Artificial Neural Network (ANN) Approach to Modelling of Selected Nitrogen Forms Removal from Oily Wastewater in Anaerobic and Aerobic GSBR Process Phases †

Abstract

:1. Introduction

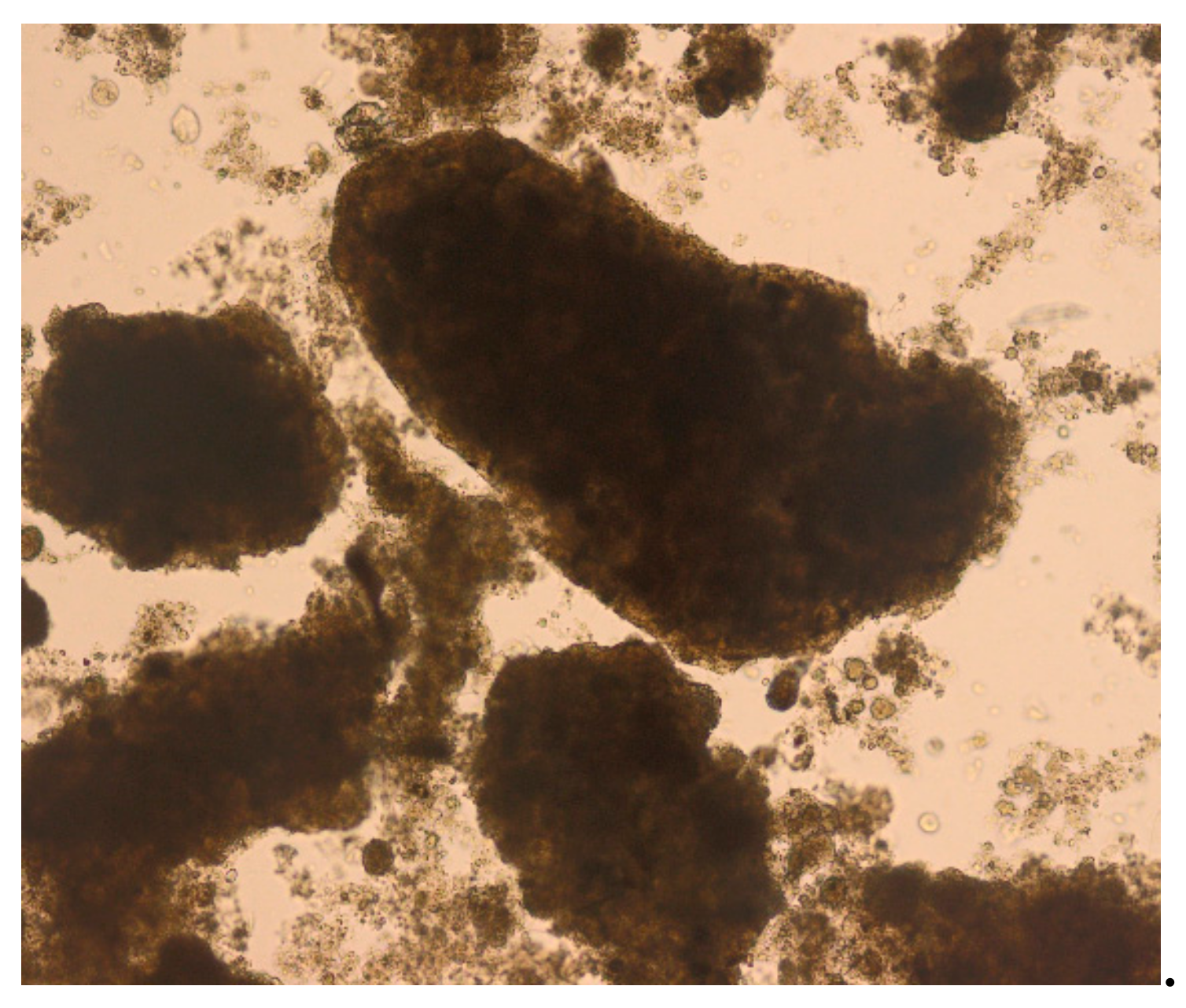

2. Materials and Methods

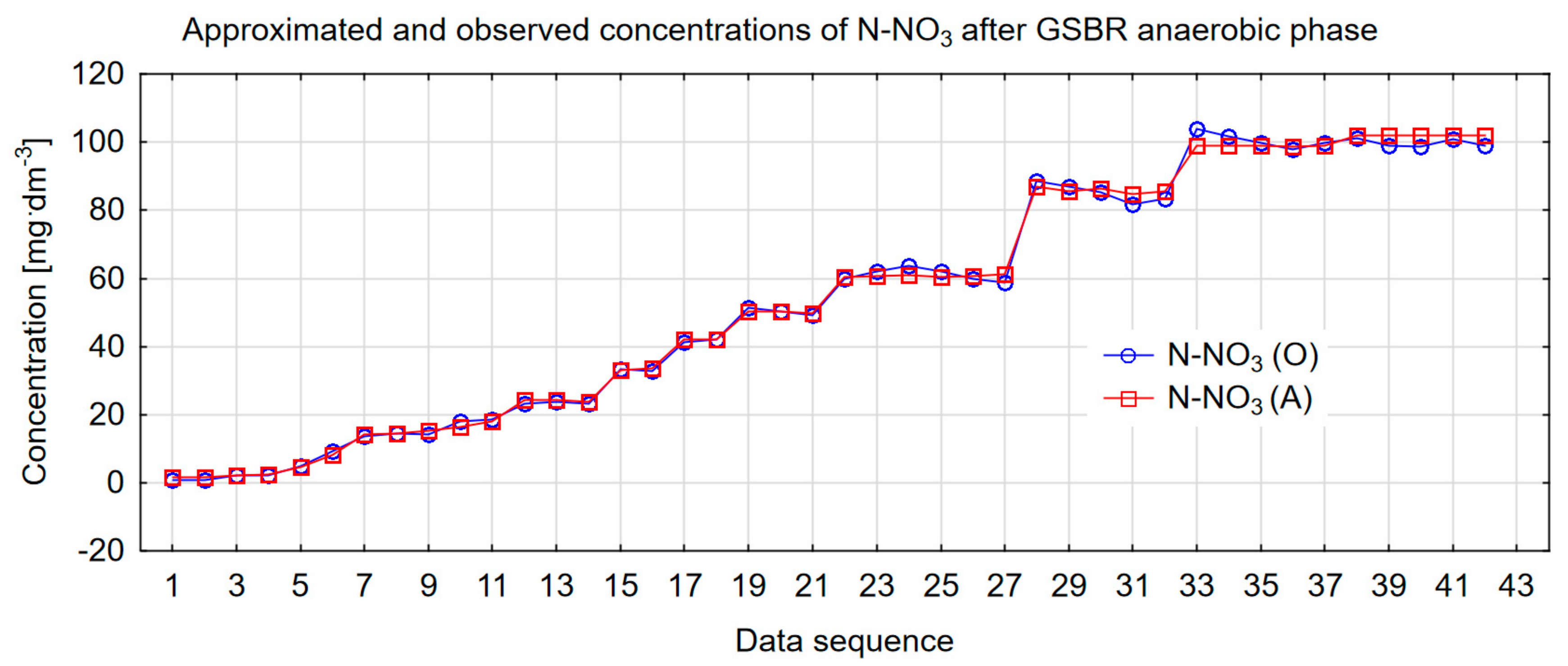

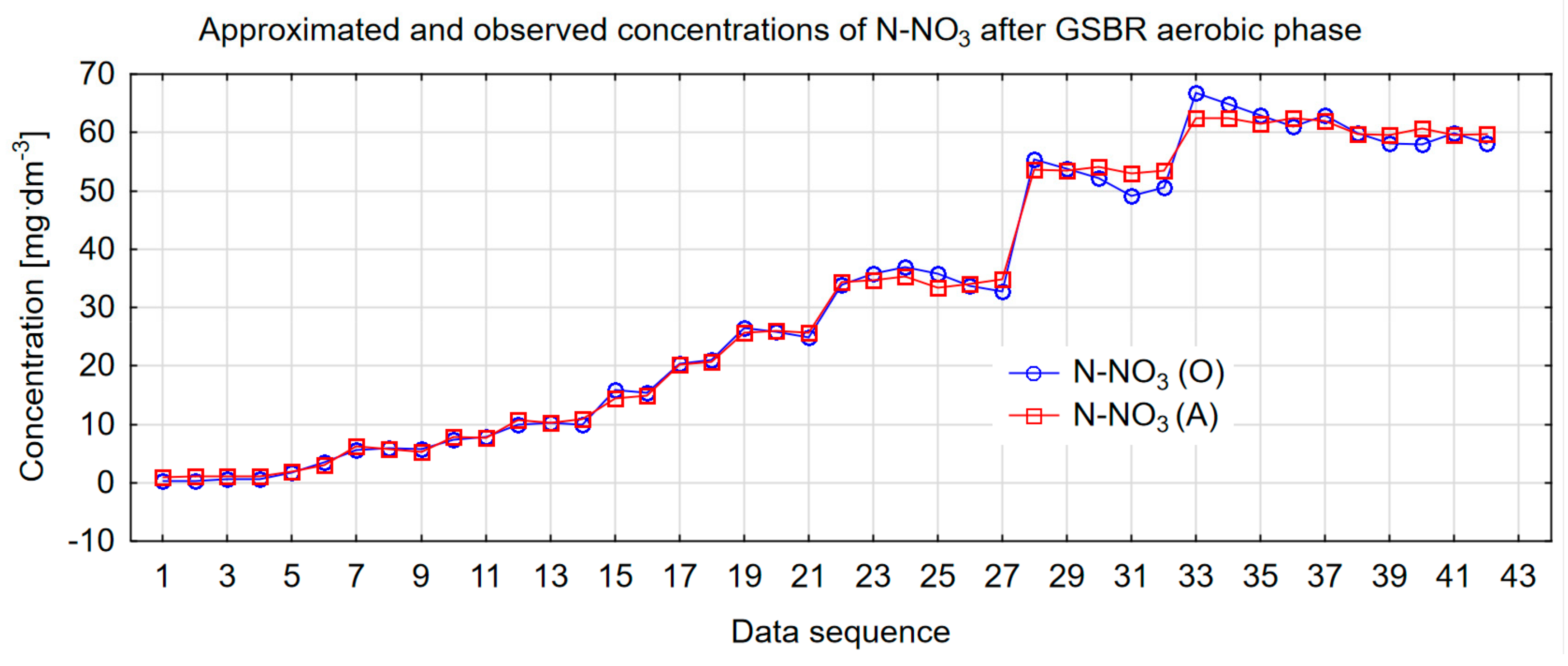

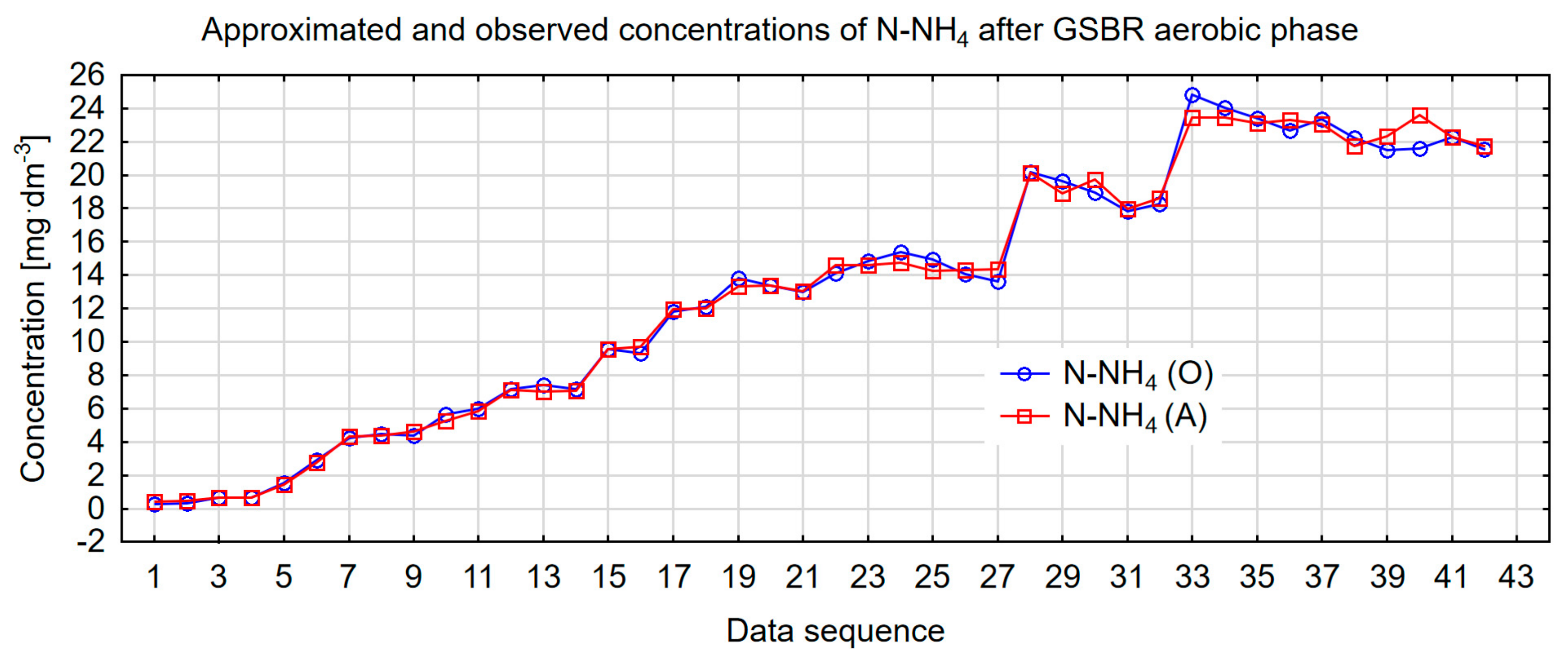

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Corsino, S.F.; Capodici, M.; Morici, C.; Torregrossa, M. Simltaneous nitrition-denitrition