1. Introduction

The utilization of biological methods in wastewater treatment has been a dominant technology worldwide for some time now [

1]. Despite its effectiveness in removing organic compounds, the biological aerobic wastewater treatment process’s main drawbacks are the large amounts of generated excess sludge and the costs of disposing it [

1]. According to the report for the European Commission [

2] the amount of sludge generated in the EU countries will reach 13,047,000 Mg

TS by the year 2020. The cost of disposing produced sludge usually exceeds 50% of the operating costs of waste water treatment plants [

3,

4].

The excess sludge, as a hazardous by-product of a biological sewage treatment process (utilizing activated sludge technology [

5]), has to be safely disposed. Several techniques of sludge disposal have been in use worldwide i.e., landfilling, anaerobic or aerobic stabilization, drying-incineration, land application [

3,

6] and recycled as building material [

3], however anaerobic digestion is a process most widely used at large sewage treatment plants [

5,

7,

8,

9,

10,

11,

12]. Digestion not only stabilizes the sludge, but also reduces its volume, improves dewaterability, makes it bacteriologically safe as well as reduces the operating costs of sewage treatment plants as a result of the biogas production. As the waste activated sludge is considered to be difficult to digest [

12], to achieve optimal results of an anaerobic stabilization, a sludge preconditioning process, called disintegration is recommended [

1,

3,

4,

6,

13,

14,

15,

16,

17,

18]. As the rate-limiting step in sludge digestion is the hydrolysis [

12], the main purpose of disintegration is to enhance the hydrolysis and consequently achieve enhanced stabilization, defined as improved solid destruction [

9] and dewatering of the digested sludge as well as enhanced biogas (methane) production [

3,

19,

20]). Listed effects can be achieved by installation of the disintegration devices into the sludge treatment line (between thickener and digestion tank).

Disintegration can be defined as a number of processes taking place in the sludge as a result of the influence of various types of energy, thus disintegration can be divided based on the energy introduced into the sludge into mechanical and non-mechanical.

Mechanical disintegration is the process based on the forces accompanying cavitation -operation of the shear forces, pressure changes, etc. [

19]. Non-mechanical disintegration can be divided into: physical disintegration (i.e., lower and higher temperature thermal process [

3,

6], freezing, microwave irradiation [

3,

15,

21], osmotic shock, electrokinetic disintegration [

3]), chemical disintegration (i.e., use of ozone [

22], alkali pre-treatment, acid pre-treatment [

14], etc.; it operates through hydrolysis and disintegration of complex macromolecules [

6]), biological disintegration (i.e., enzymatic cell lysis) [

5,

6,

7,

8,

9]. When disintegration of the sewage sludge uses more than one phenomena mentioned above, such complex conditioning methods are called hybrid disintegration. The technology of mechanical sludge pretreatment in mixers uses a rotating cutting tool designed specifically for the disintegration purposes. The shear forces generated during the rotation of the cutting tool causes at first the deagglomeration of sludge flocs and then cell destruction and as a result a release of its’ content into the aqueous phase.

Ultrasonic sludge conditioning is based upon the influence of the ultrasonic field of precisely specified parameters. Changes in sonicated sludge such as deagglomeration of flocs, microorganism cells disruption (cells lysis), sonochemical effects, rheological changes [

10,

23,

24] are mainly caused by the ultrasound cavitation, which involves formation, growth and collapse of microbubbles. The expansion and collapse of microbubbles are resulting in pressure and temperature gradients which is responsible for the disintegration effect. Studies conducted on laboratory and industrial scales provide information that ultrasonic sludge disintegration, used as a pretreatment method before digestion, is effective when carried out with low frequencies (20–30 kHz) and high intensity field (I > 1.0 W cm

−2) [

23]. Most of the research on excess sludge mechanical disintegration is focused on direct and technological effects of sludge pre-treatment [

1,

3,

4,

10,

12], less attention (especially in laboratory tests) is paid to the amount of energy used to achieve these effects. Even if the amounts of energy consumed are given, they are not related to the obtained (desired) effects, e.g., the effectiveness of the conditioning process, monitored as the increase of effect per unit of energy (i.e., g SCOD Wh

−1 etc.). In addition, research conducted in the context of economically feasible (under real-life/industrial operating conditions) energy consumption is also limited.

