1. Introduction

Recently, the structure and physicochemical properties of water treated with low-temperature, low-pressure glow plasma of low-frequency (LPGP) [

1] in the air (LPGPA) [

2], under oxygen-free nitrogen (LPGPN) [

3], carbon dioxide (LPGPC) [

4] and methane (LPGPM) [

5] were described. Depending on (i) the duration of the exposure of the water to the LPGP and (ii) the atmosphere under which the LPGP treatment was performed, the resulting water took a different macrostructure and, hence, it exhibited different functional properties. These functional properties could potentially attract the attention of agriculture, animal production and the food industry [

6,

7]. Among others, 150 days of watering peppermint (

Mentha piperita rubescens) with LPGPA stimulated the growth of the leaves and stems of the herb by 24% and 5%, respectively. Application of LPGPA for watering also changed the composition of the extracts. Although the level of menthol in the collected essential oil considerably decreased, this change had no negative effect upon the bactericidal properties of the oil. Watering with LPGPA increased the content of the

a and

b chlorophylls, carotenoids and ascorbic acid. Simultaneously, the concentration of the Mn(II), Ni(II), Ca and Mg ions in the leaves and stems of peppermint decreased. The overall bioaccumulation of various cations and anions in the plant was also influenced [

8]. The composition of the essential oil from basil (

Ocinum basilicum L.) could also be changed applying LPGPA and LGPGN. For the final result, the atmosphere in which the water was treated appeared crucial. Compared to watering basil with non-treated (control) water, watering with LPGPA provided the essential oil of an impoverished overall composition. The bactericidal properties of that oil against

Escherichia coli and

Staphylococcus aureus were partly inhibited. However, watering basil with LPGPN offered an essential oil with a considerably different composition and higher bactericidal activity against the tested microorganisms [

9].

Cress (

Lepidium sativum), known also as garden cress, curly cress, mustard, garden pepper cress, pepperwort, pepper grass or poor man’s pepper, is a fast-growing, edible herb [

10,

11]. It is suitable for cultivation hydroponically. Edible shoots are harvested within one to two weeks after planting [

12]. The raw plant possesses a high nutrient value as it is rich in A, C and K vitamins, as well as in several dietary minerals. For its specific flavor, cress is added to soups, sandwiches, salads, mayonnaise and salt. It is also eaten as sprouts, and the fresh or dried seed pods can be used as a peppery seasoning [

13,

14]. Hydroponic plantations of cress and other plants is interesting from the point of view of so-called smart cities [

15,

16]. For its sensitive physiological system, cress serves as a test plants for recognizing the effects of various chemicals on plants and the environment. Recently [

17], cress seeds were used for the evaluation of toxicity from various microplastics. In the presented study, the physiological activity of water exposed to LPGP, either in the air, under oxygen-free nitrogen, methane or carbon dioxide, was evaluated, involving cress seeds.

2. Materials and Methods

2.1. Materials

Cress seeds: Seeds only for hobby gardening manufactured by Cores BV, Nijmegen, The Netherlands, Test/P: 09, 2018, were used.

Deionized water: Commercially available deionized water of pH 7.02 ± 0.04, SEM = 219.1 ± 0.3 mV and conductivity = 0.006 ± 0.002 mS was used.

Tap water: pH 7.6, SEM = 351.8 ± 0.3 mV and conductivity = 0.444 ± 0.004 mS, municipal water from the Częstochowa supply system containing a total of 672.28 mg minerals/L (193.27 mg Ca2+/L, 46.21 mg Mg2+/L, 23.18 mg Na+/L, 5.27 mg K+/L, 351.90 mg HCO3−/L, 51.20 mg SO4−/L, 6.52 mg Cl−/L, and 40 μg Fe/L).

Nitrogen: Nitrogen from a tank was deoxygenated by passing through an absorber filled with an alkaline solution of resorcinol.

Carbon dioxide: Pure (100%) CO2 (AIR-PRODUCTS, Warsaw, Poland).

