Abstract

California is the leading dairy state in the United States. The total sale of milk and its products represents about $6.3 billion annually out of the $50 billion generated from all agricultural production in the state. However, methane emissions from dairy manure and enteric fermentation represented nearly half of all annual methane emissions in California, with dairy manure accounting for 25%, and enteric fermentation for 20%. Methane emissions originating from manure are produced primarily from anaerobic settling basins and lagoons, which are the most common manure storage systems in the state. To achieve sustainability on dairy farms and to comply with state regulations for air and climate pollutants, dairy farms have implemented technologies such as anaerobic digestion and alternative manure management technologies. In addition, governmental incentive programs have been deployed to partially fund these technologies for eligible dairies in the state. The present article reviews the design and operations, effectiveness, and economics of the most common technologies employed in Californian dairies in reducing methane emissions. The technologies studied include anaerobic digesters, mechanical separators, compost-bedded pack barns, manure vacuuming followed by drying, and weeping walls. The current status and estimated effectiveness of government incentive programs are reviewed and recommendations for improvements presented. Finally, future trends and research needs for mitigating the emissions in Californian dairies are identified.

1. Introduction

California is the United States’ national leader in milk production. The total sale of milk and its products represents about $6.3 billion annually out of the $50 billion generated from all agricultural production in the state [1]. There were 1331 dairies in California in 2017, with an average of 1304 cows per dairy [2]. According to the California Air Resources Board (CARB), statewide methane (CH4) emissions were estimated to be approximately 38.85 million metric tons of carbon dioxide equivalent (MMTCO2e) in 2020 [3]. Methane emissions from dairy manure and enteric fermentation represented nearly half of all CH4 emissions in California, with dairy manure accounting for 25.2% (9.78 MMTCO2e), and enteric fermentation accounting for 19.5% (7.56 MMTCO2e). Most dairy farms in California include manure storage lagoons in which organic matter in manure undergoes an anaerobic biochemical degradation process, which results in the production of CH4. There is also a large number of open-lot dairies that have smaller lagoons for manure storage. Lagoons are easy to operate and labor saving. Anaerobic digesters, which mitigate methane emissions by producing bioenergy in the form of biogas, have only been installed on less than 2% of dairy farms in California due to high installation costs. To increase the number of digesters on dairy farms, the California Department of Food and Agriculture (CDFA) has administered the Dairy Digester Research and Development Program (DDRDP) since 2015. The DDRDP awards competitive grants to implement dairy digesters to reduce methane emissions from Californian dairies [4]. In addition, the CDFA has also established the Alternative Manure Management Practice (AMMP) program that awards competitive grants to implement other practices for manure management focused on methane reduction [5]. The AMMP practices require less capital investment. These practices include technologies (e.g., mechanical separators) to remove part of manure prior to storing it in an anaerobic lagoon and using farm management procedures (e.g., increase pasture time). However, the effectiveness of AMMP practices on the reduction of CH4 emissions has not been well-documented. Therefore, there is a need to understand the impacts of AMMP practices on GHG and other gas emissions from dairy farms in California.

To our knowledge, there is currently no comprehensive review of the state of methane emission reducing technologies, programs, and practices on the large, diverse set of Californian dairy farms. Therefore, the objectives of this article are to: (1) review concepts of operation, design, effectiveness, and economics of the most common manure management technologies employed in Californian dairies in reducing methane emissions; (2) review the current status and estimated effectiveness of government incentive programs; and (3) propose recommendations for improvements to the performance of different technologies and articulate future trends and research needs for mitigating methane emissions in Californian dairies.

2. Manure Collection on Dairies

Manure removal from freestall barns is accomplished using flushing or scraping systems. Flushing is the most common system in Californian dairy farms for removing manure with fresh and/or recycled lagoon water a few times each day. Based on a survey of 394 herds in California, Meyer et al. [6] found that 62% of the farms used flushing alone or in combination with scraping to collect manure from barns. The use of scraping on dairy farms is more common in other parts of the US (e.g., Midwest and Northeast) due to cold temperatures experienced in these locations in winter. Converting Californian dairies from flushing to scraping manure management strategies has the potential to reduce methane and other gases’ emissions by diverting manure away from storage lagoons.

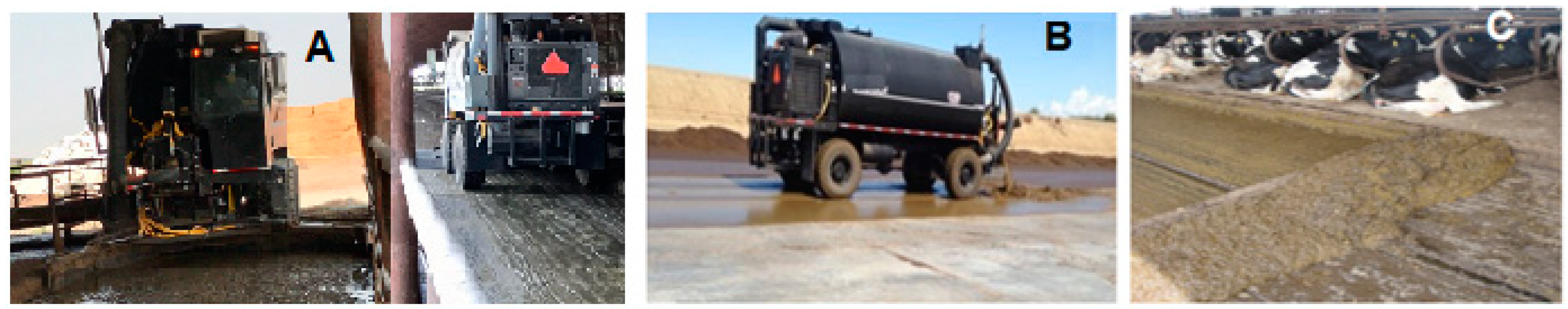

Scraped manure management can have lower methane emissions than flushing systems, and manure can be processed into more solid forms of manure through solar drying on open pads or unpaved yards, or in closed drying houses, forced evaporation using natural gas fueled dryers, or by composting [7]. Manure can be collected using vacuum trucks, automated mechanical scrapers, and front-loader or tractor-mounted rubber scrapers. The available manure vacuum trucks on the market are fully integrated vacuum trucks or vacuum tanks that can be towed behind a tractor. Figure 1A shows a vacuum truck collecting manure from a barn. Automated mechanical scrapers are composed of blades that remove manure into a collection location (Figure 1C). The blades are operated on a pulley system integrated with a cable or chain and an electric motor [7]. Although these systems can divert manure from the lagoon and reduce the emissions from lagoons, other emissions from the barns may be higher than the flushing systems. Results of Ross et al. [8] showed that the NH3 emissions from barns using scraping were greater than using flushing. This was due to the fact that scraping may leave a film of manure that could be a source of NH3 emissions due to the degradation of organic nitrogen. The manure collected from scraping in California could be distributed on land or concrete slabs for sun drying for at least 8 months when there is positive evaporation [7]. There is little information on the emissions of methane from barns after collecting manure using vacuum trucks. In addition to flushing and scraping of manure from barns, solid manure on corrals is also scraped and used as a fertilizer. Niles et al. [9] mentioned that unlike the farms using solid manure systems, farms with liquid manure systems have a limited number of technology options to manage their manure. This is reflected by the greater investments of some of the technologies needed to manage liquid manure, and the difficulties in changing them.

Figure 1.

Manure vacuuming and scraping: (A) Front and back of a vacuum truck collecting manure from a barn; (B) collected manure sprayed on a concrete slab for sun drying; and (C) scraper blades pulled with chain.

3. Anaerobic Digestion Concepts and Systems Employed on Dairies

Anaerobic digestion uses microorganisms to convert organic materials into biogas, a gaseous mixture of mainly CH4 and CO2 in the absence of oxygen. These microorganisms include anaerobic bacteria and methanogenic archaea [10]. Anaerobic digestion is commonly carried out under psychrophilic (<25 °C), mesophilic (25–45 °C), and thermophilic (45–65 °C) conditions. The most common temperatures employed in commercial digesters are mesophilic and thermophilic temperatures. However, psychrophilic digestion may be carried out under mild conditions. At psychrophilic temperatures, chemical and biological reactions proceed much slower than under mesophilic and thermophilic temperatures [11].

Anaerobic digestion has been employed on animal farms for the mitigation of the emissions of methane and other gases while producing biogas that can be used as a source of renewable energy. However, the economics of anaerobic digestion of dairy manure are often not attractive from the investment standpoint due to the low biodegradability of dairy manure and other factors [12]. In California, the economics of dairy manure digesters has been aided by certain governmental programs such as California’s Cap-and-Trade and Low Carbon Fuel Standard (LCFS) programs, and by the federal Renewable Fuel Standard, which can provide additional sources of revenue for dairy digester projects [13]. Codigestion of manure with other organic wastes could also improve the economics of digesters [14]. Codigestion of dairy manure and easily biodegradable materials such as food waste was experimentally tested and used to show the increase in energy production from a typical dairy digester in California [12]. The results showed that adding 38.2 wet tons per day of food waste to a digester treating the manure from 1800 animal units could increase the energy production by 200% compared to the digestion of manure alone. In addition to the income from the increase in energy production, owners of dairy digesters might obtain tipping fees for food waste disposal. However, the management of extra nutrients, salts, and potential contaminants (e.g., plastics) under co-digestion scenarios should be considered prior to their applications. There are some concerns of dairy farmers in California for considering codigestion because of the imported nutrients, to dairies with the codigested substrates. The imported nutrients will affect their nutrient management plans. The imported nutrients will also be an issue for dairies to comply with the Sustainable Groundwater Management Act. Moreover, codigesting dairy manure with other feedstock can also reduce the benefits that a dairy farmer could get from the LCFS. Using manure as a sole substrate for digesters, a higher carbon intensity score could be obtained than with the codigestion. Furthermore, a manure-only digester could get higher D5 Renewable Identification Numbers (D5-RINs) from the Federal Renewable Fund Standard (D5 RINs) than that (D3 RINs) of codigestion. D5RINS are more valuable than D3RINs. However, there is at least a digestion system that codigests dairy manure with creamery processing wastewater [15]. The government incentives could be revised to encourage co-digestion.