The aim of the presented study was to compare the various types of mechanical disintegration performed for the same sludge and compare the direct effects of the pre-conditioning process in relation to the energy consumption. The effectiveness of the processes, monitored as the increase of the disintegration products per unit of energy, has also been determined. Three different mechanical methods of sludge pre-conditioning were used: mechanical disintegration in laboratory or semi-technical scale homogenizing mixers, ultrasonic disintegration (US) and combined (hybrid) process (pre-mixing before sonication).

The direct effects of disintegration are monitored based upon changes in the sludge physico-chemical characteristics.

2. Materials and Methods

Excess sludge used in the research was procured from municipal sewage treatment plant located in the north east of Poland. The excess sludge was collected after the mechanical thickening, the concentration of the Total Solids in the sludge TS = 5.20%. During the research the sludge was stored in a polypropylene container at 4 °C. All the analysis was completed within the 48 h time period.

The characteristics of excess sludge before and after disintegration were described by selected parameters, such as TCOD, FCOD, SCOD, VFA, TN and TP (defined in

Section 2.1).

In order to determine the changes of FCOD, SCOD, VFA, TN and TP in the aqueous phase, the sludge was centrifuged at a speed of 20,000 rpm for 30 min at 18 °C in a refrigerated centrifuge, then it underwent filtration: for FCOD analysis through filter paper (pore size 3 µm), for SCOD, VFA, TN, TP vacuum filtration through a membrane cellulose acetate filter (pore size 0.45 µm) [

9,

11]. Total Chemical Oxygen Demand (TCOD) of sludge, FCOD, SCOD, VFA, TN and TP were analyzed using spectrophotometric method (Spectrophotometer HACH Lange DR5000 (Hach Lange GmbH, Duesseldorf, Germany) and HACH Lange cuvette tests). The characteristics of the excess sludge and its supernatant before disintegration are presented in

Table 1.

The ratio of volatile solids to total solids for the excess sludge used in the research was calculated at 80.88%, which indicates high content of organic substances [

25], the rest of the sludge parameters were presented in

Table 1. The results of the chemical disintegration utilizing NaOH solution were FCOD = 10,434.0 mg O

2·L

−1 and SCOD = 10,064.0 mg O

2·L

−1. The results of the chemical disintegration process used in the research corresponds to the maximum disintegration level [

20] and allows for the kd

DD—disintegration degree [

9,

10,

11,

20] to be calculated (Equation (1)).

During the research three methods of disintegration were used:

chemical disintegration utilizing 0.5 mol NaOH (for the calculation of kDD),

mechanical disintegration using the laboratory scale homogenizing mixer,

mechanical disintegration using the semi-technical scale sludge homogenizing mixer,

ultrasonic disintegration (US),

hybrid disintegration (combined mixing and US).

2.1. Evaluation of the Effects of Disintegration

One of the most common indicators of direct effects of disintegration is the disintegration degree. It is calculated as ratio of SCOD increase caused by analysed disintegration method in relation to the SCOD increase caused by the chemical disintegration [

20]. The degree of disintegration indicator kd

DD was calculated using the equation:

kdDD—disintegration degree,

SCODUT—Chemical Oxygen Demand of soluble substances in disintegrated sludge supernatant, mg O2·L−1,

SCODNT—Chemical Oxygen Demand of soluble substances in untreated sludge supernatant, mg O2·L−1,

SCOD

NaOH—SCOD of chemically disintegrated sludge supernatant. Disintegration performed using 0.5 mol NaOH solution, 1:1 ratio, for 22 h, mg O

2·L

−1 [

20].

