1. Introduction

Numerous studies have confirmed the health-endangering effect of fine dust particles [

1,

2,

3,

4,

5,

6]. Consequently, the emission of these particles must be avoided, or efficient processes are required for the purification of polluted air [

6]. Fibrous depth filters are a widely-used method for separating particles and to supply particulate free air in numerous applications [

7]. Due to their low investment costs and flexible design, which allows them to be adapted to the operating conditions, depth filters are a key component in, for example ventilation systems [

8]. High filtration efficiencies are required, especially for particles classified as particularly hazardous in the size class smaller than 2.5 µm [

6]. Depth filters are able to achieve the highest separation rates through high packing densities and small fiber diameters [

9,

10]. The energy consumption of a ventilation system is largely determined by the power consumption of the fans which have to overcome the pressure difference caused by the flow through the filter [

10]. The pressure difference increases during the filtration process as a result of the particulate matter clogging the filter can reach values several times higher than the initial pressure [

11]. The pressure difference characteristics during the filtration process are determined by the filter material [

12]. To achieve the goals of resource efficiency and sustainability, the increase of the pressure difference should be as low as possible.

This can be realized by adapting filter materials exhibiting a high dust-holding capacity. This is usually connected to a homogenous loading of the entire filter with particles e.g., by an optimized internal gradient porosity [

13,

14]. Progress in terms of lowering penetration rates and increasing dust holding capacity have been conducted by the use of hybrid filtration processes such as electrostatically assisted air filters [

15,

16].

However, the filter material structure in most processes was identified as a decisive parameter, and its microstructure particularly has a significant influence on the filtration efficiency and the dust holding capacity. [

13,

14,

17,

18] The selection and optimization of suitable filter materials for a given separation task is therefore an important issue when designing depth filter materials [

13,

14,

19].

In recent decades, simulations became a valuable tool, both to support the design of advanced filter materials and to allow a deeper understanding of the mechanism and the kinetics of the filtration process [

13,

14,

18,

20,

21,

22,

23,

24]. The challenge here is the degree to which the physical processes are represented in the simulations, especially if the kinetics of the filtration are to be considered [

25].

Although simulations in 3D and 2D are well developed [

26,

27], there might be a request for alternative ways to describe and predict filtration behaviors, especially when experimental data—e.g., derived by computer tomography (CT)—can be compared with the model calculations [

25].

Due to their low computing requirements, one-dimensional models have been applied to approximate filtration kinetics, i.e., filtration efficiency and pressure difference evolution of depth filter materials, during the filtration process [

19,

28,

29]. While 2D or 3D simulations describe the filtration process by means of the numerical calculation of flow fields within the meshed filter structure, 1D simulations take a different approach [

19]. These types of simulations discretize the filter in the axial (flow) direction, along with its depth in individual sub filters [

19,

28,

29]. The fluid dynamics and the particle separation in each of the sub filters are calculated using cell models according to single fiber efficiency theory. Finally, the influence of deposited particles on filtration kinetics is addressed by a dynamically alternating filter structure. In Thomas et al. [

19], the pressure difference and filtration efficiency of different filter materials were successfully described, and an optimal association of different filter materials was identified. Moreover, applications to granular filtration materials [

30] and the consecutive filtration processes of a liquid and solid aerosol were described [

31]. The question that arises is as follows: to what degree is a simplification of the filter properties such as porosity and fiber diameter possible in a one-dimensional view?

