Manual Borehole Drilling as a Cost-Effective Solution for Drinking Water Access in Low-Income Contexts

Abstract

1. Introduction

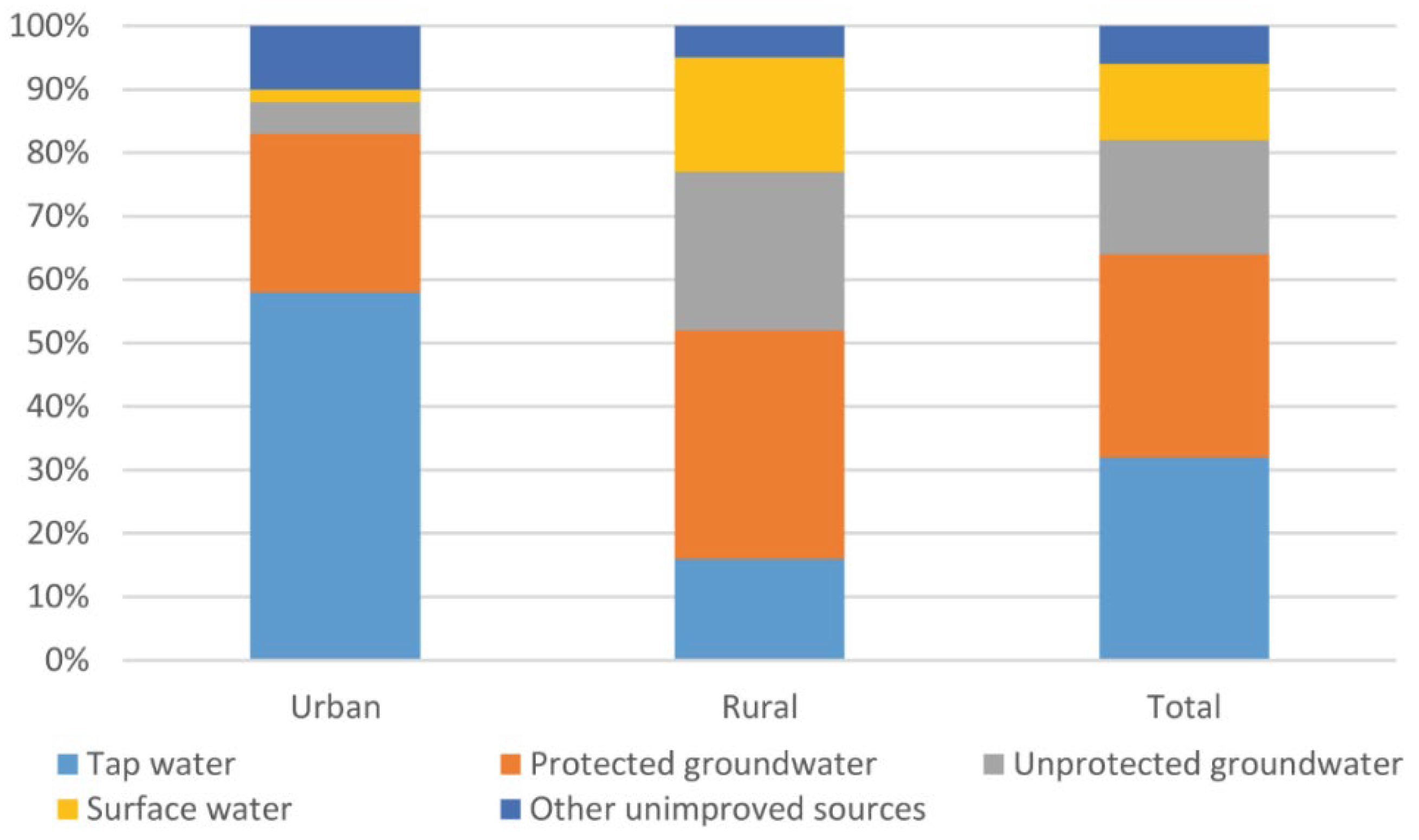

2. Social and Economic Context

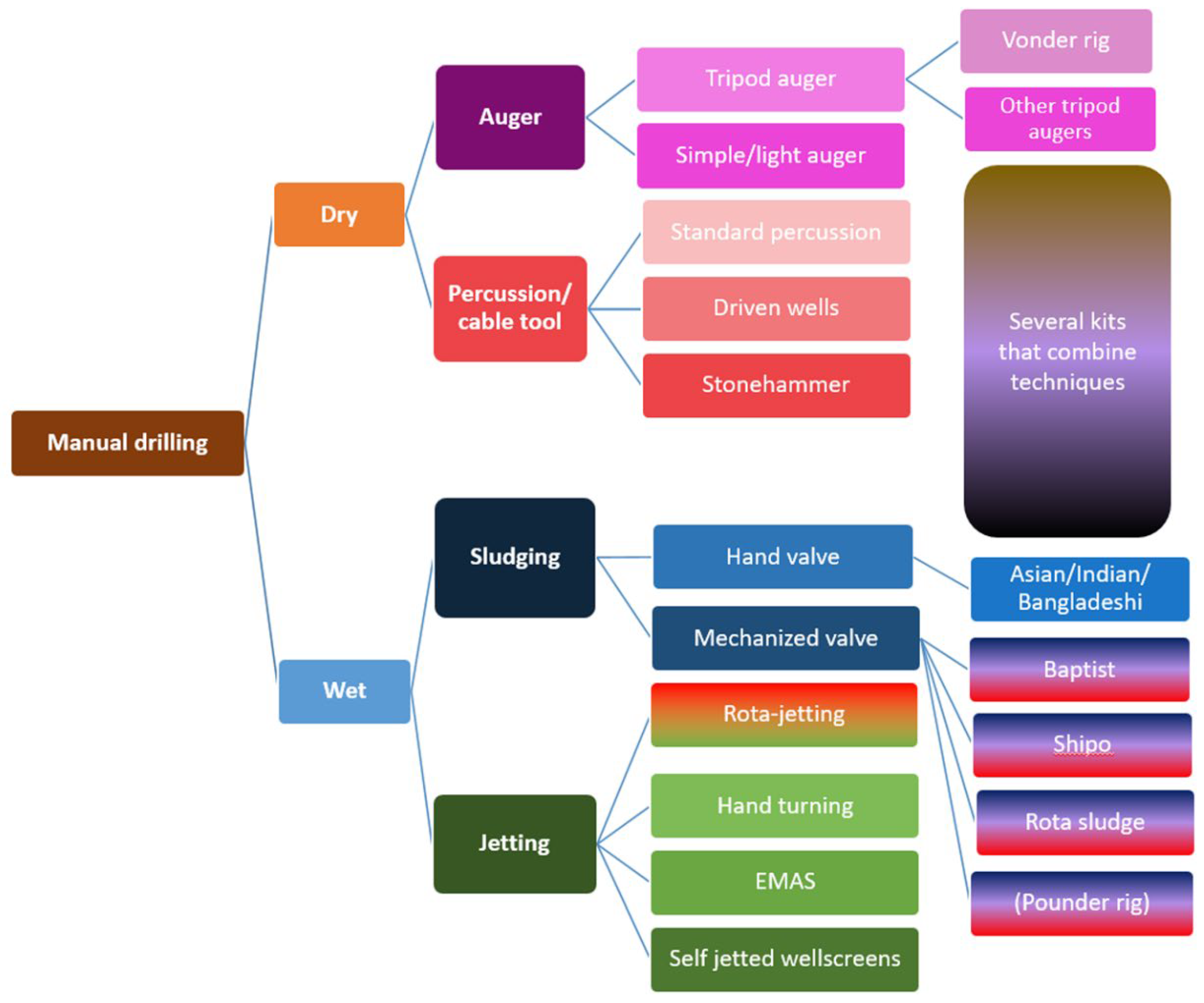

3. Manual Drilling Methods

3.1. Augering and Bailing

3.2. Percussion and Bailing

3.3. Sludging

3.4. Jetting

4. Manual Boreholes Versus other Technical Solutions

4.1. Manual Boreholes Versus Mechanized Boreholes

4.2. Manual Boreholes Versus Excavated Wells

5. Manual Boreholes: Successes and Challenges

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- United Nations. Resolution A/RES/64/292; United Nations General Assembly: New York, NY, USA, 2010. [Google Scholar]

