Carbon Emission Accounting and Emission Reduction Path of Container Terminal Under Low-Carbon Perspective

Abstract

1. Introduction

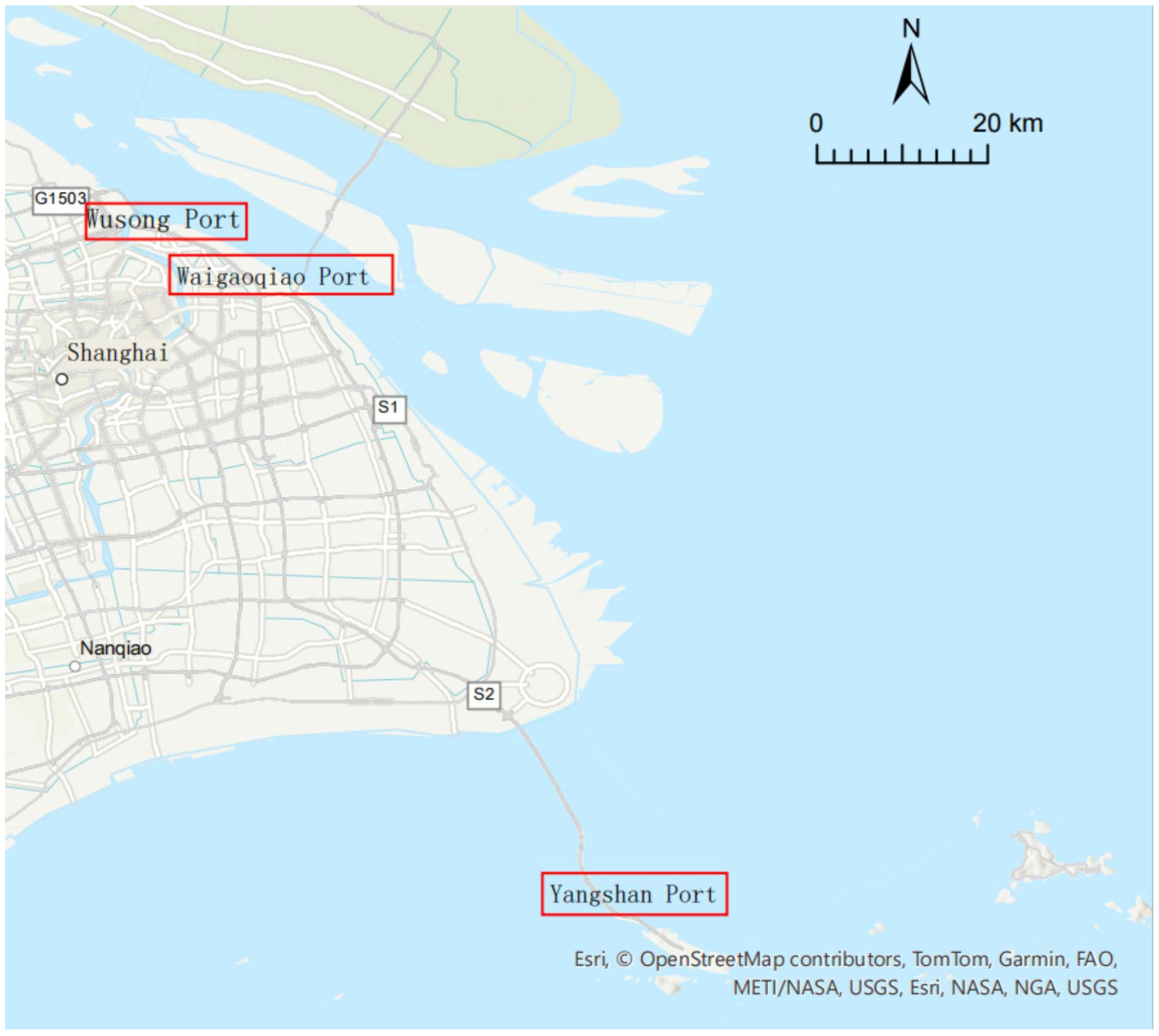

2. Accounting and Analysis of Carbon Emissions from Shanghai Port Container Terminal

2.1. Carbon Emission Accounting for Shanghai Port Container Terminals

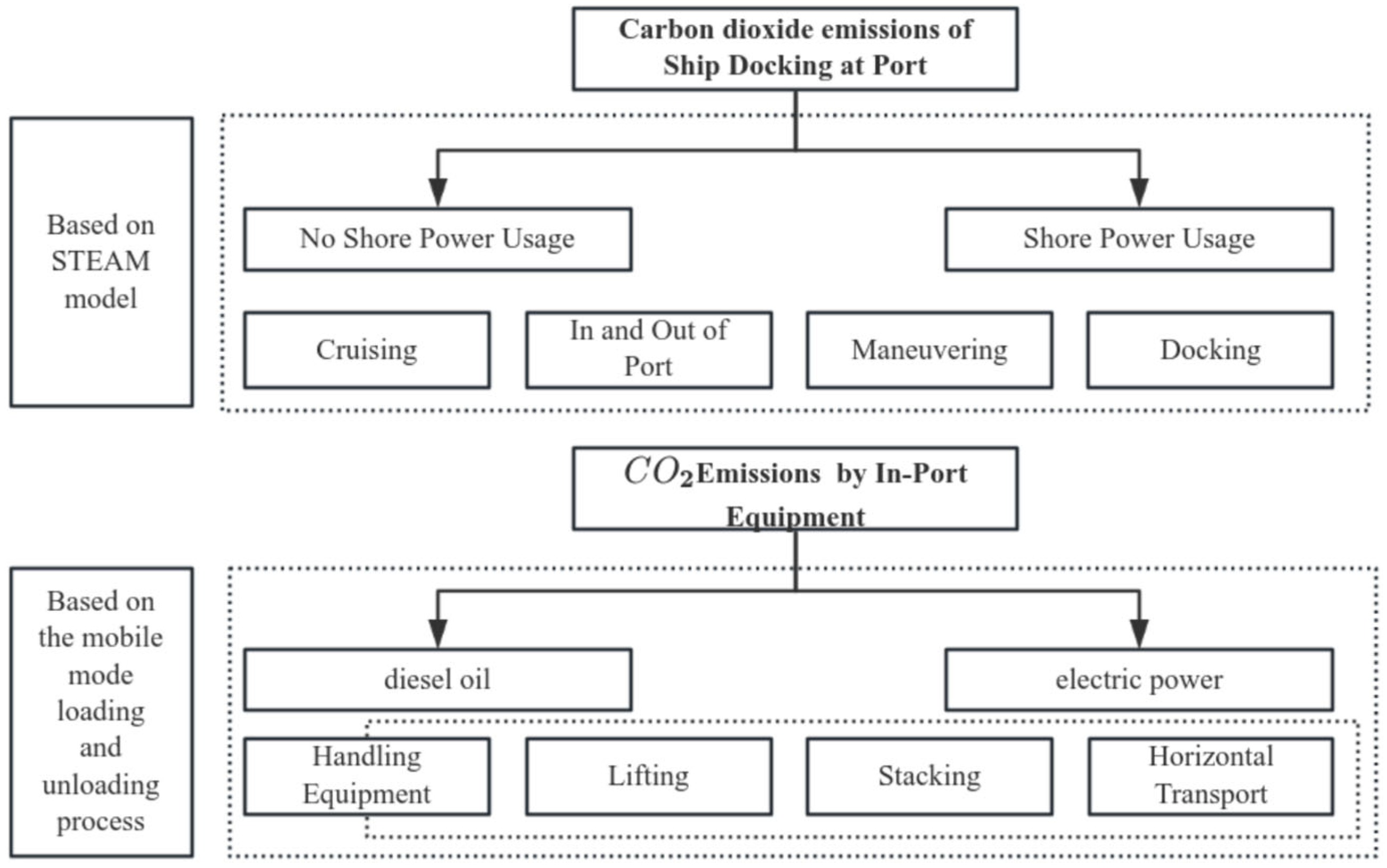

2.1.1. Carbon Emissions from Ships Based on the STEAM Accounting