for the treatment of high-strength nitrogen in hypersaline wastewater by aerobic granular sludge. Water Res. 2016, 88, 329–336. [Google Scholar] [CrossRef] [PubMed]

- Adav, S.S.; Lee, D.J.; Show, K.Y.; Tay, J.H. Aerobic granular sludge: Recent advances. Biotechnol. Adv. 2008, 26, 411–423. [Google Scholar] [CrossRef] [PubMed]

- Jamaly, S.; Giwa, A.; Hasan, S.W. Recent improvements in oily wastewater treatment: Progress, challenges, and future opportunities. J. Environ. Sci. 2015, 37, 15–30. [Google Scholar] [CrossRef] [PubMed]

- Ni, B.J.; Yu, H.Q. Mathematical modelling of aerobic granular sludge: A review. Biotechnol. Adv. 2010, 28, 895–909. [Google Scholar] [CrossRef] [PubMed]

- Baeten, J.E.; van Loosdrecht, M.C.M.; Volcke, E.I.P. Modelling aerobic granular sludge reactors through apparent half-saturation coefficients. Water Res. 2018, 146, 134–145. [Google Scholar] [CrossRef] [PubMed]

- Harrou, F.; Dairi, A.; Sun, Y.; Senouci, M. Statistical monitoring of a wastewater treatment plant: A case study. J. Environ. Manag. 2018, 223, 807–814. [Google Scholar] [CrossRef] [PubMed]

- Dąbrowski, W.; Karolniczak, B.; Malinowski, P.; Boruszko, D. Modeling of pollutants removal in subsurface vertical flow and horizontal flow constructed wetlands. Water 2019, 11, 180. [Google Scholar] [CrossRef]

- Baeten, J.E.; Batstone, D.J.; Schraa, O.; van Loosdrecht, M.C.M.; Volcke, E.I.P. Modelling anaerobic, aerobic and partial nitritation-anammox granular sludge reactors—A review. Water Res. 2019, 149, 322–341. [Google Scholar] [CrossRef]

