Abstract

While there is strong demand for cement because of its widespread use in modern society, its production is a source of international concern due to the large amounts of energy required and the greenhouse gas (GHG) emissions produced in the process. These GHGs deplete the ozone layer and speed up global warming. Therefore, it is important to investigate several methods of handling this issue, and material replacement has been proposed as the best option among many others. In this study, we examine the different strategies that have employed material substitution to reduce energy use and GHG emissions during the past decade. In this study, we provided an overview of the cement production processes and outlined the various material replacement choices available to us (including waste or recycled materials and other materials). This study found that partial (1–60%) and total material substitution in cement production processes have been reported to lower energy consumption by 5.5% to 40% and greenhouse gas emissions by 1% to 94%. This highlights the importance of material substitution in cement production for reducing energy consumption and emissions of greenhouse gases.

1. Introduction

Cement remains an indispensable basic commodity and a resource of great significance that continues to be a fundamental requirement in our everyday life and therefore affects national and international economic development [1,2]. Cement industries are well recognized for the vital roles they play in the economic growth of developing nations. This is evident in the value they provide to the home country’s production as well as the countless new jobs they generate [3,4]. As a fundamental material used in the construction and building of structures, it is extensively applied in several fields, such as civil engineering construction, industrial engineering construction, and nuclear engineering construction [2,5,6]. The constantly increasing demand of cement for various construction projects steers a corresponding increase in the production volume of cement, and with a lack of hinderance on the side of the demand, the production of cement is expected to experience constant growth. This growth in cement production has soared rapidly within the past ten years, having recorded an increase in production to a massive 3.4 B. tons (billion tons) [3,7], and this could not have been achieved without the expense of energy of various forms [8].

Generally, there have been lofty consumption of energy by various industries in the industrial sector, and this has varied from 30–70% of the total amount of energy expended in a list of selected countries as opined by various reports [8,9,10]. The process of manufacturing cement is known to be an energy-intensive process; it involves the consumption of coal (fossil fuel), electrical energy, as well as other resources of energy, and this justifies the reason why the cement manufacturing industry alone accounts for 11–15% of the total energy expended in the industry [2,3,11,12]. On averagely, the production of a ton of cement utilizes thermal energy of 3.4GJ in the dry process, which in turn requires electrical energy of about 110 kWh [3,13,14]. Moreover, the process of producing a ton of cement leads to the release of carbon IV oxide (CO2) in excess of 0.73–0.99 tons, and this is primarily dependent on the ratio of clinker-to-cement along with various factors [3,15,16,17]. This CO2 do not only get released through the combustion of fuel, but rather its release is inherently part of the manufacturing process [18]. Conversely, as opposed to most of the manufacturing companies whereby the release of GHGs, such as CO2, are mostly due to energy consumption; in the cement manufacturing industry, a combination of energy consumption and the manufacturing process of cement results in the emission of CO2 [18,19].

The various emissions in the cement industries which are energy-induced could be a result of direct or indirect energy consumption. The emissions that are related to fuel consumption are as a result of various combustions of these fuels, such as fossil fuels (generation of thermal energy), and are referred to as the direct emission, while the indirect emissions are usually spawned from the consumption of electricity (electrical energy) [18,20,21]. Emissions from energy generated as a result of thermal processes involved in raw materials conversion to achieve the clinker could further add 60–90% of the amount of CO2 to the emissions of the manufacturing process, and this is largely dependent on the type of technology applied [22]. Recently, owing to the lofty consumption of energy accompanying the manufacture of cement in the industry, most of the achievements of the cement industries have been tailored to various ways of attaining a high level of energy efficiency improvement without altering the quality of the product and having a negative impact on their production capacity [2]. As a result of this, there has been a widespread introduction of commercial retrofitting projects, which are aimed at decreasing the rate of energy consumption and the emission of CO2.

The following are the major approaches put forward to help check the intensive consumption of energy and emissions of CO2 in the cement manufacturing industry. (i) There have been noteworthy emergences of diverse technologies in the cement-producing industries for the conservation of energy owing to the non-renewable fossil fuels used as well as a shift to dry process from the conventional wet process of manufacturing cement, which has improved the efficiency of energy from 26–58% [21,23]. In the world today, the widespread use of these technologies have been applied in various parts of the world; they include the system of transportation of raw materials and the cement produced, roller mills with high efficiencies, highly efficient classifiers, roller presses with high pressure, multiple-stage pre-heating processes with a pre-calciner, a reciprocating extensive cooler, electric motors with great efficiency, adaptable speed drives, and a better enhanced refractory [3,24,25]. (ii) The utilization of alternate fuels and biomass has now become a standard in so many countries and some have used alternative fuels for the replacement of over 50% of the entire quantity of fuels used in the thermal process [21]. The use of petro-coke and coal are the universal conventional sources of fuels for the cement plants [3]; however, as earlier pointed out, these valuable resources are barely renewable; there have been several alternatives that have been introduced to reduce their use. Some of these include (a) the use of gaseous fuels, such as the waste gases from refineries and gases from landfills as alternatives, (b) the use of liquid fuels, such as hydraulic oils, (c) the use of granulated solid or pulverized fuels, such as granulated plastics and sawdust, (d) the use of roughly crushed fuels, such as crushed tires as alternatives, and (e) the use of lumpy fuels, such as plastic bales as an alternative source of fuel [3]. (iii) The clinker has been replaced with the use of other products; the raw materials composition and the finished product are known to also contribute to the consumption of energy. The clinker is produced after a host of processes have been carried out, such as the raw-materials-crushing processes, a pre-blend and the grinding of these raw materials, which are then calcined to give a semi-finished product, referred to as the clinker. The process of calcination have been reported to use approximate values of 24% and 38% of electrical and thermal energy, respectively, in the cement industry [8,13]. The reduction of the ratio of clinker-to-cement through the replacement of clinker with a more or less inert limestone filter, pozzolanic materials, such as fly ash, silica fume, and egg shells; the use of latently hydraulic substitutes, such as granulated slag from the blast furnace, could significantly decrease the required amount of energy [3,12,21,26,27,28]. (iv) CO2 emissions are reduced by capturing and storing the CO2 gases. Despite the fact that the vast majority of measures for the efficient use and conservation of energy unconditionally aid in CO2 reduction, there have been some measures that have been specifically implemented to lessen the emission of GHGs [29]. Most of the measures, including carbon capture storage (CCS), do not usually have extensive financial implications with the exception of those cement industries which are located in countries that impose a significant tax on the emission of these gases [30].

