Abstract

Benzotriazole is used as corrosion inhibitor in many industrial sectors, such as the dairy industry. Due to its widespread use in various applications and everyday consumer products, this chemical easily reaches the aquatic environment, where it may have deleterious effects. In fact, benzotriazole has been included among the so-called emerging contaminants. In this work, the occurrence and fate of a benzotriazole based anticorrosive (BTA-A) during wastewater treatment in a dairy industry has been assessed. At this dairy, a new system for wastewater treatment based on the injection of pure oxygen was recently started. This system has been proved to be efficient, economic and able to stably operate under a wide range of chemical oxygen demand and total suspended solids inputs. Then, after detecting the presence of BTA-A in the effluent of the wastewater treatment plant, it was aimed to optimize oxygen injection for the removal of this anticorrosive together with the regulated parameters. The performance of the system was evaluated at a real scale during a month period, during which the mean removal performance of the oxygen injection based treatment was 91%, 90% and 99% for chemical oxygen demand, total suspended solids and BTA-A, respectively.

1. Introduction

Benzotriazole (BTA), whose chemical structure is shown in Figure 1, is a heterocyclic compound containing three nitrogen atoms. This aromatic compound is colorless and polar and has been widely utilized in several fields such as plastics, coatings, dyes, and sunscreen. BTA has also been extensively used as metal corrosion inhibitor in a wide range of industrial applications. It is characterized by posing high water solubility (28 g/L), low vapor pressure and low octanol water distribution coefficient (log Kow: 1.23) [1].

Figure 1.

Chemical structure of benzotriazole (BTA, C6H5N3).

BTA concentrations above 0.97 mg/L have been shown to pose chronic adverse effects to Daphnia galeata [2] and concentrations above 40 mg/L have revealed toxic effects in Microtox® tests [3]. Therefore, BTA has been classified as a toxic compound to aquatic organisms that can cause long-term adversary effects in the aquatic environment [1].

Apart from its toxic properties, due to its persistence and bioaccumulation, BTA cannot be totally but only partially removed from wastewater by conventional treatment processes [4]. In fact, such conventional processes and wastewater treatment plants are not designed for the removal of unregulated contaminants such as BTA. Consequently, and due to its widespread applications, BTA has become a ubiquitous contaminant in the aquatic environment, having been classified as an emerging contaminant [5]. The definition of emerging contaminants, which include an extensive and expanding spectrum of compounds, is still under discussion, but it may be said that they are compounds that are not currently covered by existing water-quality regulations, have not been studied before, and are thought to be potential threats to environmental ecosystems and human health and safety [6]. In fact, BTA has recently been detected in water supplies around the world, which has called the attention of many environmental researchers [7].

In the industry, water has numerous uses—heating, cooling, washing, cleanup, etc.—but has traditionally been over-used due to its low cost. Nevertheless, actual increasing environmental regulations, concerns around human and ecological health, and consumer expectations of high environmental performance have placed water conservation onto the agenda of the process industry [8]. Due to the advances on water/wastewater treatment technologies, a variety of options is actually available to provide a high standard of wastewater treatment. These technologies include advanced oxidation technologies (AOTs), which have been widely investigated for the treatment of industrial wastewaters, particularly where the source waters contain high concentration of ambiguous, refractory and recalcitrant chemical compounds such as aromatics, pesticides, pharmaceuticals and personal care products, drugs and endocrine disruptors [9,10,11]. Despite their efficiency, the implementation of AOTs is not always economically affordable for local industries. Alternatively, simple oxidation processes, which can be applied straightforward at low investment costs, may, in some cases, enable quality requirements to be met and matched to specific end-uses. In fact, for any industry, decisions on wastewater treatment require the analysis of economic criteria combined with the associated environmental issues [12].

In a previous work [13], data on the start-up of a new system for dairy wastewater treatment based in the injection of pure oxygen in the homogenization tank of a traditional physicochemical treatment were presented. It was concluded that this system was able to stably operate under a wide variety of both input chemical oxygen demand (COD) and total suspended solids (TSS). Furthermore, compared with the previous physicochemical system and also with a conventional biological treatment [14,15], it was proved to be more efficient and cheap. In this work, given the use of a benzotriazole based anticorrosive (BTA-A) agent for the refrigeration towers, the main aim was to determine the occurrence and removal of this BTA-A from wastewater at the dairy treatment plant. To the best of our knowledge, few publications deal with the removal of BTA or BTA products during wastewater treatment and there are not published results on dairy wastewater.

