Multivariate Chemometric Analysis of Membrane Fouling Patterns in Biofilm Ceramic Membrane Bioreactor

Abstract

1. Introduction

- Higher mechanical strength and chemical resistance to oxidants and solvents. The modules are backwashable with the possible application of high backwash pressure/flux [71,72] and can withstand much more aggressive operation and chemical cleaning conditions (i.e., can be used in combination with ultrasonic irradiation and undergo a soaking in more concentrated NaClO, NaOH, and acidic solutions). In addition, they can undergo the influence of higher temperatures and pH without damaging the active layer [73,74,75,76,77].

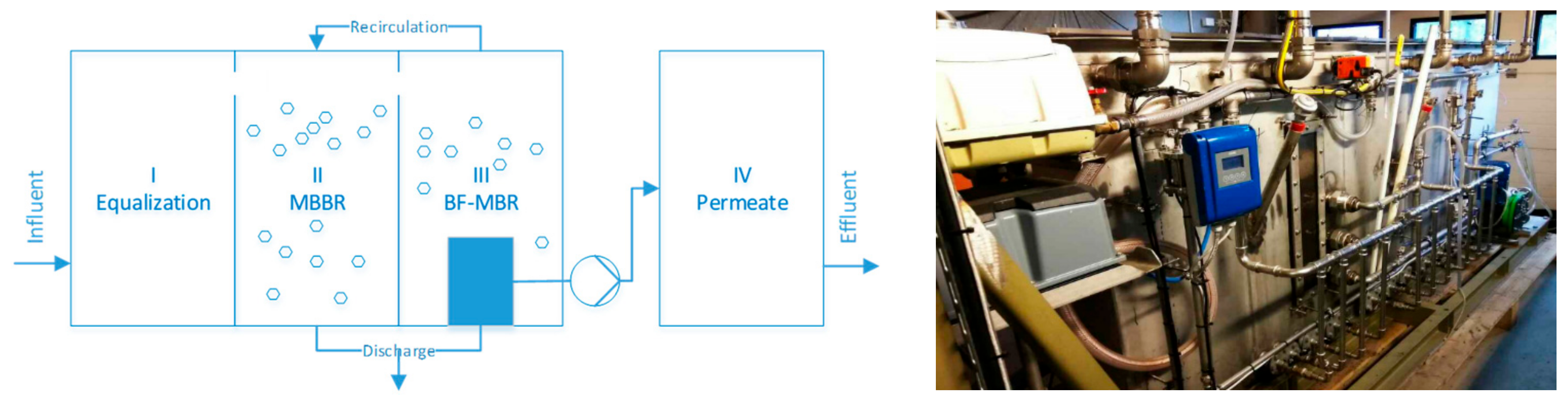

2. Materials and Methods

3. Results and Discussion

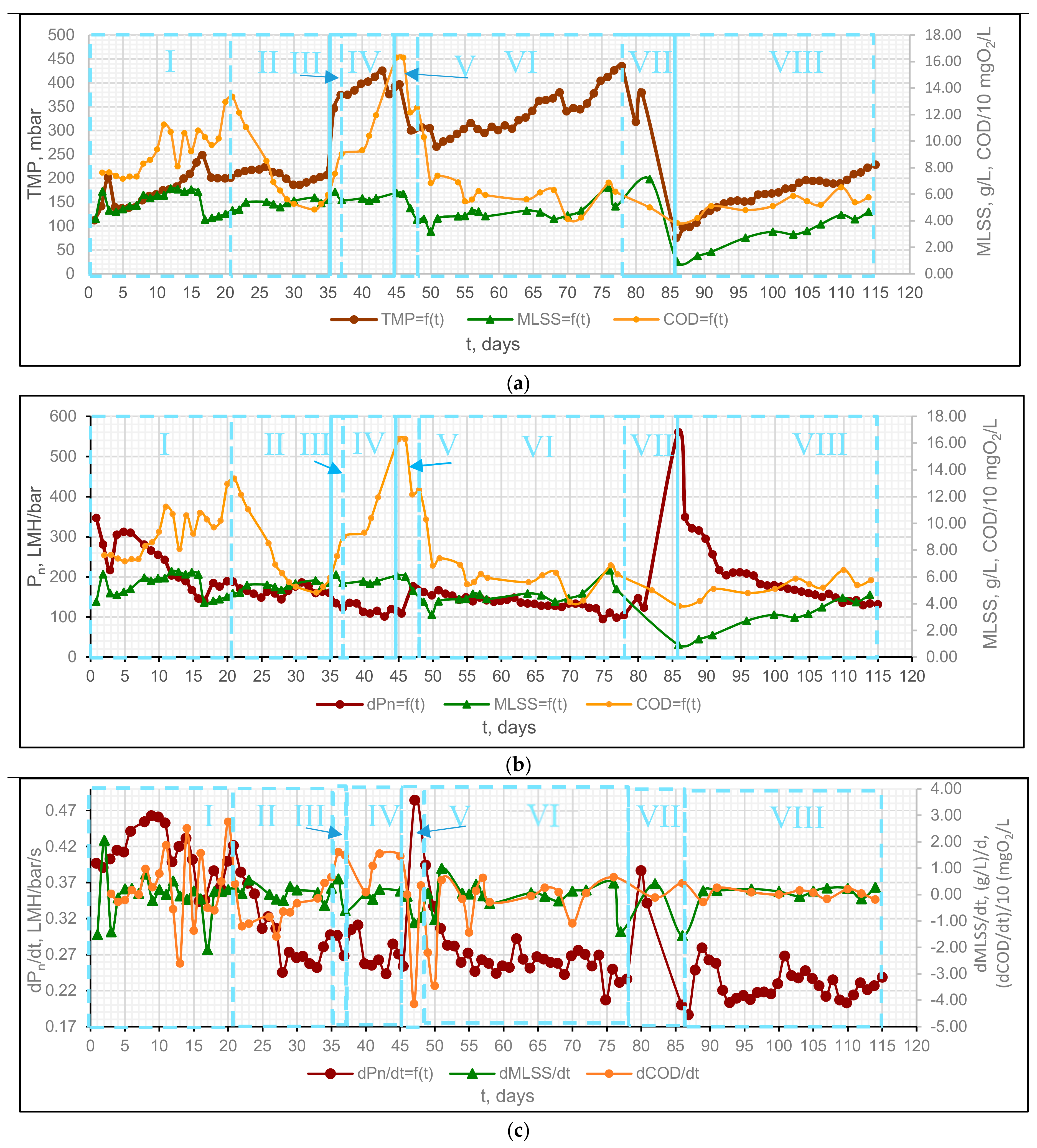

3.1. Pilot Plant Operation Results

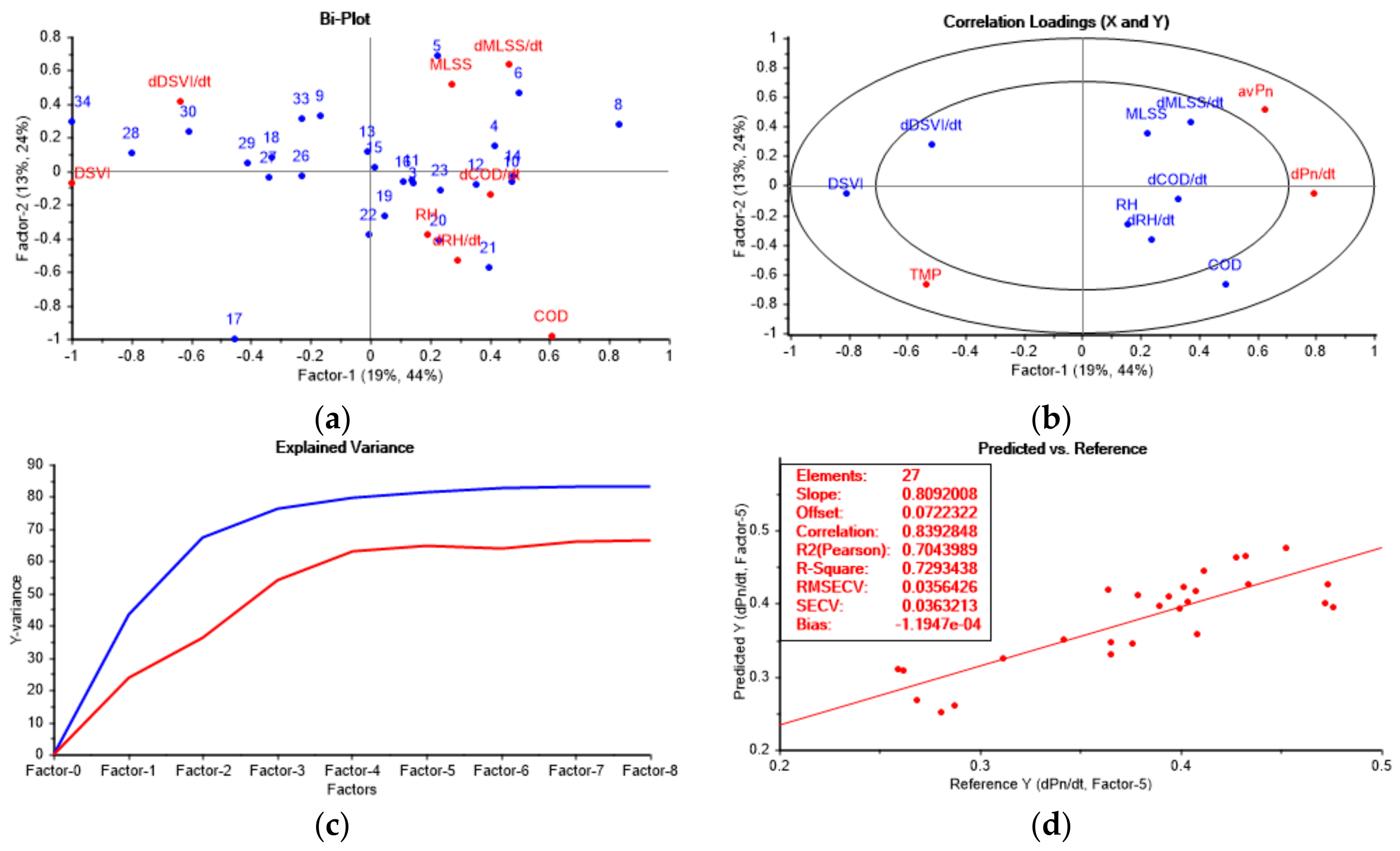