- Ofman, P.; Skoczko, I. PAH removal effectiveness comparison from hydraulic fracturing model wastewater in SBR reactors with granular and flocked activated sludge. Desalin. Water Treat. 2018, 134, 41–51. [Google Scholar] [CrossRef]

- Skoczko, I.; Struk-Sokołowska, J.; Ofman, P. Modeling changes in the parameters of treated sewage using artificial neural networks. Annu. Set Env. Prot. 2017, 19, 633–650. [Google Scholar]

- Skoczko, I.; Ofman, P.; Szatyłowicz, E. Using artificial neural networks for modeling wastewater treatment in small wastewater treatment plans. Annu. Set Environ. Prot. 2016, 18, 493–506. [Google Scholar]

- Nasr, M.S.; Moustafa, M.A.E.; Seif, H.A.E.; El Kobrosy, G. Application of artificial neural network (ANN) for prediction of EL-AGAMY wastewater treatment plant performance-EGYPT. Alex. Eng. J. 2012, 51, 37–43. [Google Scholar] [CrossRef]

- Giwa, A.; Daer, S.; Ahmed, I.; Marpu, P.R.; Hasan, S.W. Experimental investigation and artificial neural networks ANNs modeling of electrically-enhanced membrane bioreactor for wastewater treatment. J. Water Process. Eng. 2016, 11, 88–97. [Google Scholar] [CrossRef]

- Vázquez-Padín, J.R.; Mosquera-Corral, A.; Campos, J.L.; Méndez, R.; Carrera, J.; Pérez, J. Modelling aerobic granular SBR at variable COD/N ratios including accurate description of total solids concentration. Biochem. Eng. J. 2010, 49, 173–184. [Google Scholar] [CrossRef]

- Zhou, M.; Gong, J.; Yang, C.; Pu, W. Simulation of the performance of aerobic granular sludge SBR using modified ASM3 model. Bioresour. Technol. 2013, 127, 473–481. [Google Scholar] [CrossRef] [PubMed]

- Shmitt, F.; Banu, R.; Yeom, I.T.; Do, K.U. Development of artificial neural networks to predict membrane fouling in an anoxic-aerobic membrane bioreactor treating domestic wastewater. Biochem. Eng. J. 2018, 133, 47–58. [Google Scholar] [CrossRef]

- Hayder, G.; Ramil, M.Z.; Malek, M.A.; Khamis, A.; Hilmin, N.M. Prediction model development for petroleum refinery wastewater treatment. J. Water Process Eng. 2014, 4, 1–5. [Google Scholar] [CrossRef]

- Corominas, L.; Garrido-Baserba, M.; Villez, K.; Olsson, G.; Cortés, U.; Poch, M. Transforming data into knowledge for improved wastewater treatment operation: A critical review of techniques. Environ. Model. Softw. 2018, 106, 89–103. [Google Scholar] [CrossRef]

- Guo, Y.M.; Liu, Y.G.; Zeng, G.M.; Hu, X.J.; Xu, W.H.; Liu, Y.Q.; Liu, S.M.; Sun, H.S.; Ye, J.; Huang, H.J. An integrated treatment of domestic wastewater using sequencing batch biofilm reactor combined with vertical flow constructed wetland and its artificial neural network simulation study. Ecol. Eng. 2014, 64, 18–26. [Google Scholar] [CrossRef]

- Asadi, A.; Verma, A.; Yang, K.; Mejabi, B. Wastewater treatment aeration process optimization: A data mining approach. J. Environ. Manag. 2017, 203, 630–639. [Google Scholar] [CrossRef]

- Zaghloul, M.S.; Hamaza, R.A.; Iorhemen, O.T.; Tay, J.H. Performance prediction of an aerobic granular SBR using modular multilayer artificial neural networks. Sci. Total. Environ. 2018, 645, 449–459. [Google Scholar] [CrossRef] [PubMed]

- Hong, S.H.; Lee, W.M.; Lee, D.S.; Park, J.M. Monitoring of sequencing batch reactor for nitrogen and phosphorus removal using artificial neural networks. Bioche. Eng. J. 2007, 35, 365–370. [Google Scholar] [CrossRef]