2. Materials and Methods

2.1. Dairy Wastewater Treatment and Anticorrosive Agent Utilization

The wastewater treatment plant under study was implemented in Lácteos Ibéricos, which is a dairy and juice factory in Northwest Spain. This factory processes 2,700,000 L of milk/week and 900,000 L of juice/week. Of total production, 72% consists of dairy products and the remaining 28% of juices and nectars. Such a production involves the generation of around 1000 m3/day of wastewater with 61.1% of total COD corresponding to milk fat and 38.9% to juices and nectars. In the industry, wastewater must be treated before being discharged in the local sewage treatment plant (STP) under the obligatory accomplishment of tabulated limits (TSS, COD and biological oxygen demand after five days (BOD5)) and a tax payment.

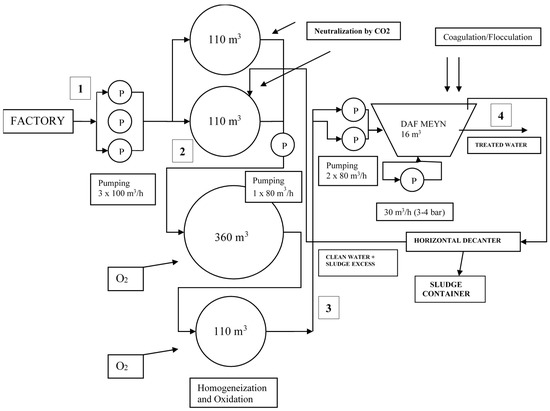

Figure 2 shows the current layout of the wastewater treatment plant at Lácteos Ibéricos. From the factory, wastewater is pumped to two homogenization rafts of 110 m3 each, where the wastewater is neutralized under CO2 injection (hydraulic retention time (HRT) = 30 min). Neutralized wastewater is then pumped to a 360 m3 raft. Next, gravity passed to another raft of 110 m3, pure O2 (99.9999%, 6.5 bar) being injected in these rafts (total HRT = 352.5 min). Injected O2 is purchased from Praxair (Madrid, Spain) at a price of 0.5 €/m3. Subsequently, wastewater is pumped to the dissolved air flotation tank (DAF), where a coagulation–flocculation treatment is applied (HRT = 15 min). Finally, the treated wastewater exits the manifold and is discharged to the municipal STP while the extracted sludge is dried by means of a horizontal decanter. The clean water extracted from the mud in the decanter as well as the excess of sludge are sent back to head of the plant (homogenization rafts).

Figure 2.

Dairy wastewater treatment plant layout. Sampling points considered for this work were: 1.—entrance of the plant (inlet); 2.—after neutralization under CO2; 3.—after O2 injection; and 4.—after the dissolved air flotation (DAF) tank, which corresponds to the effluent of the plant being discharged to the municipal sewage treatment plant (outlet).

At the dairy, a BTA-A, namely 3D TRASAR® 3DT265, from Nalco Water (Oviedo, Spain), is employed to avoid corrosion of the refrigeration towers. For this purpose, BTA-A is supplied by a peristaltic pump in the water feeding these refrigeration towers. The concentration of BTA-A in this water is weekly determined by a Nalco TRASAR Pen Fluorometer and dosage is adjusted in order to keep it in the range 90–100 mg/L, which guarantees that the desired purpose is fulfilled. Benzotriazole (BTA) is part of the composition of the referred anticorrosive agent (1.13 g/mL, 0.5–1.5% w/w BTA), which is widely used in different types of industries.

Actually, 11,750 L of BTA-A are used at the Lácteos Ibéricos dairy on a yearly basis. Due to the cleaning operations on the refrigeration towers, this anticorrosive agent will end in the dairy wastewater. Therefore, considering a yearly production of 365,000 m3 of wastewater at the dairy, a concentration of around 36.4 mg/L of BTA-A in the wastewater entering the treatment plant at the dairy may be expected, which means about 0.55–0.18 mg/L of BTA.

2.2. Laboratory-Scale Experiments

Three wastewater samples (2 L) were collected just at the entrance of the treatment plant (pointed as 1 in Figure 2). Each sample was divided into four 0.5 L sub-samples. One of them was used as the control, in the absence of oxygen injection. The other three sub-samples were treated by the injection of O2 (99.9999%, 6.5 bar), each at a different flow rate, namely 15, 20 and 25 m3/h. During such an oxygen injection treatment at laboratory, aliquots were withdrawn throughout time so to quantify TSS and COD in water, which was done according to standard methods [16]. In addition, the concentration of BTA-A in aliquots was determined by a Nalco TRASAR Pen Fluorometer. The oxygen injection treatment was maintained until the stabilization of the above parameters in wastewater samples.

