Study on Improving Pulsed-Jet Performance in Cone Filter Cartridges Using a Porous Diffusion Nozzle

Abstract

1. Introduction

2. Experiment and Modeling

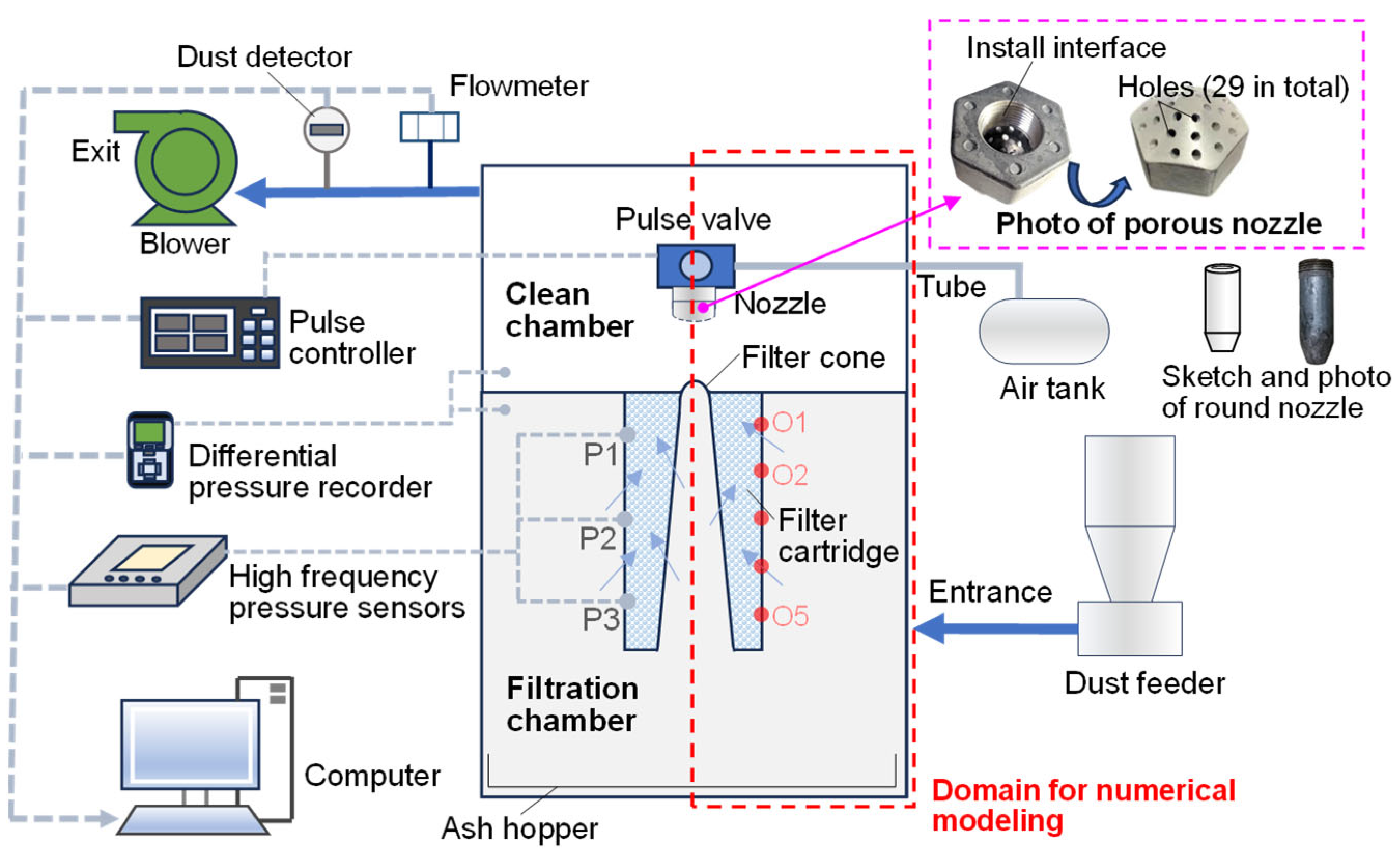

