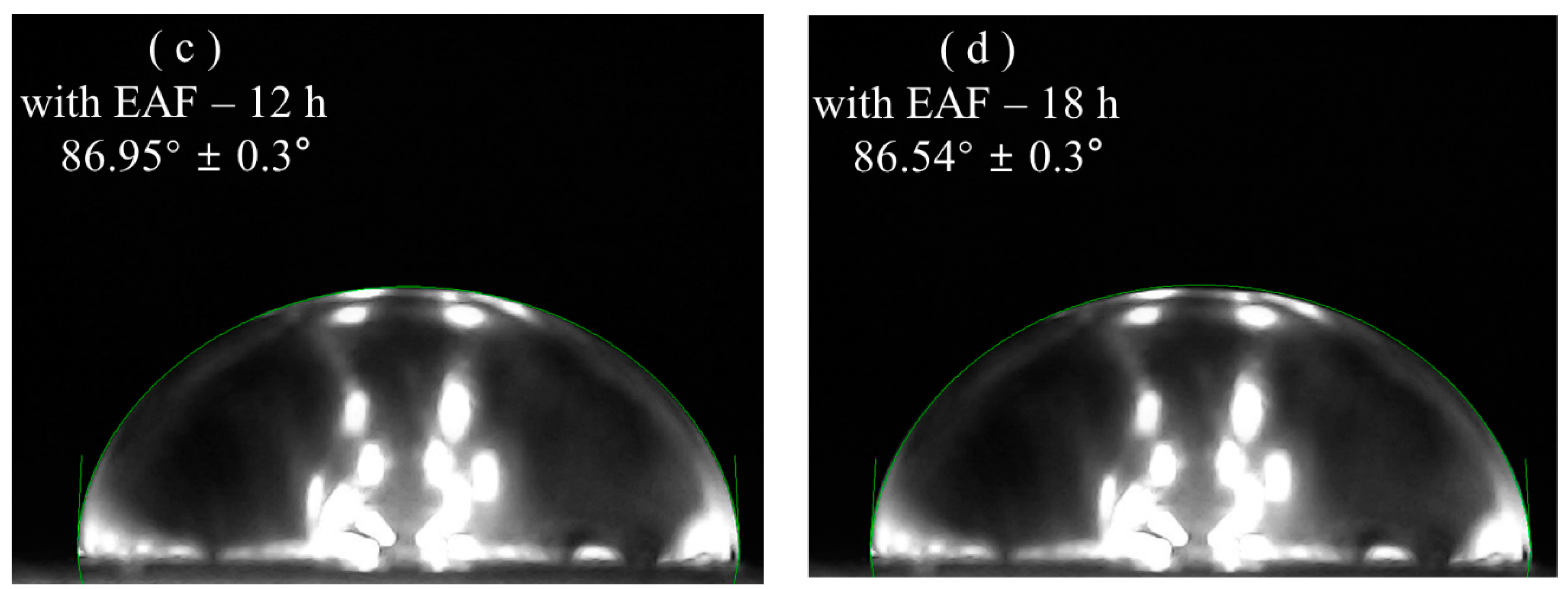

3.3. Results and Discussion of Changes of Contact Angle

4. Model Simulation and Calculation

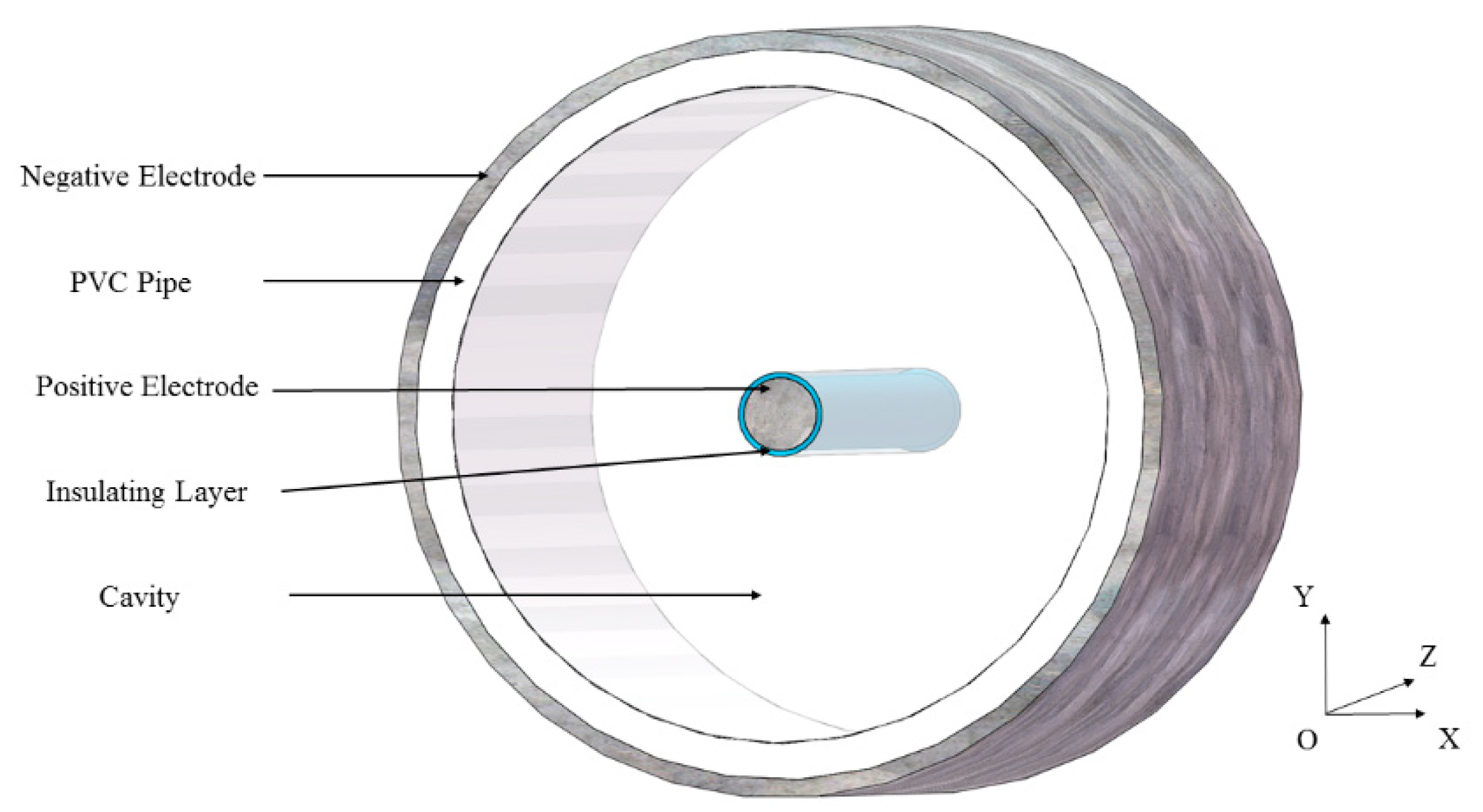

4.1. Cavity Physical Model

4.2. Calculation Conditions

4.3. Electromagnetic Field Parameters

5. Parameter Analysis

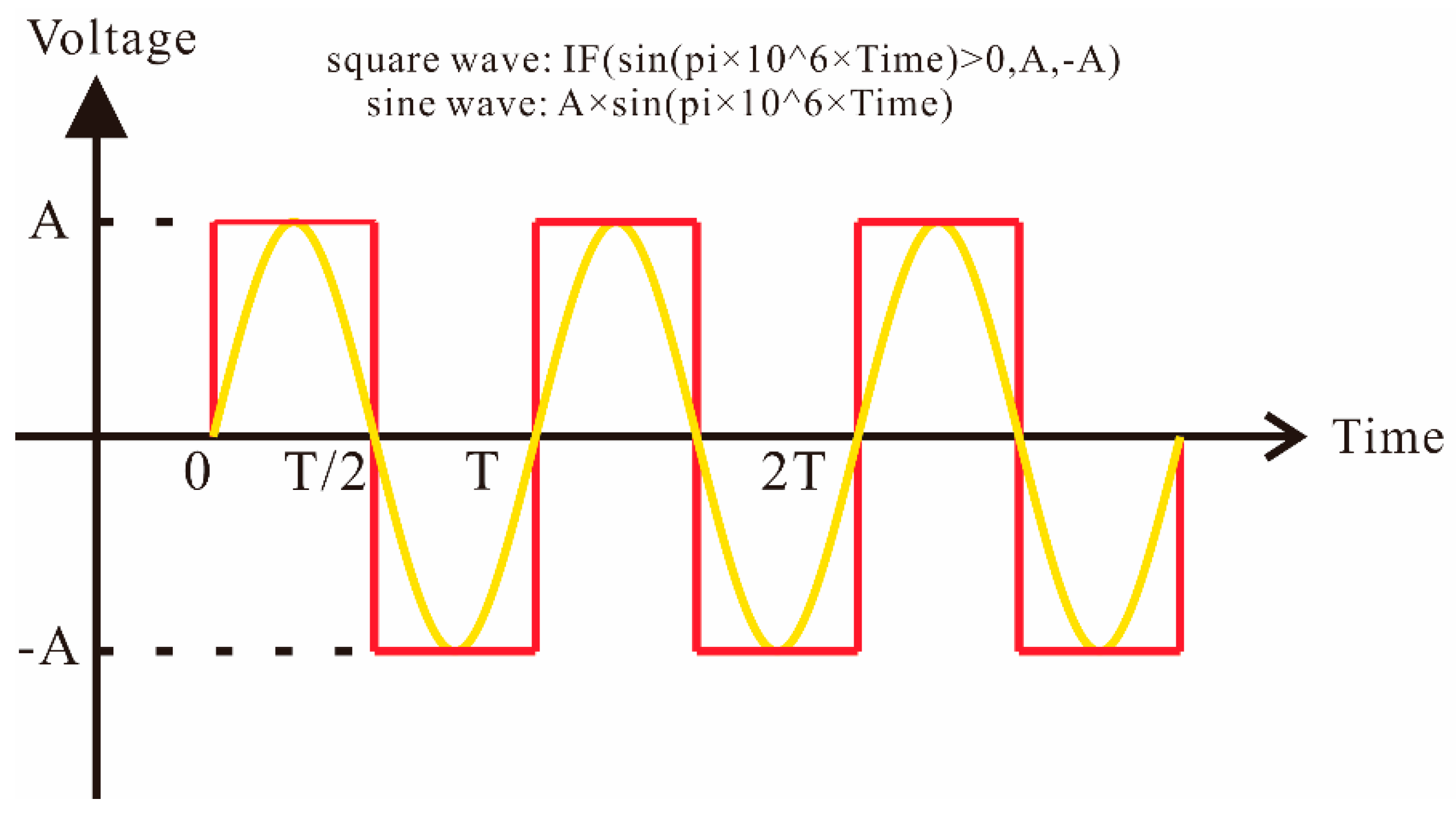

5.1. The Influence of Waveform Changes on the Electromagnetic Field