The experimental results on the removal of TSS, COD and BTA-A were described by a pseudo first-order kinetic model (Equation (1)). Fittings to this equation were obtained by GraphPad Prism 7 (GraphPad Software Inc., San Diego, CA, USA):

where %removal is the percentage of TSS, COD or BTA-A removed at a certain time under O2 injection, %max is the maximum percentage of removal that is expected to attain, k1 (min−1) is the pseudo-first order rate constant and t (min) is the time under a certain flow rate of O2.

The differences among the three O2 flow rates in terms of kinetic parameters were tested using the non-parametric Kruskal–Wallis test. When the Kruskal–Wallis test pointed to significant differences (p < 0.05), the differences between the three combinations of flows were tested using the posthoc Dunn’s test.

2.3. Plant Study at a Real Scale

Wastewater was sampled from Monday to Friday during four consecutive weeks at the following points of the wastewater treatment plant (Figure 2): 1.—at the entrance of the plant (inlet); 2.—after neutralization under CO2; 3.—after O2 injection; and 4.—after the DAF, which corresponds to the effluent of the plant being discharged to the municipal STP (outlet). At each point, three grab samples (0.5 L each) were collected daily, one every eight hours. Sampling was made to coincide with the start of each work shift so to avoid disturbing the work routine at the dairy. The following parameters were analysed according to standard methods [16]: temperature, pH, dissolved oxygen, TSS, COD. Furthermore, the BTA-A concentration in the samples was determined by a Nalco TRASAR Pen Fluorometer. Considering the flow stability of the influent and effluent in the plant (1000 m3/day) and that three samples were collected daily, the removal efficiency (%) of TSS, COD and BTA-A was calculated on the basis of their respective average daily concentrations by applying error calculation rules.

3. Results and Discussion

3.1. Laboratory-Scale Experiments

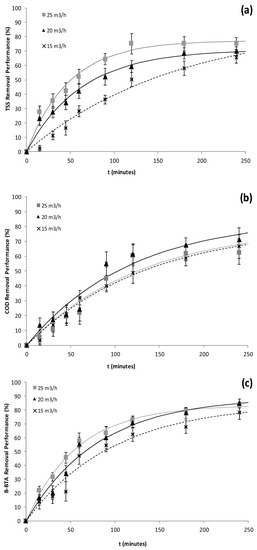

Control experiments allowed to verify that TSS, COD and BTA-A concentration remained the same during the duration of the laboratory-scale experiments. Regarding the laboratory experiments under oxidation, the percentages of TSS, COD and BTA-A removal throughout time under different O2 flow rates are represented in Figure 3 together with the corresponding fittings to the pseudo first-order kinetic model (Equation (1)). The fitted parameters of the kinetic model (k1 and %max) are depicted in Table 1, where the goodness of the fittings is represented by the determination coefficient (R2) and the deviation (Sxy).

Figure 3.

Laboratory study investigating the effect of different O2 flow rates on the removal of: (a) total suspended solids (TSS); (b) chemical oxygen demand (COD); and (c) benzotriazole based anticorrosive agent (BTA-A). Note: Error bars stand for standard deviation values (n = 3). Experimental results are shown together with fittings to the pseudo first-order kinetic model (grey continuous line, black continuous line and black discontinuous line represent fittings to removal under 25, 20 and 15 m3/h of O2, respectively).

Table 1.

Parameters obtained from the fittings of experimental results on the removal of total suspended solids(TSS), chemical oxygen demand (COD) and benzotriazole based anticorrosive (BTA-A) under different O2 flow rates to the pseudo first-order kinetic model.

As may be seen in Figure 3a, under the flow rates tested, TSS are mostly removed during the first 120 min under oxygen injection. Moreover, from 180 to 240 min, there is not a noteworthy increase of the removal percentage. Parameters in Table 1 show that the largest O2 flow rate (25 m3/h) allowed for a significantly larger kinetic constant for the removal of TSS, followed by 20 and 15 m3/h. In any case, the %max attained under these flow rates were not significantly different. With respect to the COD, removal curves in Figure 3b are similar to those of TSS (Figure 3a), COD being removed mainly during the first 120 min and with no remarkable increments between 180 and 240 min. Under the considered O2 flow rates, neither the kinetic constant nor the maximum percentage of COD removal were significantly different according to the data displayed in Table 1. Finally, results on BTA-A removal, which are represented in Figure 3c, show that elimination is near 85% at the end of 240 min under oxygenation. As for TSS and COD, BTA-A is mainly removed during the first 120 min under O2 injection and irrelevant increments on the BTA-A removal were observed for oxygenation times longer than 180 min. As for the parameters in Table 1, the k1 under 25 m3/h was significantly higher than that under 20 or 15 m3/h. However, the %max attained under these flow rates were not significantly different.

