Crop Residue Burning and Its Relationship between Health, Agriculture Value Addition, and Regional Finance

Abstract

:1. Introduction

1.1. Why Focus on Crop Residue Management Practices?

1.2. Crop Residue Burning and Ambient Air Quality

1.3. Why Farmers Are Reluctant for Crop Residue’s Sustainable Use?

2. Materials and Methods

2.1. Data

- Group-1; Jharkhand, Tripura, Chhattisgarh, Puducherry, Assam, Bengal; Index value 0.9 to 0.5;

- Group-2; Orrisa, Bihar, Arunachal, Meghalaya, Manipur, Nagaland; Index value 0.5 to 0.4;

- Group-3; Punjab, Tamil, Andhra, Goa, Uttarakhand, Jammu; Index value 0.3 to 0.2;

- Group-4; Haryana, Delhi, Karnataka, Himachal, Kerala, Gujrat, Maharashtra, Rajasthan, Mizoram; Index value 0.2 to 0.01.

2.2. Empirical Model and Specification

2.3. Narrative Review

3. Results

3.1. Data Description

3.2. Simultaneous Equation Results

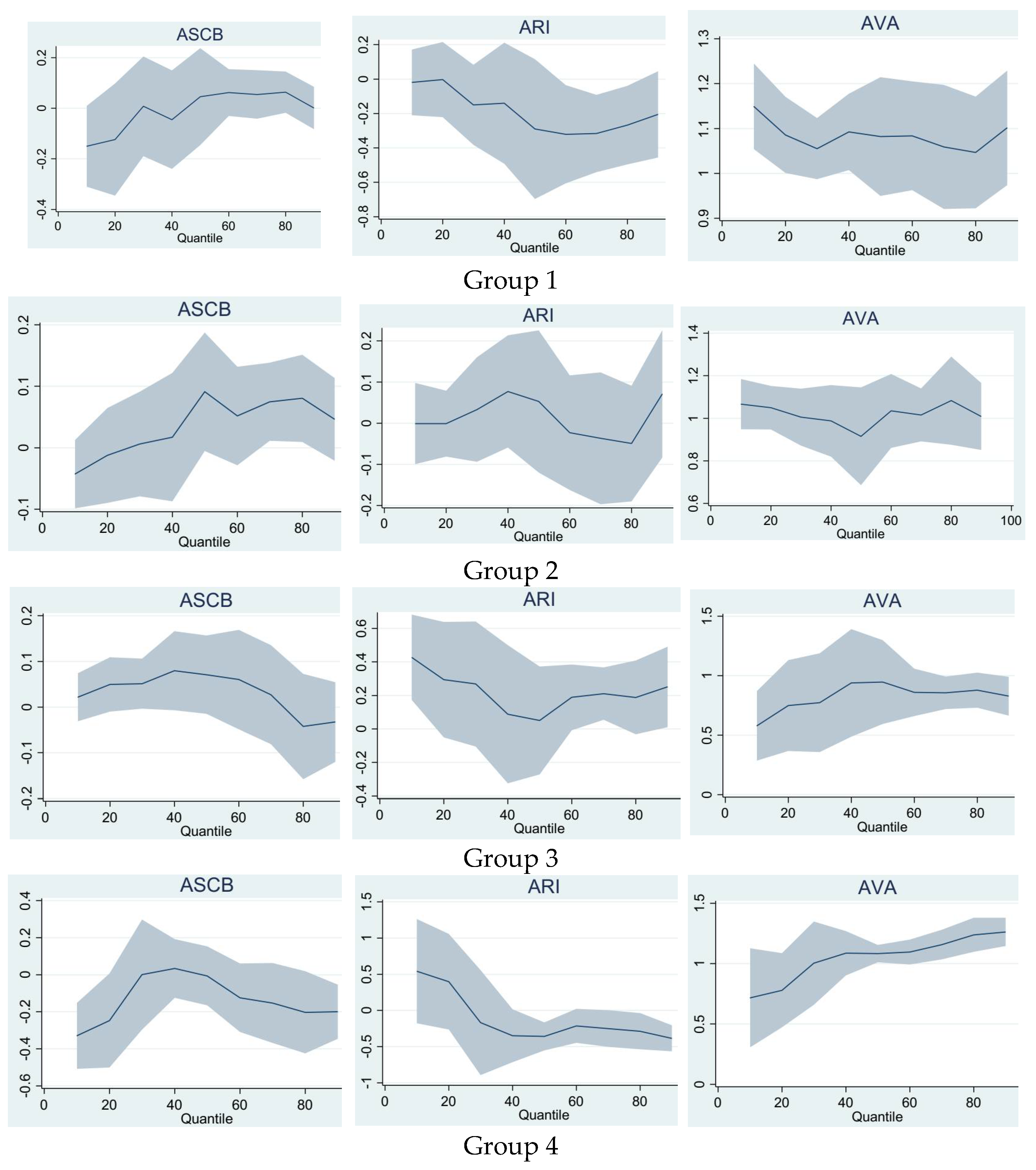

3.3. Direct Effect Estimations Based on Panel Quantile Regression

4. Discussion

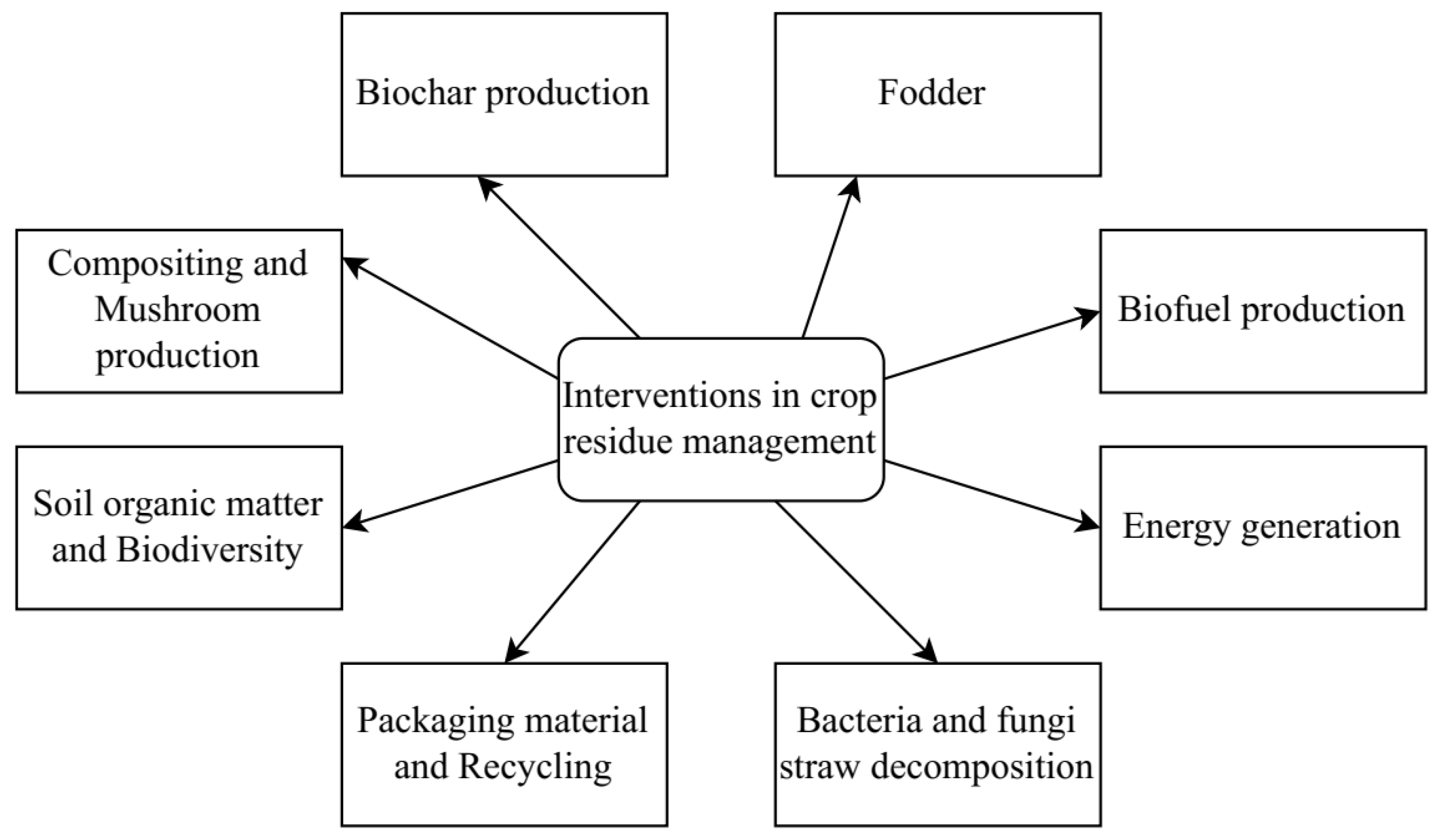

4.1. Crop Residue Management Practices

4.2. Some Other Scientific Solutions for Crop Residue

4.3. Current Policy Interventions to Minimize the Air Pollution

