Prediction of Gas Emission in the Working Face Based on LASSO-WOA-XGBoost

Abstract

:1. Introduction

2. Research Methods and LASSO-WOA-XGBoost Prediction Model Construction

2.1. LASSO Algorithm

2.2. WOA Algorithm

2.3. XGBoost Algorithm

2.4. Construction of the LASSO-WOA-XGBoost Gas Emission Prediction Model

3. Application of the LASSO-WOA-XGBoost Gas Prediction Model

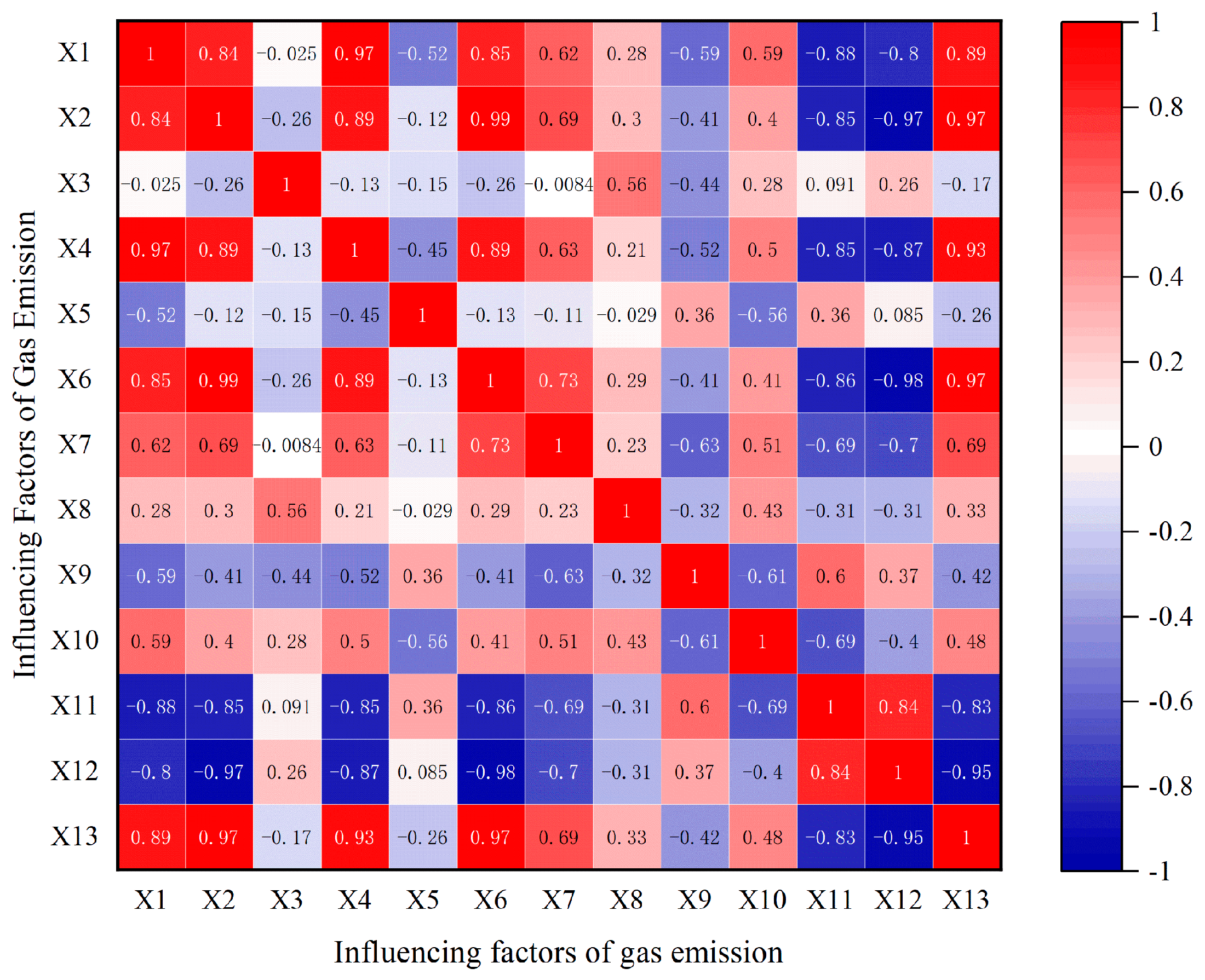

3.1. Sample Data Acquisition and Sample Data Correlation Analysis

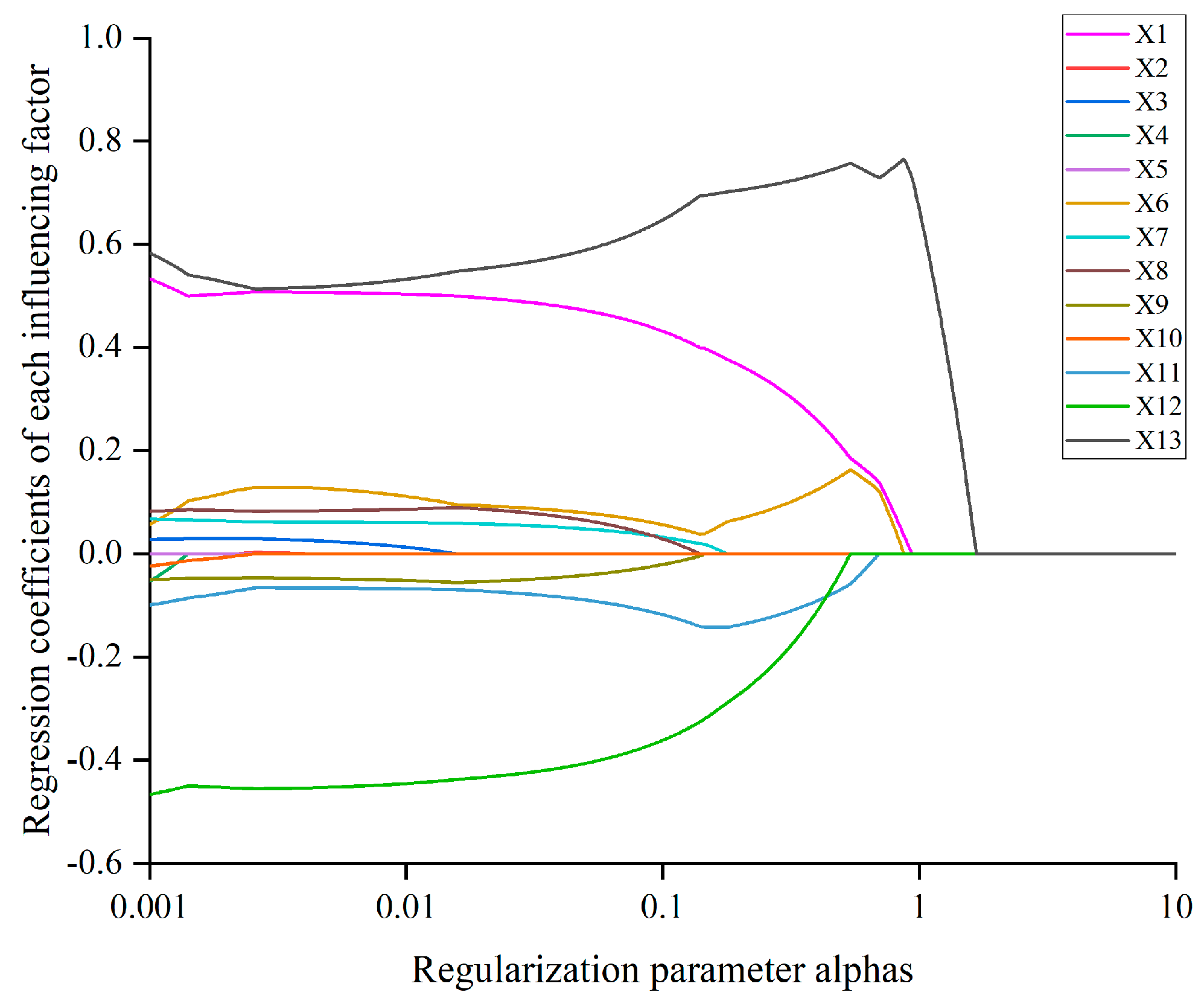

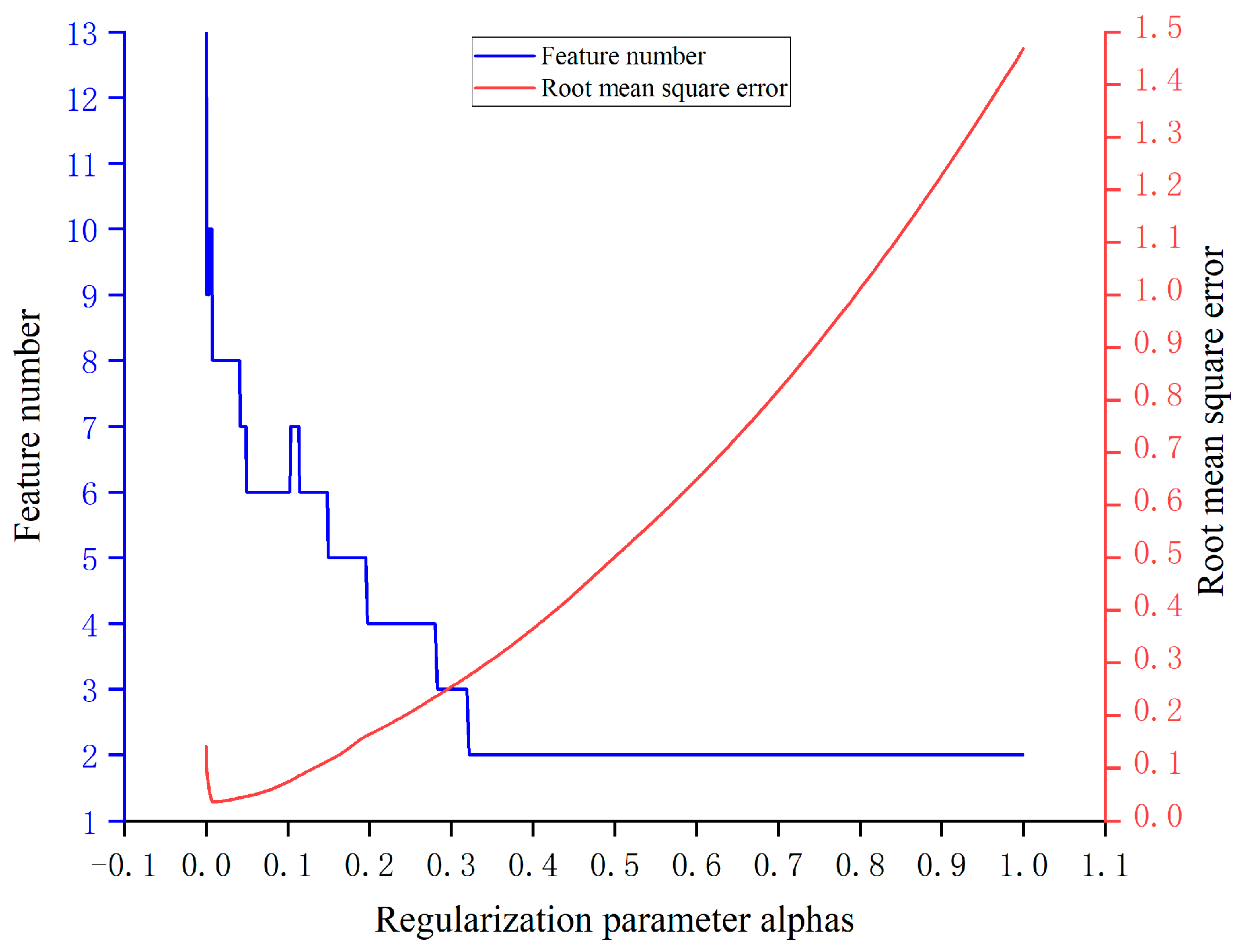

3.2. LASSO Algorithm Screening Factors

3.3. Optimization Settings of the Main Parameters of the XGBoost Algorithm