On the basis of the above results, a flow rate of 20 m3/h was selected to be injected into the dairy wastewater treatment plant for the subsequent study. Although it is true that a slightly faster TSS and BTA-A removal was attained under 25 m3/h, the maximum TSS, COD and BTA-A removals attained under the O2 flow rates considered here were not significantly different. Furthermore, at a real scale, if the plant works 720 h/month, using 25 m3/h instead of 20 m3/h would represent an extra expense of 1800 €/month, which is not worth taking into account the results here obtained at the laboratory-scale experiments.

3.2. Plant Study at a Real Scale

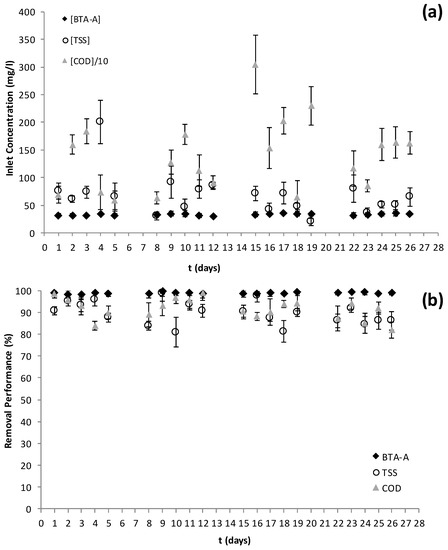

Figure 4 represents the average inlet concentration (Figure 4a) and removal efficiency (Figure 4b) of the wastewater treatment plant for TSS, COD and BTA-A. Results on the inlet TSS and COD in Figure 4a are within the range of values determined for these parameters in a previous study [13]. Regarding BTA-A inlet concentration, values are all between 30 and 35 mg/L, which is a quite narrow range as compared with TSS and COD. While TSS and COD contents in wastewater are related to production fluctuations at the dairy, the inlet BTA concentration is more stable since it is due to its dosed use as anticorrosive agent. In fact, the mean BTA-A concentration at the entrance of the wastewater treatment plant is 33 mg/L, which is close to that referred above as the expected concentration of BTA-A (36.4 mg/L) on the basis of its yearly consumption.

Figure 4.

Results at a real plant scale on: (a) the inlet concentration of total suspended solids (TSS), chemical oxygen demand (COD) and benzotriazole based anticorrosive agent (BTA-A) concentration; and (b) the efficiency performance of the dairy wastewater treatment plant on the removal of TSS, COD and BTA-A. Note: Error bars stand for standard deviation values (n = 4).

Figure 4b represents the average daily removal of TSS, COD and BTA in the dairy wastewater treatment plant throughout the sampling period. As may be seen, the percentage of TSS average removal remained between 81% and 98%. With respect to COD, average removal percentages between 82% and 99% were observed. These efficiencies are mostly higher than those obtained when the oxygen injection system was started [13]. It should be highlighted that, as said above, effluent from the dairy wastewater treatment plant is discharged to the municipal sewage system, which involves the payment of a tax on the basis of the load and volume discharged as described by the following equation:

where P is a fixed coefficient (currently, P = 0.5 €/m3) and K (1 < K < 5) is a correction factor. This factor (K) is a function of the contamination index (I) of the effluent to be discharged in the municipal STP system.

Tax (€/m3) = P × K,

The calculation of I is as follows:

where BOD5, COD and TSS are expressed in kg/m3. At the dairy industry considered here, BOD5 is not regularly determined but estimated as BOD5 = 0.65 COD, thereby I is calculated as indicated next:

I = COD + 1.65 BOD5 + 1.10 TSS,

I = 2.3 COD + 1.10 TSS.

