Material Substitution Strategies for Energy Reduction and Greenhouse Gas Emission in Cement Manufacturing

Abstract

1. Introduction

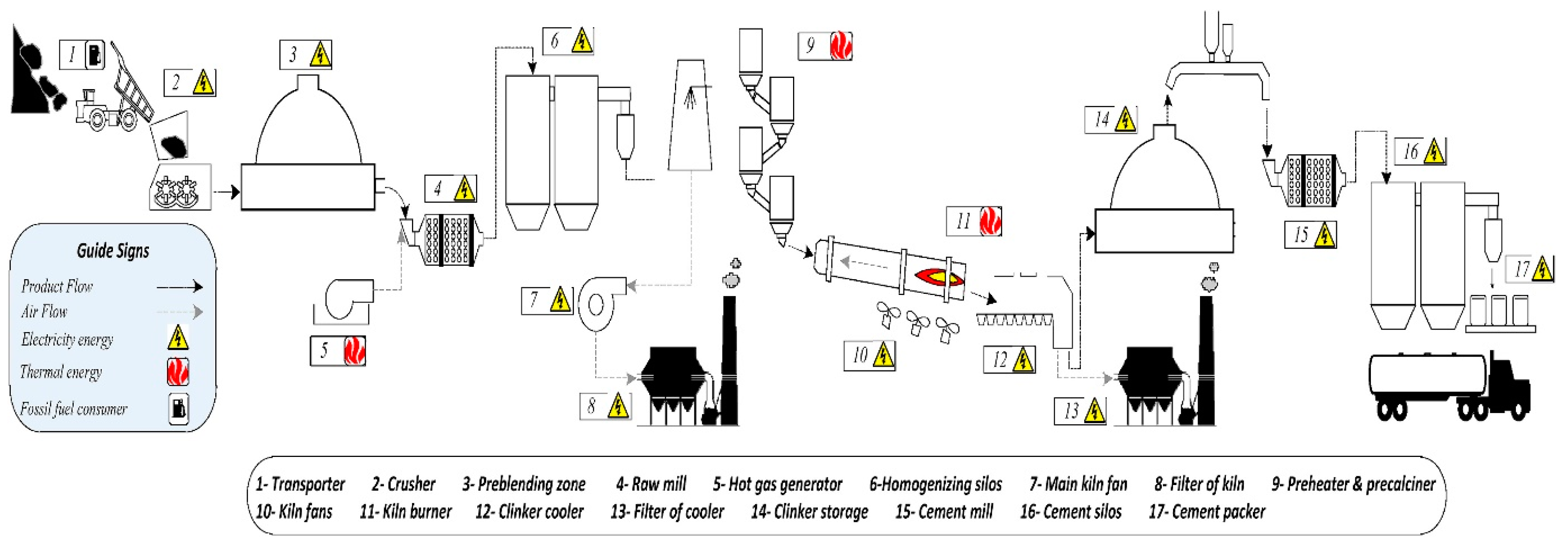

2. Description of Manufacturing Processes of Cement

3. Various Material Substitution Approaches Applied for the Reduction of Energy in the Cement-Manufacturing Process

Use of Waste or Recycled Materials

4. Future Perspectives

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Verma, Y.K.; Mazumdar, B.; Ghosh, P. Thermal energy consumption and its conservation for a cement production unit. Environ. Eng. Res. 2021, 26, 1–9. [Google Scholar]

- Zhang, Z.; Lin, B. Energy conservation and emission reduction of Chinese cement industry: From a perspective of factor substitutions. Emerg. Mark. Financ. Trade 2019, 55, 967–979. [Google Scholar] [CrossRef]

- Mokhtar, A.; Nasooti, M. A decision support tool for cement industry to select energy efficiency measures. Energy Strategy Rev. 2020, 28, 100458. [Google Scholar] [CrossRef]

- Ali, N. The Role of Cement Industry in the Economic Development of Pakistan; EduPedia Publications (P) Ltd.: Delhi, India, 2015. [Google Scholar]

- Ighalo, J.O.; Adeniyi, A.G. A perspective on environmental sustainability in the cement industry. Waste Dispos. Sustain. Energy 2020, 2, 161–164. [Google Scholar] [CrossRef]