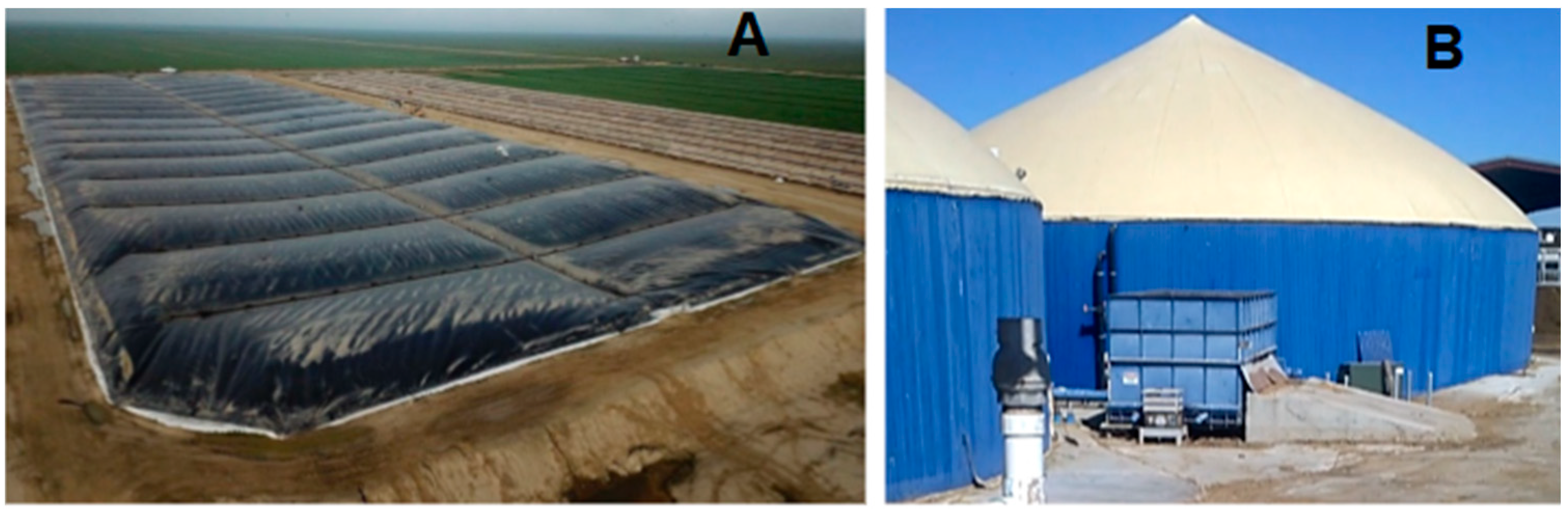

There are several anaerobic digestion systems that are used to treat manure, including covered lagoon digesters, an above-ground continuous stirred tank reactor (CSTR), and plug flow digesters. The description of the designs and operational concepts of these digesters were discussed by El Mashad and Zhang [10]. In 2015, there were 20 digesters operating in California. Of these, 13 covered lagoons, four were CSTR, and three were plug flow digesters [16]. The number of digesters increased in the subsequent seven years due to the benefits gained from the LCFS and governmental support, discussed in a following section. The covered lagoon digesters employed in California typically involve upgrading existing lagoons to a “Tier 1” double-lined status to protect groundwater [4]. Figure 2 shows the covered lagoon and above-ground CSTR digesters.

Figure 2.

Common digester types on dairies: (A) covered lagoon [4], and (B) above-ground CSTR digester.

4. Effect of Anaerobic Digestion on Methane Emissions

Anaerobic digestion removes at least 40% of the biodegradable organic matter of dairy manure. Therefore, it is expected that all the methane that can be produced from this fraction can be captured and not emitted to the atmosphere. Although well-established anaerobic digesters can be airtight with minimal methane emissions, there are still some sources of emissions from the anaerobic digestion systems, including fugitive emissions from (1) the digester itself, (2) manure temporarily stored in ambient conditions during digester feeding, and (3) the anaerobically digested manure (i.e., digestate).

Fugitive methane emissions deserves attention, depending on the digester design and operation and the manure handling system. The collection efficiency of biogas from anaerobic digesters was reported by the EPA [17]: an enclosed vessel was 99% and impermeable covered lagoon (bank to bank) was 97.5%; and an impermeable modular lagoon was 70%. While for bank-to-bank a single floating cover is used to completely cover the span of the lagoon surface, in the modular lagoon, smaller cover sections (i.e., modules) are used to cover the lagoon [18]. Further lowering fugitive emissions may require greater investment for the installation of the digester and manure handling equipment. Flesch et al. [19] found that the yearly average fugitive methane emissions from an anaerobic digester treating cattle manure and other organic feedstocks in Canada represented 3.1% of the CH4 gas production rate. The sources of these emissions were the feedstock hopper, the digester, effluent separator, generator, flare, fertilizer output tent, and the piping that tied these components together. The feedstock hopper was the main source of emissions from the system but the flare was a source with a larger order of magnitude when it was operated. Baldé et al. [20] quantified fugitive methane emissions from two anaerobic digester systems in Canada. The first system received a mixture of manure (51%) and off-farm materials (e.g., dissolved air flotation waste, food waste) (49%). The mixture for the second system was composed of the same portion of manure, with the remainder made up of a different mixture of off-farm materials (processing waste, fats, oils, and grease). The emissions from the first system were from digestate storage (5.8% of the total methane flow rate from the digester), leakage/venting (5.5%), and flaring (0.2%). The emissions from the second system were from digestate storage (10.7%) due to a shorter hydraulic retention time and lack of a screw press to extract solids from the digestate. Fugitive methane emissions from leakage were initially 3.8% in this system but were reduced to 0.6% after repairing the digester membrane cover.

While digestate left after anaerobic digestion is more stable than the original manure feedstock, it can still produce methane and other gaseous emissions from the biological decomposition of residual nutrients. Holly et al. [21] reported that mesophilic anaerobic digestion reduces the emissions of CH4 but increases the emissions of both NH3 and N2O during the storage of digestate. They found that solid–liquid separation, using a screw press, was more effective in reducing the emissions of methane than anaerobic digestion due to the low performance of the digester. Compared with storing raw manure, the reduction of methane emissions from storage was 25%, 46%, and 68% for the anaerobic digestion alone, solid separation alone, and anaerobic digestion followed by solid–liquid separation. No information was given on the reasons for the low performance of the digester.

However, the combination of anaerobic digestion and solid–liquid separation did not further reduce the emissions of GHG from storage compared to anaerobic digestion alone, which was attributed to an increase of N2O emissions, from storing manure solids after the digester that negated the abatement of total GHG emissions. In fact, CARB benefits calculators showed that anaerobic digesters are more effective in reducing the emissions of CH4 than solid–liquid separation [22,23].

In Belgium, Vergote et al. [24] measured the emissions of methane and N2O from the storage of anaerobically digested dairy manure for three months in autumn. Results showed that average methane emission rates from the storage varied from 3.9 to 8.2% of the total methane produced in the digester. The emission rates of N2O varied from 0.004 to 0.13 g/m³/day. The emissions of N2O represented 10% of the total GHG emission rates from the storage, which ranged from 170 to 478 g [CO2eq.]/m³/day. It should be mentioned that there are always tradeoffs in the emissions of different GHG when handling and treating manure.

5. Alternative Manure Management Technologies

There are several alternative technologies to anaerobic digestion that have been employed in dairies to reduce the emissions of methane and other gases, especially from storage lagoons. In the following section, technologies employed in Californian dairies to separate manure solids to reduce the potential for the emissions of CH4 are reviewed.