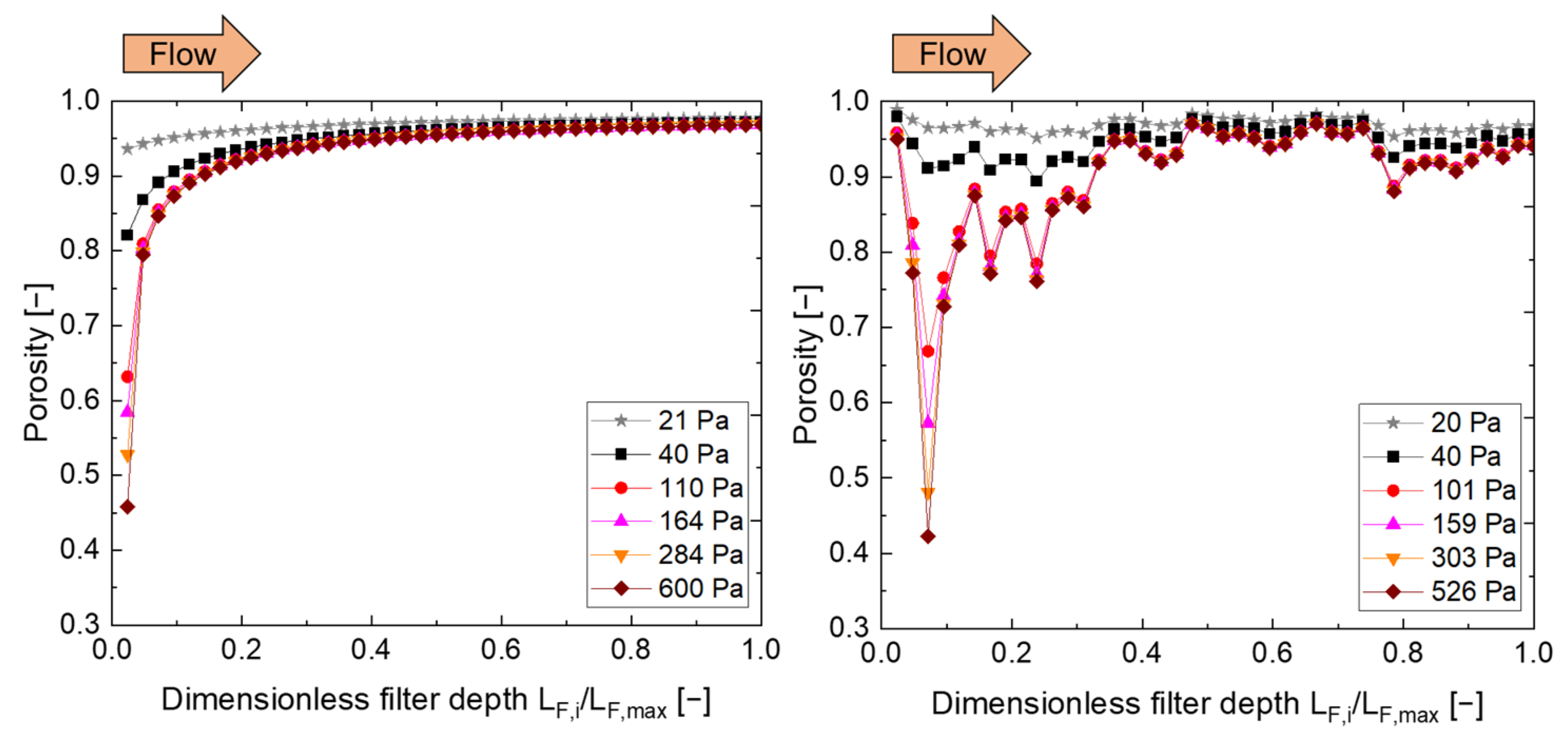

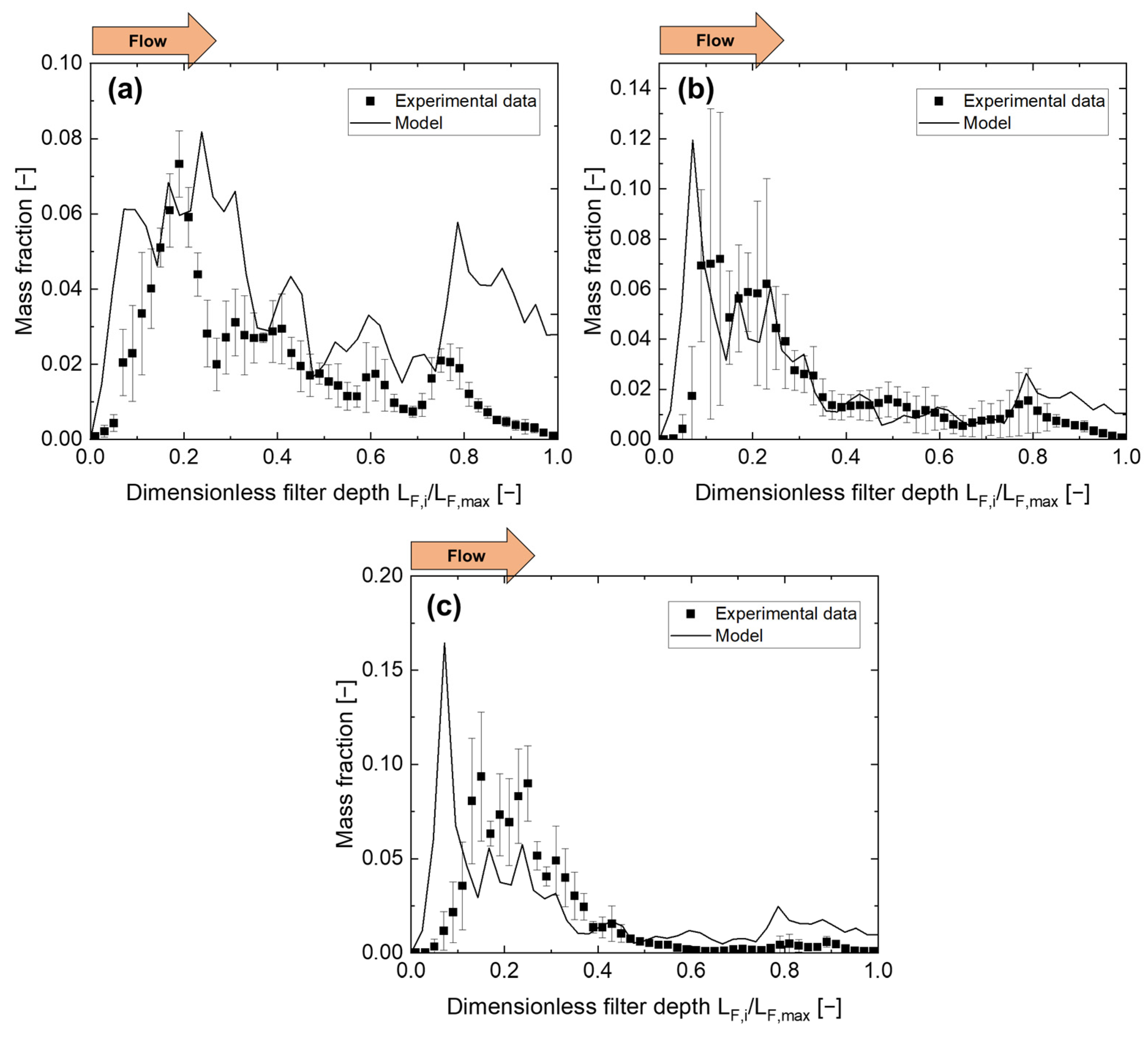

However, in most of these calculations, the microstructure of the filter material and the local distribution of accumulated particles inside the filter material were not considered in detail. Although the location of particle deposition within a filter material was quantified via experiments and compared with the modeled prediction in Thomas et al. [