- Salas, D.A.; Ramirez, A.D.; Rodriguez, C.R.; Petroche, D.M.; Boero, A.J.; Duque-Rivera, J. Environmental impacts, life cycle assessment and potential improvement measures for cement production: A literature review. J. Clean. Prod. 2016, 113, 114–122. [Google Scholar] [CrossRef]

- Khan, M.A.; Khan, M.Z.; Zaman, K.; Naz, L. Global estimates of energy consumption and greenhouse gas emissions. Renew. Sustain. Energy Rev. 2014, 29, 336–344. [Google Scholar] [CrossRef]

- Madlool, N.A.; Saidur, R.; Hossain, M.S.; Rahim, N. A critical review on energy use and savings in the cement industries. Renew. Sustain. Energy Rev. 2011, 15, 2042–2060. [Google Scholar] [CrossRef]

- Saidur, R. A review on electrical motors energy use and energy savings. Renew. Sustain. Energy Rev. 2010, 14, 877–898. [Google Scholar] [CrossRef]

- Saidur, R.; Rahim, N.A.; Hasanuzzaman, M. A review on compressed-air energy use and energy savings. Renew. Sustain. Energy Rev. 2010, 14, 1135–1153. [Google Scholar] [CrossRef]

- Avami, A.; Sattari, S. Energy conservation opportunities: Cement industry in Iran. Int. J. Energy 2007, 1, 65–71. [Google Scholar]

- Dong, R.; Zhang, Z.; Lu, H.; Yu, Y. Recovery of waste heat in cement plants for the capture of CO2. Front. Chem. Sci. Eng. 2012, 6, 104–111. [Google Scholar] [CrossRef]

- Afkhami, B.; Akbarian, B.; Beheshti, N.; Kakaee, A.; Shabani, B. Energy consumption assessment in a cement production plant. Sustain. Energy Technol. Assess. 2015, 10, 84–89. [Google Scholar] [CrossRef]

- Madlool, N.; Saidur, R.; Rahim, N.; Kamalisarvestani, M. An overview of energy savings measures for cement industries. Renew. Sustain. Energy Rev. 2013, 19, 18–29. [Google Scholar] [CrossRef]

- Energy, C.I.; Performance, C. Getting the Numbers Right; World Business Council for Sustainable Development The Cement Sustainability Initiative: Washington, DC, USA, 2009. [Google Scholar]

- Olagunju, B.D. Life Cycle Assessment of the Production of Cement: A South African Case Study. Master’s Thesis, Durban University of Technology: Dubran, South Africa, 2021. [Google Scholar]

- Olagunju, B.D.; Olanrewaju, O.A. Life Cycle Assessment of Ordinary Portland Cement (OPC) Using both Problem Oriented (Midpoint) Approach and Damage Oriented Approach (Endpoint). In Product Life Cycle-Opportunities for Digital and Sustainable Transformation; IntechOpen: London, UK, 2021. [Google Scholar]

- Talaei, A.; Pier, D.; Iyer, A.V.; Ahiduzzaman, M.; Kumar, A. Assessment of long-term energy efficiency improvement and greenhouse gas emissions mitigation options for the cement industry. Energy 2019, 170, 1051–1066. [Google Scholar] [CrossRef]

- Bumanis, G.; Korjakins, A.; Bajare, D. Environmental benefit of alternative binders in construction industry: Life cycle assessment. Environments 2022, 9, 6. [Google Scholar] [CrossRef]

- Benhelal, E.; Zahedi, G.; Shamsaei, E.; Bahadori, A. Global strategies and potentials to curb CO2 emissions in cement industry. J. Clean. Prod. 2013, 51, 142–161. [Google Scholar] [CrossRef]

- Sousa, V.; Bogas, J.A. Comparison of energy consumption and carbon emissions from clinker and recycled cement production. J. Clean. Prod. 2021, 306, 127277. [Google Scholar] [CrossRef]

- Poponi, D.; Bryant, T.; Burnard, K.; Cazzola, P.; Dulac, J.; Pales, A.F.; Husar, J.; Janoska, P.; Masanet, E.R.; Munuera, L. Energy Technology Perspectives 2016: Towards Sustainable Urban Energy Systems; International Energy Agency: Paris, France, 2016. [Google Scholar]

