Strength Deterioration of Earthen Sites Loess Solidified by Calcined Ginger Nuts under Dry–Wet and Freeze–Thaw Cycles

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation

2.3. Test Procedure

2.3.1. Shear Strength

2.3.2. Dry–Wet Cycle

2.3.3. Freeze–Thaw Cycle

3. Result and Analysis

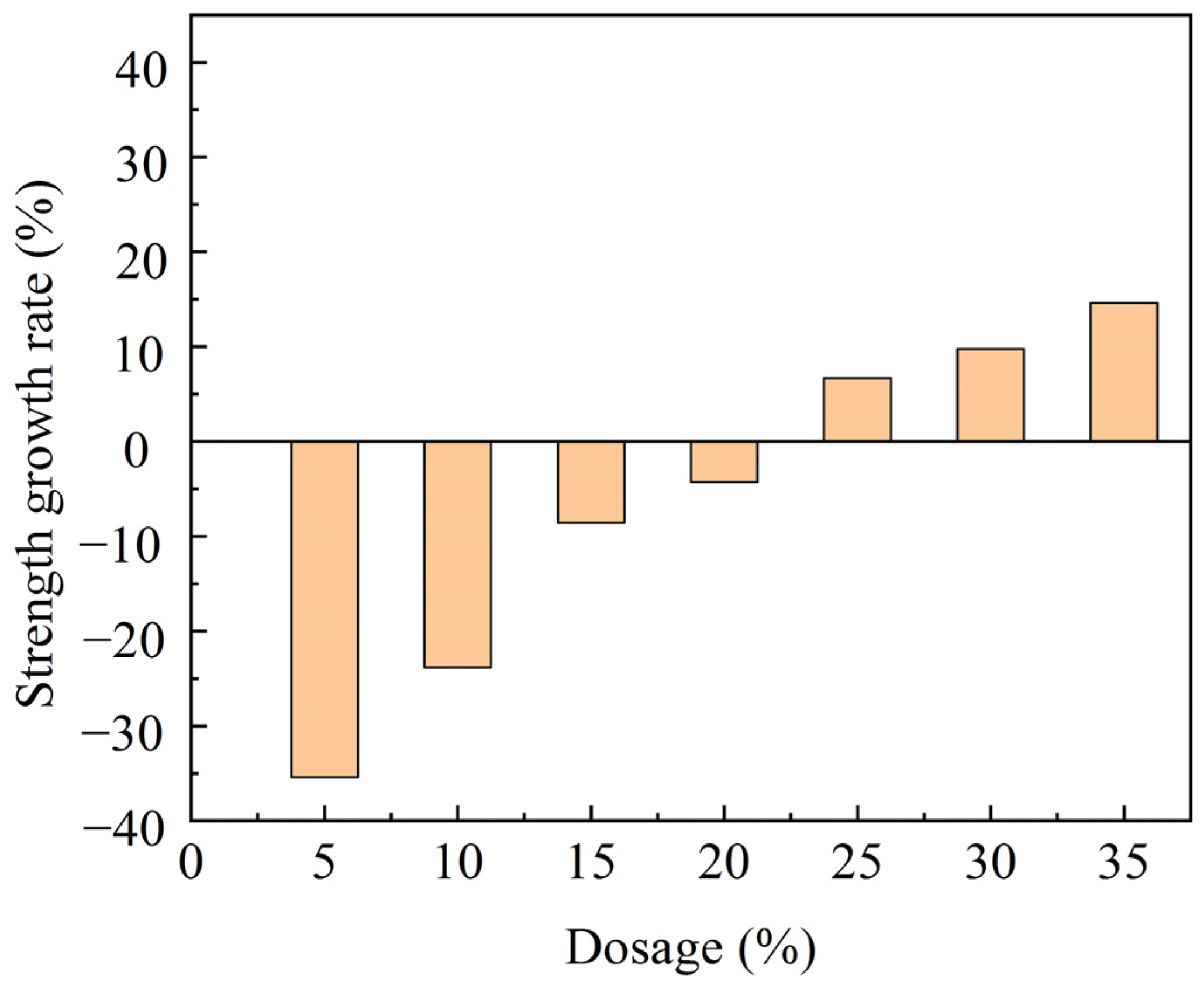

3.1. Shear Strength under Different Dosage

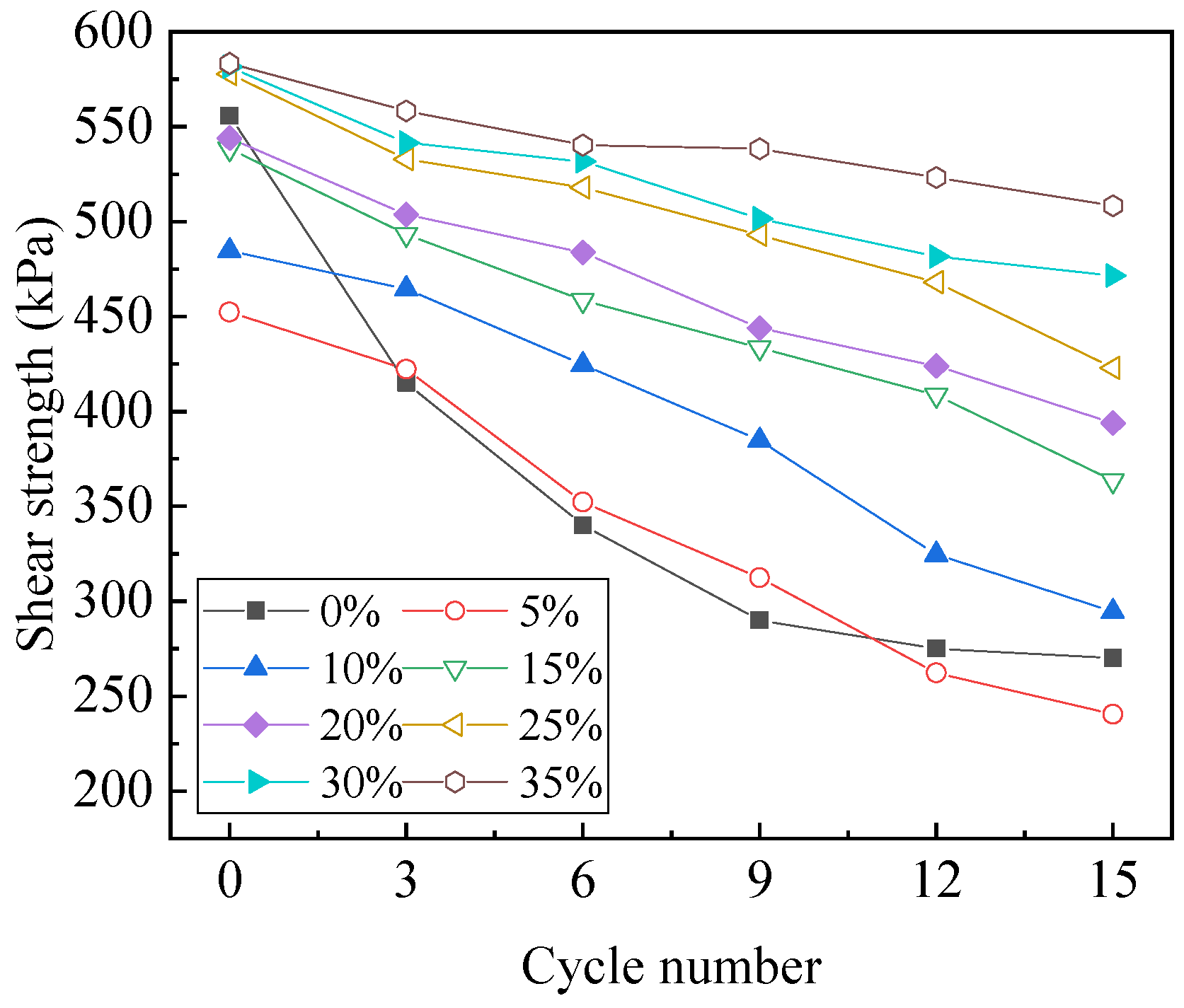