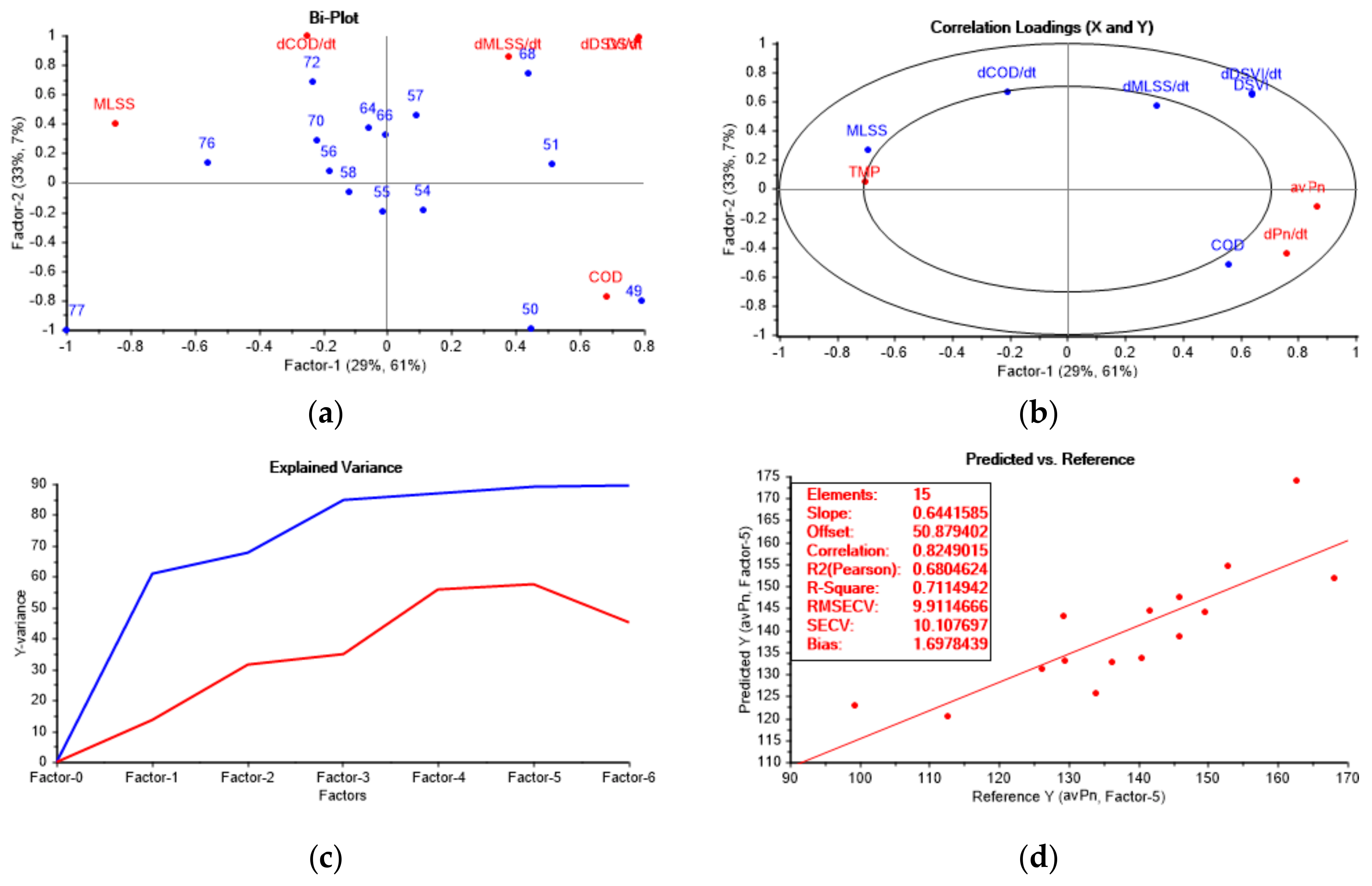

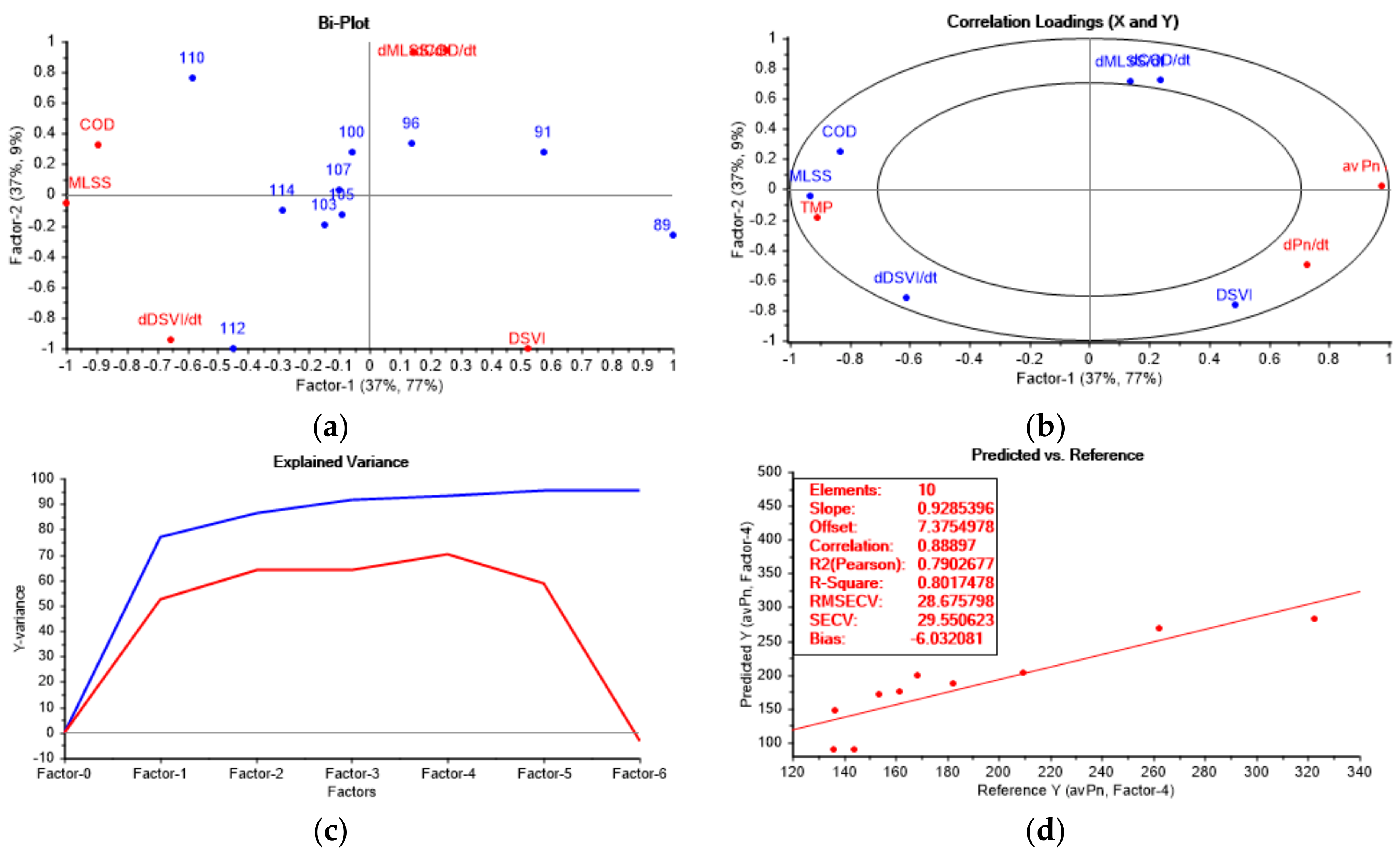

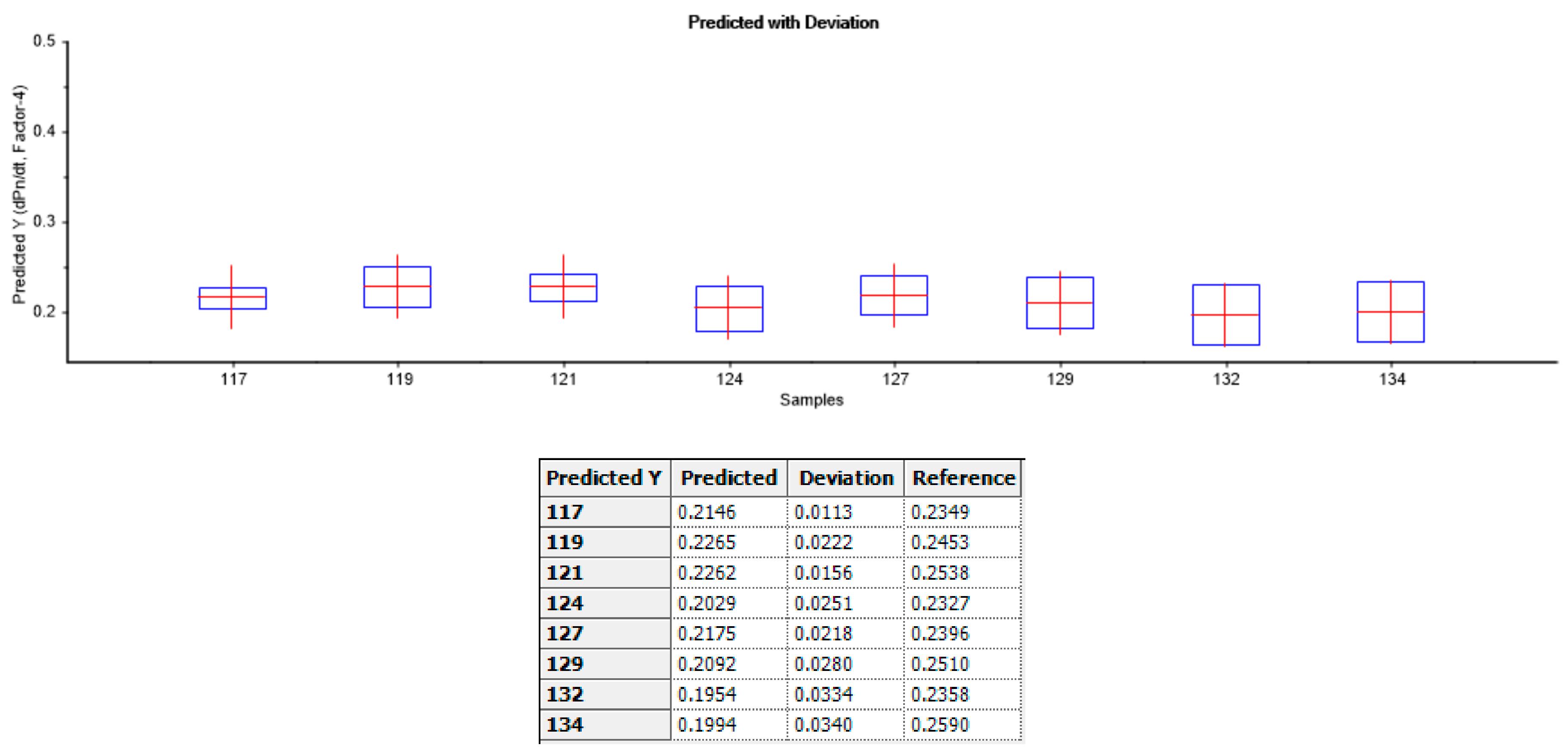

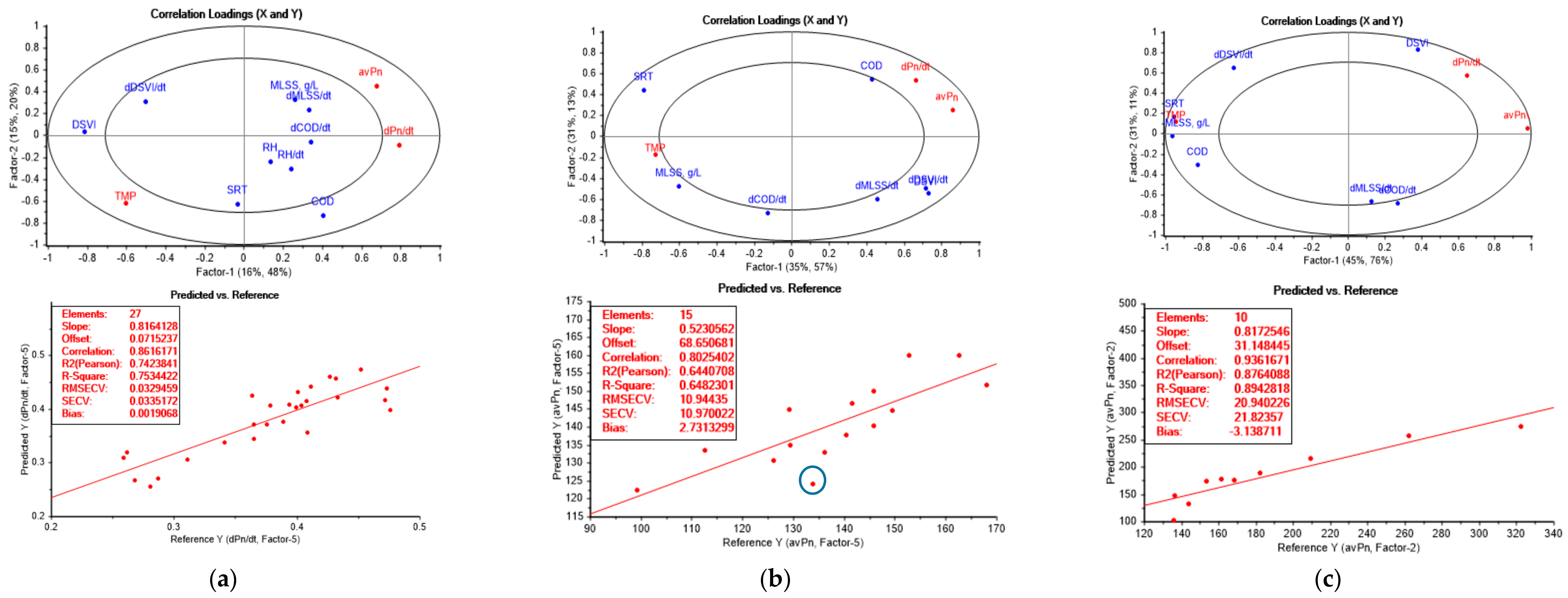

3.2. Statistical Determination of Membrane Fouling Patterns

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- World Economic Forum. The Global Risks Report 2018. Available online: https://www.weforum.org/reports/the-global-risks-report-2018 (accessed on 9 December 2017).