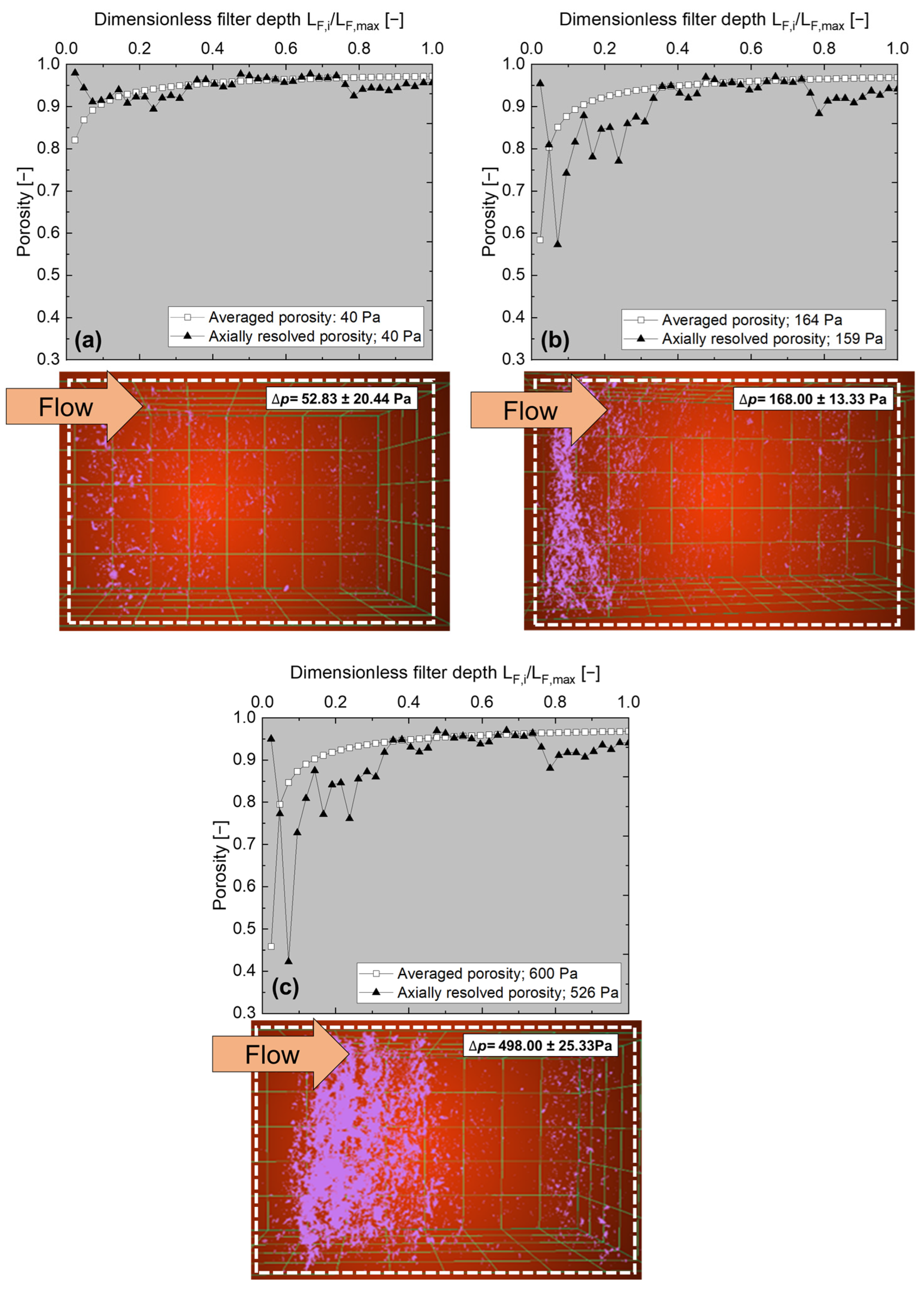

28], the influence of microstructures on the calculation and the accuracy of one-dimensional models, at the microstructural level, remains unclear. The aim of this study is to simulate the filtration process using microstructural data of the real filter material. A validation should be performed on the microscopic level considering CT-data (porosity profile) as well as on the macroscopic level using pressure difference.