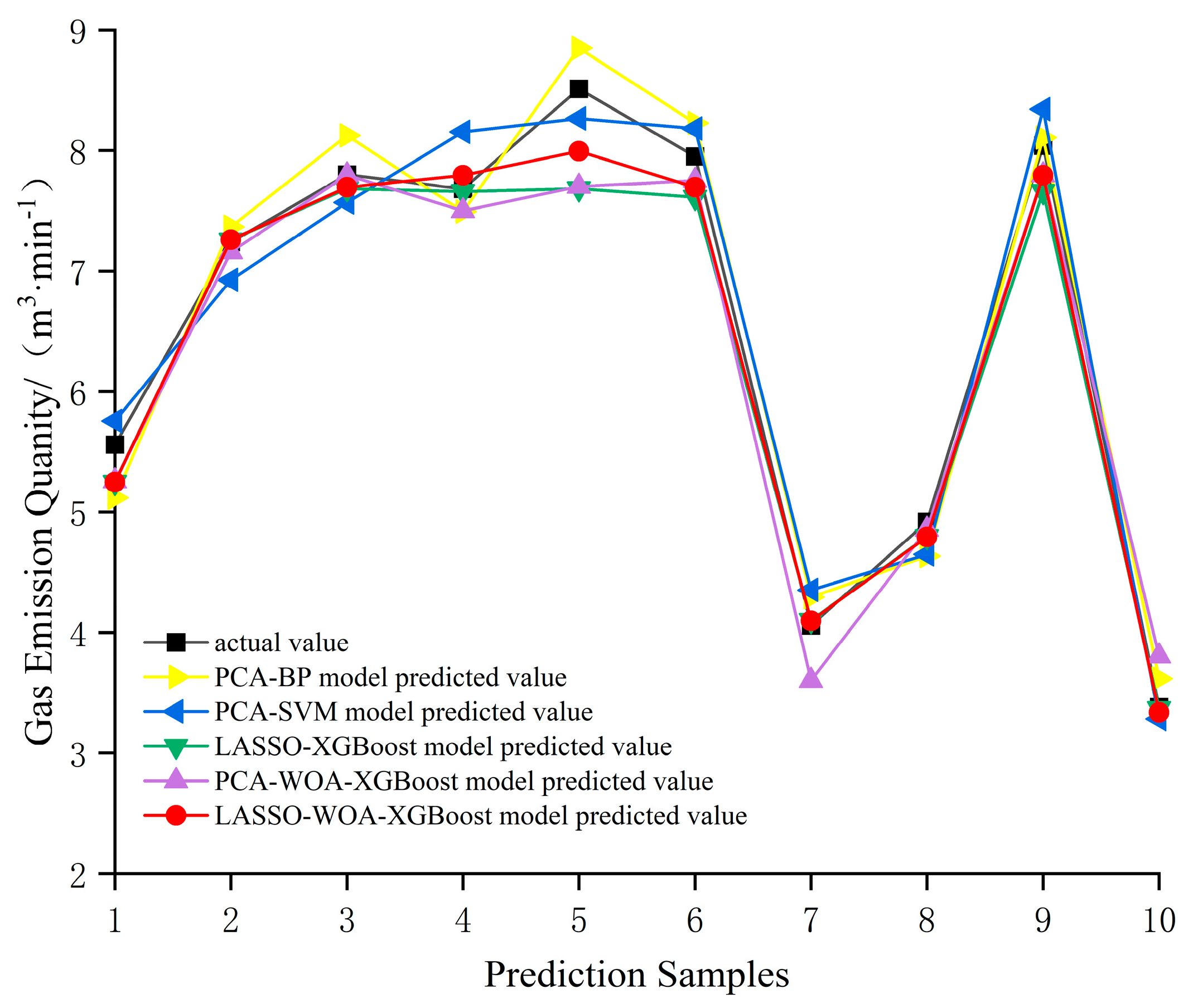

3.4. LASSO-WOA-XGBoost Model Prediction Analysis Comparison

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, F.; Cao, W.J.; Zhang, J.M.; Cao, G.M.; Guo, L.M. Current technological innovation and development direction of the 14th Five-Year Plan period in China coal industry. J. China Coal Soc. 2021, 46, 1–15. [Google Scholar] [CrossRef]

- Luo, X.Y.; Yu, Q.X. Prediction and evaluation of mine gas. China Saf. Sci. J. 1994, 3, 45–52. [Google Scholar] [CrossRef]

- Liu, X.X.; Zhao, Y.S. Predicting the Amount of Gas Gushed from Mine by Model GM(1,1) of Gray System Theory. China Saf. Sci. J. 2000, 4, 54–57. [Google Scholar] [CrossRef]

