Biogas Generation from Sonicated Excess Sludge

Abstract

1. Introduction

2. Materials and Methods

2.1. Characterization of Test Substrates

2.2. Selected Physico-Chemical Parameters of Sewage Sludge

- -

- total solids (TS), volatile suspended solids (VSS) according to PN-EN-12879 [17];

- -

- pH, alkalinity according to PN-91/C-04540/05 [18];

- -

- soluble chemical oxygen demand (SCOD) the dichromate method using the company’s spectrophotometer tests HACH 2I00N IS according to ISO 7027 [19];

- -

- volatile fatty acids (VFAs) calculated as acetic acid by steam distillation according to PN-75/C-04616/04 [20];

- -

- total organic carbon (TOC) by spectrophotometric method in the infrared (carbon analyzer multi N/C manufactured by Analytik Jena);

- -

- ammonium nitrogen according to PN-73/C-04576/02 [21];

- -

- Kjeldahl nitrogen according to PN-73/C-04576/10 [22].

2.3. Conditions of Disintegration of Excess Sludge by Ultrasonic Field

- Ia—ultrasonic wave intensity, W cm−2;

- Ea—the amount of energy supplied, J;

- S—cross-sectional area of the vessel inside which the sonicated sample has been placed, cm2;

- t—sonification time, s.

