Concentration Distribution and Physicochemical Properties of 10 nm–10 μm Coal Dust Generated by Drum Cutting Different Rank Coals: A Physical Simulation Experiment

Abstract

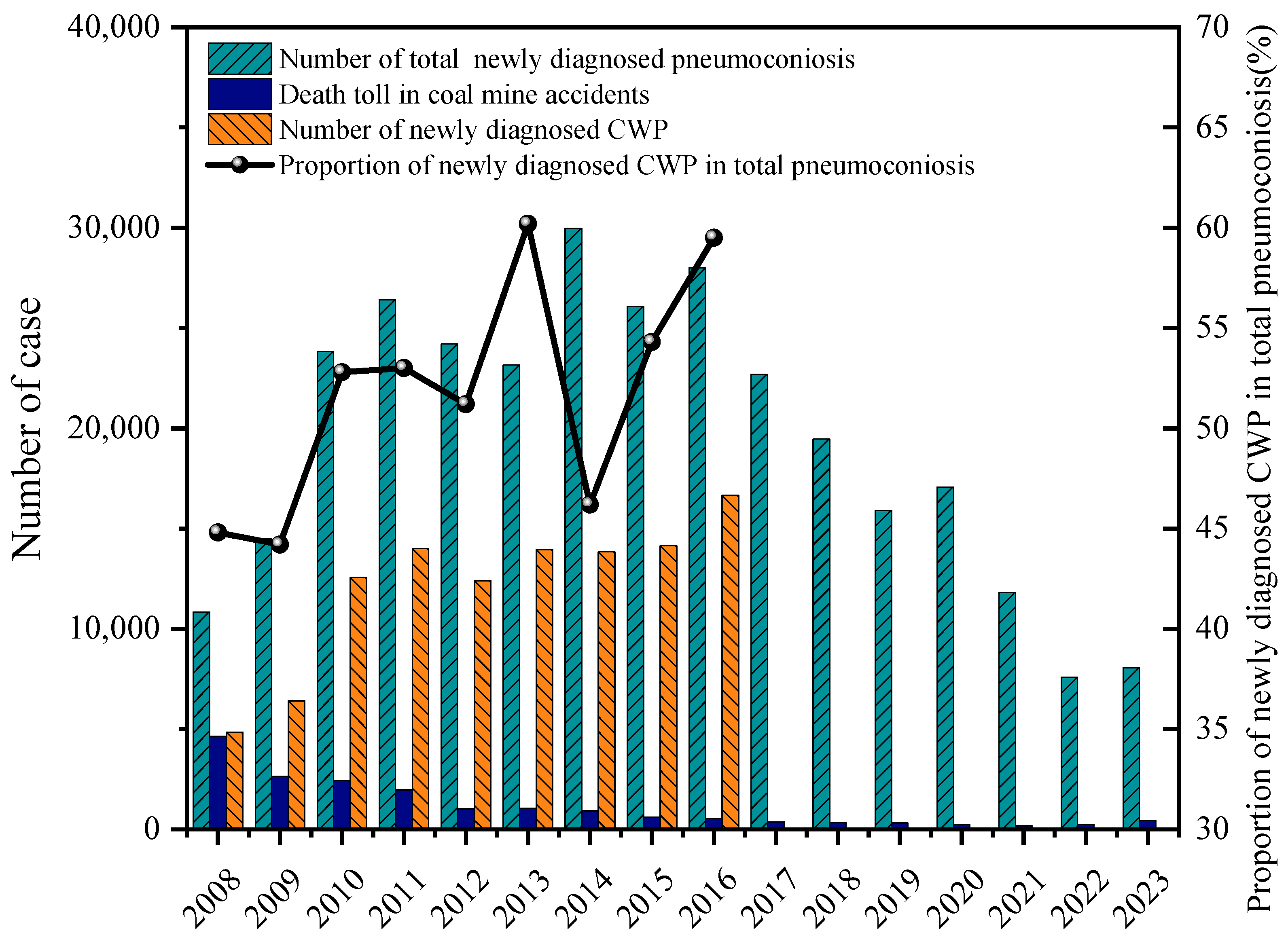

1. Introduction

2. Materials and Methods

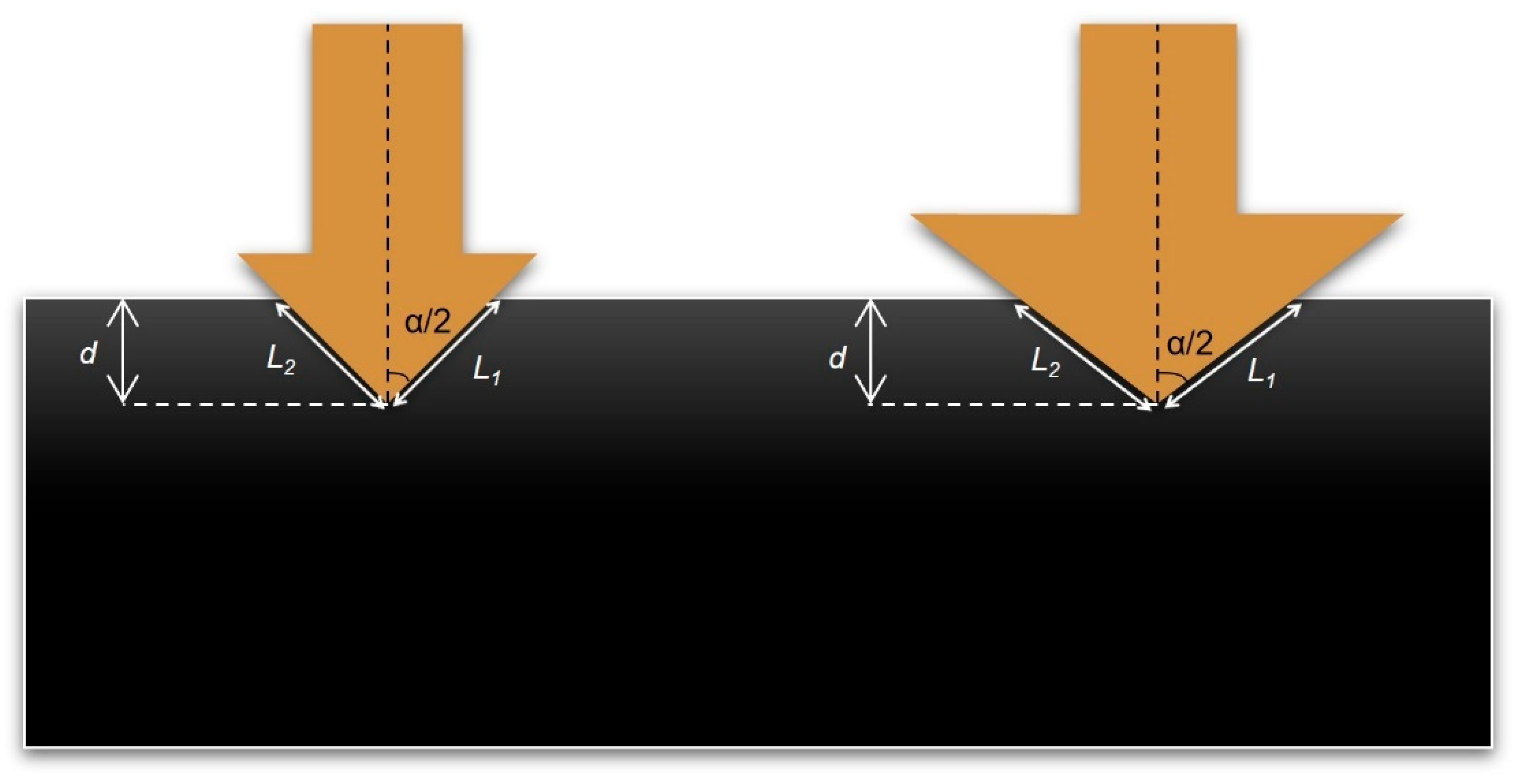

2.1. Self-Developed Experimental System for Simulating Dust Generation from Drum Cutting of Coal Bodies

2.2. Experimental Coal Samples

2.3. Drum Cutting Parameters

2.4. Experimental Procedure

3. Results

3.1. Mass Concentration Distribution of 10 nm–10 μm Coal Dust at Different Cutting Parameters

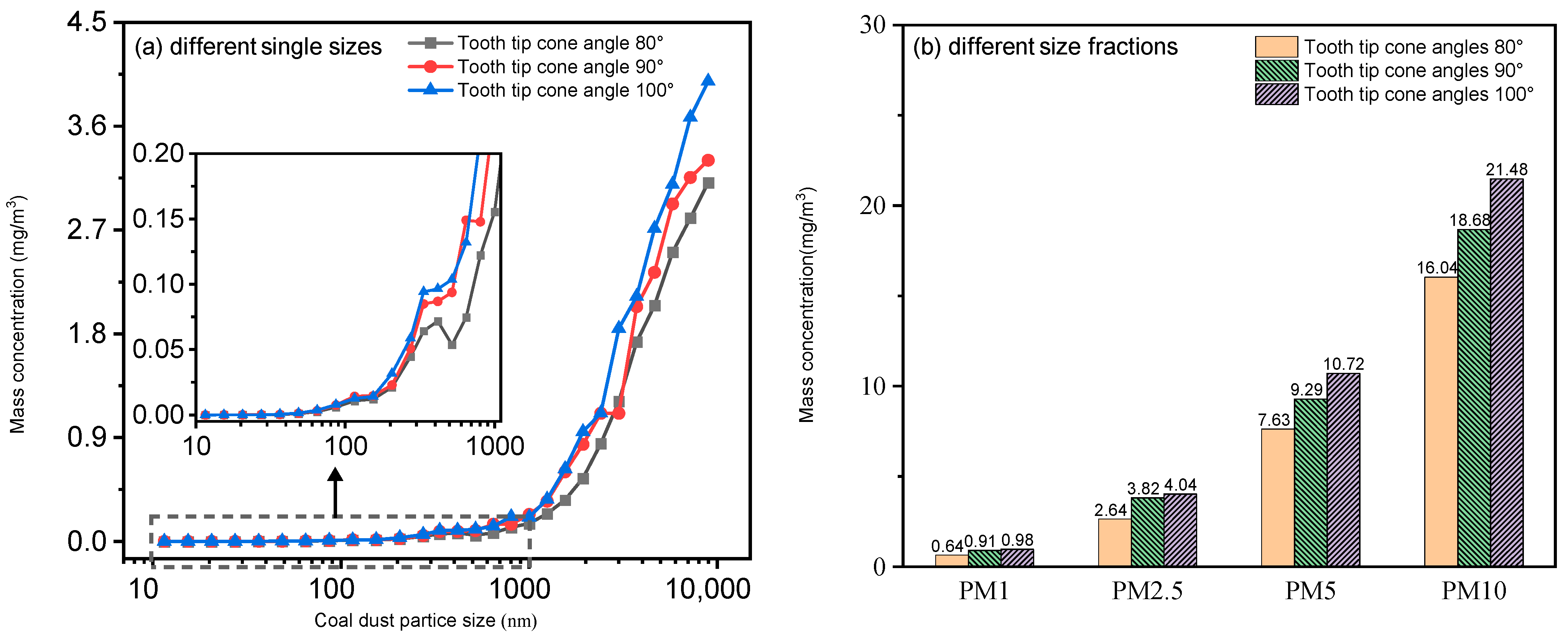