Methane: Methane from the municipal gas supply system of Częstochowa (Poland) was used. It contained 95.5% methane, 3.816% ethane, 0.216% propane, 0.031% i-butane, 0.030% n-butane, 0.06% i-pentane, 0.04% n-pentane, 0.06% C6+ hydrocarbons, 0.605% N2 and 0.030% CO2.

2.2. Methods

2.2.1. Cress Cultivation

Cress (100 seeds per pot) was planted on lignin sheets. The pots were placed in an incubator set for 24 °C. The seeds and then plants were watered by spraying for 7 days, twice a day, with 5 mL water.

2.2.2. Saturation of Water with a Gas

Through either the deionized or tap water was a stream of a given gas, which was bubbled for 15 min. Its flow rate depended on the volume of the water sample. In case of the 200 mL sample it was 10 mL/min.

2.2.3. Treating Water with LPGP

Water (200 mL) saturated with a corresponding gas was placed in 250 mL glass bottles and the free space over the liquid was additionally filled with the corresponding gas. The whole was placed in the chamber of the reactor [

1] and exposed to GP for 30 min. Plasma of 38 °C was generated at 5 × 10

−3 mbar, 800 V, 50 mA and 10 KHz frequency. The produced water was stored at ambient temperature in 100 mL closed Teflon containers.

2.2.4. Crop Yield

Weights of samples were measured with an analytical laboratory scale, namely the RADWAG AS 220.R2 (Radom, Poland), with a precision of ±0.0001 g.

2.2.5. Dry Mass

Samples were dried for 24 h at 100–105 °C. The weights of the samples were measured with an analytical laboratory scale, namely the RADWAG AS 220.R2 (Radom, Poland), with a precision of ±0.0001 g.

2.2.6. Ash

In a vessel weighed with a 0.0002 g precision, a substance was weighed with the same precision and the whole was inserted for 10 min into the front of an oven heated to 815 °C. Subsequently, the vessel with the sample was shifted (2 cm/min) into the central region of the chamber. After returning the temperature of the oven to 815 °C, the analyzed sample was maintained inside the chamber for a further 25 min. After that time, the sample was left in the open for cooling to room temperature, and then weighed with a 0.0002 g precision.

2.2.7. Fat Content

A sample thoroughly disintegrated in a mortar was weighed (5 g ± 1 mg) and then blended with anhydrous Na

2SO

4 (5 g) and transferred into an extracting casing, filling it in to no more than three quarters of its height. The filled casing was closed with fat-free cotton wool. The 3 h extraction with n-hexane (200 mL) was carried out in a Soxhlet apparatus equipped with a flask for collecting the extract weighed with a ±1 mg precision. After that time, to the flask with the extract cooled to room temperature, acetone (2 mL) was added. On blowing a stream of nitrogen, the whole was slowly heated to remove the acetone and n-hexane. The flask with the extract was heated for 10 min in a drying box at 103 °C and then left in a desiccator for cooling to room temperature, followed by the weighing. The fat content (

H) (g/100 g or %) was estimated using Equation (1).

where m

0—mass of the sample; m

1—mass of empty extracting flask; and m

2—mass of extracting flask with extract.

2.2.8. Protein Content

The Kjeldahl method [

18] was applied.

2.2.9. Carbohydrate Content

The carbohydrates mass (M) was determined from Equation (2).

2.2.10. Chlorophyll Content

Leaves of cress (200 mg) were homogenized for 2 min in a cooled mortar and then homogenized for a further 2 min with the acetone/ammonia (0.05 mol/dm3) 8/2 blend (5 cm3) cooled to 0–5 °C. The extraction was continued for 2 more minutes by addition of a subsequent 5 cm3 of the extracting acetone/ammonia blend. The resulting suspension of the well disintegrated sample was transferred into a 25 cm3 measuring cylinder, the mortar was washed with an extracting blend (10 cm3) and the wash was combined with the extract. The extract was then centrifuged for 10 min at 5000 rpm, and decanted. The volume of the extract was increased to 25 cm3 by adding the extracting blend. The experiments were run in triplicates.