Despite all these effort by the cement industries, there is still a large amount of energy being consumed in the manufacturing processes of cement as well as a lofty amount of GHGs being emitted, which is far from the vision of the 2031 plan of one of the notable commissions of the world (the European Commission) to achieve a low-carbon economy [31]. To this effect, there have been some tireless efforts by scientists to come up with various formulas that can help to ameliorate this present situation. Hence, in this review, we have tried to pull together and discuss a list of material substitution approaches applied in the manufacturing processes of cement within the past ten years as a means of reducing the intensive energy consumption and GHG emissions in the cement industry. We are aware that several researchers have carried out many studies related to this topic in terms of reviewing the possible solutions to energy conservation with some of these reviews assessing the improvement of energy efficiency over the long term [18], comparing the consumption of energy and CO2 emissions from both recycled cement and clinker production [21], and overviewing some of the measures of saving energy [14]. Additionally, some other reviews on energy reduction and CO2 emission reduction have focused on substituting some percentage of the finished product (cement) for the preparation of mortars [32,33], concretes [34,35,36], and building constructions [37]. However, none of these reviews have discussed the various material substitution approaches employed in reducing the intensive energy consumption and GHG emissions in the manufacturing processes of cement. In this study, we present a summarized description of the manufacturing process of cement, thus giving insight into the need for material substitution. We went further to critically review relevant literature that have successfully employed material replacement strategies to reduce the intensive energy consumption and GHG emissions from cement production. Lastly, we give a future perspective on how the use of material substitution in the manufacturing process of cement could aid in energy reduction and GHG emissions.

2. Description of Manufacturing Processes of Cement

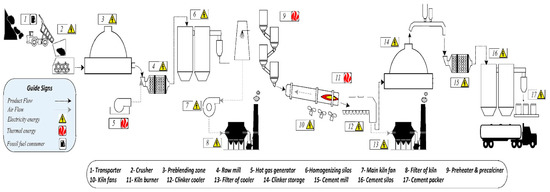

According to Madlool et al., the production of cement involves nine distinct stages that are energy intensive (Figure 1), necessitating an improvement in order to maximize energy efficiency [8]. The very first stage is the extraction and crushing of limestone, a major element quarried by an open mine process, which is usually carried out by drilling with heavy-duty machines or equipment, such as dump trucks, bulldozers, and explosives (blasting), before they are transported with the use of a mechanical conveyor. Limestone, which contains 75–90% of calcium trioxocarbonate IV (CaCO3) in the raw form with the remaining percentage made up of MgCO3 and other impurities (iron, silica, and alumina), is first fed into a primary crusher, then moved to the secondary crusher, which reduces the CaCO3 inlet sizes to 25 mm before it is finally reduced through the last crusher (tertiary) [8,38]. The principal firmness of the cement is usually provided by the lime (CaO) as well as the silica, while the iron helps in the reduction of the temperature of the reaction and gives the cement the usual grey color [8].

Figure 1.

Diagrammatical illustration of energy consumption in the manufacturing process of cement in the cement industry [3].

To obtain the required raw feed compositions, other elements, such as bauxite, quartzite, iron, and silica, must be added prior to the processing stage for the raw mix of CaCO3 and the additives to be grinded to obtain smaller fragmented particles. These additives aid in the prevention of any compositional abnormalities that may arise naturally, thus allowing them to be stored in silos or hoppers and transferred with weigh feeders via conveyor belts [8,39,40]. In this stage, a “vertical roller mill” (VRM) or a “ball mill” is employed for the process of raw mix grinding, while some of the excessive heat from the kiln is used for drying the raw mixture in this processing stage. There are many factors which governs the choice between the ball mill and the VRM and these includes the quantity of moisture present in the raw materials, the material abrasiveness, the level of energy consumption, reliability, and economic viability [8,41,42].

A major energy consuming aspect of cement production is the clinkering step [43,44] done inside the kiln (a vital piece of the plant used in manufacturing cement) and the pre-heating tower, which comes with a combustion chamber referred to as a pre-calciner. At this stage, CO2 is produced by a series of chemical reactions that causes the raw mix to melt, fuse together, and create the clinker. The red-hot clinker is thereafter exuded from the kiln and moved through various coolers in order to recover part of the thermal energy and reduce the handling temperature of the clinker [45]. The clinker when being exuded, possesses an approximate temperature of 1500 °C; thus, the cooler is used to blow an ambient air above the red-hot clinker, which helps in the reduction of the temperature of the clinker to 170 °C approximately [46].

Kiln feed compositional variations adversely affects the effectiveness of the kiln [47]; however, this natural variation of chemical in the different raw materials can be effectively reduced by increasing the relative blending proportion and homogenizing these raw materials using consecutive blending silos to reduce the amount of used clinker, which will consequently lead to a reduction in the identified energy consumption of the finished product [8]. Another important part is the mill, a cylindrically shaped metallic chamber containing balls made of metals, which is grinded with the clinker as well as the mix of additives to form the cement [8]. The grinding of the clinker alongside various other additives present in the cement mill is the final step of the process before cement is ready for use or stored in the cement silo before they are transported to their various sites of use.

3. Various Material Substitution Approaches Applied for the Reduction of Energy in the Cement-Manufacturing Process

Cement production accounts for 11–15% of all industrial energy consumption, and it is crucial to develop strategies to reduce the energy required for this process and the resulting CO2 emissions, which are the primary cause of global warming. Several researchers have come up with various ways of solving this problem with the use of material replacements, such as recycled and non-recycled materials of both biogenic and non-biogenic origins. We examined articles from peer reviewed literature databases, such as Google Scholar, Scopus, and ScienceDirect, that have employed material substitution in cement manufacturing. Several studies centered on material replacements have been reported with relation to the production of mortars, concretes, and the likes, with various amounts of energy and CO2 emission reductions reported, but due to these studies not reporting about the reduction of the consumption of energy and emission of CO2 (GHGs) in the manufacturing process of the cement used for these concretes and mortars, these studies were considered to be out of the scope of this review, and were thus, not included in the discussions below. Therefore, our focus was only on studies which have discussed the various ways of reducing the amount of energy used and CO2 emitted during the manufacturing process of cement within the past decade. A total of 40 articles were identified and included in the next section.