2.1. Experimental System

2.2. Numerical Modeling

2.2.1. Modeling

2.2.2. Settings

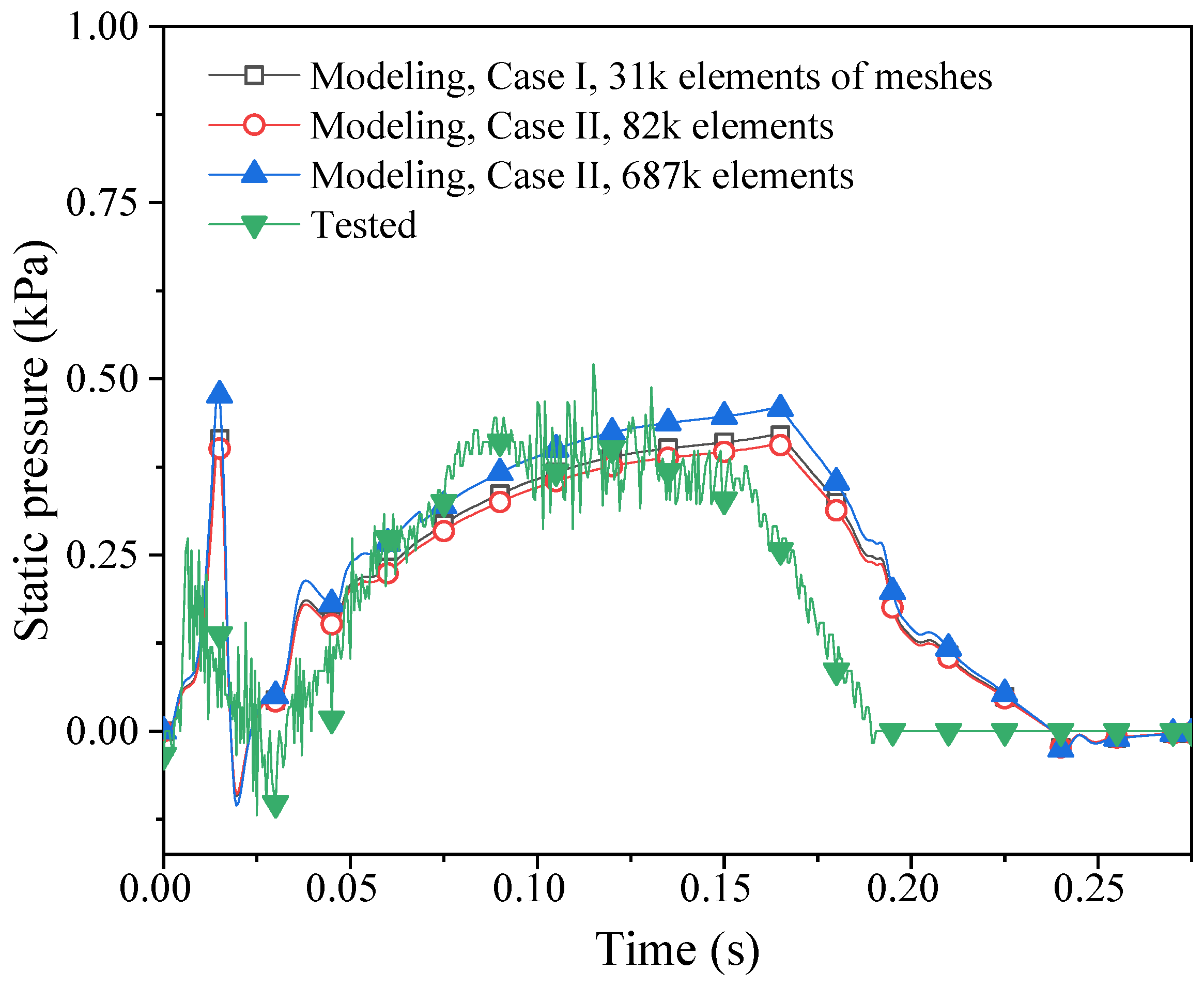

2.2.3. Model Validation

2.3. Modeling Scheme Design

- (1)