The direct effects of the sludge disintegration were also evaluated based on the values of indicators of dispersion (kd

FCOD, kd

CST), lysis (kd

SCOD—indicating the rise in SCOD caused by release of cells’ content into aqueous phase), acidification (kd

VFA which describes the ratio of VFAs of disintegrated sludge supernatant (VFAs

UT) to VFAs of untreated sludge supernatant (VFAs

NT) [

9,

11]) and nutrients release (kd

TN, kd

TP) [

9,

11]. The indicators were calculated according to the formulas:

where

FCOD—Chemical Oxygen Demand of filtered sludge supernatant (fraction < 3 µm), mg O2·L−1,

SCOD—Chemical Oxygen Demand of soluble substances in supernatant (fraction < 0.45 µm), mg O2·L−1,

CST—Capillary Suction Time, s,

VFA—Volatile Fatty Acids as CH3COOH, mg·L−1,

TN—Total Nitrogen, mg N·L−1,

TP—Total Phosphate, mg PO4-P·L−1,

NT—before disintegration,

UT—after disintegration,

The efficiency of the process, defined as the increase of the disintegration products—∆FCOD, ∆SCOD per unit of energy, was calculated according to the formulas:

where

kdeFCOD—indicator of efficiency of ∆FCOD yield, mg O2·L−1 Wh−1,

kdeSCOD—indicator of efficiency of ∆SCOD yield, mg O2·L−1 Wh−1.