- Carriço, A.; Bogas, J.A.; Guedes, M. Thermoactivated cementitious materials–A review. Constr. Build. Mater. 2020, 250, 118873. [Google Scholar] [CrossRef]

- Du Plessis, G.E.; Liebenberg, L.; Mathews, E.H. The use of variable speed drives for cost-effective energy savings in South African mine cooling systems. Appl. Energy 2013, 111, 16–27. [Google Scholar] [CrossRef]

- Atmaca, A.; Yumrutaş, R. Analysis of the parameters affecting energy consumption of a rotary kiln in cement industry. Appl. Therm. Eng. 2014, 66, 435–444. [Google Scholar] [CrossRef]

- Naeimi, A.; Bidi, M.; Ahmadi, M.H.; Kumar, R.; Sadeghzadeh, M.; Nazari, M.A. Design and exergy analysis of waste heat recovery system and gas engine for power generation in Tehran cement factory. Therm. Sci. Eng. Prog. 2019, 9, 299–307. [Google Scholar] [CrossRef]

- Scrivener, K.; Avet, F.; Maraghechi, H.; Zunino, F.; Ston, J.; Hanpongpun, W.; Favier, A. Impacting factors and properties of limestone calcined clay cements (LC3). Green Mater. 2018, 7, 3–14. [Google Scholar] [CrossRef]

- Kadhum, A.O.; Haider, M.O. Experimental Investigation of Self-Compacting High Performance Concrete Containing Calcined Kaolin Clay and Nano Lime. Civ. Eng. J. 2020, 6, 1798–1808. [Google Scholar] [CrossRef]

- Hasanbeigi, A.; Price, L.; Lin, E. Emerging energy-efficiency and CO2 emission-reduction technologies for cement and concrete production: A technical review. Renew. Sustain. Energy Rev. 2012, 16, 6220–6238. [Google Scholar] [CrossRef]

- Moya, J.A.; Pardo, N.; Mercier, A. The potential for improvements in energy efficiency and CO2 emissions in the EU27 cement industry and the relationship with the capital budgeting decision criteria. J. Clean. Prod. 2011, 19, 1207–1215. [Google Scholar] [CrossRef]

- Baghban, M.H.; Mahjoub, R. Natural kenaf fiber and LC3 binder for sustainable fiber-reinforced cementitious composite: A review. Appl. Sci. 2020, 10, 357. [Google Scholar] [CrossRef]

- Hossain, M.; Karim, M.; Hasan, M.; Hossain, M.; Zain, M. Durability of mortar and concrete made up of pozzolans as a partial replacement of cement: A review. Constr. Build. Mater. 2016, 116, 128–140. [Google Scholar] [CrossRef]

- Ramakrishnan, S.; Wang, X.; Sanjayan, J.; Wilson, J. Thermal energy storage enhancement of lightweight cement mortars with the application of phase change materials. Procedia Eng. 2017, 180, 1170–1177. [Google Scholar] [CrossRef]

- Asadi, I.; Baghban, M.H.; Hashemi, M.; Izadyar, N.; Sajadi, B. Phase change materials incorporated into geopolymer concrete for enhancing energy efficiency and sustainability of buildings: A review. Case Stud. Constr. Mater. 2022, 17, e01162. [Google Scholar] [CrossRef]

- Thomas, B.S.; Gupta, R.C. A comprehensive review on the applications of waste tire rubber in cement concrete. Renew. Sustain. Energy Rev. 2016, 54, 1323–1333. [Google Scholar] [CrossRef]

- Jani, Y.; Hogland, W. Waste glass in the production of cement and concrete–A review. J. Environ. Chem. Eng. 2014, 2, 1767–1775. [Google Scholar] [CrossRef]

- Abd Rashid, A.F.; Yusoff, S. A review of life cycle assessment method for building industry. Renew. Sustain. Energy Rev. 2015, 45, 244–248. [Google Scholar] [CrossRef]

- Seebach, H.V.; Neumann, E.; Lohnherr, L. State-of-the-Art of Energy-Efficient Grinding Systems. ZKG Int. 1996, 49, 62–67. [Google Scholar]

- GlobalSpec. Material Handling Packaging Equipment and Storage Hoppers. 2023. Available online: https://www.globalspec.com/learnmore/material_handling_packaging_equipment/material_handling_equipment/hoppers (accessed on 5 April 2023).