- Wang, X.L.; Ji, Z.G.; Xie, Y.T.; Yang, J.K.; Wu, P.; Wang, X.; Guo, X.Q. Present Situation and Development Trend of Gas Emission Prediction Technology in Coal Face. Sci. Technol. Eng. 2019, 19, 1–9. [Google Scholar] [CrossRef]

- Lv, F.; Lang, B.; Sun, J.W.; Wang, Y. Gas emission quantity prediction of working face based on principal component regression analysis method. J. China Coal Soc. 2012, 37, 113–116. [Google Scholar] [CrossRef]

- Lu, G.B.; Kang, J.K.; Bai, G.; Liu, J.; Xie, L.N. Application of PCA-BP to gas emission prediction of mining working face. J. Liaoning Tech. Univ. (Nat. Sci.) 2015, 34, 1329–1334. [Google Scholar]

- Li, B.; Zhang, C.H.; Li, X.J.; Wang, X.F. Prediction of Mine Gas Emission Based on PCA-ELM. World Sci.-Tech. Res. Dev. 2016, 38, 49–53. [Google Scholar] [CrossRef]

- Li, X.L.; Yuan, M.; Ao, X.J.; Long, N.Z.; Zhang, P. Application of PCA-SVM Model in Prediction of Coal Seam Gas Emission. Ind. Saf. Environ. Prot. 2019, 45, 35–39. [Google Scholar]

- Wu, X.; Qian, J.S.; Huang, C.H.; Zhang, L. Short-Term Coalmine Gas Concentration Prediction Based on Wavelet Transform and Extreme Learning Machine. Math. Probl. Eng. 2014, 2014, 858260. [Google Scholar] [CrossRef]

- Chen, Q.; Huang, L.B. Gas emission prediction from coalface based on Least Absolute Shrinkage and Selection Operator and Least Angle Regression. Coal Sci. Technol. 2022, 50, 171–176. [Google Scholar] [CrossRef]

