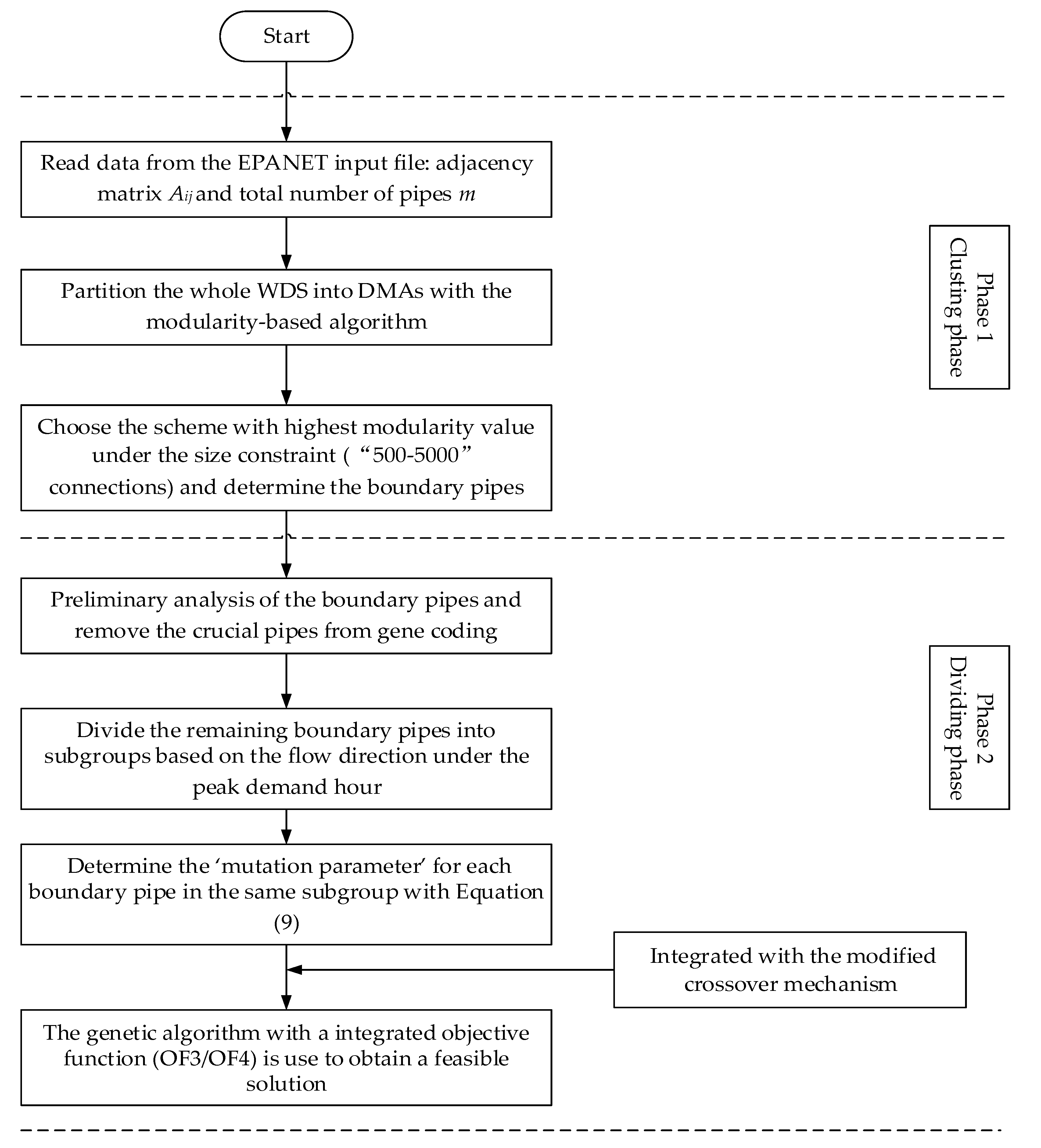

2.1. Network Clustering

Similar to many physical and social processes (e.g., business and academic circles) in the world, a water distribution system can also be naturally characterized by a simple topological graph G = G(V,E), where V represents n nodes (consumers, sources, and tanks) and E represents m edges (pipes, valves, and pumps) in a WDS. The approach adopted in this phase owns a bottom-up merge process and is based on the concept of ‘modularity’, which can quantify the quality of WDS partition [

23,

32,

33], called the Fast-Newman algorithm. The modularity

Q is expressed in Equation (1), and

Q ≥ 0.3 indicates a good division into communities [

16].

where

m represents the total number of links in the network;

v and

w are vertexes indexes;

kv (

kw) is the sum of the number of edges connected to vertex

v (w);

Avw = 1 if there is a link connecting the vertexes

v and

w;

Avw = 0 otherwise;

cv,

cw is the communities which the vertexes

v and

w belong to;

δ(cv,cw ) = 1 if vertexes

v and

w are in the same community, 0 otherwise. The brief steps of the algorithm are described below:

At first each node represents a community, and the initial modularity is calculated with Equation (1).