Use of Waste or Recycled Materials

There have been several reports on the use of different waste materials as well as the recycling of materials, such as oil-based-mud [48], waste glass powder [49], and kaolinitic waste [50], for the manufacture of cement, and various percentages of energy reduction as well as CO2 emission reduction have been recorded. A research group led by Abdul-Wahab et al. (2016) explored the use of an oil-well drilling waste in the form of an oil-based-mud (OBM) as a substitution material for limestone in one of the stages (kiln) of the manufacturing process of cement [48]. The substitutions which were made in various percentages, including 1%, 2%, 3%, 4%, and 5% of OBM in place of limestone, reportedly reduced the amount of CO2 emitted in the manufacturing process by about 1% to 6% depending on the percentage OBM substitution made. Although the authors failed to report the impact on the reduction of energy in the manufacturing process, they believed that this hydrocarbon waste (OBM) could enhance the efficiency of thermal energy used in the plant for the manufacturing process, which will in-turn reduce the consumption of energy in the cement plant. However, this is yet to be proven, and therefore, there are calls for more studies to be carried out to evaluate the effect of energy reduction using this OBM.

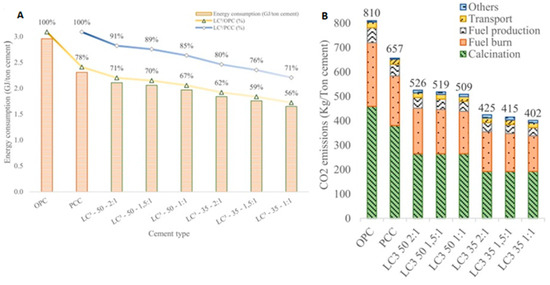

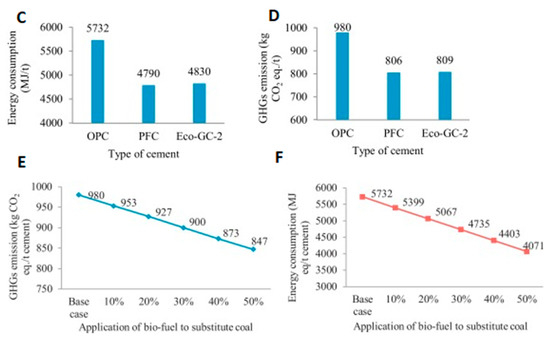

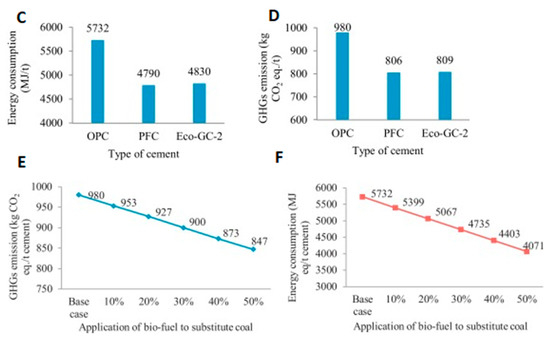

Recently in another study, Junior et al. (2023), prepared a “limestone-calcined clay cement” (LC3) with kaolinitic residue as the replacement material, and used “ordinary Portland cement” (OPC) and “Portland composite cement” (PCC) as their reference materials [50]. The composition of the prepared LC3 was made up of the clinker of OPC, gypsum, limestone, and metakaolin, having a clinker replacement of 45 percent and 60 percent with kaolin to limestone compositional ratio of “2:1, 1.5:1, and 1:1”, respectively, for each replacement percentage. From their study, it was observed that the 45% replacement of clinker (LC3–50) had an energy reduction ranging from 28% to 33%, while the 60% replacement of clinker (LC3–35) had an energy reduction ranging from 37% to 44% relative to the reference OPC, while an energy reduction between 10% and 25% was observed across the 45% and 60% clinker replacement (LC3–50 and LC3–35) relative to the reference PCC, depending on the ratio of the kaolin to limestone used (Figure 2A). In addition, the study reported a significant reduction in the amount of CO2 emitted during the process of production of the cement (Figure 2B). The 45% replacement of clinker (LC3–50) had a CO2 emission reduction ranging from 35% to 37%, while the 60% replacement of clinker (LC3–35) had a CO2 emission ranging from 47% to 50% relative to the reference OPC; the 45% replacement of clinker (LC3–50) was observed to have a reduction in the amount of CO2 emitted with a percentage ranging from 20% to 22%, while the 60% replacement of clinker (LC3–35) was observed to show a CO2 emission reduction ranging from 35% to 38% relative to the PCC reference, and these were dependent on the ratio of the metakaolin to limestone used [50]. The authors concluded that, their proposed formula would be a possible solution to the reduction of energy consumption and CO2 emission in the manufacturing process of cement in the industry, and this can be arguably correct given the significant percentage reductions obtained. However, it is important to state that the materials used were acquired from a particular location, and this means that the same material from a different location may not yield the same results, owing to their differences in constituents based on the soil type present in the area. Hence, further studies are encouraged with the same formula with collection of materials from different location for confirmation of results.

Another group of researchers led by Hossain et al. (2017) employing a “life cycle assessment” (LCA) undertook a study to explore comprehensively the amount of energy consumed and CO2 (GHGs) emitted from the manufacturing process of OPC in comparison to other types of cements whose manufacturing process were strategically modified. These modifications were in two forms, which include the form of raw materials substitution, such as the use of fly-ash (FA) and waste glass powder materials, and secondly the use of biofuel generated from wood waste alongside coal (co-fuel) [49]. The results from the LCA raw material modification strategy showed that the 20% FA-modified Portland cement (PFC) reportedly consumed about 16% lesser energy (Figure 2C) as well as emitting 18% lesser CO2 (Figure 2D), while the other type of cement with 20% modification using waste glass powder (Eco-GC-2) showed a similar lesser percentage of energy consumption (about 16%) (Figure 2C) and CO2 emission (17%) (Figure 2D) for the manufacturing process compared to the reference OPC [49].

