Effect of Soaking Time and Salt Concentration on Mechanical Characteristics of Slip Zone Soil of Loess Landslides

Abstract

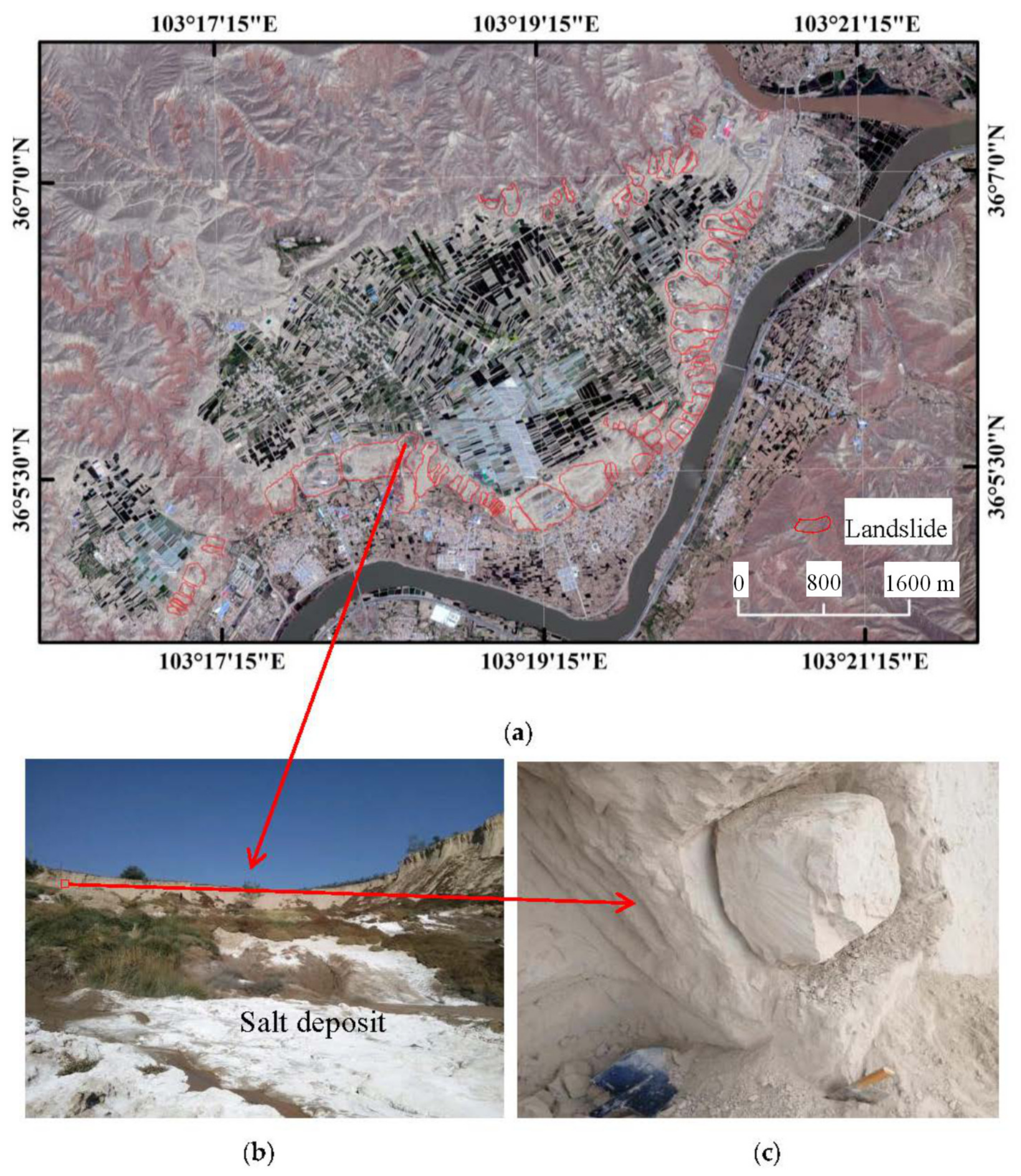

:1. Introduction

2. Materials and Methods

2.1. Test Samples

2.2. Sample Preparation with Different Soaking Time

2.3. Sample Preparation with Different Salt Concentration

2.4. Sample Preparation with Different Soaking Time

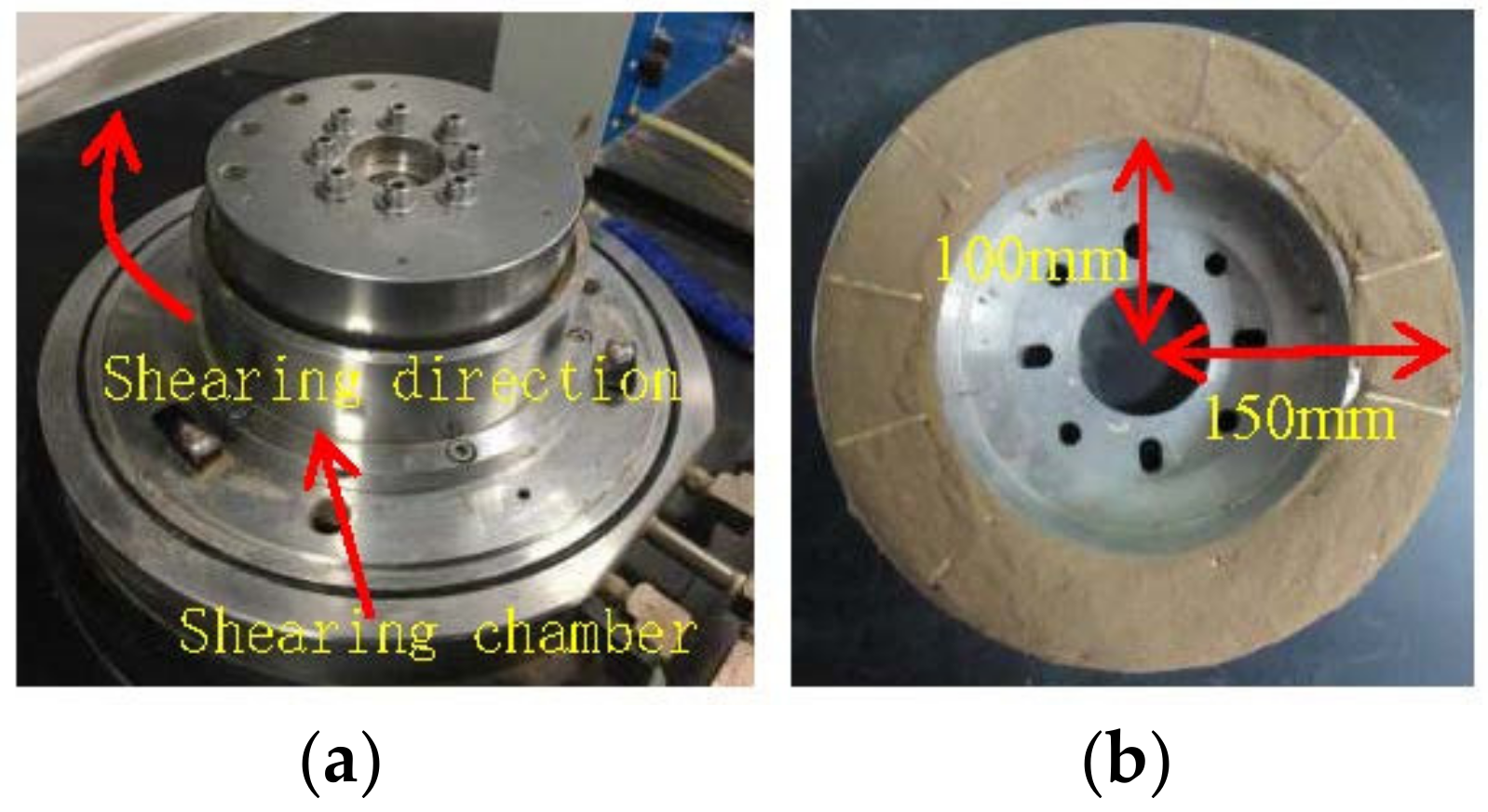

2.5. Testing Program and Procedure

3. Testing Results