- World Health Organization. Safely Managed Drinking Water—Thematic Report on Drinking Water; World Health Organization: Geneva, Switzerland, 2017. [Google Scholar]

- Pattnaik, B.K.; Dhal, D. Mobilizing from appropriate technologies to sustainable technologies based on grassroots innovations. Technol. Soc. 2015, 40, 93–110. [Google Scholar] [CrossRef]

- Kruger, P. Appropriate technologies for large-scale production of electricity and hydrogen fuel. Int. J. Hydrogen Energy 2008, 33, 5881–5886. [Google Scholar] [CrossRef]

- Martí-Herrero, J.; Chipana, M.; Cuevas, C.; Paco, G.; Serrano, V.; Zymla, B.; Heising, K.; Sologuren, J.; Gamarra, A. Low cost tubular digesters as appropriate technology for widespread application: Results and lessons learned from Bolivia. Renew. Energy 2014, 71, 156–165. [Google Scholar] [CrossRef]

- Murphy, H.M.; McBean, E.A.; Farahbakhsh, K. Appropriate technology—A comprehensive approach for water and sanitation in the developing world. Technol. Soc. 2009, 31, 158–167. [Google Scholar] [CrossRef]

- Helweg, O.J.; Smith, G. Appropriate Technology for Artificial Aquifers. Ground Water 1998, 16, 144–148. [Google Scholar] [CrossRef]

- Chigerwe, J.; Manjengwa, N.; Van Der Zaag, P.; Zhakata, W.; Rockström, J. Low head drip irrigation kits and treadle pumps for smallholder farmers in Zimbabwe: A technical evaluation based on laboratory tests. Phys. Chem. Earth 2004, 29, 1049–1059. [Google Scholar] [CrossRef]

- Skinner, B.; Shaw, R. VLOM Pumps-Technical Brief 41; Loughborough University: Loughborough, UK, 1999. [Google Scholar]

- Adekile, D.; Olabode, O. Hand Drilling in Nigeria. Why Kill an Ant with a Sledgehammer? Rural Water Supply Network, UNICEF: Field Note No 2009—1; United Nations International Children’s Emergency Fund (UNICEF): New York, NY, USA, 2009; 12p.

- Bowman, I. Well Drilling Methods. United States Geological Survey; Department of the Interior: Washington, DC, USA, 1911; p. 134.

- Danert, K. Realizing the potential of hand-drilled wells for rural water supplies. Waterlines 2009, 28, 108–129. [Google Scholar] [CrossRef]

- Tolman, C.F. Ground Water; McGraw Hill: New York, NY, USA; London, UK, 1937; p. 593. [Google Scholar]

- Danert, K. Manual Drilling Compendium Rural Water Supply Network; Skat: St Gallen, Switzerland, 2015; p. 40. [Google Scholar]

- UNICEF. Capitalisation D’experiences sur les Forages Manuels à Madagascar; Technical Report, Practica Foundation; United Nations International Children’s Emergency Fund (UNICEF): New York, NY, USA, 2012; p. 50.

- Kane, C.H.; Danert, K. Manual Drilling in the Democratic Republic of Congo: Reaching the Tipping Point within a Decade; Technical Report; Rural Water Supply Network (RWSN): St. Gallen, Switzerland, 2020. [Google Scholar]

- Danert, K.; Adelike, D.; Gesti-Canuto, J. Manually Drilled Boreholes: Providing Water in Nigeria’s Megacity of Lagos and Beyond; Skat Foundatio: Gallen, Switzerland, 2019; Available online: https://www.rural-water-supply.net/en/resources/details/618 (accessed on 15 December 2019).