- SikaGroup. Cement Additives. 2023. Available online: https://www.sika.com/en/construction/cement/additives.html (accessed on 4 May 2023).

- Alsop, P.A. Cement Plant Operations Handbook: For Dry Process Plants; Tradeship Publications Ltd.: Dorking, UK, 2007. [Google Scholar]

- Duda, W.H. International Process Engineering in the Cement Industry. In Cement Data Book; Bauverlag: Damstadt, Germany, 1985; Volume 1. [Google Scholar]

- Ludwig, H.-M.; Zhang, W. Research review of cement clinker chemistry. Cem. Concr. Res. 2015, 78, 24–37. [Google Scholar] [CrossRef]

- Alemayehu, F.; Sahu, O. Minimization of variation in clinker quality. Adv. Mater. 2013, 2, 23–28. [Google Scholar] [CrossRef]

- Ortega, J. Rotary Kiln—Clinkerization and Thermal Zones The Cement Newsletter by InfluencCement. 2022. Available online: https://www.linkedin.com/pulse/chapter-10-rotary-kiln-clinkerization-thermal-zones-juan-ortega/ (accessed on 9 April 2023).

- Zeman, F. Oxygen combustion in cement production. Energy Procedia 2009, 1, 187–194. [Google Scholar] [CrossRef]

- Aldieb, M.A.; Ibrahim, H.G. Variation of feed chemical composition and its effect on clinker formation–simulation process. In Proceedings of the World Congress on Engineering and Computer Science, San Francisco, CA, USA, 20–22 October 2010; pp. 1–7. [Google Scholar]

- Abdul-Wahab, S.A.; Al-Rawas, G.A.; Ali, S.; Al-Dhamri, H. Impact of the addition of oil-based mud on carbon dioxide emissions in a cement plant. J. Clean. Prod. 2016, 112, 4214–4225. [Google Scholar] [CrossRef]

- Hossain, M.U.; Poon, C.S.; Lo, I.M.; Cheng, J.C. Comparative LCA on using waste materials in the cement industry: A Hong Kong case study. Resour. Conserv. Recycl. 2017, 120, 199–208. [Google Scholar] [CrossRef]

- Junior, E.S.A.; de Sales Braga, N.T.; Barata, M.S. Life cycle assessment to produce LC³ cements with kaolinitic waste from the Amazon region, Brazil. Case Stud. Constr. Mater. 2023, 18, e01729. [Google Scholar]

- El-Salamony, A.-H.R.; Mahmoud, H.M.; Shehata, N. Enhancing the efficiency of a cement plant kiln using modified alternative fuel. Environ. Nanotechnol. Monit. Manag. 2020, 14, 100310. [Google Scholar] [CrossRef]

- Fyffe, J.R.; Breckel, A.C.; Townsend, A.K.; Webber, M.E. Use of MRF residue as alternative fuel in cement production. Waste Manag. 2016, 47, 276–284. [Google Scholar] [CrossRef] [PubMed]

- Vizcaíno-Andrés, L.; Sánchez-Berriel, S.; Damas-Carrera, S.; Pérez-Hernández, A.; Scrivener, K.; Martirena-Hernández, J. Industrial trial to produce a low clinker, low carbon cement. Mater. Construcción 2015, 65, e045. [Google Scholar]

- Sousa, V.; Bogas, J.A.; Real, S.; Meireles, I.; Carriço, A. Recycled cement production energy consumption optimization. Sustain. Chem. Pharm. 2023, 32, 101010. [Google Scholar] [CrossRef]

- He, Z.; Zhu, X.; Wang, J.; Mu, M.; Wang, Y. Comparison of CO2 emissions from OPC and recycled cement production. Constr. Build. Mater. 2019, 211, 965–973. [Google Scholar] [CrossRef]

- de Queiroz Lamas, W.; Palau, J.C.F.; De Camargo, J.R. Waste materials co-processing in cement industry: Ecological efficiency of waste reuse. Renew. Sustain. Energy Rev. 2013, 19, 200–207. [Google Scholar] [CrossRef]