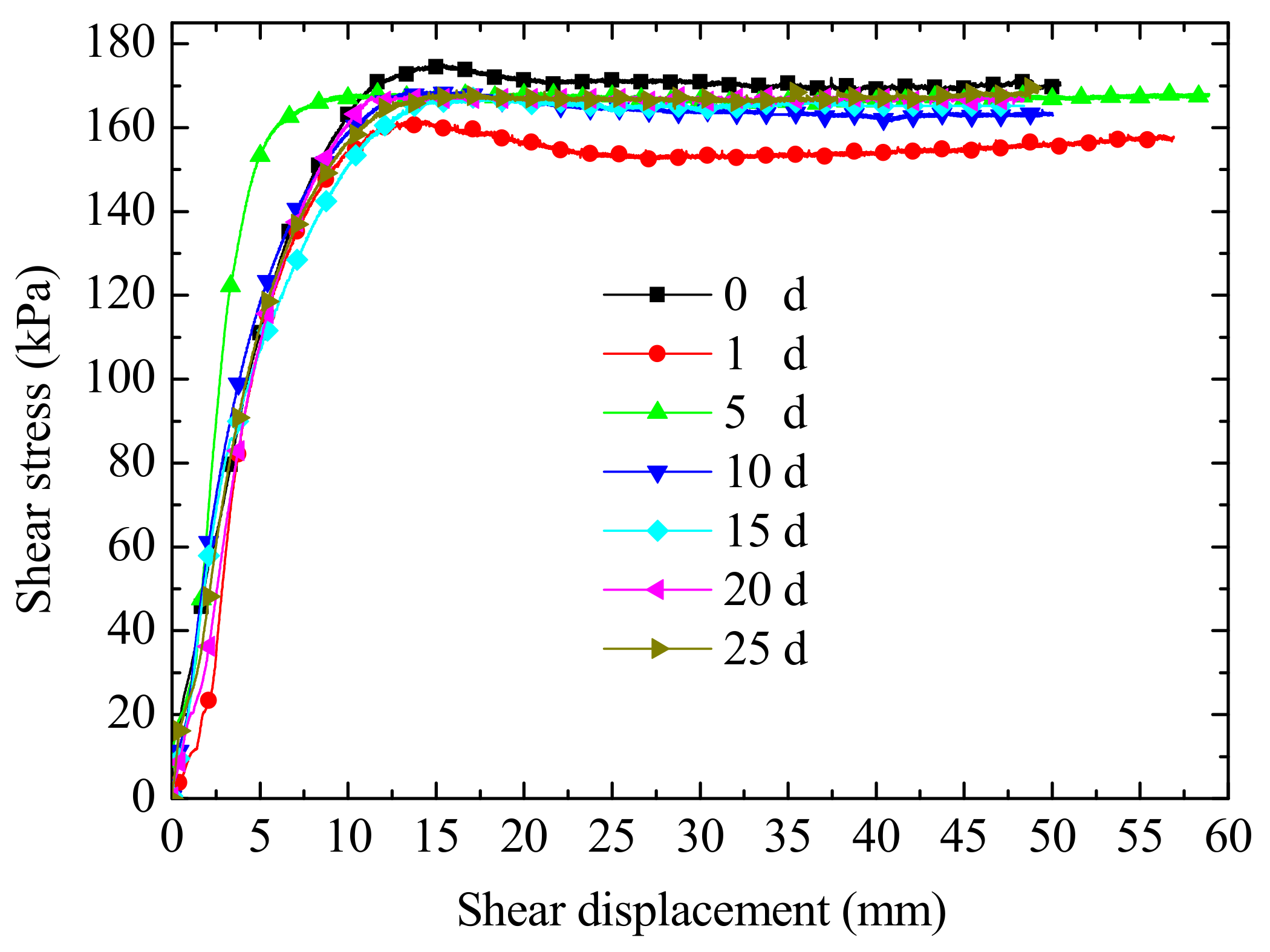

3.1. Effect of Soaking Time

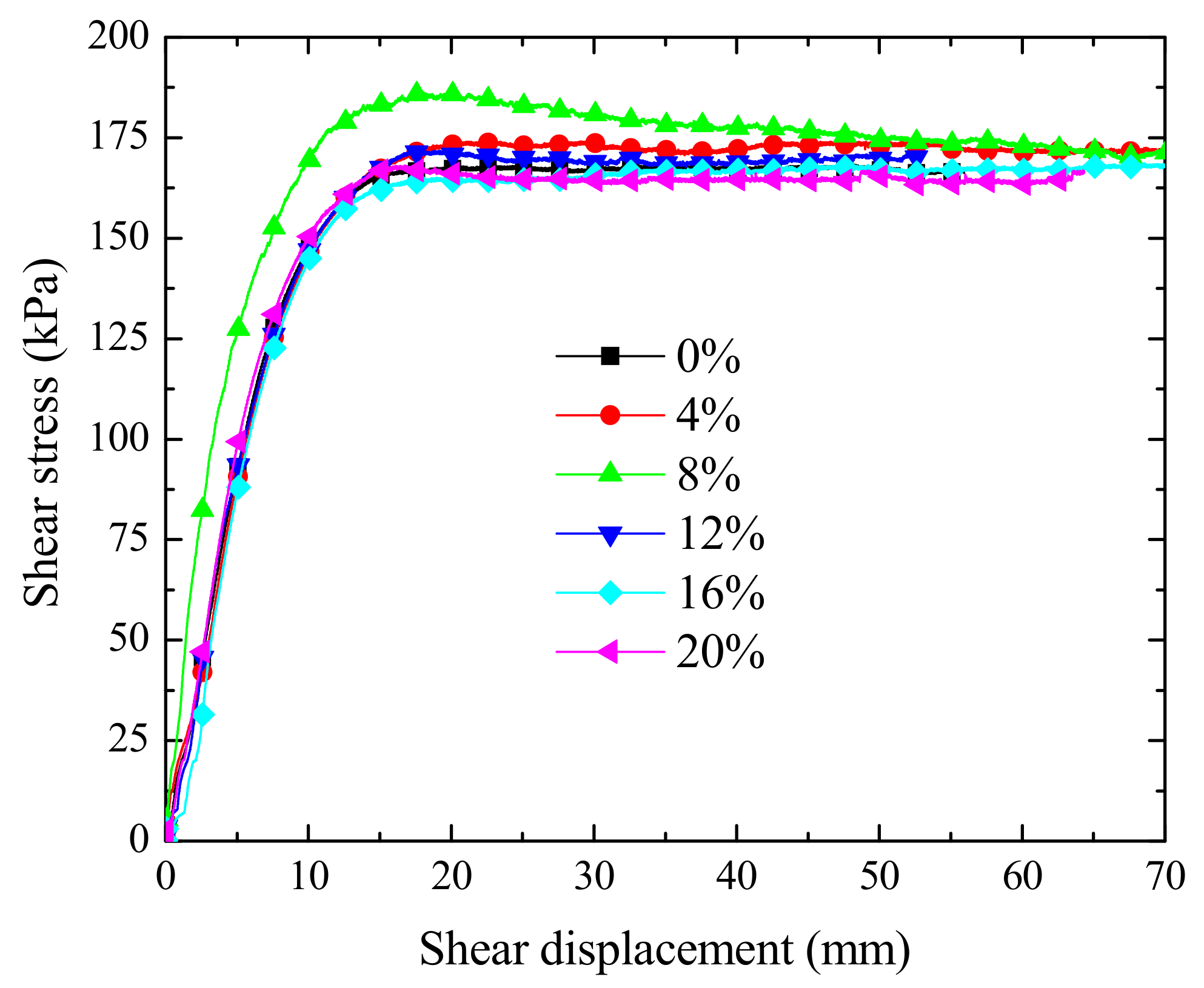

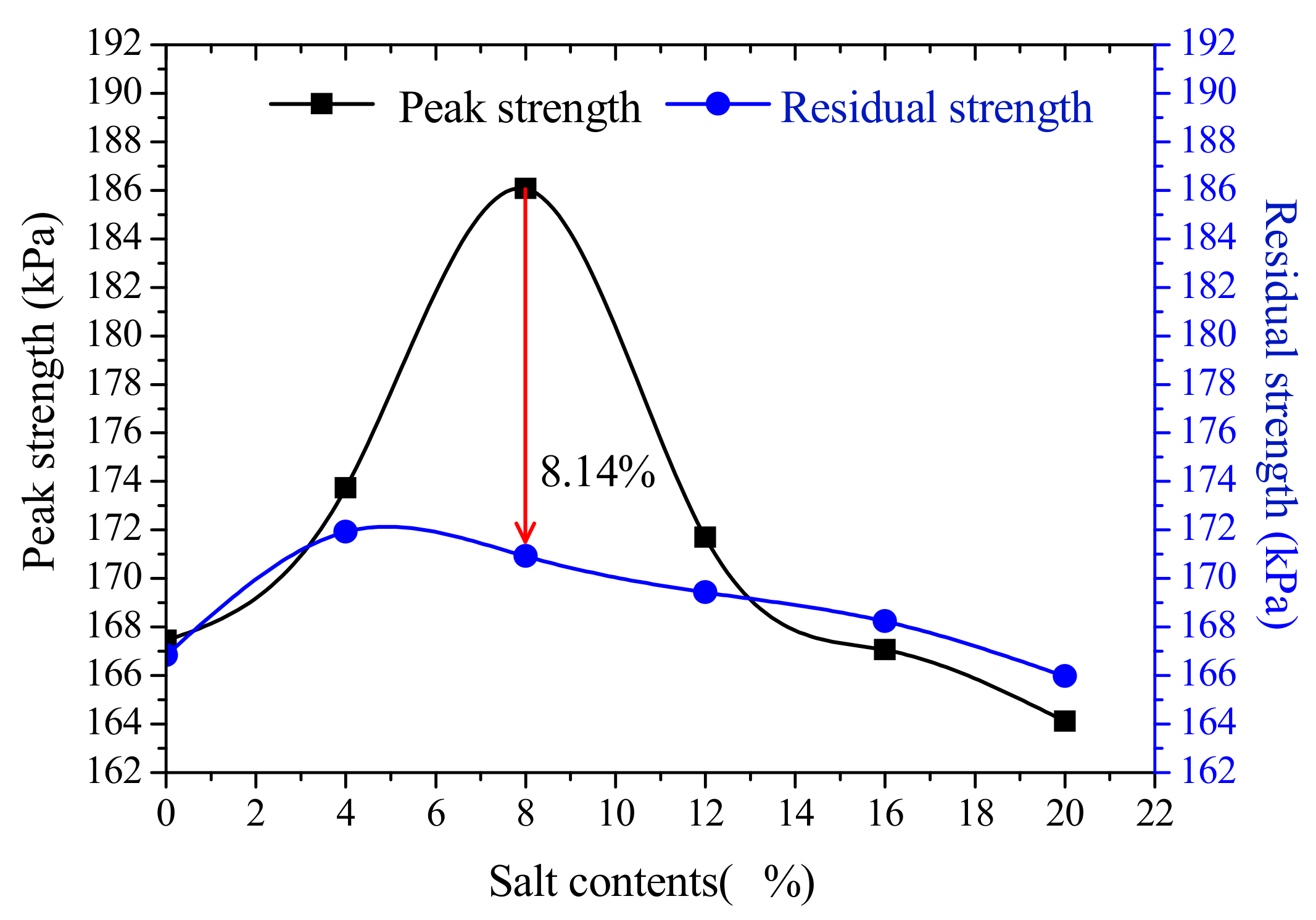

3.2. Effect of NaCl Concentration

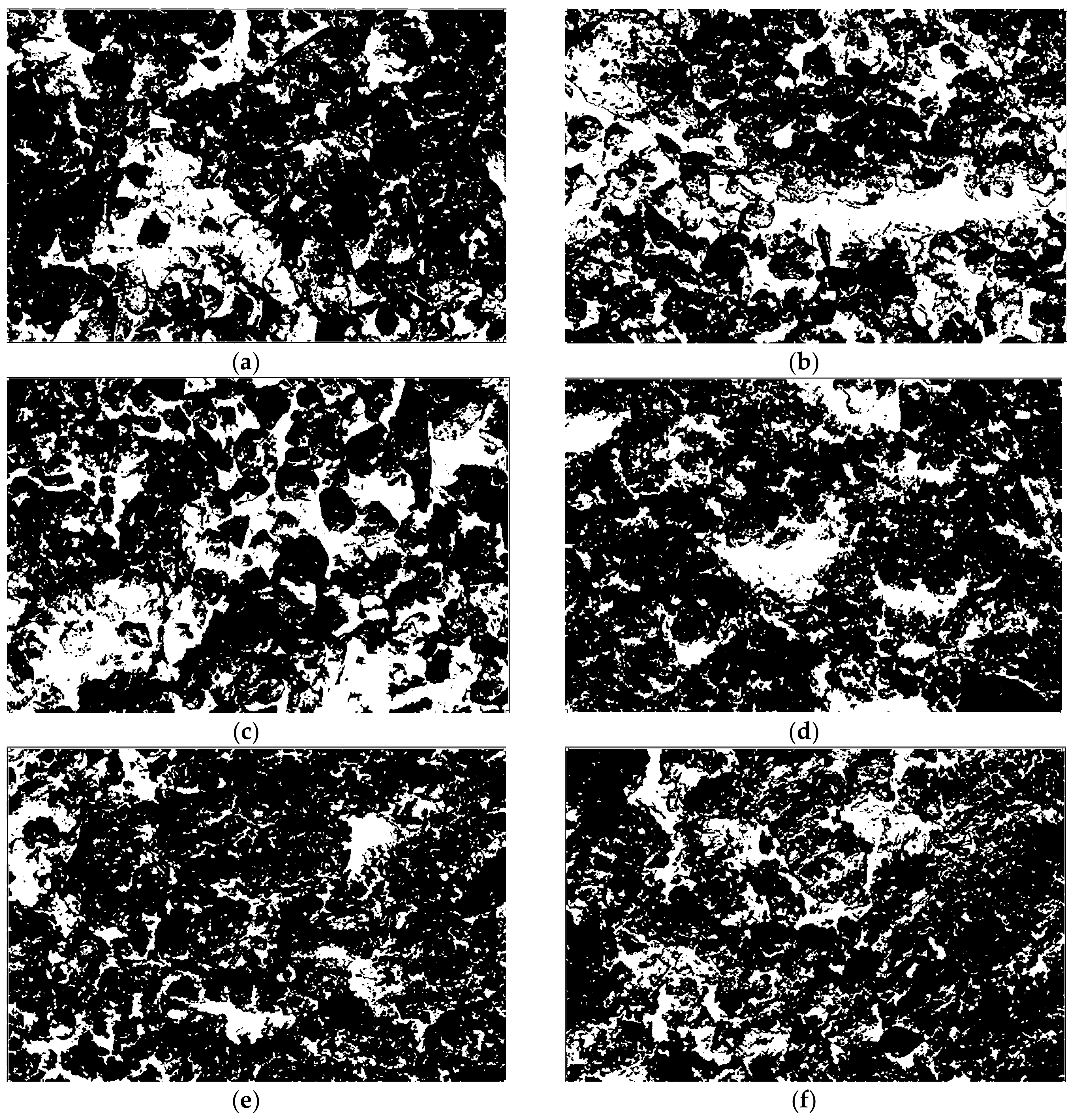

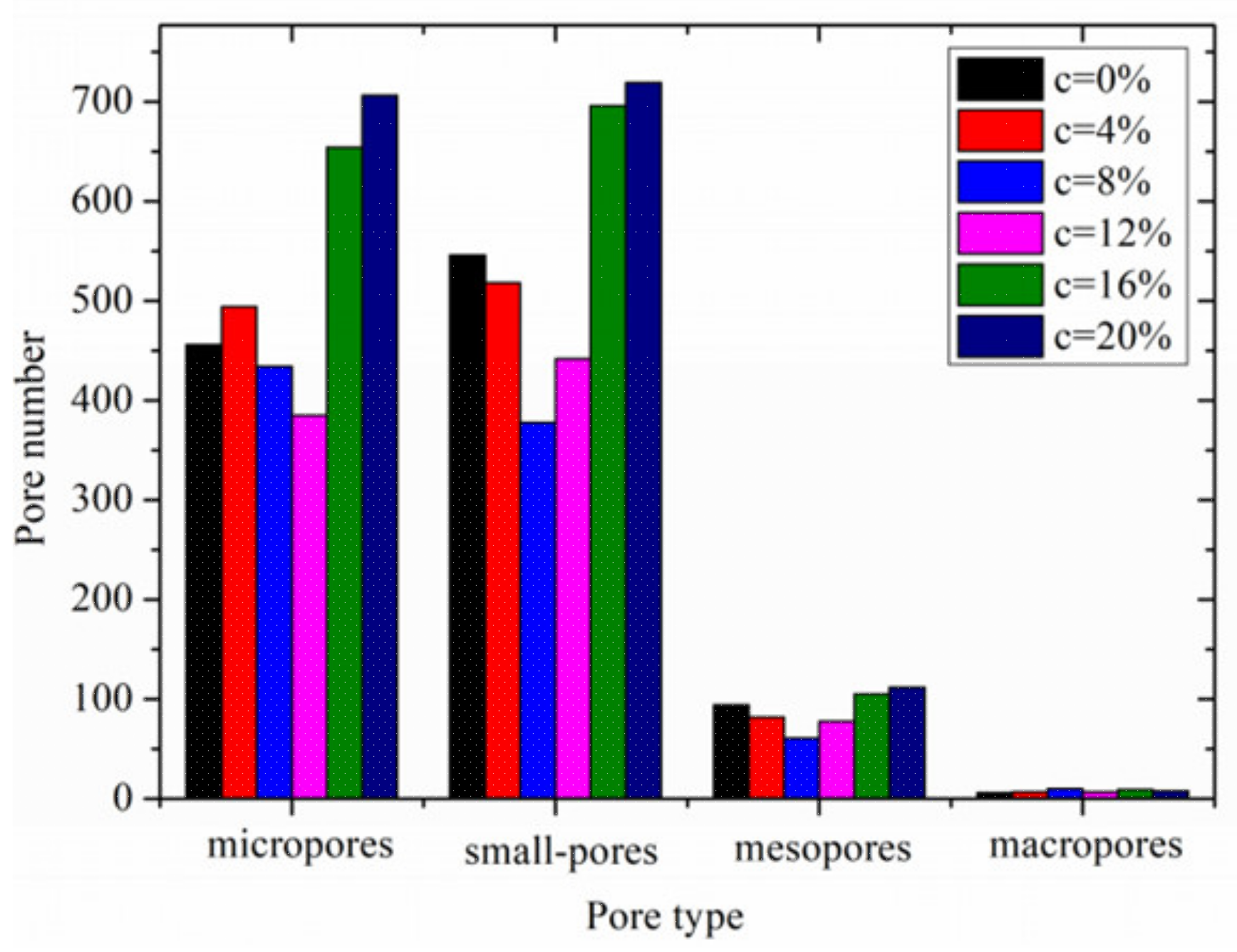

4. Changes of Surface Morphology and Microstructure of Loess Soils with Different Salt Contents

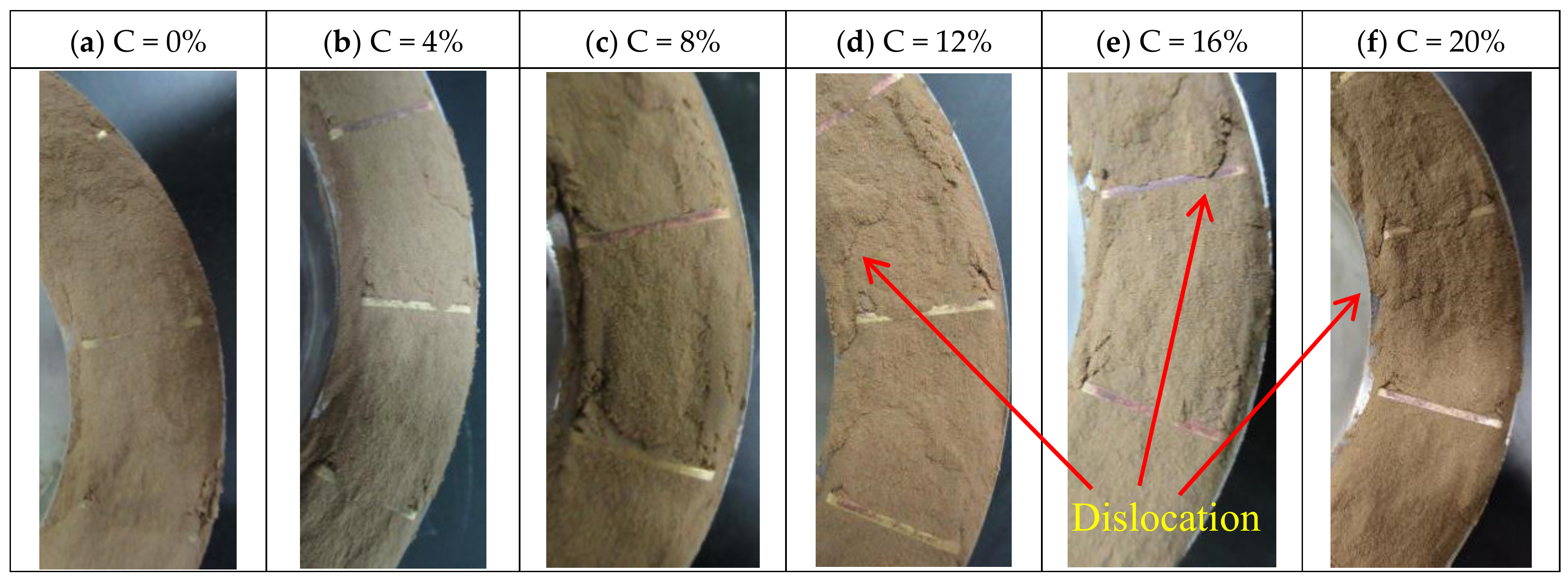

4.1. Changes of Surface Morphology

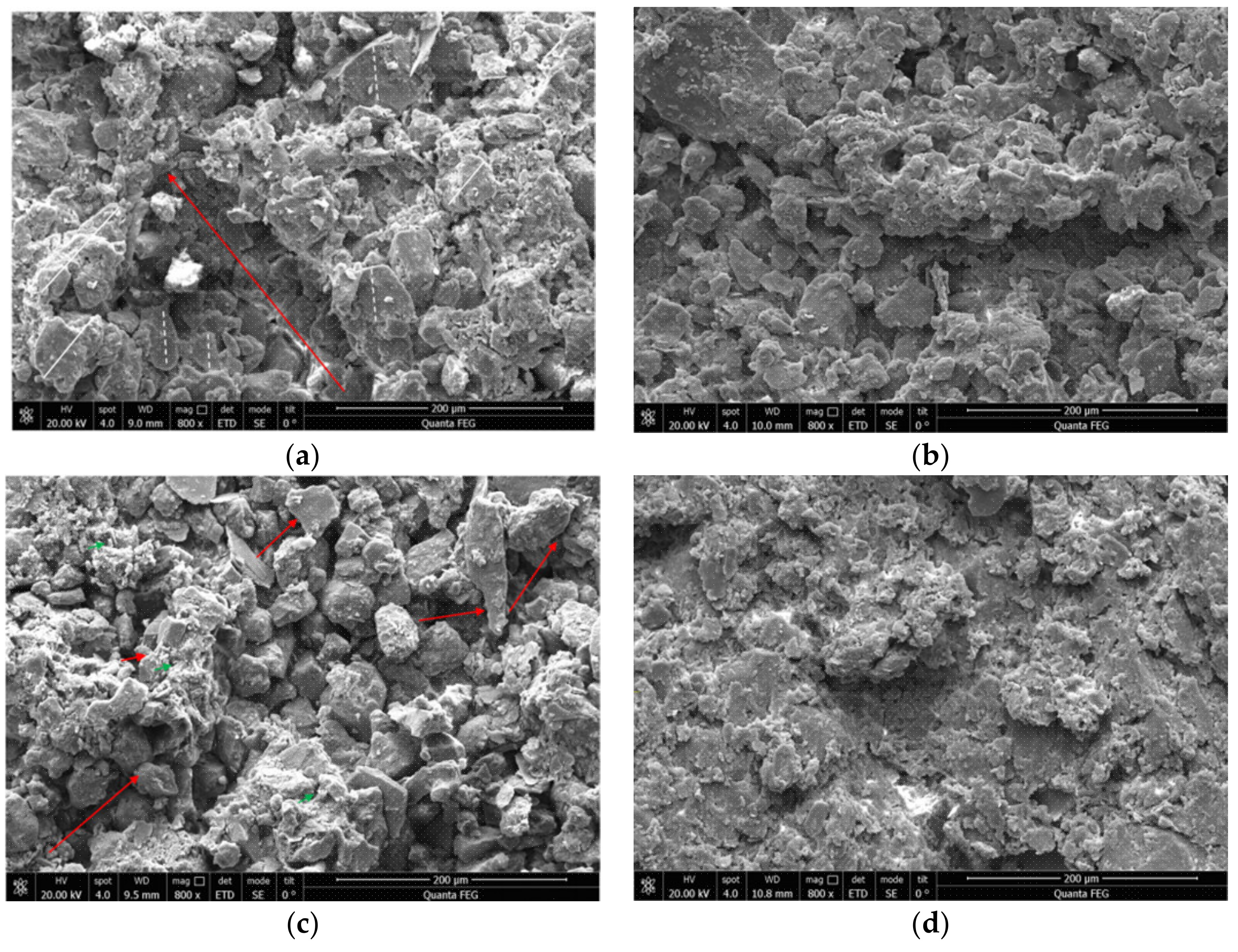

