Organizational Water Footprint to Support Decision Making: a Case Study for a German Technological Solutions Provider for the Plumbing Industry

Abstract

:1. Introduction

2. Materials and Methods

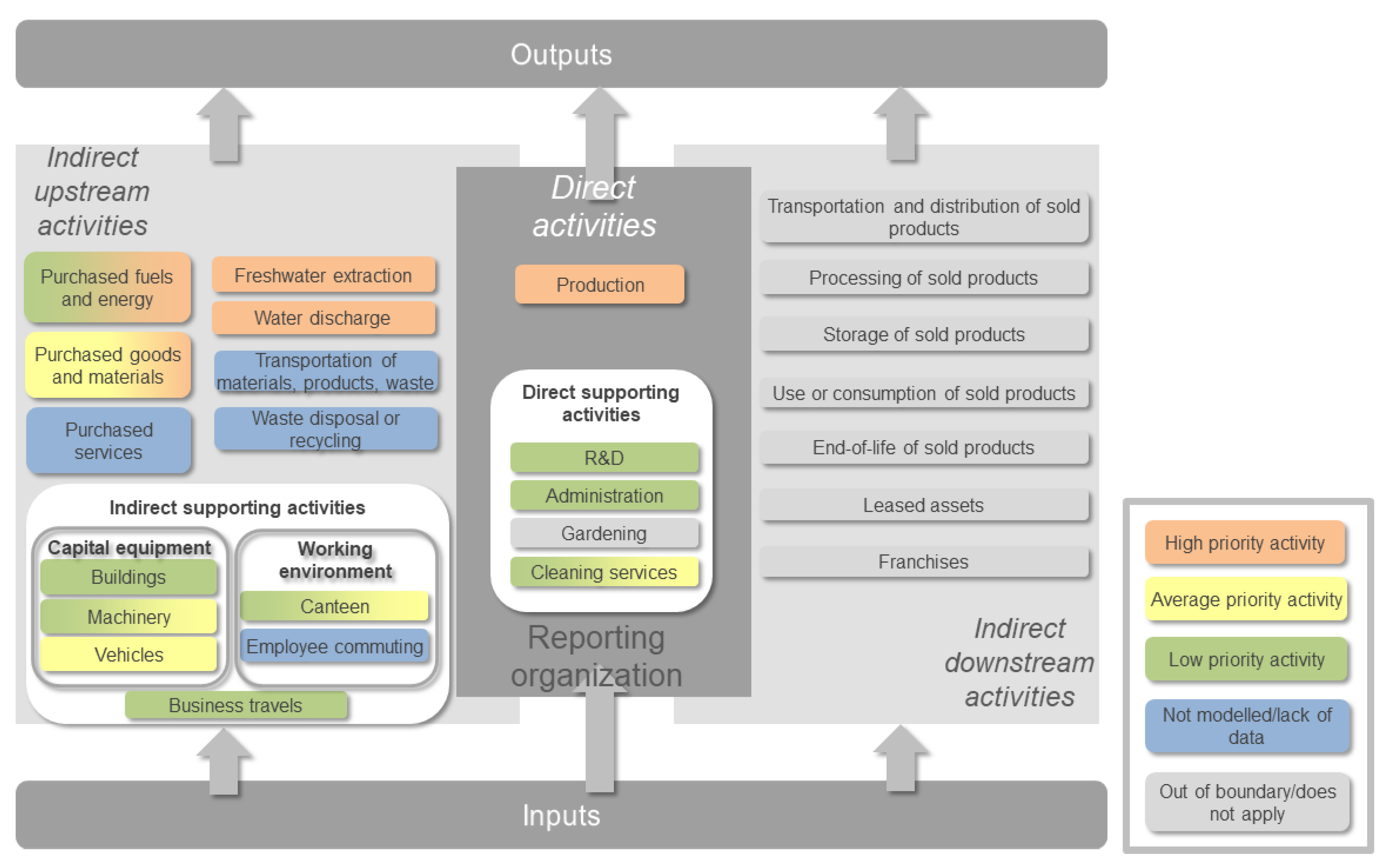

2.1. The Organizational Water Footprint Method

2.2. The Water Inventory Database

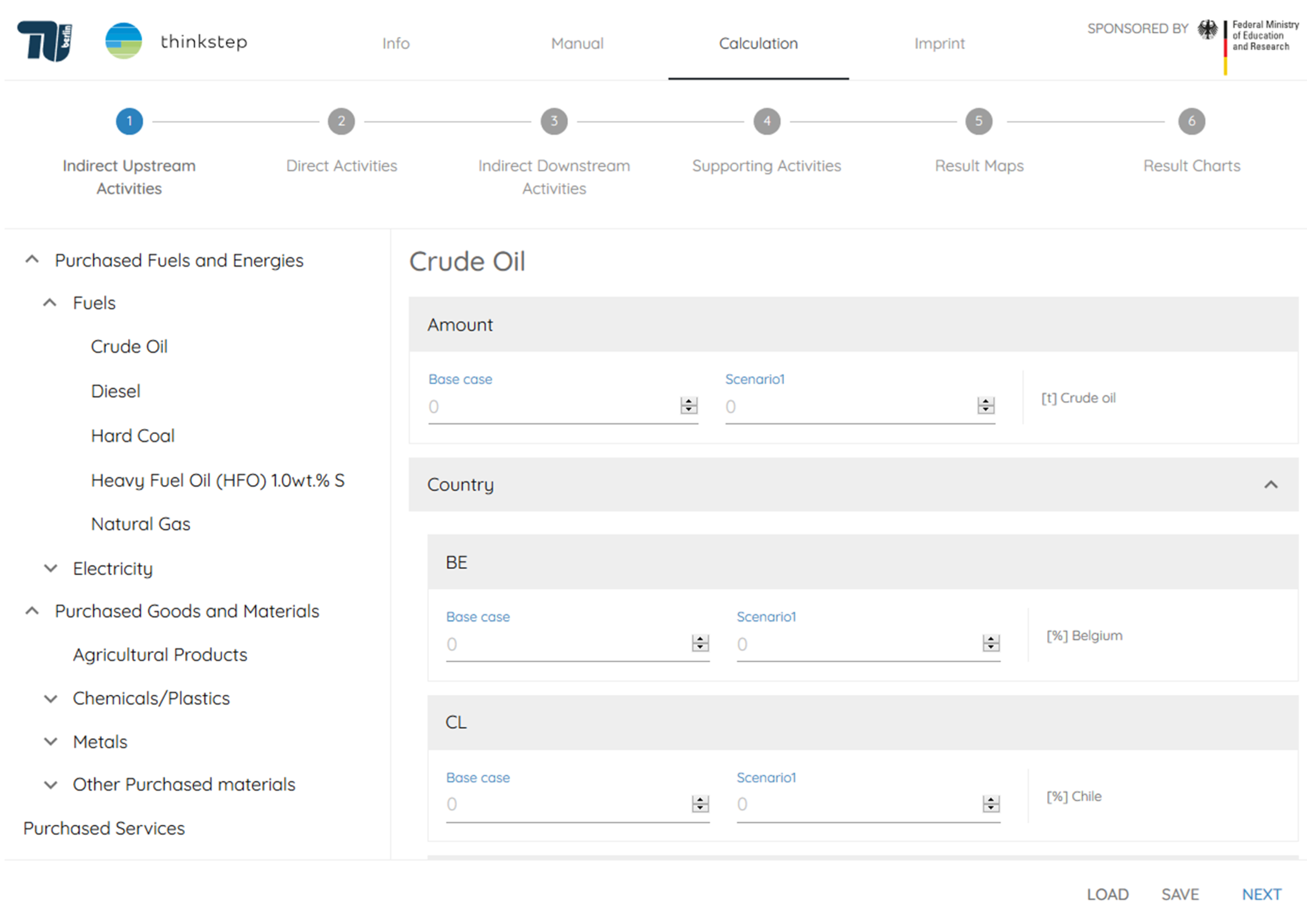

2.3. The Organizational Water Footprint (OWF) Tool

2.4. Water Scarcity Mitigation Options

3. Application of the OWF Method and Results

3.1. Goal and Scope

3.2. Life Cycle Inventory Analysis

3.2.1. Activity Categorization, Data Collection Approach and Data Sources

3.2.2. Inventory Analysis Results

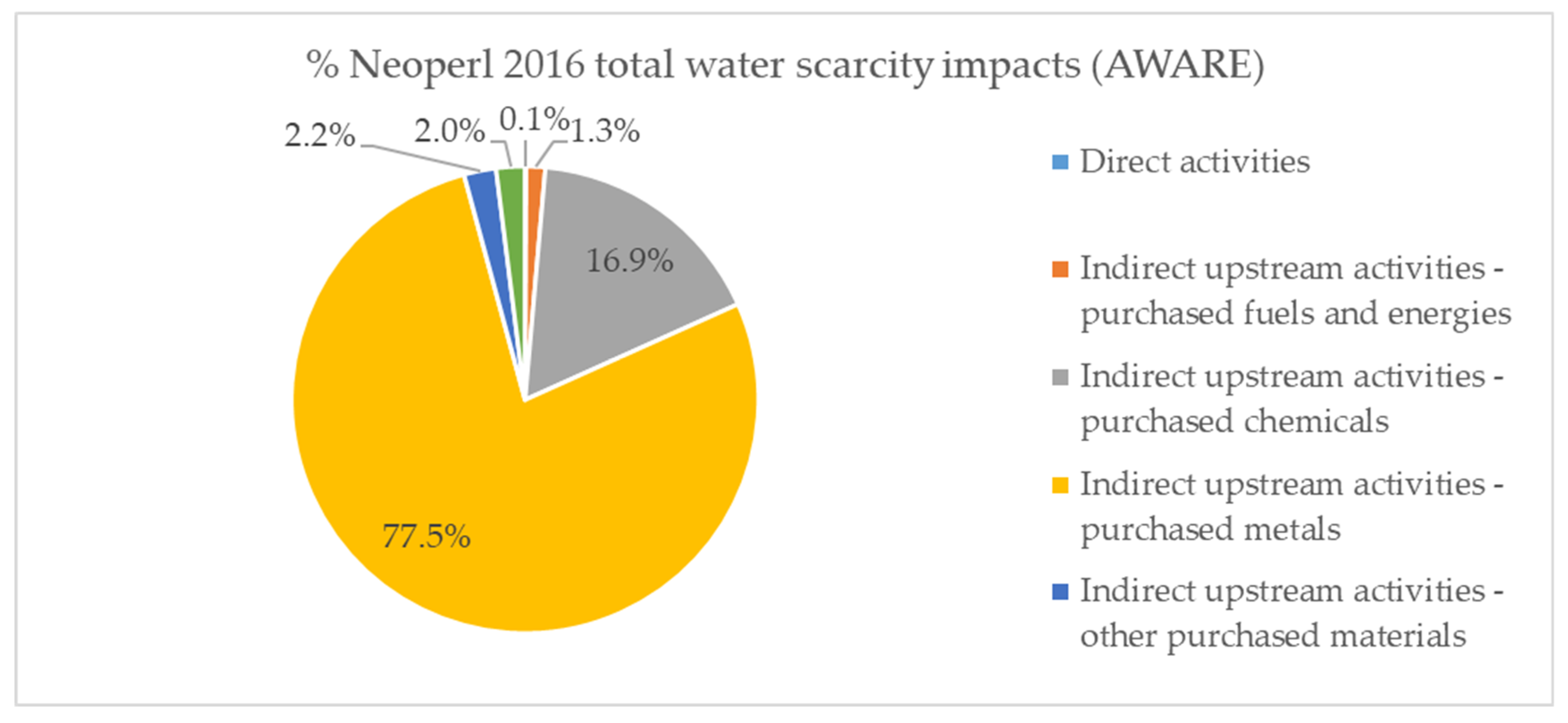

3.3. Life Cycle Impact Assessment

3.4. Life Cycle Interpretation

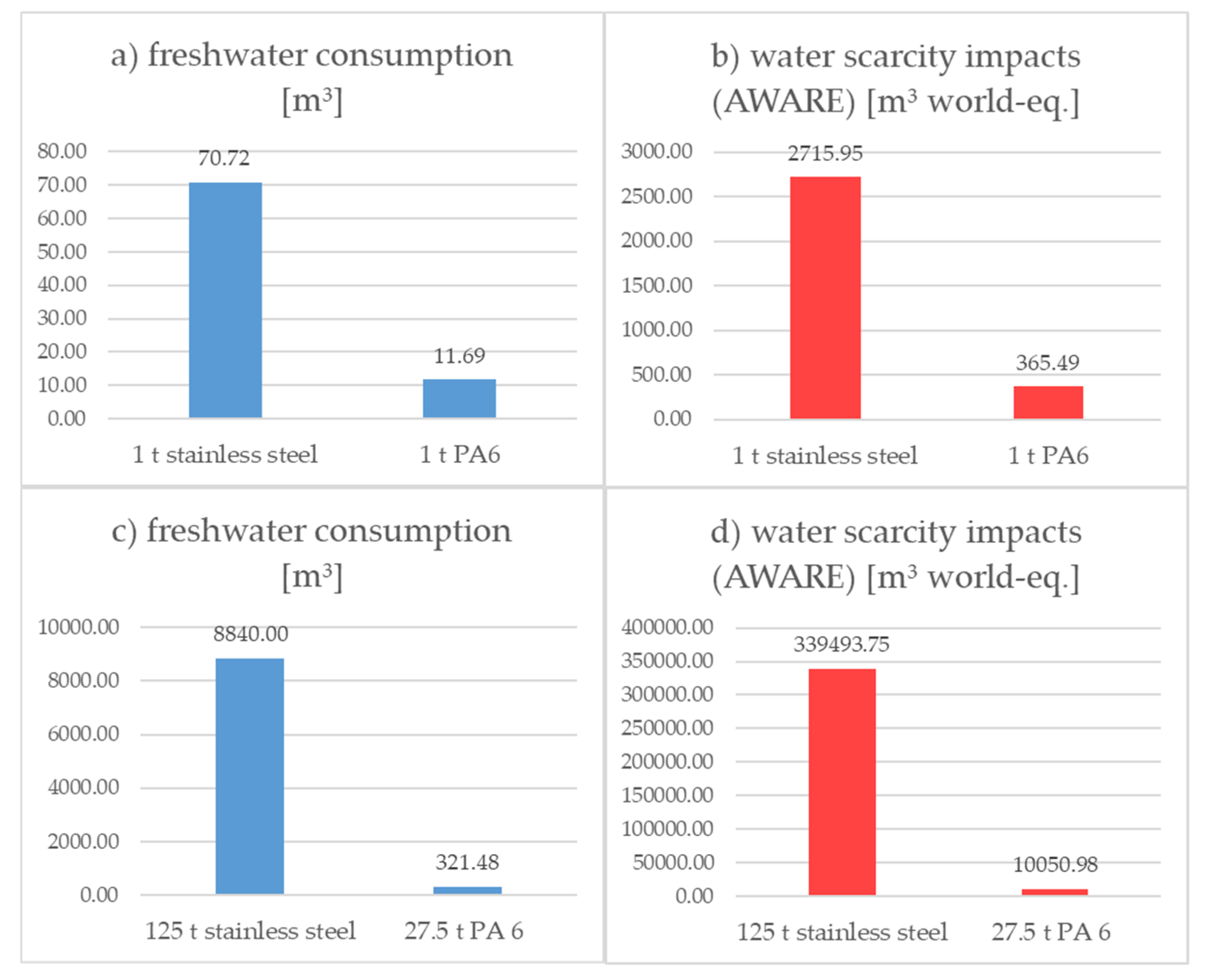

4. Water Scarcity Mitigation Measures

5. Conclusions and Outlook

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Activity Specification | Material | Collected Data | Data Source | Freshwater Consumption and Regionalization Sources/Assumptions |