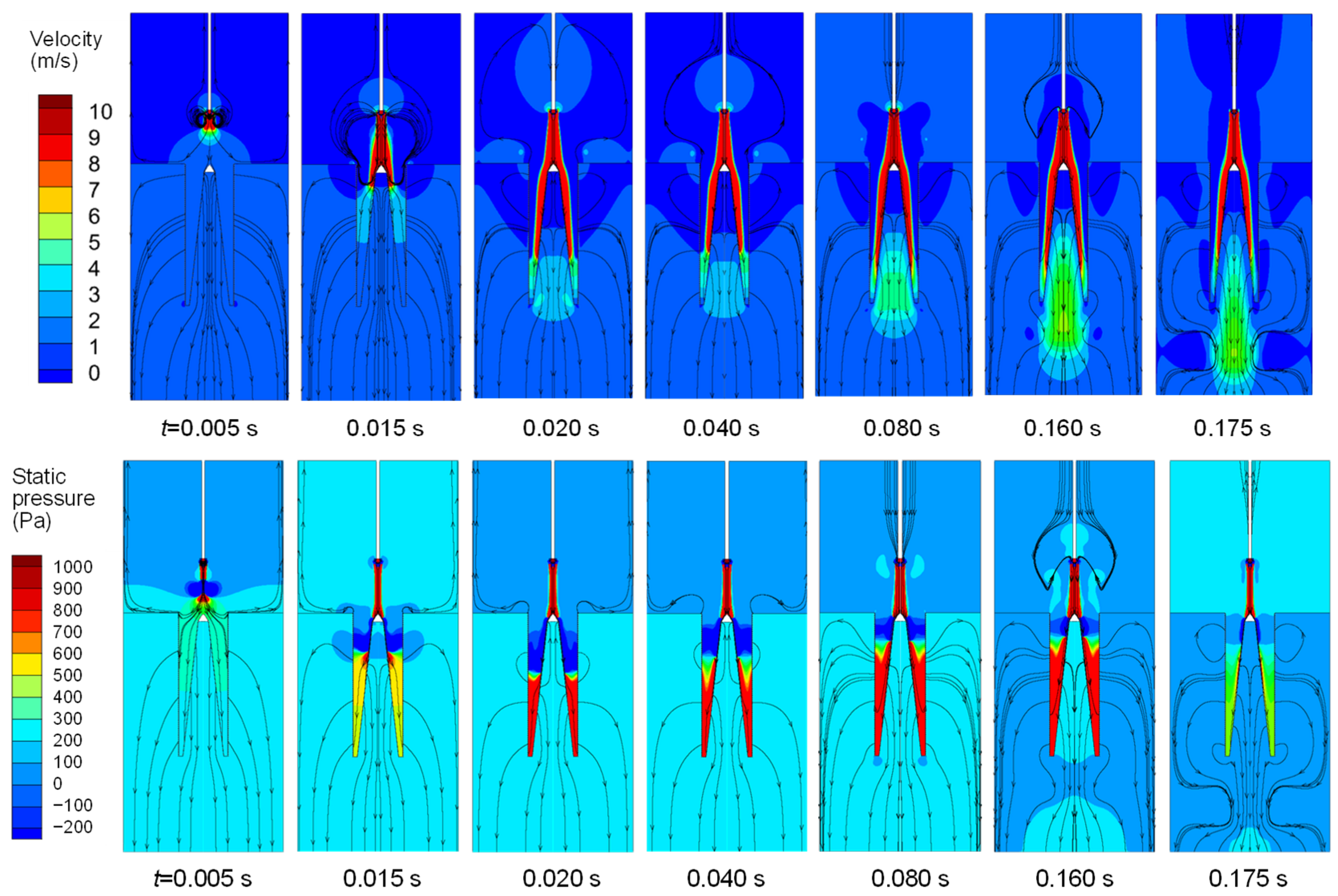

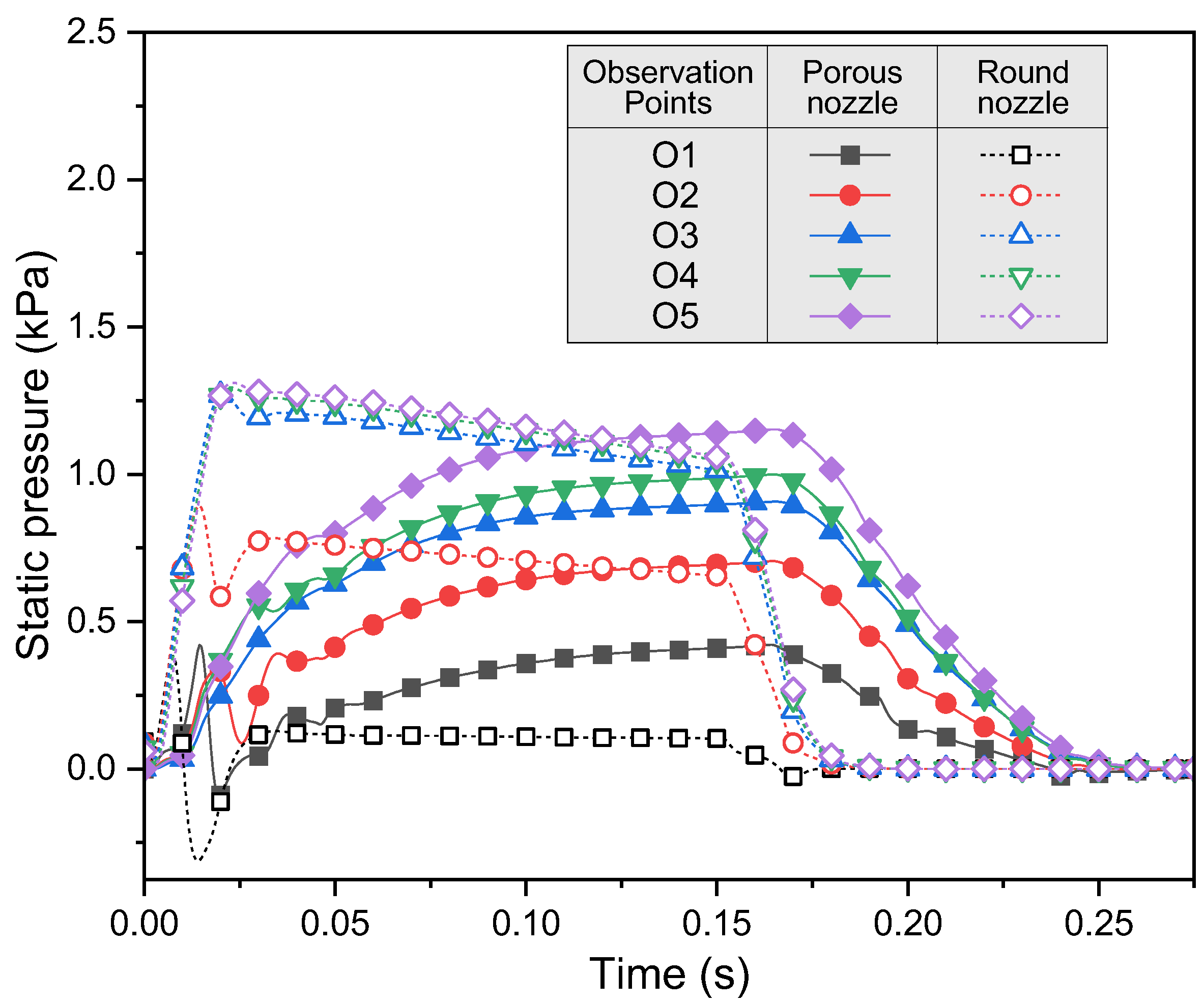

- The time-space distribution of velocity and static pressure under the operating conditions of porous nozzles is investigated using numerical modeling. The improvement mechanism of the flow field with the porous nozzle is analyzed by comparing the effects of common round nozzles and porous diffusion nozzles.

- (2)