The application of this first strategy can be seen to have an impact in the amount of energy consumed and CO2 emitted in the manufacturing process of cement. Although the impact may be regarded as being not so significant, it is a light in the positive direction for the reduction of both energy consumption and CO2 emission in the cement industry. Interestingly, the research group noted that approximately 64% of the total amount of energy consumed and 32% of CO2 emitted in the manufacturing process of the OPC were associated with the combustion of coal inside the cement-processing plant. This led to the implementation of the second strategy, which was the substitution of 10% to 50% amount of coal in the plant with a biofuel generated from wood waste. Upon applying the biofuel substitution, the consumption of non-renewable energy by the manufacturing process of OPC was significantly reduced by almost 30% (about 5.81% to 28.98%) (Figure 2F), while the percentage of CO2 emitted was reduced with about 2.76% to 13.57%, depending on the percentage replacement of coal with the biofuel (Figure 2E).

Figure 2.

(A) Consumption of energy during the process of calcination and the energy consumption reduction for LC3 relative to the references. (B) Emissions of CO2 for various cements evaluated [50]. (C) Consumption of energy during the manufacturing process of OPC, PFC, and Eco-GC-2. (D) Emission of CO2 during the manufacturing process of OPC, PFC, and Eco-GC-2. (E) Emission of CO2 during the manufacturing process of OPC upon modification of coal with biofuel. (F) Consumption of energy during the manufacturing process of OPC upon modification of coal with biofuel [49].

Apart from oil-based-mud, waste glass powder, and kaolinitic waste, various scientists have been able to come up with some other alternative sources of waste materials, which can be applied as a supplementary material, to help reduce the amount of energy consumption and GHG emissions in the manufacturing process of cement in the cement industry. In 2020, El-Salamony led a research group in study to explore how a cement plant kiln’s efficiency can be enhanced with the use of a modified alternative source of fuel [51]. This group of scientists established the fact that the mixture of rice husk with solid waste derived from refuse (alternative fuels [AFs]), such as plastic waste, garden waste, tissues, cardboard and paper, and wood, could be used as an alternative source of fuel in the kiln plant. From their study, it was reported that the successful replacement of 17% of coal with the use 0% to 5% of the mixture of these materials resulted in a corresponding reduction of about 13% of the consumption of electrical power in the manufacturing process of cement [51]. In addition, it was reported that the emission of GHGs, such as sulfuric oxides and nitric oxides, decreased owing to this substitution.

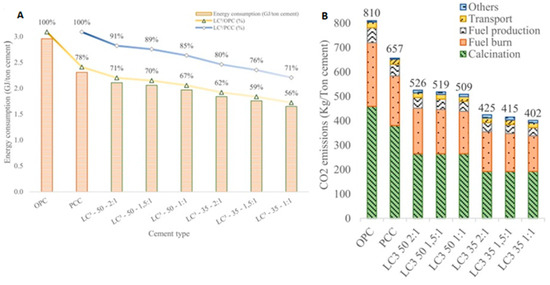

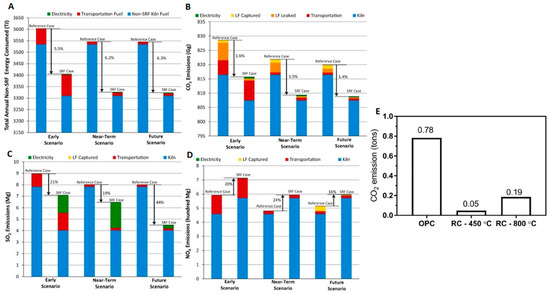

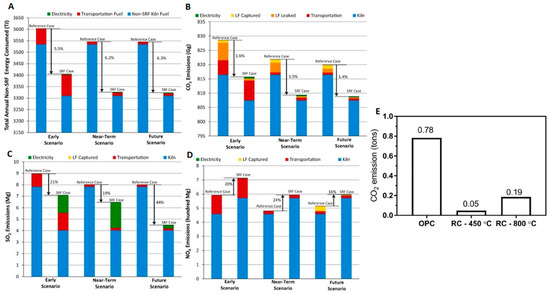

Another study led by Fyffe et al. (2016) explored the use of waste materials obtained from “municipal solid waste” landfills in the form of a “solid recycled fuel” (SRF) as a substitution material for the manufacturing process of cement [52]. According to the researchers, the energy consumption rate was reduced by 5.5% by the SRF compared to the reference cement (OPC). Additionally, conducting a near-term and future one-year scenario proposition, it was found that SRF would have energy consumption reductions of 6.2% and 6.3%, respectively, relative to the reference cement (Figure 3A). Taking the research further, the research group decided to quantify the percentage of GHGs, such as NOx, SO2, CO2, emitted during the manufacturing process of both the reference and SRF cement. From their study, they found out that SRF had a reduction in the percentage of GHGs emitted in the early, near-term, and future one-year scenario propositions (Figure 3B,C) compared to the reference cement with exception to NOx, which had a higher emission percentage compared to the reference cement (Figure 3D).

Having obtained the above results, Fyffe et al. (2016) then concluded that the use of SRF as a possible replacement of fossil fuel in the kiln of the cement plant during the manufacturing process of cement in the cement industry is of great benefit for energy efficiency as well as the environment at large [52]. However, based on the fact that the emission values for NOx obtained were higher than that of the reference, which may be as a result of the compositional content of the SRF (40:60–percentage ratio of fibrous mixture of materials to plastic materials), there is a need for more research using this SRF with varying proportions of the composition to be able to validate what percentage of what kind of waste would bring about the best possible results. The synergistic action of the use of both pozzolan and calcium hydroxide as supplementary materials for the manufacturing process of cement has also been explored by Vizcaíno-Andrés et al. (2015). The study which reported the replacement of up to 50% clinker with pozzolan and calcium hydroxide, employing the percentage amounts of 15%, 20%, and 25%, was said to have resulted in a 15% reduction of electrical energy consumption as well as a 31% CO2 emission reduction relative to OPC [53].

In addition, there have been some group of researchers who have attempted the use of waste cement by recycling the cement to produce a new cement and comparing the rate of energy consumption as well as CO2 emission to the normal traditional cement OPC. Just recently, the use of waste hardened cement by thermo-activating the cement into recycled cement (RC) was explored as a supplementary material in the manufacturing process of cement with the aim of reducing the consumption of energy and CO2 emission in the cement industry [54]. According to [54], the production of RC from the cement paste, which was secured in from waste concrete, can be seen as one of the solutions to the problem of high energy consumptions and CO2 emission in the cement-manufacturing process. This is because in their study, the manufacturing process of RC yielded the percentage energy consumption reduction of 30–40% and CO2 emission reduction of 80% relative to the cement produced using the clinker. In another study, [55] made a comparison between the manufacturing process of OPC and recycled cement (RC–450 °C and RC–800 °C). From the study, it was observed that the emission of CO2 from the raw materials per tons were for RC–450 °C: 4.3% and for RC–800 °C: 24.4% of the CO2 emission value of OPC.