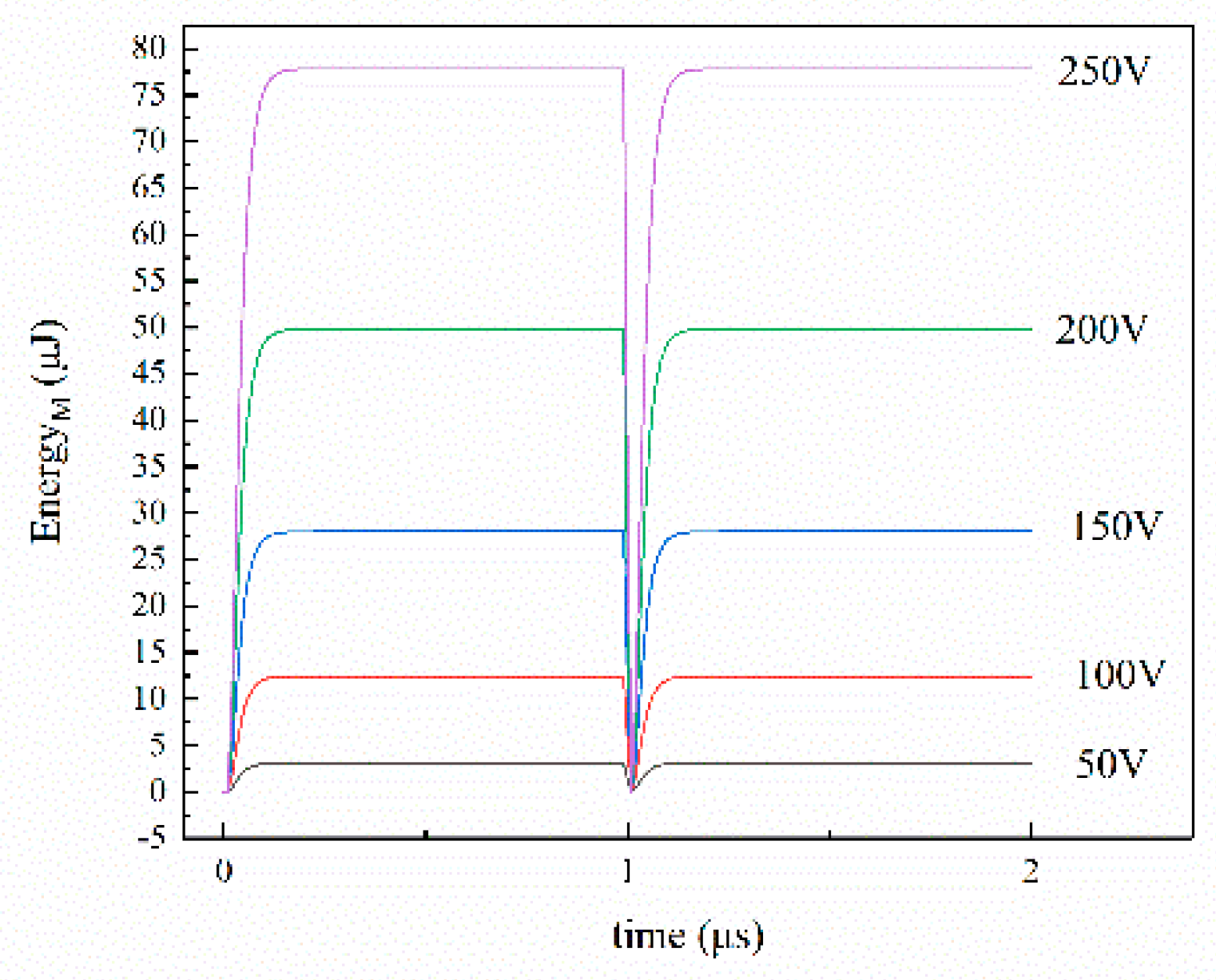

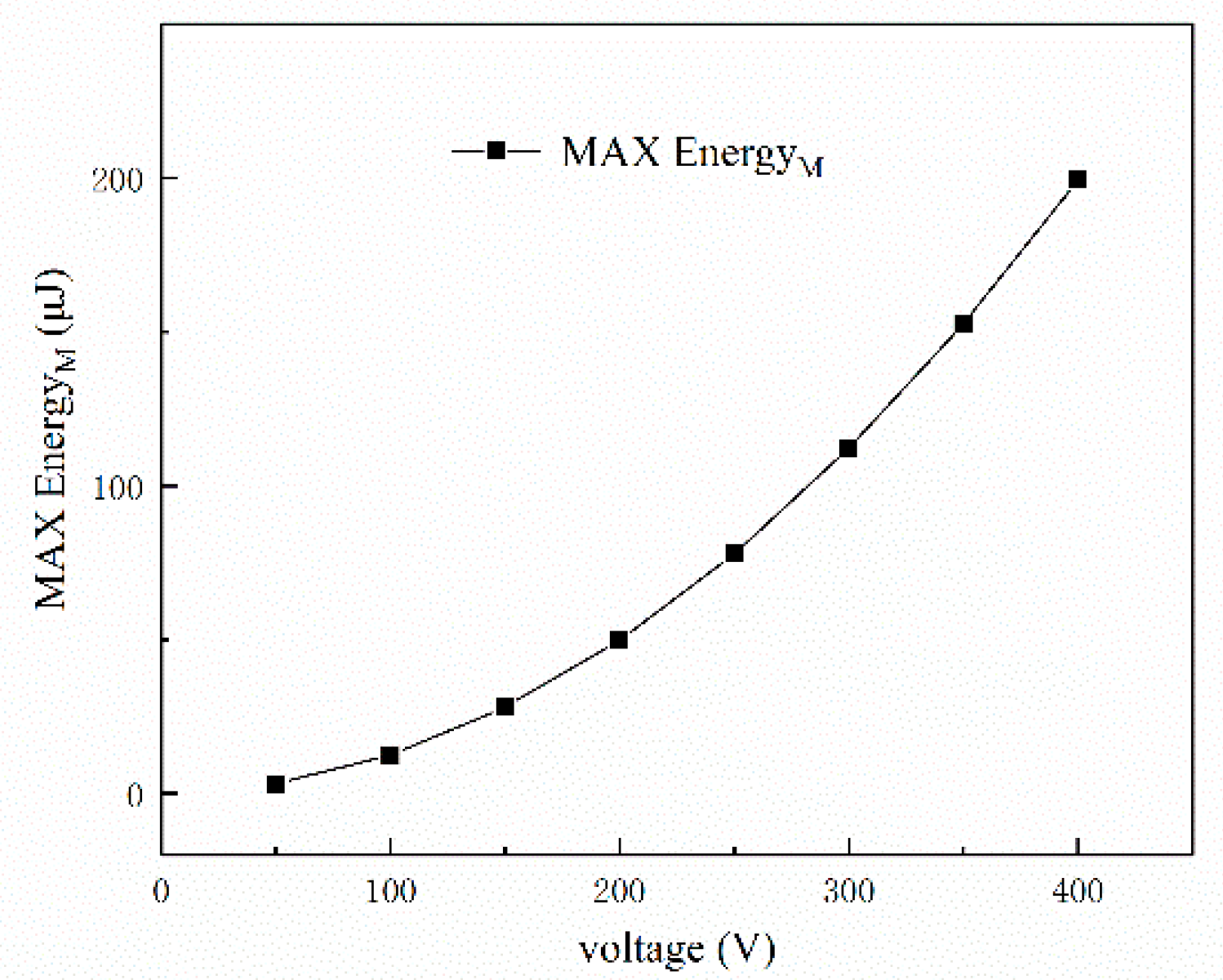

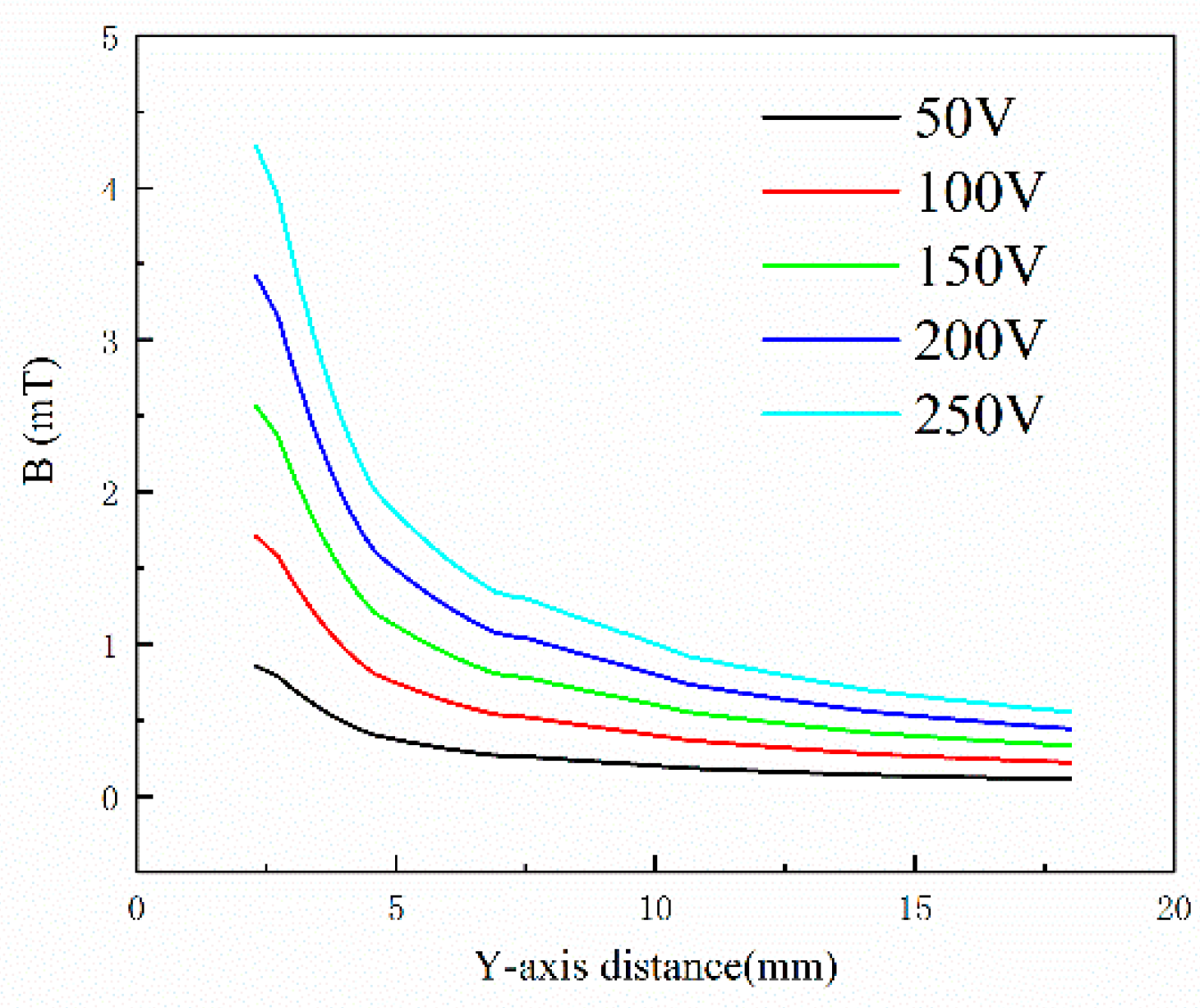

5.2. Influence of Voltage Amplitude Changes on Electromagnetic Field

5.3. Influence of Frequency Changes on the Electromagnetic Field

6. Conclusions

- (1)

- A high-frequency electromagnetic field is an effective physical descaling method. The formation of fouling on the heat transfer surface can be greatly reduced by a high-frequency electronic descaling device.

- (2)

- Ahigh-frequency electromagnetic field accelerates the growth of scale particles and destroys their surface morphology, which makes the scale layer loose and easy to peel off.

- (3)

- The contact angle decreases to a limited extent with the action of the high-frequency electromagnetic field, which is caused by the high-frequency electromagnetic field promoting the growth of water clusters and colloidal particles in the water. The contact angle can be used as an important index to measure the descaling ability of a high frequency electromagnetic field.

- (4)

- For both square and sine waves, the electric field energy can be ignored compared with the magnetic field energy, so research on the mechanism of the high-frequency electromagnetic field produced by high-frequency electronic descaling devices should be focused on the role of the magnetic field.

- (5)

- At the same amplitude and frequency, the magnetic field energy generated by the square wave is greater than that generated by the sine wave, so the high-frequency electronic descaling device with a square wave has better scale inhibition and descaling effects.