3.2. Dry–Wet Cycle’s Impact on Shear Strength

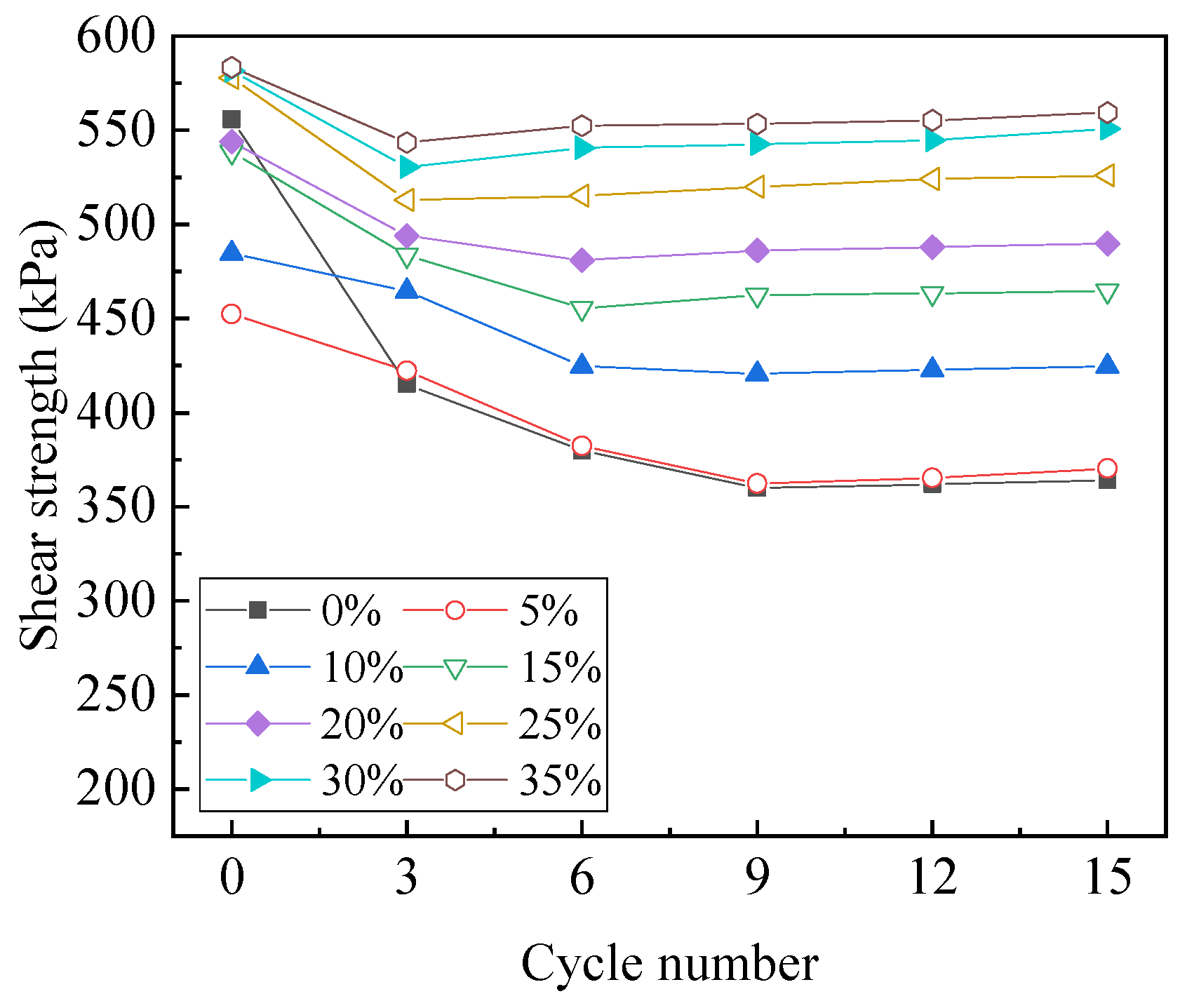

3.3. Freeze–Thaw Cycle’s Impact on Shear Strength

4. Discussion

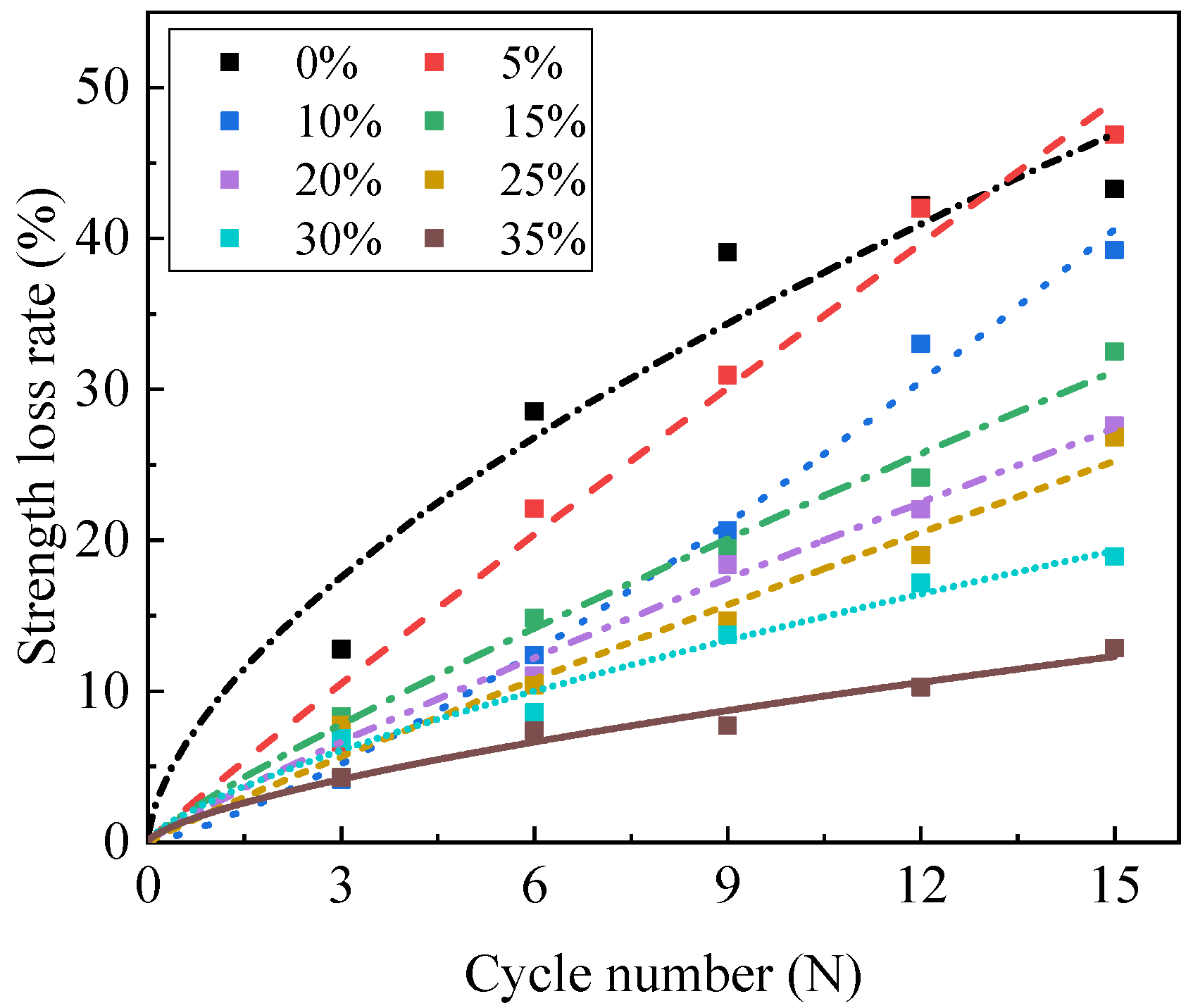

4.1. Empirical Model of Strength Degradation