In addition, the research group went ahead to quantify and compare the CO2 emissions from the entire manufacturing process, and it was observed that the CO2 emissions produced by RC–450 °C was around 0.05 in tons, while RC–800 °C was around 0.19 in tons, which was relatively low compared to OPC which was 0.78 in tons. These results translate to reduction percentages of approximately 94% and 76% for RC–450 °C and RC–800 °C, respectively, relative to the value of OPC (Figure 3E). Regrettably, the research groups were not interested in the amount of energy involved in the manufacturing process as they did not report the amount of energy expended in the manufacturing process of the cement. However, it can be agreed that just like the previous study by Sousa et al. (2023) who also explored the use of RC as a substitution material, about 80% CO2 emission reduction and between 30% to 40% energy consumption reduction were obtained [54]; if the researchers had quantified the energy consumption involved in the manufacturing process, there is a high possibility that they would have obtained close to 50% of reduction of energy consumption for RC–450 °C and RC–800 °C relative to OPC, but this can only be an assumption because it was not quantified. This gives room for more research work to be performed to prove this assumption.

Generally, from the studies above, there has been great success recorded in the process of recycling waste materials as a supplementary material in the manufacturing process of cement. A good percent of energy consumption as high as 40% can be reduced, while on the other hand, GHG emissions of up to 94% can be reduced with the use of these waste materials from various industries and the environment (Table 1). Waste products are often not well-disposed in some countries, especially the developing countries of the world, owing to their large amounts as well as the cost implications involved in disposing these waste materials, depending on the type of waste [48]. A good example is oil wastes, which are known to pose hazards to the environment and thus demand some peculiarly specific treatment. These waste materials, such as the OBM, the kaolinitic waste, glass waste powder, amongst others, have been shown to contain appreciable quantities of some of the major oxides that identify with the manufacturing processes of cement and are thus reused in place of the original traditional materials [56,57,58,59,60]. The ability to reuse these waste materials will go a long way in preserving the traditional materials and natural resources, while at the same time, promoting a better efficiency of the consumption of energy and the quest of having a carbon-free environment, owing to the reduction in the emission of CO2 from the manufacturing process of cement.

Figure 3.

(A) Energy consumption reduction, (B) CO2 emission reduction, (C) SO2 emission reduction, (D) NOx emission increment [52], and (E) CO2 emission reduction [55].

Table 1.

Use of Waste or Recycled Materials.

Just like the use of various waste or recycled materials as a substitution material for the manufacturing process of cement gave a considerably good percentage reduction of the consumption of energy and CO2 emission reduction, a study which focused on use of other materials has been explored with success recorded. In 2014, Atmaca and Yumrutaş in a study, aimed to investigate the specific consumption of energy in a rotatory kiln which is used in the manufacturing process of cement in the cement industry [25]. To achieve this aim, supplementary materials, such as alumina and magnesia spinel, were used for the preparation of the clinker. Although the replacement percentage was not reported, it was gathered that using these materials led to the energy consumption reduction of 7.27% during the process of clinker production. Although the percentage of the CO2 emission reduction was not specifically stated, it was reported that a corresponding decrease of 1,614,480 kg of CO2 emission was recorded [25]. The researchers then concluded that the ability to minimize heat loss through insulation and the reduction of temperature of the outlet gases by an effective transfer of heat within the unit as well as minimizing the leakage of steam and air through sealing, would greatly impact the reduction of the consumption of energy. Notwithstanding, the researchers conceded that the need for advanced studies involving the various parameters that may affect the optimal system performance, which could help to enhance the reduction of energy consumption in the clinker manufacturing process, is crucial and very urgent. Hence, more research is encouraged.

4. Future Perspectives

The future of energy conservation and the reduction of CO2 emissions in the cement industry is bright, and the achievement of low consumption of energy and CO2 emissions in the manufacturing processes of cement can be possible based on the outputs of the ongoing research with the use of supplementary materials to replace the traditional naturally occurring materials. The use of waste materials for this process is a welcome innovation and will help to promote the ecological preservation of various species in the environment. Various waste materials have been explored, but there exists a lot more different kind of waste materials yet to be explored. Some of these waste materials have been explored for the substitution of the finished cement products for the preparation of pavement and concrete and have recorded outstanding successes with various percentages of substitution. Some examples of these waste materials which have been used as a substitution material for finished cement products in the preparation of pavements, concrete [61,62], and/or mortar include “the ground-granulated blast-furnace slag” [63,64,65,66,67,68,69,70,71], construction and demolition waste concrete [72], asphalt mixture [73], plastic waste [74], boron waste [75], amongst others. Additionally, from the use of other materials, only one study has been reported, which gives room for many more studies to be conducted with other materials possible. Exploring these and many more options will widen the pool of materials available as supplementary materials for the manufacturing process of cement, which will in turn increase the energy efficiency and reduce CO2 emission in the cement industry.

5. Conclusions

The cement-manufacturing process is known to consume energy intensively as well as emit extensively GHGs, such as CO2, which continues to become a source of concern. The use of traditional raw materials of natural origin, such as fossil fuels and limestone, cannot be sustained owing to their constant depletion and the length of time in which it takes to renew these materials and in some cases, the materials are non-renewable. The use of supplementary materials, such as waste or recycled materials and other materials, have been shown to be a possible solution to this problem, and this can be observed from the various studies that have explored their use as a substitution material at different levels of substitution with various successes recorded. Therefore, the long-awaited approach for the reduction of intensive energy consumption and CO2 emissions could just be the application of these materials as a substitute for the raw materials used in the manufacturing processes of cement in the cement industry.