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- IBEF. Agriculture and Allied Industries. 2022. Available online: https://www.ibef.org/industry/agriculture-india (accessed on 30 July 2022).

- Dey, A.; Dinesh, R. Rice and wheat production in India: An overtime study on growth and instability. J. Pharmacogn. Phytochem. 2020, 9, 158–161. [Google Scholar]

- Nagaiah, K.; Srimannarayana, G.; Phaniraj, G. India’s Natural, Organic Farming Strategy for Rice and Wheat. Down to Earth. 15 March 2022. Available online: https://www.downtoearth.org.in/blog/agriculture/india-s-natural-organic-farming-strategy-for-rice-and-wheat-81961 (accessed on 30 July 2022).

- Kala, N. Visualizing Climate and Loss: Crop Residue Burning in India. Center for History and Economics, Harvard University. February 2021. Available online: https://histecon.fas.harvard.edu/climate-loss/crops/index.html (accessed on 31 May 2022).

- Mohanty, P. Rebooting Economy 40: Why Punjab Farmers Burn Stubble? Business Today. 26 October 2020. Available online: https://www.businesstoday.in/opinion/columns/story/indian-economy-agriculture-why-punjab-farmers-burn-stubble-crop-residue-paddy-burning-276782-2020-10-26 (accessed on 24 May 2022).