|---|---|---|---|---|

| Purchased Fuels and Energies | Diesel | Purchased mass [t] | Company’s purchase records | WELLE database for Germany |

| Purchased Fuels and Energies | Natural Gas | Purchased mass [t] | Company’s purchase records | WELLE database for Germany |

| Purchased Fuels and Energy | Electricity | Purchased quantity [MWh] | Electricity bill | WELLE database for Germany; German grid mix |

| Purchased Goods and Materials Chemicals/Plastics | ABS, PVC, PET, PBT LDPE, POM, PA6, PP, NBR, PSU, PEX, EPDM | Purchased mass [t] | Company’s purchase records | WELLE database; Freshwater consumption assumed in the country of provenience according to company’s purchase records (material shares for Taiwan (≤ 1.5%) were allocated to China). |

| Purchased Goods and Materials Metals | Cast Iron; Lead | Purchased mass [t] | Company’s purchase records | WELLE database; Freshwater consumption assumed in the country of provenience according to company’s purchase records |

| Purchased Goods and Materials Metals | Steel alloyed | Purchased mass [t] | Company’s purchase records | WELLE database; Freshwater co2nsumption for the steel production process assumed in the country of provenience according to company’s purchase records, freshwater consumption for iron ore according to WELLE tool mix 1 |

| Purchased Goods and Materials Metals | Stainless steel | Purchased mass [t] | Company’s purchase records | WELLE database; Freshwater consumption for the steel production process assumed in the country of provenience according to company’s purchase records, freshwater consumption for nickel (background process) regionalized as follows: nickel producing countries assumed to use local nickel for steel production, nickel for remaining steel production regionalized according to WELLE tool mix 2 |

| Purchased Goods and Materials Metals | Brass | Purchased mass [t] | Company’s purchase records | WELLE database; Freshwater consumption for the brass production process assumed in the country of provenience according to company’s purchase records, freshwater consumption for copper (background process) regionalized according to the WELLE tool global dataset 3 |

| Purchased Goods and Materials Other purchased materials | Wooden pallets | Purchased mass [t] | Company’s purchase records | WELLE database; Freshwater consumption assumed in the country of provenience according to company’s purchase records |

| Purchased Goods and Materials Other purchased materials | Silicone | Purchased mass [t] | Company’s purchase records | WELLE database; Freshwater consumption assumed in the country of provenience according to company’s purchase records |

| Purchased Goods and Materials Other purchased materials | Cardboard | Purchased mass [t] | Company’s purchase records | WELLE database; Freshwater consumption assumed in the country of provenience according to company’s purchase records |

