Risk Analysis and Optimization of Water Surface Deviation from Shafts in the Filling–Emptying System of a Mega-Scale Hydro-Floating Ship Lift

Abstract

:1. Introduction

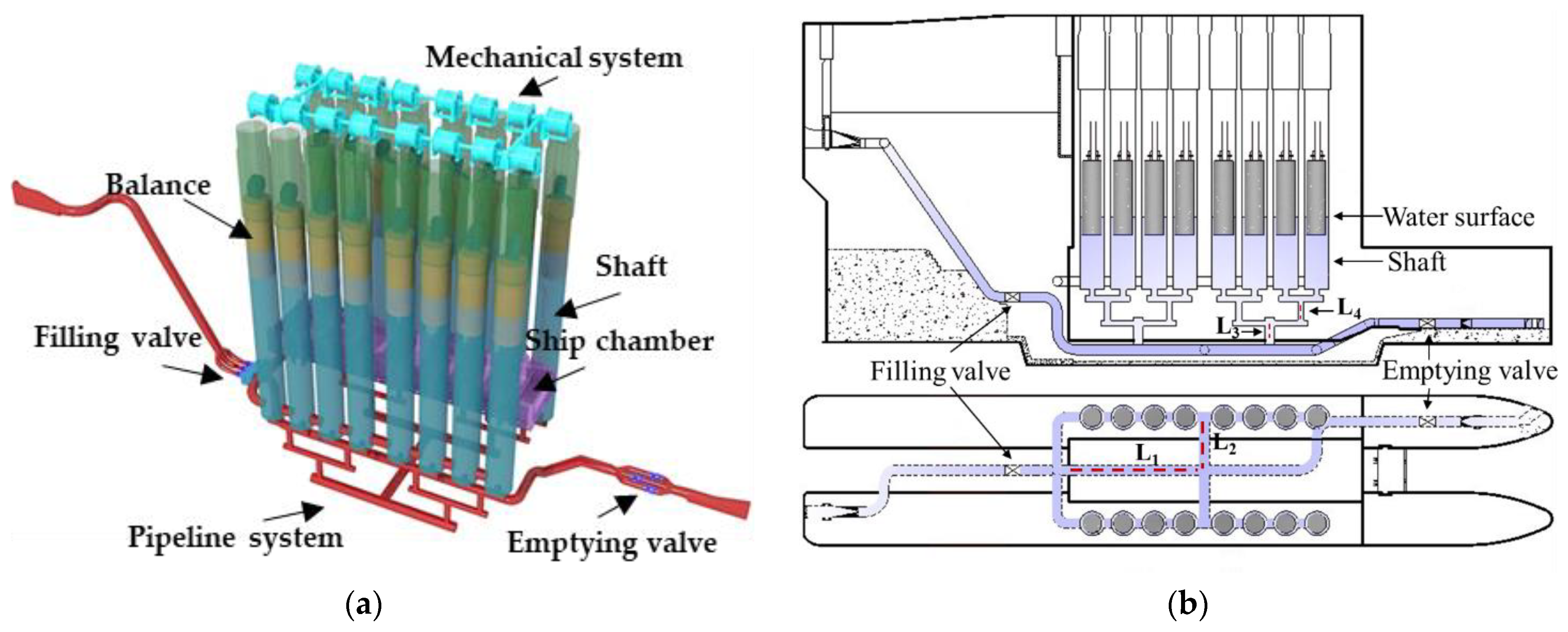

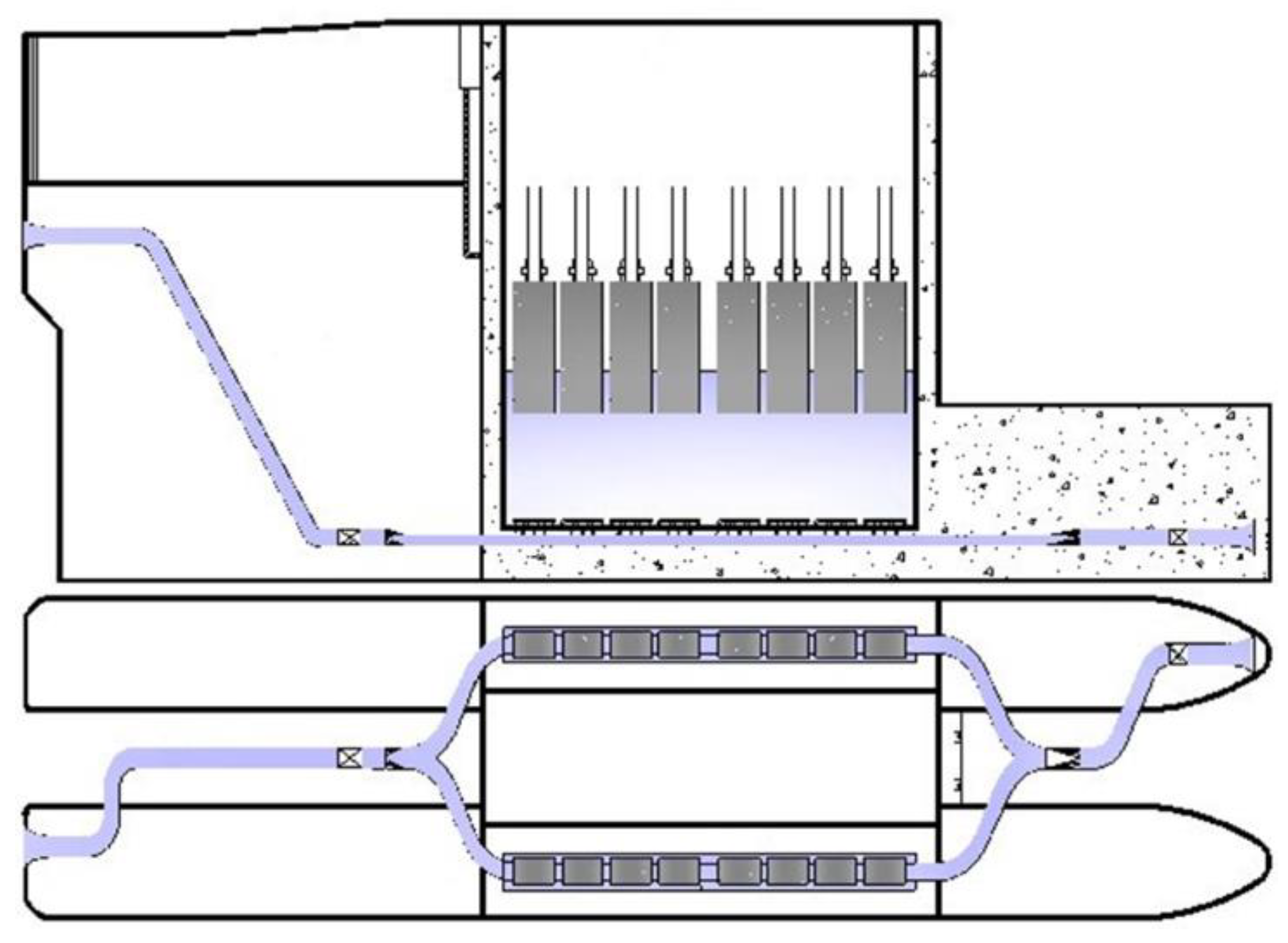

2. Materials

2.1. Study Area