Evaluate the modularity change for each pair of communities v and w with Equation (2), assuming they are combined.

Merge the pair of communities v* and w* with max () (could be negative value) and the modularity of the current structure equals the modularity of the previous structure plus max ().

Step 2 and 3 is repeated until all the nodes merged into one community.

The partition scheme with highest

Q value represents its sub-systems that have stronger internal than external connections, but is not necessarily the best solution because the DMA size needs to be controlled between 500–5000 customer connections according to the guidelines [

34]. It becomes much more difficult to control water losses and locate the new bursts when a DMA contains more than 5000 customers [

27]; meanwhile more investment will be spent if the size of DMA is too small. Therefore, what we indeed need is the scheme with highest

Q value given the premise of satisfying the size constraint. More detail about the Fast-Newman algorithm can be found in previous literature [

15,

24].

2.2. Network Dividing

For the dividing stage of WNP (Water Network Partitioning), Di Nardo et al. [

25] proposed a method based on GA with the following objective function, to protect the hydraulic performance of the original system as much as possible:

where

γ is the specific weight of water,

Qi and

Hi are the water demand and head at each network node, and

PD is the total node power of the network. Generally, partitioning schemes with more flow meters (i.e., closing fewer pipes) would have a higher objective value

PD, hence the optimal solution is the case that all the boundary pipes are installed with flow meters (i.e., remain open). However, it is not the answer we truly need as more flow meters lead to a less convenient management and higher cost. Therefore Di Nardo et al. [

25] tried to solve the above problem by determining the number of flow meters in advance, but it is difficult to decide how many flow meters should be installed as a trade-off between the hydraulic performance and cost, especially for large-scale WDN. Therefore, the number of flow meters should be considered to be one of the objective functions instead of being a predetermined value. Thus, it forms a dual-objective problem as Equation (4):

At this point, the NSGA-II algorithm [

35] is generally used to optimize this dual-objective problem. It is feasible but not the optimal selection—in the previous literature, almost all researchers agree that the number of flow meters should be reduced as much as possible in the dividing phase of WNP under the premise of meeting normal hydraulic conditions (i.e., all demand nodes should meet the minimum service pressure) [

15,

16]. If possible, the best solution would be each district own just one single inflow meter [

25], because fewer flow meters can not only simplify the calculation of the synchronous water balance and improve the reliability of flow monitoring, but also reduce the costs of initial investment and later operation and maintenance costs. Therefore, we would like the second objective function in Equation (4) to be subjected to the first one; in other words, we would give the priority to the choice of the scheme with fewer flow meters, and then consider the role of the second objective function. However, the NSGA-II algorithm cannot embody this relationship between the two objective functions, resulting in a lot of time wasted on optimizing solutions (Pareto frontier).

To address above problem, this paper proposes a new objective function form shown in Equation (5), which can not only combine the two objective functions together, but also embodies the primary and secondary relations of the two objective functions. The purpose of the first term is to minimize the number of flow meters (its value is an integer) and the second term is to search the solution that has less impact on the hydraulic performance compared to original WDN. The value of the second term is between 0 and 1, ensuring that the latter one is subject to the former one.

where

Nfm is the number of flow meters,

PD0 is the total node power of the network before WNP and

PD is the total node power after WNP.

The fitness function, Equation (6), is obtained using the boundary construction method, by changing the minimum optimization into the maximum optimization, and the fitness value can be ensured larger than zero.

where

Np is the number of boundary pipes,

Ngv represents the number of gate valves

To adjust the selective pressure effectively, a rank-based fitness assignment method [

36,

37] is adopted to better distinguish the fitness between individuals, especially in the later stage of optimization. The specific fitness assignment function is shown in Equation (7)

where

i is the rank of an individual in the population,

SP is the selection pressure and set

SP = 1.5 in this work, and

n is the size of the population. A simple example (the population size

n adopts 5) is given to better understand the role of the rank-based fitness assignment method in this work as shown in

Table 1. The real fitness values are firstly calculated with Equation (6), then rank the individuals in the following way: the best one has rank

n and the worst one has rank 1.