| Purchased Goods and Materials Other purchased materials | Auxiliary materials, e.g., acids (low tonnage) | Purchased mass [t] | Company’s purchase records | Own estimations; Freshwater consumption assumed in Germany |

| Activity | Specification | Collected Data | Data Source | Freshwater Consumption and Regionalization Sources/Assumptions |

|---|---|---|---|---|

| Supporting Activities Business Travels | Travel by car (diesel purchase) | Purchased quantity [l] | Company’s purchase records | WELLE database for Germany |

| Supporting activities Canteen | Average amount of consumed meals per day | Company canteen for canteen clients | WELLE database for Germany; 230 meals/canteen client; meal including meat assumed | |

| Supporting activities Capital equipment | Buildings | Building area and material composition | Company records | WELLE database for Germany, assumed building lifetime: 50 years |

| Supporting activities Capital equipment | Machinery | Material composition | Company records/BOMs | WELLE database for Germany, assumed machinery lifetime: 25 years |

| Supporting activities Capital equipment | Company cars | Number of vehicles | Company records | WELLE database; assumed vehicle lifetime: 15 years |

| Supporting activities Working environment | Work places | Number of work places | Company records | WELLE database: each workplace assumes 1 table, 1 chair, 1 laptop, 1 display |

Appendix B

| Activity Category | Activity | Freshwater Consumption [m3] | % Total Freshwater Consumption | % Activity Category Freshwater Consumption |

|---|---|---|---|---|

| Direct activities | 2418.78 | 2.2% | 100.0% | |

| Indirect upstream activities; purchased fuels and energies | 13,008.95 | 11.9% | 100.0% | |

| Diesel | 154.30 | 0.1% | 1.2% | |

| Natural Gas | 1.65 | 0.0% | 0.0% | |

| Electricity from grid | 12,853.00 | 11.7% | 98.8% | |

| Indirect upstream activities- purchased chemicals | 24,533.76 | 22.4% | 100.0% | |

| Ethylene propylene diene elastomer (EPDM) | 347.41 | 0.3% | 1.4% | |

| Acrylonitrile Butadiene Styrene Granulate (ABS) | 36.18 | 0.0% | 0.1% | |

| Nitrile butadiene rubber (NBR) | 435.31 | 0.4% | 1.8% | |

| Polyamide 6 Granulate (PA 6) | 1307.40 | 1.2% | 5.3% | |

| Polybutylene Terephthalate Granulate (PBT) | 63.58 | 0.1% | 0.3% | |

| Polyethylene Cross-Linked (PEXa) | 5250.60 | 4.8% | 21.4% | |

| Polyethylene high density granulate (HDPE/PE-HD) | 599.52 | 0.5% | 2.4% | |

| Polyethylene Low Density Granulate (LDPE/PE-LD) | 1207.50 | 1.1% | 4.9% | |

| Polyethylene Terephthalate Fibres (PET) | 1937.00 | 1.8% | 7.9% | |

| Polyoxymethylene Granulate (POM) | 12,178.00 | 11.1% | 49.6% | |

| Polypropylene Granulate (PP) | 543.31 | 0.5% | 2.2% | |

| Polysulfone (PSU) | 367.02 | 0.3% | 1.5% | |

| Polyvinyl Chloride Granulate (S-PVC) | 260.93 | 0.2% | 1.1% | |

| Indirect upstream activities- purchased metals | 60,295.84 | 55.0% | 100.0% | |

| Brass | 12,463.00 | 11.4% | 20.7% | |

| Cast iron part | 3041.60 | 2.8% | 5.0% | |

| Lead | 40.69 | 0.0% | 0.1% | |

| Stainless steel | 44732.00 | 40.8% | 74.2% | |

| Steel alloyed | 18.55 | 0.0% | 0.0% | |

| Indirect upstream activities- other purchased materials | 7192.70 | 6.6% | 100.0% | |

| Cardboard | 2700.20 | 2.5% | 37.5% | |

| Generic product/others | 137.00 | 0.1% | 1.9% | |

| Silicone | 1935.10 | 1.8% | 26.9% | |

| Wooden pallet | 2420.40 | 2.2% | 33.7% | |

| Supporting Activities | 2217.25 | 2.0% | 100.0% | |

| Canteen | 593.71 | 0.5% | 26.8% | |

| Capital Equipment - Building | 283.29 | 0.3% | 12.8% | |

| Capital equipment - Cars | 27.76 | 0.0% | 1.3% | |

| Capital Equipment - Machines | 1170.6 | 1.1% | 52.8% | |

| Working Environment | 141.89 | 0.1% | 6.4% | |

| Total | 109,667.28 | 100% |

| Activity Category | Activity | Water Scarcity Impacts (AWARE) [m3 world-eq.] | % Total Water Scarcity Impacts (AWARE) | % Activity Category Water Scarcity Impacts (AWARE) |