2.1.2. Carbon Emission Accounting for Container Terminals Based on Mobile Mode Loading and Unloading Processes

2.2. Results and Discussion

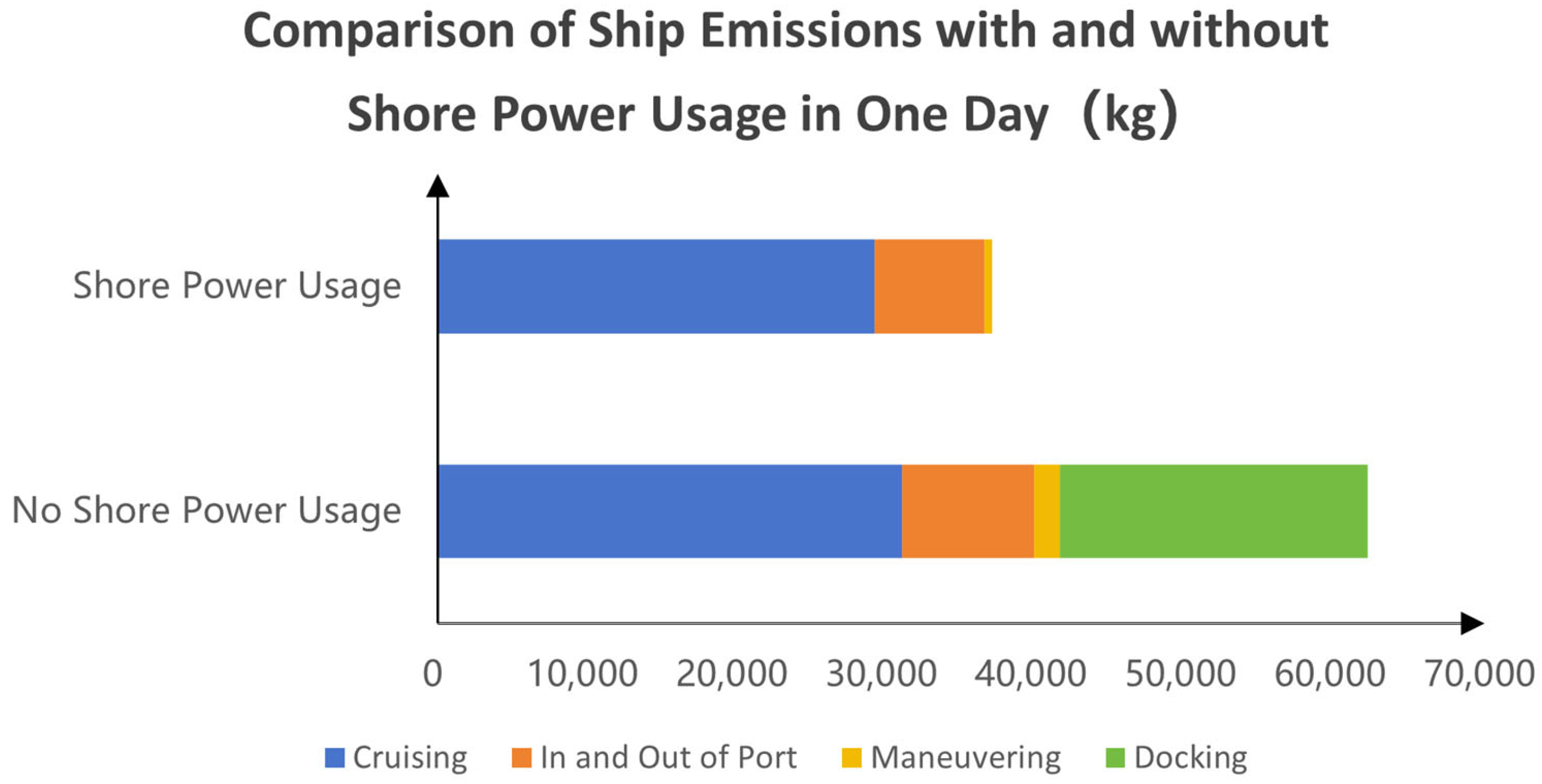

2.2.1. Carbon Emissions from Container Ship Port Call Operations Analysis of Accounting Results

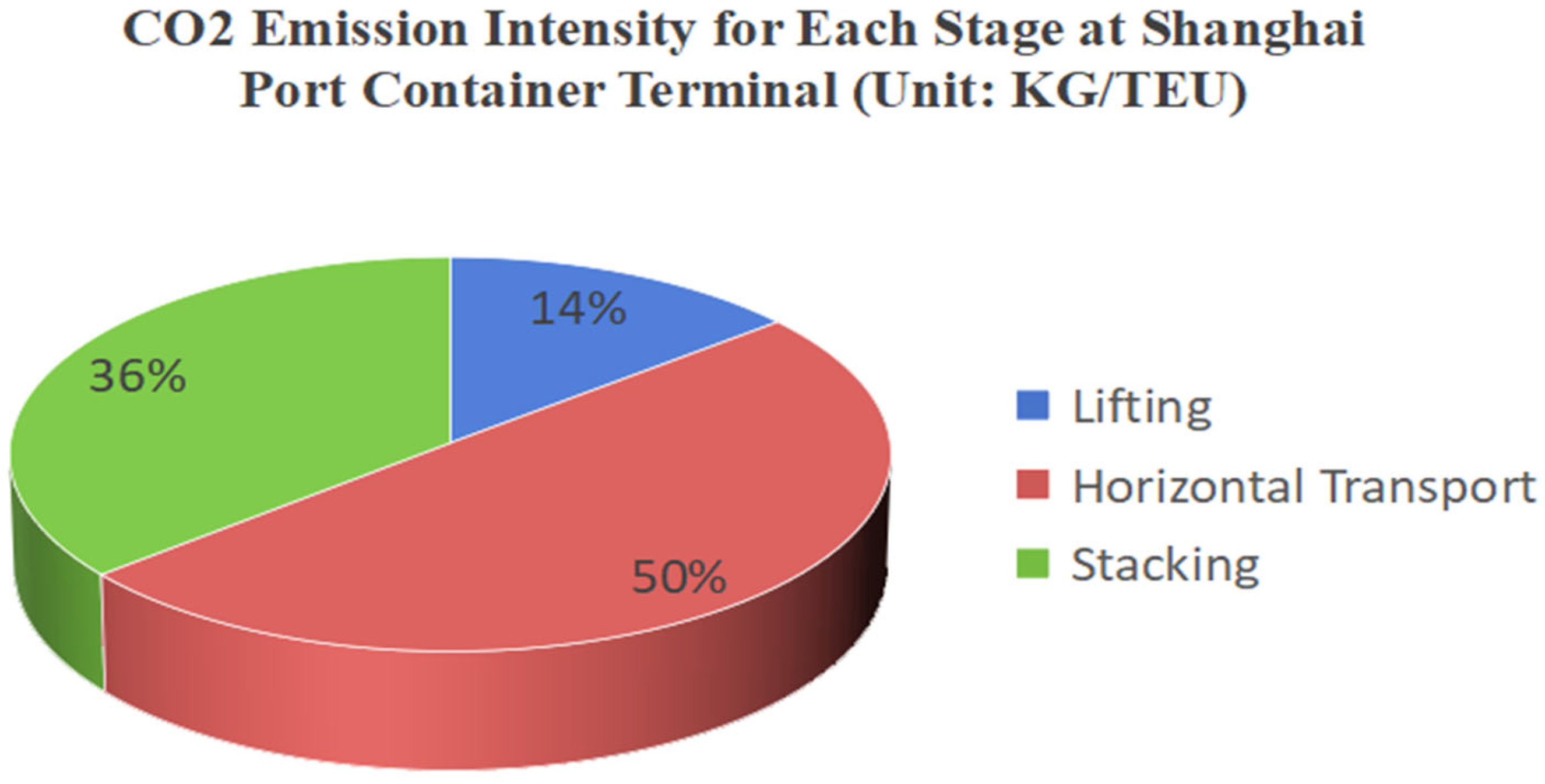

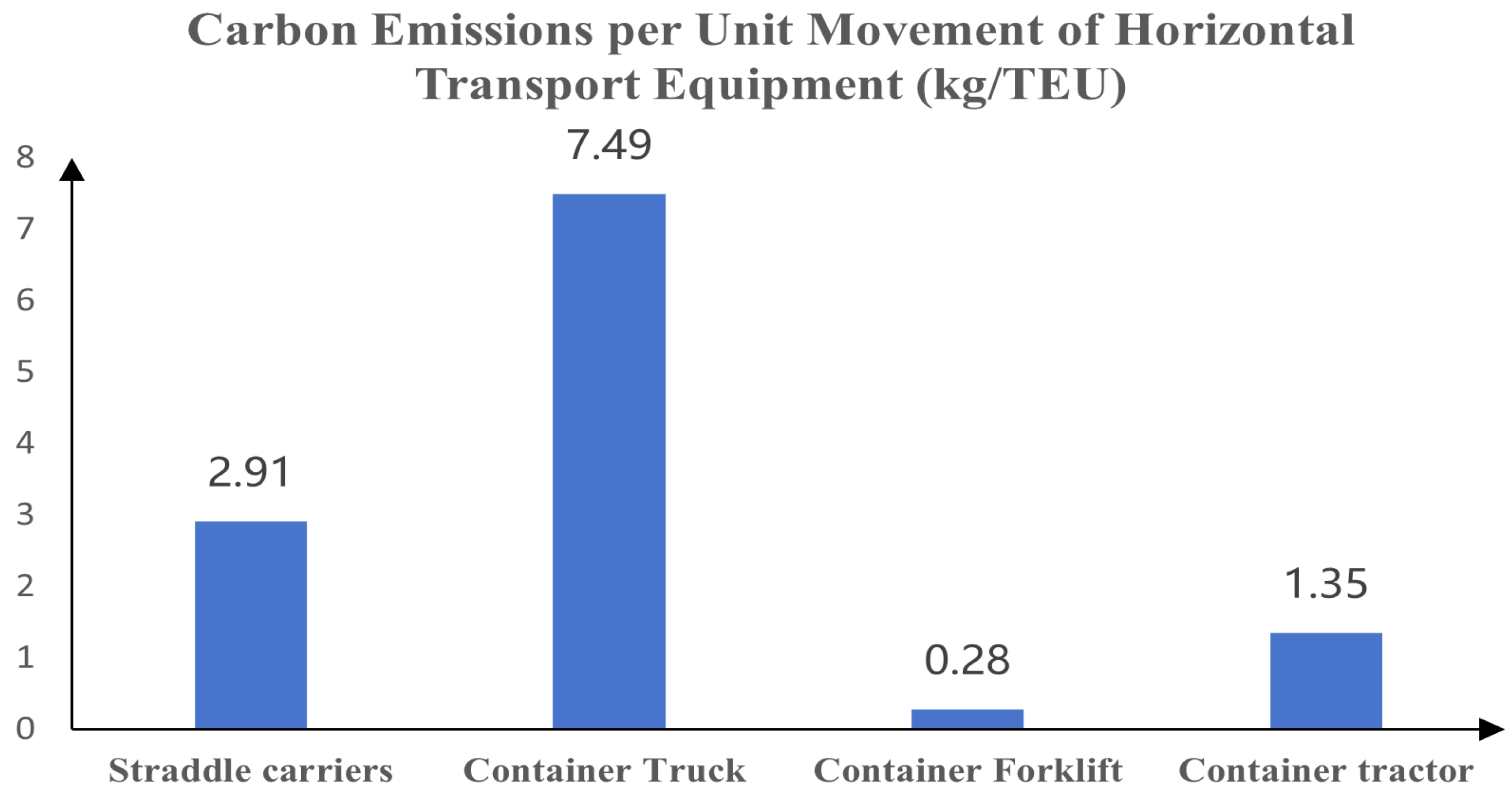

2.2.2. Carbon Emissions from Container Terminal In-Port Operations Analysis of Accounting Results

3. Shanghai Port Container Terminal Emission Reduction Path Study

3.1. Study on Emission Reduction Countermeasures for Container Ship Port Calling Process Considering Ship Shore Power Usage

- Port management and power-related departments can further optimize the power supply and power system between ports and ships, improve the degree of their matching, and enhance the technical level of the shore power system.

- Government departments can increase financial support and improve tariff preferential policies to control the cost of shore power not to be higher than the cost of fuel power generation.

- Port authorities may provide subsidies to shipping companies that use shore power during port calls. Maritime and related management departments can give priority to the passage of ships using shore power, and give priority to berths for ships with power receiving facilities, so as to enhance the enthusiasm of ships using shore power in ports and harbors.