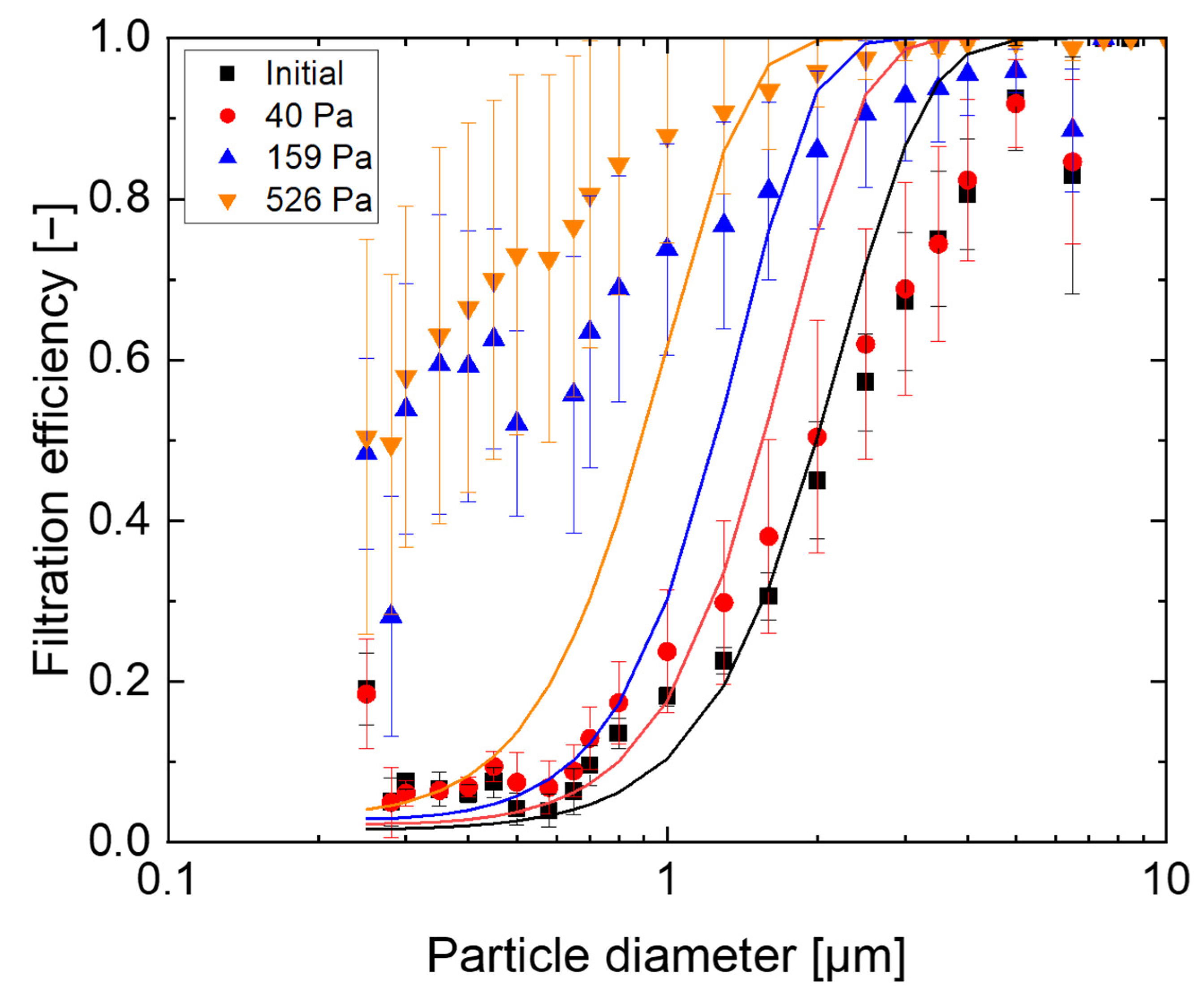

For this purpose, the microstructure of the filter material was imaged using X-ray microscopy (XRM) and applied as an input for the calculation, as described in our previous work [

32]. The filter material used for the test case is a typical coarse dust filter, as used in room air cleaners or air conditioning systems as a pre-filter in cascades to relieve downstream high-efficiency filters [

33,

34]. The model was extended to include the influence of particles deposited during filtration. The aim was to improve prediction of filtration kinetics using a one-dimensional approach by including the filter microstructure. The obtained computed data were compared with experimental data at the macroscopic level based on evolving pressure difference and filtration efficiency with respect to filtration time. At the microscopic level, calculated data were validated in comparison with experimental values based on spatially as well as temporally resolved particle deposition collected via XRM.

2. Approach for Calculating Filtration Kinetics Considering Tomographic Data

The computational effort of simulating filtration kinetics increases with the level of detail of the description of physical phenomena occurring [

25]. Due to the low computational effort, one-dimensional modeling is advantageous for calculating filtration in depth filters. The complexity of the model is reduced by only carrying out an axial discretization of the filter, and by describing fluid dynamics via semi-empirical correlations [

19].

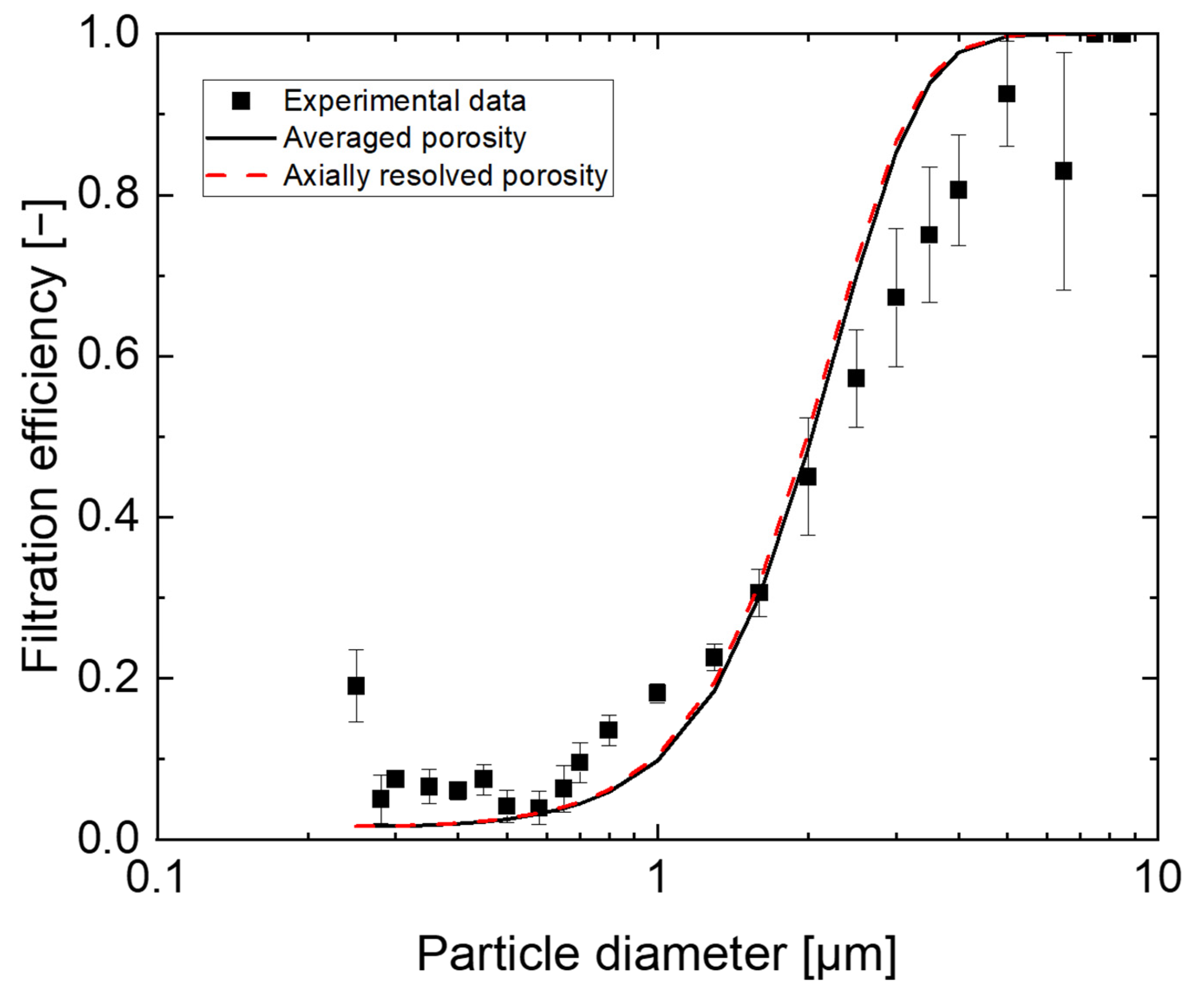

Despite these simplifications, this approach is able to reproduce the filtration properties of filter materials [