Another objective function is adopted in this paper which considers minimizing the deterioration of water quality caused by WNP. The water velocity of pipes is used as an indicator to evaluate the water quality change before and after WNP. Giving the objective function in Equation (8).

where

p is the number of pipes;

VO is the pipe volume;

v is the pipe velocity before WDP;

m1 representing the event that the pipe velocity after WDP is lower than before,

m2 representing the event that the pipe velocity after WDP is lower than 0.1 m/s, and

δ (m1, m2) = 1 if both events

m1 and

m2 are true at the same time, 0 otherwise; △

vi is the flow velocity difference before and after WNP.

2.3. Improvements for Better Optimization

The binary coding is used to encode the chromosomes (i.e., individual), one chromosome is composed of a sequence of genes. Gene

i assumes 0 if a flow meter installed in

i-th pipe; otherwise, the value is 1 if a gate valve installed. As mentioned by other scholars, the efficiency of GA is obviously affected by the number of decision variables (i.e., boundary pipes) in the optimization process of dividing phase [

15]. There are two main reasons: first, the increasing number of decision variables inevitably leads to an exponential growth in search space, significantly affecting the optimization efficiency and making the entire optimization process more time-consuming. Second, binary coding cannot truly reflect the relationship between genes [

38], which are not really independent of each other (e.g., for a DMA without water source, all the boundary pipes connecting it cannot be closed at the same time otherwise no water will be supplied in this area). Moreover, the common crossover mechanism has great damage to individuals especially for those superior individuals in the later stage of optimization because of the direct break of chromosomes, though in the earlier stage it helps to maintain the diversity of the population. This drawback becomes more apparent when the length of the chromosome increases. To address the above-mentioned issue, three improvements are proposed in this work

Step 1: Reduce the number of decision variables through preliminary analysis

In fact, there are several pipes among the boundary pipes that are not necessary to participate in gene coding, because the closure of any one of them will result in local pressure deficit or even water supply disruption (e. g. main water transmission pipes or a unique inflow pipe for one specific DMA). The gene points corresponding to those pipes must be installed with flow meters can hence be deleted from the chromosome. In this way, the search space is greatly reduced.

The specific method in the procedure is as follows: Each time close one boundary pipe (all other boundary pipes should be open except the selected one) and then run the hydraulic simulation to find the pipes where the minimum pressure is lower than the normal service pressure, i.e., this boundary pipe must be opened to satisfy the minimum pressure and can be removed from the decision variables (the chromosome). All the pipes to be removed from the chromosome can be found by repeating this procedure for all the boundary pipes.