- Song, S.; Chen, J.; Ma, L.; Zhang, L.; He, S.; Du, G.; Wang, J. Research on a working face gas concentration prediction model based on LASSO-RNN time series data. Heliyon 2023, 9, E14864. [Google Scholar] [CrossRef] [PubMed]

- Tibshirani, R. Regression shrinkage and selection via the lasso. J. R. Stat. Soc. Ser. B 1996, 58, 267–288. [Google Scholar] [CrossRef]

- Zang, Y. Prediction of Daily Fuel Consumption of Ship Based on LASSO. Navig. China 2022, 45, 129–132. [Google Scholar]

- Luo, Z.S.; Pan, K.C. Wax Deposition Rate Prediction of Waxy Crude Oil Pipelines Based on LASSO-ISAPSO-ELM Algorithm. Saf. Environ. Eng. 2022, 29, 69–77. [Google Scholar] [CrossRef]

- Oufdou, H.; Bellanger, L.; Bergam, A.; Khomsi, K. Forecasting Daily of Surface Ozone Concentration in the Grand Casablanca Region Using Parametric and Nonparametric Statistical Models. Atmosphere 2021, 12, 666. [Google Scholar] [CrossRef]

- Liu, S.; Liu, C.; Hu, Q.; Su, W.; Yang, X.; Lin, J.; Zhang, C.; Xing, C.; Ji, X.; Tan, W.; et al. Distinct Regimes of O3 Response to COVID-19 Lockdown in China. Atmosphere 2021, 12, 184. [Google Scholar] [CrossRef]

- Mirjalili, S.; Lewis, A. The Whale Optimization Algorithm. Adv. Eng. Softw. 2016, 95, 51–67. [Google Scholar] [CrossRef]

- Yang, X. Firefly algorithm, stochastic test functions and design optimisation. Int. J. Bio-Inspired Comput. 2010, 2, 78–84. [Google Scholar] [CrossRef]

- Pan, W.T. A new Fruit Fly Optimization Algorithm: Taking the financial distress model as an example. Knowl.-Based Syst. 2012, 26, 69–74. [Google Scholar] [CrossRef]

- Poli, R. Particle swarm optimization An overview. Swarm Intell. 2007, 1, 33–57. [Google Scholar] [CrossRef]

- Li, Y.L.; Wang, S.Q.; Chen, Q.R.; Wang, X.G. Comparative Study of Several New Swarm Intelligence Optimization Algorithms. Comput. Eng. Appl. 2020, 56, 1–12. [Google Scholar]

- Zhao, F.; Li, W. A Combined Model Based on Feature Selection and WOA for PM2.5 Concentration Forecasting. Atmosphere 2019, 10, 223. [Google Scholar] [CrossRef]

- Huang, S.; Yang, C.W.; Han, G.; Zhao, S.F.; Wang, M.Y. Optimal Design of a Controlled Diffusion Airfoil with the Whale Algorithm. J. Xi’an Jiaotong Univ. 2020, 54, 49–57. [Google Scholar]

- Chen, T.; Guestrin, C. XGBoost: A Scalable Tree Boosting System. In Proceedings of the 22nd ACM SIGKDD International Conference on Knowledge Discovery and Data Mining, San Francisco, CA, USA, 13–17 August 2016. [Google Scholar] [CrossRef]

- Wang, Y.S.; Guan, S.J.; Liu, L.M.; Gao, J.; Xu, Z.W. Wind power prediction method based on XGBoost extended financial factor. J. Zhejiang Univ. (Eng. Sci.) 2023, 57, 1038–1049. [Google Scholar] [CrossRef]

- Ren, C.; Yue, W.T.; Liang, X.Y.; Liang, Y.J.; Liang, J.Y.; Lin, X.Q. Risk assessment of wildfire disaster in Guilin based on XGBoost and combination weight method. J. Saf. Environ. 2023, 18, 1–9. [Google Scholar] [CrossRef]

- He, Y.; Li, H. Application of Improved NSGA-III-XGBoost Algorithm in Stock Forecasting. Comput. Eng. Appl. 2023, 47, 1–11. Available online: http://kns.cnki.net/kcms/detail/11.2127.TP.20230116.1550.003.html (accessed on 21 July 2023).