6. Mechanical Separators

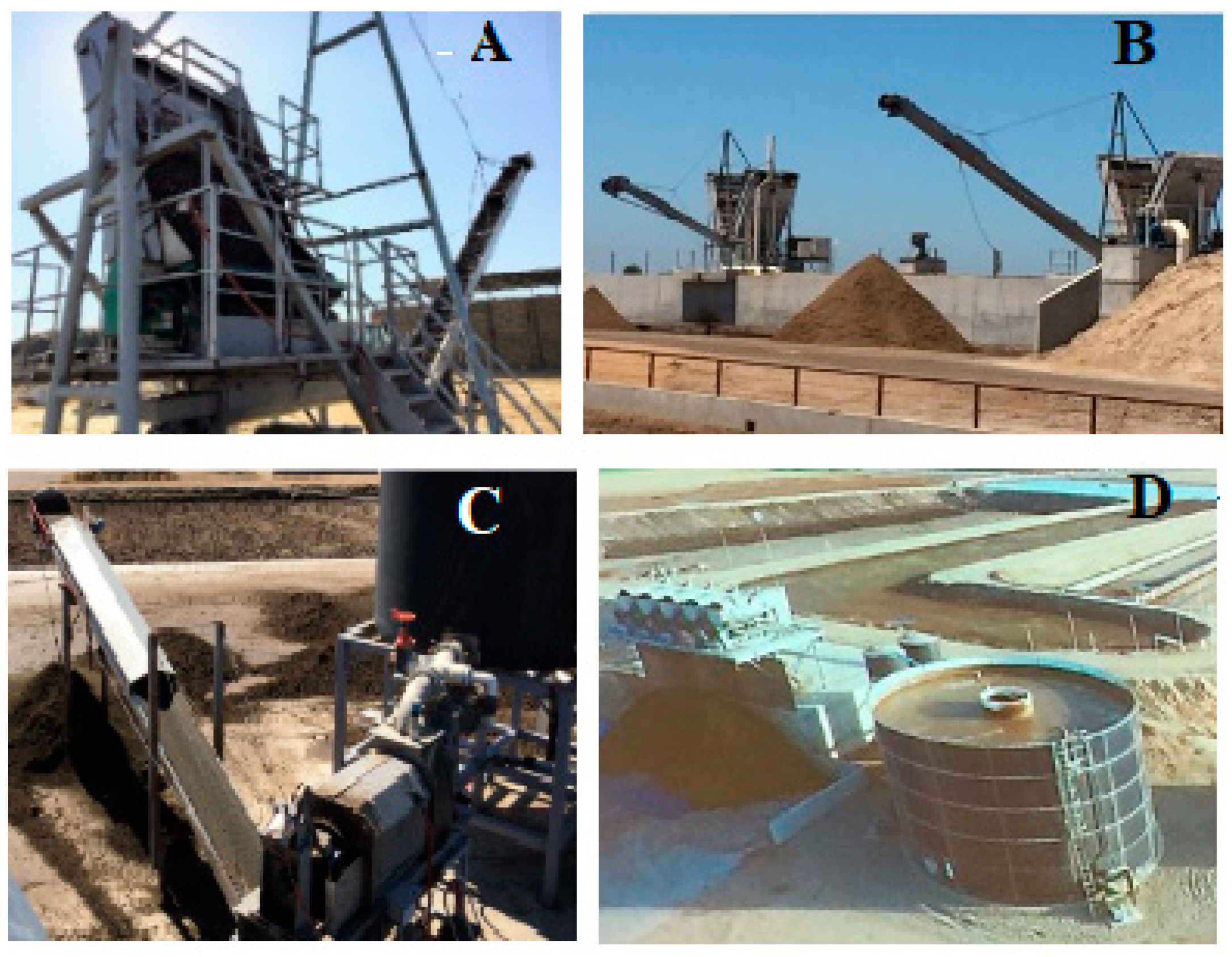

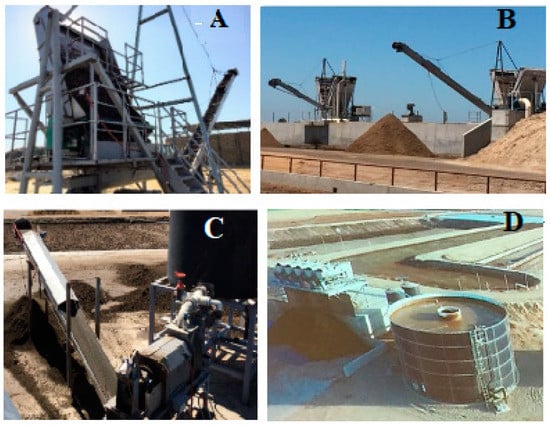

Mechanical separators are a common system used to remove manure solids prior to storage in lagoons. They include stationary screens, rotary drums, and screw presses. Manure solids are separated by passing manure, mainly flushed manure, over flat screens or through rotary drum screens with different opening sizes. Solids with particle sizes larger than the screen holes are separated while the liquid fraction passes through the holes. Screw presses operate by pressure that arises from squeezing manure between a screen and a screw conveyer along the press length. The liquid fraction passes through screen holes and solids are collected separately, usually at the end of the screw conveyor. The operational concepts and performance of different technologies used for solids separation from manure were reviewed by Zhang and Westerman [25]. Figure 3 shows selected mechanical separators that are currently employed in Californian dairies.

Figure 3.

Mechanical separators applied in Californian dairies: (A) single-stage screen; (B) two-stage sloped-dual screen; (C) screw press; and (D) advanced multistage rotary drum.

Several solid–liquid separation technologies are currently used in dairies throughout California, including screw presses, single-stage horizontal scraped screen separator, single-stage sloped screen separators, two-stage sloped dual-screen separators, and rotary drum separator systems. The performance of the mechanical screen separators depends on manure characteristics and system design and management. Most Californian dairies use some method of solids separation. According to Meyer et al. [6], 30–40% of the dairies in California use settling ponds or basins, and approximately 30% use mechanical separators, with or without settling basins. There is no known inventory that details different manure management technologies employed at all dairies in the State [6]. Table 1 shows the solids removal efficiency of several screen separators for dairy manure as reported in the literature.

Table 1.

A comparison of selected screen separators for dairy manure.

7. Effect of Mechanical Separators on Methane Emissions

Removing solids from manure prior to lagoon storage could reduce the emissions of CH4 because it reduces the organic loadings to lagoons. Hills and Kayhanian [29] compared the CH4 production potential of untreated and filtered dairy manure that was screened using 10 mesh screens. Laboratory digesters were operated continuously at 35 °C for 100 days. Results showed that manure screening reduced the methane production potential by 15%. Amon et al. [30] measured GHG (CH4 and N2O) emissions from separated and aerated manure that was stored in a concrete in-ground tank with a loose wooden cover for 80 days and then land-applied. The mean slurry temperature in storage was 17 °C. Relative GHG emissions reduction (for storage and land application combined) of the separated and aerated slurry treatments was 37% and 42%, respectively, of that from the untreated slurry. Rico [31] conducted laboratory anaerobic digestion of manure to determine the methane production potential at 35 °C for 45 days using solid and liquid dairy manure fractions. Manure with 8% solids was screened with a screen with 1 mm openings. Results showed that the screened manure produced about 40% less CH4 production potential than the unscreened manure. Using batch digesters operated at 35 °C for 30 days, El-Mashad and Zhang [32] found 28% reduction in CH4 production potential after filtering manure using a screen with 2 mm openings. Using dairy manure collected before and after a screw press, Witarsa et al. [33] investigated CH4 production potential (at 24 °C) of flush manure and solid-separated dairy manure under psychrophilic digestion conditions (<25 °C). Results showed a reduction of 30% in methane production potential from the filtrate than that of raw manure.

Edalati et al. [34] evaluated the solid removal efficiency and CH4 production potential reduction of five mechanical separation technologies at Californian dairies. Some of the systems were evaluated over the four seasons by measuring the manure inflow rate to the systems and weighing the solids removed. The efficiencies of the systems for solids’ removal and CH4 potential reduction were dependent on manure characteristics (i.e., total solid contents), system design (e.g., screen size and orientation), separator operation and management (manure flow rate), and manure processing pit type and configuration. Table 2 shows the measured average solids removal efficiencies and CH4 reduction potential. The reduction in CH4 production potential depended on the type, configuration of the mechanical separation system, and characteristics of manure. For example, while a single-stage sloped screen separator could achieve a CH4 production potential reduction of 28.9–42.2%, a single-stage sloped dual-screen separator achieved 38.2–57.2%. These values are lower than the values (69.0–83.4%) determined for a weeping wall system [35].

Table 2.

Solid removal efficiencies and CH4 reduction potential of some mechanical separation technologies installed at Californian dairies [34].

A majority of Californian dairy farms stockpiles the separated solids in windrows until they are dried, which are then used as bedding or soil amendment. Bai et al. [36] quantified the emissions of CH4, NH3, N2O, and CO2 from windrow composting (turned 21 times using a compost turner) and static stockpiling of cattle manure for 165 days at a commercial feedlot in Australia. Maximum CH4 emissions from the compost pile were determined on day 18 after pile-turning while the CH4 emissions rate from the stockpile increased over time, reaching a peak on day 135. Composting inhibited the CH4 emissions but promoted NH3 and N2O emissions. The cumulative emissions of CH4, NH3, N2O, and CO2 from composting were 1.2, 6.7, 1.3, 451.5 and from the stockpile were 2.6, 1.4, 0.3, and 280.3 g/kg dry manure, respectively. Results of Vergara and Silver [37] showed that managing compost piles by maintaining sufficient O2 concentrations through aeration and bulking could minimize the emissions of greenhouse gas. Management of compost piles should be focused on the first three weeks when organic matter, temperature, and degradation rates are highest. There is a need to measure the emissions of CH4 and other gases from solids separated using different technologies under Californian dairy conditions.

8. Weeping Walls

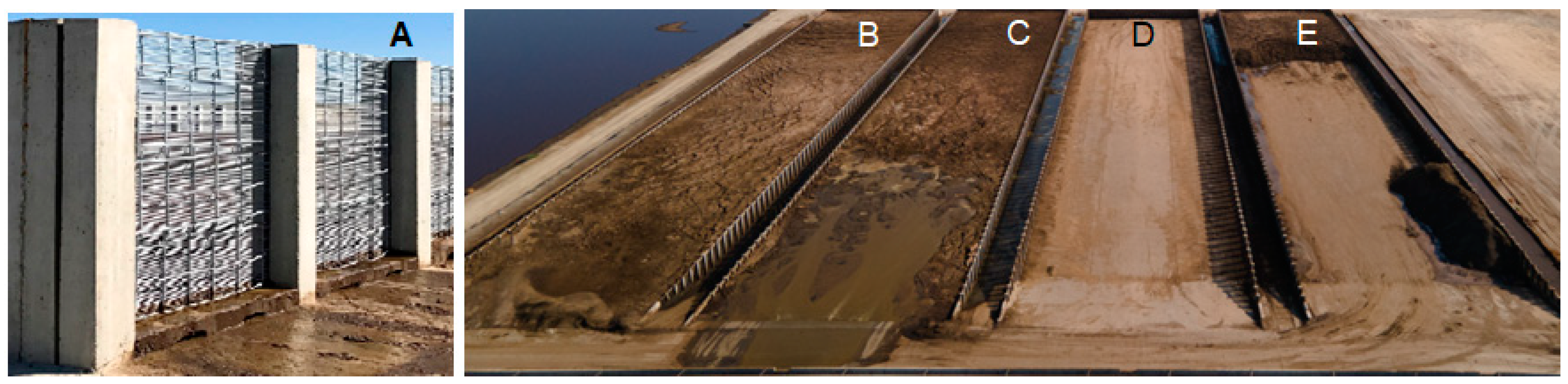

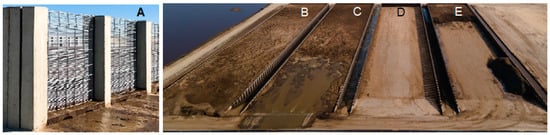

A weeping wall system is defined as a settling basin with a large dewatering surface area [38]. Compared to mechanical separation technologies, a weeping wall can provide several advantages, including: lower energy requirements, minimum equipment requirements, and lower repair and maintenance costs [39]. Well-designed and well-operated weeping walls also do not have operational downtimes. They can provide flexibility in managing manure hauling tasks and can extend storage periods for manure solids. It was estimated that weeping walls could save 5 to 10 h of labor per week by reducing required off-site manure hauling from once every week to once every three months depending on weather conditions [40]. Nooyen [41] mentioned that weeping walls are among the most cost-effective systems for dairy operations as they do not require additional energy, equipment, or labor. In the U.S., weeping walls can provide storage for manure solids for up to three months depending on the weather and number of cells. Figure 4 shows a weeping wall under two different phases.

Figure 4.

Weeping wall cells under different phases: (A) side of a weeping wall, (B) under drying cell, (C) under filling cell, (D) empty cell, and (E) under emptying cell.

