Research on Cement Demand Forecast and Low Carbon Development Strategy in Shandong Province

Abstract

1. Introduction

2. Methodology

2.1. Cement Demand Intensity Model

2.2. Cement CO2 Model

3. Scenario Settings and Data Sources

3.1. Scenario Settings

3.2. Cement Demand Parameter Setting

3.3. Cement CO2 Parameter Setting

3.4. Low-Carbon Technical Measures for the Cement Industry

4. Results and Discussion

4.1. Cement and Clinker Demand Forecast

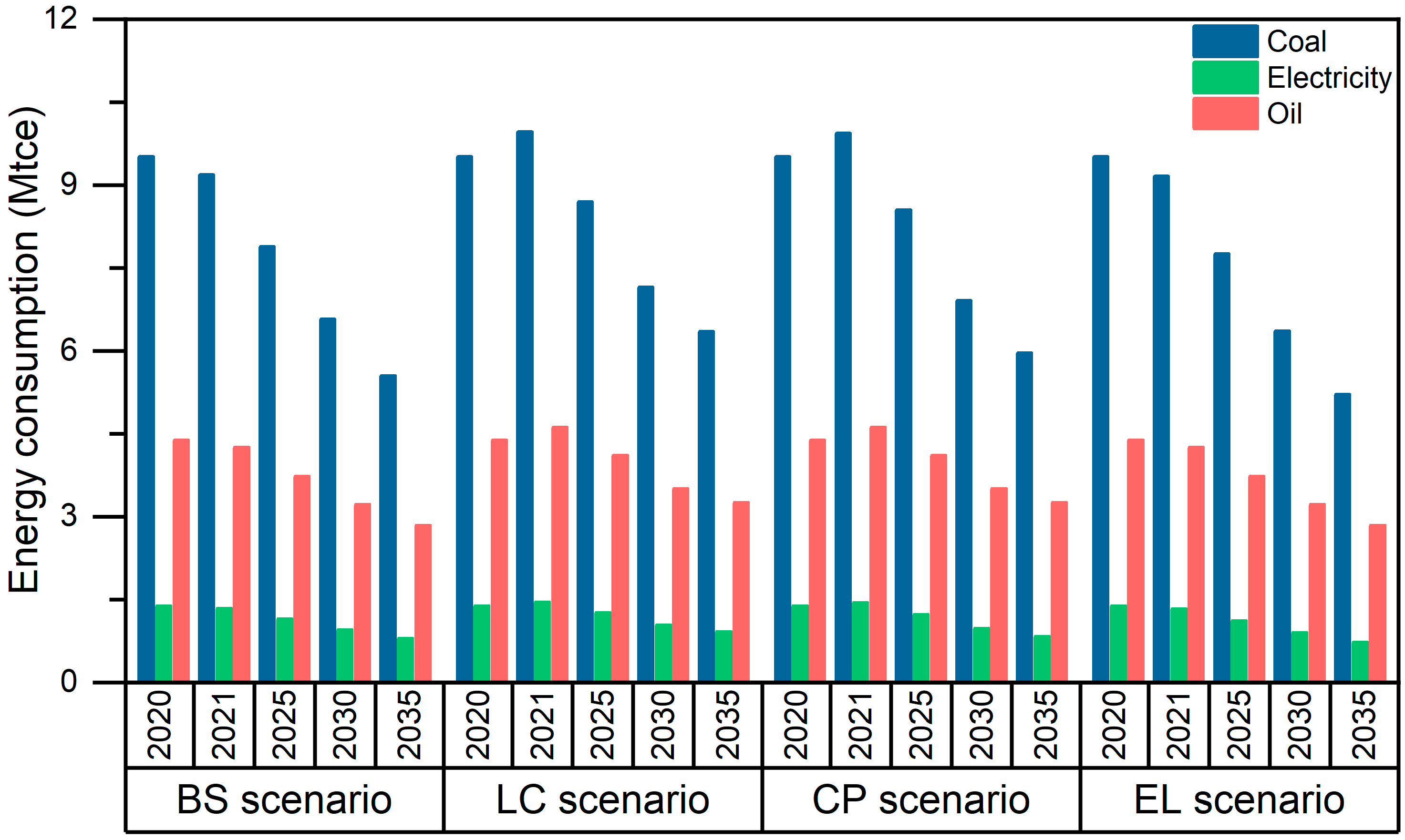

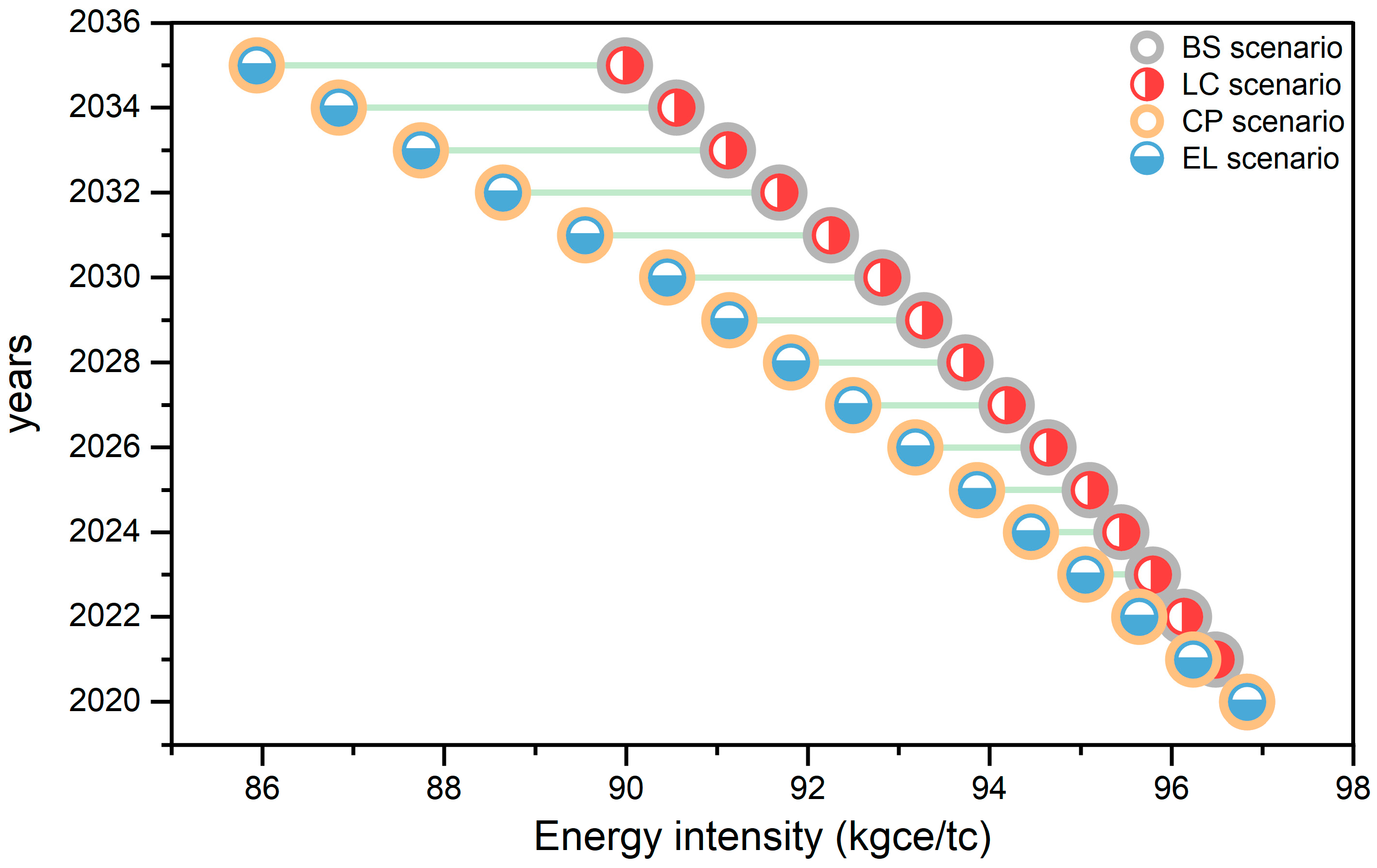