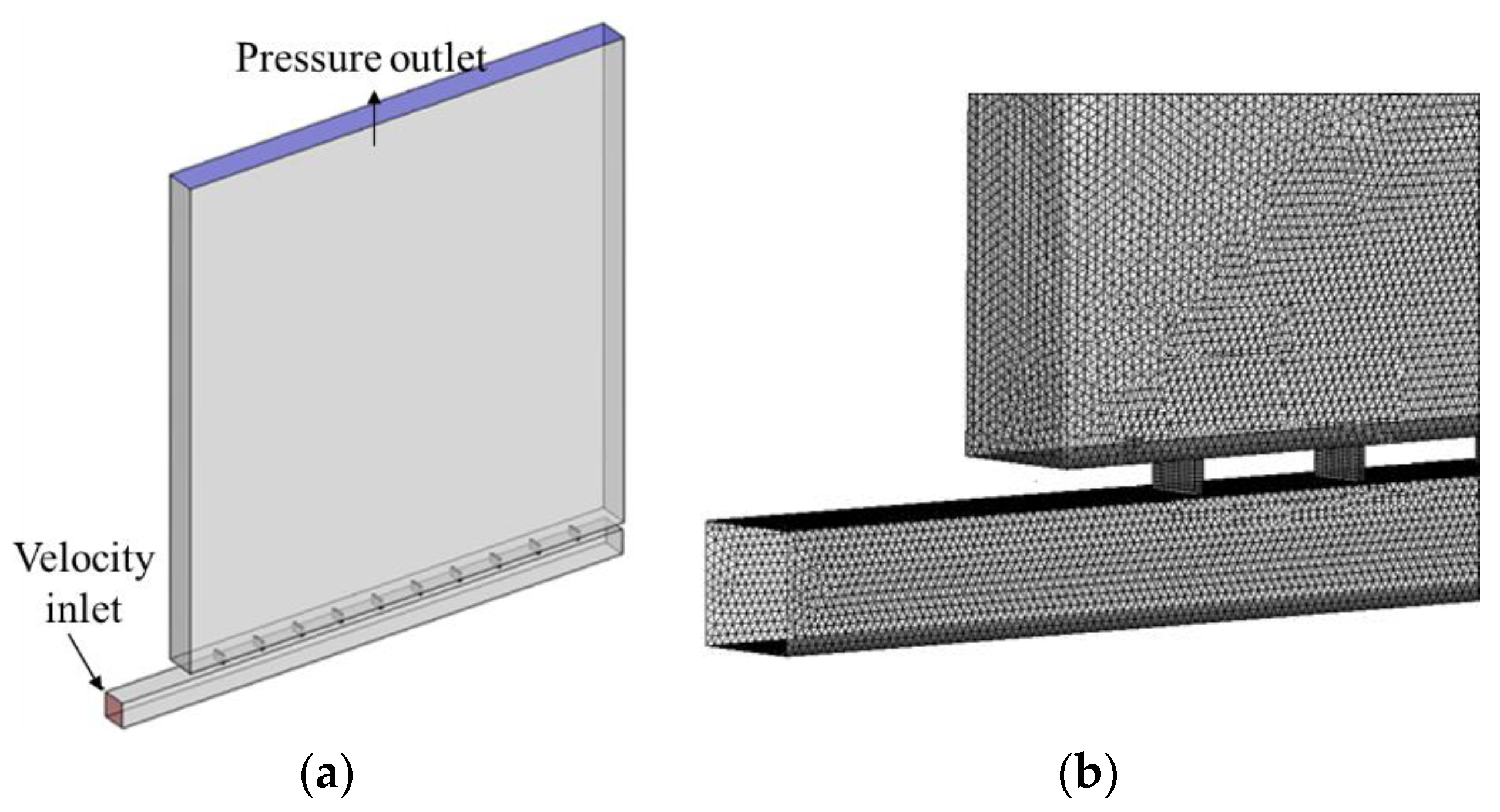

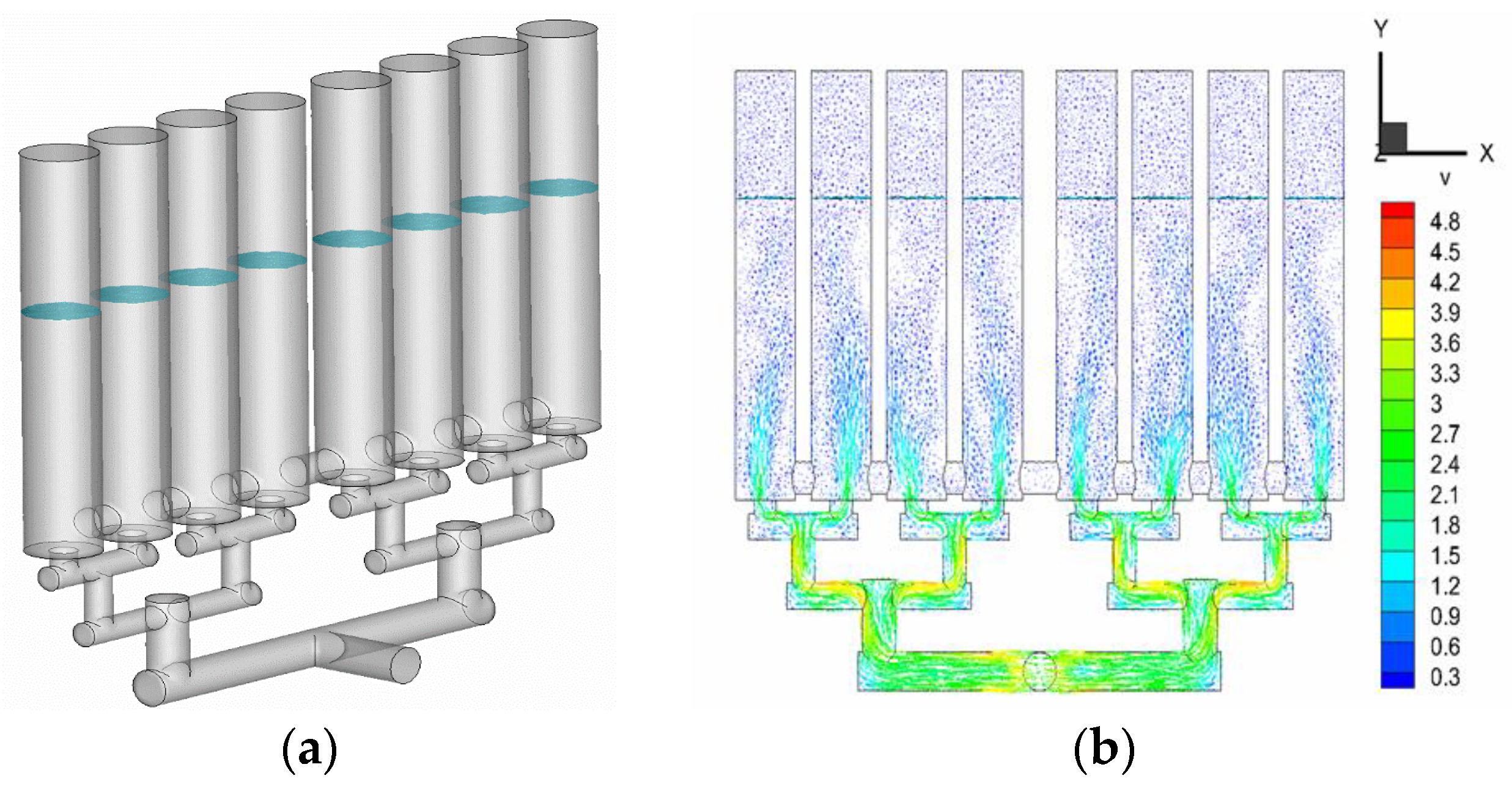

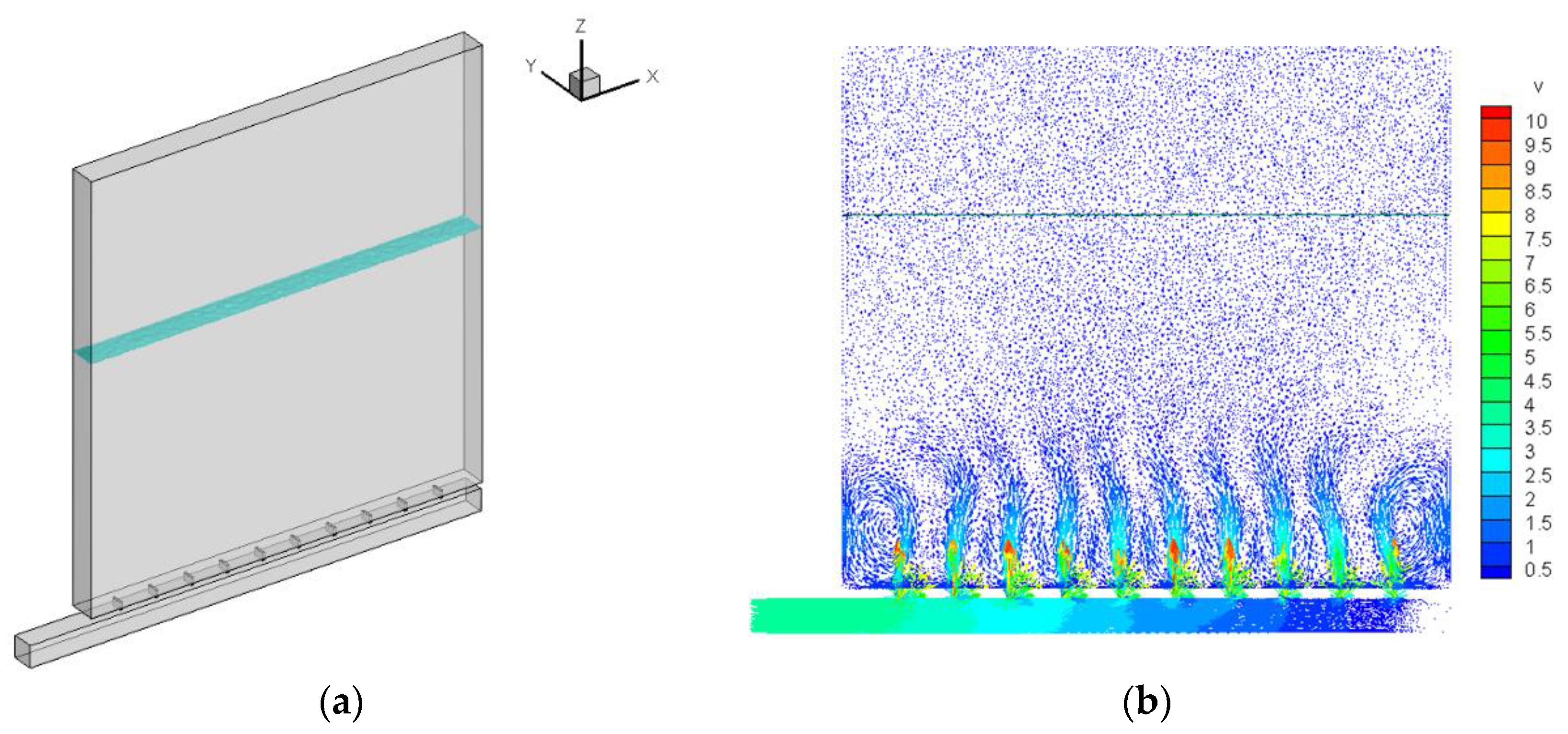

2.2. Optimization of Layout

3. Methodology

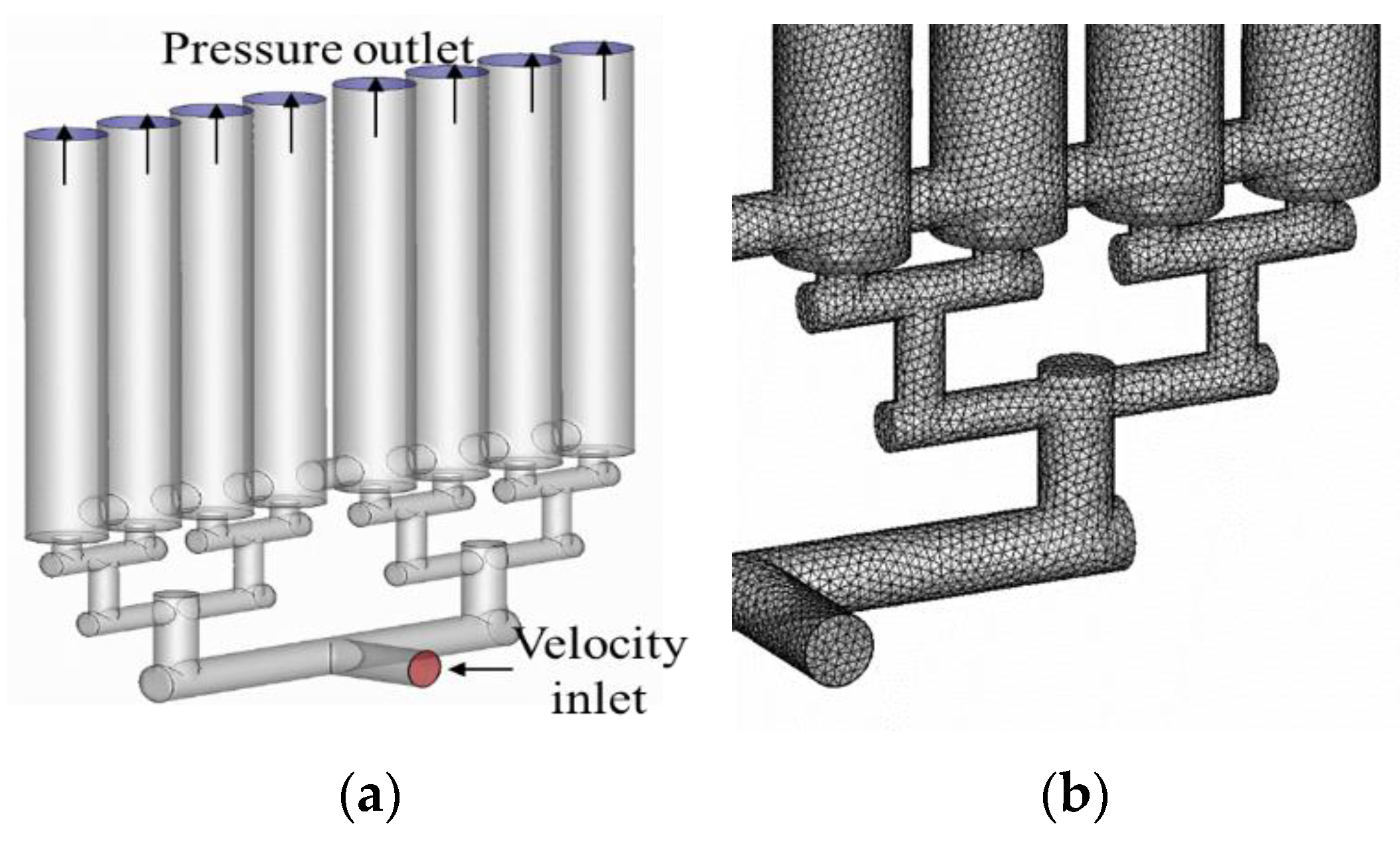

3.1. Numerical Simulation

3.2. Risk Analysis

3.2.1. Cloud Model Definition

- Ex refers to the expectation of the cloud droplets, which is the central value in the universe of the qualitative concept. In this paper, the expected value (Ex) reflects the average variation degree of water surface deviation from the shafts in the filling–emptying system.