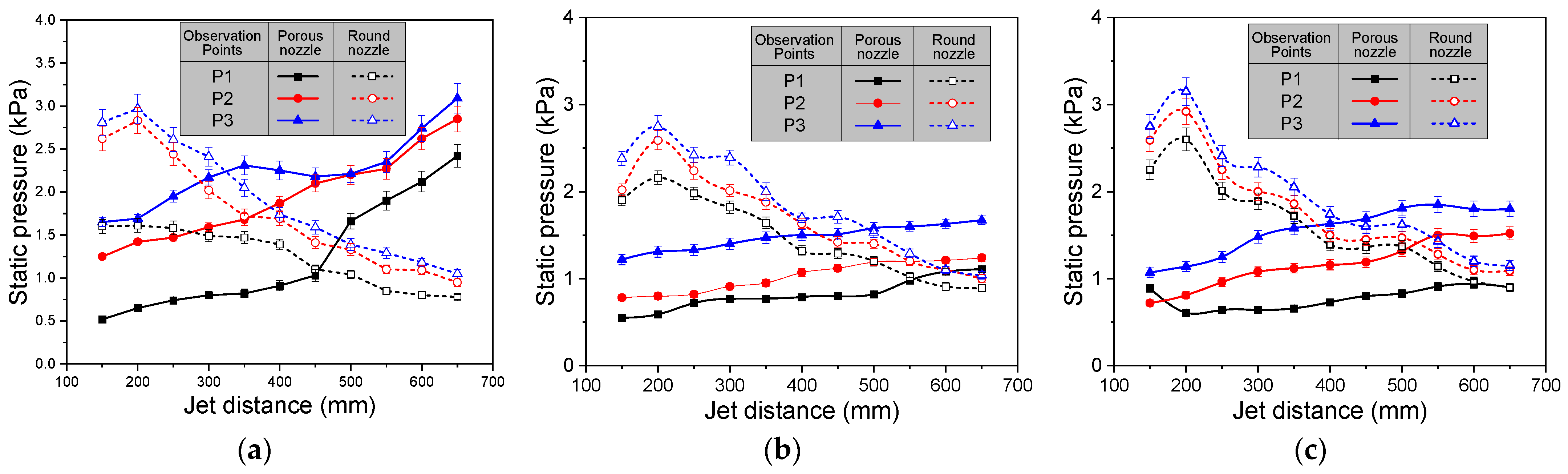

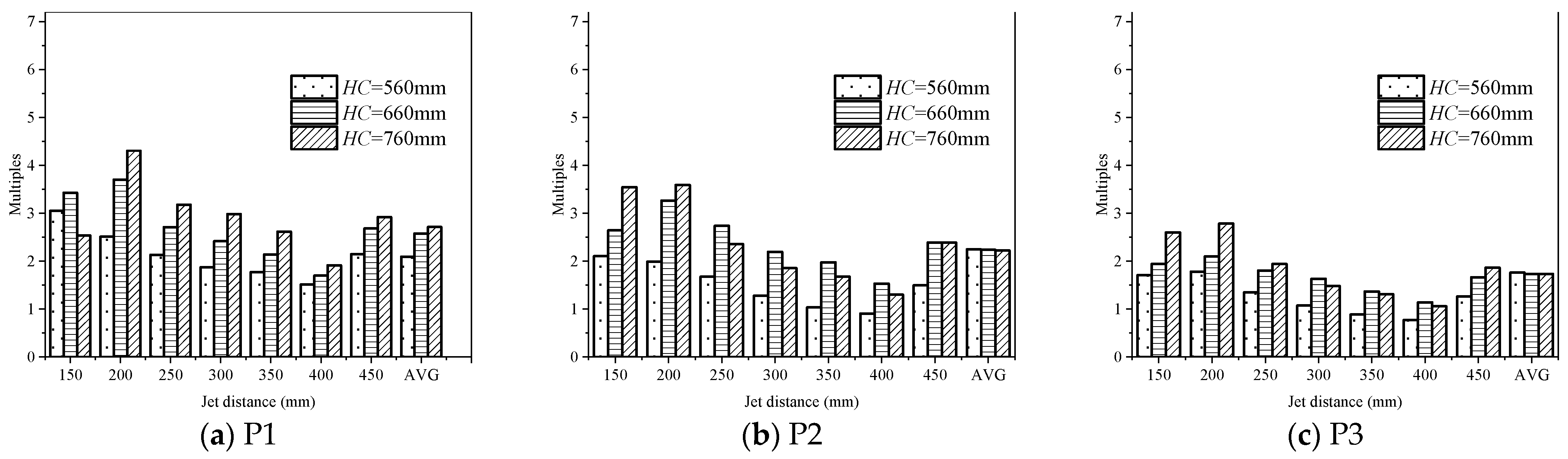

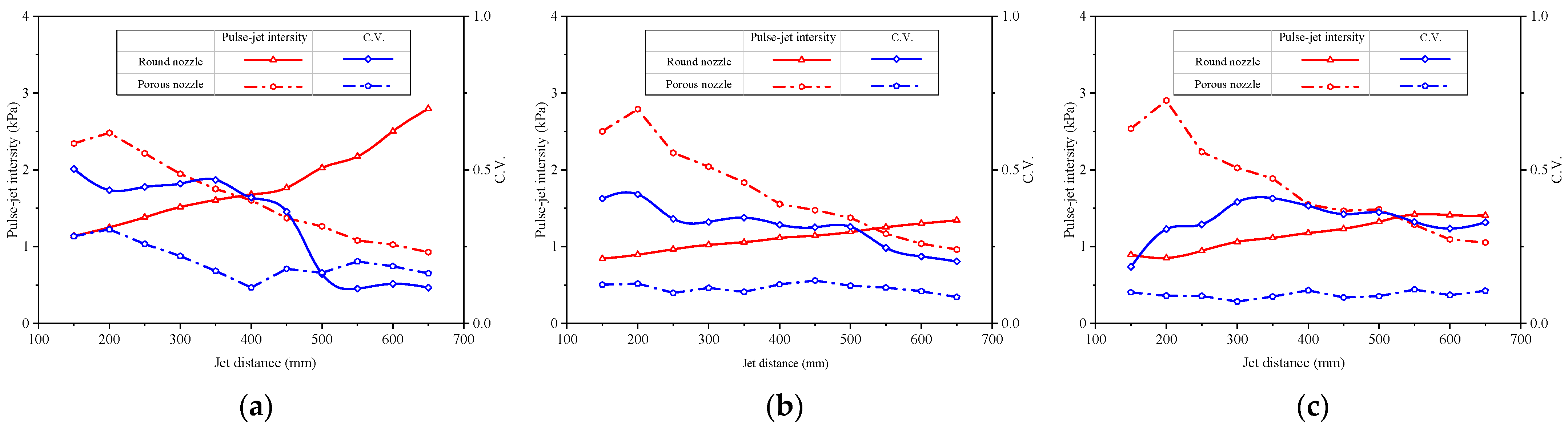

- The effect of jet distance on pulsed-jet pressure is studied by testing the variation of peak pressure of porous nozzles at jet distance JD = 150–650 mm under the condition of inner cone height HC = 560, 660, 760 mm. The effect of porous nozzles on pulsed-jet performance is analyzed by comparing them with common round hole nozzles (shortened to round nozzles) and deflector-type diffusion nozzles (shortened to deflector nozzles).