Generally, weeping wall systems consist of multiple cells, usually 2–4. Each cell is a standalone structure with concrete floors. Three sides of the cell are constructed using slotted concrete, horizontal wooden slats, or screens supported by concrete pillars [39,42]. The fourth side is used as an entry ramp for filling and emptying the cell. While the liquid manure travels along the cell, the solids accumulate inside the cell and the liquid is drained out of it. The drained liquid is usually stored in lagoons until it is used for irrigation. The accumulated solids in the cell act as a filter that aids in the capture of additional solids.

Once a cell is filled with manure solids, it is left to continue to drain and dry for a designated period of time, usually for two to four weeks depending on the number of cells and manure flow rate. While the filled cell is draining, the flushed manure from dairy barns is directed to another empty cell. After dewatering, the accumulated solids are removed using an excavator or a front loader. Then, the solids are transported to fields or to a composting area on the dairy farm.

Laubach et al. [43] described weeping walls as an increasingly popular pre-treatment technology for dairy manure. They also reported that a weeping wall could achieve solids removal of up to 50%. The accumulated solids inside the weeping wall cells are generally removed and applied to pasture or crops or compost. Nooyen [41] reported that the Tri-Bar weeping wall system could effectively remove 60–85% of total solids and up to 70% of sand. The Natural Resources Conservation Service (NRCS) of the US Department of Agriculture (USDA) reported a solid removal efficiency of the weeping walls in the range of 50–85% [44]. Edalati et al. [45] determined the efficacy of solids removal by a weeping wall system on a dairy in California. The system consisted of four cells that were alternately filled. The filling time ranged from 14–20 days, and the draining time ranged from 22–34 days. Two cells were evaluated by measuring manure inflow rate and weighing the solids separated by the weeping wall at the end of the draining time. The efficiency of total solids removal was in the range of 78–82% and volatile solids was 79–82%. Based on the volatile solid removals and the CH4 production potential, the authors estimated the reduction of CH4 production potential to be 75–81%.

Williams et al. [35] recommended the utilization of a 65% solids separation efficiency with a CH4 conversion factor (MCF) of 0.22 for weeping wall systems. The proposed MCF was calculated based on the average filling, storage and emptying times of 43, 49, and 7 days; and the MCF values of 0.1, 0.32, and 0.16 for the filling, storage and seepage, and excavation periods, respectively. The authors estimated that retention of 65% of solids in the weeping wall could reduce overall CH4 emissions by 46% due to averting biodegradable matter from lagoon storage.

9. Compost-Bedded Pack Barns

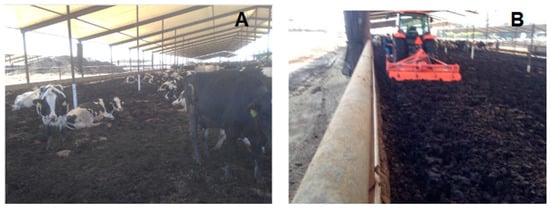

Compost-bedded pack barns are a housing system for dairy cows that have been recently introduced to California (Figure 5A). Barberg et al. [46] described compost dairy barns in Minnesota and barn management practices employed. The barns can increase cows’ comfort by providing cows with an open bedded pack area for resting and exercise. Bedding materials are usually needed and mixed with excreted manure and urine. The best bedding materials for the compost-bedded pack barns should have good physical structure, good water absorption capacity, less than 25% initial moisture, and less than 2.5 cm long [47]. Shane et al. [47] described different bedding materials used in compost-bedded pack barns including pine sawdust, corn cobs, pine woodchip fines, and soybean straw. Each of these materials can be used individually or mixed with other materials. The authors found that sawdust was the preferred choice of material to use as bedding in compost barns. It was concluded that with proper bedding management, any of the tested materials as bedding materials would work in compost-bedded pack barns. In California, straw, dried manure, or nut shells are usually employed.

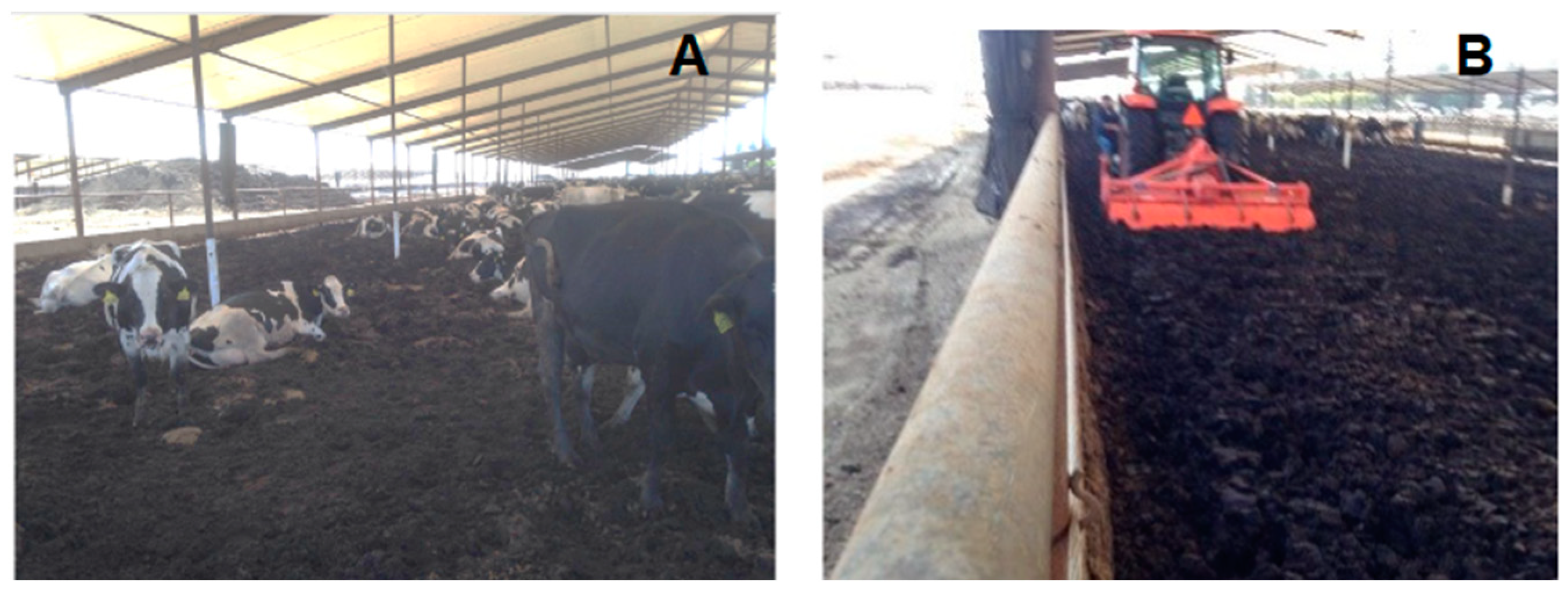

Figure 5.

Cows in compost-bedded pack barn (A), and rotary tiller agitating bedding materials in a compost-bedded pack barn (B).

Bedding can accumulate in the pack up to 1.2 m deep [47]. The bedding is usually tilled using a cultivator, chisel plow, or rotary tiller (Figure 5B). The depth of tilling is usually approximately 25 cm. The bedding should be properly managed to promote microbial activity. The number of daily turnings ranges from one to three depending on the weather conditions, type of bedding, area available for each cow in the barn, and farm management. Stirring and ventilation is usually applied to keep the pack surface dry [47]. Animal walking and laying may compact the manure surface and reduce air (e.g., oxygen) exchange with manure so that the rate of manure decomposition is reduced. Black et al. [48] surveyed 42 farms in Kentucky that were applying compost-bedded pack barns to characterize herd performance, describe system management and operation, herd performance, and satisfaction of producers. The system benefits included cow comfort and cleanliness and the low maintenance requirements (e.g., no daily manure removal is needed). Pack temperatures, measured at 20.3 cm, increased with an increase in stirring frequency, stirring depth, and ambient temperature. Compost-bedded barns had lower investment than freestall housing systems. However, their variable costs (e.g., bedding costs) may be higher. For data collected from eight bedded pack barns in Kentucky dairies, Eckelkamp [49] found that the compost internal temperature increased and compost moisture content decreased with an increased maximum barn temperature. The herd hygiene score decreased with increasing barn temperature and compost moisture content. The growth of staphylococci, streptococci, and bacilli decreased with the increase of compost internal temperature while the growth of coliform species increased. Although the compost-bedded pack barns could potentially increase the risk of poor cow hygiene, properly managed CBP can provide a health-promoting, dry, and comfortable surface for cows [50].

10. Emissions from Compost-Bedded Pack Barns

In compost-bedded pack barns, aerobic and anaerobic conditions within the manure pack can lead to emissions of CH4 and N2O depending on manure management in barns [51]. Ayadi et al. [52] measured the GHG and NH3 emissions at surfaces of simulated beef cattle bedded manure packs using corn stover or soybean stubble as bedding. Results showed that NH3, CO2, CH4, and N2O concentrations increased with increasing storage temperature. Nitrous oxide and NH3 concentrations were similar across bedded manure pack ages while CH4 concentration doubled with an increased age of the pack.