2.4. Conditions of the Methane Fermentation Process Conducting

3. Results and Discussion

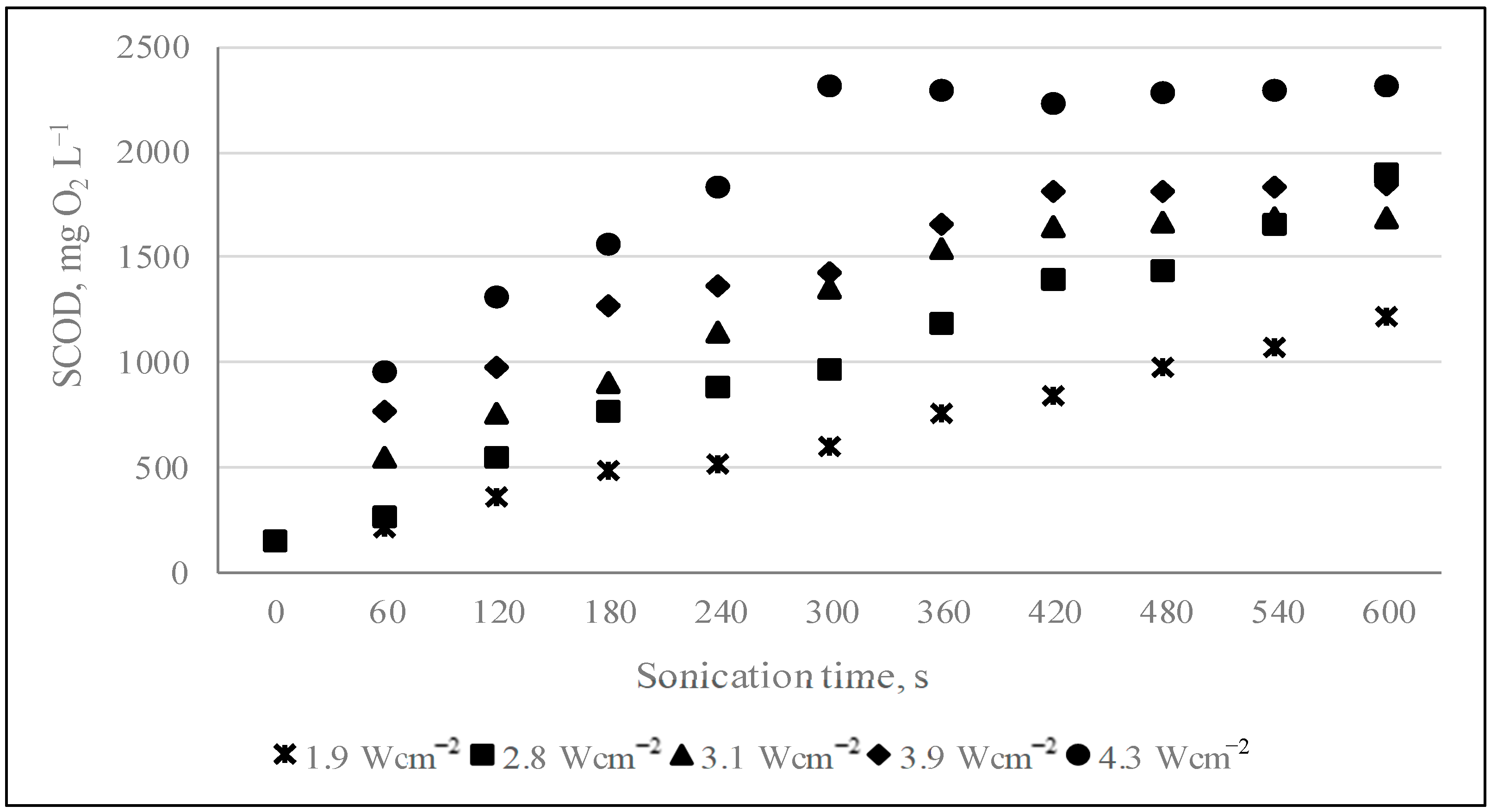

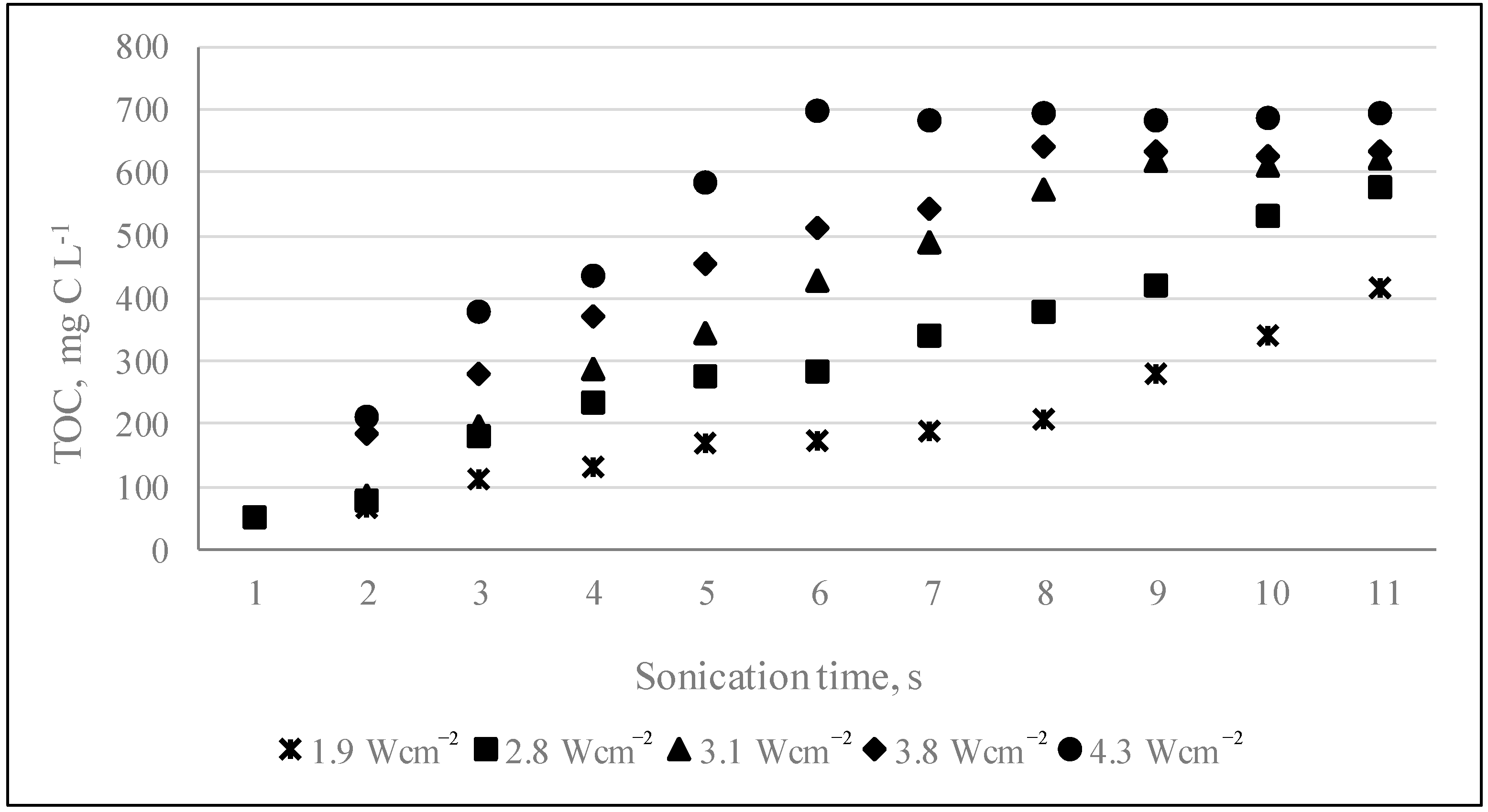

3.1. Selection of the Most Favorable Conditions for the Disintegration of Excess Sludge with an Ultrasonic Field

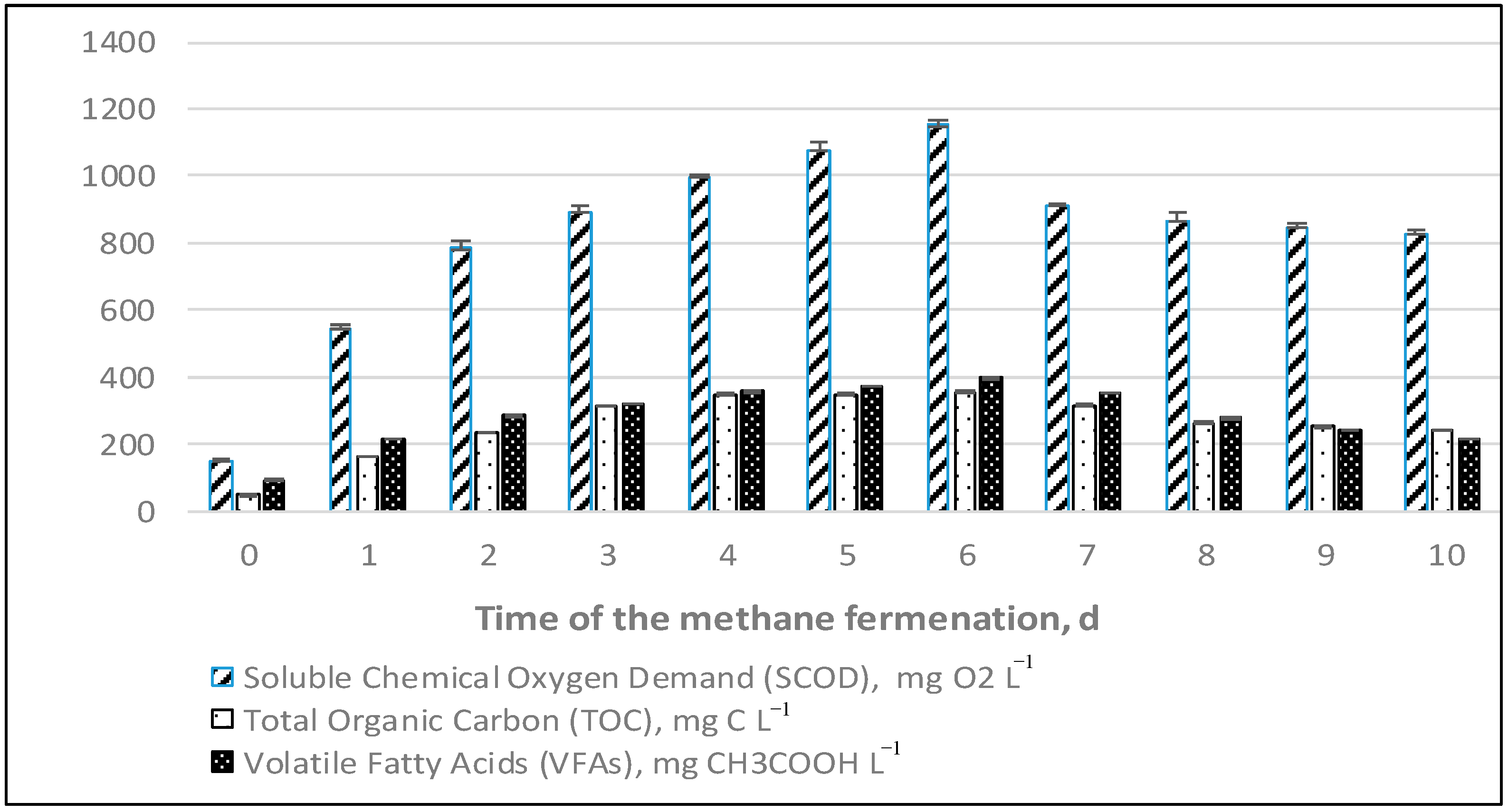