The absorbance (A) of the resulting extract was taken at 470, 647 and 664 nm. The content of chlorophylls a and b in mg/g was estimated from Equations (3) and (4), respectively.

where a = 11.78 × A

664 − 2.29 × A

647 and m denotes the weight (mg) of the fresh plant material.

where b = 20.05 A

647 − 4.77 A

664 and m denotes the weight (mg) of the fresh plant material.

2.2.11. Carotenoids Content

The carotenoids content (β-carotene and xanthophyll) was calculated from Formula (5).

where c = 1000 A

470-3.27a − 104b and m denotes the weight (mg) of the fresh plant material.

2.2.12. Determination of Ascorbic Acid

A sample of the dried plant (1 g) was disintegrated in a mortar with 50 cm

3 distilled water and 5 cm

3 of a 0.1 M aqueous solution into which potato starch was added. This solution was titrated with an iodine solution following a paper by Al Majidi and Al Qubury [

19]. The estimations were triplicated.

2.2.13. Gas Chromatographic Analyses

An Agilent 7890A gas chromatograph (Agilent Technologies, Inc., Santa Clara, CF. USA) was equipped with a Supelcowax-10 30 cm × 0.32 mm × 0.25 μm column. An injector was maintained at 270 °C. An initial temperature of 40 °C was maintained for 1 min, and then rose to 220 °C with a rate of 4 °C/min. Helium (0.5 cm3/min) was used as the gas. The analyzed sample mass ranged from 33 to 333 Da. The temperature of the ion generator was maintained at 220 °C. SPMR injections were performed in a splitless manner.

2.2.14. Analyses for Cations

Samples were mineralized in a microwave oven (MarsXpress CEM Company, Matthews, NC USA). Samples (0.5 g) were digested with nitric acid, 65%, of analytical grade (10 cm3). Determination of the metal content was performed with atomic absorption spectrometry with an electrothermal device (AA Varian 240 instrument). A palladium standard solution (1000 mg/dm3) was used as a modifier.

2.2.15. Anion Analyses with Ion Chromatography

A DX500 micropore (2 mm) ion chromatograph with a CD20 conductivity detector and GP40 gradient pump (Dionex, San Diego, CA, USA) was used for ion separation and detection. The commercially available Ionpac CG12A guard and CS12A analytical columns (Dionex, California) with carboxylic-phosphonic acid functional groups were used for cation analysis. The Ionpac AG14 guard and AS14 analytical columns (Dionex, California) with quaternary ammonium functional groups were used for anion separation. Eluents were stored in vessels pressurized at 8 psi using high purity argon (BOC gases), and the flow-rates were maintained at 0.45 mL/min for anions and 0.40 cm3/min for cations using a GP40 gradient pump (Dionex, California). Samples were loaded from an AS40 automated sampler (Dionex, California).

3. Results and Discussion

Treatment of water with the LPGP results in declusterization of the original macrostructure. If the treatment was performed without any contact with a gaseous atmosphere, then the resulting effects were unstable, and the original macrostructure was readily recovered. On the treatment of water in air, the declusterization effects are stabilized by formation of aqueous clathrates hosting inside molecular oxygen in its excited, singlet form. Small clusters as well as clathrates reach a nanometric size and for that sake such water used to be colloquially called nanowater. For its size, nanowater more readily penetrate cell membranes being simultaneously good vectors for clathrated oxygen and for ions of dissolved and dissociated minerals. The nanowater resulting from the use of LPGPA clathrates could be stable for several months, provided they reside in either a neutral or basic environment. In acidic solutions, clathrates decompose with the rate dependent on the activity of the developed protons [

2]. Decomposing clathrates liberate molecular oxygen, immediately reconverting into its triplet state and the energy consumed on the excitation triplet oxygen into its excited singlet state. Such a circumstance may be encountered in tissues of watered plants. In water treated with the LPGPN, the clathrates that are formed host variously excited states; that is, free radical forms of molecular nitrogen [

3]. On decomposition of such clathrates, the reactive forms of nitrogen can facilitate the incorporation of nitrogen into the cells and tissues.