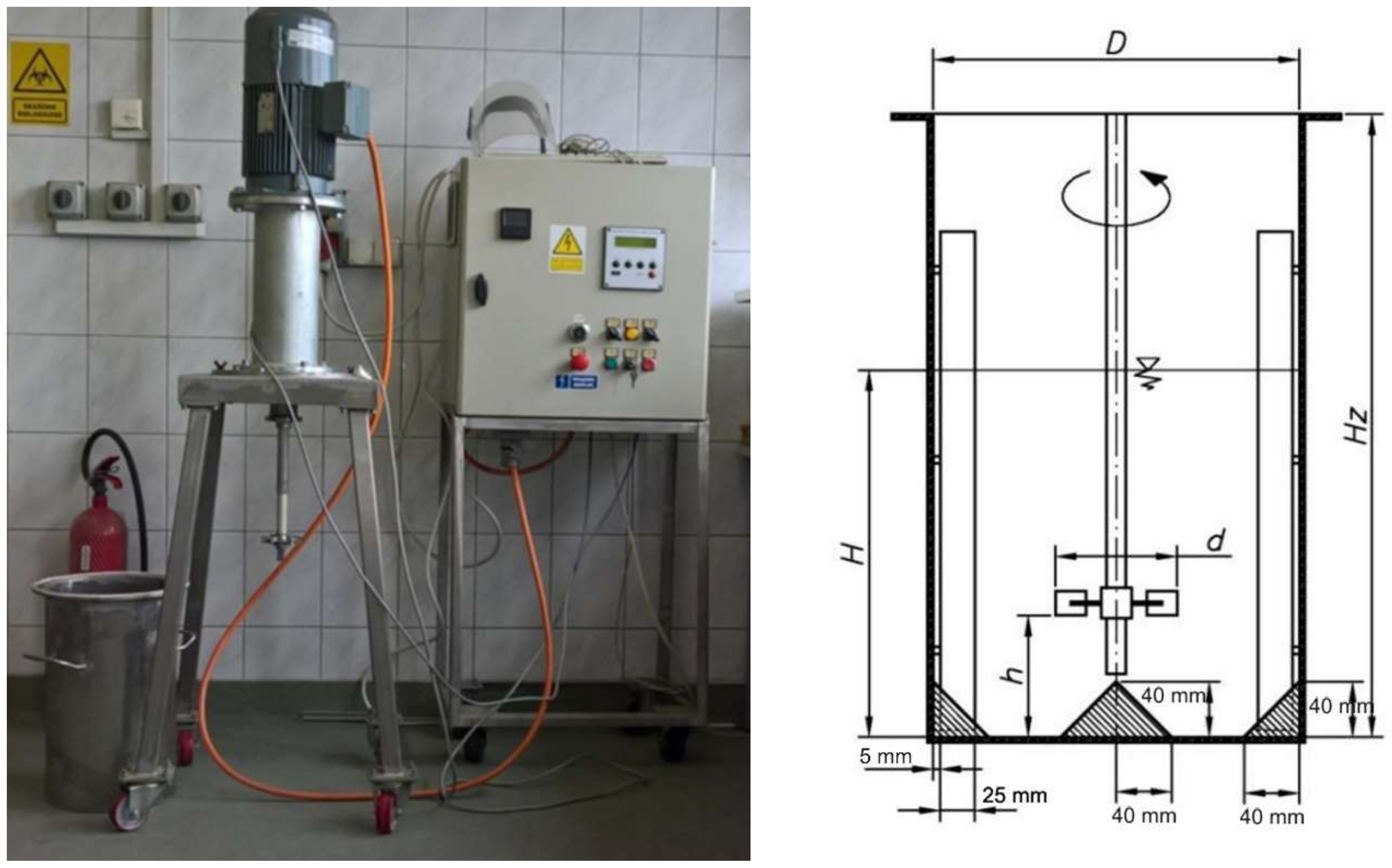

2.2. The Mechanical Disintegration in a Laboratory Scale Sludge Homogenizing Mixer

Excess sludge was mechanically disintegrated in the MPW-120 homogenizing mixer (

Figure 1) equipped with a vertical shaft with a 45 mm rotor (d

M = 45 mm) and a glass vessel of internal diameter D

M = 115 mm and operating capacity of 0.5 L; the power density PD was 280 W L

−1. This laboratory scale mixer is also equipped with control panel which allows for the parameters of the process to be set. The excess sludge was mixed for the time t

M = 60, 120, 180, 240 and 300 s at speed of 15,000 rpm, which was best suited for the sludge properties. The energy parameters of the process were monitored using Lumel n12 programmable digital panel meter and presented in

Table 2 [

11,

19,

26,

27].

2.3. The Mechanical Disintegration in a Semi-Technical Sludge Disintegrating Mixer

Excess sludge was disintegrated in a semi-technical, custom-built [

24], sludge disintegrating mixer. It was equipped with a 2200 W motor, a vertical shaft with a rotor of d = 80 mm and a steel tank of internal diameter D = 265 mm and operating capacity of 10 L (

Figure 2). The power density during the disintegration was 150 W L

−1. The disintegrator is equipped with digital control and frequency converter which allows for the disintegration parameters to be set as necessary.

The excess sludge underwent mechanical disintegration in the mixer for the time t

M = 300–1500 s at speed of 1000 rpm, which was best suited for the properties (Total Solids, TS) of the thickened excess sludge used during research. The energy parameters of the process were monitored using Lumel n12 programmable digital panel meter and presented in

Table 3 [

11,

19,

26,

27].

The results of the mechanical disintegration using laboratory scale sludge homogenizing mixer and semi-technical sludge disintegrating mixer were presented in

Section 3.1.