4.2. Energy Consumption and Energy Intensity

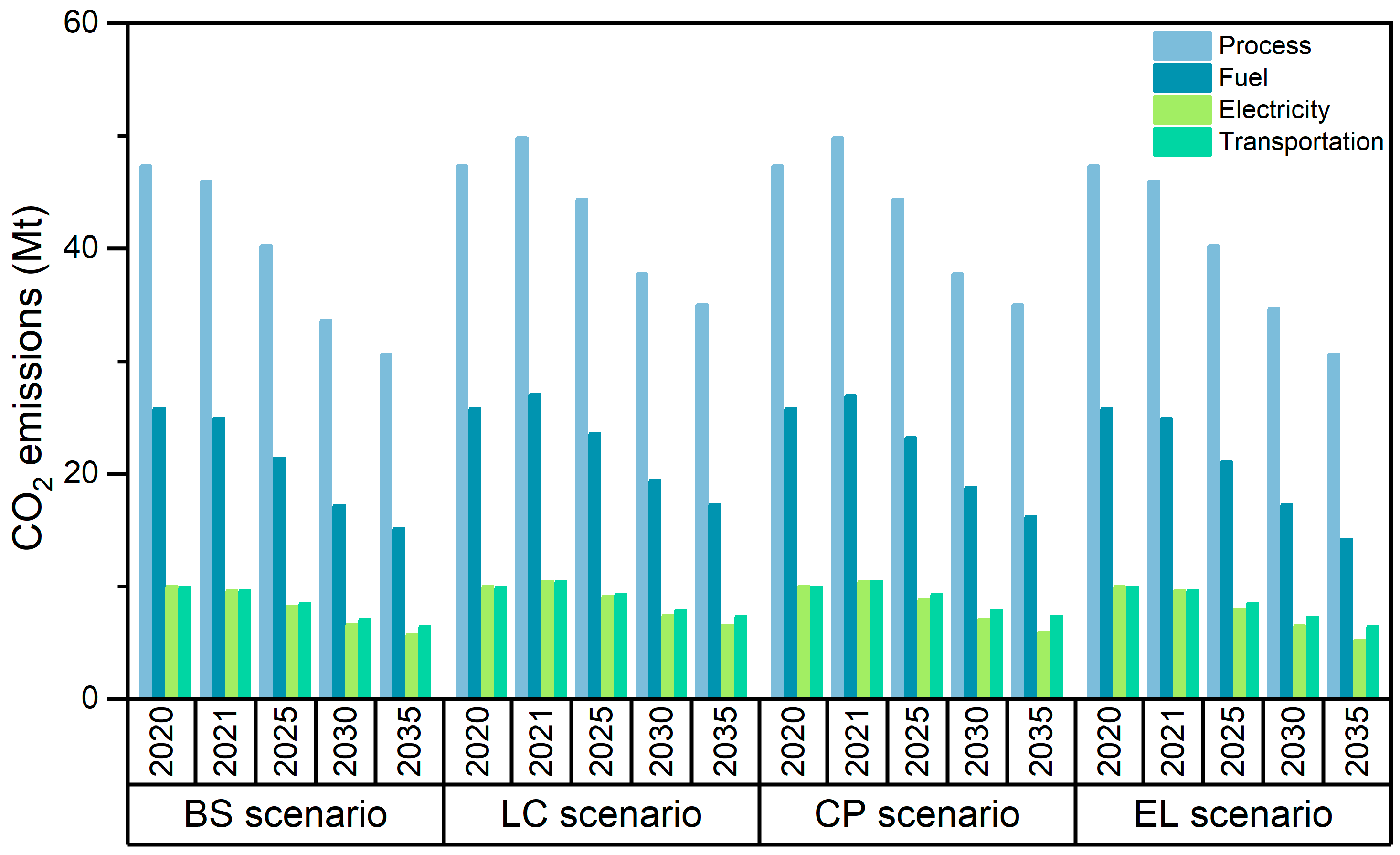

4.3. CO2 Emission and Carbon Intensity

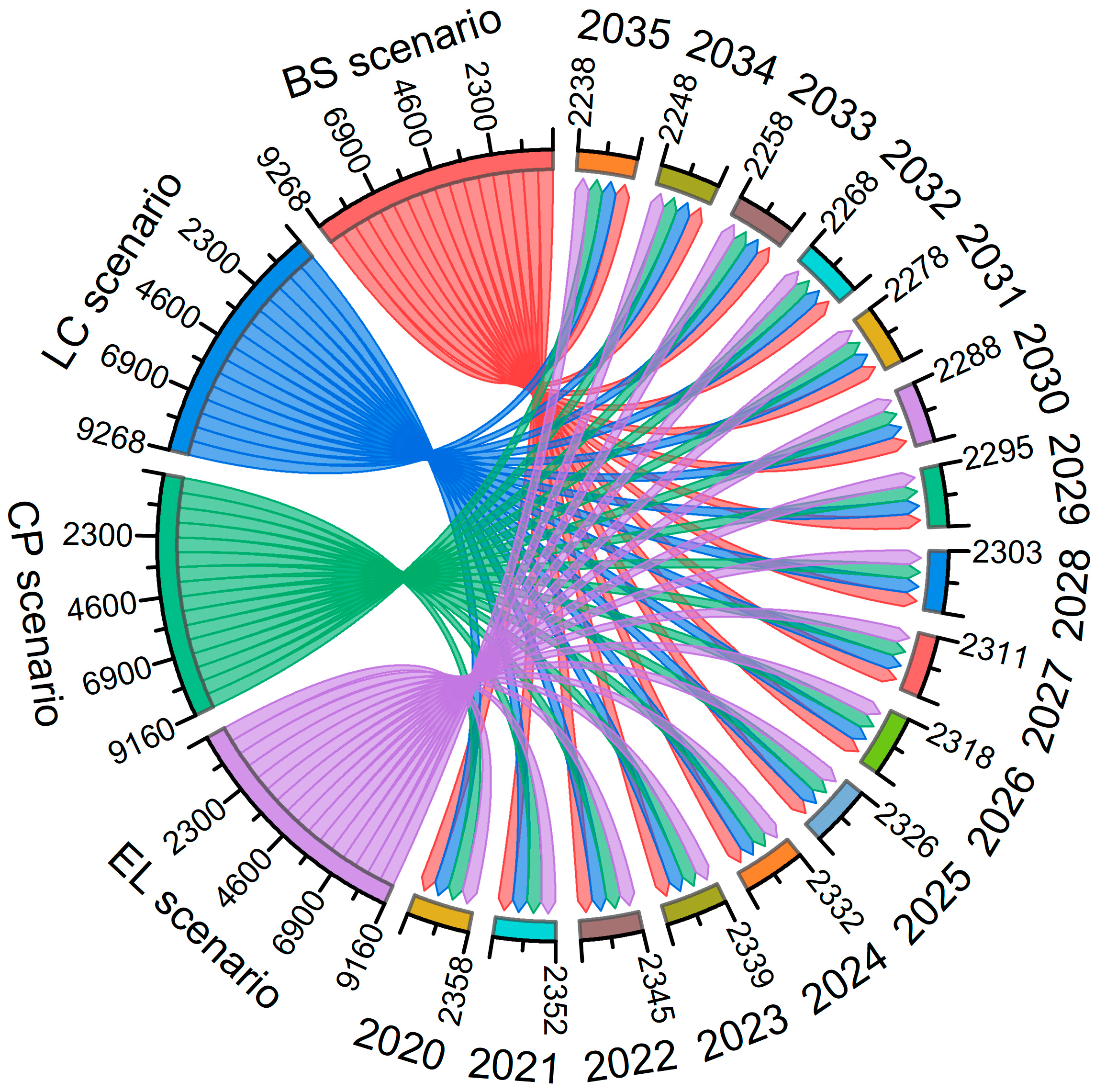

4.4. Cement Lowcarbon Technology Roadmap

5. Conclusions

- (a)

- Under the LD scenario and the MD scenario, the cement demand in Shandong Province reached a historical peak of 164.06 Mt in 2014, and the per capita cement consumption was 1.67 t. Under the HD scenario, the cement demand in Shandong Province reached a historical peak of 166 Mt in 2021, and the per capita cement consumption was 1.63 t. Although the demand for cement and clinker is still likely to increase due to the large-scale construction of real estate and infrastructure in the near future, once the investment and construction demand of the construction sector and industrial sector reaches saturation, the cement industry in Shandong Province is bound to have overcapacity. In the future, Shandong Province should focus on adjusting the structural imbalance between the supply and demand sides of the cement industry, revitalizing the stock, and optimizing the increase.