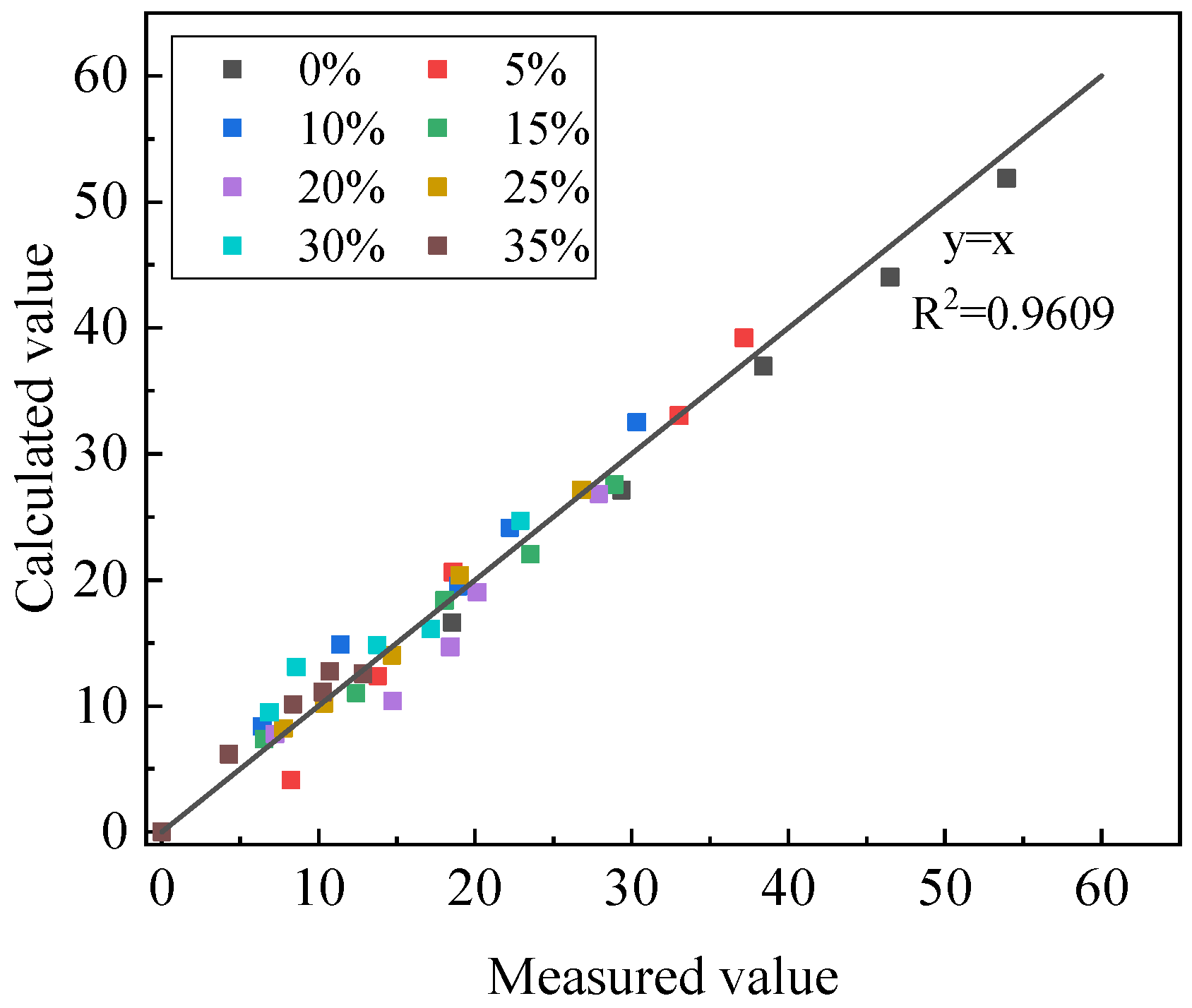

4.2. Validation of Empirical Models for Strength Deterioration

5. Conclusions

- (1)

- The strength of solidified soil can obviously be improved when the dosage of CGN is less than 25%. When the CGN dosage exceeds 25%, the strength of the solidified soil increases slowly, and the maximum strength growth rate is about 77.35%. A low CGN dosage has more prominent reinforcement effects on solidified soil.