|---|---|---|---|---|

| Direct activities | 2418.78 | 0.1% | 100.0% | |

| Indirect upstream activities; purchased fuels and energies | 41,515.44 | 1.3% | 100.0% | |

| Diesel | 1140.60 | 0.0% | 2.7% | |

| Natural Gas | 7.84 | 0.0% | 0.0% | |

| Electricity from grid | 40,367.00 | 1.3% | 97.2% | |

| Indirect upstream activities; purchased chemicals | 531,475.56 | 16.9% | 100.0% | |

| Ethylene propylene diene elastomer (EPDM) | 12,373.00 | 0.4% | 2.3% | |

| Acrylonitrile Butadiene Styrene Granulate (ABS) | 967.16 | 0.0% | 0.2% | |

| Nitrile butadiene rubber (NBR) | 14,662.00 | 0.5% | 2.8% | |

| Polyamide 6 Granulate (PA 6) | 40,862.00 | 1.3% | 7.7% | |

| Polybutylene Terephthalate Granulate (PBT) | 1613.50 | 0.1% | 0.3% | |

| Polyethylene Cross-Linked (PEXa) | 78,772.00 | 2.5% | 14.8% | |

| Polyethylene high density granulate (HDPE/PE-HD) | 14,822.00 | 0.5% | 2.8% | |

| Polyethylene Low Density Granulate (LDPE/PE-LD) | 32,492.00 | 1.0% | 6.1% | |

| Polyethylene Terephthalate Fibres (PET) | 63,473.00 | 2.0% | 11.9% | |

| Polyoxymethylene Granulate (POM) | 241,570.00 | 7.7% | 45.5% | |

| Polypropylene Granulate (PP) | 13,242.00 | 0.4% | 2.5% | |

| Polysulfone (PSU) | 10,109.00 | 0.3% | 1.9% | |

| Polyvinyl Chloride Granulate (S-PVC) | 6517.90 | 0.2% | 1.2% | |

| Indirect upstream activities; purchased metals | 2,439,615.74 | 77.5% | 100.0% | |

| Brass | 783,400.00 | 24.9% | 32.1% | |

| Cast iron part | 110,700.00 | 3.5% | 4.5% | |

| Lead | 1726.70 | 0.1% | 0.1% | |

| Stainless steel | 1,543,300.00 | 49.0% | 63.3% | |

| Steel alloyed | 489.04 | 0.0% | 0.0% | |

| Indirect upstream activities; other purchased materials | 69,957.45 | 2.2% | 100.0% | |

| Cardboard | 4152.70 | 0.1% | 5.9% | |

| Generic product/others | 186.85 | 0.0% | 0.3% | |

| Silicone | 60,917.00 | 1.9% | 87.1% | |

| Wooden pallet | 4700.90 | 0.1% | 6.7% | |

| Supporting Activities | 62,786.80 | 2.0% | 100.0% | |

| Canteen | 15,902 | 0.5% | 25.3% | |

| Capital Equipment - Building | 4007.4 | 0.1% | 6.4% | |

| Capital equipment - Cars | 426.3 | 0.0% | 0.7% | |

| Capital Equipment - Machines | 38315 | 1.2% | 61.0% | |

| Working Environment | 4136.1 | 0.1% | 6.6% | |

| Total | 3,147,769.77 | 100% |

References

- ISO. ISO 14046: Environmental Management—Water Footprint—Principles, Requirements and Guidelines; International Organization for Standardization: Geneva, Switzerland, 2014. [Google Scholar]

- UN Water. Sustainable Development Goal 6. In Synthesis Report on Water and Sanitation; Uniterd Nations: New York, NY, USA, 2018; Available online: https://sustainabledevelopment.un.org/content/documents/19901SDG6_SR2018_web_3.pdf (accessed on 16 March 2020).