- (b)

- In terms of CO2 emission structure, the industrial production process CO2 accounts for 50.89–54.32%, fuel combustion CO2 accounts for 25.12–27.76%, transportation CO2 accounts for 10.65–11.36%, and electricity CO2 accounts for 9.20–10.71%. In terms of energy structure, coal consumption accounts for about 59.43–62.25%, electricity consumption accounts for 8.22–9.04% of final energy consumption, and transportation energy consumption accounts for 28.72–32.34%.

- (c)

- When the penetration rate of low-carbon technologies remains unchanged, supply-side structural reform is the most direct way to reduce energy consumption and CO2 emissions. Compared with the CP scenario, the energy consumption and CO2 emissions in the EL scenario are reduced by 7.79–12.58%, respectively. When the demand for cement and the penetration rate of low-carbon technology changes at the same time, the relatively high intensity of capacity reduction and low-carbon technology penetration rate are conducive to curbing final energy consumption and CO2 emissions, while significantly reducing energy intensity and carbon intensity. Compared with the LC scenario, the EL scenario reduces CO2 emissions by 7.93–14.78%, energy consumption by 8.02–16.51%, and the average reduction rates of energy intensity and carbon intensity are 2.18% and 1.25%.

- (d)

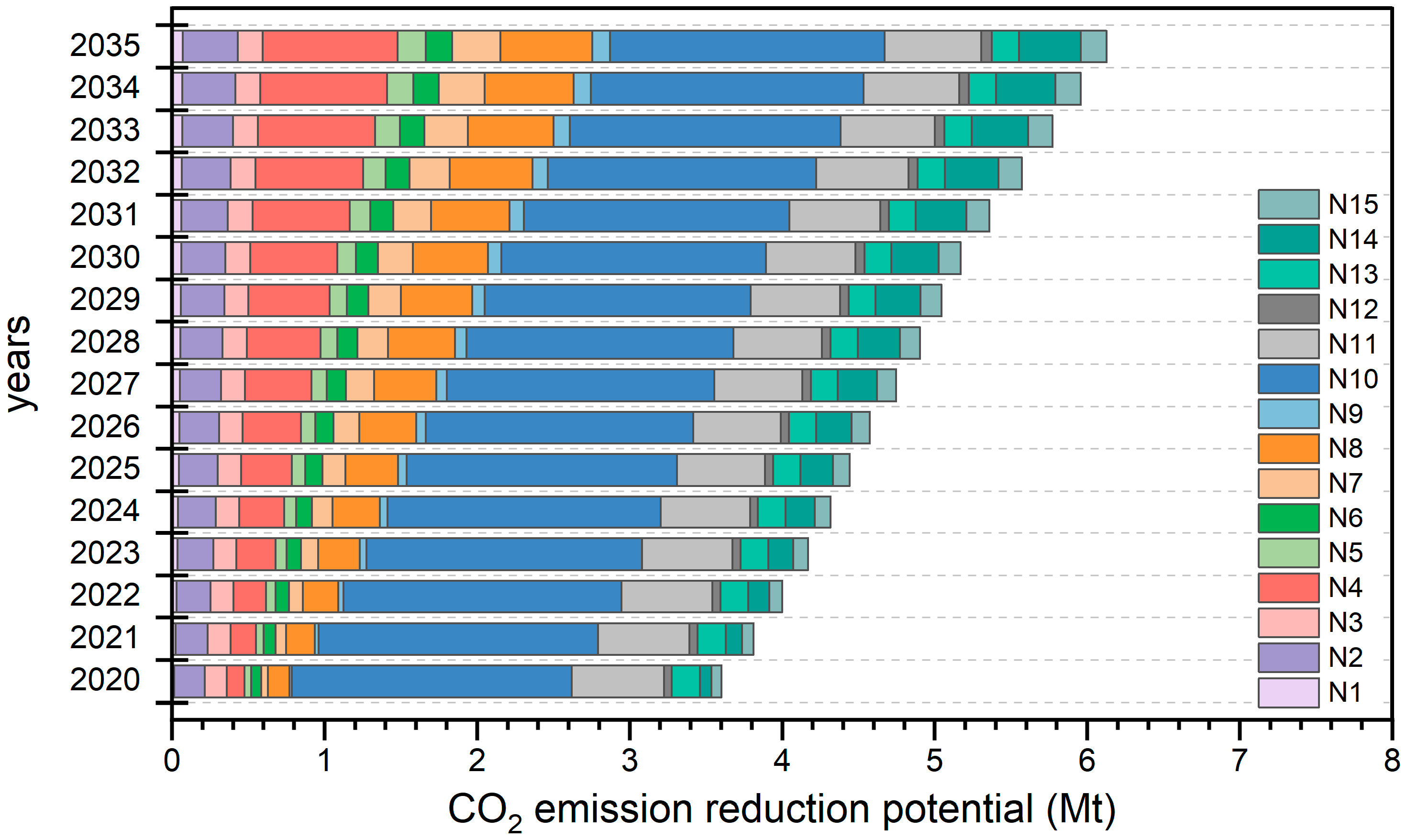

- From the perspective of the low-carbon technology roadmap, the CO2 emission reduction potential of the cement industry in Shandong Province has increased from 3.6 Mt in 2020 to 7.01 Mt in 2035, and the cumulative CO2 emission reduction potential is 85.38 Mt, which is equivalent to 91.84% of the total CO2 emissions in 2020. From a short-term perspective, the carbon emission reduction technology path of the cement industry in Shandong Province is mainly based on improving energy efficiency and comprehensive utilization of resources and energy. In the future, the Shandong provincial government should promote the green and low-carbon transformation of the cement industry through demonstration projects.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wu, T.; Ng, S.T.; Chen, J. Deciphering the CO2 emissions and emission intensity of cement sector in China through decomposition analysis. J. Clean. Prod. 2022, 352, 131627. [Google Scholar] [CrossRef]

- Benhelal, E.; Shamsaei, E.; Rashid, M.I. Challenges against CO2 abatement strategies in cement industry: A review. J. Environ. Sci. 2021, 104, 84–101. [Google Scholar] [CrossRef]

- Toro, N.; Gálvez, E.; Saldaña, M.; Jeldres, R.I. Submarine mineral resources: A potential solution to political conflicts and global warming. Miner. Eng. 2022, 179, 107441. [Google Scholar] [CrossRef]

- Intergovernmental Panel on Climate Change. Global Warming of 1.5 °C. Available online: https://www.ipcc.ch/site/assets/uploads/sites/2/2022/06/SR15_Full_Report_LR.pdf (accessed on 4 November 2022).

- Fang, K.; Tang, Y.; Zhang, Q.; Song, J.; Wen, Q.; Sun, H.; Ji, C.; Xu, A. Will China peak its energy-related carbon emissions by 2030? Lessons from 30 Chinese provinces. Appl. Energy 2019, 255, 113852. [Google Scholar] [CrossRef]

- Shandong Provincial Bureau of Statistics. Shandong Statistical Yearbook; China Statistics Press: Beijing, China, 2022.