- Weight, E.; Yoder, R.; Keller, A. Manual Well Drilling Investment Opportunity in ETHIOPIA. COLOMBO, Sri Lanka: International Water Management Institute (IWMI); IWMI Working Paper 155; IWMI: Colombo, Sri Lanka, 2013. [Google Scholar] [CrossRef]

- Martínez-Santos, P.; Martín-Loeches, M.; Solera, D.; Cano, B.; Díaz-Alcaide, S. Mapping the Viability, Time, and Cost of Manual Borehole Drilling in Developing Regions. Water 2017, 9, 262. [Google Scholar] [CrossRef]

- UNICEF-WHO. Progress on Drinking Water and Sanitation; United Nations International Children’s Emergency Fund-World Health Organization (UNICEF-WHO): New York, NY, USA, 2012.

- UNICEF-WHO. Progress on Sanitation and Drinking Water—2015 Update and MDG Assessment; United Nations International Children’s Emergency Fund-World Health Organization (UNICEF-WHO): New York, NY, USA, 2015.

- Martínez-Santos, P. Does 91% of the world’s population really have “sustainable access to safe drinking water”? Int. J. Water Resour. Dev. 2017, 33, 514–533. [Google Scholar] [CrossRef]

- Misati, A.G.; Ogendi, G.; Peletz, R.; Khush, R.; Kumpel, E. Can sanitary surveys replace water quality testing? Evidence from Kisii, Kenya. Int. J Environ. Res. Public Health 2017, 14, 152. [Google Scholar] [CrossRef]

- Shaheed, A.; Orgill, J.; Montgomery, M.A.; Jeuland, M.A.; Brown, J. Why ‘Improved’ Water Sources are not always Safe; Bulletin of the World Health Organization: Geneva, Switzerland, 2014; Volume 92, pp. 283–289. [Google Scholar]

- UNICEF-WHO. Safely Managed Drinking Water—Thematic Report on Drinking Water; United Nations International Children’s Emergency Fund-World Health Organization (UNICEF-WHO): New York, NY, USA, 2017.

- World Bank. World Bank Data. Available online: http://data.worldbank.org/ (accessed on 22 May 2018).

- Delaire, C.; Peletz, R.; Kumpel, E.; Kisiangani, J.; Bain, R.; Khush, R. How Much Will It Cost To Monitor Microbial Drinking Water Quality in Sub-Saharan Africa? Environ. Sci. Technol. 2017. [CrossRef] [PubMed]

- Lilje, J.; Mosler, H.J. Continuation of health behaviors: Psychosocial factors sustaining drinking water chlorination in a longitudinal study from Chad. Sustainability 2016, 8, 1149. [Google Scholar] [CrossRef]

- Ndé-Tchoupé, A.I.; Crane, R.A.; Mwakabona, H.T.; Noubactep, C.; Njau, K.N. Technologies for decentralized fluoride removal: Testing metallic iron based filters. Water 2015, 7, 6750–6774. [Google Scholar] [CrossRef]

- Grönwall, J.; Danert, K. Regarding Groundwater and Drinking Water Access through A Human Rights Lens: Self-Supply as A Norm. Water 2020, 12, 419. [Google Scholar] [CrossRef]

- Zekster, I.S.; Everett, L.G. Groundwater Resources of the World and Their Use; UNESCO IHP-VI Series on Groundwater. No. 6. Paris; UNESCO: New York, NY, USA, 2004; p. 342. [Google Scholar]

- Girma, M.; Assefa, A.; Molinas, M. Feasibility study of a solar photovoltaic water pumping system for rural Ethiopia. Environ. Sci. 2015, 2, 697–717. [Google Scholar] [CrossRef]