- (3)

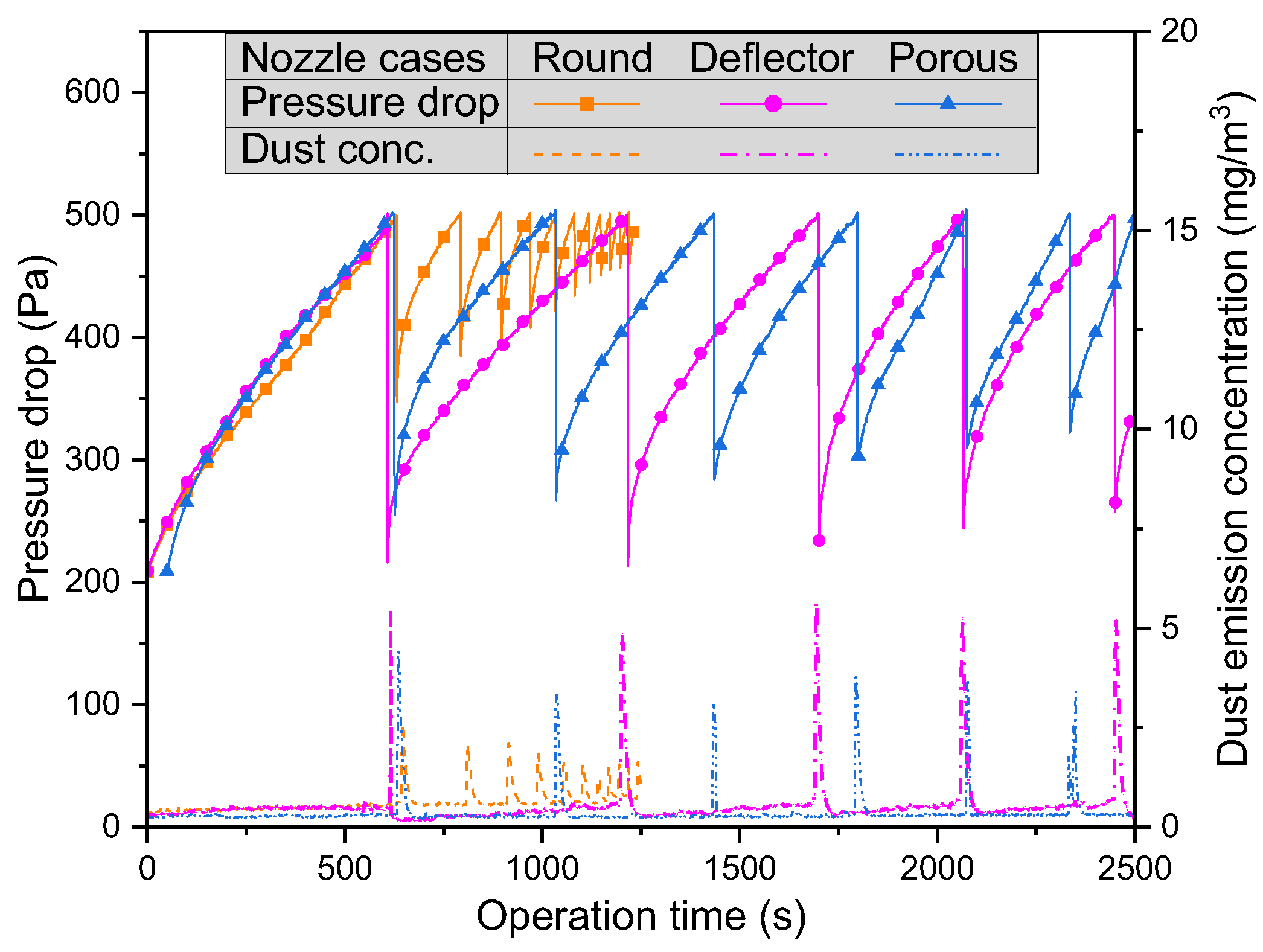

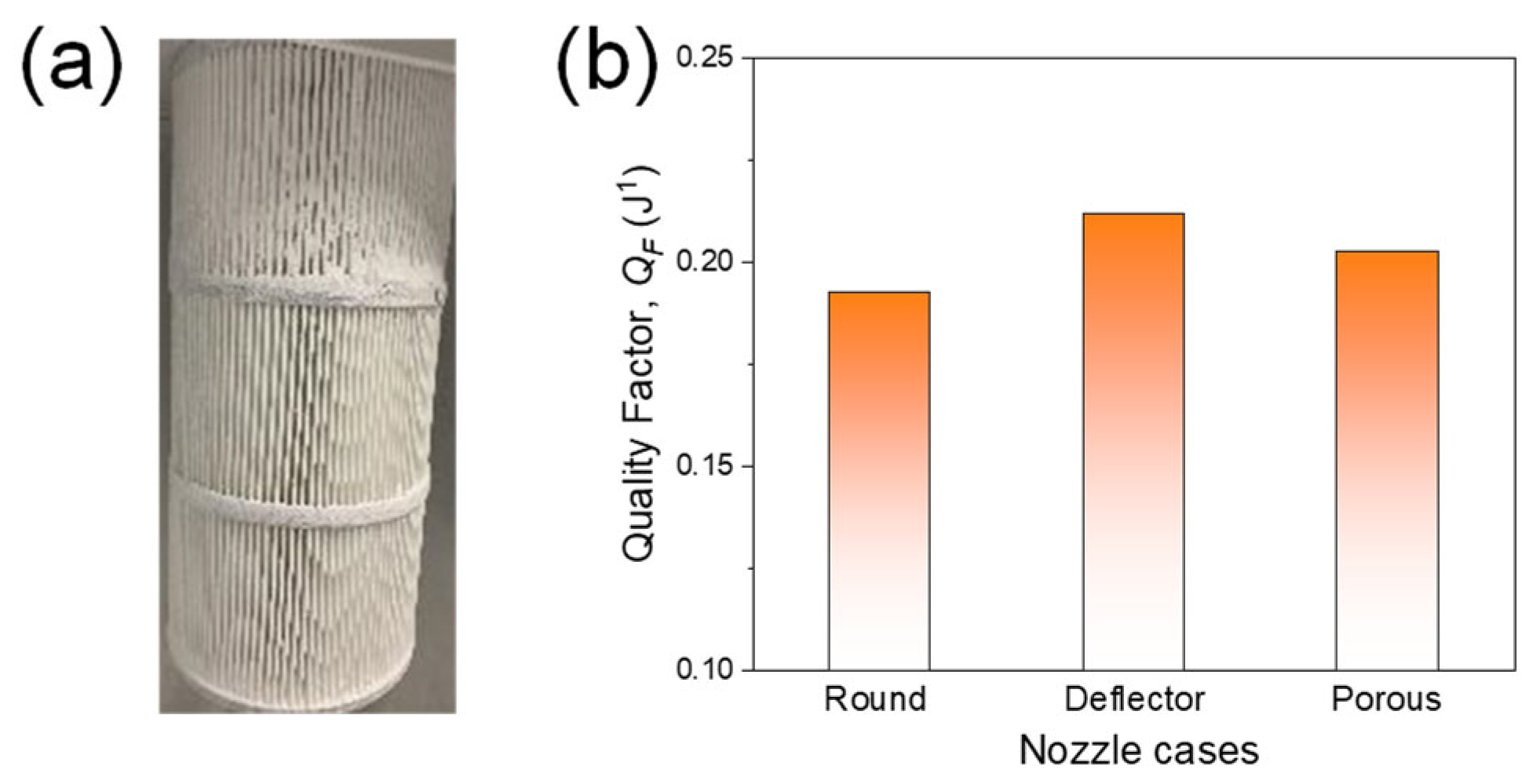

- An online filtration and dust cleaning experiment is carried out to investigate the improvement effect of porous nozzles on the operational performance of the filtration dust collector, and to analyze the changes in filtration pressure and dust concentration of the dust collection system before and after using porous nozzles.