- World Economic Forum. Grim Reaping. Available online: http://reports.weforum.org/global-risks-2018/grim-reaping/ (accessed on 10 December 2017).

- United Nations World Water Assessment Programme (WWAP). The United Nations World Water Development Report 2017, Wastewater: The Untapped Resource; UNESCO: Paris, France, 2017. [Google Scholar]

- Lautze, J.; Stander, E.; Drechsel, P.; da Silva, A.K.; Keraita, B. Global Experiences in Water Reuse; International Water Management Institute (IWMI): Colombo, Sri Lanka; CGIAR Research Program on Water, Land and Ecosystems (WLE): Montpellier, France, 2014; 31p. [Google Scholar]

- European Commission. Water is too Precious to Waste. Available online: http://ec.europa.eu/environment/water/pdf/water_reuse_factsheet_en.pdf (accessed on 13 January 2018).

- Hwang, H.; Forrester, A.; Lansey, K. Decentralized water reuse: Regional water supply system resilience benefits. Procedia Eng. 2014, 70, 853–856. [Google Scholar] [CrossRef]

- Lesjean, B.; Leiknes, T.; Hochstrat, R.; Schories, R.; Gonzalez, G.; Gonzalez, A. MBR: Technology gets timely EU cash boost. Filtr. Sep. 2006, 43, 20–23. [Google Scholar] [CrossRef]

- Hai, F.I.; Yamamoto, K.; Lee, C.-H. Membrane Biological Reactors: Theory, Modeling, Design, Management and Applications to Wastewater Reuse; IWA Publishing: London, UK, 2014; 504p, ISBN 9781780400655. [Google Scholar]

- Geilvoet, S.P. The Delft Filtration Characterisation Method: Assessing Membrane Bioreactor Activated Sludge Filterability. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 12 February 2010. [Google Scholar]

- Global $8.27 Bn Membrane Bioreactor Market, 2025. Available online: http://markets.businessinsider.com/news/stocks/global-8-27-bn-membrane-bioreactor-market-2025-1005680257 (accessed on 15 December 2017).

- Böhm, L.; Drews, A.; Prieske, H.; Bérubé, P.R.; Kraume, M. The importance of fluid dynamics for MBR fouling mitigation. Bioresour. Technol. 2012, 122, 50–61. [Google Scholar] [CrossRef] [PubMed]

- Ivanovic, I.; Leiknes, T.O. The biofilm membrane bioreactor (BF-MBR)—A review. Desalination Water Treat. 2012, 37, 288–295. [Google Scholar] [CrossRef]

- Ivanovic, I.; Leiknes, T.O.; Ødegaard, H. Fouling control by reduction of submicron particles in a BF-MBR with an integrated flocculation zone in the membrane reactor. Sep. Sci. Technol. 2008, 43, 1871–1883. [Google Scholar] [CrossRef]

- Yu, H.Y.; Xu, Z.K.; Lei, H.; Hu, M.X.; Yang, Q. Photoinduced graft polymerization of acrylamide on polypropylene microporous membranes for the improvement of antifouling characteristics in a submerged membrane-bioreactor. Sep. Purif. Technol. 2007, 53, 119–125. [Google Scholar] [CrossRef]

- Brookes, A.; Jefferson, B.; Guglielmi, G.; Judd, S.J. Sustainable Flux Fouling in a Membrane Bioreactor: Impact of Flux and MLSS. Sep. Sci. Technol. 2006, 41, 1279–1291. [Google Scholar] [CrossRef]

- Kraume, M.; Wedi, D.; Schaller, J.; Iversen, V.; Drews, A. Fouling in MBR: What use are lab investigations for full scale operation? Desalination 2009, 236, 94–103. [Google Scholar] [CrossRef]

- Yusuf, Z.; Wahab, N.A.; Abusam, A. Neural Network-based Model Predictive Control with CPSOGSA for SMBR Filtration. Int. J. Electr. Comput. Eng. 2017, 7, 1538–1545. [Google Scholar] [CrossRef]

- Song, W.; Li, Z.; Li, Y.; You, H.; Qi, P.; Liu, F.; Loy, D.A. Facile sol-gel coating process for anti-biofouling modification of poly (vinylidene fluoride) microfiltration membrane based on novel zwitterionic organosilica. J. Membr. Sci. 2018, 550, 266–277. [Google Scholar] [CrossRef]

- Gkotsis, P.K.; Mitrakas, M.M.; Tolkou, A.K.; Zouboulis, A.I. Batch and continuous dosing of conventional and composite coagulation agents for fouling control in a pilot-scale MBR. Chem. Eng. J. 2016, 311, 255–264. [Google Scholar] [CrossRef]

- Lee, J.C.; Kim, J.S.; Kang, I.J.; Cho, M.H.; Park, P.K.; Lee, C.H. Potential and limitations of alum or zeolite addition to improve the performance of a submerged membrane bioreactor. Water Sci. Technol. 2001, 43, 59–66. [Google Scholar] [CrossRef] [PubMed]

- Zarei, A.; Moslemi, M.; Mirzaei, H. The Combination of KMnO4 Oxidation and Polymeric Flocculation for the Mitigation of Membrane Fouling in a Membrane Bioreactor. Sep. Purif. Technol. 2016, 159, 124–134. [Google Scholar] [CrossRef]

- Drews, A. Membrane fouling in membrane bioreactors—Characterisation, contradictions, cause and cures. J. Membr. Sci. 2010, 363, 1–28. [Google Scholar] [CrossRef]

- Zheng, Y.; Zhang, W.; Tang, B.; Ding, J.; Zheng, Y.; Zhang, Z. Membrane fouling mechanism of biofilm-membrane bioreactor (BF-MBR): Pore blocking model and membrane cleaning. Bioresour. Technol. 2018, 250, 398–405. [Google Scholar] [CrossRef] [PubMed]

- Leiknes, T.; Ødegaard, H. The development of a biofilm membrane bioreactor. Desalination 2007, 202, 135–143. [Google Scholar] [CrossRef]

- Jin, L.; Ong, S.L.; Ng, H.Y. Fouling control mechanism by suspended biofilm carriers addition in submerged ceramic membrane bioreactors. J. Membr. Sci. 2013, 427, 250–258. [Google Scholar] [CrossRef]

- Arabi, S.; Nakhla, G. Impact of cation concentrations on fouling in membrane bioreactors. J. Membr. Sci. 2009, 343, 110–118. [Google Scholar] [CrossRef]

- Chang, I.S.; Judd, S.J. Domestic wastewater treatment by a submerged MBR (membrane bio-reactor) with enhanced air sparging. Water Sci. Technol. 2003, 47, 149–154. [Google Scholar] [CrossRef] [PubMed]

- Judd, S. The MBR Book Principles and Applications of Membrane Bioreactors in Water and Wastewater Treatment, 1st ed.; Elsevier Ltd.: London, UK, 2006; p. 325, ISBN-13 978-1-85-617481-7. [Google Scholar]

- Le-Clech, P.; Chen, V.; Fane, T.A.G. Fouling in membrane bioreactors used in wastewater treatment. J. Membr. Sci. 2006, 284, 17–53. [Google Scholar] [CrossRef]

- Mafirad, S.; Mehrnia, M.R.; Azami, H.; Sarrafzadeh, M.H. Effects of biofilm formation on membrane performance in submerged membrane bioreactors. Biofouling 2011, 27, 477–485. [Google Scholar] [CrossRef] [PubMed]

- Meng, F.; Zhang, S.; Oh, Y.; Zhou, Z.; Shin, H.-S.; Chae, S.-R. Fouling in membrane bioreactors: An updated review. Water Res. 2017, 114, 151–180. [Google Scholar] [CrossRef] [PubMed]

- Fallis, A. Experimental Methods in Wastewater Treatment. J. Chem. Inf. Model. 2013, 53. [Google Scholar] [CrossRef]

- Ferreira, M.L. Filterability and Sludge Concentration in Membrane Bioreactors. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 15 September 2011. [Google Scholar]