In the Netherlands, Van Dooren et al. [53] found that emissions of CH4 from a wood chip bedded barn were 82.1 mg/m2/h (9.0 kg/animal/year) while they ranged from 165.8–186.7 mg/m2/h (13.8–36.0 kg/animal/year) for the barns bedded with compost. However, methane emissions ranged from 6% to 25% of the reference system that was slurry storage in a pit underneath the floor. For the wood chip bedding, temperatures at depths of 20–40 cm were higher than those of the compost-bedded barns. The temperature of the former reached a maximum of 50 °C, while in the latter it was less than 25 °C. NH3 emissions from the woodchip-bedded barn were 190.4 mg/m2/h (20.87 kg/animal/year) and from a compost-bedded barn, ranged from 320.1 to 754 mg/m2/h (26.64 to 145.39 kg/animal/year). Emissions of N2O from the woodchip-bedded barn were 7.3 mg/m2/h while they ranged from 10.3 to 33.4 mg/m2/h for the barns bedded with compost. These emissions values were 3.5 to 25 times higher than that of the reference system. Wolf [54] measured the emissions of N2O, CH4, and CO2 from a compost-bedded pack barn at the University of Kentucky Coldstream Dairy using sawdust as bedding material. Emissions were high directly after tillage and stabilized with time. The emission rates of CH4 were 0.21, 0.013, and 0.082 g/m2/h, respectively at 20, 40, and 60 min after tillage. The emissions of CO2 were 100.2, 24.1, 26.4 g/m2/h, respectively. The emissions of N2O were 0.0031 g/m2/h at 20 min after tillage and negligible thereafter. The higher emissions after tillage could indicate that the gases were entrapped in the solids and once the solids were agitated by tillage, they were emitted. No information was given for the allocated area for each cow to determine the emission rate per cow. Külling et al. [55] mentioned that an addition of straw to dairy slurry decreased NH3 emission and increased N2O emission. It was found that NH3 emissions were positively related to the crude protein content of the diet. Similarly, Gilhespy et al. [56] found that increasing straw in bedding of cattle and pig farms decreased the emissions of NH3. Galama et al. [57] measured the emissions of NH3, N2O, and CH4 from six bedded pack barns in the Netherlands. Wood chips, green waste compost, and straw were used as bedding materials. The average emissions of NH3 from the bedding were 237.9, 324.1, 503.3 mg/m2/h (3224, 6396, and 5033 mg/animal/h) for wood chips, compost, and straw bedding, respectively. The emissions of N2O were 8 to 16 times higher than that from the reference systems that were free stall barns with cubicles and slatted concrete floors with slurry storage underneath. The emissions of N2O from the beddings ranged from 1.4 to 41.1 mg/m2/h. Methane emissions were considerably lower than that from the reference system. The emissions of CH4 from the beddings ranged from 6.1 to 1795.9 mg/m2/h. This wide range of emission rates per square meter depended on the allocated area for each cow that ranged from 8.7 to 22.0 m2 per cow, respectively for the low and high emission rates. The higher emissions of N2O and lower emissions of CH4 in the compost-bedded bedded pack than the reference systems may be attributed to the presence of air (i.e., oxygen) that penetrates the bedded pack. This could increase the rates of nitrification and denitrification and decrease the rate of methanogenesis.

In addition to measuring the gaseous emissions of barns, modeling could be used to predict them. Ayadi [58] developed a mathematical model for the simulated N2O and NH3 emissions from compost-bedded pack barns on beef farms. The model was developed based on the Integrated Farm Systems Model (IFSM) that was developed and described by Rotz et al. [59]. The model for NH3 emissions included degradation of urea in the urine in the bedding and mass transfer of NH3 from the bedding surface. Nitrous oxide was predicted based on denitrification losses.

In the USDA Dairy Gas Emissions Model (DairyGem) that was developed by Rotz et al. [60], methane emissions from bedded pack were modeled using the tier 2 approach of the IPCC [61] in which emissions on a given day were determined as a function of the ambient barn temperature and a CH4 conversion factor. The prediction of N2O emissions involved processes including mineralization, nitrification and denitrification, and leaching. The mineralization rate of manure organic N was modeled as a function of temperature, moisture content and a mineralization rate coefficient. Ammonium in manure is nitrified to nitrate which can undergo leaching that was modeled based on the Nitrate Leaching and Economic Analysis Package model [62]. Modeling of nitrification, denitrification and leaching processes was carried out based on relationships from the DAYCENT model [63,64]. The temperature model for bedded pack barns was adapted from Cekmecelioglu et al. [65].

11. Other Technologies for Manure Management

There are several other technologies for manure management that are not common in California. They include aeration, centrifugation, and forced hot air drying. Aeration can be applied to reduce the emissions of methane from lagoons as well as the biological oxygen demand of the manure. It stabilizes organic materials by using facultative and aerobic microorganisms to perform biological conversion processes. Table 3 shows different biological processes under different dissolved oxygen concentrations (i.e., oxidation/reduction potential). Increasing dissolved oxygen concentrations, by aeration, in manure lagoons can inhibit methanogens, which are obligate anaerobes and are killed when exposed to air. Methanogenesis can proceed well at low Oxidation Reduction Potentials (ROP) [66,67]. This results in the reduction of methane emissions. The aeration can degrade the organic matter into carbon dioxide, water, ammonium (or nitrate), and phosphate, with a small accompanying amount of cell growth.

Table 3.

Different biochemical processes under different concentrations of dissolved oxygen (DO), and redox potential [67,68].

Centrifugation can be very effective for the separation of fine particles. However, the high capital cost and energy requirement have hindered the applications of centrifuges on dairy farms [7]. Currently, our research team is evaluating the demonstration of a centrifugation system on a Californian dairy farm.

Static piling and sun drying are common practices in Californian dairy farms to produce bedding materials. Forced hot-air dryers operated with natural gas can be used for drying scraped manure. They can achieve high drying rates throughout the year with a much smaller areal footprint compared to solar drying options [7]. Solar drying has some limitations, such as large areas and labor requirement, and increased emissions of N2O [20]. Prenafeta-Boldú et al. [69] studied the solar drying of pig slurry in a pilot scale greenhouse with forced ventilation under Mediterranean conditions. The greenhouse was equipped with a biofilter for the treatment of emitted gases. Low concentrations of ammonia were detected at the greenhouse exhaust/biofilter inlet (0.5–1.0 mg NH3-N m−3). The concentrations in the biofilter outlet were below the detection level of the sensor used. The concentrations of CH4 and N2O at the biofilter inlet and outlet were not significantly different from those present in the background air. Forced air drying is costly and may not be applicable in dairies with limited accesses to natural gas. Dairies with anaerobic digesters or located in the vicinity of anaerobic digesters can use biogas for operation, but biogas has greater value for other uses. To our knowledge, no dairies in California have applied forced hot-air drying.

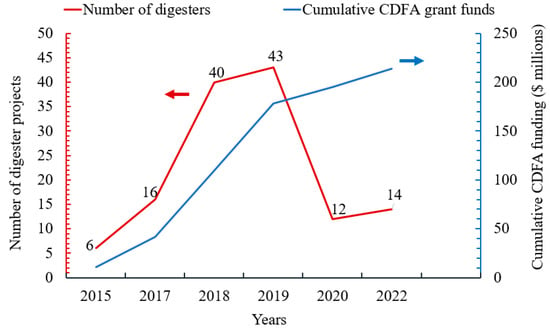

12. Status of the DDRDP

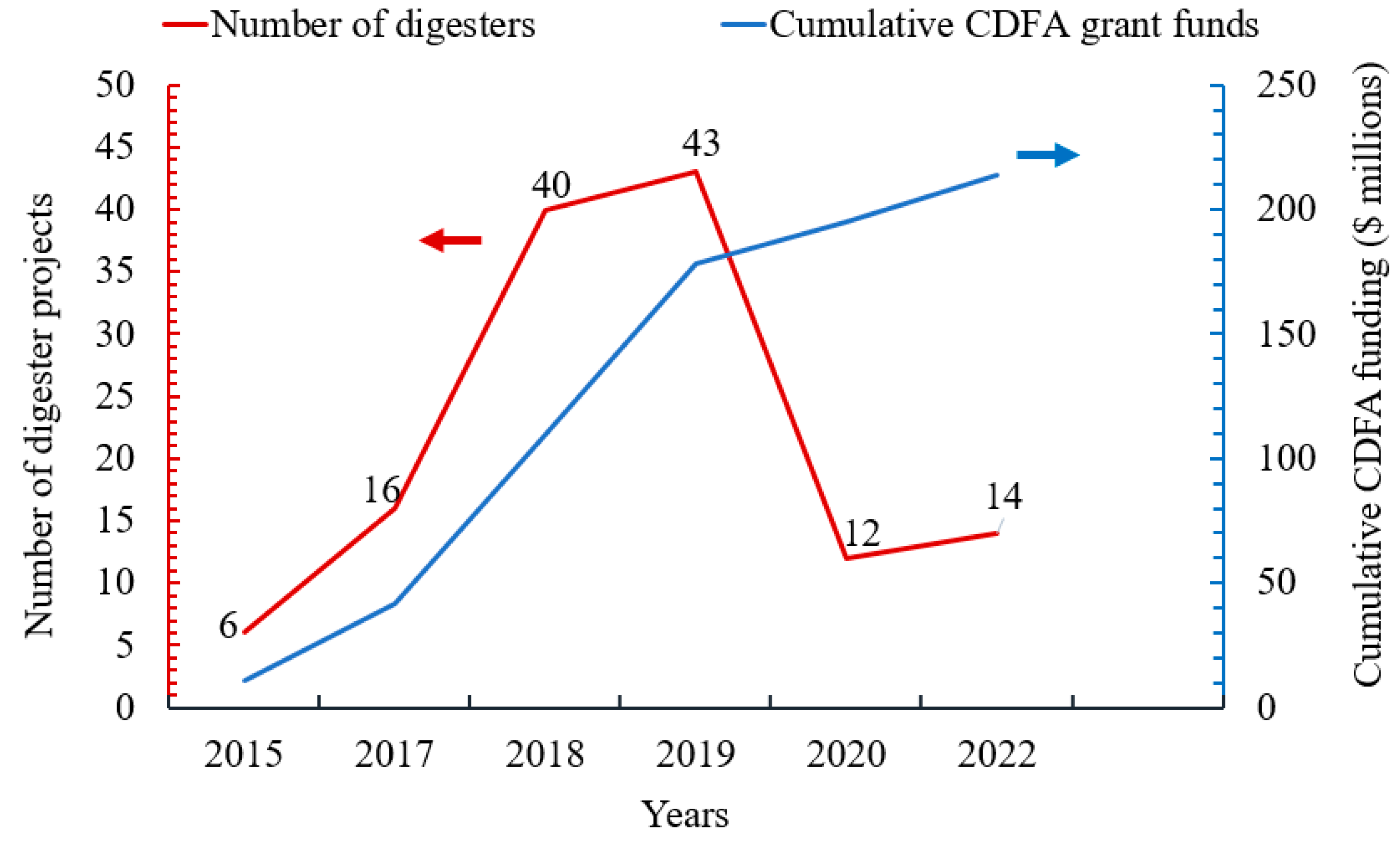

The Dairy Digester Research and Development Program (DDRDP) was established in 2015. The program awards competitive grants that partially fund anaerobic digesters in Californian dairies to minimize the emissions of CH4 from manure management and reduce its negative environmental impacts [4]. Figure 6 shows the number of digester projects and the funding from 2015–2020. From 2105 through 2022, 131 dairy digesters were funded with a total of $213.7 million and are expected to reduce 22,955,633 MTCO2e over 10 years, or 2,295,563 MTCO2e per year for at least 10 years, which is the expected minimum life of a DDRDP project. According to CDFA [4], by the end of 2022, the application of DDRDP and AMMP accounted for 2.55 MMTCO2e that represents approximately 28% of the 9.0 MMTCO2e that needs to be reduced by 2030. Aggregating the emissions reductions expected from all 233 state-funded projects yields an estimated 25,557,283 MTCO2e for at least 5 years, or 2,555,728 MTCO2e per year for at least 5 years, which is the expected minimum life of an AMMP project.