- (2)

- Under dry–wet cycles, the strength damage degree of the sample is different. The strength of plain loess decreases and tends to be flat as the number of cycles increases. During the whole cycle, the strength loss rate of plain loess was 54.74%. The strength loss of solidified soil was relatively small during the cycle. Except for the solidified soil with a dosage of 5%, solidified soils are more resistant to dry–wet cycles than plain loess.

- (3)

- The freeze–thaw cycle caused a certain degree of damage to the strength. The strength of plain loess decreased first and then tended to be flat as the freeze–thaw cycle number increased. During the whole cycle, the strength loss rate of plain loess was 34.41%. However, the strength of solidified soil decreased first and then slightly increased, and there was a clear inflection point. With the dosage of CGN increasing, the freeze–thaw cycle number corresponding to the inflection point of the sample decreased significantly. In addition, CGN could increase the strength of solidified soil after reaching the inflection point.

- (4)

- The strength loss rate of CGN-solidified soil was greatly affected by the number of dry–wet cycles. The relationship curve of Formula (4) could better represent the relationship between the number of cycles and the strength loss rate of solidified This. At the same time, parameter a decreased with the increase in the CGN dosage. It indicates that increasing the dosage of CGN can effectively reduce the strength loss rate of solidified soil.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, L.; Shao, M.; Wang, S.; Li, Z. Preservation of earthen heritage sites on the Silk Road, northwest China from the impact of the environment. Environ. Earth. Sci. 2011, 64, 1625–1639. [Google Scholar] [CrossRef]

- Pei, Q.; Guo, Q.; Wang, X.; Zhao, J.; Zhao, G.; Luo, J. Evolution and Characteristics of Tra-ditional Building Techniques for Earthen Architectural Sites. Sci. Conserv. Archaeol. 2019, 31, 1–13. [Google Scholar]

- Chen, W.; Zhang, Q.; Liu, H.; Guo, Z. Feasibility of Protecting Earthen Sites by Infiltration of Modified Polyvinyl Alcohol. Constr. Build. Mater. 2019, 204, 410–418. [Google Scholar] [CrossRef]

- Zhang, Q.; Chen, W.; Wu, G. Material Selection for the Hydrophobic Cushion Layer Applied to Earthen Sites in Northwest China. Stud. Conserv. 2023, 68, 243–257. [Google Scholar] [CrossRef]

- Pineda, P.; Irzanzo, A. Analysis of sand-loaded air flow erosion in heritage sites by computational fluid dynamics. Cult. Herit. 2017, 25, 75–86. [Google Scholar] [CrossRef]

- Pan, C.; Chen, K.; Chen, D.; Xi, S.; Geng, J.; Zhu, D. Research progress on in-situ protection status and technology of earthen sites in moisty environment. Constr. Build. Mater. 2020, 253, 119219. [Google Scholar] [CrossRef]

- Chen, W.; Jia, B.; Shan, X.; Qin, Y.; Yang, L. Preventing the secondary salt deterioration in the repaired area of basal erosion of earthen sites based on capillary barrier effect. Constr. Build. Mater. 2023, 366, 130168. [Google Scholar] [CrossRef]

- Jaquin, P.A.; Augarde, C.E.; Gerrard, C.M. Chronological description of the spatial development of rammed earth techniques. Int. J. Archit. Herit. 2008, 2, 377–400. [Google Scholar] [CrossRef]

- Miccoli, L.; Müller, U.; Fontana, P. Mechanical behaviour of earthen materials: A comparison between earth block masonry, rammed earth and cob. Constr. Build. Mater. 2014, 61, 327–339. [Google Scholar] [CrossRef]