- Meng, F.; Shi, B.; Yang, F.; Zhang, H. Effect of hydraulic retention time on membrane fouling and biomass characteristics in submerged membrane bioreactors. Bioprocess Biosyst. Eng. 2007, 30, 359–367. [Google Scholar] [CrossRef] [PubMed]

- Ji, L.; Zhou, J. Influence of aeration on microbial polymers and membrane fouling in submerged membrane bioreactors. J. Membr. Sci. 2006, 276, 168–177. [Google Scholar] [CrossRef]

- Meng, F.; Zhang, H.; Yang, F.; Zhang, S.; Li, Y.; Zhang, X. Identification of activated sludge properties affecting membrane fouling in submerged membrane bioreactors. Sep. Purif. Technol. 2006, 51, 95–103. [Google Scholar] [CrossRef]

- Vanysacker, L.; Boerjan, B.; Declerck, P.; Vankelecom, I.F.J. Biofouling ecology as a means to better understand membrane biofouling. Appl. Microbiol. Biotechnol. 2014, 98, 8047–8072. [Google Scholar] [CrossRef] [PubMed]

- Wu, B.; Fane, A.G. Microbial relevant fouling in membrane bioreactors: Influencing factors, characterization, and fouling control. Membranes 2012, 2, 565–584. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Z.; Meng, F.; He, X.; Chae, S.-R.; An, Y.; Jia, X. Metaproteomic analysis of biocake proteins to understand membrane fouling in a submerged membrane bioreactor. Environ. Sci. Technol. 2015, 49, 1068–1077. [Google Scholar] [CrossRef] [PubMed]

- Deng, L.; Guo, W.; Hao, H.; Farzana, M.; Zuthi, R.; Zhang, J.; Liang, S.; Li, J.; Wang, J.; Zhang, X. Membrane fouling reduction and improvement of sludge characteristics by bioflocculant addition in submerged membrane bioreactor. Sep. Purif. Technol. 2015, 156, 450–458. [Google Scholar] [CrossRef]

- Lee, W.; Kang, S.; Shin, H. Sludge characteristics and their contribution to microfiltration in submerged membrane bioreactors. J. Membr. Sci. 2003, 216, 217–227. [Google Scholar] [CrossRef]

- Meng, F.; Chae, S.R.; Drews, A.; Kraume, M.; Shin, H.S.; Yang, F. Recent advances in membrane bioreactors (MBRs): Membrane fouling and membrane material. Water Res. 2009, 43, 1489–1512. [Google Scholar] [CrossRef] [PubMed]

- Meng, F.; Zhang, H.; Yang, F.; Li, Y.; Xiao, J.; Zhang, X. Effect of filamentous bacteria on membrane fouling in submerged membrane bioreactor. J. Membr. Sci. 2006, 272, 161–168. [Google Scholar] [CrossRef]

- Krzeminski, P. Activated Sludge Filterability and Full-Scale Membrane Bioreactor Operation. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 22 January 2013. [Google Scholar]

- Azami, H.; Sarrafzadeh, M.H.; Mehrnia, M.R. Influence of sludge rheological properties on the membrane fouling in submerged membrane bioreactor. Desalin. Water Treat. 2011, 34, 117–122. [Google Scholar] [CrossRef]

- Chang, I.S.; Kim, S.N. Wastewater treatment using membrane filtration—Effect of biosolids concentration on cake resistance. Process Biochem. 2005, 40, 1307–1314. [Google Scholar] [CrossRef]

- Wang, Z.; Chu, J.; Song, Y.; Cui, Y.; Zhang, H.; Zhao, X.; Li, Z.; Yao, J. Influence of operating conditions on the efficiency of domestic wastewater treatment in membrane bioreactors. Desalination 2009, 245, 73–81. [Google Scholar] [CrossRef]

- Radjenović, J.; Matošić, M.; Mijatović, I. Membrane bioreactor (MBR) as an advanced wastewater treatment technology. In Handbook of Environmental Chemistry; Springer: Berlin/Heidelberg, Germany, 2008; Volume 5, pp. 37–101. [Google Scholar]

- Iorhemen, O.T.; Hamza, R.A.; Tay, J.H. Membrane bioreactor (MBR) technology for wastewater treatment and reclamation: Membrane fouling. Membranes 2016, 6, 33. [Google Scholar] [CrossRef] [PubMed]

- Reid, E.; Liu, X.; Judd, S.J. Sludge characteristics and membrane fouling in full-scale submerged membrane bioreactors. Desalination 2008, 219, 240–249. [Google Scholar] [CrossRef]

- Fan, F.; Zhou, H. Interrelated Effects of Aeration and Mixed Liquor Fractions on Membrane Fouling for Submerged Membrane Bioreactor Processes in Wastewater Treatment. Environ. Sci. Technol. 2007, 41, 2523–2528. [Google Scholar] [CrossRef] [PubMed]

- Hernandez Rojas, M.E.; Van Kaam, R.; Schetrite, S.; Albasi, C. Role and variations of supernatant compounds in submerged membrane bioreactor fouling. Desalination 2005, 17, 95–107. [Google Scholar] [CrossRef]

- Salazar-Peláez, M.L.; Morgan-Sagastume, J.M.; Noyola, A. Influence of hydraulic retention time on UASB post-treatment with UF membranes. Water Sci. Technol. 2011, 64, 2299–2305. [Google Scholar] [CrossRef] [PubMed]

- Chen, R.; Nie, Y.; Hu, Y.; Miao, R.; Utashiro, T.; Li, Q.; Xu, M.; Li, Y.Y. Fouling behaviour of soluble microbial products and extracellular polymeric substances in a submerged anaerobic membrane bioreactor treating low-strength wastewater at room temperature. J. Membr. Sci. 2017, 531, 1–9. [Google Scholar] [CrossRef]

- Jiang, T. Characterization and Modelling of Soluble Microbial Products in Membrane Bioreactors. Ph.D. Thesis, Ghent University, Gent, Belgium, 2007. [Google Scholar]

- Xie, W.M.; Ni, B.J.; Sheng, G.P.; Seviour, T.; Yu, H.Q. Quantification and kinetic characterization of soluble microbial products from municipal wastewater treatment plants. Water Res. 2016, 88, 703–710. [Google Scholar] [CrossRef] [PubMed]

- Deng, L.; Guo, W.; Ngo, H.H.; Zhang, J.; Liang, S.; Xia, S.; Zhang, Z.; Li, J. A comparison study on membrane fouling in a sponge-submerged membrane bioreactor and a conventional membrane bioreactor. Bioresour. Technol. 2014, 165, 69–74. [Google Scholar] [CrossRef] [PubMed]

- Jørgensen, M.K.; Nierychlo, M.; Nielsen, A.H.; Larsen, P.; Christensen, M.L.; Nielsen, P.H. Unified understanding of physico-chemical properties of activated sludge and fouling propensity. Water Res. 2017, 120, 117–132. [Google Scholar] [CrossRef] [PubMed]

- Van den Broeck, R.; Krzeminski, P.; Van Dierdonck, J.; Gins, G.; Lousada-Ferreira, M.; Van Impe, J.F.M.; van der Graaf, J.H.J.M.; Smets, I.Y.; van Lier, J.B. Activated sludge characteristics affecting sludge filterability in municipal and industrial MBRs: Unraveling correlations using multi-component regression analysis. J. Membr. Sci. 2011, 378, 330–338. [Google Scholar] [CrossRef]

- Liu, Y.; Fang, H.H.P. Influences of extracellular polymeric substances (EPS) on flocculation, settling, and dewatering of activated sludge. Crit. Rev. Environ. Sci. Technol. 2003, 33, 237–273. [Google Scholar] [CrossRef]

- Tu, X.; Zhang, S.; Xu, L.; Zhang, M.; Zhu, J. Performance and fouling characteristics in a membrane sequence batch reactor (MSBR) system coupled with aerobic granular sludge. Desalination 2010, 261, 191–196. [Google Scholar] [CrossRef]

- Jang, N.; Ren, X.; Choi, K.; Kim, I.S. Comparison of membrane biofouling in nitrification and denitrification for the membrane bioreactor (MBR). Water Sci. Technol. 2006, 53, 43–49. [Google Scholar] [CrossRef] [PubMed]