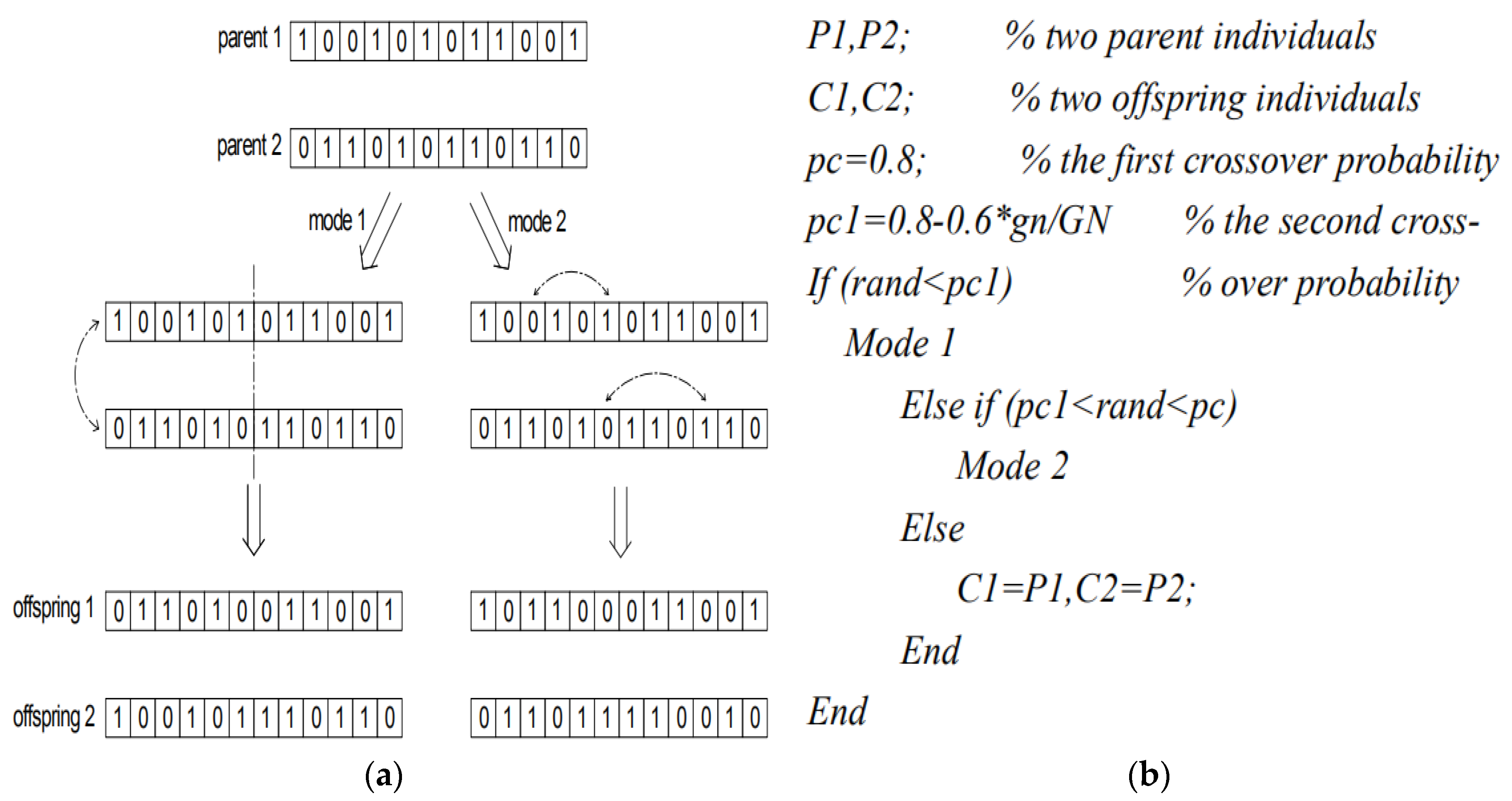

Step 2: Modify the crossover mechanism

A new crossover mechanism is proposed to better protect the individuals in the later stages of optimization; at the same time, it enhances the local search ability of the algorithm. The pseudo-code of new crossover mechanism is described in

Figure 2b, where

gn represents the current generation,

GN represents the total operation generations which should be determined in advance,

pc is the first crossover probability with a fixed value of 0.8 meanwhile

pc1 is the second crossover probability, which is related to the current generation

gn. As shown in

Figure 2a, mode 1 is the traditional crossover method meanwhile mode 2 is a new crossover method that exchanges the positions of two gene points, one coded 1, another coded 0; both of them are randomly selected (the physical meaning is to change the location of one randomly chosen flow meter meanwhile the total number of flow meters remains unchanged). As the generation (i.e.,

gn) increases, the probability of the mode 1 becomes smaller and the mode 2 becomes larger because of the declining value of

pc1. The crossover method of mode 2 can better prevent the superior individuals not being damaged.