- En is the uncertainty measurement of the qualitative concept, which is codetermined by the randomness and fuzziness of the concept. In this paper, entropy (En) can reflect the uncertainty degree of the water surface deviation from the shafts.

- He is the uncertainty measurement of En; i.e., the entropy of En. It reflects the discrete degree of the cloud droplets. A larger He value represents a higher cloud dispersion. In this paper, if the value of hyper entropy (He) is larger, the uncertainty of water surface deviation from the shafts is more discrete.

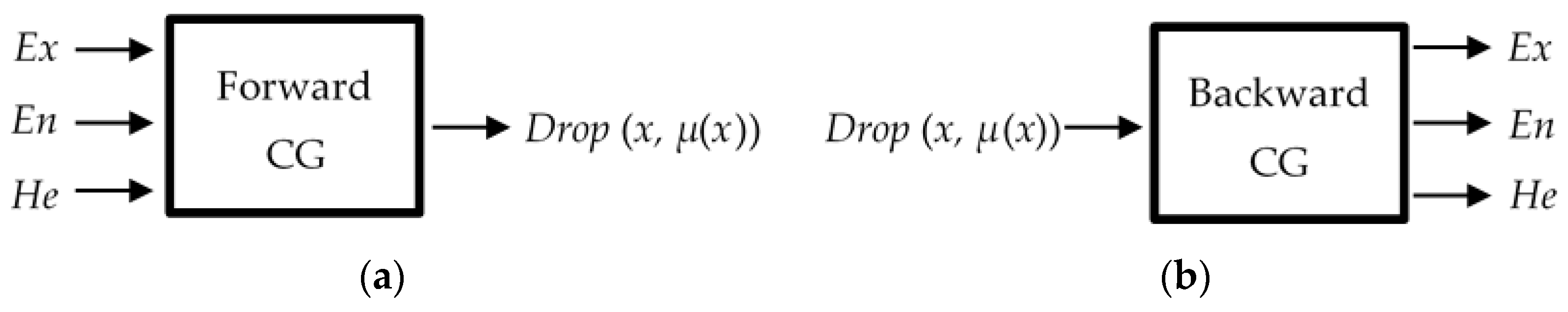

3.2.2. Cloud Generator

| Algorithm 1. Algorithm of forward cloud generator (FCG). |

| Input: Parameters Ex, En and He and the number of cloud droplets to be generated, n. Output: Quantitative values of n cloud droplets xi and their corresponding certainty degrees μ(xi) (i = 1,2,…,n). Algorithm steps: Step 1: Generate a normally distributed random number λ with expectation En and variance He: λ~n (En, He2); Step 2: Generate a normally distributed random number xi with expectation Ex and variance λ: xi~n (Ex, λ2); Step 3: Calculate the certainty degree of xi, ; Step 4: Generate a cloud drop (xi, μ(xi)), and repeat steps 1 to 3 until n cloud drops are generated. |

| Algorithm 2. Algorithm of backward cloud generator (BCG). |

| Input: Sample point data value xi (i = 1,2,…,n). Output: Parameters Ex, En, and He. Algorithm steps: Step 1: Calculate the sample mean of these data xi (i = 1,2,…,n), , and sample variance, ; Step 2: Calculate the expected value , ; Step 3: Calculate the entropy value, ; Step 4: Calculate the hyper-entropy value, . |

3.2.3. Cloud Model for the Filling–Emptying System

- (1)

- “Security”: The data regarding the hydrodynamic risk factor for the filling–emptying system fall in the cloud droplet group of the [0, Ex + En] interval. The [0, Ex + En] interval accounts for 84.13% of the total area. If the measured data of the hydrodynamic factors fall in this range, this indicates the running safety of the filling–emptying system.

- (2)

- “Weak security”: The data regarding the hydrodynamic risk factor for the filling–emptying system fall in the cloud droplet group of the [Ex + En, Ex + 2En] interval. The [Ex + En, Ex + 2En] interval accounts for 13.59% of the total area. If the measured data of the hydrodynamic factors fall in this range, this indicates the weak running safety of the filling–emptying system. The operator should pay attention to changes in the measured data.

- (3)

- “Weak risk”: The data regarding the hydrodynamic risk factor for the filling–emptying system fall in the cloud droplet group of the [Ex + 2En, Ex + 3En] interval. The [Ex + 2En, Ex + 3En] interval accounts for 2.15% of the total area. If the measured data of the hydrodynamic factors are concentrated in this interval, this indicates that the filling–emptying system of the hydro-floating ship lift is in a state of “weak risk”. The operator should report the “weak risk” of the filling–emptying system and look up possible problems.

- (4)

- “Risk”: The data regarding the hydrodynamic risk factor for the filling–emptying system fall in the cloud droplet group of the [Ex + 3En, +∞] interval. The [Ex + 3En, +∞] interval accounts for 0.13% of the total area. If the measured data for the hydrodynamic factors fall in this range, the filling–emptying system exhibits a risk state. The operator should report the “risk” state of the filling–emptying system and stop the running of the hydro-floating ship lift according to the corresponding operation process and deal with the risk-causing fault.