- Bagheri, M.; Mirbagheri, S.A.; Ehteshami, M.; Bagheri, Z. Modeling of a sequencing batch reactor treating municipal wastewater using multi-layer perceptron and radial basis function artificial neural networks. Process Saf. Environ. Prot. 2015, 93, 111–123. [Google Scholar] [CrossRef]

- Qian, W.; Ma, B.; Li, X.; Zhang, Q.; Peng, Y. Long-term effect of pH on denitrification: High pH benefits achieving partial-denitrification. Bioresour. Technol. 2019, 278, 444–449. [Google Scholar] [CrossRef] [PubMed]

| Parametr | Concentration Range |

|---|---|

| BOD | 36.00–1200.00 ± 340.51 mg·dm−3 |

| COD | 57.00–1845.00 ± 559.61 mg·dm−3 |

| N-NH4 | 1.03–34.51 ± 10.52 mg·dm−3 |

| N-NO3 | 4.66–153.24 ± 46.88 mg·dm−3 |

| Total N | 5.89–190.37 ± 58.25 mg·dm−3 |

| Oily substances | 0.032 µg·dm−3 |

| Activated Sludge Technological Parameter | Unit | Value Range |

|---|---|---|

| Activated sludge dry mass | kg·m−3 | 4.0 ± 0.1 |

| Sludge volume index | cm3·g−1 | 59–70 ± 3 |

| Hydraulic retention time | d | 31–60 ± 11 |

| Sludge retention time | d | 21–42 ± 7 |

| Correlations in Anaerobic Phase | Correlations in Aerobic Phase | ||||||

|---|---|---|---|---|---|---|---|

| Variable | SVI | HRT | SRT | Variable | SVI | HRT | SRT |

| N-NO3 | −0.79 | −0.82 | −0.83 | N-NO3 | −0.78 | −0.78 | −0.79 |

| N-NH4 | −0.79 | −0.83 | −0.84 | N-NH4 | −0.78 | −0.86 | −0.88 |

| Total N | −0.79 | −0.84 | −0.85 | Total N | −0.78 | −0.81 | −0.82 |

| Approximated N Form in Selected GSBR Process Phase | ANN Type | Machine Learning Algorithm and Epochs | Error Function | Hidden Layer Activation Function | Output Layer Activation Function |