3.2. Conventional Methane Fermentation of Excess Sludge

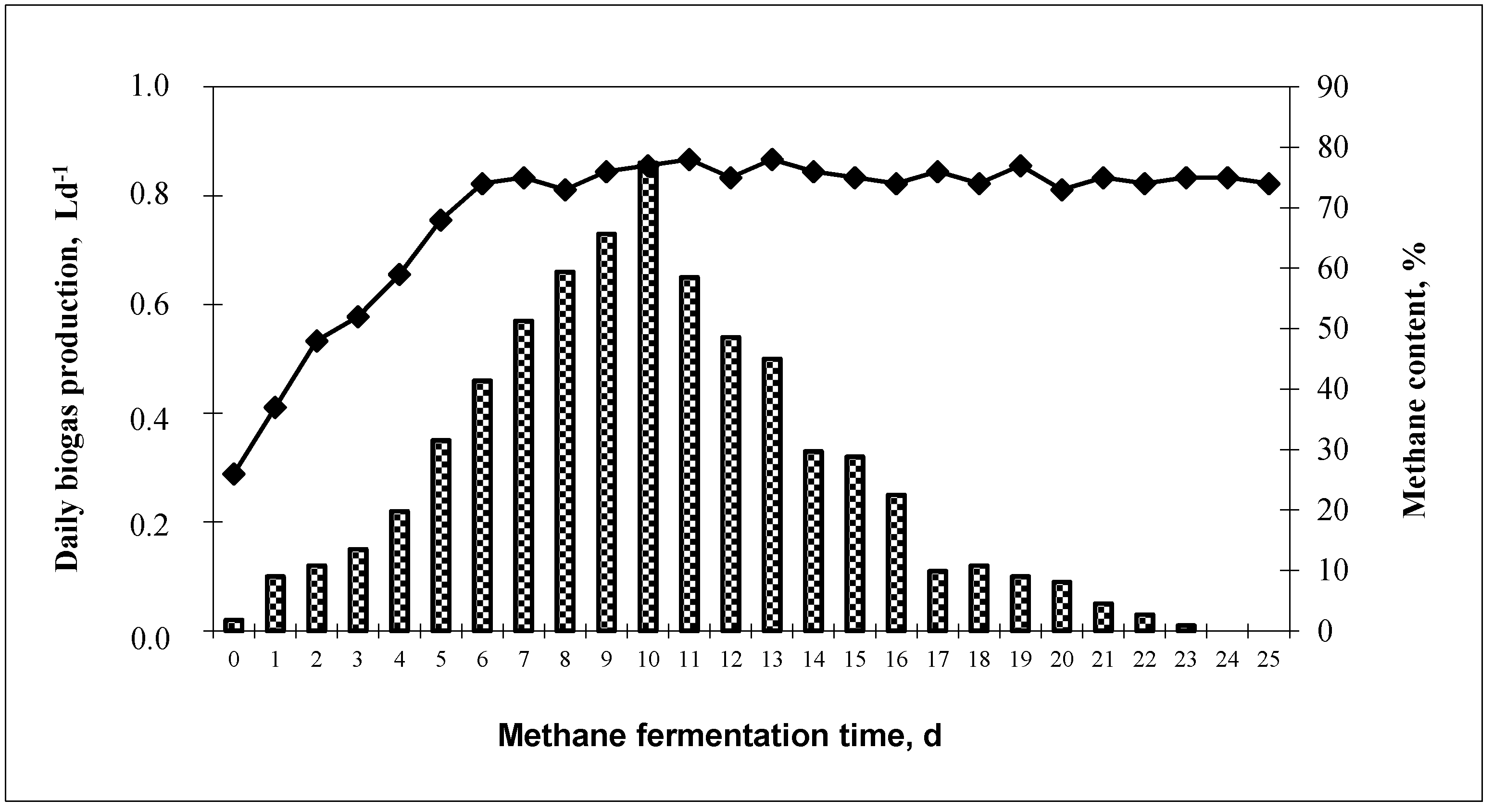

3.3. Methane Fermentation of Excess Sludge Disintegrated by an Ultrasonic Field

3.4. Research for the Future

4. Conclusions

- -

- In the case of ultrasonic disintegration about the ultrasonic field intensity in the range from 1.9 to 4.3 W cm−2, an increase of liquefaction of excess sludge was observed compared to unprepared sludge. With a value of ultrasonic field intensity of 4.3 W cm−2 and the sonication time equal to 300 s, the highest values of SCOD, TOC and VFAs concentrations were obtained.