- Zamani, M. PM2.5 Prediction Based on Random Forest, XGBoost, and Deep Learning Using Multisource Remote Sensing Data. Atmosphere 2019, 10, 373. [Google Scholar] [CrossRef]

- Jin, Q.; Fan, X.; Liu, J.; Xue, Z.; Jian, H. Estimating Tropical Cyclone Intensity in the South China Sea Using the XGBoost Model and FengYun Satellite Images. Atmosphere 2020, 11, 423. [Google Scholar] [CrossRef]

- Feng, S.C.; Shao, L.S.; Lu, W.J.; Meng, T.R.; Gao, Z.B. Application of PCA-PSO-LSSVM model in gas emission prediction. J. Liaoning Tech. Univ. (Nat. Sci.) 2019, 38, 124–129. [Google Scholar]

- Lin, H.F.; Zhou, J.; Gao, F.; Jin, H.W.; Yang, Z.Y. Coal seam gas content prediction based on fusion of feature selection and machine learning. Coal Sci. Technol. 2021, 49, 44–51. [Google Scholar] [CrossRef]

| Number | X1 | X2 | X3 | X4 | X5 | X6 | X7 | X8 | X9 | X10 | X10 | X12 | X13 | Y |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 412 | 2.5 | 8 | 2.12 | 24 | 2.0 | 2.1 | 1.53 | 4.78 | 140 | 4.16 | 0.960 | 1 528 | 2.91 |

| 2 | 423 | 1.5 | 11 | 2.14 | 17 | 1.4 | 2.55 | 1.62 | 4.75 | 180 | 4.14 | 0.950 | 1 751 | 3.52 |

| 3 | 436 | 2.3 | 10 | 2.53 | 14 | 2.2 | 2.40 | 1.48 | 4.91 | 145 | 4.67 | 0.945 | 2 074 | 3.62 |

| 4 | 459 | 2.4 | 15 | 2.45 | 24 | 2.3 | 2.42 | 1.78 | 4.75 | 155 | 4.57 | 0.944 | 2 104 | 4.13 |

| 5 | 511 | 2.8 | 13 | 3.24 | 14 | 2.4 | 2.21 | 1.72 | 4.78 | 180 | 3.45 | 0.930 | 2 241 | 4.60 |

| 6 | 515 | 2.3 | 17 | 2.85 | 17 | 2.5 | 2.77 | 1.87 | 4.51 | 170 | 3.25 | 0.940 | 1 973 | 4.94 |

| 7 | 556 | 2.7 | 9 | 3.37 | 13 | 2.5 | 1.88 | 1.42 | 4.85 | 165 | 3.68 | 0.932 | 2 287 | 4.78 |

| 8 | 550 | 3.1 | 12 | 3.67 | 15 | 2.9 | 2.32 | 1.65 | 4.83 | 155 | 4.01 | 0.920 | 2 352 | 5.25 |

| 9 | 590 | 3.0 | 11 | 3.68 | 12 | 3.6 | 3.11 | 1.46 | 4.53 | 175 | 3.53 | 0.940 | 2 410 | 5.26 |

| 10 | 581 | 5.2 | 8 | 4.31 | 17 | 5.9 | 3.47 | 1.57 | 4.76 | 170 | 2.80 | 0.797 | 3 131 | 7.26 |

| 11 | 611 | 6.7 | 9 | 4.05 | 16 | 6.7 | 3.15 | 1.80 | 4.70 | 175 | 2.64 | 0.812 | 3 354 | 7.80 |

| 12 | 408 | 2.0 | 10 | 1.92 | 20 | 2.0 | 2.02 | 1.50 | 5.03 | 155 | 4.42 | 0.960 | 1 825 | 3.34 |

| 13 | 411 | 2.0 | 8 | 2.15 | 22 | 2.0 | 2.10 | 1.21 | 4.87 | 140 | 4.16 | 0.950 | 1 527 | 2.94 |

| 14 | 420 | 1.8 | 11 | 2.14 | 19 | 1.8 | 2.64 | 1.62 | 4.75 | 175 | 4.13 | 0.950 | 1 751 | 3.56 |

| 15 | 432 | 2.3 | 10 | 2.58 | 17 | 2.3 | 2.40 | 1.48 | 4.91 | 145 | 4.67 | 0.950 | 2 078 | 3.62 |

| 16 | 456 | 2.2 | 15 | 2.40 | 20 | 2.2 | 2.55 | 1.75 | 4.63 | 160 | 4.51 | 0.940 | 2 104 | 4.17 |

| 17 | 516 | 2.8 | 13 | 3.22 | 12 | 2.8 | 2.21 | 1.72 | 4.78 | 180 | 3.45 | 0.930 | 2 242 | 4.60 |

| 18 | 527 | 2.5 | 17 | 2.80 | 11 | 2.5 | 2.81 | 1.81 | 4.51 | 180 | 3.28 | 0.940 | 1 979 | 4.92 |

| 19 | 531 | 2.9 | 9 | 3.35 | 13 | 2.9 | 1.88 | 1.42 | 4.82 | 165 | 3.68 | 0.930 | 2 288 | 4.78 |