- Yorkor, B.; Leton, T.G. Solar water supply for rural communities in Rivers State, Niger Delta of Nigeria. IJEES 2017, 5, 1–17. [Google Scholar]

- The Rural Water Supply Network Executive Steering Committee. Myths of the Rural Water Supply Sector; RWSN: St. Gallen, Switzerland, 2010. [Google Scholar]

- Foster, T. Predictors of sustainability for community-managed hand pumps in Sub-Saharan Africa: Evidence from Liberia, Sierra Leone, and Uganda. Environ. Sci. Technol. 2013, 47, 12037–12046. [Google Scholar] [CrossRef]

- Liddle, E.S.; Fenner, R. Review of Handpump-Borehole Implementation in Uganda; British Geological Survey: Nottingham, UK, 2018. [Google Scholar]

- Danert, K. (Ask for Water, Madrid, Spain) Manual drilling around the world. Seminar of the UNESCO Chair “Appropriate Technologies for Human Development” on Manual Drilling. Oral presentation. 2019. [Google Scholar]

- Danert, K.; Carter, R.C.; Adekile, D.; MacDonald, A. Cost-effective boreholes in sub-Saharan Africa. In Proceedings of the 33rd WEDC International Conference, Accra, Ghana, 7–11 April 2008. [Google Scholar]

- World Bank. Etude Sur l’optimisation du coût des Forages en Afrique de l’Ouest. Rapport de Synthèse; Rapport n 44743/A; World Bank: Orléans, France, 2007. [Google Scholar]

- Van-Kinderen, I.; Vuik, R.; Pelgrim-Adams, A. From emergency to development or viceversa? Key lessons from the innovation of a well-drilling method. In Water Sanitation and Hygiene Services Beyond 2015: Improving Access and Sustainability, Proceedings of the 38th International Conference, Loughboroug, UK, 27–31 July 2015; IWMI: Colombo, Sri Lanka, 2015. [Google Scholar]

- Carter, R.C. Human-Powered Drilling Technologies: An Overview of Human-Powered Drilling Technologies for Shallow Small Diameter Well Construction, for Domestic and Agricultural Water Supply; Technical Report; Cranfield University: Bedfordshire, UK, 2005; p. 18. [Google Scholar]

- Tapia Reed, D. Perforación Manual de Pozos Profundos Usando el Método EMAS-AYNI.; Technical Report; Universidad Técnica Federico Santa María: Valparaíso, Chile, 2008; p. 79. [Google Scholar]

- Waller, T.; (Water For All International, San Angelo, TX, USA). Personal communication, 2015.

- Practica Foundation. Sludging. Manual Drilling Series. Technical Training Handbook on Affordable Manual Well Drilling; Practica Foundation: Papendrecht, The Netherlands, 2011; p. 88. [Google Scholar]

- Martínez-Santos, P. Determinants for water consumption from improved sources in villages of southern Mali. Appl. Geogr. 2017. [Google Scholar] [CrossRef]

- Grönwall, J.; Oduro-Kwarteng, S. Groundwater as a strategic resource for improved resilience: A case study from peri-urban Accra. Environ. Earth Sci. 2018, 77, 6. [Google Scholar] [CrossRef]

- Fussi, F.; Fumagalli, L.; Fava, F.; Di Mauro, B.; Hamidou, C.; Kane, M.; Souleye, N.; Wade, S.; Hamidou, B.; Colombo, R.; et al. Classifying zones of suitability for manual drilling using textural and hydraulic parameters of shallow aquifers: A case study in northwestern Senegal. Hydrogeol. J. 2017, 25, 2263–2279. [Google Scholar] [CrossRef]

- Solera, D.; Cano, B. Cartografía de Zonas Susceptibles de Perforación Manual con el Método Baptista en los Acuíferos de Zócalo del Sector Siby-Bancoumana-Narena (sur de Mali). Posgrado de Especialización en Agua, Saneamiento e Higiene en Cooperación Internacional. Master’s Thesis, Universidad de Alcalá, Madrid, Spain, 2017. [Google Scholar]

- AECID. Experiencias de Perforación Manual Para el Abaratamiento Del Acceso al Agua en la República de Mali; Technical Report; Agencia Española de Cooperación Internacional al Desarrollo: Madrid, Spain, 2017; p. 81. ISBN 978-84-617-8426-4.