3.1.1. Mass Concentration Distribution of 10 nm–10 μm Coal Dust at Different Tooth Tip Cone Angles

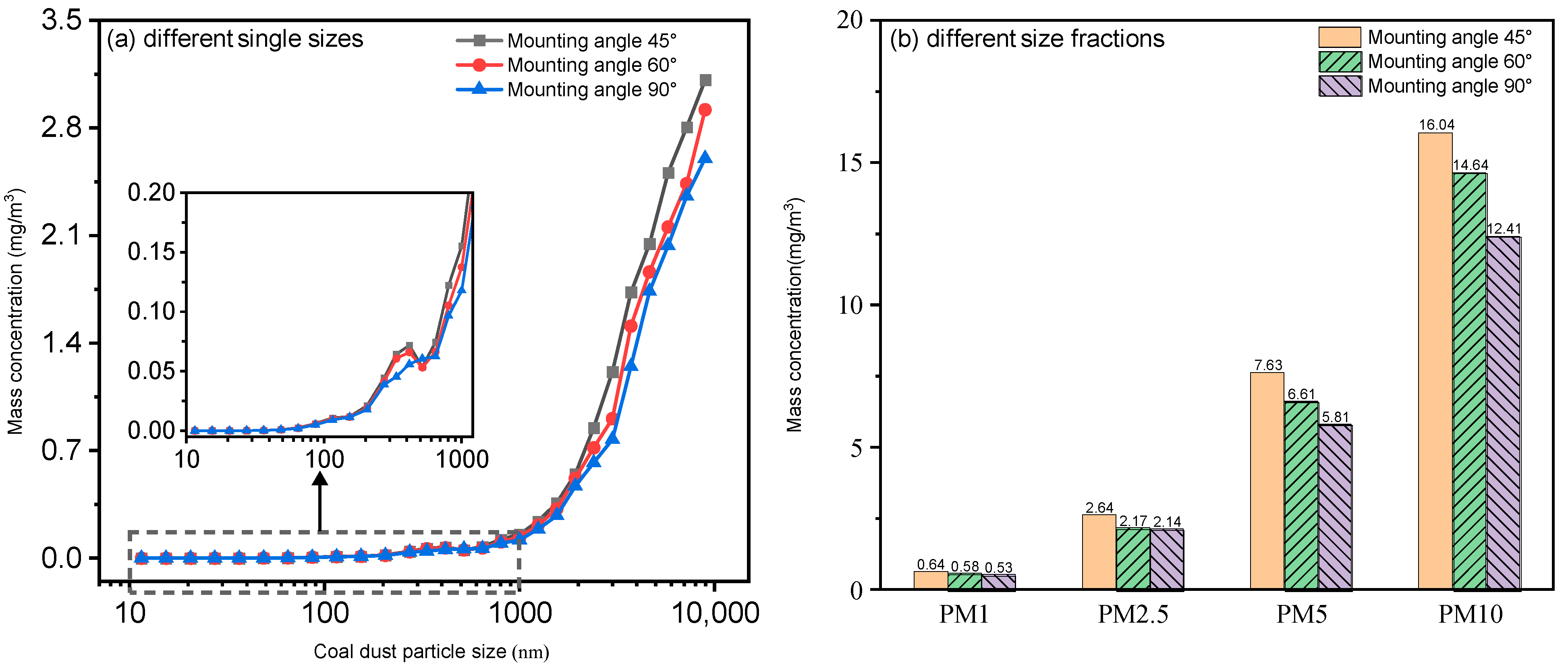

3.1.2. Mass Concentration Distribution of 10 nm–10 μm at Different Mounting Angles

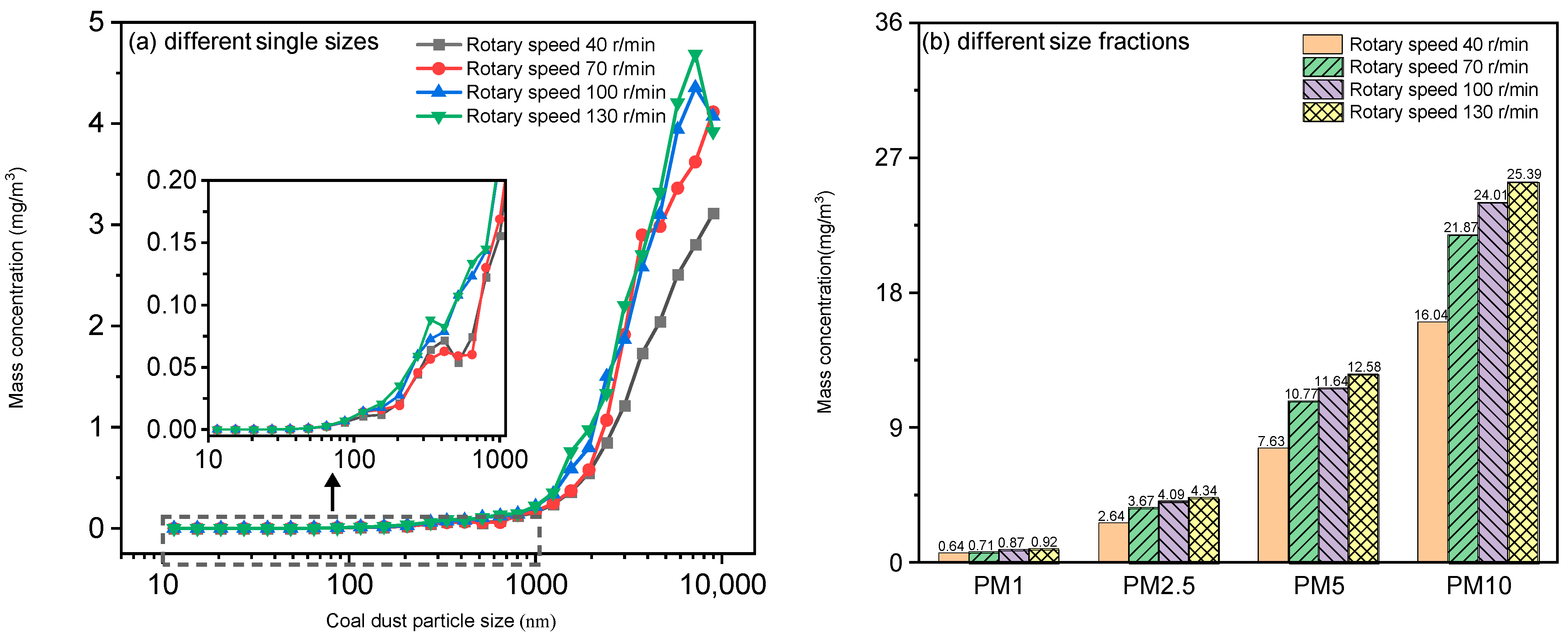

3.1.3. Mass Concentration Distribution of 10 nm–10 μm Coal Dust at Different Rotary Speeds

3.1.4. Mass Concentration Distribution of 10 nm–10 μm Coal Dust at Different Cutting Depths

3.2. Number Concentration Distribution of 10 nm–10 μm Coal Dust at Different Cutting Parameters

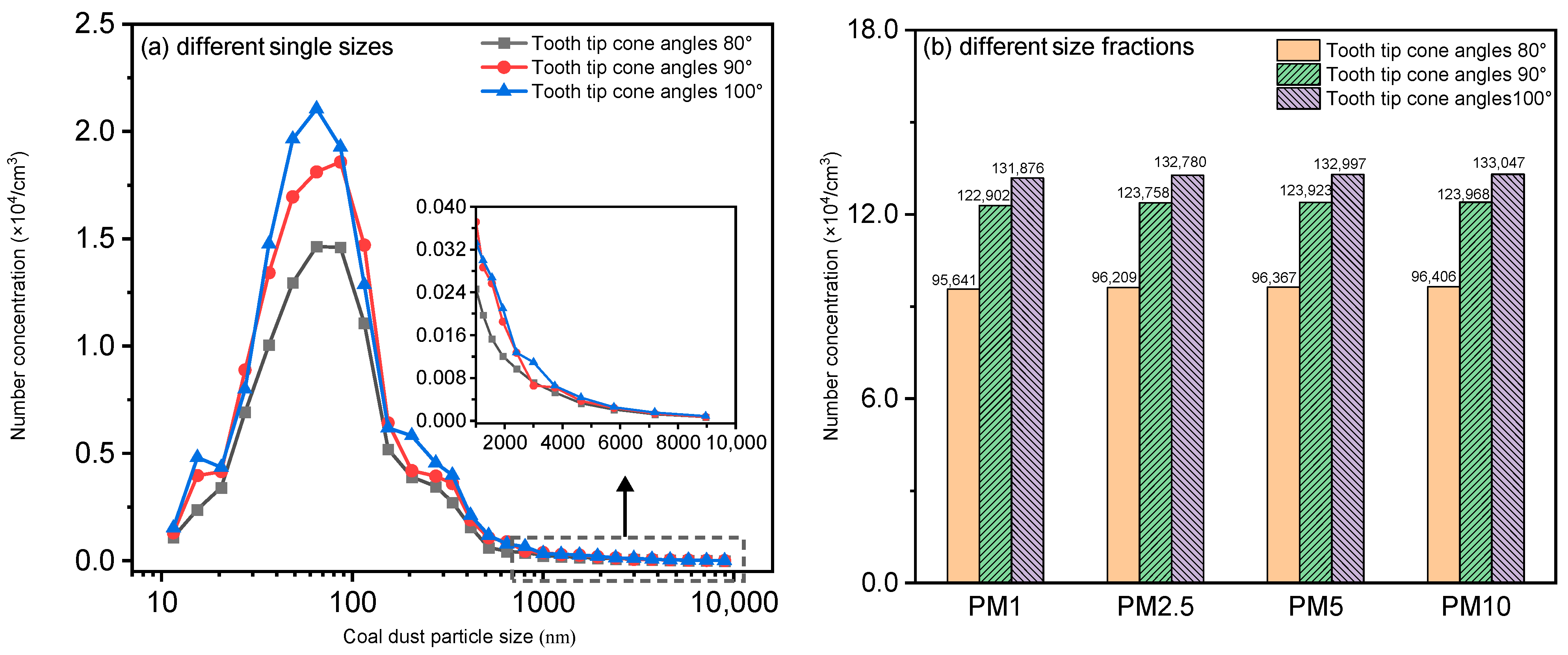