- National Bureau of Statistics. China Statistical Yearbook; China Statistics Press: Beijing, China, 2021.

- United States Geological Survey. Cement. Available online: https://pubs.usgs.gov/periodicals/mcs2021/mcs2021-cement.pdf (accessed on 27 December 2022).

- Wei, J.; Cen, K.; Geng, Y. China’s cement demand and CO2 emissions toward 2030: From the perspective of socioeconomic, technology and population. Environ. Sci. Pollut. Res. 2019, 26, 6409–6423. [Google Scholar] [CrossRef]

- Tan, C.; Yu, X.; Guan, Y. A technology-driven pathway to net-zero carbon emissions for China’s cement industry. Appl. Energy 2022, 325, 119804. [Google Scholar] [CrossRef]

- State Administration for Market Regulation; Ministry of Industry and Information Technology of the People’s Republic of China; National Development and Reform Commission; Ministry of Ecology and Environment of the People’s Republic of China; Ministry of Commerce of the People’s Republic of China; General Administration of Customs of the People’s Republic of China; China National Intellectual Property Administration. Opinions on Improving the Quality of Cement Products and Regulating the Order of the Cement Market. Available online: http://www.gov.cn/zhengce/zhengceku/2021-05/26/content_5612468.htm (accessed on 20 October 2022).

- Xu, G.; Xue, D.; Rehman, H. Dynamic scenario analysis of CO2 emission in China’s cement industry by 2100 under the context of cutting overcapacity. Mitig. Adapt. Strateg. Glob. Change 2022, 27, 53. [Google Scholar] [CrossRef]

- Wei, J.; Cen, K. Empirical assessing cement CO2 emissions based on China’s economic and social development during 2001-2030. Sci. Total Environ. 2019, 653, 200–211. [Google Scholar] [CrossRef]

- Du, Z.; Wei, J.; Cen, K. China’s carbon dioxide emissions from cement production toward 2030 and multivariate statistical analysis of cement consumption and peaking time at provincial levels. Environ. Sci. Pollut. Res. 2019, 26, 28372–28383. [Google Scholar] [CrossRef]

- Ige, O.E.; Duffy, K.J.; Olanrewaju, O.A.; Collins, O.C. An Integrated System Dynamics Model and Life Cycle Assessment for Cement Production in South Africa. Atmosphere 2022, 13, 1788. [Google Scholar] [CrossRef]

- Ke, J.; Zheng, N.; Fridley, D.; Price, L.; Zhou, N. Potential energy savings and CO2 emissions reduction of China’s cement industry. Energy Policy 2012, 45, 739–751. [Google Scholar] [CrossRef]

- Feng, X.; Lugovoy, O.; Qin, H. Co-controlling CO2 and NOx emission in China’s cement industry: An optimal development pathway study. Adv. Clim. Change Res. 2018, 9, 34–42. [Google Scholar] [CrossRef]

- Ren, M.; Ma, T.; Fang, C.; Liu, X.; Guo, C.; Zhang, S.; Zhou, Z.; Zhu, Y.; Dai, H.; Huang, C. Negative emission technology is key to decarbonizing China’s cement industry. Appl. Energy 2023, 329, 120254. [Google Scholar] [CrossRef]

- Shi, F.; Huang, T.; Tanikawa, H.; Han, J.; Hashimoto, S.; Moriguchi, Y. Toward a Low Carbon-Dematerialization Society Measuring the Materials Demand and CO2 Emissions of Building and Transport Infrastructure Construction in China. J. Ind. Ecol. 2012, 16, 493–505. [Google Scholar] [CrossRef]

- Hasanbeigi, A.; Khanna, N.; Price, L. Air Pollutant Emissions Projections for the Cement and Steel Industry in China and the Impact of Emissions Control Technologies; Lawrence Berkeley National Laboratory: Berkeley, CA, USA, 2017.