3. Results and Discussion

3.1. Temporal and Spatial Distribution of Jet Airflow Modeling

3.2. Experimental Test of the Effect of Jet Distance

3.3. Filtration and Dust Cleaning Performance

4. Conclusions

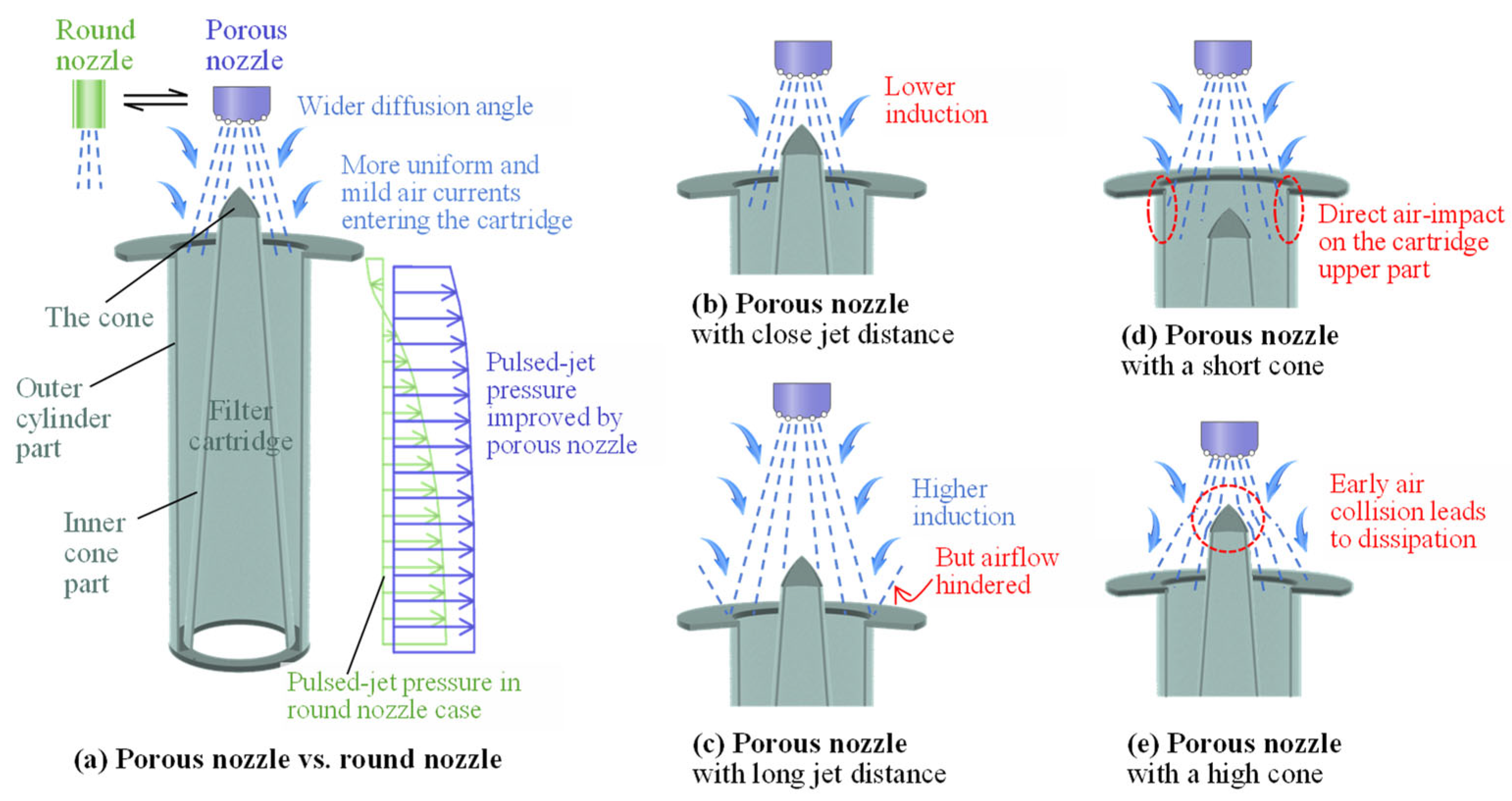

- (1)

- Compared with the common round nozzle, the airflow injected by the porous diffusion nozzle is more divergent, and the divergent effect is stronger than that of the deflector nozzle. This results in a larger entrainment of the jet stream, a milder collision of the jet stream with the gold cone, and a slower overall velocity reduction. More airflow is generated into the filter cartridge and accumulated, and the accumulated static pressure covers a larger range of the upper section of the filter cartridge and persists for a longer duration.

- (2)

- Under the condition of the porous nozzle, the peak pressure at each observation point and the overall pulsed-jet intensity in the cone filter cartridge increase first and then decrease with the increase in JD. The corresponding pulsed-jet intensity in HC = 560, 660, and 760 mm filter cartridges is 2.17, 3.30, and 3.24 times that in the round nozzle. At larger cone heights (>660 mm), the pulsed-jet intensity of the porous nozzle is higher than that of the deflector nozzle. The improvement effect of the porous nozzle on pulsed-jet uniformity is generally superior to that of the deflector nozzle.

- (3)

- In the online filtration and dust cleaning experiment, the residual pressure drop in the porous nozzle case is reduced by 27.0%, the filtration cleaning interval is increased by a factor of 3.80, the average dust emission concentration is reduced by 45.2%, and the comprehensive performance index QF is increased by 5.2% compared with that of the round nozzle. The improvement effect of the porous nozzle on comprehensive performance is weaker than that of the deflector nozzle, but the control of dust emission is better. It is suggested that porous nozzles should be used in places where dust emission concentration is difficult to meet standards or where emission requirements are stricter. For places where the dust removal efficiency is relatively high and more attention is paid to energy saving and consumption reduction, the deflector nozzle should be the preferred option.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Symbols

| α | Permeability (m2) |