3.2. Emission Reduction Path of Shanghai Port Container Terminal’s In-Harbor Operations

3.2.1. Container Terminal Handling Side Optimization

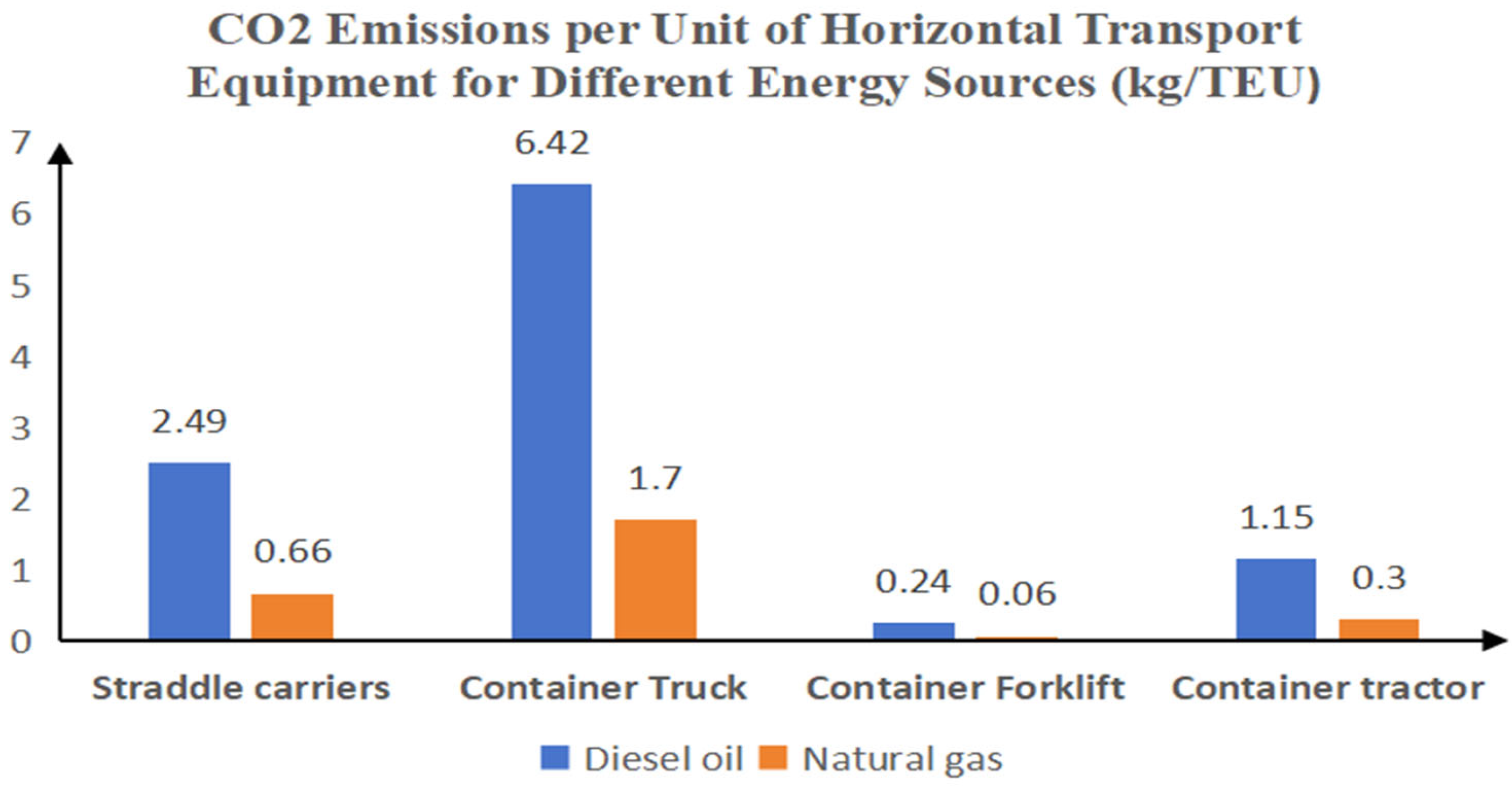

3.2.2. “Oil-to-Gas” Conversion of In-Port Transportation Equipment

3.2.3. “Oil-to-Electricity” Conversion of In-Port Transportation Equipment

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, R.; Liu, Z.; Zhao, J.Y.; Cui, D.D.; Jiang, H. Research on Carbon Emission Accounting Methods in the Logistics Industry at Home and Abroad. Transp. Energy Conserv. Environ. Prot. 2023, 19, 64–71. [Google Scholar] [CrossRef]

- Chen, W.J.; Song, B.L.; Zhang, J.S. Carbon emission from coastal container ports in China based on AIS data. China Environ. Sci. 2022, 42, 3403–3411. [Google Scholar] [CrossRef]

- Tao, X.Z.; Li, H.Q.; Wang, Q.Y. Development process, policy measures, and social benefits analysis of shore power construction and utilization in Shanghai Port. Transp. Port Navig. 2022, 9, 73–77. [Google Scholar] [CrossRef]

- Zeng, B.; Zhao, J. Exploration of ship emission reduction strategies in Shanghai Port. China Ocean. Law Rev. 2015, 2, 324–332. [Google Scholar] [CrossRef]

- Zeng, F.T.; Lv, J. Ship emission inventory and port eco-efficiency evaluation of Xiamen Port. China Environ. Sci. 2020, 40, 2304–2311. [Google Scholar] [CrossRef]

- Berechman, J.; Tseng, P.H. Estimating the environmental costs of port related emissions: The case of Kaohsiung. Transp. Res. Part D Transp. Environ. 2012, 17, 35–38. [Google Scholar] [CrossRef]