Although the treatment of water with LPGPC did not produce clathrates, carbon dioxide contributes to the modification of the original water macrostructure in two ways. Carbon dioxide molecules in their excited states can be incorporated into the declusterized water macrostructure, forming some niches that can incorporate further molecules of carbon dioxide in its ground as well as excited states [

4]. In both cases, the incorporated carbon dioxide can contribute to the biosynthesis of the carbohydrates and carboxylic acids within the cells and tissues of plants watered with such nanowater.

From a chemical point of view, water commonly used in everyday life cannot be considered pure. Even when either redistilled or thoroughly deionized, it is, in fact, a solution of the components of the atmosphere in which these operations were carried out. The gaseous components cannot be fully evacuated from those solutions even under a deep vacuum. However, thorough blowing water with, for example, methane, one can efficiently evacuate the oxygen and nitrogen molecules originally dissolved in the water in contact with air. Treatment water with LPGPM results in declusterization of the water macrostructure but clusters hosting methane are not formed. The methane molecules that reside in the treated water remain in their ground state and in such a form they are hosted in the niches of the declusterized water [

5]. Thus, such nanowater seems to be the most neutral in case of its use for plant watering.

A majority of fundamental studies on water treated with LPGP involved demineralized water. Such water was rather unsuitable for watering plants for the direction of the osmotic mass transfer between tissues. Therefore, in practice, natural LPGP-treated water should be used. As demonstrated in

Table 1, crop yields after watering cress with tap water were almost 30% higher compared to crops watered with demineralized water. Watering cress with tap water treated for 30 min with LPGPA provided a crop increase of almost 2% whereas the watering with demineralized water treated with LPGPA in the same manner decreased the crop by 4.3%. Tap water, regardless of being saturated with either nitrogen, methane or CO

2, always promoted the yield of crops. Their efficiency increased in the following order: water saturated with N

2 < water saturated with CH

4 < water saturated with CO

2 (

Table 1). Watering cress with each kind of water resulted in a further increase in the crop yield by 2.8 to 3.6%.

As deduced from the estimated dry mass and ash (

Table 1), dissolved gases as well as the mineral components of tap water could be transported to the plant tissues.