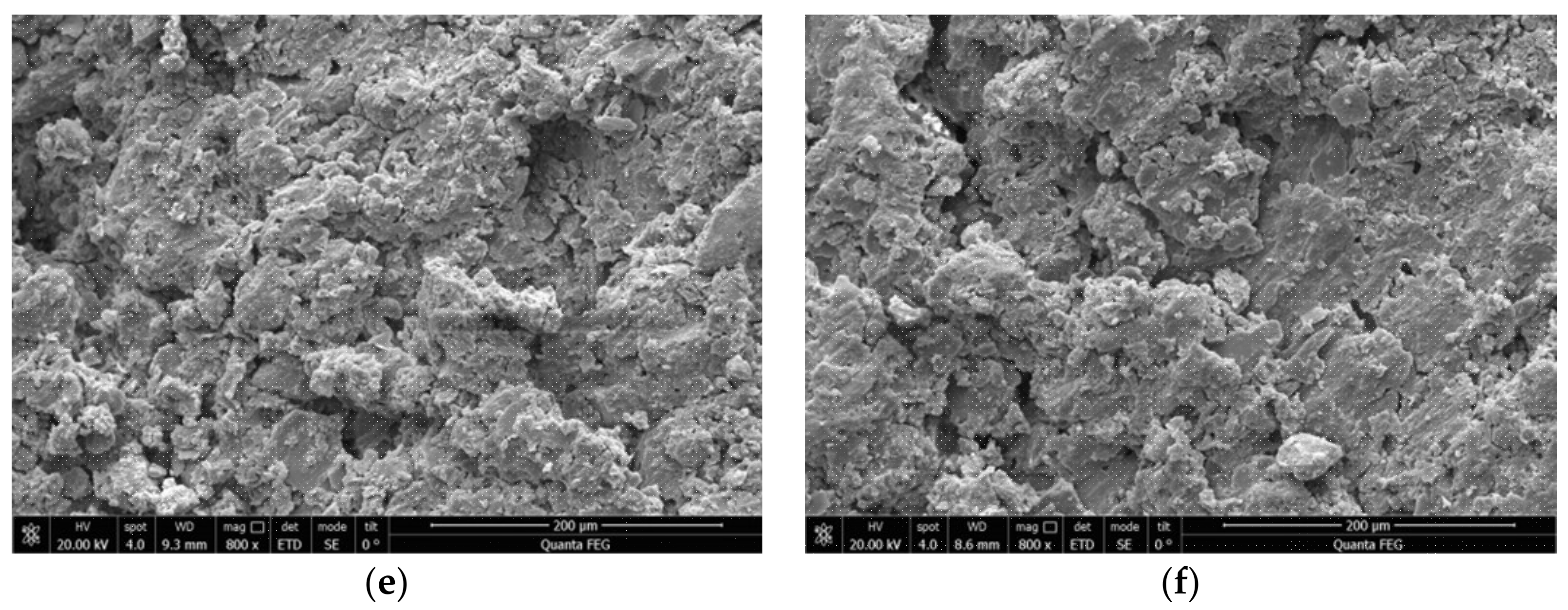

4.2. Changes of Microstructure of Loess Soils

5. Discussion

5.1. The Peak Shear Strength and Residual Strength

5.2. Implications for Loess Landslides

6. Conclusions

- (1)

- The shear behavior of loess soils is closely related to the soaking time, and the peak strength and residual strength decreases as the soaking time increases only up to a certain value. When this level is exceeded, any further increase of soaking time results in higher shear strengths.

- (2)