- Nittami, T.; Tokunaga, H.; Satoh, A.; Takeda, M.; Matsumoto, K. Influence of surface hydrophilicity on polytetrafluoroethylene flat sheet membrane fouling in a submerged membrane bioreactor using two activated sludges with different characteristics. J. Membr. Sci. 2014, 463, 183–189. [Google Scholar] [CrossRef]

- Tian, Y.; Chen, L.; Zhang, S.; Cao, C.; Zhang, S. Correlating membrane fouling with sludge characteristics in membrane bioreactors: An especial interest in EPS and sludge morphology analysis. Bioresour. Technol. 2011, 102, 8820–8827. [Google Scholar] [CrossRef] [PubMed]

- Rahimi, Y.; Torabian, A.; Mehrdadi, N.; Habibi-Rezaie, M.; Pezeshk, H.; Nabi-Bidhendi, G.R. Optimizing aeration rates for minimizing membrane fouling and its effect on sludge characteristics in a moving bed membrane bioreactor. J. Hazard. Mater. 2011, 186, 1097–1102. [Google Scholar] [CrossRef] [PubMed]

- Delrue, F.; Stricker, A.E.; Mietton-Peuchot, M.; Racault, Y. Relationships between mixed liquor properties, operating conditions and fouling on two full-scale MBR plants. Desalination 2011, 272, 9–19. [Google Scholar] [CrossRef]

- Wang, Z.; Wu, Z.; Tang, S. Impact of temperature seasonal change on sludge characteristics and membrane fouling in a submerged membrane bioreactor. Sep. Sci. Technol. 2010, 45, 920–927. [Google Scholar] [CrossRef]

- Li, X.F.; Zhang, L.N.; Du, G.C. Influence of sludge discharge on sludge settleability and membrane flux in a membrane bioreactor. Environ. Technol. 2010, 31, 1289–1294. [Google Scholar] [CrossRef] [PubMed]

- Kim, D.S.; Kang, J.S.; Lee, Y.M. The Influence of Membrane Surface Properties on Fouling in a Membrane Bioreactor for Wastewater Treatment. Sep. Sci. Technol. 2005, 39, 833–854. [Google Scholar] [CrossRef]

- Gitis, V.; Rothenberg, G. Ceramic Membranes: New Opportunities and Practical Applications; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2016; p. 394. ISBN 978-3-527-33493-3. [Google Scholar]

- Iversen, V. Comprehensive Assessment of Flux Enhancers in Membrane Bioreactors for Wastewater Treatment. Ph.D. Thesis, Technical University of Berlin, Berlin, Germany, 4 October 2010. [Google Scholar]

- Yonekawa, H.; Tomita, Y.; Watanabe, Y. Behavior of micro-particles in monolith ceramic membrane filtration with pre-coagulation. Water Sci. Technol. 2004, 50, 317–325. [Google Scholar] [CrossRef] [PubMed]

- Dickhout, J.M.; Moreno, J.; Biesheuvel, P.M.; Boels, L.; Lammertink, R.G.H.; de Vos, W.M. Produced water treatment by membranes: A review from a colloidal perspective. J. Colloid Interface Sci. 2017, 487, 523–534. [Google Scholar] [CrossRef] [PubMed]

- Jin, L.; Ong, S.L.; Ng, H.Y. Comparison of fouling characteristics in different pore-sized submerged ceramic membrane bioreactors. Water Res. 2010, 44, 5907–5918. [Google Scholar] [CrossRef] [PubMed]

- Meabe, E.; Lopetegui, J.; Ollo, J.; Lardies, S. Ceramic Membrane Bioreactor: Potential applications and challenges for the future. In Proceedings of the MBR Asia International Conference, Kuala Lumpur, Malaysia, 25–26 April 2011. [Google Scholar]

- Shi, X.; Tal, G.; Hankins, N.P.; Gitis, V. Fouling and cleaning of ultrafiltration membranes: A review. J. Water Process Eng. 2014, 1, 121–138. [Google Scholar] [CrossRef]

- Wang, Z.; Ma, J.; Tang, C.Y.; Kimura, K.; Wang, Q.; Han, X. Membrane cleaning in membrane bioreactors: A review. J. Membr. Sci. 2014, 468, 276–307. [Google Scholar] [CrossRef]

- Chen, F.; Bi, X.; Ng, H.Y. Effects of bio-carriers on membrane fouling mitigation in moving bed membrane bioreactor. J. Membr. Sci. 2016, 499, 134–142. [Google Scholar] [CrossRef]

- Lee, S.J.; Dilaver, M.; Park, P.K.; Kim, J.H. Comparative analysis of fouling characteristics of ceramic and polymeric microfiltration membranes using filtration models. J. Membr. Sci. 2013, 432, 97–105. [Google Scholar] [CrossRef]

- Larrea, A.; Rambor, A.; Fabiyi, M. Ten years of industrial and municipal membrane bioreactor (MBR) systems—Lessons from the field. Water Sci. Technol. 2014, 70, 279–288. [Google Scholar] [CrossRef] [PubMed]

- Bérubé, P.R.; Hall, E.R.; Sutton, P.M. Parameters Governing Permeate Flux in an Anaerobic Membrane Bioreactor Treating Low-Strength Municipal Wastewaters: A Literature Review. Water Environ. Res. 2006, 78, 887–896. [Google Scholar] [CrossRef] [PubMed]

- Lin, H.; Gao, W.; Meng, F.; Liao, B.-Q.; Leung, K.-T.; Zhao, L.; Chen, J.; Hong, H. Membrane Bioreactors for Industrial Wastewater Treatment: A Critical Review. Crit. Rev. Environ. Sci. Technol. 2012, 42, 677–740. [Google Scholar] [CrossRef]

- Park, S.H.; Park, Y.G.; Lim, J.-L.; Kim, S. Evaluation of ceramic membrane applications for water treatment plants with a life cycle cost analysis. Desalin. Water Treat. 2015, 54, 973–979. [Google Scholar] [CrossRef]

- Çiçek, N.; Franco, H.P.; Suidan, M.T.; Urbain, V.; Manem, J. Characterization and Comparison of a Membrane Bioreactor and a Conventional Activated-Sludge System in the Treatment of Wastewater Containing High-Molecular-Weight Compounds. Water Environ. Res. 1999, 71, 64–70. [Google Scholar] [CrossRef]

- Shang, R.; Verliefde, A.R.D.; Hu, J.; Heijman, S.G.J.; Rietveld, L.C. The impact of EfOM, NOM and cations on phosphate rejection by tight ceramic ultrafiltration. Sep. Purif. Technol. 2014, 132, 289–294. [Google Scholar] [CrossRef]

- Jeong, Y.; Kim, Y.; Jin, Y.; Hong, S.; Park, C. Comparison of filtration and treatment performance between polymeric and ceramic membranes in anaerobic membrane bioreactor treatment of domestic wastewater. Sep. Purif. Technol. 2018, 199, 182–188. [Google Scholar] [CrossRef]

- Hofs, B.; Ogier, J.; Vries, D.; Beerendonk, E.F.; Cornelissen, E.R. Comparison of ceramic and polymeric membrane permeability and fouling using surface water. Sep. Purif. Technol. 2011, 79, 365–374. [Google Scholar] [CrossRef]

- Jeong, Y.; Cho, K.; Kwon, E.E.; Tsang, Y.F.; Rinklebe, J.; Park, C. Evaluating the feasibility of pyrophyllite-based ceramic membranes for treating domestic wastewater in anaerobic ceramic membrane bioreactors. Chem. Eng. J. 2017, 328, 567–573. [Google Scholar] [CrossRef]

- Jeong, Y.; Lee, S.; Hong, S.; Park, C. Preparation, characterization and application of low-cost pyrophyllite-alumina composite ceramic membranes for treating low-strength domestic wastewater. J. Membr. Sci. 2017, 536, 108–115. [Google Scholar] [CrossRef]

- Kaniganti, C.M.; Emani, S.; Thorat, P.; Uppaluri, R. Microfiltration of Synthetic Bacteria Solution Using Low Cost Ceramic Membranes. Sep. Sci. Technol. 2015, 50, 121–135. [Google Scholar] [CrossRef]

- Li, L.; Chen, M.; Dong, Y.; Dong, X.; Cerneaux, S.; Hampshire, S.; Caoa, J.; Zhua, L.; Zhua, Z.; Liu, J. A low-cost alumina-mullite composite hollow fiber ceramic membrane fabricated via phase-inversion and sintering method. J. Eur. Ceram. Soc. 2016, 36, 2057–2066. [Google Scholar] [CrossRef]

- Lorente-ayza, M.; Pérez-fernández, O.; Alcalá, R.; Sánchez, E.; Mestre, S.; Coronas, J.; Menéndez, M. Comparison of porosity assessment techniques for low-cost ceramic membranes. Boletín de La Sociedad Española de Cerámica Y Vidrio 2017, 56, 29–38. [Google Scholar] [CrossRef]

- Tewari, P.K.; Singh, R.K.; Batra, V.S.; Balakrishnan, M. Membrane bioreactor (MBR) for wastewater treatment: Filtration performance evaluation of low cost polymeric and ceramic membranes. Sep. Purif. Technol. 2010, 71, 200–204. [Google Scholar] [CrossRef]

- Chemometric Analysis for Spectroscopy. Available online: http://www.camo.com/downloads/resources/application_notes/Chemometric%20Analysis%20for%20Spectroscopy.pdf (accessed on 19 July 2018).