- -

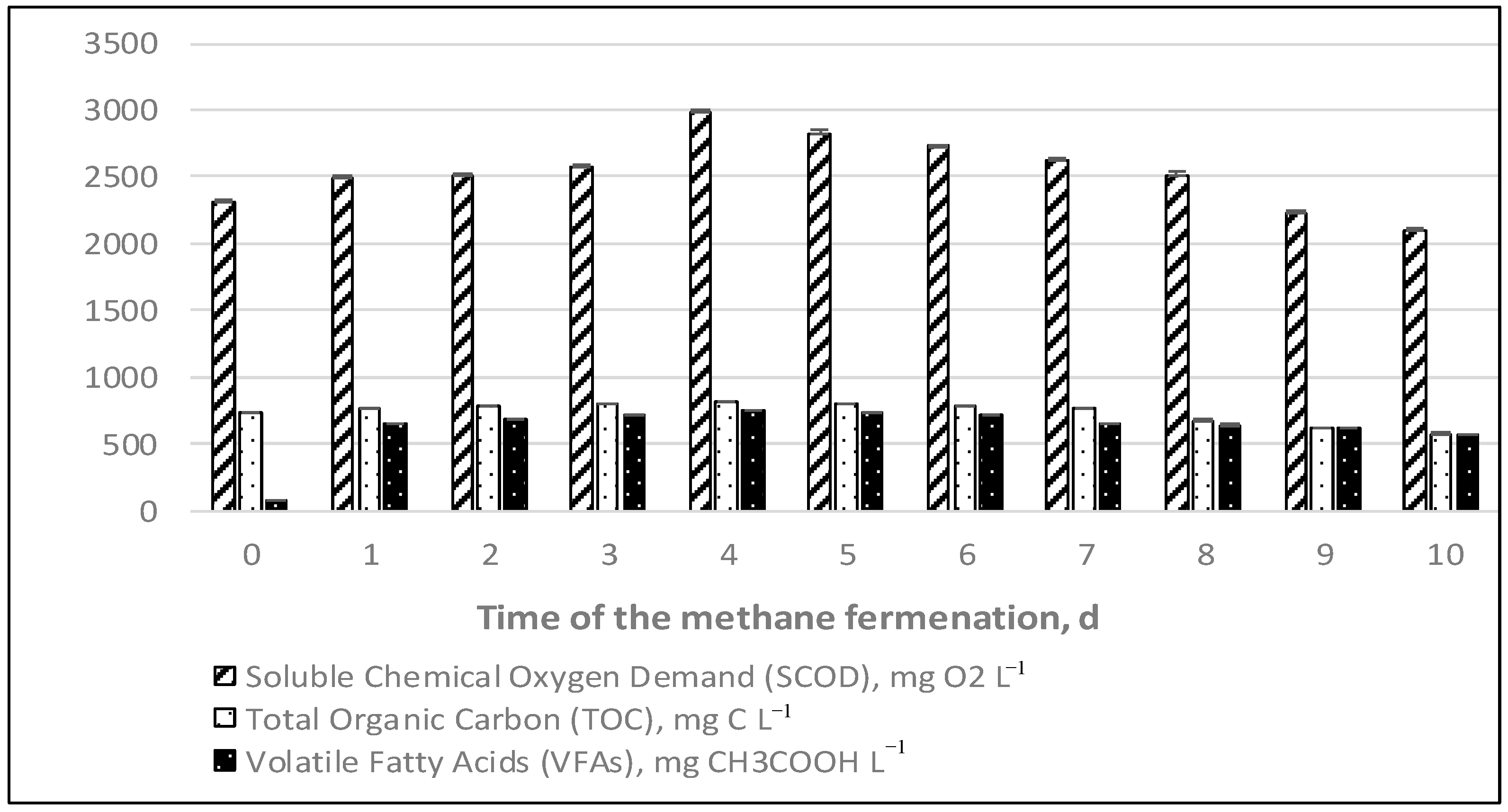

- In the 10-day conventional methane fermentation process, about a 10% digestion degree was obtained, while in the case of the sonicated excess sludge methane fermentation, about a 37% digestion degree was obtained. The highest value of indicators such as SCOD and VFAs were obtained on the 6th and 4th day of the process, respectively, which indicates the increase of the efficiency of the hydrolysis phase, which is the conditioning of the methane fermentation process.

- -

- Excess sludge is a potential source of biogas, which is a valuable energy carrier in the form of methane. Modification of conventional methane fermentation technology of excess sludge by the implementation of sonication process allows for obtaining almost the twice the increase of the biogas yield.

Author Contributions

Funding

Conflicts of Interest

References

- Wolny, L.; Kamizela, T. Technika dezintegracji ultradźwiękowej w technologii ścieków i osadów ściekowych. Ekol. Tech. 2003, 1, 3–7. [Google Scholar]

- Zielewicz, E.; Sorys, P.; Janik, M. Dezintegracja hybrydowa jako metoda poprawy efektów stabilizacji osadu. Inżynieria Ochr. Środowiska 2008, 11, 397–409. [Google Scholar]

- Kidak, R.; Wilhelm, A.M.; Delmas, H. Effect of process parameters on the energy requirement in ultrasonical treatment of waste sludge. Chem. Eng. Process. 2009, 48, 1346–1352. [Google Scholar] [CrossRef]

- Nanzai, B.; Okitsu, K.; Takenaka, N.; Bandow, H.; Tajima, N.; Maeda, Y. Effect of reaction vessel diameter on sonochemical efficiency and cavitation dynamics. Ultrason. Sonochem. 2009, 16, 163–168. [Google Scholar] [CrossRef] [PubMed]

- Iglesias-Iglesiasa, R.; Campanaro, S.; Treu, L.; Kennes, C.H.; Veiga, M.C. Valorization of sewage sludge for volatile fatty acids production and role of microbiome on acidogenic fermentation. Bioresour. Technol. 2019, 291, 121817. [Google Scholar] [CrossRef] [PubMed]

- Alibardi, L.; Green, K.; Favaro, L.; Vale, P.; Soares, A.; Cartmell, E.; Bajón Fernández, Y. Performance and stability of sewage sludge digestion under CO2 enrichment: A pilot study. Bioresour. Technol. 2017, 245, 581–589. [Google Scholar] [CrossRef]

- Zawieja, I.; Wolny, L. Generation of Volatile Fatty Acids from Thickened Excess Sludge Subjected to the Disintegration of High Acoustic Power Ultrasonic Field. Pol. J. Environ. Stud. 2011, 20, 346–350. [Google Scholar]