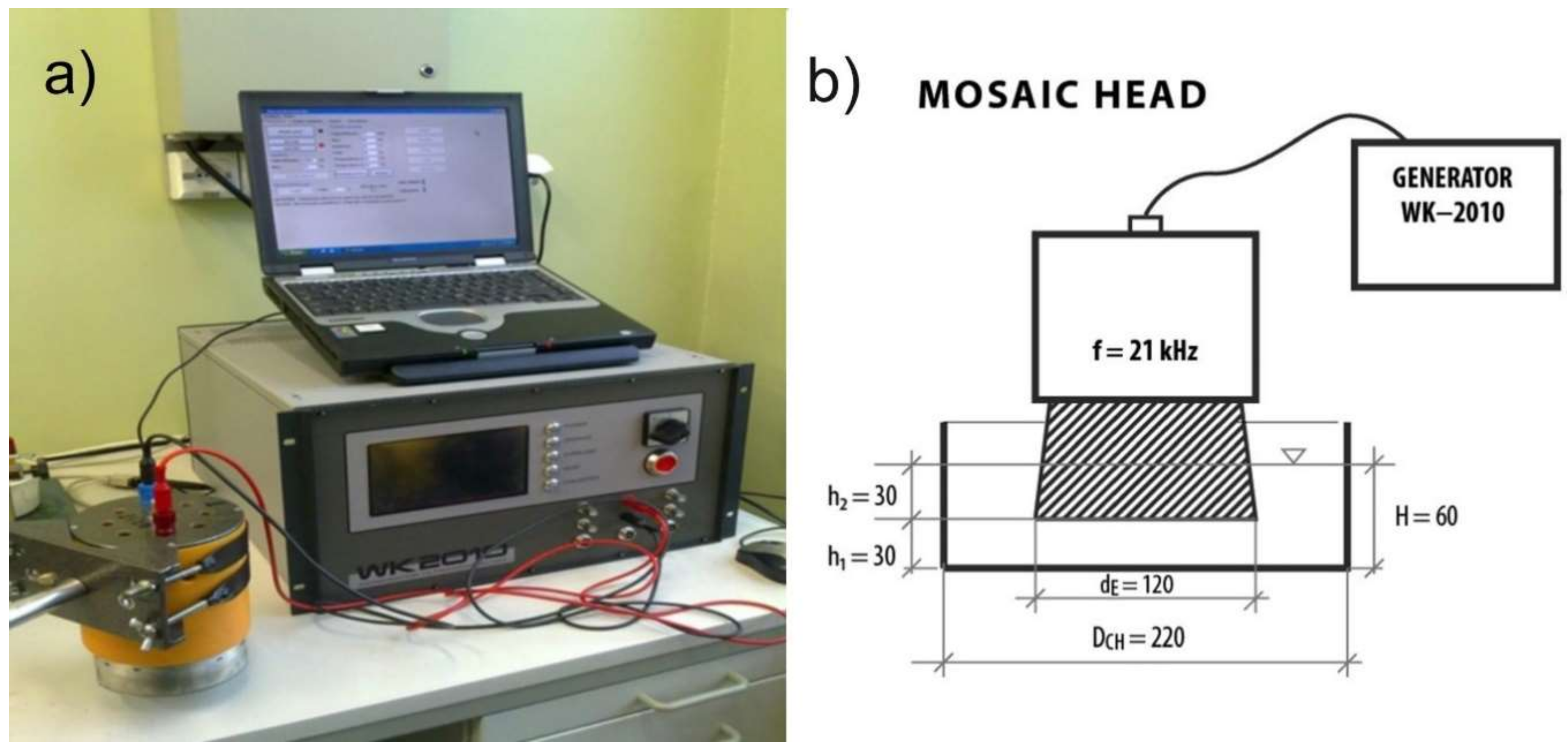

2.4. The Ultrasonic Disintegration

The ultrasonic disintegration process was conducted using a high-power, custom-built, sludge disintegrator [

10,

13]. A disintegrator setup consisted of a WK-2010 ultrasonic generator and mosaic head with short conical emitter of diameter d

E = 120 mm (

Figure 3). The diameter of the disintegration vessel was d

K = 220 mm, the length from the emitter to the bottom of the chamber was h

D = 3.0 cm.

The parameters of the ultrasonic disintegration were calculated according to the formulas [

10,

13]:

where

AE—surface area of the emitter; cm2,

ACH—surface area of the disintegration vessel; cm2,

TS—total solids; kgTS m−3

EV—volumetric energy, quantitatively corresponds to energy density, kWh m−3,

ES—specific energy, kWh kgTS−1,

PDUS—power density, kW m−3.

The ratio of the surface area of the emitter and the disintegration chamber was A

CH/A

E = 3.5. The sludge was sonicated under static conditions, at the frequency of 21 kHz. The disintegration process was performed for the generator power P

G = 950 W and head’s power P

UT = 330 W. The parameters of the ultrasonic disintegration were presented in

Table 4 [

9,

10,

11,

20,

26,

27,

28]. The energy parameters were monitored using Lumel n12 programmable digital panel meter.