4. Results and Discussion

4.1. Water Surface Deviation from the Shafts of an Equal Inertial Pipeline

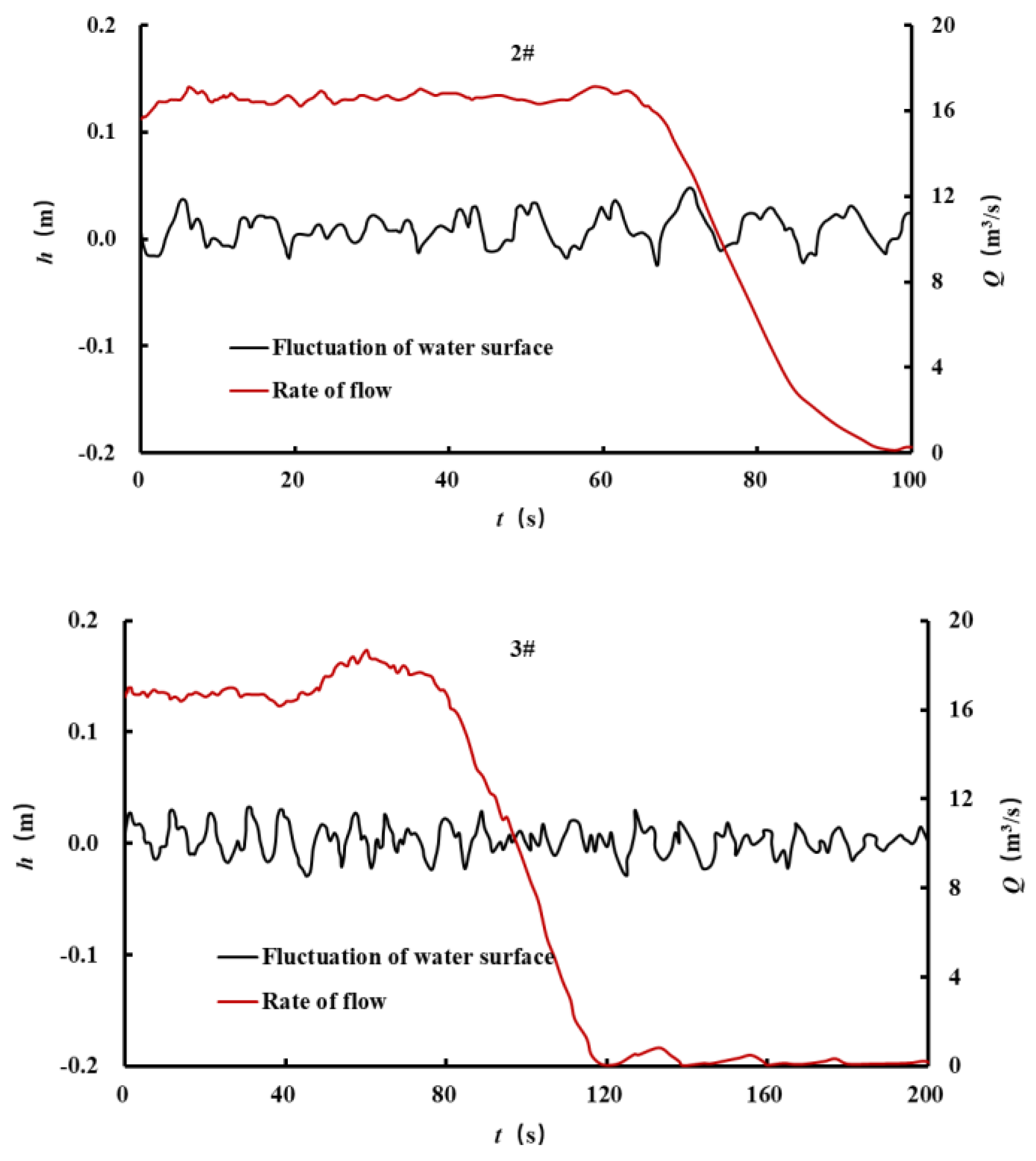

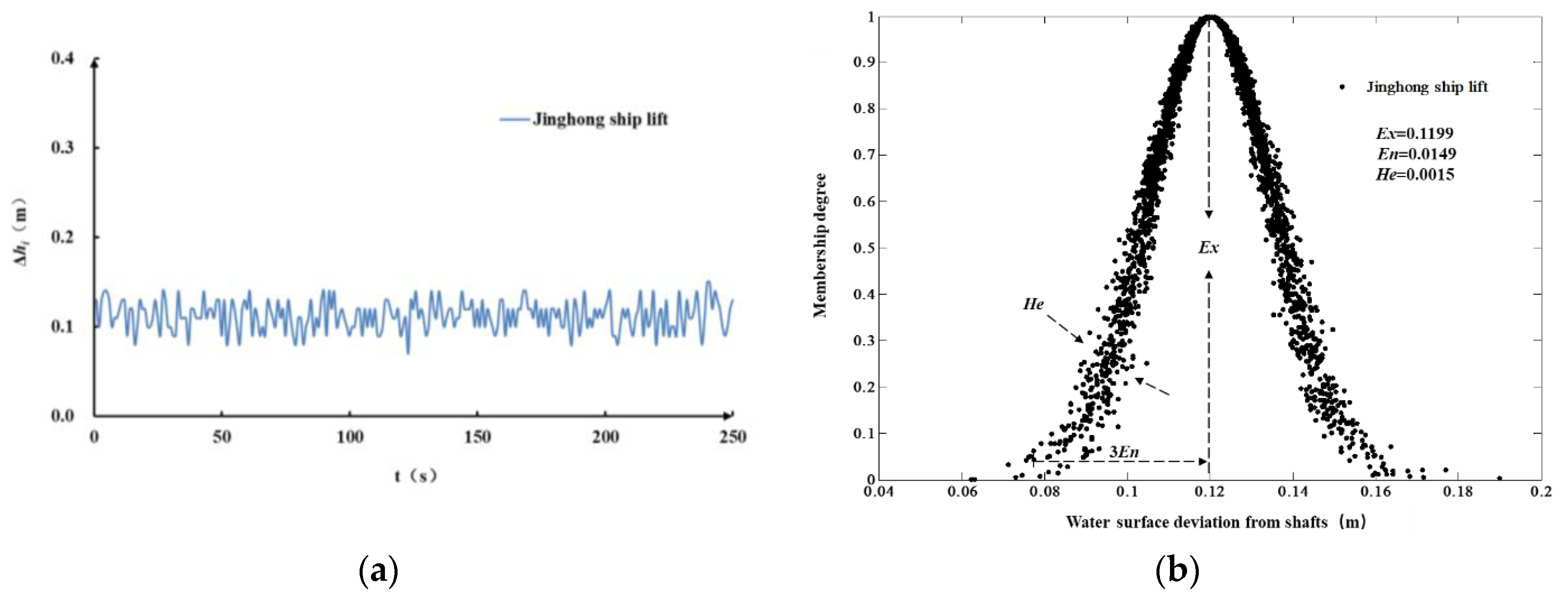

4.1.1. Jinghong Hydro-Floating Ship lift

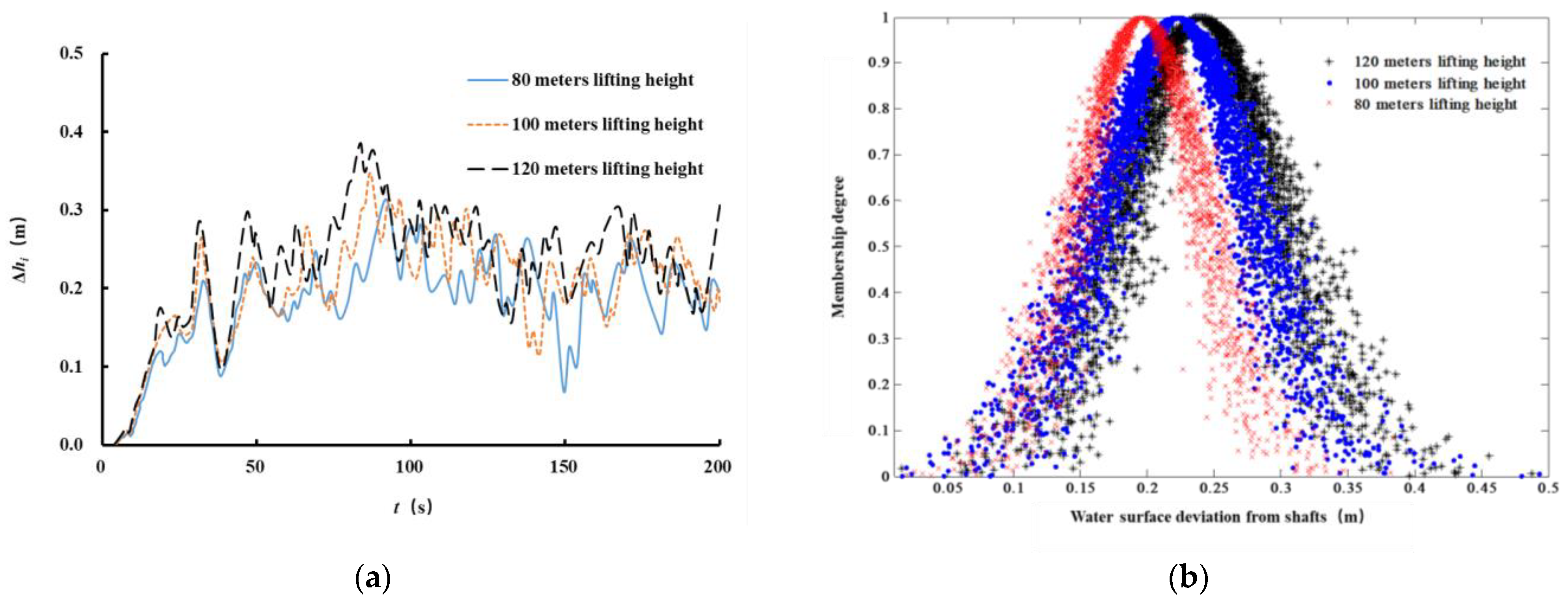

4.1.2. Numerical Simulation of 100 m Lifting Height