- Tiehm, A.; Nickel, K.; Zellhorn, M.; Neis, U. Ultrasonic waste activated sludge disintegration for improving anaerobic stabilization. Water Res. 2001, 35, 2003–2009. [Google Scholar] [CrossRef]

- Śliwiński, A. Ultrasounds and Their Application; Scientific and Technical Publisher: Warsaw, Poland, 2001. [Google Scholar]

- Wolny, L.; Kamizela, T. Technique of ultrasonic disintegration in sewage and sewage sludge technology. Ecol. Technol. 2003, 1, 3–7. [Google Scholar]

- Joyce, E.; Phull, S.S.; Lorimer, J.P.; Mason, T.J. The development and evaluation of ultrasound for the treatment of bacterial suspensions. A study of frequency, power and sonication time on cultured Bacillus species. Ultrason. Sonochem. 2003, 10, 315–318. [Google Scholar] [CrossRef]

- Chu, C.P.; Bea-Ven, C.; Liao, G.S.; Jean, D.S.; Lee, D.J. Observations on changes in ultrasonically treated waste-activated sludge. Water Res. 2001, 35, 1038–1046. [Google Scholar] [CrossRef]

- Gronroos, A.; Kyllonen, H.; Korpijarvi, K.; Pirkonen, P.; Paavola, T.; Jokela, J.; Rintala, J. Ultrasound assisted metod to increase soluble chemical oxygen demand (SCOD) of sewage sludge for digestion. Ultrason. Sonochem. 2005, 12, 115–120. [Google Scholar] [CrossRef] [PubMed]

- Nowak, D. Zastosowanie ultradźwięków do odkażania osadów ściekowych. Inżynieria Ochr. Środowiska 2015, 18, 459–469. [Google Scholar]

- Paola, F.; Bruni, L.; Andreottola, G.; Ziglio, G. Effects of sonication on bacteria viability in wastewater treatment plants evaluated by flow cytometry-Fecal indicators, wastewater and activated sludge. Water Res. 2007, 41, 235–243. [Google Scholar]

- Bourgrier, C.; Carrére, H.; Delgenés, J.P. Solubilisation of waste-activated sludge by ultrasonic treatment. Chem. Eng. J. 2005, 106, 163–169. [Google Scholar] [CrossRef]

- Appels, L.; Baeyens, J.; Degrève, J.; Dewil, R. Principles and Potential of the Anaerobic Digestion of Waste-Activated Sludge. Prog. Energy Combust. Sci. 2008, 34, 755–781. [Google Scholar] [CrossRef]

- PN-EN 12879 Standard, Water and Sewage. Special tests of sludge. In Determination of Water, Total Solids Content, Organic Substances and Mineral Substances in Sewage Sludge; Water and Sewage, Standardization Publisher: Warszawa, Poland, 2004. [Google Scholar]

- PN-91 C-04540/05 Standard, Water and Sewage. Research on pH, Acidity and Mineral Alkalinity in Urban Sewage Sludge; International Measurements Standards ISO 7027; Water and Sewage, Standardization Publisher: Warszawa, Poland, 1991. [Google Scholar]

- PN-75/C-04616/04 Standard, Water and Sewage. Special tests of sludge. In Determination of Volatile Fatty Acids in Sewage Sludge and Supersaturated Waters by Steam Distillation; Water and Sewage, Standardization Publisher: Warszawa, Poland, 1975. [Google Scholar]

- PN-ISO 5664:2002 Standard, Water and Sewage. Research on the content of nitrogen compounds. In Determination of Ammonium Nitrogen by the Titration Method; Water and Sewage, Standardization Publisher: Warszawa, Poland, 2002. [Google Scholar]

- PN-75/C-04576/17 Standard, Water and Sewage. Research on the content of nitrogen compounds. In Determination of Total Kjeldahl Nitrogen in Sewage Sludge; Water and Sewage, Standardization Publisher: Warszawa, Poland, 1975. [Google Scholar]

- Wolski, P.; Zawieja, I. Hybrid Conditioning Before Anaerobic Digestion for the Improvement of Sewage Sludge Dewatering, Desalin. Water Treat. 2014, 52, 3725–3731. [Google Scholar] [CrossRef]

- Kempa, E. Municipal Waste Management; Arkady Publishing House: Warsaw, Poland, 1983. [Google Scholar]

- Fukas-Płonka, Ł.; Zielewicz-Madej, E. Stabilization of excessive sludge in the methane fermentation process. Eng. Environ. Prot. 2000, 3, 37–48. [Google Scholar]

- Wang, F.; Ji, M.; Lu, S. Influence of ultrasonic disintegration on the dewaterability of waste activated sludge. Environ. Prog. 2006, 25, 257–260. [Google Scholar] [CrossRef]

- Zawieja, I. The impact of excess sludge disintegration on the changes of total organic carbon value. Ecol. Chem. Eng. A 2016, 23, 421–432. [Google Scholar]