3.2.1. Number Concentration Distribution of 10 nm–10 μm Coal Dust at Different Tooth Tip Cone Angles

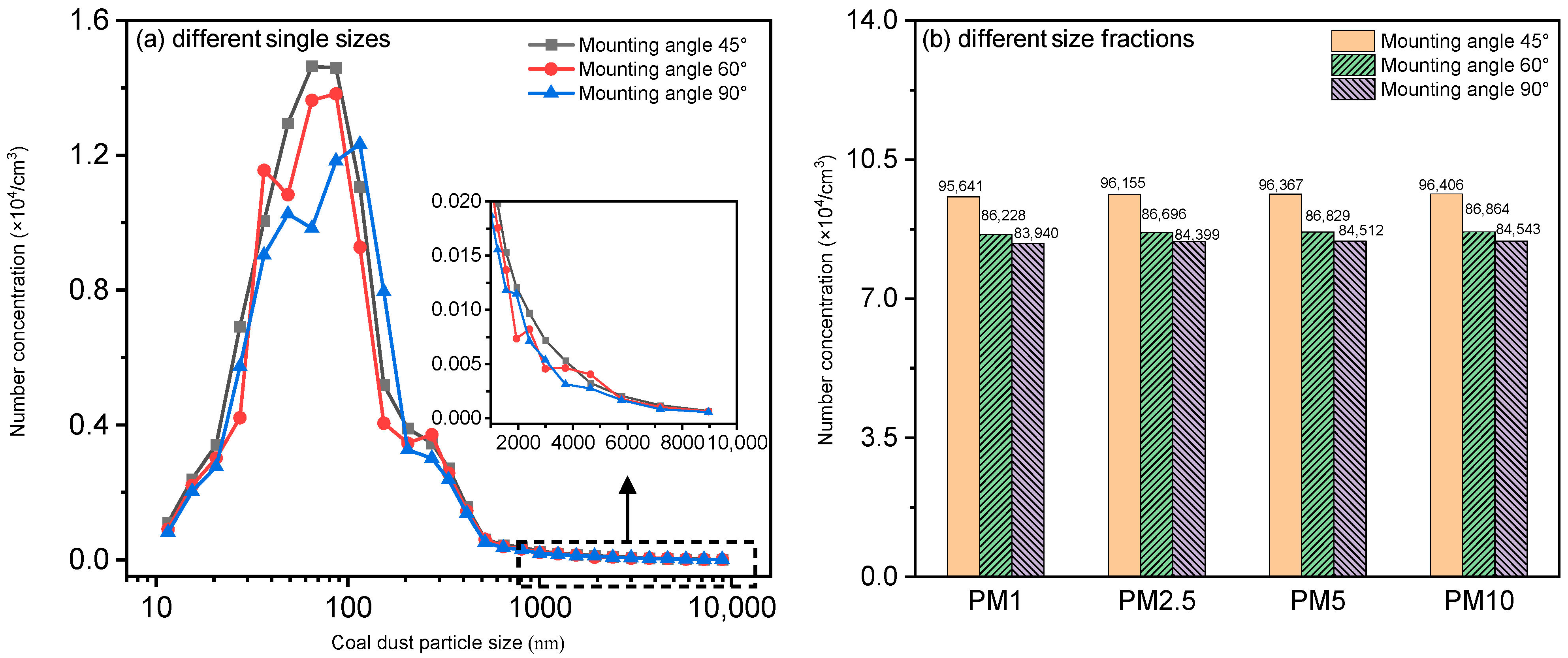

3.2.2. Number Concentration Distribution of 10 nm–10 μm Coal Dust at Different Mounting Angles

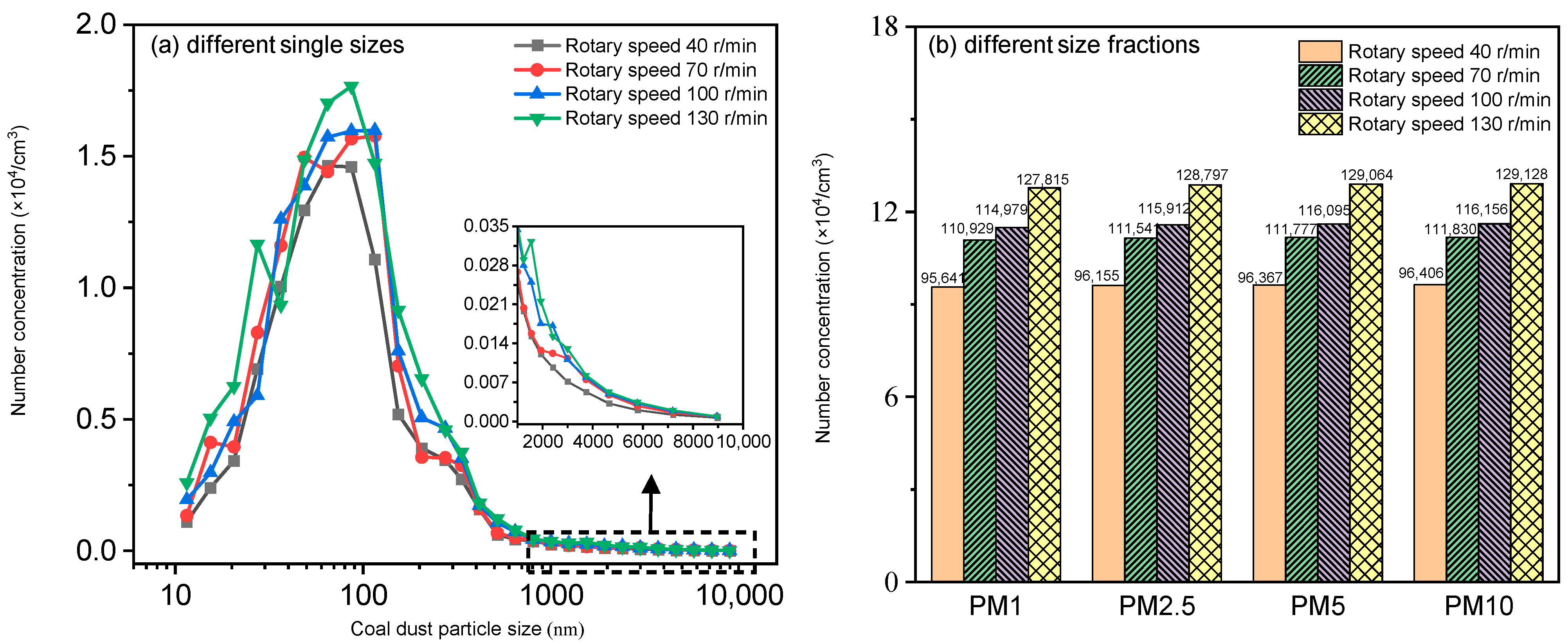

3.2.3. Number Concentration Distribution of 10 nm–10 μm Coal Dust at Different Rotary Speeds

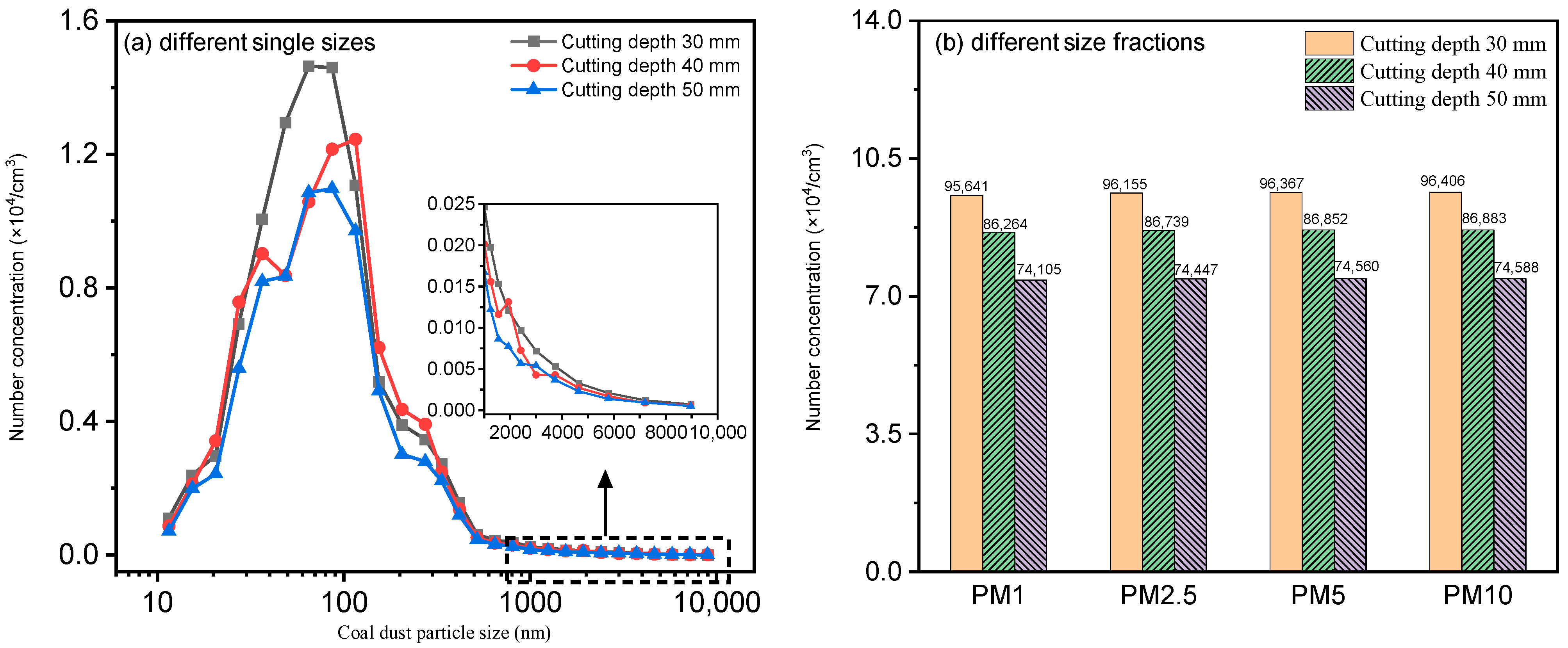

3.2.4. Number Concentration Distribution of 10 nm–10 μm Coal Dust at Different Cutting Depths

3.3. Mass and Number Percentages of Coal Dust in Different Particle Size Ranges (PM1/PM2.5, PM1/PM10, and PM2.5/PM10) at Different Cutting Parameters