Author Contributions

Conceptualization, B.D.A.; methodology, B.D.A. and D.C.A.; software, B.D.A.; validation, B.D.A., D.C.A. and O.A.O.; formal analysis, B.D.A.; investigation, B.D.A., D.C.A. and O.A.O.; resources, B.D.A., D.C.A. and O.A.O.; data curation, B.D.A.; writing—original draft preparation, B.D.A.; writing—review and editing, D.C.A. and O.A.O.; visualization, B.D.A., D.C.A. and O.A.O.; supervision, O.A.O.; project administration, O.A.O.; funding acquisition, B.D.A. and O.A.O. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by DUT Doctoral Scholarship Scheme (RFA—Green Engineering).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Verma, Y.K.; Mazumdar, B.; Ghosh, P. Thermal energy consumption and its conservation for a cement production unit. Environ. Eng. Res. 2021, 26, 1–9. [Google Scholar]

- Zhang, Z.; Lin, B. Energy conservation and emission reduction of Chinese cement industry: From a perspective of factor substitutions. Emerg. Mark. Financ. Trade 2019, 55, 967–979. [Google Scholar] [CrossRef]

- Mokhtar, A.; Nasooti, M. A decision support tool for cement industry to select energy efficiency measures. Energy Strategy Rev. 2020, 28, 100458. [Google Scholar] [CrossRef]

- Ali, N. The Role of Cement Industry in the Economic Development of Pakistan; EduPedia Publications (P) Ltd.: Delhi, India, 2015. [Google Scholar]

- Ighalo, J.O.; Adeniyi, A.G. A perspective on environmental sustainability in the cement industry. Waste Dispos. Sustain. Energy 2020, 2, 161–164. [Google Scholar] [CrossRef]

- Salas, D.A.; Ramirez, A.D.; Rodriguez, C.R.; Petroche, D.M.; Boero, A.J.; Duque-Rivera, J. Environmental impacts, life cycle assessment and potential improvement measures for cement production: A literature review. J. Clean. Prod. 2016, 113, 114–122. [Google Scholar] [CrossRef]

- Khan, M.A.; Khan, M.Z.; Zaman, K.; Naz, L. Global estimates of energy consumption and greenhouse gas emissions. Renew. Sustain. Energy Rev. 2014, 29, 336–344. [Google Scholar] [CrossRef]

- Madlool, N.A.; Saidur, R.; Hossain, M.S.; Rahim, N. A critical review on energy use and savings in the cement industries. Renew. Sustain. Energy Rev. 2011, 15, 2042–2060. [Google Scholar] [CrossRef]

- Saidur, R. A review on electrical motors energy use and energy savings. Renew. Sustain. Energy Rev. 2010, 14, 877–898. [Google Scholar] [CrossRef]

- Saidur, R.; Rahim, N.A.; Hasanuzzaman, M. A review on compressed-air energy use and energy savings. Renew. Sustain. Energy Rev. 2010, 14, 1135–1153. [Google Scholar] [CrossRef]

- Avami, A.; Sattari, S. Energy conservation opportunities: Cement industry in Iran. Int. J. Energy 2007, 1, 65–71. [Google Scholar]

- Dong, R.; Zhang, Z.; Lu, H.; Yu, Y. Recovery of waste heat in cement plants for the capture of CO2. Front. Chem. Sci. Eng. 2012, 6, 104–111. [Google Scholar] [CrossRef]

- Afkhami, B.; Akbarian, B.; Beheshti, N.; Kakaee, A.; Shabani, B. Energy consumption assessment in a cement production plant. Sustain. Energy Technol. Assess. 2015, 10, 84–89. [Google Scholar] [CrossRef]

- Madlool, N.; Saidur, R.; Rahim, N.; Kamalisarvestani, M. An overview of energy savings measures for cement industries. Renew. Sustain. Energy Rev. 2013, 19, 18–29. [Google Scholar] [CrossRef]

- Energy, C.I.; Performance, C. Getting the Numbers Right; World Business Council for Sustainable Development The Cement Sustainability Initiative: Washington, DC, USA, 2009. [Google Scholar]

- Olagunju, B.D. Life Cycle Assessment of the Production of Cement: A South African Case Study. Master’s Thesis, Durban University of Technology: Dubran, South Africa, 2021. [Google Scholar]

- Olagunju, B.D.; Olanrewaju, O.A. Life Cycle Assessment of Ordinary Portland Cement (OPC) Using both Problem Oriented (Midpoint) Approach and Damage Oriented Approach (Endpoint). In Product Life Cycle-Opportunities for Digital and Sustainable Transformation; IntechOpen: London, UK, 2021. [Google Scholar]

- Talaei, A.; Pier, D.; Iyer, A.V.; Ahiduzzaman, M.; Kumar, A. Assessment of long-term energy efficiency improvement and greenhouse gas emissions mitigation options for the cement industry. Energy 2019, 170, 1051–1066. [Google Scholar] [CrossRef]

- Bumanis, G.; Korjakins, A.; Bajare, D. Environmental benefit of alternative binders in construction industry: Life cycle assessment. Environments 2022, 9, 6. [Google Scholar] [CrossRef]

- Benhelal, E.; Zahedi, G.; Shamsaei, E.; Bahadori, A. Global strategies and potentials to curb CO2 emissions in cement industry. J. Clean. Prod. 2013, 51, 142–161. [Google Scholar] [CrossRef]

- Sousa, V.; Bogas, J.A. Comparison of energy consumption and carbon emissions from clinker and recycled cement production. J. Clean. Prod. 2021, 306, 127277. [Google Scholar] [CrossRef]

- Poponi, D.; Bryant, T.; Burnard, K.; Cazzola, P.; Dulac, J.; Pales, A.F.; Husar, J.; Janoska, P.; Masanet, E.R.; Munuera, L. Energy Technology Perspectives 2016: Towards Sustainable Urban Energy Systems; International Energy Agency: Paris, France, 2016. [Google Scholar]

- Carriço, A.; Bogas, J.A.; Guedes, M. Thermoactivated cementitious materials–A review. Constr. Build. Mater. 2020, 250, 118873. [Google Scholar] [CrossRef]

- Du Plessis, G.E.; Liebenberg, L.; Mathews, E.H. The use of variable speed drives for cost-effective energy savings in South African mine cooling systems. Appl. Energy 2013, 111, 16–27. [Google Scholar] [CrossRef]

- Atmaca, A.; Yumrutaş, R. Analysis of the parameters affecting energy consumption of a rotary kiln in cement industry. Appl. Therm. Eng. 2014, 66, 435–444. [Google Scholar] [CrossRef]