The remaining parameters of the process were: the intensity of the ultrasound field in relation to the surface area of the emitter I

US(E) = 2.7 W cm

−2, the intensity of the ultrasound field in relation to the surface area of the chamber I

US(CH) = 0.85 W cm

−2, power density PD

US = 440 W L

−1 [

9,

11]. The effects of ultrasonic disintegration were presented in

Table 5 and

Figure 4.

2.5. The Hybrid Disintegration

The hybrid disintegration process consisted of two stages: mechanical mixing and ultrasonic disintegration. The primary step was used for dispersing sludge flocs and the secondary stage for cells’ lysis and acidification. The pre-conditioning was performed for selected techniques and parameters. The process was carried out using a semi-industrial homogenizing mixer for t

M = 1500 s (E

VM = 62.50 Wh L

−1, E

S = 1.2 Wh g

TS−1). Sludge after mechanical pre-treatment has undergone ultrasonic disintegration. Only two low US energy levels were used (E

V = 10 and 20 Wh L

−1, that is E

S = 0.19 and 0.38 Wh g

TS−1) for t

US = 82 and 164 s. The other parameters of the ultrasonic sludge conditioning were the same as for the single stage processes. The results of hybrid disintegration were presented in

Table 5 and

Figure 4.

2.6. Statistics

Statistical analysis was performed using the STATISTICA 13.1 software (Dell Inc., Texas, TX, USA). Analysis of variance (ANOVA) for single factor was performed, in which a disintegration process was a grouping variable, the Tuckey test was performed to analyze the sensitivity of differences between variables. The linear correlation between analyzed variables was evaluated by Pearson’s correlation coefficient. The level of sensitivity for the analysis was d = 0.05.