| Dust emission concentrations at inlet (mg/m3) | |

| Dust emission concentrations at outlet (mg/m3) | |

| C2 | Inertial resistance loss coefficient (m−1) |

| Cij, | Empirical matrix with C2 (m−1) |

| Dij, | Empirical matrix with 1/α (m−2) |

| Fluid density (kg/m3) | |

| Compressed air pressure before pulse jet (Pa) | |

| Compressed air pressure after pulse jet (Pa) | |

| Pe | Pressure at the nozzle inlet Pe (kPa) |

| Average filtration pressure drop (Pa) | |

| Filtration air volume (m3/s) | |

| QF | Comprehensive performance evaluation index (J−1) |

| Si | Momentum source term (kg·m/s) |

| t | Time (s) |

| Viscosity coefficient (Pa·s) | |

| v | Flow velocity (m/s) |

| V_t | Air tank capacity (m3) |

| n | Jet times (-) |

References

- Yuan, L.; Xue, S.; Zheng, X.; Jiang, B. Current situation and prospects of air quality revolution technology in coal mines. J. Mine Autom. 2023, 49, 32–40. (In Chinese) [Google Scholar]

- Rana, M.S.; Wang, Q.; Wang, W.; Enyoh, C.E.; Islam, M.R.; Isobe, Y.; Kabir, M.H. Sources, Distribution, and Health Implications of Heavy Metals in Street Dust across Industrial, Capital City, and Peri-Urban Areas of Bangladesh. Atmosphere 2024, 15, 1088. [Google Scholar] [CrossRef]

- Yang, J.; Seo, J.; Jee, Y.; Kim, Y.; Sohn, J. Composition Analysis of Airborne Microbiota in Outdoor and Indoor Based on Dust Separated by Micro-sized and Nano-sized. Aerosol Air Qual. Res. 2023, 23, 210231. [Google Scholar] [CrossRef]

- Yuan, J.; Zuo, H.; Jiang, Y.; Zhang, P.; Wang, Z.; Guo, C.; Wang, Z.; Wen, Q.; Chen, Y.; Wei, Y.; et al. Exploring Sources and Health Risks in Beijing PM2.5 in 2019 and 2020. Atmosphere 2023, 14, 1060. [Google Scholar] [CrossRef]

- Kuna, P.; Janovský, B.; Pelikán, V. Effect of energy and design of ignitor on dust explosion characteristics. Fuel 2024, 358, 130339. [Google Scholar] [CrossRef]

- Park, D.H.; Hwang, J.; Shin, D.; Kim, Y.; Lee, G.; Park, I.; Kim, S.B.; Hong, K.; Han, B. Developing an Optimal Antiviral Method for the Air-filtration System of Subway Stations. Aerosol Air Qual. Res. 2023, 23, 230088. [Google Scholar] [CrossRef]

- Huang, C.; Lipatnikov, A.N.; Lövström, C.; Smajovic, N.; Andersson, L.; Ismail, A. Experimental investigation of dust explosions with a focus on black mass in battery recycling. J. Loss Prevent. Proc. 2025, 94, 105526. [Google Scholar] [CrossRef]