- Lin, M.; Begho, T. Crop residue burning in South Asia: A review of the scale, effect, and solutions with a focus on reducing reactive nitrogen losses. J. Environ. Manag. 2022, 314, 115104. [Google Scholar] [CrossRef] [PubMed]

- Saxena, P.; Sonwani, S.; Srivastava, A.; Jain, M.; Srivastava, A.; Bharti, A.; Rangra, D.; Mongia, N.; Tejan, S.; Bhardwaj, S. Impact of crop residue burning in Haryana on the air quality of Delhi, India. Heliyon 2021, 7, e06973. [Google Scholar] [CrossRef] [PubMed]

- Stegarescu, G.; Escuer-Gatius, J.; Soosaar, K.; Kauer, K.; Tõnutare, T.; Astover, A.; Reintam, E. Effect of crop residue decomposition on soil aggregate stability. Agriculture 2020, 10, 527. [Google Scholar] [CrossRef]

- Ravindra, K.; Singh, T.; Mor, S. Emissions of air pollutants from primary crop residue burning in India and their mitigation strategies for cleaner emissions. J. Clean. Prod. 2019, 208, 261–273. [Google Scholar] [CrossRef]

- Sehgal, M.; Krishnan, A.; Uttreja, M.; Lal, K. Does Air Quality from Crop Residue Burning in Close Proximity to Residential Areas Adversely Affect Respiratory Health? Study on Improvement & Management of the Air Quality in the Delhi-NCR Region. 2021. Available online: https://cpcb.nic.in/uploads/AQM/TERI_Brief_Report.pdf (accessed on 30 July 2022).