- Naeimi, A.; Bidi, M.; Ahmadi, M.H.; Kumar, R.; Sadeghzadeh, M.; Nazari, M.A. Design and exergy analysis of waste heat recovery system and gas engine for power generation in Tehran cement factory. Therm. Sci. Eng. Prog. 2019, 9, 299–307. [Google Scholar] [CrossRef]

- Scrivener, K.; Avet, F.; Maraghechi, H.; Zunino, F.; Ston, J.; Hanpongpun, W.; Favier, A. Impacting factors and properties of limestone calcined clay cements (LC3). Green Mater. 2018, 7, 3–14. [Google Scholar] [CrossRef]

- Kadhum, A.O.; Haider, M.O. Experimental Investigation of Self-Compacting High Performance Concrete Containing Calcined Kaolin Clay and Nano Lime. Civ. Eng. J. 2020, 6, 1798–1808. [Google Scholar] [CrossRef]

- Hasanbeigi, A.; Price, L.; Lin, E. Emerging energy-efficiency and CO2 emission-reduction technologies for cement and concrete production: A technical review. Renew. Sustain. Energy Rev. 2012, 16, 6220–6238. [Google Scholar] [CrossRef]

- Moya, J.A.; Pardo, N.; Mercier, A. The potential for improvements in energy efficiency and CO2 emissions in the EU27 cement industry and the relationship with the capital budgeting decision criteria. J. Clean. Prod. 2011, 19, 1207–1215. [Google Scholar] [CrossRef]

- Baghban, M.H.; Mahjoub, R. Natural kenaf fiber and LC3 binder for sustainable fiber-reinforced cementitious composite: A review. Appl. Sci. 2020, 10, 357. [Google Scholar] [CrossRef]

- Hossain, M.; Karim, M.; Hasan, M.; Hossain, M.; Zain, M. Durability of mortar and concrete made up of pozzolans as a partial replacement of cement: A review. Constr. Build. Mater. 2016, 116, 128–140. [Google Scholar] [CrossRef]

- Ramakrishnan, S.; Wang, X.; Sanjayan, J.; Wilson, J. Thermal energy storage enhancement of lightweight cement mortars with the application of phase change materials. Procedia Eng. 2017, 180, 1170–1177. [Google Scholar] [CrossRef]

- Asadi, I.; Baghban, M.H.; Hashemi, M.; Izadyar, N.; Sajadi, B. Phase change materials incorporated into geopolymer concrete for enhancing energy efficiency and sustainability of buildings: A review. Case Stud. Constr. Mater. 2022, 17, e01162. [Google Scholar] [CrossRef]

- Thomas, B.S.; Gupta, R.C. A comprehensive review on the applications of waste tire rubber in cement concrete. Renew. Sustain. Energy Rev. 2016, 54, 1323–1333. [Google Scholar] [CrossRef]

- Jani, Y.; Hogland, W. Waste glass in the production of cement and concrete–A review. J. Environ. Chem. Eng. 2014, 2, 1767–1775. [Google Scholar] [CrossRef]

- Abd Rashid, A.F.; Yusoff, S. A review of life cycle assessment method for building industry. Renew. Sustain. Energy Rev. 2015, 45, 244–248. [Google Scholar] [CrossRef]

- Seebach, H.V.; Neumann, E.; Lohnherr, L. State-of-the-Art of Energy-Efficient Grinding Systems. ZKG Int. 1996, 49, 62–67. [Google Scholar]

- GlobalSpec. Material Handling Packaging Equipment and Storage Hoppers. 2023. Available online: https://www.globalspec.com/learnmore/material_handling_packaging_equipment/material_handling_equipment/hoppers (accessed on 5 April 2023).

- SikaGroup. Cement Additives. 2023. Available online: https://www.sika.com/en/construction/cement/additives.html (accessed on 4 May 2023).

- Alsop, P.A. Cement Plant Operations Handbook: For Dry Process Plants; Tradeship Publications Ltd.: Dorking, UK, 2007. [Google Scholar]

- Duda, W.H. International Process Engineering in the Cement Industry. In Cement Data Book; Bauverlag: Damstadt, Germany, 1985; Volume 1. [Google Scholar]

- Ludwig, H.-M.; Zhang, W. Research review of cement clinker chemistry. Cem. Concr. Res. 2015, 78, 24–37. [Google Scholar] [CrossRef]

- Alemayehu, F.; Sahu, O. Minimization of variation in clinker quality. Adv. Mater. 2013, 2, 23–28. [Google Scholar] [CrossRef]

- Ortega, J. Rotary Kiln—Clinkerization and Thermal Zones The Cement Newsletter by InfluencCement. 2022. Available online: https://www.linkedin.com/pulse/chapter-10-rotary-kiln-clinkerization-thermal-zones-juan-ortega/ (accessed on 9 April 2023).

- Zeman, F. Oxygen combustion in cement production. Energy Procedia 2009, 1, 187–194. [Google Scholar] [CrossRef]

- Aldieb, M.A.; Ibrahim, H.G. Variation of feed chemical composition and its effect on clinker formation–simulation process. In Proceedings of the World Congress on Engineering and Computer Science, San Francisco, CA, USA, 20–22 October 2010; pp. 1–7. [Google Scholar]

- Abdul-Wahab, S.A.; Al-Rawas, G.A.; Ali, S.; Al-Dhamri, H. Impact of the addition of oil-based mud on carbon dioxide emissions in a cement plant. J. Clean. Prod. 2016, 112, 4214–4225. [Google Scholar] [CrossRef]

- Hossain, M.U.; Poon, C.S.; Lo, I.M.; Cheng, J.C. Comparative LCA on using waste materials in the cement industry: A Hong Kong case study. Resour. Conserv. Recycl. 2017, 120, 199–208. [Google Scholar] [CrossRef]

- Junior, E.S.A.; de Sales Braga, N.T.; Barata, M.S. Life cycle assessment to produce LC³ cements with kaolinitic waste from the Amazon region, Brazil. Case Stud. Constr. Mater. 2023, 18, e01729. [Google Scholar]

- El-Salamony, A.-H.R.; Mahmoud, H.M.; Shehata, N. Enhancing the efficiency of a cement plant kiln using modified alternative fuel. Environ. Nanotechnol. Monit. Manag. 2020, 14, 100310. [Google Scholar] [CrossRef]