The value of I is periodically determined for a composed sample and it may be verified by the STP at any moment. Then, the K coefficient is the value of I rounded to units (units will be left the same if the tenth value is less than 5, but units will be increased by one if the tenth value is five or more). The minimum applicable value of K is 1 and the maximum value is 5, which will be applied when the calculated I is 5 or larger. For the dairy, it is a priority that the STP tax is as low as possible. Therefore, it must be ensured that wastewater treatment implemented at the dairy allows for a K = 1 in order to minimize the STP tax to be paid. In the present study, the mean outlet TSS and COD concentrations within the sampling period were 6.5 and 126 mg/L, respectively, which guarantees that the correction factor (K) that is applied for the calculation of the municipal STP tax is equal to 1.

Regarding the removal of BTA-A, percentages above 98% have been always attained throughout the four weeks considered period. It may be observed that the removal of BTA-A is larger and remains mostly unchanged as compared with the removal of TSS and COD. These facts must be associated to the more stable inlet BTA-A concentrations, which do not depend on the dairy production. On the other hand, comparing results in Figure 3 with those in Figure 4, it is evident that removal efficiencies at a real scale were higher than those observed at a laboratory-scale. This must be related to the existence of three consecutive steps at the dairy wastewater treatment plant, namely CO2 injection, O2 injection and coagulation–flocculation, while, at a laboratory scale, only O2 injection was applied.

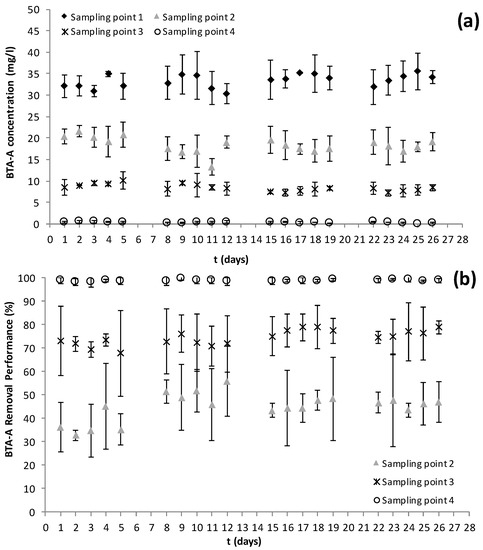

A main question about BTA-A removal in the dairy wastewater treatment plant is the contribution of each treatment stage. In order to assess this issue, the concentration of BTA-A in the dairy wastewater and the removal at each stage of the treatment plant is represented in Figure 5. Figure 5a allows for comparing the daily average concentrations of BTA-A at the entrance of the wastewater treatment plant (sampling point (1)), after neutralization by CO2 injection (sampling point (2)), after O2 injection (sampling point (3)) and after the DAF (sampling point (4)). As it was highlighted above, the mean BTA-A concentration at the entrance of the wastewater treatment plant throughout the period under study is 33 mg/L, with values between 26 and 40 mg/L. Meanwhile, the mean BTA-A concentration after CO2 injection is 19 mg/L, with values between 13 and 23 mg/L. After O2 injection, the mean BTA-A concentration is 8 mg/L, varying between 6 and 12 mg/L. Finally, after the DAF, BTA-A daily average concentrations are between 0.86 and 0.06 mg/L with a mean of 0.35 mg/L. Therefore, BTA-A concentration progressively decreases along with subsequent treatments at the dairy wastewater treatment plant. In addition, it may be seen that, from one stage to the subsequent one, BTA-A concentration values get more stable within the sampling period with a decreasing daily standard deviation.

Figure 5.

Results on (a) the benzotriazole based anticorrosive (BTA-A) concentration; and (b) cumulative BTA-A removal percentage at the different stages of the dairy wastewater treatment plant, namely at the sampling point 2.—after neutralization under CO2; sampling point 3.—after O2 injection; and sampling point 4.—after the DAF, which corresponds to the effluent of the plant being discharged to the municipal sewage treatment plant (outlet). Cumulative removal percentages were calculated respect the entering BTA-A concentration at the sampling point 1.—entrance of the plant (inlet). Note: Error bars stand for standard deviation values (n = 3).