- Simonetti, M.; Rossi, G.; Cabbai, V.; Goi, D. Tests on the effect of ultrasonic treatment on two different activated sludge waste. Environ. Prot. Eng. 2014, 40, 23–34. [Google Scholar]

- Feng, X.; Lei, H.Y.; Deng, J.C.; Yu, Q.; Li, H. Physical and chemical characteristics of waste activated sludge treated ultrasonically. Chem. Eng. Process. 2009, 48, 187–194. [Google Scholar] [CrossRef]

- Tytła, M. The Effects of Ultrasonic Disintegration as a Function of Waste Activated Sludge Characteristics and Technical Conditions of Conducting the Process-Comprehensive Analysis. Int. J. Environ. Res. Public Health 2018, 15, 2311. [Google Scholar] [CrossRef] [PubMed]

- Salihu, A.; Alam, M.D. Pretreatment methods of organic wastes for biogas production. J. Appl. Sci. 2016, 16, 124–137. [Google Scholar] [CrossRef]

- Pavlostathis, S.G.; Gossrt, J.M. A kinetic model for anaerobic digestion of biological sludge. Biotechnol. Bioeng. 1986, 27, 1519. [Google Scholar] [CrossRef]

- Lizama, A.C.; Figueiras, C.C.; Herrera, R.R.; Pedreguera, A.Z.; Espinoza, J.E.R. Effects of ultrasonic pretreatment on the solubilization and kinetic study of biogas production from anaerobic digestion of waste activated sludge. Int. Biodeterior. Biodegrad. 2017, 123, 1–9. [Google Scholar] [CrossRef]

- Sahinkaya, S. Disintegration of municipal waste activated sludge by simultaneous combination of acid and ultrasonic pretreatment. Process. Saf. Environ. Prot. 2015, 93, 201–205. [Google Scholar] [CrossRef]

- Galvano, A.; Chiodo, V.; Urbani, F.; Freni, F. Biogas as hydrogen source for fuel cell applications. Int. J. Hydrog. Energy 2013, 38, 3913–3920. [Google Scholar] [CrossRef]

- Alves, H.J.; Bley Junior, C.; Niklevicz, R.R.; Frigo, E.P.; Frigo, M.; Coimbra-Araujo, C.H. Overview of hydrogen production technologies from biogas and the applications in fuel cells. Int. J. Hydrog. Energy 2013, 38, 5215–5225. [Google Scholar] [CrossRef]

- Lanzini, A.; Leone, P. Experimental investigation of direct internal reforming of biogas in solid oxide fuel cells. Int. J. Hydrog. Energy 2010, 35, 2463–2476. [Google Scholar] [CrossRef]

- Nahar, G.; Mote, D.; Dupont, V. Hydrogen production from reforming of biogas: Review of technological advances and an Indian perspective. Renew. Sustain. Energy Rev. 2017, 76, 1032–1052. [Google Scholar] [CrossRef]

| Physico-Chemical Parameters | The Type of Sludge Used in the Research | |

|---|---|---|

| Excess Sludge | Digested Sludge (inoculum) | |

| Total solids (TS) | 12.4 ÷ 15.3 g L−1 | 17.0 ÷ 19.6, mg L−1 |

| Volatile Suspended Solids (VSS) | 8.1 ÷ 10.15 g L−1 | 10.8 ÷ 13.2 g L−1 |

| Soluble Chemical Oxygen Demand (SCOD) | 142 ÷ 164 mg O2 L−1 | 1056 ÷ 1278 mg O2 L−1 |

| Total Organic Carbon (TOC) | 43 ÷ 58 mg C L−1 | 324 ÷ 467 mg C L−1 |

| Volatile Fatty Acids (VFAs) | 74 ÷ 97 mg CH3COOH L−1 | 487 ÷ 675 mg CH3COOH L−1 |

| Alkalinity | 780 ÷ 960 mg CaCO3 L−1 | 2700 mg ÷ 3450 CaCO3 L−1 |

| Kjeldahl Nitrogen | 87 ÷ 143 mg N L−1 | 612 ÷ 876 mg N L−1 |

| Ammonium Nitrogen | 68 ÷ 124 mg N-NH4+ L−1 | 585 ÷ 815 mg N-NH4+ L−1 |

| pH | 7.2 ÷ 7.4 | 7.3 ÷ 7.6 |

| Indicator/Unit | Methane Fermentation Time, d | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | |

| Volatile Suspended Solids (VSS), g L−1 | 8.16 ± 0.07 | 8.07 ± 0.12 | 8.01 ± 0.15 | 7.92 ± 0.32 | 7.85 ± 0.25 | 7.82 ± 0.18 | 7.73 ± 0.37 | 7.67 ± 0.43 | 7.53 ± 0.28 | 7.49 ± 0.37 | 7.41 ± 0.25 |