|---|---|---|---|---|---|

| N-NO3 in anaerobic phase | MLP 5-6-1 | BFGS 118 | SOS | Logistic | Logistic |

| N-NH4 in anaerobic phase | MLP 5-7-1 | BFGS 174 | SOS | Logistic | Tanh |

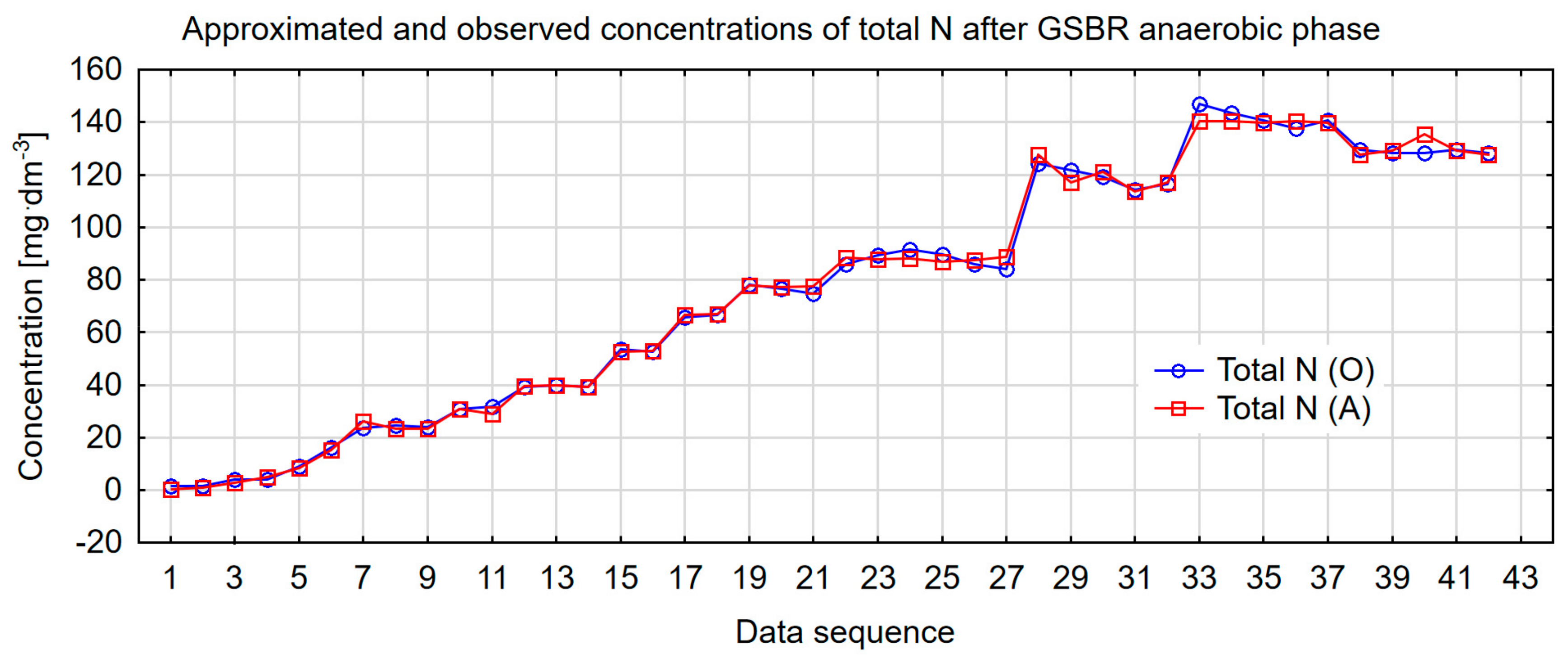

| Total N in anaerobic phase | MLP 5-9-1 | BFGS 124 | SOS | Logistic | Tanh |

| N-NO3 in aerobic phase | MLP 5-9-1 | BFGS 56 | SOS | Logistic | Exponential |

| N-NH4 in aerobic phase | MLP 5-4-1 | BFGS 122 | SOS | Logistic | Tanh |

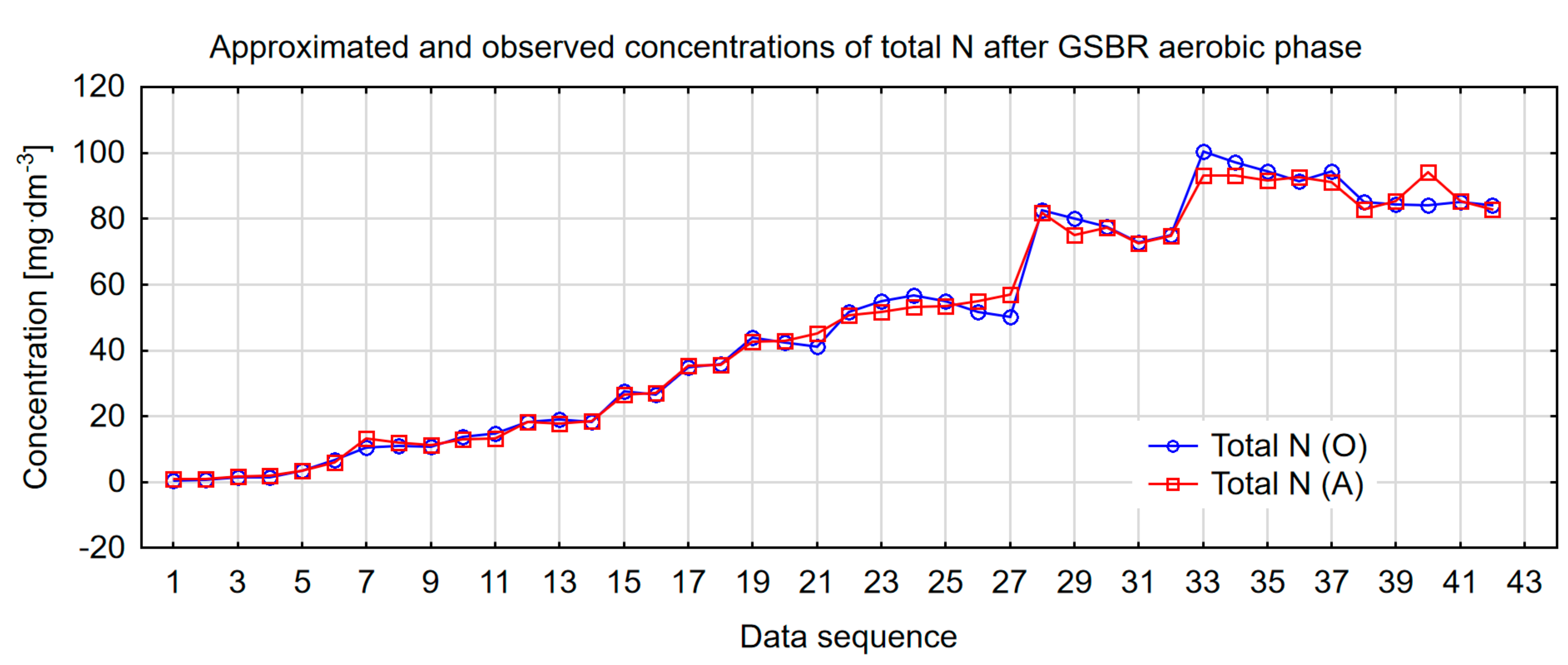

| Total N in aerobic phase | MLP 5-3-1 | BFGS 73 | SOS | Logistic | Linear |

| ANN Topology | Estimated N Form | Variables Rank (w) | ANN Prediction Quality (r) | ANN Error | ||||

|---|---|---|---|---|---|---|---|---|

| BOD Load | N Form | SRT | SVI | HRT | ||||

| MLP 5-6-1 | N-NO3 in anaerobic phase | 82.37 | 71.84 | 3.33 | 1.68 | 1.20 | 0.999 | 1.373 |

| MLP 5-7-1 | N-NH4 in anaerobic phase | 22.77 | 1215.16 | 5.47 | 3.85 | 7.70 | 0.999 | 0.061 |

| MLP 5-9-1 | Total N in anaerobic phase | 84.34 | 87.47 | 3.06 | 3.69 | 1.06 | 0.999 | 2.757 |

| MLP 5-9-1 | N-NO3 in aerobic phase | 46.80 | 46.42 | 6.97 | 1.36 | 2.97 | 0.998 | 1.115 |

| MLP 5-4-1 | N-NH4 in aerobic phase | 59.43 | 69.98 | 7.23 | 3.60 | 4.49 | 0.998 | 0.139 |