- The peak strength and residual strength increased with increasing salt concentration before reaching a maximum value at the salt concentration of 8%. Above this concentration, the peak strength and residual strength decrease with further increase in the salt concentration, and both strengths decreases to a relatively small value after about salt concentration of 16%.

- (3)

- The maximum difference between the peak strength and residual strength was attained with the salt concentration of 8% and soaking time of 1 d, which may be attributed to the variation in the solution salt and pore structure between the soil particles.

Author Contributions

Funding

Conflicts of Interest

References

- Derbyshire, E.; Dijkstra, T.A.; Smalley, I.J. Failure mechanisms in loess and the effects of moisture content changes on remoulded strength. Quat. Int. 1994, 24, 5–15. [Google Scholar] [CrossRef]

- Dijkstra, T.A.; Rogers, C.D.F.; Smalley, I.J.; Derbyshire, E.; Yong, J.L.; Xing, M.M. The loess of north-central China: Geotechnical properties and their relation to slope stability. Eng. Geol. 1994, 36, 153–171. [Google Scholar] [CrossRef]

- Muhs, D.R. The geochemistry of loess: Asian and North American deposits compared. J. Asian Earth Sci. 2018, 155, 81–115. [Google Scholar] [CrossRef] [Green Version]

- Lian, B.; Peng, J.; Zhan, H.; Huang, Q.; Wang, X.; Hu, S. Formation mechanism analysis of irrigation-induced retrogressive loess landslides. Catena 2020, 195, 104441. [Google Scholar] [CrossRef]