- Li, N.; Ma, D.; Chen, W. Quantifying the impacts of decarbonisation in China’s cement sector: A perspective from an integrated assessment approach. Appl. Energy 2017, 185, 1840–1848. [Google Scholar] [CrossRef]

- Zhang, S.; Ren, H.; Zhou, W.; Yu, Y.; Chen, C. Assessing air pollution abatement co-benefits of energy efficiency improvement in cement industry: A city level analysis. J. Clean. Prod. 2018, 185, 761–771. [Google Scholar] [CrossRef]

- Zheng, C.; Zhang, H.; Cai, X.; Chen, L.; Liu, M.; Lin, H.; Wang, X. Characteristics of CO2 and atmospheric pollutant emissions from China’s cement industry: A life-cycle perspective. J. Clean. Prod. 2021, 282, 124533. [Google Scholar] [CrossRef]

- Wen, Z.; Chen, M.; Meng, F. Evaluation of energy saving potential in China’s cement industry using the Asian-Pacific Integrated Model and the technology promotion policy analysis. Energy Policy 2015, 77, 227–237. [Google Scholar] [CrossRef]

- Wei, J.; Cen, K. A preliminary calculation of cement carbon dioxide in China from 1949 to 2050. Mitig. Adapt. Strateg. Glob. Change 2019, 24, 1343–1362. [Google Scholar] [CrossRef]

- Shen, W.; Cao, L.; Li, Q.; Zhang, W.; Wang, G.; Li, C. Quantifying CO2 emissions from China’s cement industry. Renew. Sustain. Energy Rev. 2015, 50, 1004–1012. [Google Scholar] [CrossRef]

- Ma, X.; Li, C.; Li, B. Carbon Emissions of China’s Cement Packaging: Life Cycle Assessment. Sustainability 2019, 11, 5554. [Google Scholar] [CrossRef]

- Li, M.; Zhang, M.; Du, C.; Chen, Y. Study on the spatial spillover effects of cement production on air pollution in China. Sci. Total Environ. 2020, 748, 141421. [Google Scholar] [CrossRef] [PubMed]

- Rahman, M.M.; Rahman, M.S.; Chowdhury, S.R.; Elhaj, A.; Razzak, S.A.; Abu Shoaib, S.; Islam, M.K.; Islam, M.M.; Rushd, S.; Rahman, S.M. Greenhouse Gas Emissions in the Industrial Processes and Product Use Sector of Saudi Arabia-An Emerging Challenge. Sustainability 2022, 14, 7388. [Google Scholar] [CrossRef]

- Talaei, A.; Pier, D.; Iyer, A.V.; Ahiduzzaman, M.; Kumar, A. Assessment of long-term energy efficiency improvement and greenhouse gas emissions mitigation options for the cement industry. Energy 2019, 170, 1051–1066. [Google Scholar] [CrossRef]

- Cai, B.; Wang, J.; He, J.; Geng, Y. Evaluating CO2 emission performance in China’s cement industry: An enterprise perspective. Appl. Energy 2016, 166, 191–200. [Google Scholar] [CrossRef]

- Liao, S.; Wang, D.; Xia, C.; Tang, J. China’s provincial process CO2 emissions from cement production during 1993–2019. Sci. Data 2022, 9, 165. [Google Scholar] [CrossRef]

- Wang, Y.; Höller, S.; Viebahn, P.; Hao, Z. Integrated assessment of CO2 reduction technologies in China’s cement industry. Int. J. Greenhouse Gas Control 2014, 20, 27–36. [Google Scholar] [CrossRef]

- Ofosu-Adarkwa, J.; Xie, N.; Javed, S.A. Forecasting CO2 emissions of China’s cement industry using a hybrid Verhulst-GM(1,N) model and emissions’ technical conversion. Renew. Sustain. Energy Rev. 2020, 130, 109945. [Google Scholar] [CrossRef]

- Andrew, R.M. Global CO2 emissions from cement production, 1928–2018. Earth Syst. Sci. Data 2019, 11, 1675–1710. [Google Scholar] [CrossRef]

- Ishak, S.A.; Hashim, H. Effect of mitigation technologies on the total cost and carbon dioxide emissions of a cement plant under multi-objective mixed linear programming optimisation. Chem. Eng. Res. Des. 2022, 186, 326–349. [Google Scholar] [CrossRef]

- Wei, J.; Cen, K.; Geng, Y. Evaluation and mitigation of cement CO2 emissions: Projection of emission scenarios toward 2030 in China and proposal of the roadmap to a low-carbon world by 2050. Mitig. Adapt. Strateg. Glob. Change 2019, 24, 301–328. [Google Scholar] [CrossRef]

- Oral, H.V.; Saygin, H. Simulating the future energy consumption and greenhouse gas emissions of Turkish cement industry up to 2030 in a global context. Mitigation and Adaptation Strategies for Global Change 2019, 24, 1461–1482. [Google Scholar] [CrossRef]