- Abdurrahman, M.I.; Chaki, S.; Saini, G. Stubble burning: Effects on health & environment, regulations and management practices. Environ. Adv. 2020, 2, 100011. [Google Scholar] [CrossRef]

- Balakrishnan, K.; Dey, S.; Gupta, T.; Dhaliwal, R.S.; Brauer, M.; Cohen, A.J.; Stanaway, J.D.; Beig, G.; Joshi, T.K.; Aggarwal, A.N.; et al. The impact of air pollution on deaths, disease burden, and life expectancy across the states of India: The Global Burden of Disease Study 2017. Lancet Planet. Health 2019, 3, e26–e39. [Google Scholar] [CrossRef]

- Nair, M.; Bherwani, H.; Kumar, S.; Gulia, S.; Goyal, S.; Kumar, R. Assessment of contribution of agricultural residue burning on air quality of Delhi using remote sensing and modelling tools. Atmos. Environ. 2020, 230, 117504. [Google Scholar] [CrossRef]

- Raza, M.H.; Abid, M.; Faisal, M.; Yan, T.; Akhtar, S.; Mehedi Adnan, K.M. Mehedi Adnan, Environmental and Health Impacts of Crop Residue Burning: Scope of Sustainable Crop Residue Management Practices. Int. J. Environ. Res. Public Health 2022, 19, 4753. [Google Scholar] [CrossRef]

- Ghosh, P.; Sharma, S.; Khanna, I. Scoping Study for South Asia Air Pollution. 2019. Available online: www.teriin.org (accessed on 30 July 2022).

- Amândio, M.S.T.; Pereira, J.M.; Rocha, J.M.S.; Serafim, L.S.; Xavier, A.M.R.B. Getting Value from Pulp and Paper Industry Wastes: On the Way to Sustainability and Circular Economy. Energies 2022, 15, 4105. [Google Scholar] [CrossRef]

- Gupta, P.K.; Sahai, S.; Singh, N.; Dixit, C.K.; Singh, D.P.; Sharma, C.; Tiwari, M.K.; Gupta, R.K.; Garg, S.C. Residue burning in rice-wheat cropping system: Causes and implications. Curr. Sci. 2004, 87, 1713–1717. [Google Scholar]

- Sharma, R.; Kumar, R.; Sharma, D.K.; Son, L.H.; Priyadarshini, I.; Pham, B.T.; Bui, D.T.; Rai, S. Inferring air pollution from air quality index by different geographical areas: Case study in India. Air Qual. Atmos. Health 2019, 12, 1347–1357. [Google Scholar] [CrossRef]

- IFPRI. Air Pollution from India’s Stubble Burning Leads to USD 35 Billion Economic Losses, Poses Significant Health Risk. South Asia IFPRI. 4 March 2019. Available online: https://www.ifpri.org/news-release/new-study-air-pollution-indias-stubble-burning-leads-usd-15-billion-economic-losses (accessed on 31 May 2022).

- Dey, S. Air pollution in India has caused losses of up to Rs 7 lakh crore annually. Down to Earth. 22 April 2022. Available online: https://www.downtoearth.org.in/blog/air/black-carbon-particles-contribute-to-increasing-covid-19-cases-78130 (accessed on 31 May 2022).

- IANS. Not Just on Health, Delhi Smog is Taking Toll on Economic Activity too. Deccan Herald. 9 November 2021. Available online: https://www.deccanherald.com/science-and-environment/not-just-on-health-delhi-smog-is-taking-toll-on-economic-activity-too-1048831.html (accessed on 31 May 2022).

- Garg, T.; Jagnani, M.; Pullabhotla, H.K. Agricultural Labor Exits Increase Crop Fires. 2021, 92093. Available online: https://www.terry.uga.edu/sites/default/files/inline-files/garg_2021.pdf (accessed on 30 July 2022).

- Bimbraw, A.S. Generation and Impact of Crop Residue and its Management. Curr. Agric. Res. J. 2019, 7, 304–309. [Google Scholar] [CrossRef]

- Huybrechs, F.; Bastiaensen, J.; van Hecken, G. Exploring the potential contribution of green microfinance in transformations to sustainability. Curr. Opin. Environ. Sustain. 2019, 41, 85–92. [Google Scholar] [CrossRef]

- Mayrand, K.; Paquin, M. Payments for Environmental Services: A Survey and Assessment of Current Schemes; Unisféra International Centre: Montreal, QC, Canada, 2004; pp. 1–52. 52p, Available online: http://scholar.google.com/scholar?hl=en&btnG=Search&q=intitle:Payments+for+Environmental+Services+:+A+Survey+and+Assessment+of+Current+Schemes#0 (accessed on 30 July 2022).