Figure 6.

Number of digester projects and total funding for the DDRDP [4].

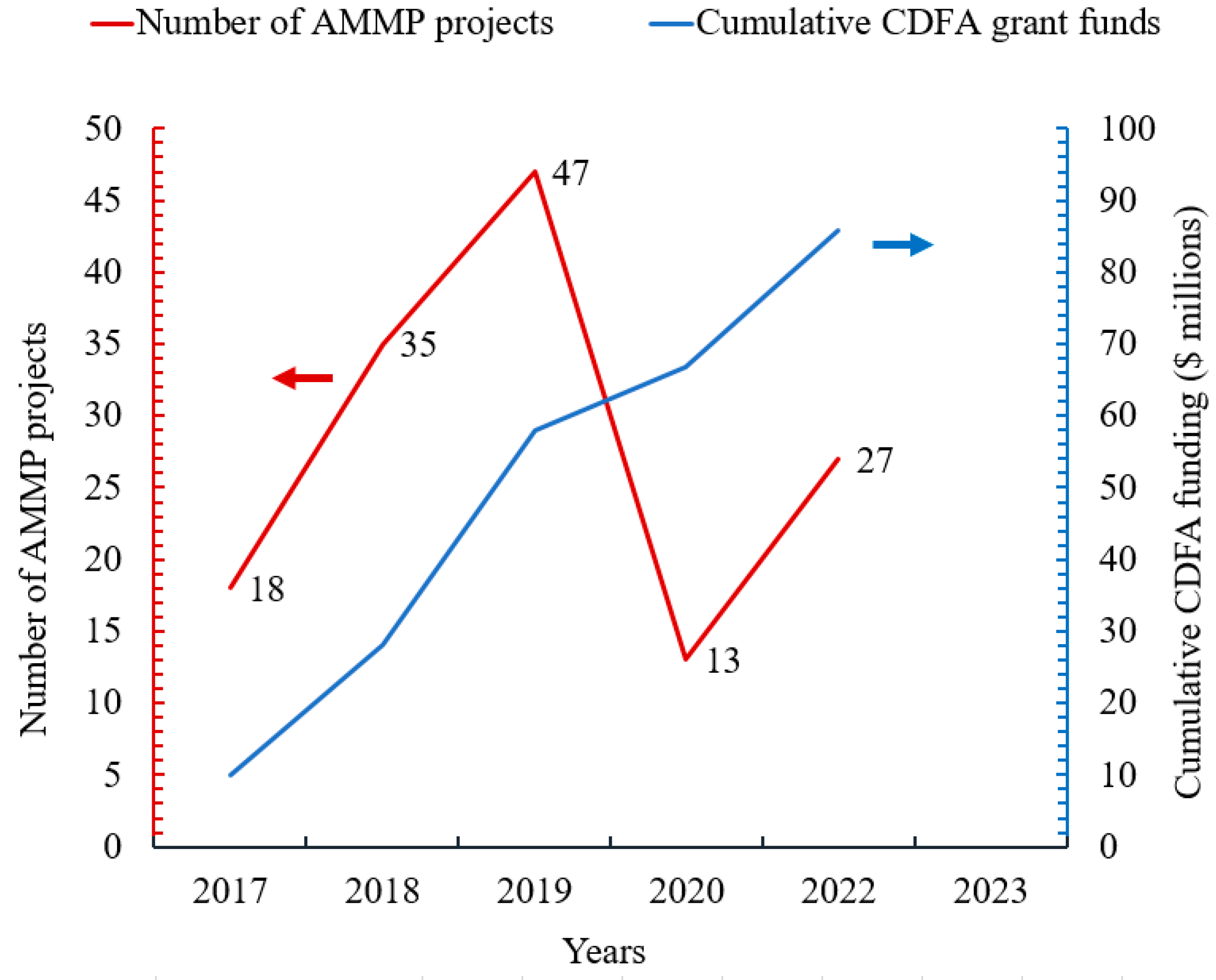

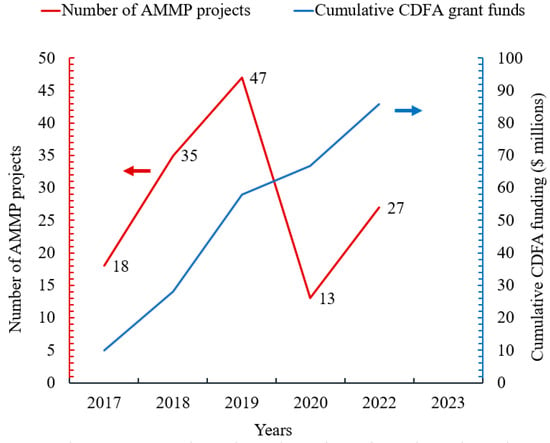

13. Status of the AMMP

The Alternative Manure Management Program (AMMP) was established in 2017 to award competitive grants to fund dairy farmers to install alternative technologies, to anaerobic digesters, for manure management. In the last five years, 140 projects have received funding with a total of $85.7 million (Figure 7). The estimated reduction of CH4 using these technologies over 5 years was 1,300,822 MTCO2e or 260,165 MTCO2e per year.

Figure 7.

Number of digester projects and total funding for the AMMP.

14. Economics of Anaerobic Digestion and Alternative Manure Management Practices

A 2016 report modeled the economics of various anaerobic digestion and alternative manure management options for Californian dairy farms [7]. Specific scenarios investigated included: (1) Upgrading lagoons with additional lining and cover materials and flaring the biogas, (2) anaerobic digestion with energy recovery, (3) partially converting flush systems to scrape systems and employing drying or composting practices, (4) increasing solids/liquid separation before flush lagoon storages, and (5) lagoon aeration. Several sub-scenarios were investigated for each category and cost and mitigation potentials were developed based on assumed “model” dairies ranging in size from 300 to 10,000 milking cows with flushing of about 60% of adult cow manure to lagoon storage prior to mitigation. Costs were then integrated with a statewide dairy size database to approximate “mitigation cost supply curves”, or otherwise summed to estimate industry-wide mitigation and total 10-year treatment costs. Mitigation potentials ranged from 1.2 to 8.3 Tg CO2e/y if applied to essentially the full industry and from 0.6 to 4.1 Tg CO2e/y for treatment at the 225 largest dairies. Average mitigation costs ranged from $44 to $290 per Mg CO2e mitigated (2022 USD) among scenarios for the full industry treatment case and $36 to $229 per Mg CO2e for the largest 225 dairies (Table 4). Scenarios with the lowest average mitigation costs included upgrading the lagoon to cover-and-flare, aeration, and installing a lagoon digester with a reciprocating engine for energy recovery. While upgrading of biogas to renewable natural gas (RNG) for pipeline injection or use as a vehicle fuel was among the higher-cost digester options due to the additional equipment needed, this practice is currently popular among new dairy manure digesters in California due mainly to the value of LCFS and/or RFS credits, as outlined earlier, and corresponds to 92% of state-funded projects. Development over time since the 2015 report has resulted in the creation of an alternative AD model, not evaluated at that time. Centralized gas conditioning facilities have been created, supplied by clusters of dairies with covered lagoon digesters that pipe raw biogas to the facility. The facility then conditions and injects or otherwise markets the renewable natural gas produced. The highest mitigation cost scenarios included conversion to scrape management with covered solar drying or forced drying using natural gas, or composting where costs for requisite bulking agents dominate. The authors noted that water and air impacts are significant for each scenario and further research and analyses are warranted to improve confidence in the indicated results.

Table 4.

Scenario summary: mitigation potential and 10-year cost [7].

15. Conclusions, Future Perspectives and Research Need

The increased interest in reducing the emissions of methane and other GHGs necessitates the increase in adoption of different technologies for manure management. Although there are many technologies available in the market, several factors affect the adoption of these technologies, including the energy consumption and cost, ease of operation and monitoring, maintenance costs, quality and market value of products recovered from these technologies; policies and incentives affecting the income from manure management (e.g., LCFS, DDRDP, and AMMP). There are many mature manure management technologies, but there is still a research need to assist dairy farmers to increase the lifespan of these technologies (e.g., by decreasing wear and abrasion of equipment) and decreasing the operation and maintenance costs. It is also imperative to develop cost-effective technologies to remove sand prior to mechanical separation. These technologies are important to increase the efficiency of mechanical separators, reduce screen wear, and reduce sand accumulation in lagoons. There is a need for better determination of methane conversion factors associated with different-sized solids separated using different manure separation technologies. These will help in the better estimation of emission reduction [7]. The cost of constructing and maintaining compost-bedded pack barns needs to be studied with respect to its allocation between their intended purposes as an animal housing and emission mitigation technology. Feedstocks needed for bedding may be an issue. Overall, long-term monitoring of emissions, in different seasons, from different manure streams (e.g., liquid stream and separated solids) on dairy farms after application of different manure management technologies is needed. More research is needed on the fate of inorganic and non-digestible materials fed to the lagoon digesters. Simple and cost-effective technologies to increase manure biodegradability and create valuable products from digested manure need to be developed and evaluated at farm scale systems.

Research is needed to measure the emissions of methane and other gases from barn floors after the application of vacuum trucks. The effect of partially flushing the barns, after using the vacuum trucks, on the emissions needs to be studied. All types of emissions from weeping walls need to be determined under different dairy conditions. These may include the measurements of the emissions at different phases of the operation of the weeping walls (e.g., filling, storage, and emptying). Research is also needed on the modeling of the emissions from treated manure with different technologies. There is a need to study the agronomic value of digestate, lagoon solids, and novel manure products resulting from advanced treatments like centrifuges and nutrient recovery technologies with respect to availability of nutrients in the digestate and needs of different plants in different soil types.