- Willis, R.M.; Stewart, R.A.; Giurco, D.P.; Talebpour, M.R.; Mousavinejad, A. End use water consumption in households: Impact of socio-demographic factors and efficient devices. J. Clean. Prod. 2013, 60, 107–115. [Google Scholar] [CrossRef] [Green Version]

- Schuetze, T.; Santiago-Fandiño, V. Quantitative Assessment of Water Use Efficiency in Urban and Domestic Buildings. Water 2013, 5, 1172–1193. [Google Scholar] [CrossRef] [Green Version]

- Berger, M.; Söchtig, M.; Weis, C.; Finkbeiner, M. Amount of water needed to save 1 m3 of water: Life cycle assessment of a flow regulator. Appl. Water Sci. 2017, 7, 1399–1407. [Google Scholar] [CrossRef] [Green Version]

- Forin, S.; Berger, M.; Finkbeiner, M.; Tikana, L.; Ockenfeld, K.; Bischer, L.-M.; Binder, M.; Wojciechowski, A.; Kirchner, M.; Gossmann, J.; et al. WELLE: Organizational water footprint—Local measures in global value chains. In Proceedings of the GRoW Midterm Conference—Global Analyses and Local Solutions for Sustainable Water Resources Management, Frankfurt am Main, Germany, 20–21 February 2019; GRoWnet Networking and Transfer Project, Ed.; Welle: Boon, Germany, 2019; pp. 36–39. ISBN 978-3-942664-00-4. [Google Scholar]

- Forin, S.; Mikosch, N.; Berger, M.; Finkbeiner, M. Organizational water footprint: A methodological guidance. Int. J. Life Cycle Assess 2019, 46, 4091. [Google Scholar] [CrossRef] [Green Version]

- WELLE Project. WELLE Database. 2019. Available online: http://welle.see.tu-berlin.de/data/ (accessed on 16 March 2020).

- WELLE project. The project. Available online: http://welle.see.tu-berlin.de (accessed on 16 March 2020).

- Forin, S.; Berger, M.; Finkbeiner, M. Measuring Water-Related Environmental Impacts of Organizations: Existing Methods and Research Gaps. Adv. Sustain. Syst. 2018, 2, 1700157. [Google Scholar] [CrossRef]

- ISO. ISO/TS 14072: Environmental Management—Life Cycle Assessment—Requirements and Guidelines for Organizational Life Cycle Assessmen; International Organization for Standardization: Geneva, Switzerland, 2014. [Google Scholar]

- Thinkstep. GaBi LCA Database Documentation. Available online: http://www.gabi-software.com/international/support/gabi/ (accessed on 16 March 2020).

- Thinkstep. WELLE Organizational Water Footprint Tool Database documentation. Version 1.3 February 2020. 2020. Available online: http://welle.see.tu-berlin.de/data/ (accessed on 16 March 2020).

- Thinkstep. GaBi Envision—Automation. Available online: http://www.gabi-software.com/international/software/gabi-envision/automation/ (accessed on 16 March 2020).

- Boulay, A.-M.; Bare, J.; Benini, L.; Berger, M.; Lathuillière, M.J.; Manzardo, A.; Margni, M.; Motoshita, M.; Núñez, M.; Pastor, A.V.; et al. The WULCA consensus characterization model for water scarcity footprints: Assessing impacts of water consumption based on available water remaining (AWARE). Int. J. Life Cycle Assess 2018, 23, 368–378. [Google Scholar] [CrossRef] [Green Version]

- Boulay, A.-M.; Bare, J.; de Camillis, C.; Döll, P.; Gassert, F.; Gerten, D.; Humbert, S.; Inaba, A.; Itsubo, N.; Lemoine, Y.; et al. Consensus building on the development of a stress-based indicator for LCA-based impact assessment of water consumption: Outcome of the expert workshops. Int. J. Life Cycle Assess 2015, 20, 577–583. [Google Scholar] [CrossRef]

- WULCA. AWARE: Download AWaRe Factors. Available online: http://www.wulca-waterlca.org/aware.html (accessed on 16 March 2020).

- ISO. ISO 14001: Environmental Management Systems – Requirements with Guidance for Use; International Organization for Standardizaton: Geneva, Switzerland, 2015. [Google Scholar]

- Amending the User’s Guide Setting Out the Steps Needed to Participate in EMAS, Under REGULATION (EC) No 1221/2009 of the European Parliament and of the Council on the Voluntary Participation by Organisations in a Community Eco-Management and Audit Scheme (EMAS). Off. J. Eur. Union 2017, 38–86, C/2017/8072.

- Alliance for Water Stewardship. International Water Stewardship Standard Version 2.0. 2019. Available online: https://a4ws.org/the-aws-standard-2-0/download-the-aws-standard-2-0/ (accessed on 16 March 2020).