- Li, X.D.; Kuang, H.B.; He, H.Y. Evolutionary game research on emission reduction in port and shipping systems under government environmental regulation. J. Transp. Syst. Eng. Inf. Technol. 2023, 23, 17–29. [Google Scholar] [CrossRef]

- Chen, Z.S.; Huang, Y.D.; Zhang, Y. Discussion on Statistical and Calculation Methods for Transportation Carbon Emissions. West. China Commun. Sci. Technol. 2023, 7, 204–206. [Google Scholar] [CrossRef]

- Liu, L.; Ding, H. Review of Estimation and Decomposition Methods for Greenhouse Gas Emissions. Value Eng. 2010, 29, 223–224. [Google Scholar]

- Zhang, Z.; Rong, W.; Liu, Y.; Yang, Y. Port carbon emission estimation: Principles, practices, and machine learning applications. Transp. Res. Part E: Logist. Transp. Rev. 2025, 199, 104159. [Google Scholar] [CrossRef]

- Freitas, D.; Gervásio, H. The challenge of benchmarking carbon emissions in maritime ports. Environ. Pollut. 2024, 363, 125170. [Google Scholar] [CrossRef]

- Mou, N.; Zhang, X.; Yang, T.; Xu, H.; Zheng, Y.; Wang, J.; Niu, J. Carbon footprints: Uncovering multilevel spatiotemporal changes of ship emissions during 2019–2021 in the US. Sci. Total Environ. 2024, 912, 169395. [Google Scholar] [CrossRef]

- Villalba, G.; Gemechu, E.D. Estimating GHG emissions of marine ports—The case of Barcelona. Energy Policy 2011, 39, 1363–1368. [Google Scholar] [CrossRef]

- Fan, A.H.; Yan, X.P.; Li, Z.K.; Zhang, H.Y. The Demand, Pathways, and Prospects of Green and Low-Carbon Development in China's Shipping Industry. Ship Ocean. Eng. 2024, 53, 1–5+12. [Google Scholar]