- Singh, K.P.; Malik, A.; Mohan, D.; Sinha, S.; Singh, V.K. Chemometric data analysis of pollutants in wastewater—A case study. Anal. Chim. Acta 2005, 532, 15–25. [Google Scholar] [CrossRef]

- Torgersen, G.; Rød, J.K.; Kvaal, K.; Bjerkholt, J.T.; Lindholm, O.G. Evaluating flood exposure for properties in Urban areas using a multivariate modelling technique. Water 2017, 9, 318. [Google Scholar] [CrossRef]

- Philippe, N.; Racault, Y.; Stricker, A.E.; Spérandio, M.; Vanrolleghem, P.A. Modelling the long-term evolution of permeability in full-scale municipal MBRs: A multivariate statistical modelling approach. Procedia Eng. 2012, 44, 574–580. [Google Scholar] [CrossRef]

- Kaneko, H.; Funatsu, K. Visualization of Models Predicting Transmembrane Pressure Jump for Membrane Bioreactor. Ind. Eng. Chem. Res. 2012, 51, 9679–9686. [Google Scholar] [CrossRef]

- De Temmerman, L.; Naessens, W.; Maere, T.; Marsili-Libelli, S.; Villez, K.; Nopens, I.; Temmink, H.; Nopens, I. Detecting membrane fouling occurrences in a full-scale membrane bioreactor with principal component analysis. In Proceedings of the 11th IWA Conference on Instrumentation Control and Automation (ICA), Narbonne, France, 18–20 September 2013. [Google Scholar]

- Ji, J.; Qiu, J.; Wong, F.; Li, Y. Enhancement of filterability in MBR achieved by improvement of supernatant and floc characteristics via filter aids addition. Water Res. 2008, 42, 3611–3622. [Google Scholar] [CrossRef] [PubMed]

- Wu, J.; Huang, X. Use of ozonation to mitigate fouling in a long-term membrane bioreactor. Bioresour. Technol. 2010, 101, 6019–6027. [Google Scholar] [CrossRef] [PubMed]

- Todt, D.; Heistad, A.; Jenssen, P.D. Load and distribution of organic matter and nutrients in a separated household wastewater stream. Environ. Technol. 2015, 36, 1584–1593. [Google Scholar] [CrossRef] [PubMed]

- Ying, Z.; Ping, G. Effect of powdered activated carbon dosage on retarding membrane fouling in MBR. Sep. Purif. Technol. 2006, 52, 154–160. [Google Scholar] [CrossRef]

- Judd, S. The status of membrane bioreactor technology. Trends Biotechnol. 2008, 26, 109–116. [Google Scholar] [CrossRef] [PubMed]

- Rosenberg, M.; Gutnick, D.; Rosenberg, E. Adherence of bacteria to hydrocarbons: A simple method for measuring cell-surface hydrophobicity. FEMS Microbiol. Lett. 1980, 9, 29–33. [Google Scholar] [CrossRef]

- Effect of MLSS on Flux—MLSS Paradox. Available online: http://onlinembr.info/membrane-process/effect-of-mlss-on-flux-mlss-paradox/ (accessed on 22 January 2018).

- Brookes, A.; Judd, S.; Reid, E.; Germain, E.; Smith, S.; Alvarez-Vazquez, H.; Le-Clech, P.; Stephenson, T.; Turra, E.; Jefferson, B. Biomass characterisation in membrane bioreactors. In Proceedings of the International Membrane Science and Technology Conference (IMSTEC), Sydney, Australia, 10–14 November 2003. [Google Scholar]

- Jefferson, B.; Brookes, A.; Le-Clech, P.; Judd, S.J. Methods for understanding organic fouling in MBRs. Water Sci. Technol. 2004, 49, 237–244. [Google Scholar] [CrossRef] [PubMed]

- Huang, X.; Wu, J. Improvement of membrane filterability of the mixed liquor in a membrane bioreactor by ozonation. J. Membr. Sci. 2008, 318, 210–216. [Google Scholar] [CrossRef]

- Chae, S.R.; Ahn, Y.T.; Kang, S.T.; Shin, H.S. Mitigated membrane fouling in a vertical submerged membrane bioreactor (VSMBR). J. Membr. Sci. 2006, 280, 572–581. [Google Scholar] [CrossRef]

- Ng, H.Y.; Hermanowicz, S.W. Membrane bioreactor operation at short solids retention times: Performance and biomass characteristics. Water Res. 2005, 39, 981–992. [Google Scholar] [CrossRef] [PubMed]

- Fan, F.; Zhou, H.; Husain, H. Identification of wastewater sludge characteristics to predict critical flux for membrane bioreactor processes. Water Res. 2006, 40, 205–212. [Google Scholar] [CrossRef] [PubMed]

- Wu, J.; Huang, X. Effect of mixed liquor properties on fouling propensity in membrane bioreactors. J. Membr. Sci. 2009, 342, 88–96. [Google Scholar] [CrossRef]

- Lee, W.-N.; Chang, I.-S.; Hwang, B.-K.; Park, P.-K.; Lee, C.-H.; Huang, X. Changes in biofilm architecture with addition of membrane fouling reducer in a membrane bioreactor. Process Biochem. 2007, 42, 655–661. [Google Scholar] [CrossRef]

- Kunacheva, C.; Stuckey, D. Analytical methods for soluble microbial products (SMP) and extracellular polymers (ECP) in wastewater treatment systems: A review. Water Res. 2014, 61, 1–18. [Google Scholar] [CrossRef] [PubMed]

- Lesjean, B.; Rosenberger, S.; Laabs, C.; Jekel, M.; Gnirss, R.; Amy, G. Correlation between membrane fouling and soluble/colloidal organic substances in membrane bioreactors for municipal wastewater treatment. Water Sci. Technol. 2005, 51, 1–8. [Google Scholar] [CrossRef] [PubMed]

- CAMO. The Unscrambler, Tutorials CAMO Process AS 2006; CAMO Software AS: Oslo, Norway, 2006. [Google Scholar]

- Deng, L.; Guo, W.; Hao Ngo, H.; Zhang, H.; Wang, J.; Li, J.; Xia, S.; Wu, Y. Biofouling and control approaches in membrane bioreactors. Bioresour. Technol. 2016, 221, 656–665. [Google Scholar] [CrossRef] [PubMed]

- Isma Aida, M.I.; Idris, A.; Omar, R.; Razreena Putri, A.R. Effects of SRT and HRT on Treatment Performance of MBR and Membrane Fouling. Int. J. Chem. Mol. Nucl. Mater. Metall. Eng. 2014, 8, 488–492. [Google Scholar]

- Van den Broeck, R.; Van Dierdonck, J.; Nijskens, P.; Dotremont, C.; Krzeminski, P.; van der Graaf, J.H.J.M.; van Lier, J.B.; Van Impe, J.F.M.; Smets, I.Y. The influence of solids retention time on activated sludge bioflocculation and membrane fouling in a membrane bioreactor (MBR). J. Membr. Sci. 2012, 401–402, 48–55. [Google Scholar] [CrossRef]

- Yigit, N.O.; Harman, I.; Civelekoglu, G.; Koseoglu, H.; Cicek, N.; Kitis, M. Membrane fouling in a pilot-scale submerged membrane bioreactor operated under various conditions. Desalination 2008, 231, 124–132. [Google Scholar] [CrossRef]