| MLP 5-3-1 | Total N in aerobic phase | 30.37 | 30.75 | 2.58 | 2.12 | 2.67 | 0.996 | 3.950 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ofman, P.; Struk-Sokołowska, J. Artificial Neural Network (ANN) Approach to Modelling of Selected Nitrogen Forms Removal from Oily Wastewater in Anaerobic and Aerobic GSBR Process Phases. Water 2019, 11, 1594. https://doi.org/10.3390/w11081594

Ofman P, Struk-Sokołowska J. Artificial Neural Network (ANN) Approach to Modelling of Selected Nitrogen Forms Removal from Oily Wastewater in Anaerobic and Aerobic GSBR Process Phases. Water. 2019; 11(8):1594. https://doi.org/10.3390/w11081594

Chicago/Turabian StyleOfman, Piotr, and Joanna Struk-Sokołowska. 2019. "Artificial Neural Network (ANN) Approach to Modelling of Selected Nitrogen Forms Removal from Oily Wastewater in Anaerobic and Aerobic GSBR Process Phases" Water 11, no. 8: 1594. https://doi.org/10.3390/w11081594

APA StyleOfman, P., & Struk-Sokołowska, J. (2019). Artificial Neural Network (ANN) Approach to Modelling of Selected Nitrogen Forms Removal from Oily Wastewater in Anaerobic and Aerobic GSBR Process Phases. Water, 11(8), 1594. https://doi.org/10.3390/w11081594