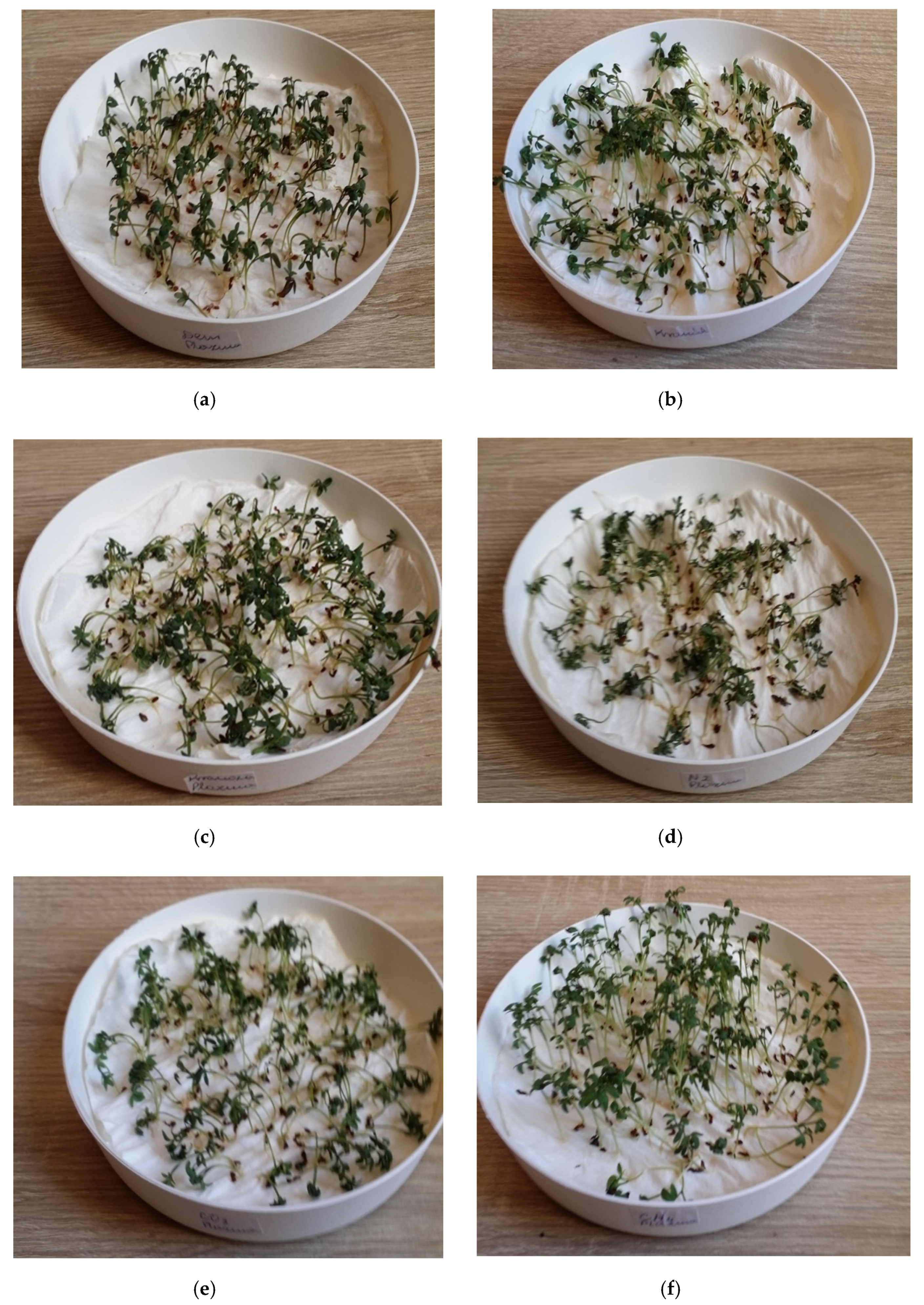

Figure 1 presents condition of the planted cress watered with various kinds of treated water.

One could see that appearance of the cultivated plants do not necessarily reflect the yield of the crops. The most smart-looking cress was watered with deionized, non-treated water and with LPGPM water, and provided the lowest (1.1044 g) and a fairly high (2.0686 g) crop yield, respectively. The most poorly looking plants resulted from watering plants with LPGPN and LPGPC-treated water. The resulting yields were 2.0045 and 2.4222 g (the highest among all recorded), respectively. The quoted values corresponded to the lowest and the highest content of ash and dry mass, respectively. Thus, the appearance of the plants could be associated with the ability to uptake the given water used for watering. Again, it could depend on the degree of declusterization of the water on the GP treatment. Watering with deionized water treated with LPGPA could transport to the plant solely clathrated oxygen molecules. Non-treated tap water delivered to the plants the minerals dissolved in it. The oxygen dissolved in it was not clathrated and, therefore, its uptake was relatively poor. It resulted in a worse appearance of the cress. The same water treated with LPGPA, apart from the minerals transported, also transported molecular oxygen, providing in that manner still a worse appearance of the plant. Water treated with LPGM transported minerals and neutral methane to the watered plants. No molecular oxygen was transported to the growing cress. Thus, molecular oxygen in its excited state, molecular nitrogen in its excited state and the carbon dioxide introduced to the plant tissues increased the crop yield, as well as the dry mass and ash content of the crops, spoiling simultaneously their appearance.