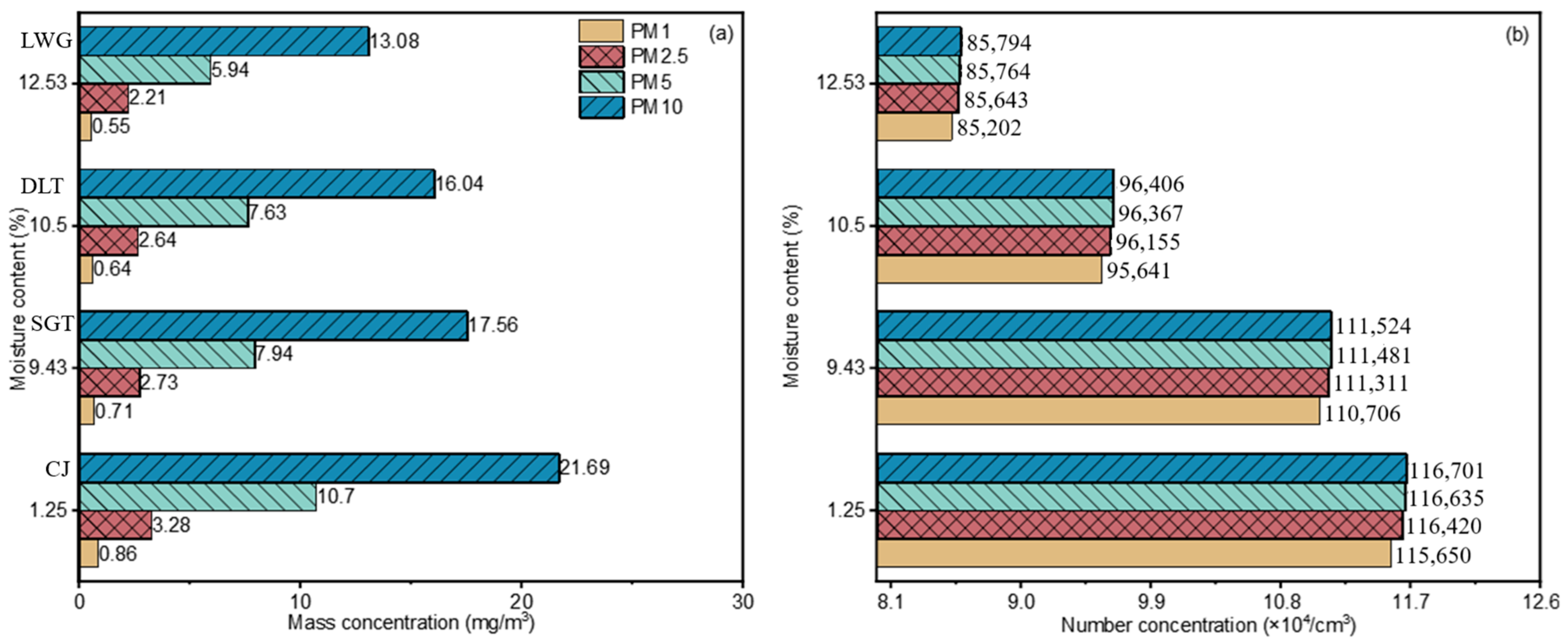

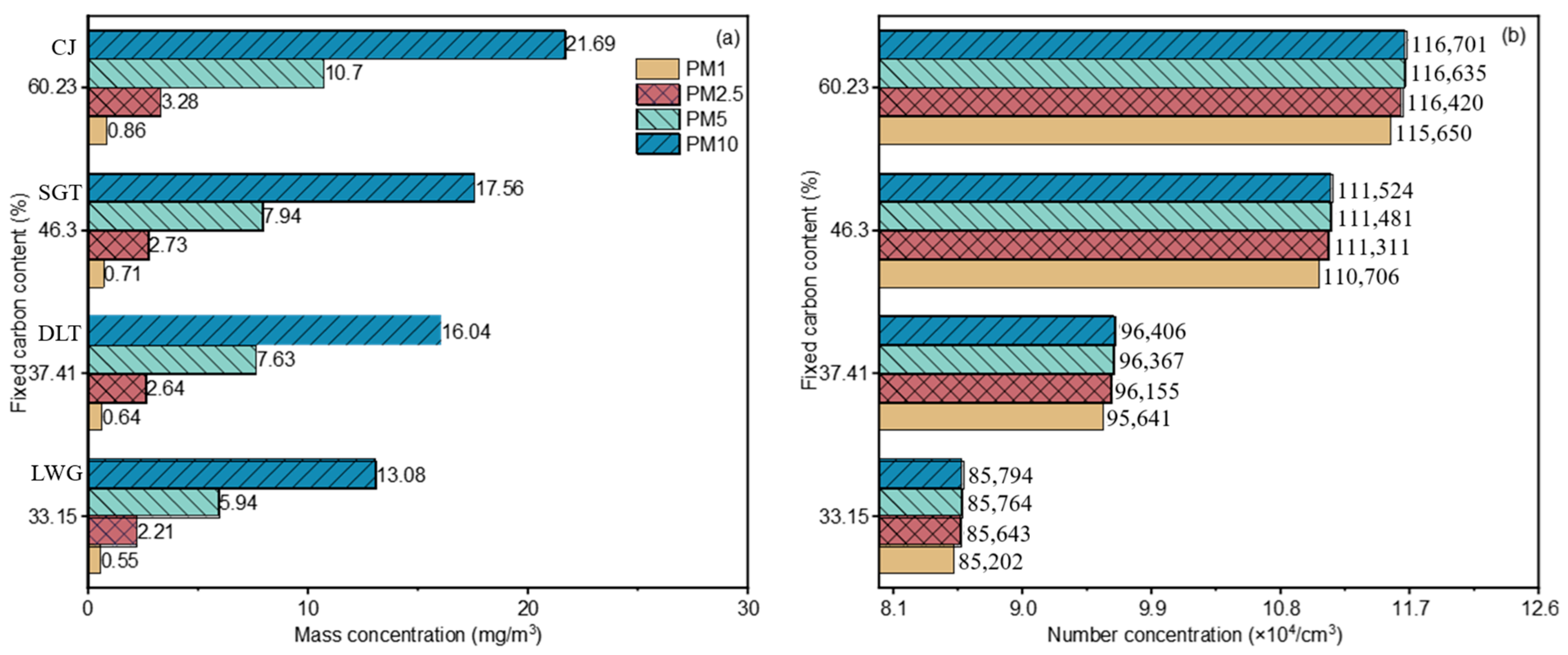

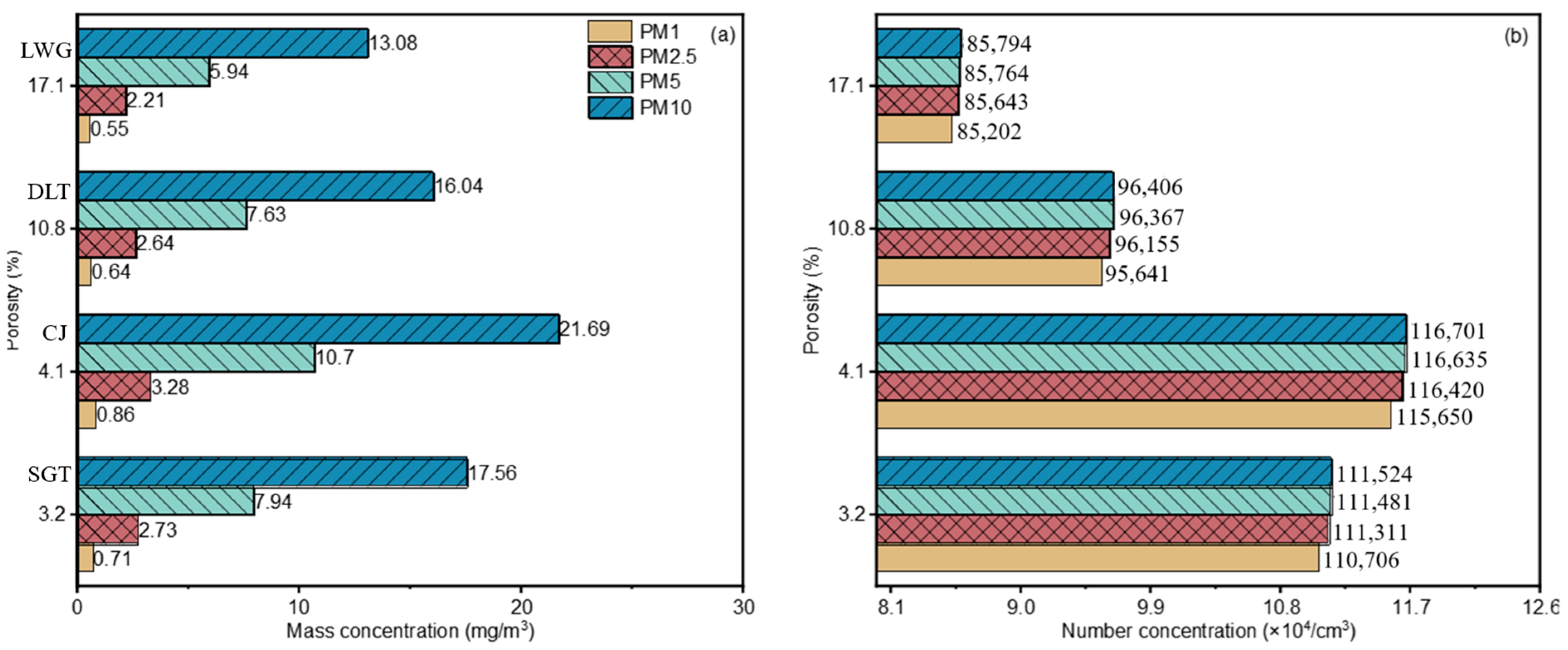

3.4. Mass and Number Concentration Distributions of 10 nm–10 μm Coal Dust When Cutting Different Rank Coals

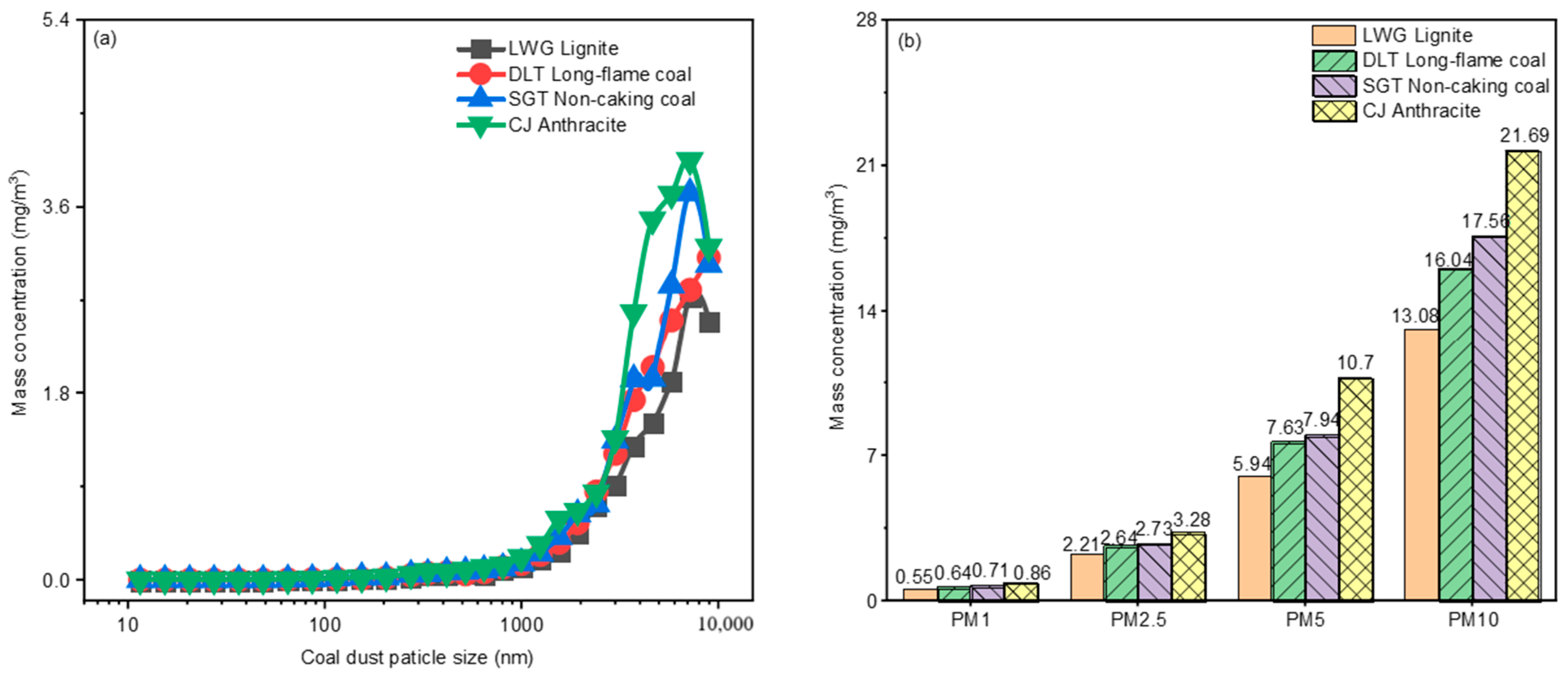

3.4.1. Mass Concentration Distribution of 10 nm–10 μm Coal Dust When Cutting Different Rank Coals

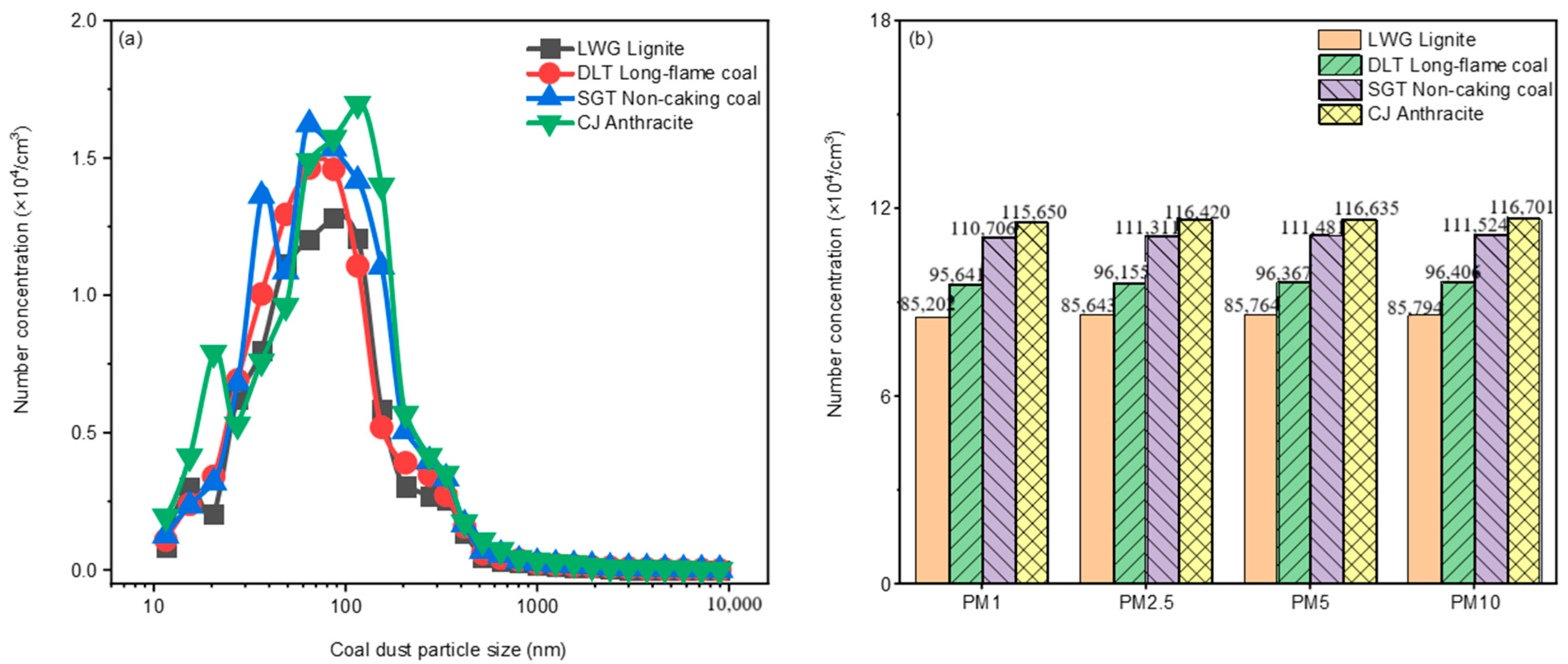

3.4.2. Number Concentration Distribution of 10 nm–10 μm Coal Dust When Cutting Different Rank Coals

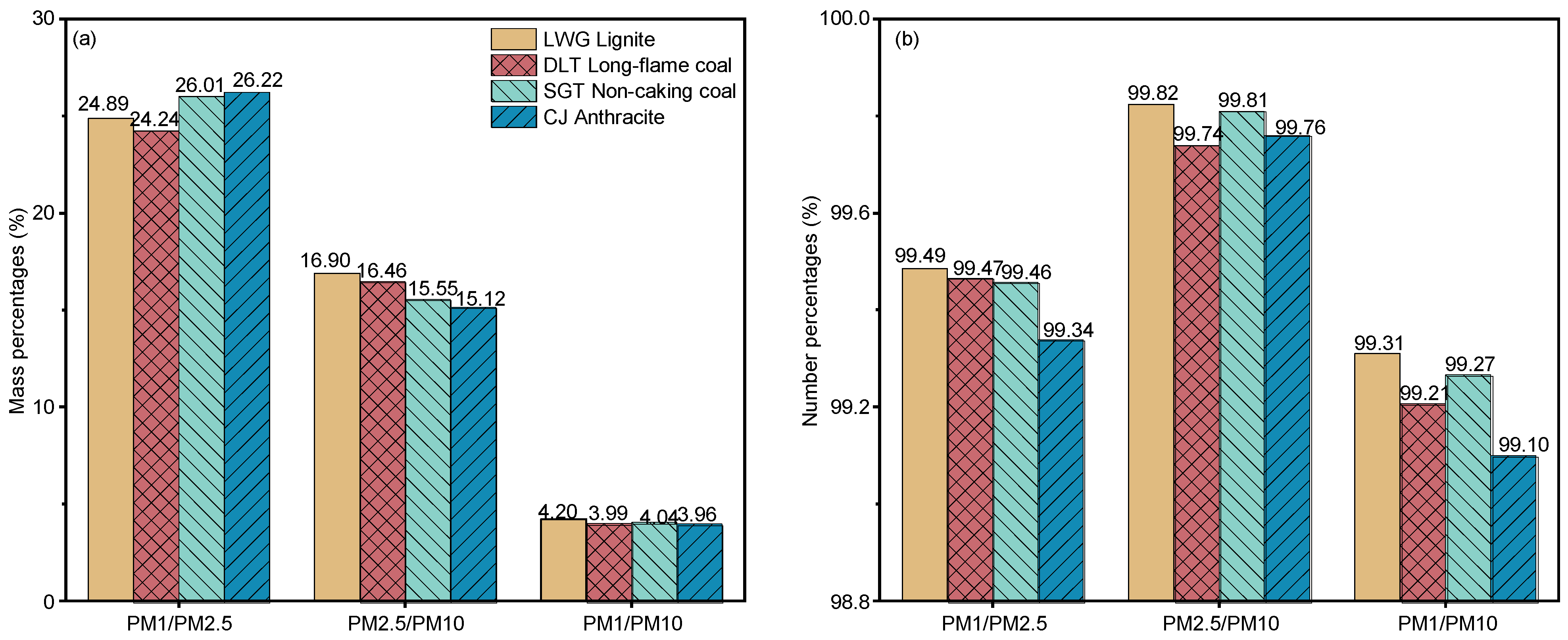

3.4.3. Mass and Number Percentages of PM1/PM10, PM1/PM2.5, and PM2.5/PM10 When Cutting Different Rank Coals

3.5. Physicochemical Properties of PM10 Coal Dust Generated by Cutting Different Rank Coals

3.5.1. Free SiO2 Percentage of PM10 Coal Dust Generated by Cutting the Four Different Rank Coals

3.5.2. Microscopic Morphology of PM10 Coal Dust Generated by Cutting the Four Different Rank Coals

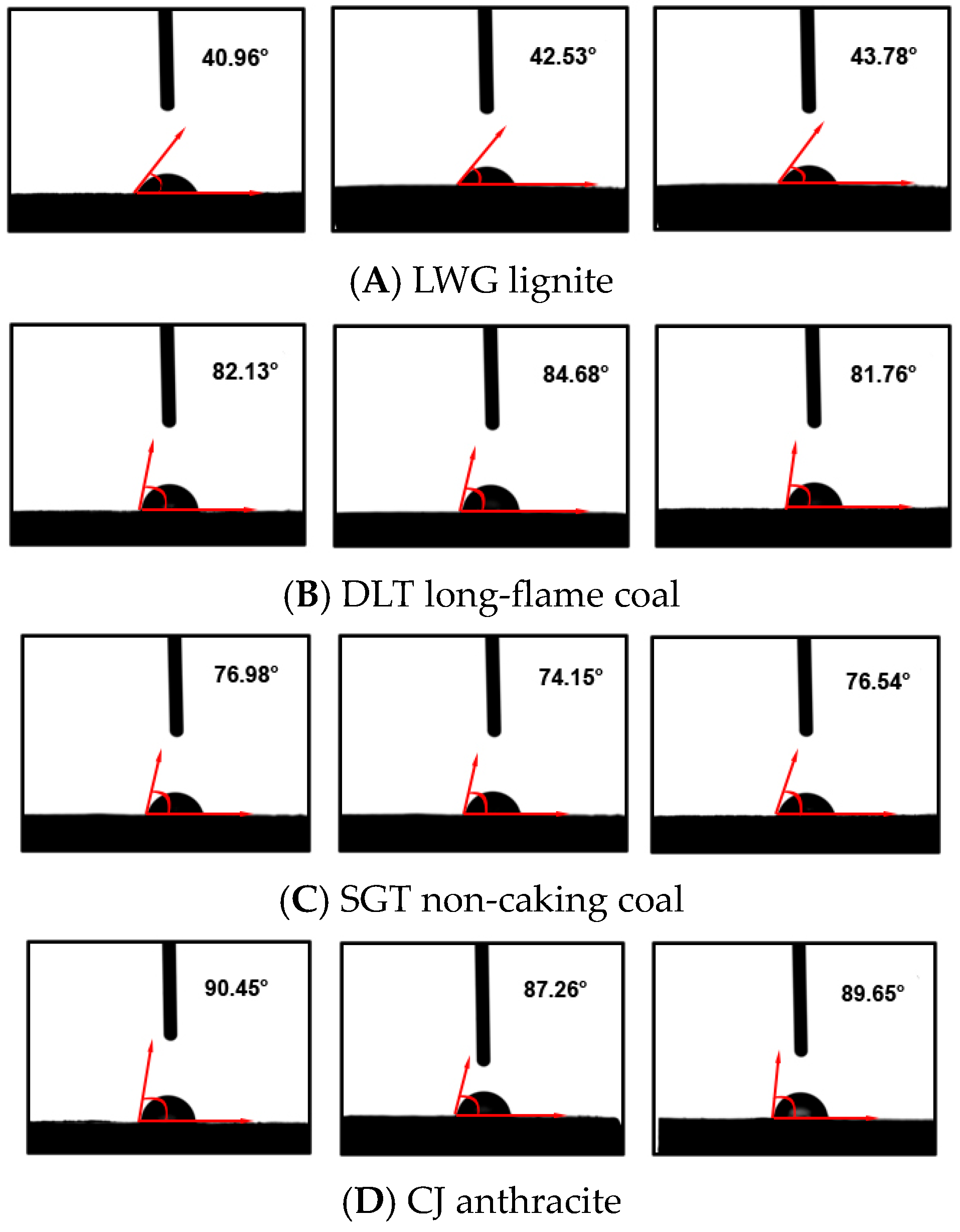

3.5.3. Contact Angle of PM10 Coal Dust Generated by Cutting the Four Different Rank Coals

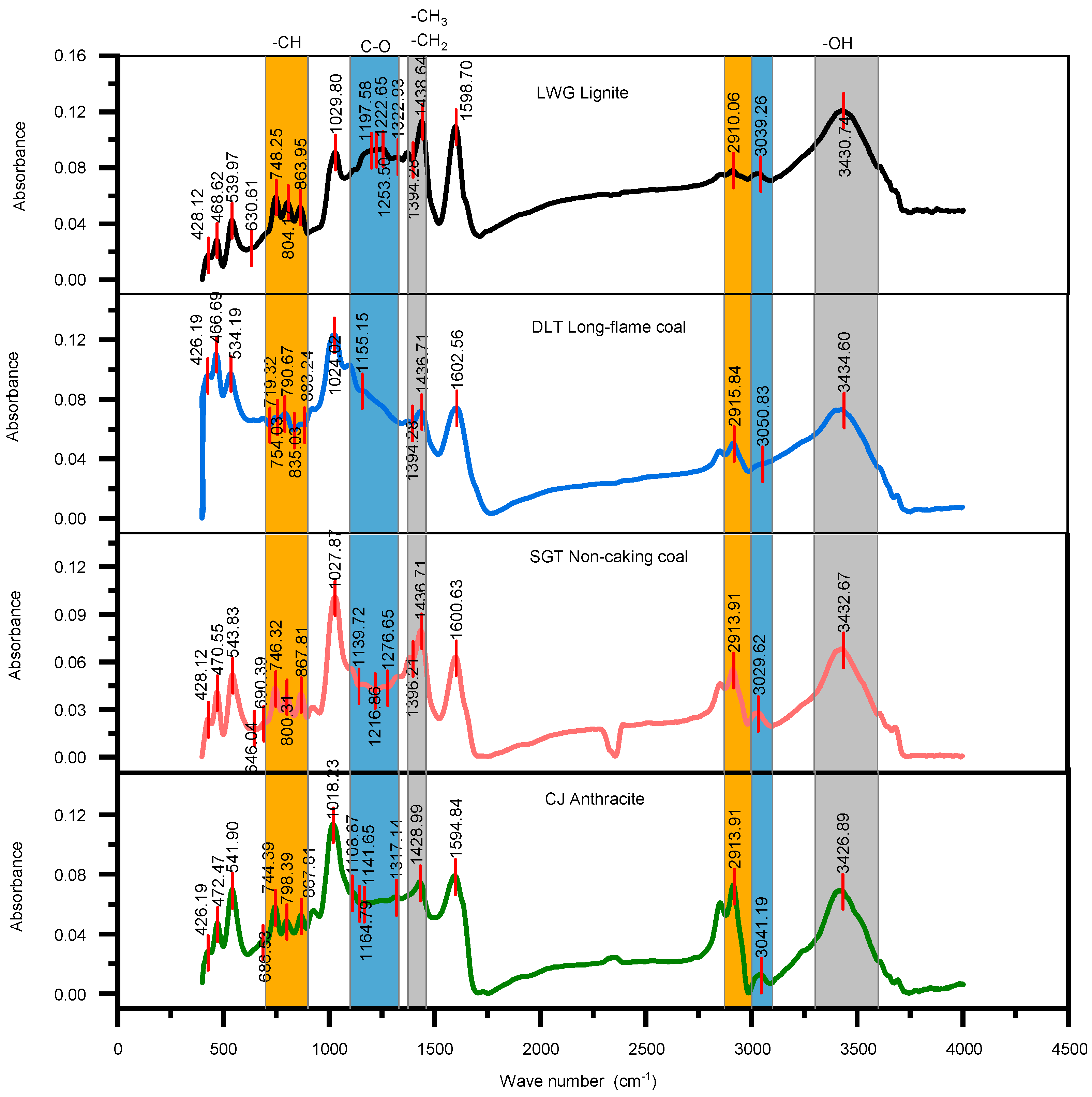

3.5.4. FTIR Spectra of PM10 Coal Dust Generated by Cutting the Four Different Rank Coals

4. Discussion

4.1. Influence of Different Drum Cutting Parameters on the 10 nm–10 μm Coal Dust Generation

4.1.1. Influence of Tooth Tip Cone Angle on 10 nm–10 μm Coal Dust Generation

4.1.2. Influence of Mounting Angle on 10 nm–10 μm Coal Dust Generation

4.1.3. Influence of Rotary Speed on 10 nm–10 μm Coal Dust Generation

4.1.4. Influence of Cutting Depth on 10 nm–10 μm Coal Dust Generation

4.2. Influence of the Physicochemical Properties of the Cut Coal Body on the Generated 10 nm–10 μm Coal Dust

4.2.1. Relationship Between Moisture Content of the Cut Coal Body and the Generated 10 nm–10 μm Coal Dust

4.2.2. Relationship Between Fixed Carbon Content of the Cut Coal Body and the Generated 10 nm–10 μm Coal Dust

4.2.3. Relationship Between Firmness Coefficient of the Cut Coal Body and the Generated 10 nm–10 μm Coal Dust

4.2.4. Relationship Between Porosity of the Cut Coal Body and the Generated 10 nm–10 μm Coal Dust

4.3. Number Percentages of 10 nm–1 μm in 10 nm–10 μm Coal Dust Generated by Coal Cutting

4.4. Physicochemical Properties of Coal Dust Generated by Cutting Different Rank Coals

4.4.1. Free SiO2 Percentage of PM10 Coal Dust Generated by Cutting Different Rank Coals

4.4.2. The Microscopic Morphology of PM10 Coal Dust Generated by Cutting Different Rank Coals

4.4.3. Contact Angle of PM10 Coal Dust Generated by Cutting Different Rank Coals

4.4.4. FTIR Spectra of PM10 Coal Dust Generated by Cutting Different Rank Coals

- (1)

- First, we did not consider the significant changes in cone angle caused by its wear during prolonged coal cutting; second, we failed to quantitatively provide the optimal values for cutting parameter selection; and last but not least, we only considered the perspective of dust reduction and did not conduct in-depth research on coal hardness, nor on the increase in cone angle caused by teeth wear during prolonged coal cutting.

- (2)

- Prior to the formal experiments, we conducted pilot studies (pre-experiments) under representative experimental conditions to test result reproducibility. The outcomes demonstrated excellent repeatability—data variations (e.g., dust concentration, particle size distribution) were minimal, confirming the stability of our self-developed simulated drum cutting system. Based on this verification, we did not perform full replication for all experimental conditions. In the meantime, a key practical constraint that limited comprehensive replication was the challenge associated with large raw coal blocks. Specifically, the sampling, sample preparation, and intact transportation of large raw coal blocks are highly difficult, as these processes require avoiding structural damage to preserve the coal’s natural physical properties. Consequently, the quantity of available intact large coal blocks was limited, which prevented us from conducting systematic replication for every combination of experimental conditions.