- Naugle, J.; Hangen, M.; Brubacher, C. Examples of Manual Drilling in Remote, or Difficult to Serve Areas. Hand Drilling Cluster Group. Available online: https://dgroups.org/rwsn/groundwater/handdrilling/discussions (accessed on 15 December 2019).

- Kent, B. Hand-Dug Water Wells: A Vanishing Technology. In Proceedings of the Colloque International OH2 Origines et Histoire de l’Hydrologie, Dijon, France, 9–11 May 2001; Available online: https://www.pseau.org/outils/ouvrages/iahs_hand_dug_water_wells_a_vanishing_technology_2001.pdf (accessed on 15 December 2019).

- Liddle, E.S.; Mager, S.M.; Nel, E.L. The suitability of shallow hand dug wells for safe water provision in sub-Saharan Africa: Lessons from Ndola, Zambia. Appl. Geogr. 2015, 57, 80–90. [Google Scholar] [CrossRef]

- Martínez-Santos, P.; Martín-Loeches, M.; García-Castro, N.; Solera, D.; Díaz-Alcaide, S.; Montero, E.; García-Rincón, J. A survey of domestic wells and pit latrines in rural settlements of Mali: Implications of on-site sanitation on the quality of water supplies. Int. J. Hyg. Environ. Health. 2017, 220, 1179–1189. [Google Scholar] [CrossRef] [PubMed]

- Wanke, H.; Nakwafila, A.; Hamutoko, J.T.; Lohe, C.; Neumbo, F.; Petrus, I.; David, A.; Beukes, H.; Masule, N.; Quinger, M. Hand dug wells in Namibia: An underestimated water source or a threat to human health? Phys. Chem. Earth 2014, 76–78, 104–113. [Google Scholar] [CrossRef]

- United Nations International Children’s Emergency Fund. The rights to safe water and to sanitation. Curr. Issues 2014, 3, 1–5. [Google Scholar]

- Martínez-Santos, P.; Cerván, J.A.; Cano, B.; Díaz-Alcaide, S. Water versus Wireless Coverage in Rural Mali: Links and Paradoxes. Water 2017, 9, 375. [Google Scholar] [CrossRef]

- Practica Foundation. The Impact of Manual Drilling for the Construction of Sustainable Water-Points in Chad. Fact Sheet. 59; Practica Foundation: Madagascar, The Netherland, 2009; Volume 12. [Google Scholar]

- Capstick, S.; Whitmarsh, L.; Healy, A.; Bristow, G. Resilience in Groundwater Supply Systems: Findings from a Survey of Private Households in Lagos, Nigeria; RIGSS Working Paper; RIGSS: Phuentsholing, Bhutan, 2017. [Google Scholar]

- Jabbi, H.; (Department of Water Resources of the Gambia, Banjul, The Gambia). Personal communication, March 2017.

| Category | Term | Definition |

|---|---|---|

| Wells and boreholes | Borehole | A narrow shaft bored in the ground for the purpose of extracting groundwater. Boreholes are cased, gravel packed and equipped with a pump and wellhead protection. |

| Manual borehole | A borehole drilled by manual means, replicating the work of a mechanical rig by hand. Typically less than 50 m deep, with a casing diameter of 70 to 400 mm. May be gravel packed and equipped with a pump and wellhead protection. | |

| Mechanized borehole | A borehole drilled by means of a mechanical rig. It may be hundreds of meters deep. | |