Accumulative percentages of the BTA-A removal in the dairy wastewater treatment plant throughout the period under study are shown in Figure 5b for each treatment stage. Throughout the whole period, the average removal of BTA-A under CO2 injection (sampling point (2)) remains between 33% and 56%, with a mean of 44%. Then, after the O2 injection stage (sampling point (3)), a mean removal of 74% is achieved within the whole sampling period. Finally, after the DAF (sampling point (4)), the mean performance of the plant on the elimination of BTA-A is 99% within the sampling period, with average values ranging between 98.3% and 99.7%. Then, the individual weight of each stage for this overall removal may be calculated as 44%, 30% and 25% for CO2 injection, O2 injection and coagulation–flocculation, respectively. Therefore, the importance of each stage on the overall removal of BTA-A from wastewater is progressively decreasing. However, when considering the BTA-A concentration entering at each stage, the mean removal performance of the coagulation–flocculation DAF stage is 95.6%. This is a remarkable efficiency as compared with the previous treatments, namely CO2 and O2 injection, which respective mean efficiencies were of 44% and 56% relatively to the corresponding BTA-A input. Polymeric cationic flocculants are used at the dairy wastewater treatment plant; thus, given the low Kow of BTA [1], either a combination of charge neutralization and bridging or bridging, but not sorption, must be the main mechanisms for BTA-A removal at the DAF. On the other hand, as compared with the DAF treatment, large daily deviations in the performance of the CO2 and, especially, of the O2 injection stages may be observed in Figure 5b. In addition, for these stages, a certain variation from day to day between average performance values may be observed. On the contrary, the global removal shows relative small variations within and inter days throughout the period here considered. This is quite relevant, since the dairy wastewater treatment plant gets to ensure a short range of low BTA-A concentrations in the effluent. Even so, considering the BTA content of the BTA-A used here, the effluent from the dairy wastewater treatment plant must have a BTA concentration of 0.003–0.013 mg/L.

To our best knowledge, there are not published results on the occurrence of benzotriazole or benzotriazole based anticorrosives in dairy wastewaters, neither on their removal. Several authors have studied the removal of BTA during activated sludge (AS) batch experiments [17,18,19]. However, information on the removal of BTA during wastewater treatment is scarce in the literature. In the case of municipal wastewaters, Voutsa et al. [1] made a deep study on the occurrence and fate of benzotriazoles in wastewater treatment plants (WWTPs) and presented data on the concentrations of BTA in samples of primary and secondary effluents from 24 different WWPTs in Switzerland. The median outlet concentrations of BTA were 18 and 10 μg/L, respectively [1], which are similar to the outlet BTA concentration at the dairy wastewater treatment plant throughout the sampling period carried out in the present work. Voutsa et al. [1] highlighted that the elimination of BTA in WWTPs was relatively low, with maximum values of 62% obtained from 10 WWTPs in the Glatt Valley catchment. More recently, it was highlighted that benzotriazoles, which are polar and poorly degradable pollutants, are insufficiently removed by biological treatment at conventional wastewater treatment plants as concluded from the reported BTA removals (29–58%) in wastewater treatment plants [20]. Even under higher removals (around 75% for BTA), it has been pointed out that large average daily loads are discharged via treated wastewater to the aquatic environment [21].

Compared with the above values, the performance of the oxygen injection based dairy wastewater treatment plant here studied is quite satisfactory. Likewise, it must be considered that the treated effluent from the dairy is discharged to the local STP [13]), where BTA-A may be further removed. In any case, efficient wastewater treatment processes and zero discharge treatment units are desirable for dairies sustainability [22]. Additional in-plant treatments could be implemented in the dairy wastewater treatment plant to improve the quality of the outlet effluent. In this sense, hybrid membrane processes combining powdered activated carbon (PAC) adsorption with ultrafiltration (UF), which have been successfully used for the removal of BTA from wastewater [23] could be implemented after the DAF. Future studies must be carried out on the implementation of such treatments, and on the direct analysis of BTA and its transformation products in the dairy wastewater.

4. Conclusions

A benzotriazole based anticorrosive agent (BTA-A) is used at the dairy for inhibiting corrosion of the refrigeration towers. Then, water used for cleaning operations of these towers is treated at the dairy wastewater treatment plant where a new oxygen injection system was recently established. It was verified in this work that BTA-A is present in the dairy wastewater, concentration values between 26 and 40 mg/L having been determined during a four-week sampling period. After a laboratory scale study, a 20 m3/h O2 (99.9999%, 6.5 bar) injection flow rate was set up at the dairy wastewater treatment plant in order to remove total suspended solids (TSS), chemical oxygen demand (COD) and BTA-A and to minimize oxygen associated costs. During the sampling period, the removal of TSS and COD at the dairy wastewater treatment plant remained between 81–98% and 82–99%, respectively, with mean outlet concentrations of 6.5 mg/L TSS and 126 mg/L COD. This operation efficiency guaranteed the minimization of the tax to be paid to the municipal sewage treatment plant (STP) where the treated wastewater from the dairy is discharged. Regarding BTA-A, removal at the dairy wastewater treatment plant was always above 97%, progressive elimination occurring at the three treatment stages, namely neutralization under CO2 injection, oxidation under O2 injection and coagulation–flocculation at the dissolved air flotation tank (DAF). No published results have been found on BTA or BTA based anticorrosive agents in dairy wastewater, but, compared with data on conventional STPs, the removal efficiency of the wastewater treatment plant here considered is quite satisfactory.