- Wang, X.; Wang, J.; Zhan, H.; Li, P.; Hu, S. Moisture content effect on the creep behavior of loess for the catastrophic Baqiao landslide. Catena 2019, 187, 104371. [Google Scholar] [CrossRef]

- Leng, Y.; Peng, J.; Wang, Q.; Meng, Z.; Huang, W. A fluidized landslide occurred in the Loess Plateau: A study on loess landslide in South Jingyang tableland. Eng. Geol. 2018, 236, 129–136. [Google Scholar] [CrossRef]

- Xu, L.; Coop, M.R.; Zhang, M.; Wang, G. The mechanics of a saturated silty loess and implications for landslides. Eng. Geol. 2018, 236, 29–42. [Google Scholar] [CrossRef]

- Zhang, D.; Wang, G.; Luo, C.; Chen, J.; Zhou, Y. A rapid loess flowslide triggered by irrigation in China. Landslides 2009, 6, 55–60. [Google Scholar] [CrossRef]

- Kimura, S.; Nakamura, S.; Vithana, S.B.; Sakai, K. Shearing rate effect on residual strength of landslide soils in the slow rate range. Landslides 2014, 11, 969–979. [Google Scholar] [CrossRef]

- Lian, B.; Peng, J.; Wang, X.; Huang, Q. Moisture content effect on the ring shear characteristics of slip zone loess at high shearing rates. Bull. Eng. Geol. Environ. 2020, 79, 999–1008. [Google Scholar] [CrossRef]

- Sassa, K.; Fukuoka, H.; Wang, G.; Ishikawa, N. Undrained dynamic-loading ring-shear apparatus and its application to landslide dynamics. Landslides 2004, 1, 7–19. [Google Scholar] [CrossRef]

- Conte, E.; Pugliese, L.; Troncone, A. Post-failure stage simulation of a landslide using the material point method. Eng. Geol. 2019, 253, 149–159. [Google Scholar] [CrossRef]

- Conte, E.; Pugliese, L.; Troncone, A. Post-failure analysis of the Maierato landslide using the material point method-ScienceDirect. Eng. Geol. 2020, 277, 105788. [Google Scholar] [CrossRef]

- Wen, B.P.; He, L. Influence of lixiviation by irrigation water on residual shear strength of weathered red mudstone in Northwest China: Implication for its role in landslides’ reactivation. Eng. Geol. 2012, 151, 56–63. [Google Scholar] [CrossRef]

- Xu, L.; Dai, F.; Gong, Q.; Tham, L.; Min, H. Irrigation-induced loess flow failure in Heifangtai Platform, north-west China. Environ. Earth Sci. 2012, 66, 1707–1713. [Google Scholar] [CrossRef]

- Wu, L.; Zhou, Y.; Sun, P.; Shi, J.; Liu, G.; Bai, L. Laboratory characterization of rainfall-induced loess slope failure. Catena 2017, 150, 1–8. [Google Scholar] [CrossRef]

- Fan, X.; Xu, Q.; Scaringi, G.; Li, S.; Peng, D. A chemo-mechanical insight into the failure mechanism of frequently occurred landslides in the Loess Plateau, Gansu Province, China. Eng. Geol. 2017, 228, 337–345. [Google Scholar] [CrossRef]

- Fu, J.-T.; Hu, X.-S.; Li, X.-L.; Yu, D.-M.; Liu, Y.-B.; Yang, Y.-Q.; Zhao-xin, Q.; Li, S.-X. Influences of soil moisture and salt content on loess shear strength in the Xining Basin, northeastern Qinghai-Tibet Plateau. J. Mt. Sci. 2019, 16, 1184–1197. [Google Scholar] [CrossRef]

- Zhang, F.; Wang, G.; Kamai, T.; Chen, W.; Zhang, D.; Yang, J. Undrained shear behavior of loess saturated with different concentrations of sodium chloride solution. Eng. Geol. 2013, 155, 69–79. [Google Scholar] [CrossRef] [Green Version]

- Di Maio, C.; Scaringi, G. Shear displacements induced by decrease in pore solution concentration on a pre-existing slip surface. Eng. Geol. 2016, 200, 1–9. [Google Scholar] [CrossRef]

- Xu, J.; Li, Y.; Ren, C.; Lan, W. Damage of saline intact loess after dry-wet and its interpretation based on SEM and NMR. Soils Found. Tokyo 2020, 60, 911–928. [Google Scholar] [CrossRef]

- Xu, P.; Zhang, Q.; Qian, H. Effect of Sodium Chloride Concentration on Saturated Permeability of Remolded Loess. Minerals 2020, 10, 199. [Google Scholar] [CrossRef] [Green Version]

- Wen, B.P.; Yan, Y.J. Influence of structure on shear characteristics of the unsaturated loess in Lanzhou, China. Eng. Geol. 2014, 168, 46–58. [Google Scholar] [CrossRef]

- Zhang, F.; Wang, G. Effect of irrigation-induced densification on the post-failure behavior of loess flowslides occurring on the Heifangtai area, Gansu, China. Eng. Geol. 2018, 236, 111–118. [Google Scholar] [CrossRef]

- Bing, H.; Zhang, Y.; Ma, M. Impact of Desalination on Physical and Mechanical Properties of Lanzhou Loess. Eurasian Soil Sci. 2017, 50, 1444–1449. [Google Scholar] [CrossRef]

- Qi, X.; Xu, Q.; Li, B.; Peng, D.; Zhou, F. Preliminary study on mechanism of surface water infiltration at tHeifangtai loess landslides in Gansu. J. Eng. Geol. 2016, 24, 419–424. (In Chinese) [Google Scholar]

- Zeng, R.; Meng, X.; Zhang, F.; Wang, S.; Cui, Z.; Zhang, M.; Zhang, Y.; Chen, G. Characterizing hydrological processes on loess slopes using electrical resistivity tomography—A case study of the Heifangtai Terrace, Northwest China. J. Hydrol. 2016, 541, 742–753. [Google Scholar] [CrossRef]

- Qi, X.; Xu, Q.; Liu, F. Analysis of retrogressive loess flowslides in Heifangtai, China. Eng. Geol. 2018, 236, 119–128. [Google Scholar] [CrossRef]

- Li, S. Experimental Study of Influence on Strength of Loess Soaked in Water for Long-Term in Heifangtai, Gansu Province; Chengdu University of Technology: Chengdu, China, 2016. (In Chinese) [Google Scholar]