- (3)

- This study only adopts a similar simulation approach. Moreover, it examines the impact of different cutting parameters of the shearer drum on dust generation solely from the perspective of source dust reduction, without taking mining intensity into account. Therefore, the somewhat regular results we obtained—specifically regarding the influence of different cutting parameters on the generated 10 nm~10 μm floating coal dust—cannot be the sole basis for determining the cutting parameters of the shearer drum in actual production processes.

- (4)

- This study has several limitations regarding result scalability. First, the cutting parameter optimization was only conducted on DLT long-flame coal, and while parameters align with on-site ranges, their applicability to other ranks (e.g., CJ anthracite) requires further verification. Second, as a physical simulation, this study focuses on cutting-dust generation mechanisms but neglects mining intensity, coal seam inhomogeneity, and multi-equipment interference, so the results cannot directly quantify on-site dust concentrations. Third, similarity criteria were partially simplified: Reynolds number matching was omitted due to the focus on source mechanisms, and while Stokes number consistency was ensured for target particles via 0.3 m/s airflow, it was not systematically calibrated across all size fractions.

5. Conclusions

- (1)

- When drum cutting different rank coals, the generated 10 nm–10 μm coal dust showed a monotonously increasing in mass concentration with coal particle size and a single-peak distribution in number concentration with peaks located in the coal particle size range of 60–120 nm.

- (2)

- The mass and number concentrations of the 10 nm–10 μm coal dust generated by the cutting process were mainly concentrated in 2–10 μm and 10–200 nm, respectively, which, respectively, accounted for about 90% of the total.

- (3)

- Under different coal cutting conditions, the mass concentration percentages of PM1/PM10, PM1/PM2.5, and PM2.5/PM10 were 3.25–4.87%, 19.35–26.73%, and 14.82–18.81%, respectively, whereas the number concentration rations of N-PM1/N-PM10, N-PM1/N-PM2.5, and N-PM2.5/N-PM10 all exceeded 99%.

- (4)

- Either the reduction in the tooth tip cone angle, the rotary speed, or the increase in the mounting angle or the cutting depth can effectively inhibit the generation of 10 nm–10 μm coal dust.

- (5)

- Lower rank coal cutting generates lower mass and number concentrations of 10 nm–10 μm coal dust, and either higher moisture content or firmness coefficient, or lower fixed carbon content of the cut coal body can effectively reduce the 10 nm–10 μm coal dust generation.

- (6)

- The pore structure characteristics of coal dust (e.g., size distribution, morphology) change with coal rank, with higher-rank coal dust exhibiting fewer surface pores; additionally, higher-rank coal dust particles have smoother surfaces, larger contact angles, more hydrophobic groups such as aliphatic hydrocarbons and aromatic hydrocarbons, and fewer hydrophilic oxygen-containing functional groups such as hydroxyls, carbonyls, and ether bonds, showing poorer hydrophilicity.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, L.; Zhou, G.; Ma, Y.; Jing, B.; Sun, B.; Han, F.; He, M.; Chen, X. Numerical analysis on spatial distribution for concentration and particle size of particulate pollutants in dust environment at fully mechanized coal mining face. Powder Technol. 2021, 383, 143–158. [Google Scholar] [CrossRef]