- Verma, Y.; Mazumdar, B.; Ghosh, P. Dataset on the electrical energy consumption and its conservation in the cement manufacturing industry. Data Brief 2020, 28, 104967. [Google Scholar] [CrossRef]

- Jaiboon, N.; Wongsapai, W.; Daroon, S.; Bunchuaidee, R.; Ritkrerkkrai, C.; Damrongsak, D. Greenhouse gas mitigation potential from waste heat recovery for power generation in cement industry: The case of Thailand. Energy Reports 2021, 7, 638–643. [Google Scholar] [CrossRef]

- An, J.; Middleton, R.S.; Li, Y.N. Environmental Performance Analysis of Cement Production with CO2 Capture and Storage Technology in a Life-Cycle Perspective. Sustainability 2019, 11, 2626. [Google Scholar] [CrossRef]

- Ali, M.B.; Saidur, R.; Hossain, M.S. A review on emission analysis in cement industries. Renewable Sustainable Energy Rev. 2011, 15, 2252–2261. [Google Scholar] [CrossRef]

- Lin, B.; Zhang, Z. Carbon emissions in China׳s cement industry: A sector and policy analysis. Renewable Sustainable Energy Rev. 2016, 58, 1387–1394. [Google Scholar] [CrossRef]

- Intergovernmental Panel on Climate Change. 2006 IPCC Guidelines for National Greenhouse Gas Inventories; Institute for Global Environmental Strategies: Hayama, Japan, 2006.

- National Development and Reform Commission. Greenhouse Gas Emission Accounting Method and Reporting Guidelines for Chinese Cement Production Enterprises (Trial). Available online: https://www.ndrc.gov.cn/xxgk/zcfb/tz/201311/W020190905508186941483.pdf (accessed on 27 October 2022).

- Witt, T.; Dumeier, M.; Geldermann, J. Combining scenario planning, energy system analysis, and multi-criteria analysis to develop and evaluate energy scenarios. J. Cleaner Prod. 2020, 242, 118414. [Google Scholar] [CrossRef]

- National Bureau of Statistics. China Statistical Yearbook on Construction; China Statistics Press: Beijing, China, 2021.

- Liu, S.; Gao, Q.; Fu, J. Analysis of China’s main cement application fields and forecast of future demand trends. Dev. Guide Build. Mater. 2012, 10, 17–19. (In Chinese) [Google Scholar]

- Chen, M.; Ye, C.; Zhou, Y. Comments on Mulligan’s “Revisiting the urbanization curve”. Cities 2014, 41, S54–S56. [Google Scholar] [CrossRef]

- Liu, Q.; Liu, L.; Liu, X.; Li, S.; Liu, G. Building stock dynamics and the impact of construction bubble and bust on employment in China. J. Ind. Ecol. 2021, 25, 1631–1643. [Google Scholar] [CrossRef]

- Hong, L.; Zhou, N.; Feng, W.; Khanna, N.; Fridley, D.; Zhao, Y.; Sandholt, K. Building stock dynamics and its impacts on materials and energy demand in China. Energy Policy 2016, 94, 47–55. [Google Scholar] [CrossRef]

- Cui, S.; Liu, W. Analysis of CO2 emission mitigation potential in cement producing processes. China Cem. 2008, 4, 57–59. (In Chinese) [Google Scholar]

- Li, C.; Nie, Z.; Cui, S.; Gong, X.; Wang, Z.; Meng, X. The life cycle inventory study of cement manufacture in China. J. Cleaner Prod. 2014, 72, 204–211. [Google Scholar] [CrossRef]

- Chen, W.; Hong, J.; Xu, C. Pollutants generated by cement production in China, their impacts, and the potential for environmental improvement. J. Cleaner Prod. 2015, 103, 61–69. [Google Scholar] [CrossRef]

- Nie, S.; Zhou, J.; Yang, F.; Lan, M.; Li, J.; Zhang, Z.; Chen, Z.; Xu, M.; Li, H.; Sanjayan, J.G. Analysis of theoretical carbon dioxide emissions from cement production: Methodology and application. J. Cleaner Prod. 2022, 334, 130270. [Google Scholar] [CrossRef]

- National Development and Reform Commission. National Key Energy-Saving and Low-Carbon Technology Promotion Catalog (2017, Energy Saving Part). Available online: https://www.ndrc.gov.cn/?code=&state=123 (accessed on 12 March 2022).

- Ministry of Industry and Information Technology of the People’s Republic of China. National Industrial Energy Efficiency Technology Application Guidelines and Cases (2020). Available online: https://www.ndrc.gov.cn/?code=&state=123 (accessed on 15 March 2022).

- Ministry of Industry and Information Technology of the People’s Republic of China. National Industrial Energy-Saving Technology and Equipment Recommended Directory (2020). Available online: https://www.ndrc.gov.cn/?code=&state=123 (accessed on 12 March 2022).