As shown in

Table 2, watering cress with water saturated solely with CO

2 and CH

4 had a certain effect upon the fat content. The treatment of tap water with LPGP slightly improved the yield of fat; only when the water was treated under CH

4 and water treated with LPGP under CO

2 reduced the fat content. In other cases, the plasma treatment was meaningless regarding the fat content. Practically, the gas used for the water saturation and the treatment of saturated water were quite meaningless regarding the content of carbohydrates. Water saturated with nitrogen, regardless whether it was treated or non-treated, positively influenced the protein content in cress. The other kinds of water either slightly influenced it or had no effect upon the protein content.

Watering cress with water saturated with N

2 and CO

2 slightly increased the content of total chlorophyll whereas watering with water saturated with CH

4 significantly decreased it. Watering with water treated with LPGP always resulted in an increase in the total chlorophyll content but this increase was fairly subtle (

Table 3).

Except for tap water, watering cress with LPGP-treated water resulted in an increase in the level of chlorophyll a. The level of chlorophyll b changed less uniformly on application of the LPGP-treated waters. The use of treated deionized, tap and saturated with N2 water provided a slight increase in the level of that chlorophyll whereas a fairly significant level in this respect could be noted when the treated water saturated with CO2 was used. Water saturated with CH4 clearly decreased the level of chlorophyll b and the plasma treated water had no influence on the level of that chlorophyll.

As shown in

Table 3, the effect of the gas used for saturation of the water and the treatment’s resulting water had a minor effect upon the content of carotenoids and ascorbic acid. Tap water saturated with N

2, CO

2 and CH

4 prior to and after the treatment performed better than tap water saturated with air prior and after the treatment, respectively.

Watering cress with water saturated with particular gases influenced also the bioaccumulation of cations (

Table 4) and anions (

Table 5). Obviously, for the direction of the osmotic mass transfer, the lowest bioaccumulation of those species was observed in case of watering with deionized water. In the remaining cases, the bioaccumulation of cations and anions increased in the orders differing individually for particular cations and anions. In case of cations, invariably the bioaccumulation from water saturated with either CH

4 or CO

2 was lower than from water saturated with air and N

2.

Water treated with LPGP offered better bioaccumulation of the Na and Se cations and suppressed bioaccumulation of the Ca cations although the effect of the treated water saturated with CO2 and CH4 on bioaccumulation of Se was negligible. The same effect was noted also in case of bioaccumulation of K and Mg cations in cress watered with treated water saturated with CH4.

Water saturated with particular gases exhibited no effect on the bioaccumulation of the NO

2 anion. The water saturated with N

2 suppressed the bioaccumulation of the Cl anion whereas the water saturated with CH

4 most efficiently suppressed the bioaccumulation of the NO

3, SO

4 and PO

4 anions. The treatment of particular kinds of water showed their chimeric effect on the level of bioaccumulation of particular anions (

Table 5).

4. Conclusions

Yield of cress crops and their nutritional value—that is, the content of the ascorbic acid, chlorophyll as well as bioaccumulated cations and anions—can be modified to various extents when water treated with low-pressure, low temperature glow plasma of low frequency prepared in contact with various gases (air, oxygen-free nitrogen, carbon dioxide or methane) is used for watering.

The removal of air dissolved in tap water for watering by its saturation with either nitrogen, carbon dioxide or methane increased the crop yield by 14.3, 39.8 and 18.4%, respectively. After the treatment of those kinds of water with glow plasma, the crop yield increased additionally by almost 2–4%, and the highest fat and protein content was provided by watering cress with tap water saturated with N2 and treated with glow plasma. Neither the kind of water nor its treatment had any effect on the level of carbohydrates. Watering with water saturated with CO2 and then treated with plasma offered the highest level of total chlorophyll and the effect of watering with water saturated with N2 was slightly worse. These kinds of water were also most efficient in increasing the level of carotenoids. Watering with water saturated with CO2 provided the highest level of ascorbic acid and the treatment of that water additionally increased the level of that acid.

The appearance of cress cultivated by applying various kinds of water exposed to low-pressure, low temperature glow plasma of low frequency prepared in contact with various gases is controlled by water uptake, introducing building material to the plant. The higher the uptake is, the worse the plant’s appearance is.