- Petsonk, E.L.; Rose, C.; Cohen, R. Coal Mine Dust Lung Disease. New Lessons from an Old Exposure. Am. J. Respir. Crit. Care Med. 2013, 187, 1178–1185. [Google Scholar] [CrossRef]

- National Health Commission of the People’s Republic of China. Statistical Bulletin on the Development of Health Care in China. 2023. Available online: https://www.gov.cn/lianbo/bumen/202408/content_6971241.htm (accessed on 1 August 2025).

- Hu, Y.; Duan, K.; Zhao, Y.; Ma, G. Study on Suppressing the Dust Concentration at Fully Mechanized Coal Face Using Water Injection. China Saf. Sci. J. 1998, 8, 50–53. [Google Scholar] [CrossRef]

- Yang, H.; Liu, Z.; Zhao, D.; Lv, J.; Yang, W. Insights into the fluid wetting law and fractal characteristics of coal particles during water injection based on nuclear magnetic resonance. Chaos Solitons Fractals 2022, 159, 112109. [Google Scholar] [CrossRef]

- Zhang, C.; Yuan, S.; Zhang, N.; Li, C.; Li, H.; Yang, W. Dust-suppression and cooling effects of spray system installed between hydraulic supports in fully mechanized coal-mining face. Build. Environ. 2021, 204, 108106. [Google Scholar] [CrossRef]

- Wang, P.; Tan, X.; Cheng, W.; Guo, G.; Liu, R. Dust removal efficiency of high pressure atomization in underground coal mine. Int. J. Min. Sci. Technol. 2018, 28, 685–690. [Google Scholar] [CrossRef]

- Seaman, C.E.; Shahan, M.R.; Beck, T.W.; Mischler, S.E. Design of a water curtain to reduce accumulations of float coal dust in longwall returns. Int. J. Min. Sci. Technol. 2020, 30, 443–447. [Google Scholar] [CrossRef]

- Peng, H.; Nie, W.; Zhang, S.; Cheng, W.; Liu, Q.; Guo, C.; Ma, Q.; Zhou, Z.; Xu, C.; Hua, Y.; et al. Research on negative pressure jet dust-removal water curtain technology for coal mine cleaner production. Fuel 2022, 310, 122378. [Google Scholar] [CrossRef]

- Sjöström, S.; Klintenäs, E.; Johansson, P.; Nyqvist, J. Optimized model-based control of main mine ventilation air flows with minimized energy consumption. Int. J. Min. Sci. Technol. 2020, 30, 533–539. [Google Scholar] [CrossRef]

- Saki, S.A.; Brune, J.F.; Khan, M.U. Optimization of gob ventilation boreholes design in longwall mining. Int. J. Min. Sci. Technol. 2020, 30, 811–817. [Google Scholar] [CrossRef]

- Jin, H.; Li, S.; Yu, H.; Yuan, L.; Zhou, F.; Tan, Z. Filtration of dust particles in underground coal mines. Powder Technol. 2023, 423, 118506. [Google Scholar] [CrossRef]

- Li, S.; Xie, B.; Hu, S.; Jin, H.; Liu, H.; Tan, X.; Zhou, F. Removal of dust produced in the roadway of coal mine using a mining dust filtration system. Adv. Powder Technol. 2019, 30, 911–919. [Google Scholar] [CrossRef]

- Wang, P.; Tan, X.; Zhang, L.; Li, Y.; Liu, R. Influence of particle diameter on the wettability of coal dust and the dust suppression efficiency via spraying. Process Saf. Environ. Prot. 2019, 132, 189–199. [Google Scholar] [CrossRef]

- Ji, B.; Jiang, B.; Yuan, L.; Yu, C.; Zhou, G.; Zhao, Y.; Wang, S.; Wang, X. Experimental and molecular dynamics simulation study on the influence of SDS and JFC composite ratios on bituminous coal wettability. Process Saf. Environ. Prot. 2023, 174, 473–484. [Google Scholar] [CrossRef]

- Zhou, W.; Wang, H.; Zhang, J.; He, F.; Liu, J.; Wang, D. A novel method for reducing the amount of dust produced by roadheaders based on the numerical simulation of coal breakage. Fuel 2023, 343, 127978. [Google Scholar] [CrossRef]