| Alkalinity, mg CaCO3 L−1 | 860 ± 17.6 | 1020 ± 2.9 | 1060 ± 20.8 | 1080 ± 11.5 | 1120 ± 10.4 | 1180 ± 23.1 | 1220 ± 30.6 | 1270 ± 25.2 | 1340 ± 10.4 | 1360 ± 7.6 | 1460 ± 24.7 |

| VFAs/Alkalinity | - | 0.21 | 0.27 | 0.29 | 0.34 | 0.32 | 0.29 | 0.26 | 0.21 | 0.18 | 0.15 |

| Indicator/Unit | Methane Fermentation Time, d | |

|---|---|---|

| 0 | 25 | |

| Total Solids (TS), g L−1 | 12.52 ± 0.54 | 8.69 ± 0.67 |

| Volatile Suspended Solids (VSS), g L−1 | 8.16 ± 0.32 | 5.14 ± 0.17 |

| Alkalinity, mg CaCO3 L−1 | 860 ± 11.5 | 1960 ± 20.0 |

| Soluble Chemical Oxygen Demand (SCOD), mg O2 L−1 | 147 ± 12.2 | 287 ± 17.6 |

| Total Organic Carbon (TOC), mg C L−1 | 48 ± 3.4 | 87 ± 6.2 |

| Volatile Fatty Acids (VFAs), mg CH3COOH L−1 | 92 ± 8.5 | 112 ± 3.8 |

| Kjeldahl Nitrogen, mg N L−1 | 97 ± 6.3 | 568 ± 11.7 |

| Ammonium Nitrogen, mg N-NH4+ L−1 | 63 ± 5.4 | 521 ± 13.6 |

| pH | 7.4 | 7.3 |

| VFAs/Alkalinity | - | 0.06 |

| Indicator/Unit | Methane Fermentation Time, d | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | |

| Volatile Suspended Solids (VSS), g L−1 | 9.12 ± 0.45 | 9.06 ± 0.21 | 8.78 ± 0.76 | 8.65 ± 0.43 | 8.17 ± 0.98 | 7.67 ± 0.58 | 7.34 ± 0.37 | 7.15 ± 0.79 | 6.78 ± 0.93 | 6.32 ± 0.54 | 5.76 ± 0.77 |

| Alkalinity, mg CaCO3 L−1 | 960 ± 8.7 | 1320 ± 13.2 | 1380 ± 20.0 | 1420 ± 10.0 | 1480 ± 15.3 | 1670 ± 18.9 | 1720 ± 17.6 | 1840 ± 7.6 | 2040 ± 15.3 | 2270 ± 17.6 | 2320 ± 15.3 |

| VFAs/Alkalinity | - | 0.50 | 0.50 | 0.51 | 0.51 | 0.44 | 0.41 | 0.36 | 0.32 | 0.27 | 0.24 |

| Indicator/Unit | Methane Fermentation Time, d | |

|---|---|---|

| 0 | 25 | |

| Total Solids (TS), g L−1 | 11.98 ± 0.57 | 5.14 ± 0.24 |

| Volatile Suspended Solids (VSS), g L−1 | 9,12 ± 0.18 | 3,28 ± 0.42 |

| Alkalinity, mg CaCO3 L−1 | 960 ± 27.8 | 3250 ± 45.4 |

| Soluble Chemical Oxygen Demand (SCOD), mg O2 L−1 | 2316 ± 18.4 | 527 ± 11.7 |

| Total Organic Carbon (TOC), mg C L−1 | 734 ± 8.7 | 187 ± 4.6 |

| Volatile Fatty Acids (VFAs), mg CH3COOH L−1 | 786 ± 11.7 | 234 ± 84.5 |

| Kjeldahl Nitrogen, mg N L−1 | 356 ± 11.4 | 765 ± 15.8 |

| Ammonium Nitrogen, mg N-NH4+ L−1 | 273 ± 5.3 | 715 ± 8.7 |

| pH | 7.2 | 7.1 |

| VFAs/Alkalinity | - | 0.07 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zawieja, I.; Włodarczyk, R.; Kowalczyk, M. Biogas Generation from Sonicated Excess Sludge. Water 2019, 11, 2127. https://doi.org/10.3390/w11102127

Zawieja I, Włodarczyk R, Kowalczyk M. Biogas Generation from Sonicated Excess Sludge. Water. 2019; 11(10):2127. https://doi.org/10.3390/w11102127

Chicago/Turabian StyleZawieja, Iwona, Renata Włodarczyk, and Mariusz Kowalczyk. 2019. "Biogas Generation from Sonicated Excess Sludge" Water 11, no. 10: 2127. https://doi.org/10.3390/w11102127

APA StyleZawieja, I., Włodarczyk, R., & Kowalczyk, M. (2019). Biogas Generation from Sonicated Excess Sludge. Water, 11(10), 2127. https://doi.org/10.3390/w11102127