- Downing, A.S.; Kumar, M.; Andersson, A.; Causevic, A.; Gustafsson, Ö.; Joshi, N.U.; Krishnamurthy, C.K.B.; Scholtens, B.; Crona, B. Unlocking the unsustainable rice-wheat system of Indian Punjab: Assessing alternatives to crop-residue burning from a systems perspective. Ecol. Econ. 2022, 195, 107364. [Google Scholar] [CrossRef]

- Faisal, M.; Abbas, A.; Xia, C.; Raza, M.H.; Akhtar, S.; Ajmal, M.A.; Mushtaq, Z.; Cai, Y. Assessing small livestock herders’ adaptation to climate variability and its impact on livestock losses and poverty. Clim. Risk Manag. 2021, 34, 100358. [Google Scholar] [CrossRef]

- Jayachandran, S.; Kelsey, J.; Kala, N.; Pande, R. The Impact of Payments for Ecosystem Services on Crop Burning in India, J-Pal. 2019. Available online: https://www.povertyactionlab.org/evaluation/impact-payments-ecosystem-services-crop-burning-india (accessed on 18 July 2022).

- Nguyen, T.Q.; Huynh, N.T.; Hsu, W.-K.K. Estimate the Impact of Payments for Environmental Services on Local Livelihoods and Environment: An Application of Propensity Scores. SAGE Open 2021, 11, 1–14. [Google Scholar] [CrossRef]

- Badola, R.; Barthwal, S.C.; Hussain, S.A. Payment for Ecosystem Services for Balancing Conservation and Development in the Rangelands of the Indian Himalayan Region. High Alt. Rangel. Interfaces Hindu Kush Himalayas 2013, 16, 175–189. [Google Scholar]

- MoAFW. Central Sector Scheme on Promotion of Agricultural Mechanization for In-Situ Management of Crop Residue In the States Of Punjab, Haryana, Uttar Pradesh And NCT Of Delhi. 2020. Available online: https://agrimachinery.nic.in/Files/Guidelines/CRM.pdf (accessed on 30 July 2022).

- Goel, V.; Hazarika, N.; Kumar, M.; Singh, V. Source apportionment of black carbon over Delhi: A case study of extreme biomass burning events and Diwali festival. Urban Clim. 2021, 39, 100926. [Google Scholar] [CrossRef]

- Beig, G.; Sahu, S.K.; Singh, V.; Tikle, S.; Sobhana, S.B.; Gargeva, P.; Ramakrishna, K.; Rathod, A.; Murthy, B. Objective evaluation of stubble emission of North India and quantifying its impact on air quality of Delhi. Sci. Total Environ. 2020, 709, 136126. [Google Scholar] [CrossRef]

- Singh, R.; Yadav, D.B.; Ravisankar, N.; Yadav, A.; Singh, H. Crop residue management in rice–wheat cropping system for resource conservation and environmental protection in north-western India. Environ. Dev. Sustain. 2020, 22, 3871–3896. [Google Scholar] [CrossRef]

- Kumar, S.; Sharma, D.K.; Singh, D.R.; Biswas, H.; Praveen, K.V.; Sharma, V. Estimating loss of ecosystem services due to paddy straw burning in North-west India. Int. J. Agric. Sustain. 2019, 17, 146–157. [Google Scholar] [CrossRef]

- Sekhar, S.R.M.; Siddesh, G.M.; Jain, S.; Singh, T.; Biradar, V.; Faruk, U. Faruk, Assessment and Prediction of PM2.5 in Delhi in View of Stubble Burn from Border States Using Collaborative Learning Model. Aerosol Sci. Eng. 2021, 5, 44–55. [Google Scholar] [CrossRef]

- Chhapariya, K.; Kumar, A.; Upadhyay, P. A fuzzy machine learning approach for identification of paddy stubble burnt fields. Spat. Inf. Res. 2021, 29, 319–329. [Google Scholar] [CrossRef]

- Parija, P. Why Punjab’s Farmers Continue to Burn Stubble and Poison Delhi’s Air. 12 November 2019. Available online: https://theprint.in/environment/why-punjabs-farmers-continue-to-burn-stubble-and-poison-delhis-air/319601/ (accessed on 24 May 2022).