- (6)

- Given the same frequency and square wave waveform, the energy of the magnetic field increases and the speed of growth is faster with an increase in the voltage. However, an excessively high voltage may lead to breaking molecular chains. The selection of the voltage amplitude needs to consider the promotion of crystallization and the role of molecular fracture.

- (7)

- The descaling effect of the high-frequency electronic descaling device will not increase indefinitely as the frequency increases. Given a constant voltage and a square wave waveform, the peak values of the magnetic field energy and magnetic flux gradually decrease with an increase in the frequency. As the frequency increases, the influence of the relaxation time becomes more significant. Over a certain frequency range (0.5–5 MHz), changes in the magnetic field energy and magnetic flux are very small, so the design and selection of parameters can be carried out in this range.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, B.C.; Cao, K.; Li, G.L.; Li, Y.Y.; Jia, W.G.; Zhang, Y.F. Experimental study on magnetic induction property of solenoid coil used in cooling water treatment system. J. Water Supply Res Technol. Aqua 2017, 66, 353–360. [Google Scholar] [CrossRef][Green Version]

- Teng, K.H.; Amiri, A.; Kazi, S.N.; Bakar, M.A.; Chew, B.T.; Al-Shamma’a, A.; Shaw, A. Retardation of heat exchanger surfaces mineral fouling by water-based diethylenetriamine pentaacetate-treated CNT nanofluids. Appl. Therm. Eng. 2017, 110, 495–503. [Google Scholar] [CrossRef]

- Lee, G.J.; Tijing, L.D.; Pak, B.C.; Baek, B.J.; Cho, Y.I. Use of catalytic materials for the mitigation of mineral fouling. Int. Commun. Heat Mass Transf. 2006, 33, 14–23. [Google Scholar] [CrossRef]

- Kim, W.; Cho, Y.I. Benefit of filtration in physical water treatment for the mitigation of mineral fouling in heat exchangers. Int. Commun. Heat Mass Transf. 2011, 38, 1008–1013. [Google Scholar] [CrossRef]

- Lin, L.; Jiang, W.B.; Xu, X.S.; Xu, P. A critical review of the application of electromagnetic fields for scaling control in water systems: Mechanisms, characterization, and operation. NPJ Clean Water 2020, 3, 25. [Google Scholar] [CrossRef]

- Xu, Z.M.; Chang, H.L.; Wang, B.B.; Wang, J.T.; Zhao, Q. Characteristics of calcium carbonate fouling on heat transfer surfaces under the action of electric fields. J. Mech. Sci. Technol. 2018, 32, 3445–3451. [Google Scholar] [CrossRef]

- Kazi, S.N.; Teng, K.H.; Zakaria, M.S.; Sadeghinezhad, E.; Bakar, M.A. Study of mineral fouling mitigation on heat exchanger surface. Desalination 2015, 367, 248–254. [Google Scholar] [CrossRef]

- Baig, H.; Antar, M.A.; Zubair, S.M. Performance evaluation of a once-through multi-stage flash distillation system: Impact of brine heater fouling. Energy Conv. Manag. 2011, 52, 1414–1425. [Google Scholar] [CrossRef]

- Muller-Steinhagen, H.; Malayeri, M.R.; Watkinson, A.P. Heat Exchanger Fouling: Mitigation and Cleaning Strategies. Heat Transf. Eng. 2011, 32, 189–196. [Google Scholar] [CrossRef]

- Sohaili, J.; Shi, H.S.; Lavania, B.; Zardari, N.H.; Ahmad, N.; Muniyandi, S.K. Removal of scale deposition on pipe walls by using magnetic field treatment and the effects of magnetic strength. J. Clean Prod. 2016, 139, 1393–1399. [Google Scholar] [CrossRef]

- Kim, W.; Cho, D.J.; Cho, Y.I. Use of RF electric fields for simultaneous mineral and bio-fouling control in a heat exchanger. Int. Commun. Heat Mass Transf. 2011, 38, 1003–1007. [Google Scholar] [CrossRef]

- Caputo, A.C.; Pelagagge, P.M.; Salini, P. Joint economic optimization of heat exchanger design and maintenance policy. Appl. Therm. Eng. 2011, 31, 1381–1392. [Google Scholar] [CrossRef]

- Cho, Y.I.; Kim, W.T.; Cho, D.J. Electro-flocculation mechanism of physical water treatment for the mitigation of mineral fouling in heat exchangers. Exp. Heat Transf. 2007, 20, 323–335. [Google Scholar] [CrossRef]

- Sronsri, C.; U-yen, K.; Sittipol, W. Quantitative analysis of calcium carbonate formation in magnetized water. Mater. Chem. Phys. 2020, 245, 122735. [Google Scholar] [CrossRef]