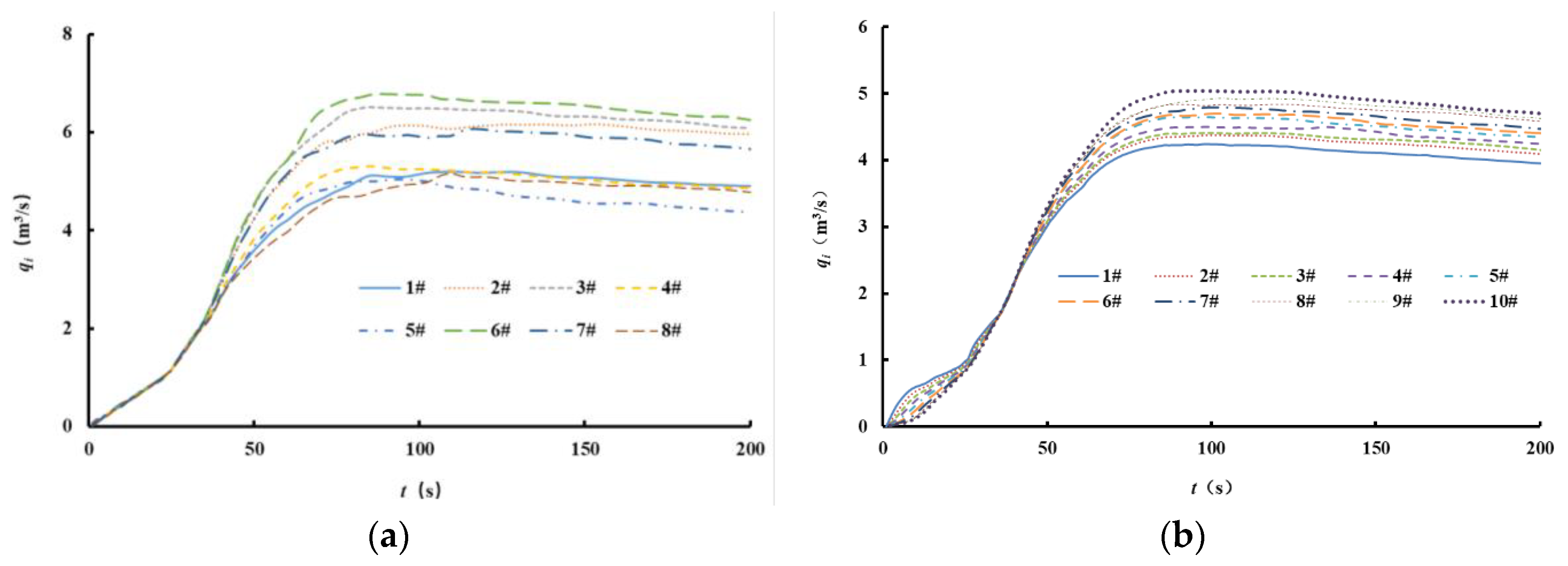

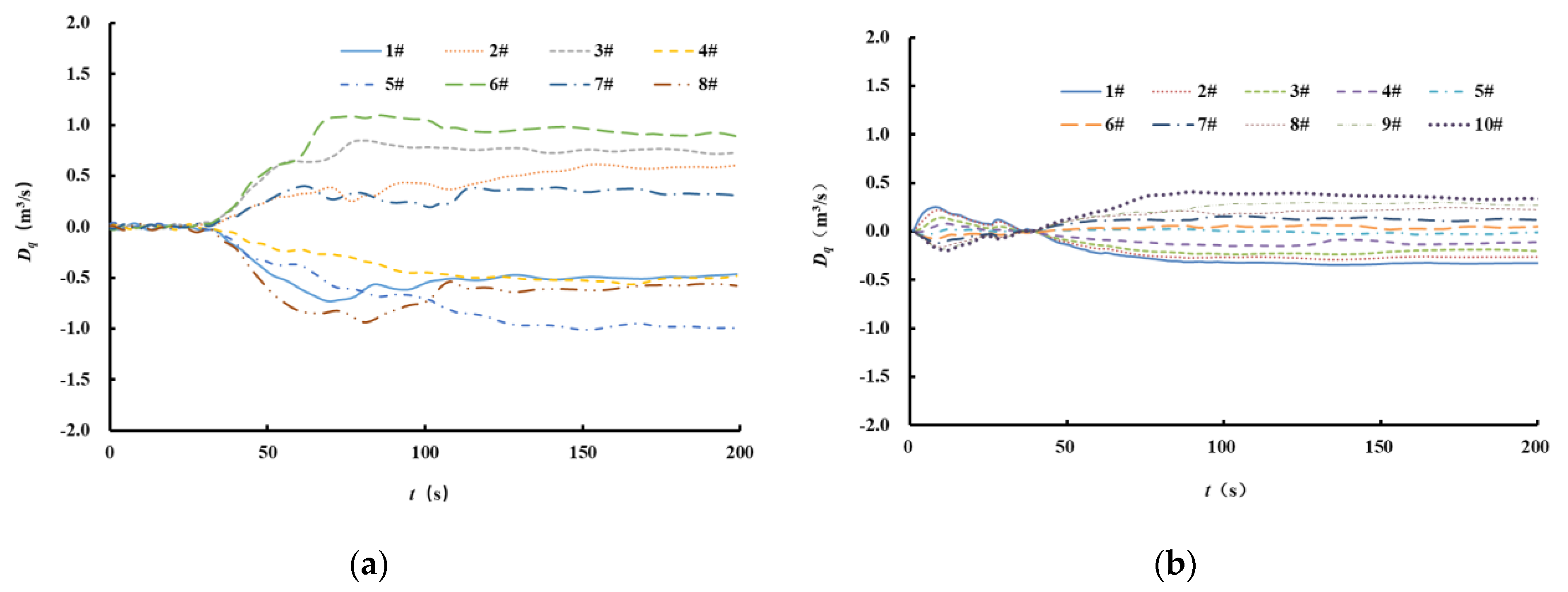

4.2. Risk Analysis of Water Surface Deviation from the shafts in the Longitudinal Culvert

- (1)

- Flow of branch outlet

- (2)

- Water surface deviation from the shafts

4.3. Optimization of Water Surface Deviation from the Shafts

5. Conclusions

- (1)