- Budiyanto, M.A.; Huzaifi, M.H.; Sirait, S.J.; Prayoga, P.H.N. Evaluation of CO2 emissions and energy us with different container terminal layouts. Sci. Rep. 2021, 11, 5476. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.C. Operating strategies of CO2 reduction for a container terminal based on carbon footprint perspective. J. Clean. Prod. 2017, 141, 472–480. [Google Scholar] [CrossRef]

- Chang, C.C.; Wang, C.M. Evaluating the effects of green port policy: Case study of Kaohsiung harbor in Taiwan. Transp. Res. Part D Transp. Environ. 2012, 17, 185–189. [Google Scholar] [CrossRef]

- Yang, Y.C.; Lin, C.L. Performance analysis of cargo-handling equipment from a green container terminal perspective. Transp. Res. Part D Transp. Environ. 2013, 23, 9–11. [Google Scholar] [CrossRef]

- Okşaş, O. Carbon emission strategies for container handling equipment using the activity-based method: A case study of Ambarlı container port in Turkiye. Mar. Policy 2023, 149, 105480. [Google Scholar] [CrossRef]

- Zhang, Y.; Peng, Y.Q.; Wang, W.; Gu, J.; Wu, X.J.; Feng, X.J. Air emission inventory of container ports’ cargo handling equipment with activity-based “bottom-up” method. Adv. Mech. Eng. 2017, 9, 1687814017711389. [Google Scholar] [CrossRef]

- Wang, L.; Li, Y. Estimation methods and reduction strategies of port carbon emissions-what literatures say? Mar. Pollut. Bull. 2023, 195, 115451. [Google Scholar] [CrossRef]

- Zhang, C.; Yang, Y.; Wang, N. Port governance and sustainable development: The impact of port smartization on port carbon emission efficiency. Ocean. Coast. Manag. 2024, 259, 107485. [Google Scholar] [CrossRef]

- Qi, Y.; Yang, J.; Qin, K.S. Spatial-temporal analysis of carbon emissions from ships in ports based on AIS data. Ocean. Eng. 2024, 308, 118394. [Google Scholar] [CrossRef]

- Yang, A.; Meng, X.; He, H.; Wang, L.; Gao, J. Towards optimized armgs’ low-carbon transition investment decision based on real options. Energies 2022, 15, 5153. [Google Scholar] [CrossRef]

- Li, Q. Current Situation of Carbon Emissions in China’s Waterway Transportation and Analysis of Carbon Reduction Paths . Transp. Energy Conserv. Environ. Prot. 2021, 17, 1–4+12. [Google Scholar] [CrossRef]

- Liang, J.B.; Chen, R. Research and Application of a Port Carbon Emission Accounting System. Port Waterw. Eng. 2024, 07, 51–55. [Google Scholar] [CrossRef]

- Peng, C.S. Port Carbon Emissions Accounting Methods: A Case Study of the 2010 Carbon Footprint Report of Jurong Port, Singapore. Port Econ. 2012, 7, 5–9. [Google Scholar]

- Tai, H.H.; Chang, Y.H. Reducing pollutant emissions from vessel maneuvering in port areas. Marit. Econ. Logist. 2022, 24, 651. [Google Scholar] [CrossRef]

- Zhou, C.; Tang, W.; Liu, Z.; Huang, H.; Huang, L.; Xiao, C.; Wu, L. Exploring carbon emission reduction in inland port ship based on a multi-scenario model. J. Mar. Sci. Eng. 2024, 12, 1553. [Google Scholar] [CrossRef]

- Chang, Y.T.; Song, Y.; Roh, Y. Assessing greenhouse gas emissions from port vessel operations at the Port of Incheon. Transp. Res. Part D Transp. Environ. 2013, 25, 1–4. [Google Scholar] [CrossRef]

- Fu, Q.; Shen, Y.; Zhang, J. Study on the Emission Inventory of Atmospheric Pollutants from Ships in Shanghai Port. J. Saf. Environ. 2012, 12, 57–64. [Google Scholar] [CrossRef]

- Xuan, H.; Liang, P.; Sun, J.; Zhang, Q. Problems and Countermeasures for the Green and Low-Carbon Development of the Waterway Transport Industry. Environ. Impact Assess. 2022, 44, 59–64. [Google Scholar] [CrossRef]

- Kontovas, C.; Psaraftis, H.N. Reduction of emissions along the maritime intermodal container chain: Operational models and policies. Marit. Policy Manag. 2011, 38, 451–469. [Google Scholar] [CrossRef]

- Georgakaki, A.; Coffey, R.A.; Lock, G.; Sorenson, S.C. Transport and Environment Database System (TRENDS): Maritime air pollutant emission modelling. Atmos. Environ. 2005, 39, 2357–2365. [Google Scholar] [CrossRef]