- Raudino, M.; Sarri, F.; Tatini, D.; Ambrosi, M.; Aloisi, G.D.; Ninham, B.W.; Dei, L.; Lo Nostro, P. The Effect of Temperature and Magnetic Field on the Precipitation of Insoluble Salts of Alkaline Earth Metals. J. Solut. Chem. 2020, 49, 289–305. [Google Scholar] [CrossRef]

- Zhang, L.X.; Li, X.; Gao, M.; Ma, L.; Zhao, S.X. Study on descaling characteristics of an induction-type electronic descaling device outside the heat transfer tubes of evaporative cooler. Appl. Therm. Eng. 2017, 127, 1627–1631. [Google Scholar] [CrossRef]

- Zhang, L.X.; Chen, Y.B.; Gao, M.; Li, X.; Lin, Z.H. Validation of electronic anti-fouling technology in the spray water side of evaporative cooler. Int. J. Heat Mass Transf. 2016, 93, 624–628. [Google Scholar] [CrossRef]

- Salman, M.A.; Al-Nuwaibit, G.; Safar, M.; Al-Mesri, A. Performance of physical treatment method and different commercial antiscalants to control scaling deposition in desalination plant. Desalination 2015, 369, 18–25. [Google Scholar] [CrossRef]

- Tijing, L.D.; Lee, D.H.; Kim, D.W.; Cho, Y.I.; Kim, C.S. Effect of high-frequency electric fields on calcium carbonate scaling. Desalination 2011, 279, 47–53. [Google Scholar] [CrossRef]

- Piyadasa, C.; Ridgway, H.F.; Yeager, T.R.; Stewart, M.B.; Pelekani, C.; Gray, S.R.; Orbell, J.D. The application of electromagnetic fields to the control of the scaling and biofouling of reverse osmosis membranes—A review. Desalination 2017, 418, 19–34. [Google Scholar] [CrossRef]

- Cai, R.; Yang, H.W.; He, J.S.; Zhu, W.P. The effects of magnetic fields on water molecular hydrogen bonds. J. Mol. Struct. 2009, 938, 15–19. [Google Scholar] [CrossRef]

- Pang, X.-F.; Deng, B.; Tang, B. Influences of magnetic field on macroscopic properties of water. Mod. Phys. Lett. B 2012, 26, 1250069. [Google Scholar] [CrossRef]

- Chang, K.T.; Weng, C.I. The effect of an external magnetic field on the structure of liquid water using molecular dynamics simulation. J. Appl. Phys. 2006, 100, 043917. [Google Scholar] [CrossRef]

- Alimi, F.; Tlili, M.M.; Ben Amor, M.; Maurin, G.; Gabrielli, C. Effect of magnetic water treatment on calcium carbonate precipitation: Influence of the pipe material. Chem. Eng. Process. 2009, 48, 1327–1332. [Google Scholar] [CrossRef]

- Tai, C.Y.; Chang, M.C.; Shieh, R.J.; Chen, T.G. Magnetic effects on crystal growth rate of calcite in a constant-composition environment. J. Cryst. Growth 2008, 310, 3690–3697. [Google Scholar] [CrossRef]

- Madsen, H.E.L. Crystallization of calcium carbonate in magnetic field in ordinary and heavy water. J. Cryst. Growth 2004, 267, 251–255. [Google Scholar] [CrossRef]

- Tijing, L.D.; Kim, H.Y.; Lee, D.H.; Kim, C.S.; Cho, Y.I. Use of an oscillating electric field to mitigate mineral fouling in a heat exchanger. Exp. Heat Transf. 2009, 22, 257–270. [Google Scholar] [CrossRef]

- Cho, Y.I.; Choi, B.G. Validation of an electronic anti-fouling technology in a single-tube heat exchanger. Int. J. Heat Mass Transf. 1999, 42, 1491–1499. [Google Scholar] [CrossRef]

- Cho, Y.I.; Fan, C.; Choi, B.G. Theory of electronic anti-fouling technology to control precipitation fouling in heat exchangers. Int. Commun. Heat Mass Transf. 1997, 24, 757–770. [Google Scholar] [CrossRef]

- Coey, J.M.D. Magnetic water treatment—How might it work? Philos. Mag. 2012, 92, 3857–3865. [Google Scholar] [CrossRef]

- Koza, J.A.; Muhlenhoff, S.; Zabinski, P.; Nikrityuk, P.A.; Eckert, K.; Uhlemann, M.; Gebert, A.; Weier, T.; Schultz, L.; Odenbach, S. Hydrogen evolution under the influence of a magnetic field. Electrochim. Acta 2011, 56, 2665–2675. [Google Scholar] [CrossRef]

- Zhao, J.D.; Liu, Z.A.; Zhao, E.J. Combined effect of constant high voltage electrostatic field and variable frequency pulsed electromagnetic field on the morphology of calcium carbonate scale in circulating cooling water systems. Water Sci. Technol. 2014, 70, 1074–1082. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, T.T.; Lee, W.G.; Lee, S.J.; Park, M.; Kim, H.M.; Won, D.; Yoo, J.; Yang, H.S. A simplified model of coaxial, multilayer high-temperature superconducting power cables with Cu formers for transient studies. Energies 2019, 12, 1514. [Google Scholar] [CrossRef]