- Sassa, K.; Wang, G.; Fukuoka, H. Performing undrained shear tests on saturated sands in a new intelligent type of ring shear apparatus. Geotech. Test. J. 2003, 26, 257–265. [Google Scholar]

- Tiwari, B.; Marui, H. Objective oriented multistage ring shear test for shear strength of landslide soil. J. Geotech. Geoenvironmental Eng. 2004, 130, 217–222. [Google Scholar] [CrossRef]

- Li, H.-D.; Tang, C.-S.; Cheng, Q.; Li, S.-J.; Gong, X.-P.; Shi, B. Tensile strength of clayey soil and the strain analysis based on image processing techniques. Eng. Geol. 2019, 253, 137–148. [Google Scholar] [CrossRef]

- Moore, C.; Donaldson, C. Quantifying soil microstructure using fractals. Geotechnique 1995, 45, 105–116. [Google Scholar] [CrossRef]

- Tang, C.-S.; Lin, L.; Cheng, Q.; Zhu, C.; Wang, D.-W.; Lin, Z.-Y.; Shi, B. Quantification and characterizing of soil microstructure features by image processing technique. Comput. Geotech. 2020, 128, 103817. [Google Scholar] [CrossRef]

- Li, P.; Xie, W.; Pak, R.Y.; Vanapalli, S.K. Microstructural evolution of loess soils from the Loess Plateau of China. Catena 2019, 173, 276–288. [Google Scholar] [CrossRef]

- Wang, S.-L.; Lv, Q.-F.; Baaj, H.; Li, X.-Y.; Zhao, Y.-X. Volume change behaviour and microstructure of stabilized loess under cyclic freeze–thaw conditions. Can. J. Civ. Eng. 2016, 43, 865–874. [Google Scholar] [CrossRef] [Green Version]

- Xie, W.-L.; Li, P.; Zhang, M.-S.; Cheng, T.-E.; Wang, Y. Collapse behavior and microstructural evolution of loess soils from the Loess Plateau of China. J. Mt. Sci. 2018, 15, 1642–1657. [Google Scholar] [CrossRef]

- Lei, X. Pore type and collapsibility of loess in China. Sci. China (Ser. B) 1987, 17, 1309–1316. [Google Scholar]

- Nguyen, T.S.; Likitlersuang, S. Reliability analysis of unsaturated soil slope stability under infiltration considering hydraulic and shear strength parameters. Bull. Eng. Geol. Environ. 2019, 78, 5727–5743. [Google Scholar] [CrossRef]

- Qi, X.-H.; Li, D.-Q. Effect of spatial variability of shear strength parameters on critical slip surfaces of slopes. Eng. Geol. 2018, 239, 41–49. [Google Scholar] [CrossRef]

- Skempton, A. Long-term stability of clay slopes. Geotechnique 1964, 14, 77–102. [Google Scholar] [CrossRef] [Green Version]

- Wen, B.; Aydin, A.; Duzgoren-Aydin, N.; Li, Y.; Chen, H.; Xiao, S. Residual strength of slip zones of large landslides in the Three Gorges area, China. Eng. Geol. 2007, 93, 82–98. [Google Scholar] [CrossRef]

- Moore, R. The chemical and mineralogical controls upon the residual strength of pure and natural clays. Geotechnique 1991, 41, 35–47. [Google Scholar] [CrossRef]

- Wang, G.; Sassa, K.; Fukuoka, H.; Tada, T. Experimental study on the shearing behavior of saturated silty soils based on ring-shear tests. J. Geotech. Geoenviron. Eng. 2007, 133, 319–333. [Google Scholar] [CrossRef]

- Wang, J.; Liu, W.; Chen, W.; Liu, P.; Jia, B.; Xu, H.; Wen, L. Study on the mechanism of loess landslide induced by chlorine salt in Heifangtai terran. Jpn. Geotech. Soc. Spec. Publ. 2019, 7, 159–167. [Google Scholar] [CrossRef]

- Gu, T.-F.; Zhang, M.-S.; Wang, J.-D.; Wang, C.-X.; Xu, Y.-J.; Wang, X. The effect of irrigation on slope stability in the Heifangtai Platform, Gansu Province, China. Eng. Geol. 2019, 248, 346–356. [Google Scholar] [CrossRef]

- Cui, S.-H.; Pei, X.-J.; Wu, H.-Y.; Huang, R.-Q. Centrifuge model test of an irrigation-induced loess landslide in the Heifangtai loess platform, Northwest China. J. Mt. Sci. 2018, 15, 130–143. [Google Scholar] [CrossRef]

| ρ | ρd | W | WL | Wp | Grain Size Fractions (%) | ||

|---|---|---|---|---|---|---|---|

| <0.005 mm | 0.005–0.05 mm | >0.05 mm | |||||

| 1.58 | 1.36 | 16 | 26.37 | 22.55 | 13.38 | 61.27 | 25.34 |

| Soaking Time (d) | Peak Strength (kPa) | Residual Strength (kPa) | NaCl Concentration (%) | Peak Strength (kPa) | Residual Strength (kPa) |

|---|---|---|---|---|---|

| 0 | 174.80 | 169.84 | 0 | 167.45 | 166.83 |

| 1 | 161.19 | 155.67 | 4 | 173.73 | 171.92 |

| 5 | 167.60 | 166.89 | 8 | 186.07 | 170.92 |

| 10 | 167.12 | 163.03 | 12 | 171.69 | 169.43 |

| 15 | 167.43 | 165.25 | 16 | 167.05 | 168.24 |

| 20 | 167.23 | 167.15 | 20 | 164.11 | 165.97 |

| 25 | 167.42 | 168.15 | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xue, C.; Wang, X.; Liu, K. Effect of Soaking Time and Salt Concentration on Mechanical Characteristics of Slip Zone Soil of Loess Landslides. Water 2020, 12, 3465. https://doi.org/10.3390/w12123465

Xue C, Wang X, Liu K. Effect of Soaking Time and Salt Concentration on Mechanical Characteristics of Slip Zone Soil of Loess Landslides. Water. 2020; 12(12):3465. https://doi.org/10.3390/w12123465

Chicago/Turabian StyleXue, Chen, Xingang Wang, and Kai Liu. 2020. "Effect of Soaking Time and Salt Concentration on Mechanical Characteristics of Slip Zone Soil of Loess Landslides" Water 12, no. 12: 3465. https://doi.org/10.3390/w12123465

APA StyleXue, C., Wang, X., & Liu, K. (2020). Effect of Soaking Time and Salt Concentration on Mechanical Characteristics of Slip Zone Soil of Loess Landslides. Water, 12(12), 3465. https://doi.org/10.3390/w12123465