- Li, Z.; Zhao, L.; Li, L. Light weight concrete of Yangshao Period of China: The earliest concrete in the world. Sci. China Technol. Sci. 2012, 55, 629–639. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, L.; Zhao, L.; Liu, D.; Guo, Q.; Pei, Q. Property changes of anchor grout calcined ginger nuts admixed with fly ash and quartz sand after accelerated ageing tests. J. Cent. South. Univ. 2019, 26, 3114–3125. [Google Scholar] [CrossRef]

- Chen, W.; Zhang, K.; Wang, D.; Zhou, J.; Zhang, Q. Laboratory study on properties of calcined ginger nuts mixed with earthen sites’ soil for grouting materials. J. Cent. South. Univ. 2018, 49, 1519–1525. (In Chinese) [Google Scholar]

- Zhao, L.; Wang, X.; Li, L.; Yan, S.; Jiang, S.; Li, Z.; Li, Z.; Fang, Y. The lab selection study on Yangshao concrete grouting materials to treat the cracks of sandstone grottoes. Sci. Conserv. Archaeol. 2016, 28, 48–54. [Google Scholar]

- Zhang, J.; Chen, W.; Li, Z.; Wang, X.; Guo, Q.; Wang, N. Study on workability and durability of calcined ginger nuts-based grouts used in anchoring conservation of earthen sites. J. Cult. Herit. 2015, 16, 831–837. [Google Scholar] [CrossRef]

- Wang, N.; Chen, W.; Zhang, J.; Liao, R.; Li, J.; Zhao, L.; Yu, Z. Evolution of properties under realistic curing conditions of calcined ginger nut grouting mortars used in anchoring conservation of earthen sites. Cult. Herit. 2019, 40, 69–79. [Google Scholar] [CrossRef]

- Liang, X.; Li, L.; Zhang, J.; Shao, M.; Liu, J.; Wang, N. Laboratory study on potential grouting materials for crack flling in kins of the Maritime Silk Road. Sci. Conserv. Archaeol. 2018, 30, 41–50. [Google Scholar]

- Peng, E.; Li, D.; Hu, X.; Sheng, Y.; Chou, Y.; Cao, W.; Chen, J.; Li, Q. Feasibility of ramming erosion area of earthen sites using solidified soil induced by an ancient curing Agent, calcined ginger nuts. Constr. Build. Mater. 2023, 370, 130442. [Google Scholar] [CrossRef]

- Zhang, Q.; Chen, W.; Fan, W. Protecting earthen sites by soil hydrophobicity under freeze–thaw and dry–wet cycles. Constr. Build. Mater. 2021, 262, 120089. [Google Scholar] [CrossRef]

- Jia, B.; Chen, W.; Chen, H.; Li, X.; Jun, B. Effects of snowmelt and rainfall infiltration on the water and salt migration of earthen sites during freeze–thaw process. Int. J. Archit. Herit. 2023, 17, 573–584. [Google Scholar] [CrossRef]

- Fujii, Y.; Fodde, E.; Watanabe, K.; Murakami, K. Digital photogrammetry for the documentation of structural damage in earthen archaeological sites: The case of Ajina Tepa, Tajikistan. Eng. Geol. 2008, 105, 124–133. [Google Scholar] [CrossRef]

- Qiu, K.; Ding, L.; Yu, W.; Chen, K.; Huang, S.; Gao, K. Experimental investigation of shear strength of carbonate saline soil under freeze–thaw cycles. Atmosphere 2022, 13, 2063. [Google Scholar] [CrossRef]

- GB/T50123-2019; Ministry of Water Resources of the People’s Republic of China. Standard for Soil Test Method. China Planning Press: Beijing, China, 2019. (In Chinese)

- Qin, Y.; Li, G.; Chen, X.; Fan, K. Study on shear strength and structure of Malan loess under wetting–drying cycles. Arab. J. Geosci. 2021, 14, 2854. [Google Scholar] [CrossRef]