| 20 | 550 | 2.9 | 12 | 3.61 | 14 | 2.9 | 2.12 | 1.60 | 4.83 | 155 | 4.02 | 0.920 | 2 352 | 5.23 |

| 21 | 563 | 3 | 11 | 3.68 | 12 | 3.0 | 3.11 | 1.46 | 4.53 | 175 | 3.53 | 0.940 | 2 410 | 5.56 |

| 22 | 590 | 5.9 | 8 | 4.21 | 18 | 5.9 | 3.40 | 1.50 | 4.77 | 170 | 2.85 | 0.795 | 3 139 | 7.24 |

| 23 | 604 | 6.2 | 9 | 4.03 | 16 | 6.2 | 3.15 | 1.80 | 4.70 | 180 | 2.64 | 0.812 | 3 354 | 7.80 |

| 24 | 607 | 6.1 | 9 | 4.34 | 17 | 6.1 | 3.02 | 1.74 | 4.62 | 165 | 2.77 | 0.785 | 3 087 | 7.68 |

| 25 | 634 | 6.5 | 12 | 4.80 | 15 | 6.5 | 2.98 | 1.92 | 4.55 | 175 | 2.92 | 0.773 | 3 620 | 8.51 |

| 26 | 640 | 6.3 | 11 | 4.67 | 15 | 6.3 | 2.56 | 1.75 | 4.60 | 175 | 2.75 | 0.802 | 3 412 | 7.95 |

| 27 | 450 | 2.2 | 12 | 2.43 | 16 | 2.2 | 2.00 | 1.70 | 4.84 | 160 | 4.32 | 0.950 | 1 996 | 4.06 |

| 28 | 544 | 2.7 | 11 | 3.16 | 13 | 2.7 | 2.30 | 1.80 | 4.90 | 165 | 3.81 | 0.930 | 2 207 | 4.92 |

| 29 | 629 | 6.4 | 13 | 4.62 | 19 | 6.4 | 3.35 | 1.61 | 4.63 | 170 | 2.80 | 0.803 | 3 456 | 8.04 |

| 30 | 401 | 2.0 | 10 | 1.87 | 25 | 2.4 | 2.14 | 1.78 | 5.12 | 150 | 4.52 | 0.950 | 1 855 | 3.38 |

| Influencing Factors | LASSO Regression Coefficient | Influencing Factors | LASSO Regression Coefficient |

|---|---|---|---|

| X1 | 0.5004 | X8 | 0.0889 |

| X2 | 0.0000 | X9 | −0.0548 |

| X3 | 0.0025 | X10 | 0.0000 |

| X4 | 0.0000 | X11 | −0.0692 |

| X5 | 0.0000 | X12 | −0.4392 |

| X6 | 0.0984 | X13 | 0.5444 |

| X7 | 0.0595 |

| Number | X1 | X3 | X6 | X7 | X8 | X9 | X11 | X12 | X13 | Y |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 412 | 8 | 2.0 | 2.1 | 1.53 | 4.78 | 4.16 | 0.96 | 1 528 | 2.91 |