| Excavated well, dug well, well | A large diameter hole in the ground used for the purpose of extracting groundwater. Typically dug with peak and shovel. It may be lined with concrete or bricks and equipped with a wellhead for protection. Generally less than 20–30 m deep. | |

| Pumps | Commercial pump | A commercially available pump used to extract groundwater from a borehole. Most standard pumps require casing diameters in excess of 200 mm. Yields are variable. |

| Factory-made hand pump | A pump powered by hand. If the aquifer is sufficiently productive, yields are limited by the pumping capacity of a human being. | |

| Electric submersible pump | A pump powered by electricity from the grid, using gasoil or solar energy. If the aquifer is sufficiently productive, yields may exceed those from hand and locally made pumps. | |

| Locally made handpump | A non-commercial hand pump. Typically made with inexpensive local materials and powered by human action. Less durable than a factory-made hand pump, but easier to make and cheaper to fix. The flow rate is similar. |

| Country | Estimated Number | Location | Techniques | Date | Costs |

|---|---|---|---|---|---|

| Bangladesh | Millions | Most sedimentary basins | Sludging | 1900s to date | $1 per meter |

| Bolivia | 30,000 | EMAS, Baptist | 1983 to date | $300 | |

| Chad | Thousands | Central Chad | 1960s to date | ||

| Democratic Republic of Congo | >1000 | West, south and some in the east | Jetting, village drill | 2007 to date | |

| Kenya | 10,000 | Various regions | Augering, sludging, percussion, Baptist | 1979 to date | $4000 (augered to 40 m) |

| India | Millions | Various regions | Sludging, jetting, augering | Indigenous technology | |

| Madagascar | 12,000 | East and west coast (driven wells), throughout the country (jetting, rota-sludge) | Driven wells, jetting, rota-sludge | 1960s to date (driven); early 2000s to date (jetting, rota-sludge) | $35 to $50 (driven wells); $1000 to $3000 (<30 m depth) |

| Nepal | >100,000 | Terai (lowland) | Sludging | 1950s to date | $20–$450 |

| Niger | 16,000 | Maradi and Zinder regions | Augering, jetting, rota-sludge, percussion | 1900s (irrigation; 2005 to date | |

| Nigeria | 30,000 | At least 27 of the 36 states | Jetting, augering, percussion, Baptist | Early 1980s to date | $2500 or less |

| Senegal | >4000 | Various regions | Augering, jetting, percussion, rota-jetting | 1991 to date | $1600 to $2000 |

| Uganda | <1000 | Lake Victoria, west, north and south | Rotary-sludge, rotary jetting, Baptist | Late 1980s to early 1990s; pilot projects from 1998 to 2013. | |

| Vietnam | >100,000 | Sludging | 1980s |

| Technique | Material | Advantages | Disadvantages | Drilling Range (m) |

|---|---|---|---|---|

| Augering | Unconsolidated sediments | Simple, cheap, fast in soft sediments | Limited to soft materials and to relatively small depths. May be problematic when drilling below the water table. | 15–20 |

| Jetting | Unconsolidated sediments | Fast in soft sediments | Potentially expensive equipment. A large volume of water is needed. | 25–50 |

| Percussion and bailing | Unconsolidated sediments and soft weathered rock | Can drill through moderately hard rocks. May be coupled with sludging. | Slower and potentially more expensive than other methods. | 25–50 |

| Sludging | Unconsolidated sediments | Ease of use. Fast in soft sediments. | Limited to soft materials. | 25–50 |

| Aspect | Excavated Wells | Manual Boreholes | Mechanized Boreholes |

|---|---|---|---|

| Business investment | Very low—digging tools typically amount to less than $50. | Low—between $500 and $2000, depending on geographical and technical considerations. | Very high—a drilling rig costs hundreds of thousands of dollars. |

| Drilling cost | Very low (≈0) if the user digs the well of if labor exchange is involved. More expensive if labor is hired or if well is lined/protected ($50–$400). | Low—$5 to $25 per meter for a borehole equipped with grid, gravel pack and well-head protection. | High—$80 to $1000 per meter (in extreme cases) for a borehole equipped with grid, gravel pack and well-head protection. |