- Saif Al-Dhamri, H.; Black, L. Use of oil-based mud cutting waste in cement clinker manufacturing. In Proceedings of the 34th Cement and Concrete Science Conference, Sheffield, UK, 15 September 2014; pp. 427–430. [Google Scholar]

- Rodríguez, N.H.; Martínez-Ramírez, S.; Blanco-Varela, M.T.; Donatello, S.; Guillem, M.; Puig, J.; Fos, C.; Larrotcha, E.; Flores, J. The effect of using thermally dried sewage sludge as an alternative fuel on Portland cement clinker production. J. Clean. Prod. 2013, 52, 94–102. [Google Scholar] [CrossRef]

- Li, H.; Xu, W.; Yang, X.; Wu, J. Preparation of Portland cement with sugar filter mud as lime-based raw material. J. Clean. Prod. 2014, 66, 107–112. [Google Scholar] [CrossRef]

- Silva, L.H.P.; Nehring, V.; de Paiva, F.F.G.; Tamashiro, J.R.; Galvín, A.P.; López-Uceda, A.; Kinoshita, A. Use of blast furnace slag in cementitious materials for pavements-Systematic literature review and eco-efficiency. Sustain. Chem. Pharm. 2023, 33, 101030. [Google Scholar] [CrossRef]

- Vijayan, D.; Arvindan, S.; Janarthanan, T.S. Evaluation of ferrock: A greener substitute to cement. Mater. Today: Proc. 2020, 22, 781–787. [Google Scholar] [CrossRef]

- Anastasiou, E.; Liapis, A.; Papayianni, I. Comparative life cycle assessment of concrete road pavements using industrial by-products as alternative materials. Resour. Conserv. Recycl. 2015, 101, 1–8. [Google Scholar] [CrossRef]

- Barišić, I.; Marković, B.; Zagvozda, M. Freeze–thaw resistance assessment of cement-bound steel slag aggregate for pavement structures. Int. J. Pavement Eng. 2019, 20, 448–457. [Google Scholar] [CrossRef]

- Bilir, T.; Yüksel, I.; Topcu, I.B.; Gencel, O. Effects of bottom ash and granulated blast furnace slag as fine aggregate on abrasion resistance of concrete. Sci. Eng. Compos. Mater. 2017, 24, 261–269. [Google Scholar] [CrossRef]

- El-Hassan, H.; Kianmehr, P. Pervious concrete pavement incorporating GGBS to alleviate pavement runoff and improve urban sustainability. Road Mater. Pavement Des. 2018, 19, 167–181. [Google Scholar] [CrossRef]

- Ho, H.-L.; Huang, R.; Hwang, L.-C.; Lin, W.-T.; Hsu, H.-M. Waste-based pervious concrete for climate-resilient pavements. Materials 2018, 11, 900. [Google Scholar] [CrossRef] [PubMed]

- Moradi, S.; Shahnoori, S. Eco-friendly mix for Roller-Compacted Concrete: Effects of Persian-Gulf-Dredged marine sand on durability and resistance parameters of concrete. Constr. Build. Mater. 2021, 281, 122555. [Google Scholar] [CrossRef]

- Eyo, E.U.; Ng’ambi, S.; Abbey, S. Performance of clay stabilized by cementitious materials and inclusion of zeolite/alkaline metals-based additive. Transp. Geotech. 2020, 23, 100330. [Google Scholar] [CrossRef]

- Sua-iam, G.; Makul, N.; Cheng, S.; Sokrai, P. Workability and compressive strength development of self-consolidating concrete incorporating rice husk ash and foundry sand waste–A preliminary experimental study. Constr. Build. Mater. 2019, 228, 116813. [Google Scholar] [CrossRef]

- Javid, A.A.S.; Nejad, M.A.A. Packing density and surface finishing condition effects on the mechanical properties of various concrete pavements containing cement replacement admixtures. Constr. Build. Mater. 2017, 141, 307–314. [Google Scholar] [CrossRef]

- Özbay, E.; Erdemir, M.; Durmuş, H.İ. Utilization and efficiency of ground granulated blast furnace slag on concrete properties–A review. Constr. Build. Mater. 2016, 105, 423–434. [Google Scholar] [CrossRef]