| 2 | 423 | 11 | 1.4 | 2.55 | 1.62 | 4.75 | 4.14 | 0.95 | 1 751 | 3.52 |

| 3 | 436 | 10 | 2.2 | 2.40 | 1.48 | 4.91 | 4.67 | 0.945 | 2 074 | 3.62 |

| 4 | 459 | 15 | 2.3 | 2.42 | 1.78 | 4.75 | 4.57 | 0.944 | 2 104 | 4.13 |

| 5 | 511 | 13 | 2.4 | 2.21 | 1.72 | 4.78 | 3.45 | 0.93 | 2 241 | 4.60 |

| 6 | 515 | 17 | 2.5 | 2.77 | 1.87 | 4.51 | 3.25 | 0.94 | 1 973 | 4.94 |

| 7 | 556 | 9 | 2.5 | 1.88 | 1.42 | 4.85 | 3.68 | 0.932 | 2 287 | 4.78 |

| 8 | 550 | 12 | 2.9 | 2.32 | 1.65 | 4.83 | 4.01 | 0.92 | 2 352 | 5.25 |

| 9 | 590 | 11 | 3.6 | 3.11 | 1.46 | 4.53 | 3.53 | 0.94 | 2 410 | 5.26 |

| 10 | 581 | 8 | 5.9 | 3.47 | 1.57 | 4.76 | 2.80 | 0.797 | 3 131 | 7.26 |

| 11 | 611 | 9 | 6.7 | 3.15 | 1.80 | 4.70 | 2.64 | 0.812 | 3 354 | 7.80 |

| 12 | 408 | 10 | 2.0 | 2.02 | 1.50 | 5.03 | 4.42 | 0.96 | 1 825 | 3.34 |

| 13 | 411 | 8 | 2.0 | 2.10 | 1.21 | 4.87 | 4.16 | 0.95 | 1 527 | 2.94 |

| 14 | 420 | 11 | 1.8 | 2.64 | 1.62 | 4.75 | 4.13 | 0.95 | 1 751 | 3.56 |

| 15 | 432 | 10 | 2.3 | 2.40 | 1.48 | 4.91 | 4.67 | 0.95 | 2 078 | 3.62 |

| 16 | 456 | 15 | 2.2 | 2.55 | 1.75 | 4.63 | 4.51 | 0.94 | 2 104 | 4.17 |

| 17 | 516 | 13 | 2.8 | 2.21 | 1.72 | 4.78 | 3.45 | 0.93 | 2 242 | 4.60 |

| 18 | 527 | 17 | 2.5 | 2.81 | 1.81 | 4.51 | 3.28 | 0.94 | 1 979 | 4.92 |

| 19 | 531 | 9 | 2.9 | 1.88 | 1.42 | 4.82 | 3.68 | 0.93 | 2 288 | 4.78 |

| 20 | 550 | 12 | 2.9 | 2.12 | 1.60 | 4.83 | 4.02 | 0.92 | 2 352 | 5.23 |

| Number | X1 | X3 | X6 | X7 | X8 | X9 | X11 | X12 | X13 | Y |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 563 | 11 | 3.0 | 3.11 | 1.46 | 4.53 | 3.53 | 0.94 | 2 410 | 5.56 |

| 2 | 590 | 8 | 5.9 | 3.4.0 | 1.50 | 4.77 | 2.85 | 0.795 | 3 139 | 7.24 |

| 3 | 604 | 9 | 6.2 | 3.15 | 1.80 | 4.70 | 2.64 | 0.812 | 3 354 | 7.80 |

| 4 | 607 | 9 | 6.1 | 3.02 | 1.74 | 4.62 | 2.77 | 0.785 | 3 087 | 7.68 |

| 5 | 634 | 12 | 6.5 | 2.98 | 1.92 | 4.55 | 2.92 | 0.773 | 3 620 | 8.51 |

| 6 | 640 | 11 | 6.3 | 2.56 | 1.75 | 4.60 | 2.75 | 0.802 | 3 412 | 7.95 |

| 7 | 450 | 12 | 2.2 | 2.00 | 1.70 | 4.84 | 4.32 | 0.95 | 1 996 | 4.06 |

| 8 | 544 | 11 | 2.7 | 2.30 | 1.80 | 4.90 | 3.81 | 0.93 | 2 207 | 4.92 |

| 9 | 629 | 13 | 6.4 | 3.35 | 1.61 | 4.63 | 2.80 | 0.803 | 3 456 | 8.04 |

| 10 | 401 | 10 | 2.4 | 2.14 | 1.78 | 5.12 | 4.52 | 0.95 | 1 855 | 3.38 |

| Parameter Name | Defaults | WOA Optimized Values | Ranges | Parameter Meaning |

|---|---|---|---|---|

| n_estimators | 100 | 464 | [1, 500] | number of trees |

| learning_rate | 0.1 | 0.2869 | [0, 1] | learning rate |

| max_depth | 6 | 8 | [1, 10] | tree depth |

| Model Name | Mean Absolute Error (MAE) | Root Mean Square Error (RMSE) |

|---|---|---|

| PCA-BP | 0.2518 | 0.2721 |

| PCA-SVM | 0.26555 | 0.2810 |

| LASSO-XGBoost | 0.2191 | 0.3278 |

| PCA-WOA-XGBoost | 0.2767 | 0.3575 |

| LASSO-WOA-XGBoost | 0.1775 | 0.2697 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, W.; Han, X.; Qi, J. Prediction of Gas Emission in the Working Face Based on LASSO-WOA-XGBoost. Atmosphere 2023, 14, 1628. https://doi.org/10.3390/atmos14111628

Song W, Han X, Qi J. Prediction of Gas Emission in the Working Face Based on LASSO-WOA-XGBoost. Atmosphere. 2023; 14(11):1628. https://doi.org/10.3390/atmos14111628

Chicago/Turabian StyleSong, Weihua, Xiaowei Han, and Jifei Qi. 2023. "Prediction of Gas Emission in the Working Face Based on LASSO-WOA-XGBoost" Atmosphere 14, no. 11: 1628. https://doi.org/10.3390/atmos14111628

APA StyleSong, W., Han, X., & Qi, J. (2023). Prediction of Gas Emission in the Working Face Based on LASSO-WOA-XGBoost. Atmosphere, 14(11), 1628. https://doi.org/10.3390/atmos14111628