19]. However, there are still few data available related to how this type of simulation deals with filter microstructure. In order to explicitly represent the microstructure of a filter material (e.g., a porosity gradient), an approach was presented in previous work in which one-dimensional modeling was combined with tomographic data of the microstructure of two filter materials [

32]. However, the approach already presented was limited to the initial state of the filter material. In the following, this approach was taken up again and extended by two methods to account for the influence of the filter loading on the calculated filtration parameters.

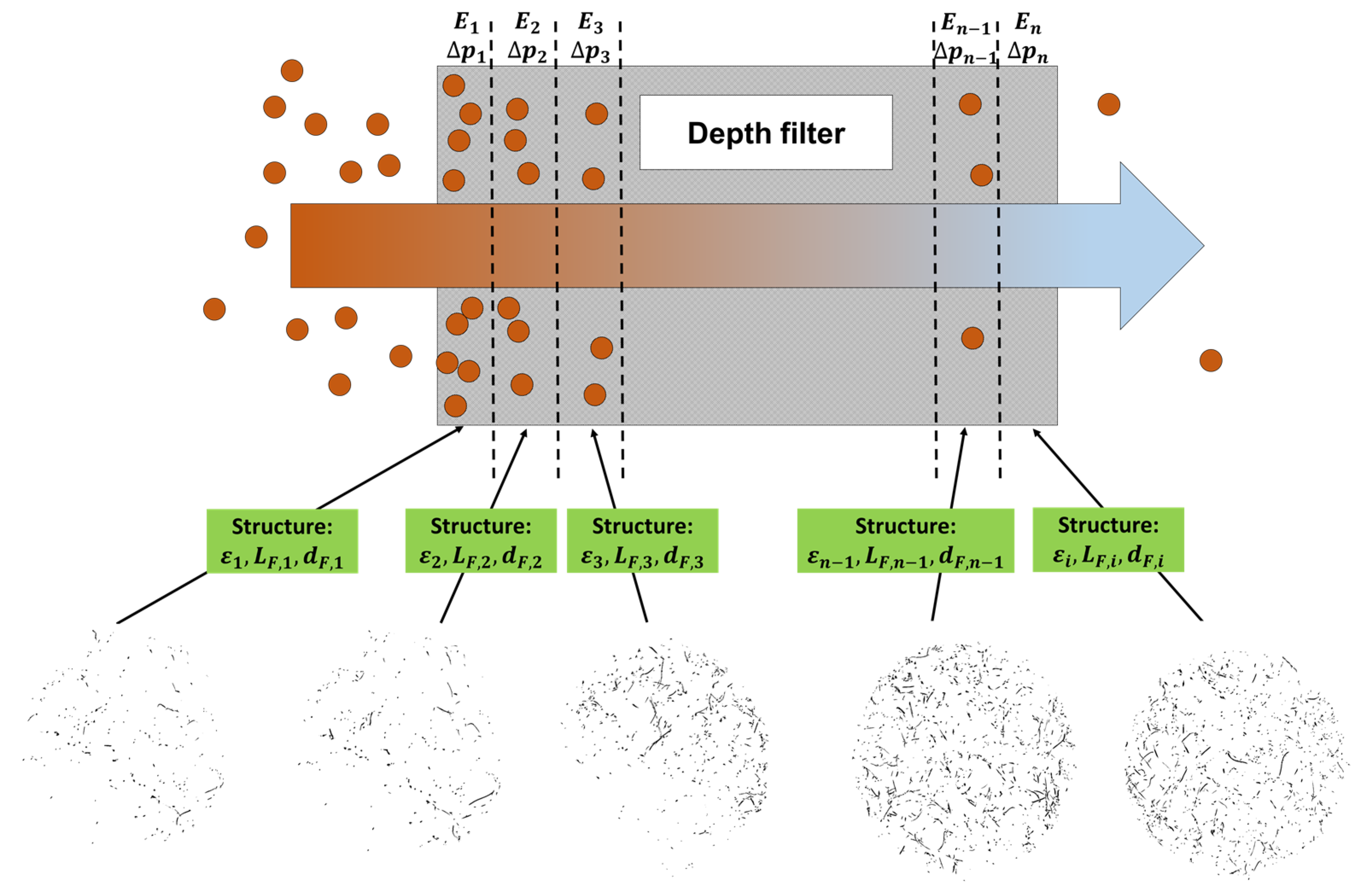

The procedure of the original modeling scheme is visualized in

Figure 1. The filter was discretized into a defined number of sub filters (

) along the axial flow direction in which calculation of pressure difference and particle deposition takes place. Microstructural properties, such as information about axial resolved porosity, were assigned to each sub filter. In the

Figure 1 below, this is represented by sectional images of the filter’s microstructure as provided by tomographic imaging techniques. The number and thickness of the sub filters, having the index

, initially corresponds to those of the axial resolution of the measurement system used.

The filtration efficiency (

) in each subfilter

can be written according to Equation (1), applying the porosity (

), fiber diameter (

) the adhesion coefficient

and filter depth (

) of each subfilter.

The single fiber efficiency (

) was expressed by summarizing individual separation efficiencies based on diffusion (

), inertial effects (

), and interception (

) (Equation (2)). It must be pointed out that a combination of these effects is responsible for the separation of a particle, and that the sum of individual separation efficiencies cannot exceed the value of 1.