- Akhtar, A.; Sarmah, A.K. Construction and demolition waste generation and properties of recycled aggregate concrete: A global perspective. J. Clean. Prod. 2018, 186, 262–281. [Google Scholar] [CrossRef]

- Milad, A.A.; Ali, A.S.B.; Yusoff, N.I.M. A review of the utilisation of recycled waste material as an alternative modifier in asphalt mixtures. Civ. Eng. J. 2020, 6, 42–60. [Google Scholar] [CrossRef]

- Rahman, M.J.; Setiawan, A.; Ihsan, M. Examining polyethylene terephthalate (pet) as artificial coarse aggregates in concrete. Civ. Eng. J. 2020, 6, 2416–2424. [Google Scholar]

- Aldakshe, A.; Çağlar, H.; Çağlar, A.; Avan, Ç. The investigation of use as aggregate in lightweight concrete production of boron wastes. Civ. Eng. J. 2020, 6, 1328–1335. [Google Scholar] [CrossRef]

| Type of Replacement Materials Used | The Percentage Replacement | Percentage of Energy Reduction | Percentage of GHGs (NOx, SO2, CO2) Reduction or Increment | References |

|---|---|---|---|---|

| Oil-Based Mud; Metakaolin; and Fly Ash + Glass waste + Bio-fuel | ||||

| Oil-based mud | OBM: 1–5% | Not stated | OBM: 1% to 6% | [48] |

| Metakaolin (kaolinitic residue) | OPC: 45% & 60% PCC: 45% & 60% | OPC 45%: 28% to 33%. OPC 60%: 37% to 44% PCC 45% & 60%: 10% to 25% | OPC 45%: 35% to 37% OPC 60%: 47% to 50% PCC 45%: 20% to 22% PCC 60%: 35% to 38% | [50] |