- Li, S.; Wei, Y.; Han, M.; Hu, S.; Jin, H.; Huang, Y.; Zhou, G.; Jiang, B.; Li, J.; Hu, P. Research on the dust removal performance of a novel transverse cyclone cartridge filter. Sep. Purif. Technol. 2025, 356, 129994. [Google Scholar] [CrossRef]

- Wu, Q.; Xing, Z.; Chen, D.; Chen, J.; Yang, B.; Zhong, J.; Huang, H.; Ma, Z.; Huang, S.; You, D.; et al. Influence of Particle Surface Energy and Sphericity on Filtration Performance Based on FLUENT-EDEM Coupling Simulation. Atmosphere 2024, 15, 787. [Google Scholar] [CrossRef]

- Li, J.; Chen, D.; Li, S.; Zhou, F. Reverse pulsed-flow cleaning for filtration unit regeneration: A review. Sep. Purif. Technol. 2024, 330, 125441. [Google Scholar] [CrossRef]

- Li, S.; Cheng, H.; Hu, S.; Wen, G.; Zhou, A.; Gui, C.; Yuan, L.; Zhou, F. Study on the influence of built-in open-hole dust cleaner on the cleaning performance of cartridge filter. Process Saf. Environ. 2023, 173, 786–799. [Google Scholar] [CrossRef]

- Hu, S.; Li, S.; Jin, H.; Xie, B.; Liu, H.; Tan, X.; Zhou, F. Study of a new type slit injection pipe on pulse cleaning performance to the rectangular flat pleated filter. Powder Technol. 2021, 394, 459–467. [Google Scholar] [CrossRef]

- Li, J.; Wang, P.; Wu, D.; Chen, D. Numerical study of opposing pulsed-jet cleaning for pleated filter cartridges. Sep. Purif. Technol. 2020, 234, 116086. [Google Scholar] [CrossRef]

- Handte, J.; Bisogni, D.; Huckaby, R.; Listenbee, R.; Simino, A.; Wells, A.; Vangilder, D. Filter Cartridge Comprising a Flow Guiding Device Protruding from a Filter Element, Filter System and Method for Cleaning a Filter Cartridge. US2019247776(A1), 15 August 2019. [Google Scholar]

- Zhang, Y.R.; Han, Y.L.; Qian, F.P.; Li, H.F.; Lu, J.L. Numerical simulation on performances of a new type filter cartridge. Chin. J. Process Eng. 2016, 16, 48–54. (In Chinese) [Google Scholar]

- Li, J.; Zhao, Y.; Sun, Z.; Wu, Q.; Zhong, Y.; Wu, Q.; Ma, Z.; Wu, D. Numerical simulation of improved pulse jet performance by annular slit nozzle for the filter cartridge with an inner cone deflector. J. Nanchang Univ. (Eng. Technol.) 2023, 45, 9–15. (In Chinese) [Google Scholar]

- Qiu, J.; Wu, D.; Chen, D.; Li, J. Reverse pulsed-flow cleaning of pleated filter cartridges having an inner pleated filter cone. Process Saf. Environ. 2021, 146, 481–489. [Google Scholar] [CrossRef]

- Chen, Q. Numerical Simulation and Experimental Study of Diffusion Nozzle Improving Pulse Jet Cleaning Performance of Gold Cone Filter Cartridge; Nanchang University: Nanchang, China, 2021. (In Chinese) [Google Scholar]

- Su, Z. Research on Pulsed-Jet Cleaning Performance for Golden Cone Filter Cartridge and Its Improvement Using Venturi Nozzle; Nanchang University: Nanchang, China, 2022. (In Chinese) [Google Scholar]

- Yang, B.; Chen, J.; Li, J.; Xie, W.; Wu, Q.; You, D.; Huang, S.; Sun, S.; Jiang, Z. A numerical study on the design of a diffuser nozzle for pulsed-jet cleaning of cone filter cartridges. Atmosphere 2025, 16, 379. [Google Scholar] [CrossRef]

- Li, J.; Xie, W.; Wu, Q.; Chen, D.; Shi, D.; Chen, Q.; Ma, Z.; Wu, D. Improved pulsed-jet cleaning of pleated cone filter cartridges using a diffusion nozzle. Aerosol Air Qual. Res. 2023, 23, 220324. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, Q.; Xing, Z.; Xu, Y.; Tang, Y.; Li, Y.; Wang, Y.; Wang, H.; Liu, Z.; Xie, W.; Sun, S.; et al. Study on Improving Pulsed-Jet Performance in Cone Filter Cartridges Using a Porous Diffusion Nozzle. Atmosphere 2025, 16, 1206. https://doi.org/10.3390/atmos16101206

Wu Q, Xing Z, Xu Y, Tang Y, Li Y, Wang Y, Wang H, Liu Z, Xie W, Sun S, et al. Study on Improving Pulsed-Jet Performance in Cone Filter Cartridges Using a Porous Diffusion Nozzle. Atmosphere. 2025; 16(10):1206. https://doi.org/10.3390/atmos16101206

Chicago/Turabian StyleWu, Quanquan, Zhenqiang Xing, Yufan Xu, Yuanbing Tang, Yangyang Li, Yuxiu Wang, Heli Wang, Zhuo Liu, Wenjun Xie, Shukai Sun, and et al. 2025. "Study on Improving Pulsed-Jet Performance in Cone Filter Cartridges Using a Porous Diffusion Nozzle" Atmosphere 16, no. 10: 1206. https://doi.org/10.3390/atmos16101206

APA StyleWu, Q., Xing, Z., Xu, Y., Tang, Y., Li, Y., Wang, Y., Wang, H., Liu, Z., Xie, W., Sun, S., You, D., & Li, J. (2025). Study on Improving Pulsed-Jet Performance in Cone Filter Cartridges Using a Porous Diffusion Nozzle. Atmosphere, 16(10), 1206. https://doi.org/10.3390/atmos16101206