- ISO. ISO 14006: Environmental Management Systems—Guidelines for Incorporating Ecodesign; International Organization for Standardization: Geneva, Switzerland, 2011. [Google Scholar]

- Cosme, N.; Hauschild, M.Z.; Molin, C.; Rosenbaum, R.K.; Laurent, A. Learning-by-doing: Experience from 20 years of teaching LCA to future engineers. Int. J. Life Cycle Assess 2019, 24, 553–565. [Google Scholar] [CrossRef] [Green Version]

- Marconi, M.; Favi, C. Eco-design teaching initiative within a manufacturing company based on LCA analysis of company product portfolio. J. Clean. Prod. 2020, 242, 118424. [Google Scholar] [CrossRef]

- Berger, M.; Pfister, S.; Bach, V.; Finkbeiner, M. Saving the Planet’s Climate or Water Resources? The Trade-Off between Carbon and Water Footprints of European Biofuels. Sustainability 2015, 7, 6665–6683. [Google Scholar] [CrossRef] [Green Version]

- Seuring, S.; Müller, M. From a literature review to a conceptual framework for sustainable supply chain management. J. Clean. Prod. 2008, 16, 1699–1710. [Google Scholar] [CrossRef]

- Step-by-Step Guide to Sustainable Supply Chain Management—A Practical Guide for Companies; BMUB, Division G I 5, Annette Schmidt-Räntsch; UBA, Section I 1.4; Töpfer, C.; Huckestein, B. (Eds.) Federal Ministry for the Environment, Nature Conservation, Building and Nuclear Safety (BMUB): Berlin, Germany, 2017. [Google Scholar]

- Seuring, S. A review of modeling approaches for sustainable supply chain management. Decis. Support Syst. 2013, 54, 1513–1520. [Google Scholar] [CrossRef]

- Cholette, S.; Venkat, K. The energy and carbon intensity of wine distribution: A study of logistical options for delivering wine to consumers. J. Clean. Prod. 2009, 17, 1401–1413. [Google Scholar] [CrossRef]

- Halldórsson, Á.; Edwards, J.B.; McKinnon, A.C.; Cullinane, S.L. Comparative analysis of the carbon footprints of conventional and online retailing. Int. Jnl. Phys. Dist. Log. Manag. 2010, 40, 103–123. [Google Scholar] [CrossRef]

- Ferretti, I.; Zanoni, S.; Zavanella, L.; Diana, A. Greening the aluminium supply chain. Int. J. Prod. Econ. 2007, 108, 236–245. [Google Scholar] [CrossRef]

- Sonesson, U.; Berlin, J. Environmental impact of future milk supply chains in Sweden: A scenario study. J. Clean. Prod. 2003, 11, 253–266. [Google Scholar] [CrossRef]

- Guidelines for Social Life Cycle Assessment of Products; Benoît, C.; Mazijn, B. (Eds.) UNEP: Paris, France, 2009; ISBN 978-92-807-3021-0. [Google Scholar]

- UNEP. Guidance on Organizational Life Cycle Assessment; UNEP: Paris, France, 2015; ISBN 978-92-807-3453-9. [Google Scholar]

- Flörke, M.; Kynast, E.; Bärlund, I.; Eisner, S.; Wimmer, F.; Alcamo, J. Domestic and industrial water uses of the past 60 years as a mirror of socio-economic development: A global simulation study. Glob. Environ. Chang. 2013, 23, 144–156. [Google Scholar] [CrossRef]

- Young, S.B. Responsible sourcing of metals: Certification approaches for conflict minerals and conflict-free metals. Int. J. Life Cycle Assess 2018, 23, 1429–1447. [Google Scholar] [CrossRef]

- WELLE project. Organizational Water Footprint Tool—Manual. Available online: http://wf-tools.see.tu-berlin.de/wf-tools/owf/#/manual (accessed on 16 March 2020).

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Forin, S.; Gossmann, J.; Weis, C.; Thylmann, D.; Bunsen, J.; Berger, M.; Finkbeiner, M. Organizational Water Footprint to Support Decision Making: a Case Study for a German Technological Solutions Provider for the Plumbing Industry. Water 2020, 12, 847. https://doi.org/10.3390/w12030847

Forin S, Gossmann J, Weis C, Thylmann D, Bunsen J, Berger M, Finkbeiner M. Organizational Water Footprint to Support Decision Making: a Case Study for a German Technological Solutions Provider for the Plumbing Industry. Water. 2020; 12(3):847. https://doi.org/10.3390/w12030847

Chicago/Turabian StyleForin, Silvia, Jutta Gossmann, Christoph Weis, Daniel Thylmann, Jonas Bunsen, Markus Berger, and Matthias Finkbeiner. 2020. "Organizational Water Footprint to Support Decision Making: a Case Study for a German Technological Solutions Provider for the Plumbing Industry" Water 12, no. 3: 847. https://doi.org/10.3390/w12030847

APA StyleForin, S., Gossmann, J., Weis, C., Thylmann, D., Bunsen, J., Berger, M., & Finkbeiner, M. (2020). Organizational Water Footprint to Support Decision Making: a Case Study for a German Technological Solutions Provider for the Plumbing Industry. Water, 12(3), 847. https://doi.org/10.3390/w12030847