Models used for calculating individual separation mechanisms according to single fiber efficiency theory applied are summarized in

Table 1. The fluid dynamics were calculated using the Kuwabara cell model [

35].

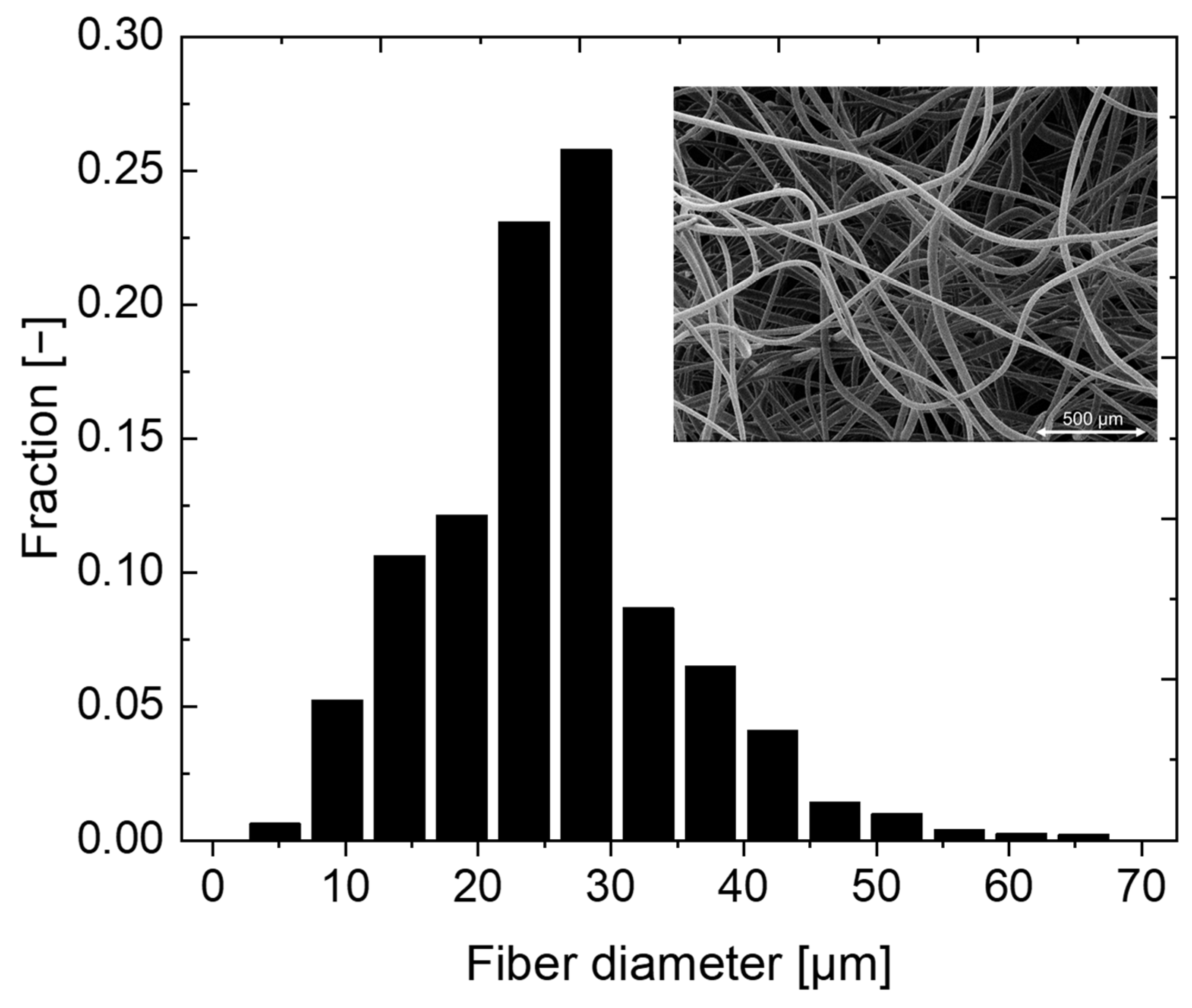

The diameter distribution of the collectors have a significant influence on the calculation of filtration efficiencies or pressure differences [

30,

38,

39,

40,

41]. In contrast to the previously discussed approach [

32], where the median diameter of the fibers was applied, the distribution of the fiber diameter was utilised here. Filtration efficiencies were calculated for each occurring fiber diameter j according to Equation (1). These were weighted by their fraction in the fiber distribution

according to Equation (3).

The overall filtration efficiency (

) was computed by summarizing the filtration efficiency of all considered sub filters (Equation (4)). The filtration efficiency can be individually expressed in terms of particle diameter, total mass, or total number.

The pressure difference in each sub filter

was determined using Davies’ Equation (5) [

42]. Calculations were carried out using the packing density (

), and the dynamic viscosity (

) of air at ambient pressure and 25 °C.

The influence of the fiber diameter distribution on the pressure difference was taken into account, analogous to Equation (3). The total pressure difference of the filter material

was derived by adding the individual pressure differences of each sub-filter (

).

To describe the dynamic change of filtration parameters, such as the pressure difference or filtration efficiency during the filtration process, a change in filter structural properties due to the deposited particles was addressed. First, a decrease in porosity due to the deposition of particles in a sub filter was considered (Equation (8)). For this purpose, the porosity of a sub filter

in the next time step (

) was re-calculated using the porosity in the current time step (

), the number of particles deposited in sub filter

at the time step

and their volume (

calculated assuming ideal spherical particles), as well as the volume of the sub filter

in the initial state of the filter

.