- Hasanbeigi, A.; Morrow, W.; Masanet, E.; Sathaye, J.; Xu, T. Energy efficiency improvement and CO2 emission reduction opportunities in the cement industry in China. Energy Policy 2013, 57, 287–297. [Google Scholar] [CrossRef]

- Zhang, S.; Worrell, E.; Crijns-Graus, W. Evaluating co-benefits of energy efficiency and air pollution abatement in China’s cement industry. Appl. Energy 2015, 147, 192–213. [Google Scholar] [CrossRef]

- Doh Dinga, C.; Wen, Z. Many-objective optimization of energy conservation and emission reduction in China’s cement industry. Appl. Energy 2021, 304, 117714. [Google Scholar] [CrossRef]

| Scenario | 2021–2025 | 2026–2030 | 2031–2035 |

|---|---|---|---|

| LD | 0.27% | 0.17% | 0.15% |

| MD | 0.3% | 0.2% | 0.18% |

| HD | 0.35% | 0.25% | 0.22% |

| Scenario | 2025 | 2030 | 2035 |

|---|---|---|---|

| LD | 67% | 70% | 73% |

| MD | 68% | 72% | 75% |

| HD | 69% | 75% | 78% |

| Building Type | Scenario | 2025 | 2030 | 2035 |

|---|---|---|---|---|

| Rural | LD | 7% | 4.5% | 3.7% |

| MD | 7.5% | 5% | 4% | |

| HD | 8% | 5.5% | 4.3% | |

| Urban | LD | 7.5% | 5% | 4% |

| MD | 8% | 5.5% | 4.3% | |

| HD | 8.5% | 6% | 4.6% | |

| Commercial | LD | −1.8% | −2.1% | −2.3% |

| MD | −1.5% | −1.8% | −2% | |

| HD | −1.2% | −1.5% | −1.7% |

| Type | Scenario | 2025 | 2030 | 2035 |

|---|---|---|---|---|

| Highway | LD | 3% | 2.5% | 2% |

| MD | 3.5% | 3% | 2.5% | |

| HD | 5% | 4% | 3.5% | |

| Railway | LD | 20% | 14% | 7% |

| MD | 25% | 17% | 10% | |

| HD | 30% | 20% | 13% |

| Scenario | 2025 | 2030 | 2035 |

|---|---|---|---|

| LD | 6% | 5% | 4% |

| MD | 8% | 6.5% | 5.5% |

| HD | 10% | 8% | 7% |

| Type | Substance | Material Mass (t/tc) | Transportation Mileage (km) |

|---|---|---|---|

| Resource | limestone | 1.15 | 10 |

| sandstone | 0.055 | 30 | |

| iron slag | 0.015 | 30 | |

| plaster | 0.05 | 60 | |

| waste mineral admixture | 0.2 | 50 | |

| Energy | coal | 0.14 | 350 |

| Product | cement | 1 | 300 |

| Measure | Number | Energy Saving kgce/tcl | Electricity Saving kWh/tcl | Penetration Rate (%) | |||

|---|---|---|---|---|---|---|---|

| 2020 | 2025 | 2030 | 2035 | ||||

| External circulation raw meal vertical mill technology | N1 | / | 7.00 | 3.0 | 10.0 | 15.0 | 20.0 |

| Ball mill + high pressure roller press for cement grinding | N2 | / | 10.00 | 25.0 | 37.5 | 50.0 | 70.0 |

| High efficiency motors | N3 | / | 4.58 | 40.0 | 50.0 | 60.0 | 70.0 |

| Precalcination with high solid to gas ratio | N4 | 16.00 | / | 3.0 | 10.0 | 20.0 | 35.0 |

| Upgrading the preheater from 5 to 6 stages | N5 | 3.75 | −1.17 | 5.0 | 12.5 | 20.0 | 35.0 |

| Low thermal conductivity multi-layer composite mullite brick | N6 | 1.13 | 4.81 | 10.0 | 20.0 | 30.0 | 40.0 |

| New cement clinker cooling technology and equipment | N7 | 2.81 | 2.57 | 5.0 | 20.0 | 35.0 | 55.0 |

| Cement clinker firing system optimization technology | N8 | 7.23 | / | 8.0 | 23.0 | 38.0 | 53.0 |

| Coprocessing of municipal solid waste in cement kilns | N9 | 4.65 | −4.00 | 2.0 | 8.0 | 15.0 | 22.0 |

| Low temperature waste heat recovery for power generation | N10 | / | 35.00 | 66.0 | 75.0 | 85.0 | 100 |

| Utilization of steel slag as an alternative raw material for cement production | N11 | 61.80 | / | 4.0 | 4.5 | 5.3 | 6.5 |

| Production of cement clinker by using iron ore tailings instead of iron powder | N12 | 21.30 | / | 1.0 | 1.2 | 1.5 | 2.0 |

| Production of cement clinker using fly ash instead of clay | N13 | 15.10 | / | 5.0 | 5.7 | 6.5 | 7.5 |

| Energy-saving monitoring and optimization system technology | N14 | 8.22 | 6.32 | 3.0 | 10.0 | 17.0 | 25.0 |

| Visual energy management system | N15 | / | 16.47 | 5.0 | 10.0 | 15.0 | 20.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, C.; Gong, Y.; Yan, G. Research on Cement Demand Forecast and Low Carbon Development Strategy in Shandong Province. Atmosphere 2023, 14, 267. https://doi.org/10.3390/atmos14020267

Xu C, Gong Y, Yan G. Research on Cement Demand Forecast and Low Carbon Development Strategy in Shandong Province. Atmosphere. 2023; 14(2):267. https://doi.org/10.3390/atmos14020267

Chicago/Turabian StyleXu, Chongqing, Yangyang Gong, and Guihuan Yan. 2023. "Research on Cement Demand Forecast and Low Carbon Development Strategy in Shandong Province" Atmosphere 14, no. 2: 267. https://doi.org/10.3390/atmos14020267

APA StyleXu, C., Gong, Y., & Yan, G. (2023). Research on Cement Demand Forecast and Low Carbon Development Strategy in Shandong Province. Atmosphere, 14(2), 267. https://doi.org/10.3390/atmos14020267