- Dong, G.; He, X. Research on Carbon Emissions of Container Terminals Based on Loading and Unloading Processes. Mod. Manag. Sci. 2014, 2, 99–101. [Google Scholar] [CrossRef]

| Ship Attributes | Data (Unit) | |

|---|---|---|

| Average Ship Length Average Ship Width Average Tonnage Average Type Main Engine Rated Power Auxiliary Engine Rated Power Boiler Power Usage | 400 m 60 m 200,000 t 20,000 TEU 77,000 kw 3000 kw 1000 kw | |

| Main Engine/Auxiliary Engine Load Factor | Cruising In and Out of Port Maneuvering Docking | 0.37/0.13 0.14/0.25 0.01/0.5 0/0.17 |

| Average Activity Time | Cruising In and Out of Port Maneuvering Docking | 1.5 h 1 h 0.6 h 15.6 h |

| Category | SO2 |

|---|---|

| Main Engine Auxiliary Engine Boiler Boiler | 0.012 0.012 0.017 |

| Fuel Type | CO2 | SO2 |

|---|---|---|

| Diesel | 1 | 0.56 |

| 0.5% Light Diesel | 1 | 0.18 |

| 0.2% Light Diesel | 1 | 0.07 |

| Function | Equipment Name |

|---|---|

| Lifting | Gantry Crane Barge Crane |

| Horizontal Transport | Container Transporter Container Truck Container Forklift Container tractors |

| Stacking | Reach Stacker Rail Mounted Gantry Crane Automatic Stacking |

| Drive | Equipment | Number of Unit Container Displacements Completed (Times/TEU) | Unit Fixed Energy Consumption | Unit Variable Energy Consumption | Operation Distance per Unit Container Displacement (km/Times) |

|---|---|---|---|---|---|

| diesel oil | Container Transporter | 0.65 | 0.80 L | 3.50 L/km | 0.25 |

| Container Truck | 0.86 | 1.10 L | 1.80 L/km | 1.2 | |

| Container Forklift | 0.04 | / | 4.00 L/km | 0.65 | |

| Container tractor | 0.06 | / | 4.20 L/km | 2 | |

| electric power | Gantry Crane | 0.48 | 6.00 kwh | / | / |

| Barge Crane | 0.29 | 4.00 kwh | / | / | |

| Tire Crane | 1 | 5.00 kwh | / | / | |

| Automatic Stacking Crane | 1 | 5.00 kwh | / | / |

| Shore Power Usage | Activity Stage | CO2 Emissions (kg) | Percentage (%) |

|---|---|---|---|

| No Shore Power Usage | Cruising | 31,042.55 | 49.93 |

| In and Out of Port | 8844.99 | 14.23 | |

| Maneuvering | 1722.61 | 2.77 | |

| Docking | 20,565.95 | 33.07 | |

| Shore Power Usage | Cruising | 29,188.00 | 78.72 |

| In and Out of Port | 7362.74 | 19.86 | |

| Maneuvering | 525.91 | 1.42 | |

| Docking | 0.00 | 0.00 |

| Stage | Equipment | CO2 Unit Emission (kg/TEU) |

|---|---|---|

| Lifting | Gantry Crane | 1.62 |

| Barge Crane | 0.65 | |

| Stacking | Tire Crane | 2.81 |

| Automatic Stacking Crane | 2.81 | |

| Horizontal Transport | Straddle carriers | 2.91 |

| Container Truck (Horizontal Transport) | 7.49 | |

| Container Forklift | 0.28 | |

| Container tractor | 1.35 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, B.; Cheng, L.; Wang, H.; Li, J.; Xu, Z.; Pan, C. Carbon Emission Accounting and Emission Reduction Path of Container Terminal Under Low-Carbon Perspective. Atmosphere 2025, 16, 1158. https://doi.org/10.3390/atmos16101158

Li B, Cheng L, Wang H, Li J, Xu Z, Pan C. Carbon Emission Accounting and Emission Reduction Path of Container Terminal Under Low-Carbon Perspective. Atmosphere. 2025; 16(10):1158. https://doi.org/10.3390/atmos16101158

Chicago/Turabian StyleLi, Bingbing, Long Cheng, Huangqin Wang, Jiaren Li, Zhenyi Xu, and Chengrong Pan. 2025. "Carbon Emission Accounting and Emission Reduction Path of Container Terminal Under Low-Carbon Perspective" Atmosphere 16, no. 10: 1158. https://doi.org/10.3390/atmos16101158

APA StyleLi, B., Cheng, L., Wang, H., Li, J., Xu, Z., & Pan, C. (2025). Carbon Emission Accounting and Emission Reduction Path of Container Terminal Under Low-Carbon Perspective. Atmosphere, 16(10), 1158. https://doi.org/10.3390/atmos16101158