Acknowledgements

The Fundação para a Ciência e a Tecnologia (FCT, Lisboa, Portugal) is acknowledged for support through the FCT Investigator Program (IF/00314/2015). Thanks are due for the financial support to CESAM (UID/AMB/50017)through national funds (Programa de Investimento e Despesas de Desenvolvimento da Administração Central, PIDDAC) by FCT/Ministério da Ciência, Tecnologia e Ensino Superior (MCTES), and through co-funding (POCI-01-0145-FEDER-007638) by the Fundo Europeu de Desenvolvimento Regional (FEDER), within the PT2020 Partnership Agreement and Compete 2020 (Programa Operacional Competitividade e Internacionalização, POCI).

Author Contributions

Santiago Martín-Rilo, Ricardo N. Coimbra and Marta Otero conceived the work and designed the experiments; Santiago Martín-Rilo performed the sampling and chemical analysis; Ricardo N. Coimbra, Carla Escapa and Marta Otero analysed the results and wrote the manuscript; and Marta Otero supervised this study. The final version was approved by all authors.

Conflicts of Interest

The authors declare no conflict of interest. Authors also declare that the founding agents did not participate in the design of the study; in the sample collection or sample analysis; in the interpretation of data; in the writing of the manuscript; and in publishing results.

References

- Voutsa, D.; Hartmann, P.; Schaffner, C.; Giger, W. Benzotriazoles, alkylphenols and bisphenol A in municipal wastewaters and in the Glatt River, Switzerland. Environ. Sci. Pollut. Res. 2006, 13, 333–341. [Google Scholar] [CrossRef]

- Seeland, A.; Oetken, M.; Kiss, A.; Fries, E.; Oehlmann, J. Acute and chronic toxicity of benzotriazoles to aquatic organisms. Environ. Sci. Pollut. Res. 2012, 19, 1781–1790. [Google Scholar] [CrossRef] [PubMed]

- Pedrazzani, R.; Ceretti, E.; Zerbini, I.; Casale, R.; Gozio, E.; Bertanza, G.; Gelatti, U.; Donato, F.; Feretti, D. Biodegradability, toxicity and mutagenicity of detergents: Integrated experimental evaluations. Ecotoxicol. Environ. Saf. 2012, 84, 274–281. [Google Scholar] [CrossRef] [PubMed]

- Ye, J.; Zhou, P.; Chen, Y.; Ou, H.; Liu, J.; Li, C.; Li, Q. Degradation of 1H-benzotriazole using ultraviolet activating persulfate: Mechanisms, products and toxicological analysis. Chem. Eng. J. 2018, 334, 1493–1501. [Google Scholar] [CrossRef]

- Xu, J.; Li, L.; Guo, C.; Zhang, Y.; Wang, S. Removal of benzotriazole from solution by BiOBr photocatalysis under simulated solar irradiation. Chem. Eng. J. 2013, 221, 230–237. [Google Scholar] [CrossRef]

- Farré, M.L.; Pérez, S.; Kantiani, L.; Barceló, D. Fate and toxicity of emerging pollutants, their metabolites and transformation products in the aquatic environment. TrAC Trends Anal. Chem. 2008, 27, 991–1007. [Google Scholar] [CrossRef]

- Alotaibi, M.D.; McKinley, A.J.; Patterson, B.M.; Reeder, A.Y. Benzotriazoles in the aquatic environment: A review of their occurrence, toxicity, degradation and analysis. Water Air Soil Pollut. 2015, 226, 226. [Google Scholar] [CrossRef]

- Barrington, D.J.; Prior, A.; Ho, G. The role of water auditing in achieving water conservation in the process industry. J. Clean. Prod. 2013, 52, 356–361. [Google Scholar] [CrossRef]

- Asghar, A.; Raman, A.A.A.; Daud, W.M.A.W. Advanced oxidation processes for in-situ production of hydrogen peroxide/hydroxyl radical for textile wastewater treatment: A review. J. Clean. Prod. 2015, 87, 826–838. [Google Scholar] [CrossRef]