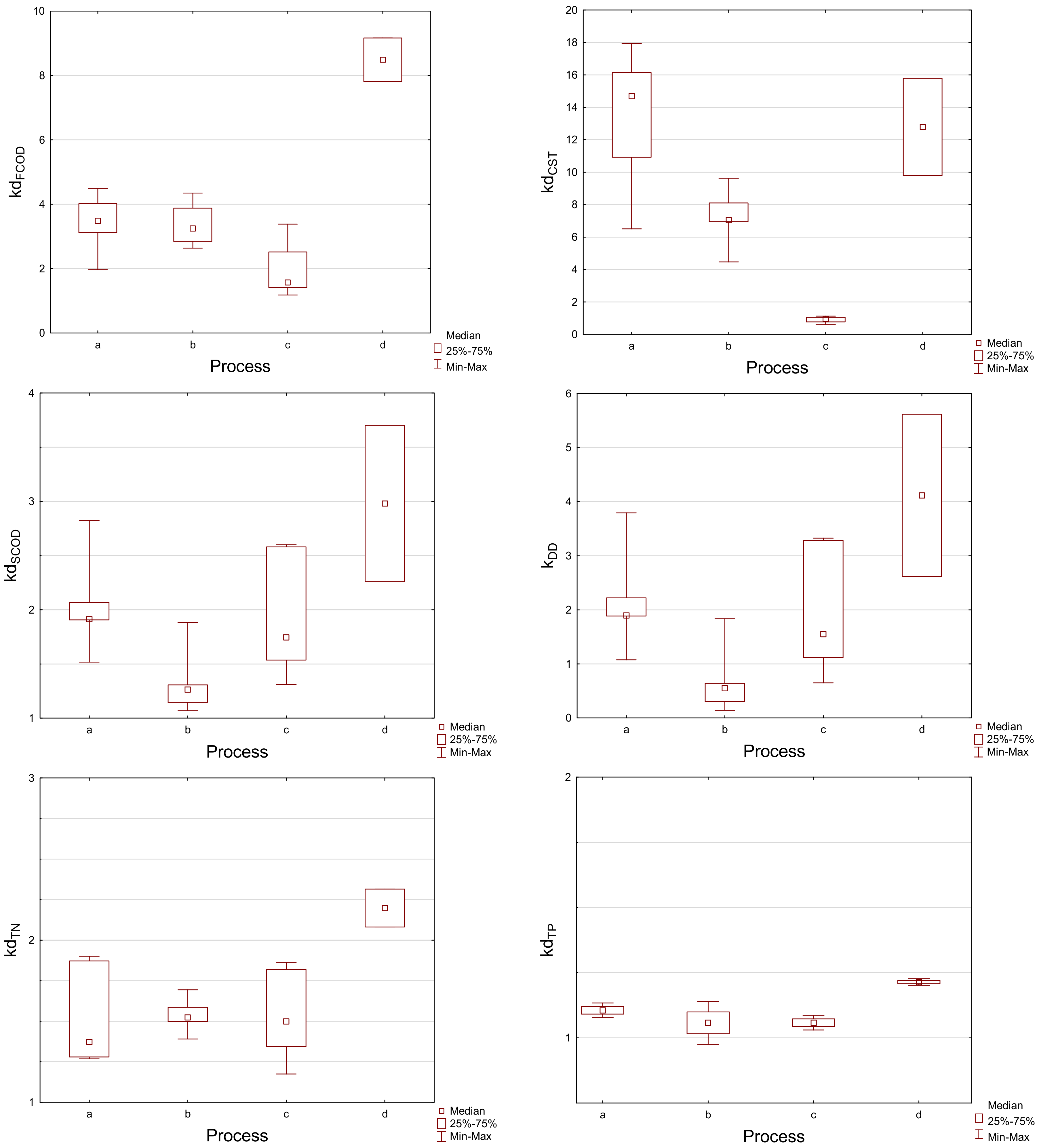

4. Conclusions

The effects of mechanical disintegration were dependent on the type of the mechanical pre-treatment and the scale of the device. The obtained results demonstrate the correlation of the disintegrator type and the results of the sludge preconditioning process. In terms of mechanical pre-treatment utilizing mixers, the direct effects of disintegration for comparable volumetric energy, were higher for the laboratory mixer than for the semi-technical disintegrating mixer—i.e., dispersion indicators kdCST, kdFCOD were 158% and 58% higher, respectively, lysis indicator kdSCOD was 145% higher, acidification indicator kdVFA was 63% higher and nutrient release indicator kdTN was 27% higher. For the sludge used in the research, the process of mixing in semi-technical scale device promotes mainly deagglomeration and subsequently lysis, while sonication promotes firstly lysis and subsequently deagglomeration of sludge flocs. For comparable EV values the kdFCOD and kdCST obtained for the mixer were respectfully 1103% and 141% higher than for the US disintegrator, while the lysis indicator kdSCOD was 12% lower for the same conditions. The use of hybrid disintegration, pre-mixing and sonication combined, delivers better direct results than two pre-treatment methods used separately. The results of hybrid disintegration were the highest in terms of dispersion (kdFCOD reached 9.16) and lysis (kdSCOD = 3.70) among the methods used in the research. The hybrid sludge pre-treatment was also more efficient in terms of the FCOD and SCOD yield per unit of volumetric energy. The kde∆FCOD and kde∆SCOD (mg O2·L−1 per 1 Wh), were considerably higher for the hybrid disintegration than for a single stage pre-treatment. The efficiency of FCOD yield per energy unit was higher by up to 85% when compared to the results for the semi-technical sludge mixer and 5.21 times higher than for the US process (for comparable volumetric energy). The efficiency of SCOD yield per energy unit was 23% higher than for the disintegration using semi-technical mixer and 65% higher than for the US process only (for comparable EV). The addition of mixing as the first stage of the hybrid pretreatment improves the efficiency of US disintegration (i.e., the ∆SCOD obtained during sonication of the pre-mixed sludge is 5.83 times higher than for the sonication of the unmixed sludge at EV = 20 kWh m−3).