| Cost of extraction devices | Negligible if water is extracted with buckets. Between $300–$4000 if commercial pumps are used. | Negligible if water is extracted with a locally-made hand pump. Between $300–$4000 if commercial pumps are used. | Commercial pump almost always used ($300–$4000). |

| Depth | Up to 20–30 m (may be considerably deeper occasionally). Collapse risk when digging below the water table in unconsolidated sediments. | Average depths usually range between 25 and 50 m. May exceed 100 m in very favourable conditions. | Up to several hundred meters deep. May capture groundwater at great depths. |

| Accessibility of technology for users | Widely accessible. Users may dig their own wells. | Users may drill their own boreholes with some guidance. Small-scale enterprises can also provide the service. | Users always need to rely on professional drilling enterprises. |

| Time and labour | Very laborious and time-consuming. Wells usually take weeks to dig. | Under very favourable conditions boreholes can be drilled in one day and installed on the following one. In most settings, boreholes may take a few weeks to drill. | Typically quick. In some cases boreholes can be drilled, equipped and developed within two or three days. However, transporting a mechanized rig to the site may be time-consuming (even unfeasible). |

| Geological constrains | Can make it through hard rock, but will take a long time (weeks to years in extreme cases). Digging is often restricted to the end of the dry season. | Typically suited to soft, unconsolidated sediments, but some methods (i.e., percussion and variations of percussion) may traverse consolidated rocks of medium hardness (sandstone, laterite). Can drill at any time of the year. | Usable under most geological conditions at any time of the year. |

| Yield | Dependent on diameter, extraction device (i.e., buckets or pump). In some cases several people can extract water simultaneously. Typically 0.5–4 m3/h. | Dependent on extraction device. Typically 0.5–1.2 m3/h for hand pumps, and 1–4 m3/h with powered pumps. | Dependent on extraction device. Typically 0.5–1.2 m3/h for hand pumps. Several hundred m3/h with a powered pump (subject to hydrogeological conditions). |

| Frequent hazards | Collapses and materials dropping into the hole during construction. Also prone to contamination and drying due to shallowness. Nearby contamination sources can compromise supplies. | Insufficient technical expertise leading to poor borehole construction or to the loss of the borehole during construction. Nearby contamination sources can compromise supplies. | Combed or inclined boreholes. Contractor ill-will or insufficient technical expertise leading to poor borehole construction. Nearby contamination sources can compromise supplies. |

| Suitability for consumption | Only protected wells qualify as improved water sources. | Qualify as improved water sources if adequately protected. | Qualify as improved water sources if adequately protected. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Martínez-Santos, P.; Martín-Loeches, M.; Díaz-Alcaide, S.; Danert, K. Manual Borehole Drilling as a Cost-Effective Solution for Drinking Water Access in Low-Income Contexts. Water 2020, 12, 1981. https://doi.org/10.3390/w12071981

Martínez-Santos P, Martín-Loeches M, Díaz-Alcaide S, Danert K. Manual Borehole Drilling as a Cost-Effective Solution for Drinking Water Access in Low-Income Contexts. Water. 2020; 12(7):1981. https://doi.org/10.3390/w12071981

Chicago/Turabian StyleMartínez-Santos, Pedro, Miguel Martín-Loeches, Silvia Díaz-Alcaide, and Kerstin Danert. 2020. "Manual Borehole Drilling as a Cost-Effective Solution for Drinking Water Access in Low-Income Contexts" Water 12, no. 7: 1981. https://doi.org/10.3390/w12071981

APA StyleMartínez-Santos, P., Martín-Loeches, M., Díaz-Alcaide, S., & Danert, K. (2020). Manual Borehole Drilling as a Cost-Effective Solution for Drinking Water Access in Low-Income Contexts. Water, 12(7), 1981. https://doi.org/10.3390/w12071981