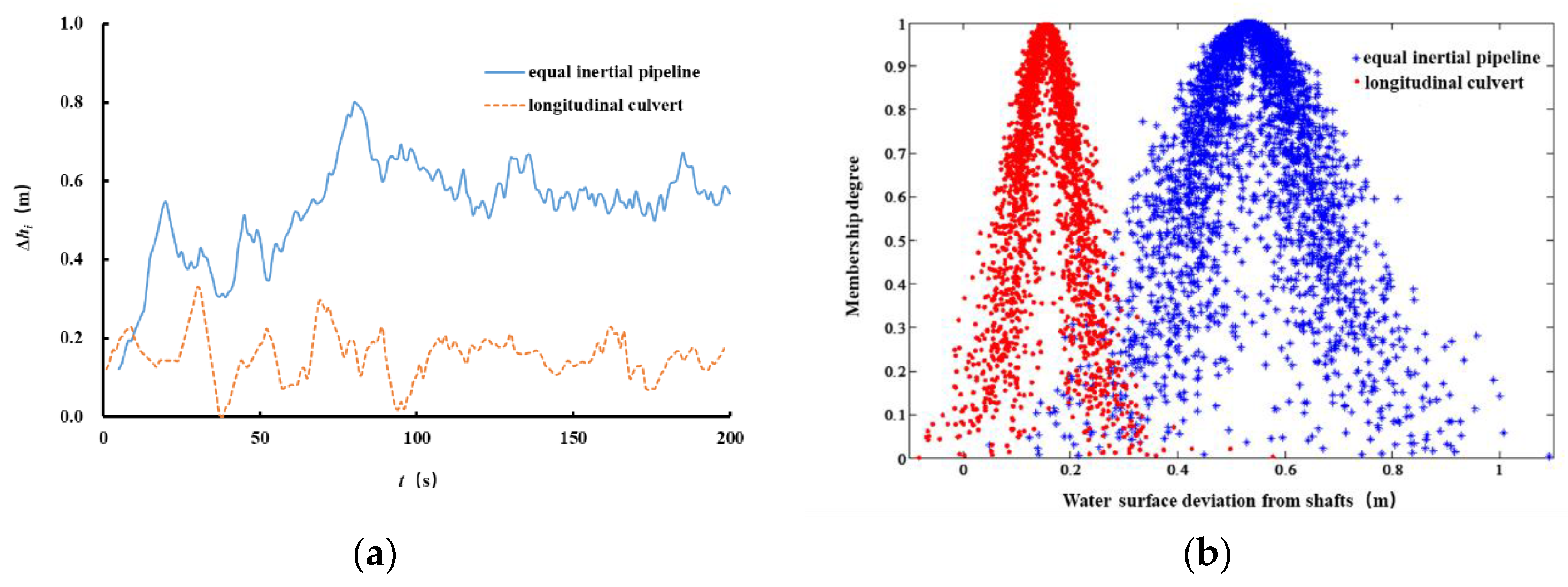

- A layout optimization method for the longitudinal culvert filling–emptying system was put forward to be applied in a hydro-floating ship lift. Two kinds of filling–emptying system were compared and analyzed by using a numerical simulation method and cloud model theory.

- (2)

- Taking the engineering project of the Jinghong hydro-floating ship lift as an example, the uniformity of the diverging flow and synchronicity of the water level among the shafts showed a chaotic trend in the equal inertial pipeline filling–emptying system under the condition of a 100 m scale lifting height. The lifting height forces the water surface deviation from the shafts to increase, and the hydrodynamic risk will therefore be greatly increased.

- (3)

- To analyze the hydrodynamic risk of water surface deviation from the shafts, two kinds of filling–emptying systems (equal inertial pipeline and longitudinal culvert) were compared with each other under the condition of a 150 m lifting height. The longitudinal culvert filling–emptying system was better than the equal inertial pipeline in the branch outflow and better able to solve the risk problem of water surface deviation from the shafts.

- (4)

- A longitudinal culvert was applied for the optimization of running safety in the filling–emptying system. Three parameters (Ex, En, He) showed that the layout of the longitudinal culvert significantly reduced the uncertainty of water surface deviation from the shafts.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Hu, Y.; Li, Z.; Li, Y.; Xuan, G. Research developments in the field of major ship lift in China. Port Waterw. Eng. 2016, 12, 10–19. (In Chinese) [Google Scholar] [CrossRef]

- Li, K.; Yi, Z.; Ling, C.; Yuan, Z.; Jiang, X. Weight minimization of ship chamber structure in vertical ship lift design based on multi-level structural optimization method. J. Mar. Sci. Technol. 2018, 26, 562–574. [Google Scholar] [CrossRef]

- Zhong, Y.; Tu, J.; Que, G.; Tu, B.; Xu, J. Analysis and control of the coupled vibration between the ship lift and ship chamber. Int. J. Civ. Eng. 2016, 14, 307–324. [Google Scholar] [CrossRef]

- Liu, J.; Hu, Y.; Xue, S. Risk assessment of water conveyance system in hydraulic ship lift based on cloud model. Port Waterw. Eng. 2020, 9, 14–18. (In Chinese) [Google Scholar] [CrossRef]

- Shi, D.; Cai, D.; Wu, Z. Finite element analysis on nut post structure of Three Gorges Project ship lift. J. Cent. South Univ. Technol. 2009, 16, 0614–0620. [Google Scholar] [CrossRef]

- Wang, J.; Wang, M.; Zhou, J.; Zuo, Q.; Shi, X. Simulation based optimal evacuation plan in vertical ship lift: A case study. Eng. Comput. 2020, 37, 1757–1786. [Google Scholar] [CrossRef]

- Zhou, Y. Fuzzy semi-active control and analysis of wind-induced vibration of a ship lift. Mater. Struct. 2015, 48, 3307–3316. [Google Scholar] [CrossRef]

- Shi, D.; Wang, Y.; Peng, H.; Zhao, T.; Cheng, S. Finite element and experimental analysis of pinion bracket-assembly of three gorges project ship lift. J. Cent. South Univ. 2015, 22, 1307–1314. [Google Scholar] [CrossRef]

- Ma, H.; Cao, X. Research on the key technologies of hydraulic new type ship lift. J. Hydraul. Eng. 2018, 49, 446–455. (In Chinese) [Google Scholar] [CrossRef]

- Liu, J.; Hu, Y.; Xue, S.; Li, Z. Risk analysis of important risk sources for running safety of hydraulic ship lift. Port Waterw. Eng. 2020, 12, 27–32. (In Chinese) [Google Scholar] [CrossRef]

- Fuertes-Miquel, V.S.; Coronado-Hernández, O.E.; Mora-Meliá, D.; Iglesias-Rey, P.L. Hydraulic modeling during filling and emptying processes in pressurized pipelines: A literature review. Urban Water J. 2019, 16, 299–311. [Google Scholar] [CrossRef]

- Schindfessel, L.; Mulder, T.; Creelle, S.; Schohl, G. On analytical formulae for navigation lock filling–emptying and overtravel. J. Hydraul. Res. 2015, 53, 134–148. [Google Scholar] [CrossRef] [Green Version]

- Hite, J.E.; Stockstill, R.L. Hydraulic design of a longitudinal culvert for lock filling and emptying systems. J. Hydraul. Eng. 2004, 130, 381–388. [Google Scholar] [CrossRef]

- Gobbetti, L. Design of the filling and emptying system of the new Panama Canal locks. J. Appl. Water Eng. Res. 2013, 1, 28–38. [Google Scholar] [CrossRef]

- Zhang, R.; Zhang, J.; Wu, Y.; Cao, Y. Numerical simulation of water conveyance system in hydraulic floating shiplift. J. Hydraul. Eng. 2007, 38, 624–629. (In Chinese) [Google Scholar] [CrossRef]

- Zhang, R.; Wu, Y.; Zhang, J.; Zhang, D.; Gao, J. Numerical simulation on synchronous characteristic of the shafts’ water levels in Jinghong hydraulic floating ship lift. J. Hydrodyn. 2007, 22, 31–39. (In Chinese) [Google Scholar] [CrossRef]

- Li, S.; Zhou, X.; Wang, Y.; Zhou, J.; Du, X.; Chen, Z. Study of risk acceptance criteria for dams. Sci. China Technol. Sci. 2015, 58, 1263–1271. [Google Scholar] [CrossRef]

- Morales-Torres, A.; Escuder-Bueno, I.; Serrano-Lombillo, A.; Castillo Rodríguez, J. Dealing with epistemic uncertainty in risk-informed decision making for dam safety management. Reliab. Eng. Syst. Saf. 2019, 191, 106562. [Google Scholar] [CrossRef]