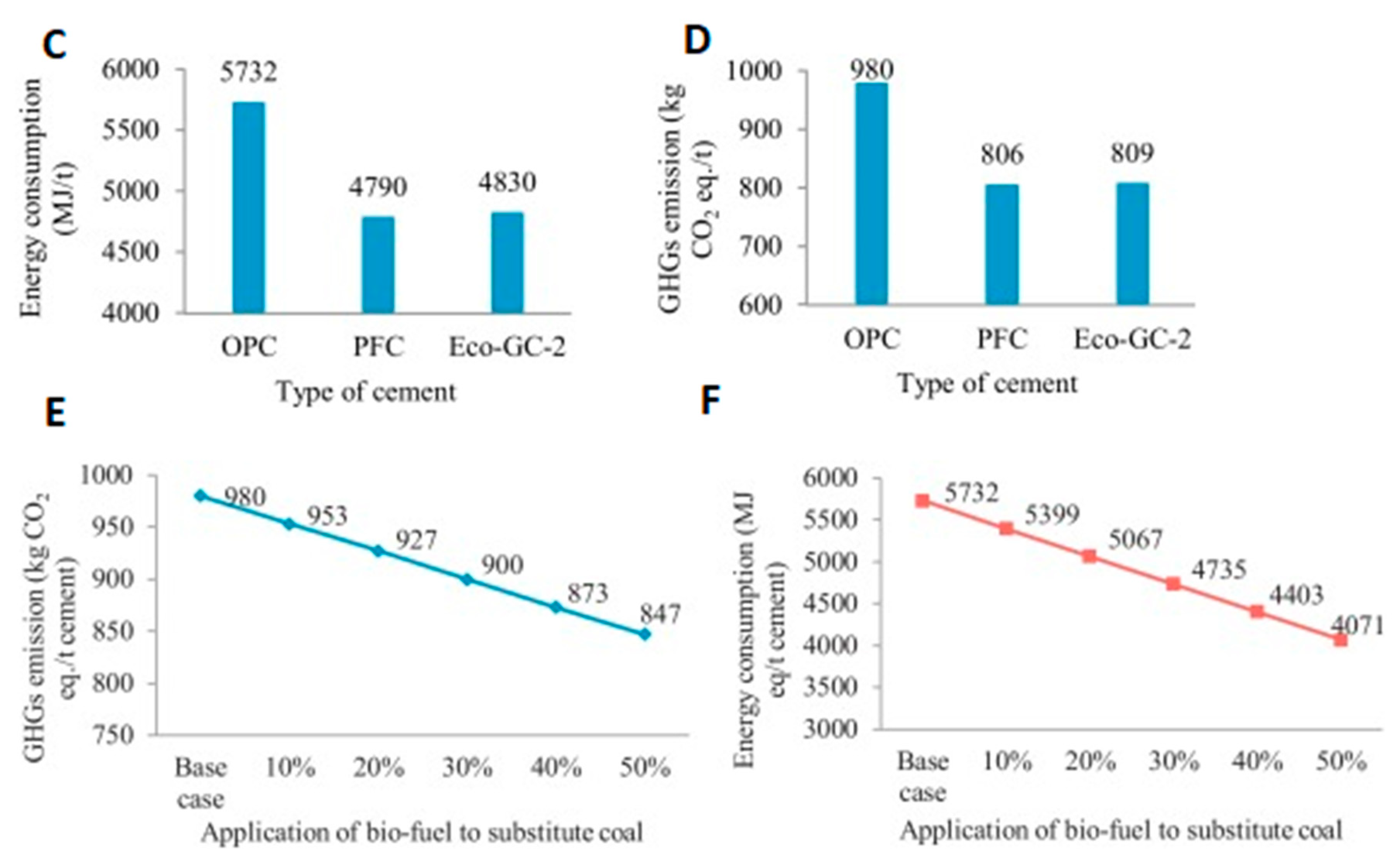

| Fly-ash, glass waste powder, and wood waste (biofuel) | PFC: 20% Eco-GC-2: 20% Biofuel: 10–50% | PFC: 16% Eco-GC-2: 16% OPC: 5.81% to 28.98% | PFC: 18% Eco-GC-2: 17% OPC: 2.76% to 13.57% | [49] |

| Rice Husk + Solid Waste; Solid Recovered Fuel from Landfills; and Pozzolan + Calcium Hydroxide | ||||

| Rice husk, Solid waste from refuse, such as plastic waste, garden waste, wood, tissues, cardboard, and paper. | AFs: 0–5% | AFs: 13% | Not stated | [51] |

| Solid recycled fuel containing about 60% of plastic and about 40% of fibrous mixture of materials. | Not stated | SRF: 5.5% (early scenario); 6.2% (near-term scenario); 6.3% (future scenario) | CO2: 1.6% (early scenario); 1.5% (near-term scenario); 1.4% (future scenario). SO2: 21% (early scenario); 19% (near-term scenario); 44% (future scenario). NOx: 20% increment (early scenario); 24% increment (near-term scenario); 16% increment (future scenario). | [52] |

| Pozzolan and calcium hydroxide | 15%, 20%, and 25% | 15% | 31% | [53] |

| Use of Recycled Cement | ||||

| Hardened waste cement | RC–complete replacement | 30–40% | 80% | [54] |

| Waste or recycled cement | RC–complete replacement | Not stated | RC–450 °C: 94% RC–800 °C: 76% | [55] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Akintayo, B.D.; Akintayo, D.C.; Olanrewaju, O.A. Material Substitution Strategies for Energy Reduction and Greenhouse Gas Emission in Cement Manufacturing. Atmosphere 2023, 14, 1200. https://doi.org/10.3390/atmos14081200

Akintayo BD, Akintayo DC, Olanrewaju OA. Material Substitution Strategies for Energy Reduction and Greenhouse Gas Emission in Cement Manufacturing. Atmosphere. 2023; 14(8):1200. https://doi.org/10.3390/atmos14081200

Chicago/Turabian StyleAkintayo, Busola Dorcas, Damilola Caleb Akintayo, and Oludolapo Akanni Olanrewaju. 2023. "Material Substitution Strategies for Energy Reduction and Greenhouse Gas Emission in Cement Manufacturing" Atmosphere 14, no. 8: 1200. https://doi.org/10.3390/atmos14081200

APA StyleAkintayo, B. D., Akintayo, D. C., & Olanrewaju, O. A. (2023). Material Substitution Strategies for Energy Reduction and Greenhouse Gas Emission in Cement Manufacturing. Atmosphere, 14(8), 1200. https://doi.org/10.3390/atmos14081200