- Fyffe, J.R.; Breckel, A.C.; Townsend, A.K.; Webber, M.E. Use of MRF residue as alternative fuel in cement production. Waste Manag. 2016, 47, 276–284. [Google Scholar] [CrossRef] [PubMed]

- Vizcaíno-Andrés, L.; Sánchez-Berriel, S.; Damas-Carrera, S.; Pérez-Hernández, A.; Scrivener, K.; Martirena-Hernández, J. Industrial trial to produce a low clinker, low carbon cement. Mater. Construcción 2015, 65, e045. [Google Scholar]

- Sousa, V.; Bogas, J.A.; Real, S.; Meireles, I.; Carriço, A. Recycled cement production energy consumption optimization. Sustain. Chem. Pharm. 2023, 32, 101010. [Google Scholar] [CrossRef]

- He, Z.; Zhu, X.; Wang, J.; Mu, M.; Wang, Y. Comparison of CO2 emissions from OPC and recycled cement production. Constr. Build. Mater. 2019, 211, 965–973. [Google Scholar] [CrossRef]

- de Queiroz Lamas, W.; Palau, J.C.F.; De Camargo, J.R. Waste materials co-processing in cement industry: Ecological efficiency of waste reuse. Renew. Sustain. Energy Rev. 2013, 19, 200–207. [Google Scholar] [CrossRef]

- Saif Al-Dhamri, H.; Black, L. Use of oil-based mud cutting waste in cement clinker manufacturing. In Proceedings of the 34th Cement and Concrete Science Conference, Sheffield, UK, 15 September 2014; pp. 427–430. [Google Scholar]

- Rodríguez, N.H.; Martínez-Ramírez, S.; Blanco-Varela, M.T.; Donatello, S.; Guillem, M.; Puig, J.; Fos, C.; Larrotcha, E.; Flores, J. The effect of using thermally dried sewage sludge as an alternative fuel on Portland cement clinker production. J. Clean. Prod. 2013, 52, 94–102. [Google Scholar] [CrossRef]

- Li, H.; Xu, W.; Yang, X.; Wu, J. Preparation of Portland cement with sugar filter mud as lime-based raw material. J. Clean. Prod. 2014, 66, 107–112. [Google Scholar] [CrossRef]

- Silva, L.H.P.; Nehring, V.; de Paiva, F.F.G.; Tamashiro, J.R.; Galvín, A.P.; López-Uceda, A.; Kinoshita, A. Use of blast furnace slag in cementitious materials for pavements-Systematic literature review and eco-efficiency. Sustain. Chem. Pharm. 2023, 33, 101030. [Google Scholar] [CrossRef]

- Vijayan, D.; Arvindan, S.; Janarthanan, T.S. Evaluation of ferrock: A greener substitute to cement. Mater. Today: Proc. 2020, 22, 781–787. [Google Scholar] [CrossRef]

- Anastasiou, E.; Liapis, A.; Papayianni, I. Comparative life cycle assessment of concrete road pavements using industrial by-products as alternative materials. Resour. Conserv. Recycl. 2015, 101, 1–8. [Google Scholar] [CrossRef]

- Barišić, I.; Marković, B.; Zagvozda, M. Freeze–thaw resistance assessment of cement-bound steel slag aggregate for pavement structures. Int. J. Pavement Eng. 2019, 20, 448–457. [Google Scholar] [CrossRef]

- Bilir, T.; Yüksel, I.; Topcu, I.B.; Gencel, O. Effects of bottom ash and granulated blast furnace slag as fine aggregate on abrasion resistance of concrete. Sci. Eng. Compos. Mater. 2017, 24, 261–269. [Google Scholar] [CrossRef]

- El-Hassan, H.; Kianmehr, P. Pervious concrete pavement incorporating GGBS to alleviate pavement runoff and improve urban sustainability. Road Mater. Pavement Des. 2018, 19, 167–181. [Google Scholar] [CrossRef]

- Ho, H.-L.; Huang, R.; Hwang, L.-C.; Lin, W.-T.; Hsu, H.-M. Waste-based pervious concrete for climate-resilient pavements. Materials 2018, 11, 900. [Google Scholar] [CrossRef] [PubMed]

- Moradi, S.; Shahnoori, S. Eco-friendly mix for Roller-Compacted Concrete: Effects of Persian-Gulf-Dredged marine sand on durability and resistance parameters of concrete. Constr. Build. Mater. 2021, 281, 122555. [Google Scholar] [CrossRef]

- Eyo, E.U.; Ng’ambi, S.; Abbey, S. Performance of clay stabilized by cementitious materials and inclusion of zeolite/alkaline metals-based additive. Transp. Geotech. 2020, 23, 100330. [Google Scholar] [CrossRef]

- Sua-iam, G.; Makul, N.; Cheng, S.; Sokrai, P. Workability and compressive strength development of self-consolidating concrete incorporating rice husk ash and foundry sand waste–A preliminary experimental study. Constr. Build. Mater. 2019, 228, 116813. [Google Scholar] [CrossRef]

- Javid, A.A.S.; Nejad, M.A.A. Packing density and surface finishing condition effects on the mechanical properties of various concrete pavements containing cement replacement admixtures. Constr. Build. Mater. 2017, 141, 307–314. [Google Scholar] [CrossRef]

- Özbay, E.; Erdemir, M.; Durmuş, H.İ. Utilization and efficiency of ground granulated blast furnace slag on concrete properties–A review. Constr. Build. Mater. 2016, 105, 423–434. [Google Scholar] [CrossRef]

- Akhtar, A.; Sarmah, A.K. Construction and demolition waste generation and properties of recycled aggregate concrete: A global perspective. J. Clean. Prod. 2018, 186, 262–281. [Google Scholar] [CrossRef]

- Milad, A.A.; Ali, A.S.B.; Yusoff, N.I.M. A review of the utilisation of recycled waste material as an alternative modifier in asphalt mixtures. Civ. Eng. J. 2020, 6, 42–60. [Google Scholar] [CrossRef]

- Rahman, M.J.; Setiawan, A.; Ihsan, M. Examining polyethylene terephthalate (pet) as artificial coarse aggregates in concrete. Civ. Eng. J. 2020, 6, 2416–2424. [Google Scholar]

- Aldakshe, A.; Çağlar, H.; Çağlar, A.; Avan, Ç. The investigation of use as aggregate in lightweight concrete production of boron wastes. Civ. Eng. J. 2020, 6, 1328–1335. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).