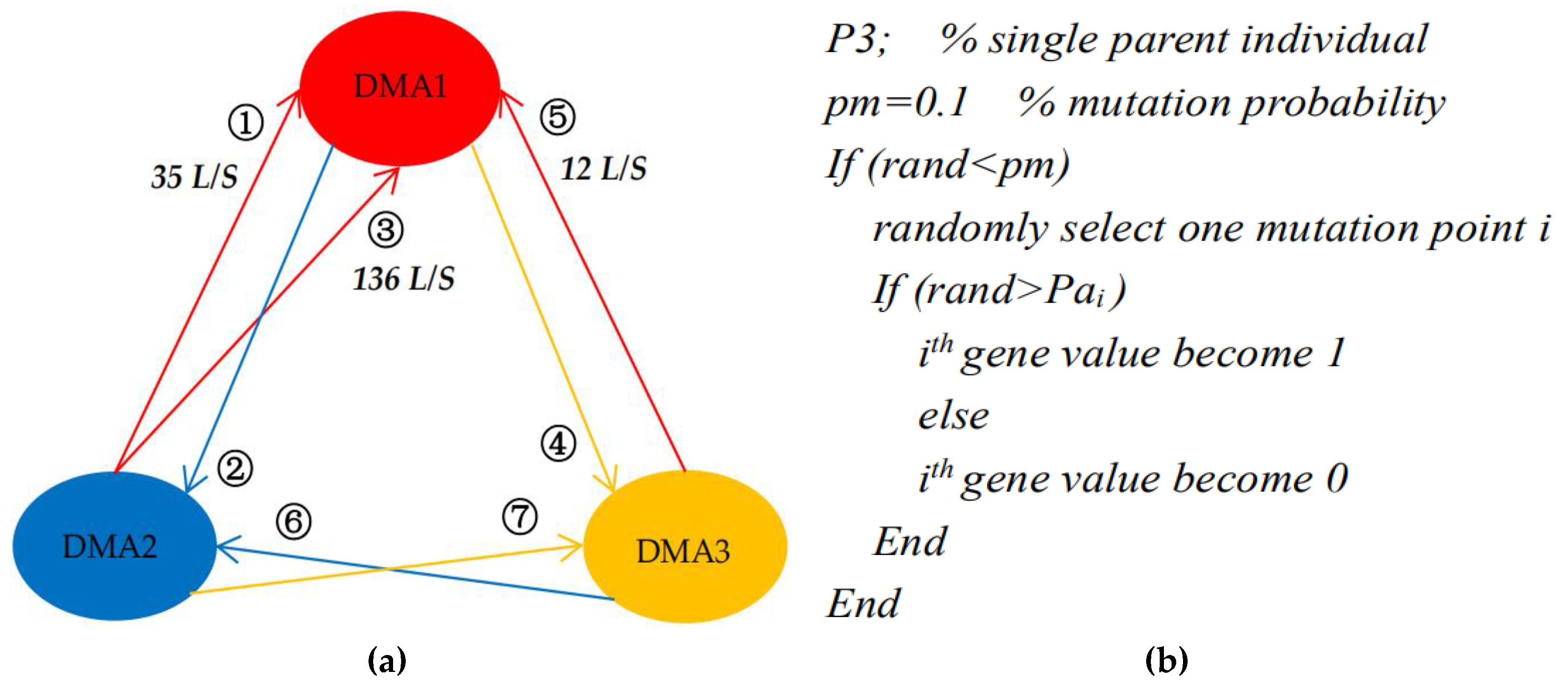

Step 3: Improve the mutation parameter

Through assigning ‘mutation parameter’ to each gene point, the importance level of each boundary pipe can hence be embodied and mutually distinguished in the optimization procedure, effectively accelerating the convergence velocity. At the same time, it will not lose the ability to search for potentially better solution such as the iterative method because of the absolute ordering relationship.

The boundary pipes are first divided into subgroups based on the flow direction under the peak demand hour. To better illustrate the method, an example is shown in

Figure 3a; pipe 1, 3, 5 are classified together because they are all the inflow pipes belonging to DMA1 and pipe 2, 6 are grouped together likewise. The pipes classified in the same subgroup play an identical role in the WDS (i.e., supply water for the same DMA), hence they are substitutes for each other and can be classified together for comparison to show the distinction in importance.

Then we determine the ‘mutation parameter’ for each boundary pipe according to Equation (9). Taking

Figure 3a as an example, for DMA1, the flow rates of three inflow pipes 1, 3, 5 are 35 L/s, 136 L/s, 12 L/s respectively, and the corresponding ‘mutation parameters’ are 0.4290, 0.7049, 0.3661 as calculated by Equation (9).

where

Pai,j is the ‘mutation parameter’ of

jth pipe in

ith group;

Qi,j is the flow rate of

jth pipe in

ith group;

Meani is the average flow rate of

ith group;

Sumi is the sum of the flow rate of all pipes in

ith group. The 0.5 in Equation (9) means the boundary pipes have the same possibility to install flow meters or gate valves if we do not consider any hydraulic characteristics, and the second term in RHS of Equation (9) considers their hydraulic importance (the 0.5 in the second term ensures

Pai,j less than 1).

As we can see, the more important pipe owns larger values of ‘mutation parameter’ such that it has greater possibility of being an inflow pipe with the flow meter installed (

Figure 3b shows the pseudo-code). Taking pipe 3 as an example, it is the most important one of the three and owns the highest value 0.7049. Then, when its corresponding gene point is selected as the mutation point, if a randomly generated number (ranging from 0 to 1) is greater than 0.7049, the gene value becomes 1 (i.e., install the valve), otherwise it becomes 0 (i.e., install the flow meter). In this way the more important pipe has a larger opportunity to become an inflow pipe outside of being closed.