- Taskin, O.; Ferhan, F. Effect of freezing and thawing processes on soil aggregate stability. Catena 2003, 52, 1–8. [Google Scholar]

- Egloff, B. Principles for the conservation of heritage sites in China. Hist. Environ. 2003, 17, 46–47. [Google Scholar]

- Zhang, B.; Yin, H.; Tie, J. The problems and new materials in conservation of historic stone structures. Sci. Conserv. Archaeol. 2000, 12, 1–4. [Google Scholar]

- Shang, H.; Ou, J.; Song, Y. Analysis on reliability and freeze–thaw damage theory of concrete. J. Eng. Mech-Asce. 2011, 28, 70–74. [Google Scholar]

- Tang, L.; Nilsson, L. Chloride binding capacity and binding isotherms of OPC pastes and mortars. Cement Concrete Res. 1993, 23, 247–253. [Google Scholar]

- Takeshi, K.; Aly, A.; Toshihide, S. Effect of freeze–thaw cycles on durability and strength of very soft clay soil stabilised with recycled Bassanite. Cold Reg. Sci. Technol. 2012, 82, 124–129. [Google Scholar]

- Ni, W.; Shi, H. Influence of freezing-thawing cycles on micro-structure and shear strength of Loess. J. Glaciol. Geocryol. 2014, 36, 922–927. [Google Scholar]

- Xiang, B.; Liu, E.; Yang, L. Influences of freezing-thawing actions on mechanical properties of soils and stress and deformation of soil slope in cold regions. Sci. Rep. 2022, 12, 5387. [Google Scholar] [CrossRef]

| Specific Gravity | Plastic Limit (%) | Liquid Limit (%) | Plasticity Index | Optimal Moisture Content (%) | Maximum Dry Density (g/cm3) |

|---|---|---|---|---|---|

| 2.67 | 12.28 | 28.52 | 16.24 | 14.10 | 1.61 |

| Specific Gravity | Plastic Limit (%) | Liquid Limit (%) | Plasticity Index |

|---|---|---|---|

| 2.65 | 35.07 | 42.62 | 7.55 |

| Parameter | Dosage of CGN (%) | |||||||

|---|---|---|---|---|---|---|---|---|

| 0 | 5 | 10 | 15 | 20 | 25 | 30 | 35 | |

| a | 8.9893 | 3.6604 | 3.2768 | 3.0350 | 2.5218 | 2.0517 | 2.0185 | 1.9882 |

| b | 0.6104 | 0.8320 | 0.8632 | 0.9393 | 0.9493 | 1.0702 | 1.3231 | 1.4566 |

| R2 | 0.9038 | 0.9719 | 0.9884 | 0.9839 | 0.9887 | 0.9543 | 0.9685 | 0.9529 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Q.; Dang, B.; Li, D.; Hu, X. Strength Deterioration of Earthen Sites Loess Solidified by Calcined Ginger Nuts under Dry–Wet and Freeze–Thaw Cycles. Atmosphere 2023, 14, 868. https://doi.org/10.3390/atmos14050868

Li Q, Dang B, Li D, Hu X. Strength Deterioration of Earthen Sites Loess Solidified by Calcined Ginger Nuts under Dry–Wet and Freeze–Thaw Cycles. Atmosphere. 2023; 14(5):868. https://doi.org/10.3390/atmos14050868

Chicago/Turabian StyleLi, Qifeng, Bing Dang, Dandan Li, and Xiaoying Hu. 2023. "Strength Deterioration of Earthen Sites Loess Solidified by Calcined Ginger Nuts under Dry–Wet and Freeze–Thaw Cycles" Atmosphere 14, no. 5: 868. https://doi.org/10.3390/atmos14050868

APA StyleLi, Q., Dang, B., Li, D., & Hu, X. (2023). Strength Deterioration of Earthen Sites Loess Solidified by Calcined Ginger Nuts under Dry–Wet and Freeze–Thaw Cycles. Atmosphere, 14(5), 868. https://doi.org/10.3390/atmos14050868