- Zhang, S.; Feng, H.S.; Zhuang, M.; Ding, K.Z.; Liu, C.L.; Zhou, Y.Q. Experimental research of a 10 kA HTS current lead using YBCO tapes. IEEE Trans. Appl. Supercond. 2020, 30, 1–7. [Google Scholar] [CrossRef]

- Liang, J.H.; Chen, Z.H.; Wang, L.N. Magnetic field effect on critical current of different structural HTS DC cables. IEEE Trans. Appl. Supercond. 2019, 29, 1–3. [Google Scholar] [CrossRef]

- Otsuka, I.; Ozeki, S. Does magnetic treatment of water change its properties? J. Phys. Chem. B 2006, 110, 1509–1512. [Google Scholar] [CrossRef] [PubMed]

- Cho, Y.I.; Lee, S.H. Reduction in the surface tension of water due to physical water treatment for fouling control in heat exchangers. Int. Commun. Heat Mass Transf. 2005, 32, 1–9. [Google Scholar] [CrossRef]

| Items | Anhydrous Calcium Chloride | Sodium Bicarbonate |

|---|---|---|

| Purity (%) | ≥97 | ≥99.5 |

| Dosage (g) | 66.6 | 100.8 |

| Chemical formula | CaCl2 | NaHCO3 |

| Relative molecular mass | 110.99 | 84.01 |

| Symbol | Characteristic | Unit |

|---|---|---|

| K0 | overall heat transfer | Wm−2 K−1 |

| K1 | Heat transfer coefficient of copper pipe | Wm−2 K−1 |

| K2 | Total heat transfer coefficient of scale layer | Wm−2 K−1 |

| A | Heat exchange area (outside surface) | m2 |

| Tw | Temperature of inner wall surface of brass pipe | K |

| Tb | Temperature of outer wall surface of brass pipe | K |

| Ts | Water film temperature of spray water | K |

| D1 | Inner diameter of brass pipe | m |

| D2 | Outer diameter of brass pipe | m |

| P | Heating power of heating rod in fouling monitoring device | W |

| Rf | fouling resistance | m2 KW−1 |

| Frequency (MHz) | Average (J) | MAX (J) | Decrease | Cycle Number |

|---|---|---|---|---|

| 0.5 | 4.75704 × 10−5 | 4.98124 × 10−5 | 5% | 1 |

| 1 | 4.61133 × 10−5 | 4.98124 × 10−5 | 7% | 2 |

| 5 | 3.45778 × 10−5 | 4.91981 × 10−5 | 30% | 10 |

| 10 | 2.25671 × 10−5 | 4.45636 × 10−5 | 49% | 20 |

| 20 | 1.06845 × 10−5 | 2.95166 × 10−5 | 64% | 40 |

| Frequency (MHz) | Average (Wb) | MAX (Wb) | Decrease | Cycle Number |

|---|---|---|---|---|

| 0.5 | 9.73722 × 10−10 | 1.00746 × 10−9 | 3% | 1 |

| 1 | 9.53964 × 10−10 | 1.00746 × 10−9 | 5% | 2 |

| 5 | 7.94713 × 10−10 | 1.00425 × 10−9 | 21% | 10 |

| 10 | 6.20447 × 10−10 | 9.52905 × 10−10 | 35% | 20 |

| 20 | 4.11440 × 10−10 | 7.75518 × 10−10 | 47% | 40 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Y.; Zhang, L.; Zhao, X.; Liu, J.; Gao, M. Research on Descaling Characteristics and Simulation Calculation of a Coaxial High-Frequency Electronic Descaling Device. Water 2021, 13, 789. https://doi.org/10.3390/w13060789

Zhao Y, Zhang L, Zhao X, Liu J, Gao M. Research on Descaling Characteristics and Simulation Calculation of a Coaxial High-Frequency Electronic Descaling Device. Water. 2021; 13(6):789. https://doi.org/10.3390/w13060789

Chicago/Turabian StyleZhao, Yan, Lixin Zhang, Xin Zhao, Jin Liu, and Ming Gao. 2021. "Research on Descaling Characteristics and Simulation Calculation of a Coaxial High-Frequency Electronic Descaling Device" Water 13, no. 6: 789. https://doi.org/10.3390/w13060789

APA StyleZhao, Y., Zhang, L., Zhao, X., Liu, J., & Gao, M. (2021). Research on Descaling Characteristics and Simulation Calculation of a Coaxial High-Frequency Electronic Descaling Device. Water, 13(6), 789. https://doi.org/10.3390/w13060789