- Chatzisymeon, E.; Foteinis, S.; Mantzavinos, D.; Tsoutsos, T. Life cycle assessment of advanced oxidation processes for olive mill wastewater treatment. J. Clean. Prod. 2013, 54, 229–234. [Google Scholar] [CrossRef]

- Chong, M.N.; Sharma, A.K.; Burn, S.; Saint, C.P. Feasibility study on the application of advanced oxidation technologies for decentralised wastewater treatment. J. Clean. Prod. 2012, 35, 230–238. [Google Scholar] [CrossRef]

- Rodríguez, R.; Espada, J.J.; Gallardo, M.; Molina, R.; López-Muñoz, M.J. Life cycle assessment and techno-economic evaluation of alternatives for the treatment of wastewater in a chrome-plating industry. J. Clean. Prod. 2018, 172, 2351–2362. [Google Scholar] [CrossRef]

- Martín-Rilo, S.; Coimbra, R.N.; Martín-Villacorta, J.; Otero, M. Treatment of dairy industry wastewater by oxygen injection: Performance and outlay parameters from the full scale implementation. J. Clean. Prod. 2015, 86, 15–23. [Google Scholar] [CrossRef]

- Asplund, S. The Biogas Production Plant at Umeå Dairy. Evaluation of Design and Start Up. Master’s Thesis, Linköpings Universitet, Sweden, 2005. Available online: http://www.diva-portal.org/smash/get/diva2:21340/FULLTEXT01.pdf (accessed on 15 November 2017).

- Passeggi, M.; López, I.; Borzacconi, L. Modified UASB reactor for dairy industry wastewater: Performance indicators and comparison with the traditional approach. J. Clean. Prod. 2012, 26, 90–94. [Google Scholar] [CrossRef]

- Eaton, A.D.; Clesceri, L.S.; Greenberg, A.E. Standard Methods for the Examination of Water and Wastewater, 19th ed.; American Public Health Association (APHA): Washington, DC, USA, 1995; ISBN 0-87553-223-3. [Google Scholar]

- Herzog, B.; Lemmer, H.; Huber, B.; Horn, H.; Müller, E. Xenobiotic benzotriazoles-biodegradation under meso- and oligotrophic conditions as well as denitrifying, sulfate-reducing, and anaerobic conditions. Environ. Sci. Pollut. Res. 2014, 21, 2795–2804. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Ying, G.; Shareef, A.; Kookana, R.S. Biodegradation of three selected benzotriazoles under aerobic and anaerobic conditions. Water Res. 2011, 45, 5005–5014. [Google Scholar] [CrossRef] [PubMed]

- Mazioti, A.A.; Stasinakis, A.S.; Pantazi, Y.; Andersen, H.R. Biodegradation of benzotriazoles and hydroxy-benzothiazole in wastewater by activated sludge and moving bed biofilm reactor systems. Bioresour. Technol. 2015, 192, 627–635. [Google Scholar] [CrossRef] [PubMed]

- Reemtsma, T.; Miehe, U.; Duennbier, U.; Jekel, M. Polar pollutants in municipal wastewater and the water cycle: Occurrence and removal of benzotriazoles. Water Res. 2010, 44, 596–604. [Google Scholar] [CrossRef] [PubMed]

- Stasinakis, A.S.; Thomaidis, N.S.; Arvaniti, O.S.; Asimakopoulos, A.G.; Samaras, V.G.; Ajibola, A.; Mamais, D.; Lekkas, T.D. Contribution of primary and secondary treatment on the removal of benzothiazoles, benzotriazoles, endocrine disruptors, pharmaceuticals and perfluorinated compounds in a sewage treatment plant. Sci. Total Environ. 2013, 463–464, 1067–1075. [Google Scholar] [CrossRef] [PubMed]

- Tiwari, S.; Behera, C.R.; Srinivasan, B. Simulation and experimental studies to enhance water reuse and reclamation in India’s largest dairy industry. J. Environ. Eng. Chem. 2016, 4, 601–616. [Google Scholar] [CrossRef]

- Löwenberg, J.; Zenker, A.; Baggenstos, M.; Koch, G.; Kazner, C.; Wintgens, T. Comparison of two PAC/UF processes for the removal of micropollutants from wastewater treatment plant effluent: Process performance and removal efficiency. Water Res. 2014, 56, 26–36. [Google Scholar] [CrossRef] [PubMed]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).