- Achanti, V.B.; Khair, A.W. Cutting efficiency through optimised bit configuration—An experimental study using a simulated continuous miner. Miner. Resour. Eng. 2001, 10, 427–434. [Google Scholar] [CrossRef]

- Fowell, R.J.; Ochei, N.N. A comparison of dust make and energy requirements for rock cutting tools. Int. J. Min. Eng. 1984, 2, 73–83. [Google Scholar] [CrossRef]

- Li, X.H.; Liu, S.M.; Huang, Z.L.; Du, W. Study of the Effects of Shearer’ Kinematic Parameters on on-Way Distribution of Dust on Coal Face. Appl. Mech. Mater. 2012, 127, 400–405. [Google Scholar] [CrossRef]

- Zhou, W.; Wang, H.; Wang, D.; Zhang, K.; Du, Y.; Yang, H. The effect of geometries and cutting parameters of conical pick on the characteristics of dust generation: Experimental investigation and theoretical exploration. Fuel Process. Technol. 2020, 198, 106243. [Google Scholar] [CrossRef]

- Srikanth, R.; Ramani, R. Single-breakage studies to determine the relationships between respirable dust generation and coal seam characteristics. Appl. Occup. Environ. Hyg. 1996, 11, 662–668. [Google Scholar] [CrossRef]

- Organiscak, J.A.; Page, S.J. Airborne Dust Liberation During Coal Crushing. Coal Prep. 2000, 21, 423–453. [Google Scholar] [CrossRef]

- Zheng, L.; Li, D.; Xu, S. Analysis on the impact crushing dust generation test method and its influencing factors. Powder Technol. 2021, 388, 100–109. [Google Scholar] [CrossRef]

- Zhou, W.; Wang, H.; Wang, D.; Du, Y.; Zhang, K.; Kang, W. The effect of coal proximate compositions on the characteristics of dust generation using a conical pick cutting system. Powder Technol. 2019, 355, 573–581. [Google Scholar] [CrossRef]

- Zhou, W.; Wang, H.; Wang, D.; Du, Y.; Zhang, K.; Zhang, J. The influence of pore structure of coal on characteristics of dust generation during the process of conical pick cutting. Powder Technol. 2020, 363, 559–568. [Google Scholar] [CrossRef]

- Zhu, J.; He, X.; Wang, L.; Liao, X.; Teng, G.; Jing, P. Performance of N95 elastomeric respirators in high humidity and high coal dust concentration environment. Int. J. Min. Sci. Technol. 2022, 32, 215–224. [Google Scholar] [CrossRef]

- Hall, N.B.; Blackley, D.J.; Halldin, C.N.; Laney, A.S. Current Review of Pneumoconiosis Among US Coal Miners. Curr. Environ. Health Rep. 2019, 6, 137–147. [Google Scholar] [CrossRef]

- Wang, Q.; Geng, X.; Li, Y.; Zhang, F.; Tuo, L.; Zhang, Y. Effect of nanoparticles and silicone surfactants on the foam properties and wettability of dust removal foam. Chem. Eng. Sci. 2023, 281, 119147. [Google Scholar] [CrossRef]

- Cheng, W.; Zhou, G.; Chen, L.; Wang, G.; Nie, W.; Zhang, Q. Research progress and prospect of dust control theory and technology in China’s coal mines in the past 20 years. Coal Sci. Technol. 2020, 48, 1–20. [Google Scholar] [CrossRef]

- Wu, L.; Sun, Y. Cytotoxicity of mixed coal-silica dust. J. Toxicol. 2003, 4, 243–244. [Google Scholar] [CrossRef]

- Zhang, J.; Li, H.; Liu, Y.; Li, X.; Xie, J.; Dai, Z.; Ye, S.; Li, L.; Zhou, W.; Zhao, Y.; et al. Micro-wetting characteristics of coal dust and preliminary study on the development of dust suppressant in Pingdingshan mining area. J. China Coal Soc. 2021, 46, 812–825. [Google Scholar] [CrossRef]

- Phan Quang, V. The determination of coal dust emission and percentage of quartz in coal dust emission during the cutting anthracite coal by shearing and bottom blade of the plow. Procedia Earth Planet. Sci. 2009, 1, 250–256. [Google Scholar] [CrossRef][Green Version]

- Liu, M.; Chen, S.; Liu, Y.; Su, L.; Shi, R.; Qi, X.; Li, B.; Zhang, Z. Characterization of sphericity and wall thickness uniformity of thick-walled hollow microspheres. High Power Laser Part. Beams 2014, 26, 159–163. [Google Scholar] [CrossRef]

- Saikia, B.K.; Saikia, J.; Rabha, S.; Silva, L.F.O.; Finkelman, R. Ambient nanoparticles/nanominerals and hazardous elements from coal combustion activity: Implications on energy challenges and health hazards. Geosci. Front. 2018, 9, 863–875. [Google Scholar] [CrossRef]

- Jing, Q.; Liu, Q.; Wang, D.; Shen, Y.; Wang, Z. Calculation model for drag coefficient and multi-phase flow characteristics in dust removal process: Comparison between flake aluminum powder and spherical aluminum powder. Powder Technol. 2022, 405, 117550. [Google Scholar] [CrossRef]

- Mischler, S.E.; Cauda, E.G.; Di Giuseppe, M.; McWilliams, L.J.; Croix, C.S.; Sun, M.; Franks, J.; Ortiz, L.A. Differential activation of RAW 264.7 macrophages by size-segregated crystalline silica. J. Occup. Med. Toxicol. 2016, 11, 57. [Google Scholar] [CrossRef]

- Doroodchi, E.; Zulfiqar, H.; Moghtaderi, B. A combined experimental and theoretical study on laboratory-scale comminution of coal and biomass blends. Powder Technol. 2013, 235, 412–421. [Google Scholar] [CrossRef]

- Zhao, Z.; Yang, C.; Sun, C.; Shu, X. Experimental study of coal dust wettability. J. China Coal Soc. 2011, 36, 442–446. [Google Scholar] [CrossRef]

- Wang, C.; Lin, B.; Li, Q.; Dai, H. Effects of Oxygen Containing Functional Groups on Coal Dust Wettability. Saf. Coal Mines 2014, 45, 173–176. [Google Scholar] [CrossRef]

- Cheng, W.; Liu, W.; Nie, W.; Zhou, G.; Cui, X.; Sun, X. The Prevention and Control Technology of Dusts in Heading and Winning Faces and Its Development Tendency. J. Shandong Univ. Sci. Technol. 2010, 29, 77–82. [Google Scholar] [CrossRef]

- Wang, W. Appliation Present Status and Outlook of Seam Water Injection Dust Control Technology. Coal Sci. Technol. 2011, 39, 57–60. [Google Scholar] [CrossRef]

- Yang, J.; Tan, Y.; Wang, Z.; Shang, Y.; Zhao, W. Study on the coal dust surface characteristics and wetting mechanism. J. China Coal Soc. 2007, 32, 737–740. [Google Scholar] [CrossRef]

- An, W.; Wang, L. Mechanical properties and modification of coal under the action of surfactant. J. China Coal Soc. 2020, 45, 4074–4086. [Google Scholar] [CrossRef]

- Liu, S.; Ge, S.; Wang, J.; Sun, L.; Chen, X.; Jing, D.; Kang, J. Influence of surfactants on wettability mechanism of different coals based on quantum chemistry analysis. J. Saf. Sci. Technol. 2021, 17, 105–111. [Google Scholar]

- Zhang, J.; Liu, Y.; Wang, M.; Wang, Y.; Li, H.; Xie, J.; Zhao, Y.; Zhou, W.; Ye, S.; Li, L.; et al. Influence Mechanism of Nonionic Surfactant on Coal Wettability Based on Molecular Dynamics Simulation. Adv. Eng. Sci. 2022, 54, 191–202. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, L.; Wang, D.; He, X. Experimental investigation on the wettability of respirable coal dust based on infrared spectroscopy and contact angle analysis. Adv. Powder Technol. 2017, 28, 3130–3139. [Google Scholar] [CrossRef]

- Liang, C.; Liang, W.; Li, W. Functional groups of different coal ranks based on infrared spectroscopy. Coal Sci. Technol. 2020, 48, 182–186. [Google Scholar]

- Baysal, M.; Yürüm, A.; Yıldız, B.; Yürüm, Y. Structure of some western Anatolia coals investigated by FTIR, Raman, 13C solid state NMR spectroscopy and X-ray diffraction. Int. J. Coal Geol. 2016, 163, 166–176. [Google Scholar] [CrossRef]

- Jiang, J.; Yang, W.; Cheng, Y.; Liu, Z.; Zhang, Q.; Zhao, K. Molecular structure characterization of middle-high rank coal via XRD, Raman and FTIR spectroscopy: Implications for coalification. Fuel 2019, 239, 559–572. [Google Scholar] [CrossRef]

- Wang, H.; Fan, S.; Yao, H. FTIR Analysis on Surface Chemical Structure of Two Different Degrees of Metamorphic Coal. Saf. Coal Mines 2018, 49, 194–197. [Google Scholar] [CrossRef]

- Cheng, W.; Xue, J.; Zhou, G.; Nie, W.; Liu, L. Study of coal dust wettability based on FTIR. J. China Coal Soc. 2014, 39, 2256–2262. [Google Scholar] [CrossRef]

- Kampa, M.; Castanas, E. Human health effects of air pollution. Environ. Pollut. 2008, 151, 362–367. [Google Scholar] [CrossRef]

- Nemmar, A.; Hoet, P.M.; Vanquickenborne, B.; Dinsdale, D.; Thomeer, M.; Hoylaerts, M.; Vanbilloen, H.; Mortelmans, L.; Nemery, B. Passage of inhaled particles into the blood circulation in humans. Circulation 2002, 105, 411–414. [Google Scholar] [CrossRef]

- Liu, T.; Liu, S. The impacts of coal dust on miners’ health: A review. Environ. Res. 2020, 190, 109849. [Google Scholar] [CrossRef] [PubMed]

- Maynard, A.D.; Kuempel, E.D. Airborne Nanostructured Particles and Occupational Health. J. Nanopart. Res. 2005, 7, 587–614. [Google Scholar] [CrossRef]

- Oberdörster, G.; Oberdörster, E.; Oberdörster, J. Nanotoxicology: An Emerging Discipline Evolving from Studies of Ultrafine Particles. Environ. Health Perspect. 2005, 113, 823–839. [Google Scholar] [CrossRef] [PubMed]

- Magrez, A.; Kasas, S.; Salicio, V.; Pasquier, N.; Seo, J.W.; Celio, M.; Catsicas, S.; Schwaller, B.; Forró, L. Cellular Toxicity of Carbon-Based Nanomaterials. Nano Lett. 2006, 6, 1121–1125. [Google Scholar] [CrossRef] [PubMed]

- Zhang, R.; Liu, S.; Zheng, S. Characterization of nano-to-micron sized respirable coal dust: Particle surface alteration and the health impact. J. Hazard. Mater. 2021, 413, 125447. [Google Scholar] [CrossRef]

- GB/T 212-2008; Proximate Analysis of Coal. Standardization Administration of the People’s Republic of China: Beijing, China, 2008. Available online: https://std.samr.gov.cn/gb/search/gbDetailed?id=71F772D77AA5D3A7E05397BE0A0AB82A (accessed on 1 September 2025).

- GB/T 23561.12-2010; Methods for Determining the Physical and Mechanical Properties of Coal and Rock—Part 12: Method for Determining Coal Hardiness Coefficient. Standardization Administration of the People’s Republic of China: Beijing, China, 2010.

- GB/T 23561.4-2009; Methods for Determining the Physical and Mechanical Properties of Coal and Rock—Part 4: Methods for Calculating the Porosity of Coal and Rock. Standardization Administration of the People’s Republic of China: Beijing, China, 2009.