Mitloehner et al. [68] asserted that there were insufficient peer-reviewed publications documenting aeration performance to support claims that aerators generate the level of oxygenation necessary to achieve appreciable improvements in air quality. There is still a need for research to: evaluate the ORP and dissolved oxygen in dairy lagoons and settling basins for different aerators; determine the emissions of methane and other gases emissions from dairy lagoon under different ORP and dissolved oxygen levels; and determine the economics of applying aeration as a means of mitigation of non-methane GHGs. The economics of aeration need to be studied with respect to the energy consumption and the use of renewable energy sources that could be generated on dairy farms, such as solar and biogas electricity. Longer-term measurements of the emissions of the fugitive gases from aerated lagoons and their effects on air and water contamination are needed [7].

Costs for anaerobic digesters and alternative manure management technologies need to be calculated and compared with respect to incentives for GHG mitigation. This would support policy development and implementation that helps more dairies to adopt anaerobic digesters and AMMP technologies. Developing cost-effective technologies for treating digester effluents and undigested manure to produce easily transferable fertilizers and soil amendments with a high concentration of nutrients, especially nitrogen, which is usually lost during composting and sun-drying, is needed (common technologies employed on dairies).

Author Contributions

Conceptualization, H.M.E.M., F.M., R.Z. and S.K.; methodology H.M.E.M., T.J.B., R.B.F., R.Z.; S.K. and F.M.; validation, R.Z., S.K. and F.M.; formal analysis, H.M.E.M., T.J.B., R.B.F., R.Z., S.K. and F.M.; investigation, H.M.E.M., T.J.B., R.Z., S.K. and F.M.; data curation, H.M.E.M., T.J.B., R.B.F., R.Z., S.K. and F.M.; writing—original draft preparation, H.M.E.M. and T.J.B.; writing—review and editing, H.M.E.M., T.J.B., R.B.F., R.Z., S.K. and F.M.; visualization, H.M.E.M., T.J.B. and R.B.F. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- CDFA. Agricultural Statistics Review. 2019. Available online: https://www.cdfa.ca.gov/statistics/PDFs/2018-2019AgReportnass.pdf (accessed on 10 February 2021).

- CDFA. California Dairy Statistics Annual 2017 Data. 2018. Available online: https://www.cdfa.ca.gov/dairy/pdf/Annual/2017/2017_Statistics%20Annual.pdf (accessed on 27 September 2018).

- CARB. Greenhouse Gas Emissions Inventory Summary [2000–2020]. 2022. Available online: https://ww2.arb.ca.gov/applications/greenhouse-gas-emission-inventory-0 (accessed on 9 November 2022).

- CDFA. Report of Funded Projects (2015–2022). Available online: https://www.cdfa.ca.gov/oefi/ddrdp/docs/2022_DDRDP_Legislative_Report.pdf (accessed on 3 October 2022).

- CDFA. 2022. Available online: https://www.cdfa.ca.gov/oefi/AMMP/ (accessed on 20 October 2022).

- Meyer, D.; Price, P.L.; Rossow, H.A.; Silva-del-Rio, N.; Karle, B.M.; Robinson, P.H.; DePeters, E.J.; Fadel, J.G. Survey of dairy housing and manure management practices in California. J. Dairy Sci. 2011, 94, 4744–4750. [Google Scholar] [CrossRef] [PubMed]

- Kaffka, S.; Barzee, T.; El-Mashad, H.; Williams, R.; Zicari, S.; Zhang, R. Evaluation of Dairy Manure Management Practices for Greenhouse Gas Emissions Mitigation in California, 2016. Final Technical Report to the State of California Air Resources Board. Available online: https://biomass.ucdavis.edu/wp-content/uploads/ARB-Report-Final-Draft-Transmittal-Feb-26-2016.pdf (accessed on 30 October 2022).

- Ross, E.G.; Peterson, C.B.; Zhao, Y.; Pan, Y.; Mitloehner, F.M. Manure Flushing vs. Scraping in Dairy Freestall Lanes Reduces Gaseous Emissions. Sustainability 2021, 13, 5363. [Google Scholar] [CrossRef]

- Niles, M.T.; Wiltshire, S.; Lombard, J.; Branan, M.; Vuolo, M.; Chintala, R.; Tricarico, J. Manure management strategies are interconnected with complexity across U.S. dairy farms. PLoS ONE 2022, 17, e0267731. [Google Scholar] [CrossRef] [PubMed]

- El Mashad, H.M.; Zhang, R. Biogas Energy from Organic Wastes. In The Introduction to Biosystems Engineering Textbook; ASABE: St. Joseph, MI, USA, 2020. [Google Scholar]

- Lettinga, G.; Rebac, S.; Zeeman, G. Challenge of psychrophilic anaerobic wastewater treatment. Trends Biotechnol. 2001, 19, 363–370. [Google Scholar] [CrossRef]

- El-Mashad, H.M.; Zhang, R. Co-digestion of food waste and dairy manure for biogas production. Trans. ASABE 2007, 50, 1815–1821. [Google Scholar] [CrossRef]

- AcMoody, A.; Sousa, P. Interest in California Dairy Manure Methane Digesters Follows the Money. Available online: https://www.cobank.com/documents/7714906/7715329/Interest-in-California-Dairy-Manure-Methane-Digesters-Follows-the-Money-Aug2020.pdf/be11d7d6-80df-7a7e-0cbd-9f4ebe730b25?t=1603745079998 (accessed on 20 October 2022).

- Angelidaki, I.; Ellegaard, L. Co-digestion of manure and organic wastes in centralized biogas plants. Appl. Biochem. Biotech. 2003, 109, 95–105. [Google Scholar] [CrossRef]

- BioCycle. Crystal Creamery Anaerobic Digester Partnership Honored. 2017. Available online: https://www.biocycle.net/anaerobic-digest-71/ (accessed on 10 November 2022).

- California Environmental Associates. Greenhouse Gas Mitigation Strategies for California Dairies. 2015. Available online: https://www.ceaconsulting.com/wp-content/uploads/GHG_Mitigation_for_Dairies_Final_July2015.pdf (accessed on 10 October 2022).

- EPA. Technical Support Document for Manure Management Systems: Proposed Rule for Mandatory Reporting of Greenhouse Gases 2009; Climate Change Division Office of Atmospheric Programs U.S. Environmental Protection Agency: Washington, DC, USA, 2009.

- EPA. AgSTAR Digest, 2000. EPA-430/F-00-012. Available online: http://www.epa.gov/agstar (accessed on 11 November 2022).

- Flesch, T.K.; Desjardins, R.L.; Worth, D. Fugitive methane emissions from an agricultural biodigester. Biomass Bioenergy 2011, 35, 3927–3935. [Google Scholar] [CrossRef]

- Baldé, H.; Wagner-Riddle, C.; MacDonald, D.; VanderZaag, A. Fugitive methane emissions from two agricultural biogas plants. Waste Manag. 2022, 151, 123–130. [Google Scholar] [CrossRef]

- Holly, M.A.; Larson, R.A.; Powell, J.M.; Ruark, M.D.; Aguirre-Villegas, H. Greenhouse gas and ammonia emissions from digested and separated dairy manure during storage and after land application. Agric. Ecosyst. Environ. 2017, 239, 410–419. [Google Scholar] [CrossRef]

- CARB. California Department of Food and Agriculture Alternative Manure Management Program. 2022. Available online: https://ww2.arb.ca.gov/sites/default/files/auction-proceeds/cdfa_ammp_finalqm_3-10-22.pdf (accessed on 20 October 2022).

- CARB. California Department of Food and Agriculture Dairy Digester Research and Development Program. 2020. Available online: https://ww2.arb.ca.gov/sites/default/files/auction-proceeds/cdfa_ddrdp_finalqm_2-3-20.pdf (accessed on 3 October 2022).

- Vergote, T.L.I.; Bodé, S.; De Dobbelaere, A.E.J.; Buysse, J.; Meers, E.; Volcke, E.I.P. Monitoring methane and nitrous oxide emissions from digestate storage following manure mono-digestion. Biosys. Eng. 2020, 196, 159–171. [Google Scholar] [CrossRef]

- Zhang, R.H.; Westerman, P.W. Solid-liquid separation of animal manure for odor control and nutrients management. Trans. ASABE 1997, 13, 657–664. [Google Scholar]

- Hegg, R.O.; Larson, R.E.; Moore, J.A. Mechanical liquid-solid separation in beef, dairy, and swine waste slurries. Trans. ASAE 1981, 24, 159–163. [Google Scholar] [CrossRef]

- Graves, R.E.; Clayton, J.T.; Light, R.G. Renovation and Reuse of Water for Dilution and Hydraulic Transport of Dairy Cattle Manure (PROC-271); ASAE: St. Joseph, MI, USA, 1971. [Google Scholar]

- Chastain, J.P.; Vanotti, M.B.; Wingfield, M.M. Effectiveness of liquid-solid separation for treatment of flushed dairy manure: A case study. Trans. ASAE 2001, 17, 343–354. [Google Scholar] [CrossRef]

- Hills, D.J.; Kayhanian, M. Methane from settled and filtered flushed dairy wastes. Trans. ASAE 1985, 28, 865–869. [Google Scholar] [CrossRef]

- Amon, B.; Kryvoruchko, V.; Amon, T.; Zechmeister-Boltenstern, S. Methane, nitrous oxide and ammonia emissions during storage and after application of dairy cattle slurry and influence of slurry treatment. Agric. Ecosyst. Environ. 2006, 112, 153–162. [Google Scholar] [CrossRef]

- Rico, J.L.; García, H.; Rico, C.; Tejero, I. Characterization of solid and liquid fractions of dairy manure with regard to their component distribution and methane production. Biores. Tech. 2007, 98, 971–997. [Google Scholar] [CrossRef]

- El Mashad, H.M.; Zhang, R. Biogas production from co-digestion of dairy manure and food waste. Biores. Tech. 2010, 101, 4021–4028. [Google Scholar] [CrossRef]

- Witarsa, F.; Lansing, S. Quantifying methane production from psychrophilic anaerobic digestion of separated and unseparated dairy manure. Ecol. Eng. 2015, 78, 95–100. [Google Scholar] [CrossRef]

- Edalati, A.; Chen, Y.; Barzee, T.J.; El-Mashad, H.M.; Zhang, R. Effect of mechanical solids separators on the mitigation of methane emissions from dairy manure lagoons. Submitt. Trans. ASABE 2022. [Google Scholar]

- Williams, R.; El-Mashad, H.; Kaffka, S. Research and Technical Analysis to Support and Improve the Alternative Manure Management Program Quantification Methodology. Research Report CARB Agreement No. 17TTD010. Available online: https://ww2.arb.ca.gov/sites/default/files/auction-proceeds/ucd_ammp_qm_analysis_final_april2020.pdf (accessed on 13 October 2020).