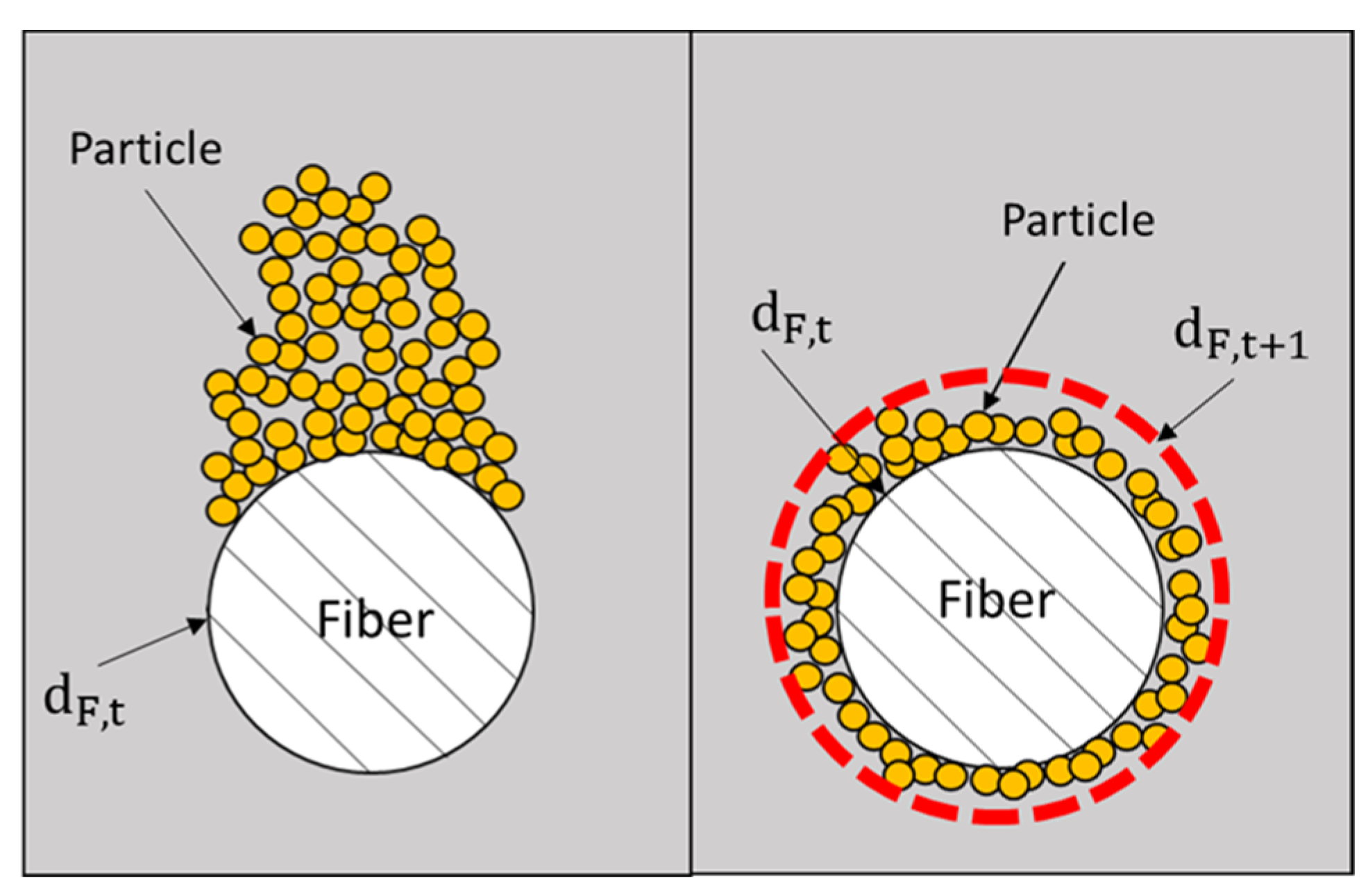

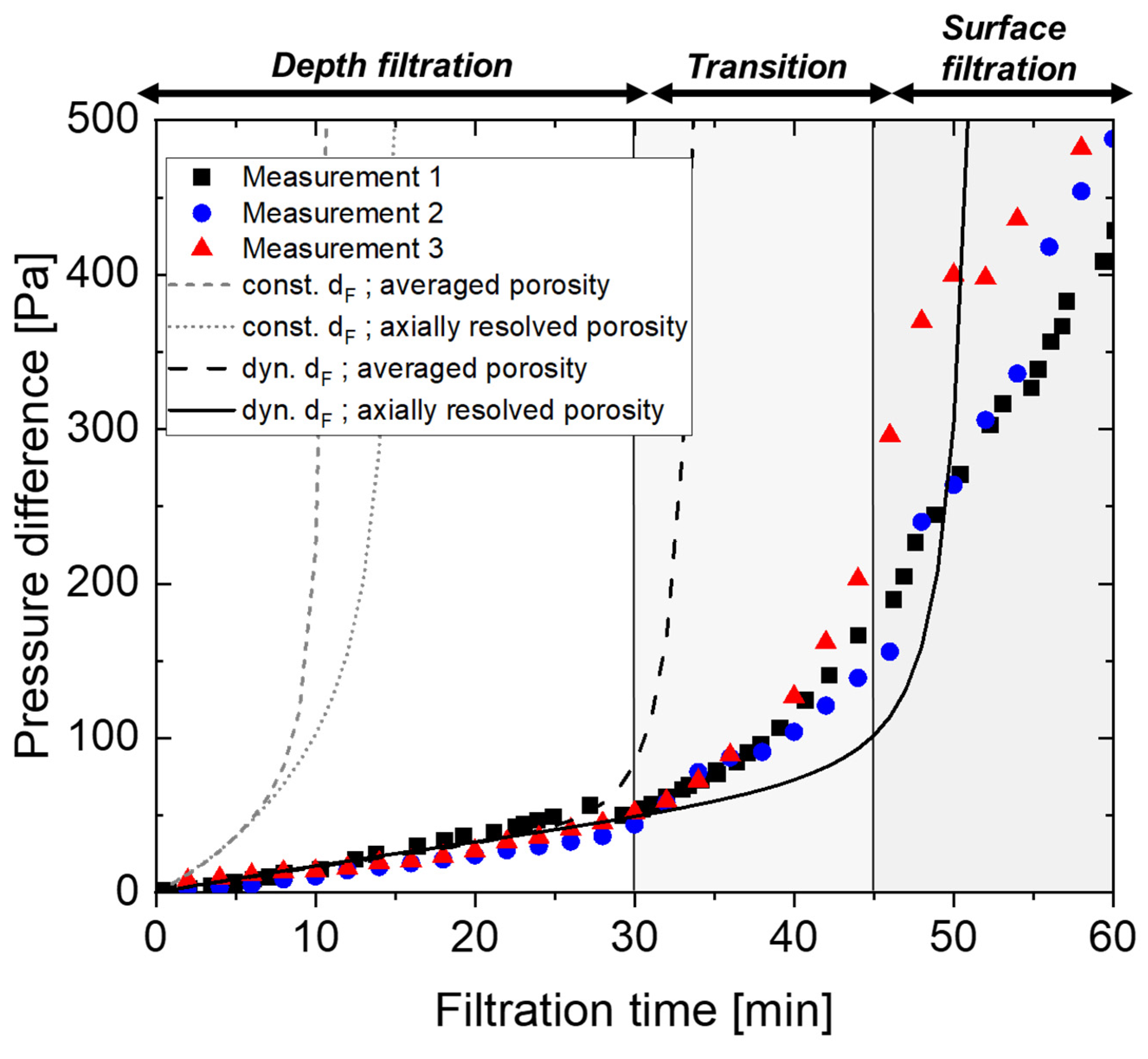

A commonly used approach additionally assumes a constantly increasing fiber diameter

(

Figure 2, right) for the next time step (Equation (9)) as for example described in [

28,

31].

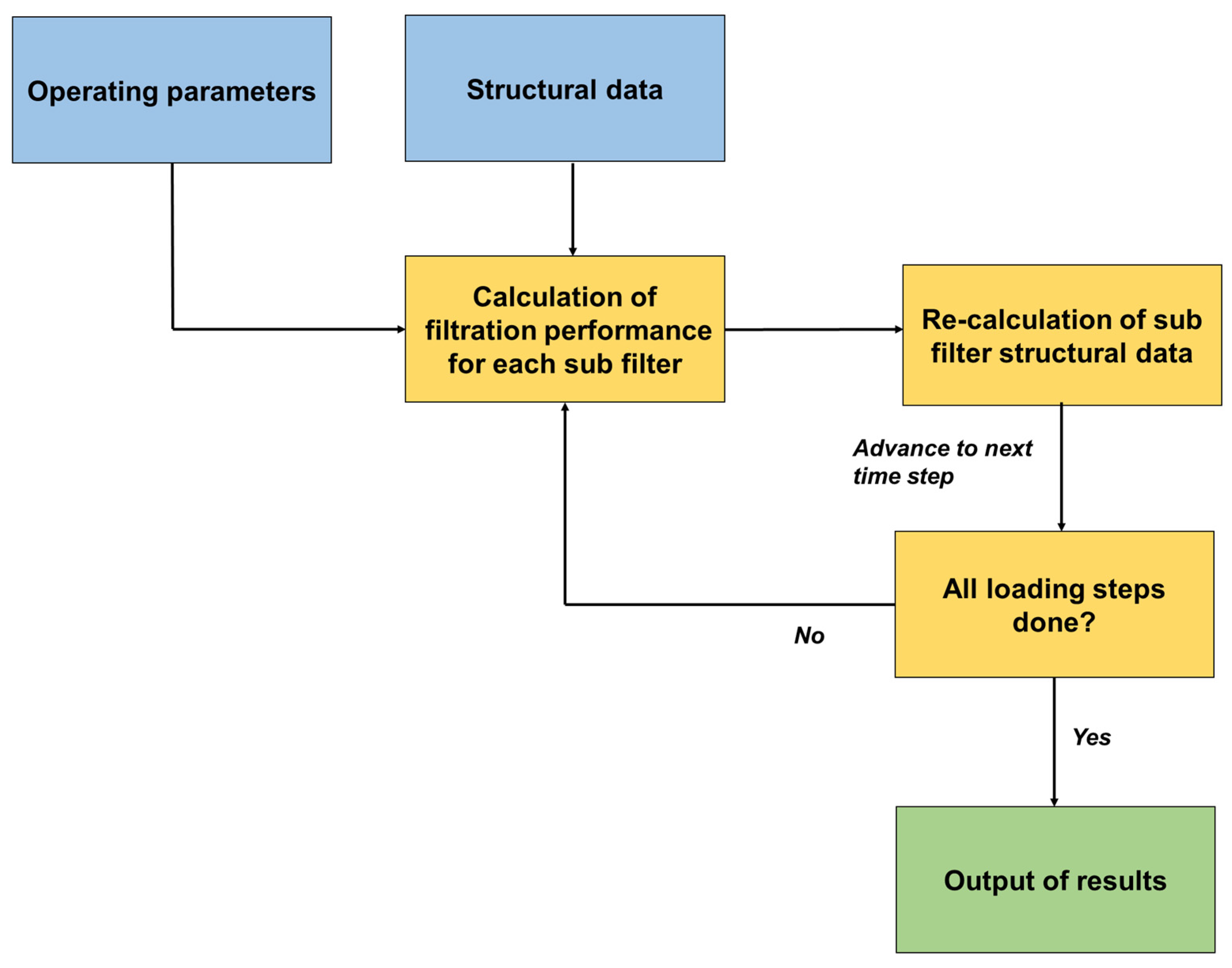

Both presented calculation methods were used to re-calculate the filter structure after each loading step, applying a sequential algorithm illustrated in

Figure 3. Calculations of pressure difference and filtration efficiency (Equations (1)–(7)), as well as filter structure (Equations (8) and (9)), were repeated for each considered time step.

The described approach was implemented in MATLAB 2018a (MathWorks Inc., Natick, MA, USA).