- Morales-Torres, A.; Serrano-Lombillo, A.; Escuder-Bueno, I.; Altarejos-García, L. The suitability of risk reduction indicators to inform dam safety management. Struct. Infrastruct. Eng. 2016, 12, 1465–1476. [Google Scholar] [CrossRef]

- Serrano-Lombillo, A.; Morales-Torres, A.; Escuder-Bueno, I.; Altarejos-García, L. A new risk reduction indicator for dam safety management combining efficiency and equity principles. Struct. Infrastruct. Eng. 2017, 13, 1157–1166. [Google Scholar] [CrossRef] [Green Version]

- Delenne, C.; Cappelaere, B.; Guinot, V. Uncertainty analysis of river flooding and dam failure risks using local sensitivity computations. Reliab. Eng. Syst. Saf. 2012, 107, 171–183. [Google Scholar] [CrossRef] [Green Version]

- Chen, H.; Mehrabani, M. Reliability analysis and optimum maintenance of coastal flood defences using probabilistic deterioration modelling. Reliab. Eng. Syst. Saf. 2019, 185, 163–174. [Google Scholar] [CrossRef]

- Gersonius, B.; Morselt, T.; Nieuwenhuijzen, L.; Ashley, R.; Zevenbergen, C. How the failure to account for flexibility in the economic analysis of flood risk and coastal management strategies can result in maladaptive decisions. J. Waterw. Port Coast. Ocean Eng. 2012, 138, 386–393. [Google Scholar] [CrossRef] [Green Version]

- Zhou, C.; Liu, W.; Chen, Y.; Hu, R.; Wei, K. Inverse modeling of leakage through a rockfill dam foundation during its construction stage using transient flow model, neural network and genetic algorithm. Eng. Geol. 2015, 187, 183–195. [Google Scholar] [CrossRef]

- Chang, L. Guiding rational reservoir flood operation using penalty-type genetic algorithm. J. Hydrol. 2008, 354, 65–74. [Google Scholar] [CrossRef]

- Lei, X.; Zhang, J.; Wang, H.; Wang, M.; Khu, S.; Li, Z.; Tan, Q. Deriving mixed reservoir operating rules for flood control based on weighted non-dominated sorting genetic algorithm II. J. Hydrol. 2018, 564, 967–983. [Google Scholar] [CrossRef]

- Park, C.; Joo, J.; Kim, J. Integrated washland optimization model for flood mitigation using multi-objective genetic algorithm. J. Hydro-Environ. Res. 2012, 6, 119–126. [Google Scholar] [CrossRef]

- Kalinina, A.; Spada, M.; Burgherr, P. Application of a Bayesian hierarchical modeling for risk assessment of accidents at hydropower dams. Saf. Sci. 2018, 110, 164–177. [Google Scholar] [CrossRef]

- Chen, J.; Zhong, P.; An, R.; Zhu, F.; Xu, B. Risk analysis for real-time flood control operation of a multi-reservoir system using a dynamic Bayesian network. Environ. Modell. Softw. 2019, 111, 409–420. [Google Scholar] [CrossRef]

- Xiang, M.; Lin, X.; Yang, X.; Zhang, S. Ecological environment evaluation of forest ecosystem nature reserves using an unweighted cloud model. Water 2020, 12, 1905. [Google Scholar] [CrossRef]

- Wang, X.; Shi, K.; Shi, Q.; Dong, H.; Chen, M. A Normal Cloud Model-Based Method for Risk Assessment of Water Inrush and Its Application in a Super-Long Tunnel Constructed by a Tunnel Boring Machine in the Arid Area of Northwest China. Water 2020, 12, 644. [Google Scholar] [CrossRef] [Green Version]

- Yang, S.; Han, X.; Cao, B.; Li, B.; Yan, F. Cloud-model-based method for risk assessment of mountain torrent disasters. Water 2018, 10, 830. [Google Scholar] [CrossRef] [Green Version]

- Li, D.; Meng, H.; Shi, X. Membership clouds and membership cloud generators. J. Comput. Res. Dev. 1995, 6, 15–20. (In Chinese) [Google Scholar]

- Li, D.; Liu, C.; Gan, W. A new cognitive model: Cloud model. Int. J. Intell. Syst. 2009, 24, 357–375. [Google Scholar] [CrossRef]

| Item | Design Value | Item | Design Value |

|---|---|---|---|

| Maximum lifting height (m) | 66.86 | Highest navigable water levels upstream (m) | 602.00 |

| Maximum passing ship tonnage (tons) | 500 | Lowest navigable water levels upstream (m) | 591.00 |

| Ship chamber size (m) | 69.1 × 12.0 × 2.5 (length × width × depth) | Highest navigable water levels downstream (m) | 544.90 |

| Ship chamber single running time (min) | 17 | Lowest navigable water levels downstream (m) | 534.80 |

| Total weight of the ship chamber (tons) | 3140 | Freight traffic in main years (ten thousand tons) | 135 |

| Item | Equal Inertial Pipeline | Longitudinal Culvert |

|---|---|---|

| Main pipe diameter (m) | 2.5 | 2.5 |

| Shaft sectional area (m2) | 531 | 554 |

| Flow coefficient | 0.297 | 0.318 |

| Resistance coefficient | 0.321 | 0.334 |

| Lifting Height (m) | Threshold of Water Surface Deviation from Shafts (m) | |||

|---|---|---|---|---|

| Security | Weak Security | Weak Risk | Risk | |

| 80 | (0, 0.24) | (0.24, 0.29) | (0.29, 0.35) | (0.35, +∞) |

| 100 | (0, 0.28) | (0.28, 0.33) | (0.33, 0.39) | (0.39, +∞) |

| 120 | (0, 0.31) | (0.31, 0.35) | (0.35, 0.41) | (0.41, +∞) |

| Parameters of Cloud Model | Equal Inertial Pipeline | Longitudinal Culvert | ||||

|---|---|---|---|---|---|---|

| Jinghong (66.86 m) | 80 m Lifting | 100 m Lifting | 120 m Lifting | 150 m Lifting | 150 m Lifting | |

| Ex | 0.1199 | 0.1959 | 0.2223 | 0.2394 | 0.5334 | 0.1545 |

| En | 0.0149 | 0.0463 | 0.0547 | 0.0568 | 0.1131 | 0.0531 |

| He | 0.0015 | 0.0089 | 0.0107 | 0.0121 | 0.0494 | 0.0198 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, J.; Hu, Y.; Li, Z.; Xue, S. Risk Analysis and Optimization of Water Surface Deviation from Shafts in the Filling–Emptying System of a Mega-Scale Hydro-Floating Ship Lift. Water 2021, 13, 1377. https://doi.org/10.3390/w13101377

Liu J, Hu Y, Li Z, Xue S. Risk Analysis and Optimization of Water Surface Deviation from Shafts in the Filling–Emptying System of a Mega-Scale Hydro-Floating Ship Lift. Water. 2021; 13(10):1377. https://doi.org/10.3390/w13101377

Chicago/Turabian StyleLiu, Jingkai, Yaan Hu, Zhonghua Li, and Shu Xue. 2021. "Risk Analysis and Optimization of Water Surface Deviation from Shafts in the Filling–Emptying System of a Mega-Scale Hydro-Floating Ship Lift" Water 13, no. 10: 1377. https://doi.org/10.3390/w13101377

APA StyleLiu, J., Hu, Y., Li, Z., & Xue, S. (2021). Risk Analysis and Optimization of Water Surface Deviation from Shafts in the Filling–Emptying System of a Mega-Scale Hydro-Floating Ship Lift. Water, 13(10), 1377. https://doi.org/10.3390/w13101377