- Bai, M.; Flesch, T.; Trouvé, R.; Coates, T.; Butterly, C.; Bhatta, B.; Hill, J.; Chen, D. Gas emissions during cattle manure composting and stockpiling. J. Environ. Qual. 2020, 49, 228–235. [Google Scholar] [CrossRef] [PubMed]

- Vergara, S.E.; Silver, W.L. Greenhouse gas emissions from windrow composting of organic wastes: Patterns and emissions factors. Environ. Res. Lett. 2019, 14, 124027. [Google Scholar] [CrossRef]

- Meyer, D.; Harner, J.P.; Tooman, E.E.; Collar, C. Evaluation of weeping wall efficiency of solid liquid separation. Appl. Eng. Agric. 2004, 20, 349–354. [Google Scholar] [CrossRef]

- Mukhtar, S.; Borhan, M.S.; Beseda, J., II. Evaluation of a weeping wall solid-liquid separation system for flushed dairy manure. Appl. Eng. Agric. 2011, 27, 135–142. [Google Scholar] [CrossRef]

- Sustainable Conservation. Capturing Nutrients in Dairy Manure: Innovative Solid-Liquid Separation Systems. In Cost-Effective and Environmentally Beneficial Dairy Manure Management Practices; Hughes, K., Wilkie, A.C., Eds.; USDA: San Francisco, CA, USA, 2005; Available online: https://www.suscon.org/pdfs/dairies/pdfs/NDESCreportCostEffective.pdf (accessed on 4 September 2009).

- Nooyen. Tri-Bars, 2018. Available online: http://www.nooyenky.com (accessed on 9 July 2018).

- Houlbrooke, D.; Longhurst, B.; Orchiston, T.; Muirhead, R. Characterizing Dairy Manures and Slurries. Envirolink Tools Report AGRX0901; 2011. Available online: https://www.envirolink.govt.nz/assets/Envirolink/R5-4-Characterising-Dairy-Manures-and-Slurries.pdf (accessed on 3 January 2022).

- Laubach, J.; Heubeck, S.; Pratt, C.; Woodward, K.B.; Guieysse, B.; van der Weerden, T.J.; Chung, M.L.; Shilton, N.A.; Craggs, R.J. Review of greenhouse gas emissions from the storage and land application of farm dairy effluent. N. Zealand J. Agric. Res. 2015, 58, 203–233. [Google Scholar] [CrossRef]

- NRCS. Waste Separation Facility—Conservation Practice Standard 632; Natural Resources Conservation Service: Washington, DC, USA, 2014. Available online: https://efotg.sc.egov.usda.gov/references/public/NY/nyps632.pdf (accessed on 3 October 2022).

- Edalati, A.; Chen, Y.; Barzee, T.J.; El-Mashad, H.M.; Zhang, R. Solid separation and methane emissions reduction from dairy manure using weeping walls. Unpublished data. 2022. [Google Scholar]

- Barberg, A.E.; Endres, M.I.; Janni, K.A. Compost dairy barns in Minnesota: A descriptive study. Appl. Eng. Agric. 2007, 23, 231–238. [Google Scholar] [CrossRef]

- Shane, E.M.; Endres, M.I.; Johnson, D.G.; Reneau, J.K. Bedding options for an alternative housing system for dairy cows: A descriptive study. Appl. Eng. Agric. 2010, 26, 659–666. [Google Scholar] [CrossRef]

- Black, R.A.; Taraba, J.L.; Day, G.B.; Damasceno, F.A.; Bewley, J.M. Compost bedded pack dairy barn management, performance, and producer satisfaction. J. Dairy Sci. 2013, 96, 8060–8074. [Google Scholar] [CrossRef]

- Eckelkamp, E.A.; Taraba, J.L.; Akers, K.A.; Harmon, R.J.; Bewley, J.M. Understanding compost bedded pack barns: Tractions among environmental factors, bedding characteristics, and udder health. Livest. Sci. 2016, 190, 35–42. [Google Scholar] [CrossRef]

- Leso, L.; Barbari, M.; Lopes, M.A.; Damasceno, F.A.; Galama, P.; Taraba, J.L.; Kuipers, A. Invited review: Compost-bedded pack barns for dairy cows. J. Dairy Sci. 2020, 103, 1072–1099. [Google Scholar] [CrossRef]

- Rotz, C.A. Modeling greenhouse gas emissions from dairy farms. J. Dairy Sci. 2018, 101, 6675–6690. [Google Scholar] [CrossRef]

- Ayadi, F.Y.; Cortus, E.L.; Spiehs, M.J.; Miller, D.N.; Djira, G.D. Ammonia and greenhouse gas concentrations at surfaces of sim-ulated beef cattle bedded manure packs. Trans. ASABE 2015, 58, 783–795. [Google Scholar]

- Van Dooren, H.J.C.; Galama, P.J.; Blanken, K. On Farm Development of Bedded Pack Dairy Barns in The Netherlands, Gaseous Emissions from Bedding. In Wageningen Livestock Research, Report 710; Wageningen Livestock Research: Wageningen, The Netherlands, 2016. [Google Scholar] [CrossRef]

- Wolf, K. A Portable Sensor for Measuring Gas Emissions from Dairy Compost Bedded Pack Barns. Master’s Thesis, University of Kentucky, Lexington, Kentucky, 2017. Available online: https://uknowledge.uky.edu/cgi/viewcontent.cgi?article=1053&context=bae_etds (accessed on 4 September 2022).

- Külling, D.R.; Menzi, H.; Kröber, T.F.; Neftel, A.; Sutter, F.; Lischer, P.; and Kreuzer, M. Emissions of ammonia, nitrous oxide and methane from different types of dairy manure during storage as affected by dietary protein content. J. Agric. Sci. 2001, 137, 235–250. [Google Scholar] [CrossRef]

- Gilhespy, S.L.; Webb, J.; Chadwick, D.R.; Misselbrook, T.H.; Kay, R.; Camp, V.; Retter, A.L.; Bason, A. Will additional straw bedding in buildings housing cattle and pigs reduce ammonia emissions? Biosyst. Eng. 2009, 102, 180–189. [Google Scholar] [CrossRef]

- Galama, P.J.; de Boer, H.C.; van Dooren, H.J.C.; Ouweltjes, W.; Driehuis, F. Sustainability Aspects of Ten Bedded Pack Dairy Barns in The Netherlands. Wageningen UR (University & Research Centre) Livestock Research, Livestock Research Report 873. 2015. Available online: https://edepot.wur.nl/350932 (accessed on 10 October 2022).

- Ayadi, F.Y. A Process-Based Nutrient Model for the Bedded Manure Pack of Confined Beef Systems. Ph.D. Thesis, South Dakota State University, Brookings, SD, USA, 2015. [Google Scholar]

- Rotz, C.A.; Corson, M.S.; Chianese, D.S.; Montes, F.; Hafner, S.D.; Bonifacio, F.B.; Coiner, C.U. The Integrated Farm System Model. Reference Manual Version 4.7. Available online: https://www.ars.usda.gov/ARSUserFiles/80700500/Reference%20Manual.pdf (accessed on 11 November 2022).

- Rotz, C.A.; Chianese, D.S.; Montes, F.; Hafner, S.; Bonifacio, H.F. Dairy Gas Emission Model, Reference Manual. 2016. Available online: https://www.ars.usda.gov/ARSUserFiles/80700500/dairygemreferencemanual.pdf (accessed on 23 October 2022).

- IPCC. Guidelines for National Greenhouse Inventories; Intergovernmental Panel on Climate Change: Geneva, Switzerland, 2006; Volume 3, p. 3.75. Available online: http://www.ipccnggip.iges.or.jp/public/2006gl/pdf/3_Volume3/V3_3_Ch3_Chemical_Industry.pdf (accessed on 24 November 2020).

- Shaffer, M.J.; Halvorson, A.D.; Pierce, F.J. Nitrate leaching and economic analysis packager (NLEAP): Model description and application. In Managing Nitrogen for Groundwater Quality and Farm Profitability; Follett, R.F., Deeney, D.R., Cruse, R.M., Eds.; Soil Science Society of America, Inc.: Madison, WI, USA, 1991; pp. 285–298. [Google Scholar]

- Natural Resource Ecology Laboratory, Colorado State University. DAYCENT. DAYCENT; Version 4.5; Natural Resource Ecology Laboratory, Colorado State University: Fort Collins, CO, USA, 2007. [Google Scholar]

- Bonifacio, H.F.; Rotz, C.A.; Leytem, A.B.; Waldrip, H.M.; Todd, R.W. Process-based modeling of ammonia and nitrous oxide emissions from open-lot beef and dairy facilities. Trans. ASABE 2015, 58, 827–846. [Google Scholar]

- Cekmecelioglu, D.; Heinemann, P.H.; Demirci, A.; Graves, R.E. Modeling of compost temperate and inactivation of Salmonella and E. Coli O157:H7 during windrow food waste composting. Trans. ASAE 2005, 48, 849–858. [Google Scholar] [CrossRef]

- Conrad, R. Control of methane production in terrestrial ecosystems. In Exchange of Trace Gases between Terrestrial Ecosystems and the Atmosphere; Andreae, M.O., Schimel, D.S., Eds.; Biddles Ltd.: Guildford, UK, 1989. [Google Scholar]

- Liu, X.; Yan, Z.; Yue, Z.B. Biogas. In Comprehensive Biotechnology, 2nd ed.; Moo-Young, M., Ed.; Academic Press: Cambridge, MA, USA, 2011. [Google Scholar]

- Mitloehner, F.M.; Marcillac, N.M.; Eslinger, K.M.; Schnitz, A.L.; Zhang, R.H. Effects of dairy liquid manure aeration on air quality and nutrient cycling. In Proceedings of the 43rd Annual Dairy Cattle Day, University of California Department of Animal Science Davis, Davis, CA, USA; 2004. [Google Scholar]

- Prenafeta-Boldú, F.X.; Fernández, B.; Viñas, M.; Noguerol, J.; Soler, J.; Illa, J. Combined Acidification and Solar Drying of Pig Slurries for Nutrient Recovery and Controlled Atmospheric Emissions. Agronomy 2021, 11, 222. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).