- Li, X.H.; Li, G.X.; Zheng, L.H. Experimental Research of Cutting Performance. J. Fuxin Min. Inst. (Nat. Sci.) 1995, 3, 78–83. Available online: https://kns.cnki.net/kcms2/article/abstract?v=Ut-mckhA-RtRewJ_jqkFRXgV57viZSN3p4_AoF0B59IX8XQ4Fub9AZ_cJzxciUM1GieZPgsZV5cuGMp_vM7mFPwqVm3DuZk6ldiLeXT1sqwaVa311ChJKxm_mNIVc7WsDjXNY15TEtqgvjel2rKwztzAt1ZdwbyS&uniplatform=NZKPT (accessed on 1 September 2025).

- Wang, G.; Zhou, W.; Wang, Z.; Lu, X.; Zhang, Y. Characterization and Concentration Prediction of Dust Pollution in Open-Pit Coal Mines. Atmosphere 2024, 15, 1408. [Google Scholar] [CrossRef]

- GBZ/T 192.4-2007; Method for Determination of Dust in the Air of Workplace Part 4: Content of Free Silica in Dust. Standardization Administration of the People’s Republic of China: Beijing, China, 2007.

- GB/T 39251-2020; Additive Manufacturing—Methods to Characterize Performance of Metal Powders. Standardization Administration of the People’s Republic of China: Beijing, China, 2020.

- YS/T 1297-2019; Measuring Method for Sphericity Ratio of Titanium and Titanium Alloy Powders. Standardization Administration of the People’s Republic of China: Beijing, China, 2019. Available online: https://std.samr.gov.cn/hb/search/stdHBDetailed?id=A35FFACCACC23A35E05397BE0A0A44D5 (accessed on 1 September 2025).

- GB/T 30447-2013; Measurement Method for Contact Angle of Nano-Film Surface. Standardization Administration of the People’s Republic of China: Beijing, China, 2013.

- GB/T 6040-2019; General Rules for Infrared Analysis. Standardization Administration of the People’s Republic of China: Beijing, China, 2019.

- Evans, I. A theory of the cutting force for point-attack picks. Int. J. Min. Eng. 1984, 2, 63–71. [Google Scholar] [CrossRef]

- Roepke, W.W.; Voltz, J.I. Coal Cutting Forces and Primary Dust Generation Using Radial Gage Cutters; U.S. Department of Energy: Washington, DC, USA, 1983. [Google Scholar]

- Park, J.-Y.; Kang, H.; Lee, J.-W.; Kim, J.-H.; Oh, J.-Y.; Cho, J.-W.; Rostami, J.; Kim, H.D. A study on rock cutting efficiency and structural stability of a point attack pick cutter by lab-scale linear cutting machine testing and finite element analysis. Int. J. Rock Mech. Min. Sci. 2018, 103, 215–229. [Google Scholar] [CrossRef]

- Wang, H.; Tan, C.; Jiang, Z.; Zhang, Y.; Wang, M. Numerical simulation and field measurement of dust distribution for multi-source dust at fully mechanized caving face. J. Harbin Inst. Technol. 2015, 47, 106–112. [Google Scholar]

- Bakhtavar, E.; Shahriar, K. Selection of a practicable shearer loader based on mechanical properties of coal for Parvadeh 1 mine. Arch. Min. Sci. 2013, 58, 145–157. [Google Scholar] [CrossRef]

- Liu, S.; Du, C.; Cui, X. Experimental research on picks arrangement of shearer drum. J. Cent. South Univ. (Sci. Technol.) 2009, 40, 1281–1287. [Google Scholar]

- Yao, Q.; Li, X.; Zhou, J.; Ju, M.; Chong, Z.; Zhao, B. Experimental study of strength characteristics of coal specimens after water intrusion. Arab. J. Geosci. 2015, 8, 6779–6789. [Google Scholar] [CrossRef]

- Liu, J.; Qiao, L.; Li, P. Experimental studies and constitutive model of elastoplastic mechanical behaviors of sandstone with hydro-physicochemical influencing effects. Chin. J. Rock Mech. Eng. 2009, 28, 20–29. [Google Scholar] [CrossRef]

- Qiao, L.; Liu, J.; Feng, X. Study on damage mechanism of sandstone under hydro-physico-chemical effects. Chin. J. Rock Mech. Eng. 2007, 10, 2117–2124. [Google Scholar] [CrossRef]

- Zipf, R.K.; Bieniawski, Z.T. Estimating the crush zone size under a cutting tool in coal. Int. J. Min. Geol. Eng. 1988, 6, 279–295. [Google Scholar] [CrossRef]

- Dacombe, P.; Pourkashanian, M.; Williams, A.; Yap, L. Combustion-induced fragmentation behavior of isolated coal particles. Fuel 1999, 78, 1847–1857. [Google Scholar] [CrossRef]

- Zhong, S.; Baitalow, F.; Reinmöller, M.; Meyer, B. Relationship between the tensile strength of irregularly shaped coal particles and various fuel properties. Fuel 2019, 236, 92–99. [Google Scholar] [CrossRef]

- McCunney, R.J.; Morfeld, P.; Payne, S. What Component of Coal Causes Coal Workers’ Pneumoconiosis? J. Occup. Environ. Med. 2009, 51, 462–471. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Li, Q.; Hu, Q.; Cao, J.; Sun, X. Experimental study on particle size distribution characteristics of coal with different hardness under impact crushing. Min. Saf. Environ. Prot. 2020, 47, 1–6. [Google Scholar] [CrossRef]

- Wang, L.; Liao, X.; Zha, M.; Zhang, R.; Pei, X.; Pan, R. Study on wetting characteristics of coal dust in soft coal based on principal component analysis. Coal Sci. Technol. 2020, 48, 104–109. [Google Scholar] [CrossRef]

- Dang, G.; Wu, C.; Zhao, K.; Liang, C.; Jiang, W. Pore property and its impact on the coalbed methane adsorption of anthracite from Zhu-Zang syncline, Guizhou Province. Coal Geol. Explor. 2017, 45, 72–78. [Google Scholar]

- Zhu, C.; Xei, G.; Wang, L.; Wang, C.; Hou, J. Experimental study on the influence of moisture content and porosity on soft coal strength characteristics. J. Min. Saf. Eng. 2017, 34, 601–607. [Google Scholar] [CrossRef]

- Peng, R.; Zhang, Y.; Yang, Y.; Liu, Z. Numerical simulation of porous rock damage and failure. J. China Coal Soc. 2014, 39, 1039–1048. [Google Scholar] [CrossRef]

- Zare, Y. Study of nanoparticles aggregation/agglomeration in polymer particulate nanocomposites by mechanical properties. Compos. Part A Appl. Sci. Manuf. 2016, 84, 158–164. [Google Scholar] [CrossRef]

- Attfield, M.; Castranova, V.; Hale, J.M.; Suarthana, E.; Thomas, K.C.; Wang, M.L. Coal Mine Dust Exposures and Associated Health Outcomes—A Review of Information Published Since 1995; U.S. Department of Health & Human Services, Public Health Service, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health: Washington, DC, USA, 2011. [Google Scholar]

- Mathews, J.P.; Eser, S.; Hatcher, P.G.; Scaroni, A.W. The Shape of Pulverized Bituminous Vitrinite Coal Particles. KONA Powder Part. J. 2007, 25, 145–152. [Google Scholar] [CrossRef][Green Version]

- Zhang, J.; Xu, B.; Zhang, P.; Cai, M.; Li, B. Effects of surface roughness on wettability and surface energy of coal. Front. Earth Sci. 2023, 10, 1054896. [Google Scholar] [CrossRef]

- Li, Z.; Ren, T.; Li, X.; Qiao, M.; Yang, X.; Tan, L.; Nie, B. Multi-scale pore fractal characteristics of differently ranked coal and its impact on gas adsorption. Int. J. Min. Sci. Technol. 2023, 33, 389–401. [Google Scholar] [CrossRef]

- Wang, Y.; Song, E.; Zhang, Q. Dem analysis of the aggregate shape effect onmechanical properties of rockfill. Eng. Mech. 2022, 39, 137–146. [Google Scholar]

- Qin, T.; Jiang, S.; Zhang, W. Research Progress on Coal Wettability. Saf. Coal Mines 2017, 48, 163–166. [Google Scholar] [CrossRef]

- Yan, J.; Xie, J.; Shu, X.; Zhang, J.; Ma, X. Study on wetting ability of coal dust pore structure. Appl. Chem. Ind. 2019, 48, 748–751. [Google Scholar] [CrossRef]

- Li, J.; Li, K. Influence factors of coal surface wettability. J. China Coal Soc. 2016, 41, 448–453. [Google Scholar] [CrossRef]

| Coal Mine | Coal Rank | Location |

|---|---|---|

| Longwanggou (LWG) | Lignite | Inner Mongolia, China |

| Daliuta (DLT) | Long-flame coal | Inner Mongolia, China |

| Shigetai (SGT) | Non-caking coal | Inner Mongolia, China |

| Chengjiao (CJ) | Anthracite | Henan, China |

| Coal Sample | Moisture Content/% | Fixed Carbon Content/% | Firmness Coefficient | Porosity/% |

|---|---|---|---|---|

| LWG Lignite | 12.53 | 33.15 | 0.65 | 17.1 |

| DLT Long-flame coal | 10.5 | 37.41 | 0.92 | 10.8 |

| SGT Non-caking coal | 9.32 | 46.3 | 1.17 | 3.2 |

| CJ Anthracite | 1.54 | 60.23 | 1.32 | 4.1 |

| Cutting Parameters | Tooth Tip Cone Angle (°) | Mounting Angle (°) | Rotary Speed (r/min) | Cutting Depth (mm) |

|---|---|---|---|---|

| Tooth tip cone angle | 80 | 45 | 40 | 30 |

| 90 | ||||

| 100 | ||||

| Mounting angle | 80 | 45 | 40 | 30 |

| 60 | ||||

| 90 | ||||

| Rotary speed | 80 | 45 | 40 | 30 |

| 70 | ||||

| 100 | ||||

| 130 | ||||

| Cutting depth | 80 | 45 | 40 | 30 |

| 40 | ||||

| 50 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, H.; Jia, R.; Zhu, J.; Wang, L.; Tong, J.; Liu, Y.; Tian, Q.; Liu, W.; An, C.; Oduro, N.B. Concentration Distribution and Physicochemical Properties of 10 nm–10 μm Coal Dust Generated by Drum Cutting Different Rank Coals: A Physical Simulation Experiment. Atmosphere 2025, 16, 1114. https://doi.org/10.3390/atmos16101114

Liu H, Jia R, Zhu J, Wang L, Tong J, Liu Y, Tian Q, Liu W, An C, Oduro NB. Concentration Distribution and Physicochemical Properties of 10 nm–10 μm Coal Dust Generated by Drum Cutting Different Rank Coals: A Physical Simulation Experiment. Atmosphere. 2025; 16(10):1114. https://doi.org/10.3390/atmos16101114

Chicago/Turabian StyleLiu, Hui, Rong Jia, Jintuo Zhu, Liang Wang, Jiamu Tong, Yu Liu, Qingyang Tian, Wenbo Liu, Caixia An, and Nkansah Benjamin Oduro. 2025. "Concentration Distribution and Physicochemical Properties of 10 nm–10 μm Coal Dust Generated by Drum Cutting Different Rank Coals: A Physical Simulation Experiment" Atmosphere 16, no. 10: 1114. https://doi.org/10.3390/atmos16101114

APA StyleLiu, H., Jia, R., Zhu, J., Wang, L., Tong, J., Liu, Y., Tian, Q., Liu, W., An, C., & Oduro, N. B. (2025). Concentration Distribution and Physicochemical Properties of 10 nm–10 μm Coal Dust Generated by Drum Cutting Different Rank Coals: A Physical Simulation Experiment. Atmosphere, 16(10), 1114. https://doi.org/10.3390/atmos16101114