- Malamis, S.; Andreadakis, A. Fractionation of proteins and carbohydrates of extracellular polymeric substances in a membrane bioreactor system. Bioresour. Technol. 2009, 100, 3350–3357. [Google Scholar] [CrossRef] [PubMed]

- Sivchenko, N.; Kvaal, K.; Ratnaweera, H. Evaluation of image texture recognition techniques in application to wastewater coagulation. Cogent Eng. 2016, 3. [Google Scholar] [CrossRef]

- Jiang, T.; Kennedy, M.D.; Guinzbourg, B.F.; Vanrolleghem, P.A.; Schippers, J.C. Optimising the operation of a MBR pilot plant by quantitative analysis of the membrane fouling mechanism. Water Sci. Technol. 2005, 51, 19–25. [Google Scholar] [CrossRef] [PubMed]

- Le Clech, P.; Jefferson, B.; Chang, I.S.; Judd, S.J. Critical flux determination by the flux-step method in a submerged membrane bioreactor. J. Membr. Sci. 2003, 227, 81–93. [Google Scholar] [CrossRef]

- Ognier, S.; Wisniewski, C.; Grasmick, A. Membrane bioreactor fouling in sub-critical filtration conditions: A local critical flux concept. J. Membr. Sci. 2004, 229, 171–177. [Google Scholar] [CrossRef]

- Miller, D.J.; Kasemset, S.; Paul, D.R.; Freeman, B.D. Comparison of membrane fouling at constant flux and constant transmembrane pressure conditions. J. Membr. Sci. 2014, 454, 505–515. [Google Scholar] [CrossRef]

| Parameter | Correlation with the Fouling | Possible Fouling Mechanism | References |

|---|---|---|---|

| MLSS 1 | Positive | Intense cake layer formation on the membrane surface. Increase in the suspension viscosity. Excessive growth of filamentous bacteria. Increase in microbial metabolic products such as SMP 2 and EPS 3, which are the major foulants. | [34,45,46,47,48,49,50,51] |

| MLSS 1 | Negative (irreversible fouling) | MLSS 1 12–18 g/L: The formed cake layer causes the prevention of the pore blocking development and induces an increased porosity of the cake layer. | [15,45] |

| COD 4 | Positive | COD 4 in the form of colloids proteins (adsorption mechanism) and other soluble organic fractions, causing irreversible fouling; higher organic load causes an increase in the production of specific EPS 3 and macromolecules in the SMP 2/EPS 3 fractions, deflocculation of the mixed liquor, and a fast formation of cake layers. | [9,29,35,52,53,54,55,56] |

| RH 6 (mostly hydrophilic membranes) | Negative | RH 6 increase: Enhanced AS 5 flocculation due to more intense hydrophobic interactions between sludge flocs, resulting in the formation of larger aggregates with less water content, and decreased interaction between the flocs and membrane surface. RH 6 decrease: Floc deterioration. | [57,58,59,60,61,62] |

| Positive | RH 6 increase: A formation of a thin cake layer, promoting the adhesion of proteins and carbohydrates in the form of SMP 2 on the membrane surface and its pores, resulting in irreversible and irrecoverable fouling. | [26,63] | |

| SVI (DSVI) 7 | Positive | High DSVI 7: Evolution of the flocs to the more irregular rougher shapes which more likely adhere to the surface of the membrane, intertwisting with the fibers. This forms a dense, non-porous cake with large thickness. The possible decrease of the bound protein and release of SMP 2 triggers deflocculation and the increase in fouling intensity. | [64,65,66,67,68,69] |

| Period | Days | Adjustments in Settings | Processes and Changes in the System |

|---|---|---|---|

| I | 1–20 | Jn(net) 1 = 8.2 LMH, Jn(gross) 2 = 37.6 LMH Filtration cycle settings: tfiltr = 300 s, trelaxI = 60 s, trelaxII = 120 s, tBW = 15 s RASpulse interval 3 = 1620 s, SRTav 4 =20 days | Conditions for sludge adaptation and conditional fouling of fresh membranes. |

| II | 21–34 | Jn(net) 1 = 5.3 LMH, Jn(gross) 2 = 32.6 LMH, RASpulse interval 3 = 740 s, SRTav 4 =20 days | System stabilization and an increase of sludge recirculation between separation and MBBR 5 chambers through the decrease of RAS 6 interval. |

| III | 35–36 | Jn(net) 1 = 12.2 LMH, Jn(gross) 2 = 44.0 LMH | Increase of net-flux in order to get close to TMP 7 jump. |

| IV | 37–44 | Jn(net) 1 = 10.0 LMH, Jn(gross) 2 = 43.7 LMH, tBW = 19.5, trelaxI = 30 | Prolongation of backwash in order to stabilize the system and TMP 7 jump. |

| V | 45–47 | CIP 8 I, 1% NaOCl, 2% Citric acid | TMP 7 ↓; Pn ↑ (58%), dPn/dt ↑ (88%)—removal of reversible and irreversible fouling. |

| VI | 48–77 | Same as in period IV, SRT = 31 days | Reproduction of last stable operation. |

| VII | 78–85 | CIP 8 II | TMP 7 ↓ (82%), Pn ↑ (82%), dPn/dt ↑. |

| VIII | 86–114 | Jn(net) 1 = 4.5 LMH, Jn(gross) 2 = 30.4 LMH, Infinite SRT (no wastage/sludge discharge) | Lower hydraulic loading. |

| Parameter | Value |

|---|---|

| MLSS, g/L | 5–6.5 |

| dMLSS/dt, (g/L)/day | −0.61–2.06 |

| DSVI, mL/g | 118–272 |

| dDSVI/dt, (mL/g)/day | −91–57 |

| RH, % | 20.5–61.5 |

| dRH/dt, %/day | −27–35 |

| CODdis, mgO2/L | 38–134 |

| dCOD/dt, mgO2/L/day | −35–27.5 |

| Period | Predictors | Responses |

|---|---|---|

| A | MLSS, dMLSS/dt, DSVI dDSVI/dt, RH, dRH/dt, CODdis, dCOD/dt | TMP, Pn, dPn/dt |

| B | MLSS, dMLSS/dt, DSVI dDSVI/dt, CODdis, dCOD/dt | TMP, Pn, dPn/dt |

| C | MLSS, dMLSS/dt, DSVI dDSVI/dt, CODdis, dCOD/dt | TMP, Pn, dPn/dt |

| TMPav 1, Bar | av dPn/dt 2 | avPn 3, LMH/Bar | DSVI 4, mL/g | dDSVI/dt 5 | MLSS 6, g/L | dMLSS/dt 7 | CODf 8, mgO2/L | dCOD/dt 9 | |

|---|---|---|---|---|---|---|---|---|---|

| max. | 266.16 | 0.26 | 125.45 | 185.41 | 5.52 | 5.74 | 0.35 | 69.80 | 5.00 |

| min. | 232.30 | 0.23 | 112.98 | 142.60 | −7.79 | 5.32 | −0.17 | 45.40 | −3.83 |

| average | 249.26 | 0.24 | 120.66 | 166.56 | −1.96 | 5.48 | 0.02 | 55.52 | −0.44 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kulesha, O.; Maletskyi, Z.; Ratnaweera, H. Multivariate Chemometric Analysis of Membrane Fouling Patterns in Biofilm Ceramic Membrane Bioreactor. Water 2018, 10, 982. https://doi.org/10.3390/w10080982

Kulesha O, Maletskyi Z, Ratnaweera H. Multivariate Chemometric Analysis of Membrane Fouling Patterns in Biofilm Ceramic Membrane Bioreactor. Water. 2018; 10(8):982. https://doi.org/10.3390/w10080982

Chicago/Turabian StyleKulesha, Olga, Zakhar Maletskyi, and Harsha Ratnaweera. 2018. "Multivariate Chemometric Analysis of Membrane Fouling Patterns in Biofilm Ceramic Membrane Bioreactor" Water 10, no. 8: 982. https://doi.org/10.3390/w10080982

APA StyleKulesha, O., Maletskyi, Z., & Ratnaweera, H. (2018). Multivariate Chemometric Analysis of Membrane Fouling Patterns in Biofilm Ceramic Membrane Bioreactor. Water, 10(8), 982. https://doi.org/10.3390/w10080982