- Yadav, R.S. Stubble Burning: A Problem for the Environment, Agriculture and Humans. Down to Earth, 4 June 2019. Available online: https://www.downtoearth.org.in/blog/agriculture/stubble-burning-a-problem-for-the-environment-agriculture-and-humans-64912 (accessed on 24 May 2022).

- Taskin, B. All about Stubble Burning, Its Alternatives and Steps Taken by Centre and State Govts. The Print. 8 November 2020. Available online: https://theprint.in/theprint-essential/all-about-stubble-burning-its-alternatives-and-steps-taken-by-centre-and-state-govts/538466/ (accessed on 24 May 2022).

- Kumar, P.; Singh, R.K. Selection of sustainable solutions for crop residue burning: An environmental issue in northwestern states of India. Environ. Dev. Sustain. 2021, 23, 3696–3730. [Google Scholar] [CrossRef]

- Ghosh, M. Why Punjab’s Farmers Burn Stubble & Are Averse to Seeder Machines? Council on Energy, Environment and Water. 3 November 2021. Available online: https://www.ceew.in/blogs/ceew-explains-why-punjab-farmers-burn-stubble-and-are-averse-to-using-seeder-machines (accessed on 8 June 2022).

- Rathore, V. The Hits and Misses of the Pusa Capsule, the Delhi Government’s Solution to Stubble Burning. The Bastion. 22 October 2021. Available online: https://thebastion.co.in/politics-and/the-hits-and-misses-of-the-pusa-capsule-the-delhi-governments-solution-to-stubble-burning/ (accessed on 8 June 2022).

- PIB. Measures to Reduce Pollution Due to Stubble Burning. Ministry of Environment, Forest and Climate Change. 2021. Available online: https://pib.gov.in/PressReleasePage.aspx?PRID=1779712 (accessed on 20 July 2022).

- Kurinji, L.S.; Kumar, S. Is Ex-Situ Crop Residue Management Solve Punjab’s Stubble Burning? Council on Energy, Environment and Water: New Delhi, India, 2021; Available online: https://www.ceew.in/publications/ex-situ-crop-residue-management-scalable-solution-stubble-burning (accessed on 8 June 2022).

- Raza, M.H.; Abid, M.; Yan, T.; Ali Naqvi, S.A.; Akhtar, S.; Faisal, M. Understanding farmers’ intentions to adopt sustainable crop residue management practices: A structural equation modeling approach. J. Clean. Prod. 2019, 227, 613–623. [Google Scholar] [CrossRef]

- Kurinji, L.S. Punjab’s Farmers Explain Why They Burn Crop Stubble|CEEW Study. Council on Energy, Environment and Water. 15 November 2021. Available online: https://www.ceew.in/blogs/punjab-farmers-explain-why-they-burn-crop-stubble (accessed on 8 June 2022).

- Grover, D.; Chaudhry, S. Ambient air quality changes after stubble burning in rice—Wheat system in an agricultural state of India. Environ. Sci. Pollut. Res. 2019, 26, 20550–20559. [Google Scholar] [CrossRef]

- Venkatramanan, V.; Shah, S.; Rai, A.K.; Prasad, R. Nexus Between Crop Residue Burning, Bioeconomy and Sustainable Development Goals Over North-Western India. Front. Energy Res. 2021, 8, 614212. [Google Scholar] [CrossRef]

- Kaushal, L.A.; Prashar, A. Agricultural crop residue burning and its environmental impacts and potential causes–case of northwest India. J. Environ. Plan. Manag. 2020, 64, 464–484. [Google Scholar] [CrossRef]

- Bhuvaneshwari, S.; Hettiarachchi, H.; Meegoda, J.N. Crop residue burning in India: Policy challenges and potential solutions. Int. J. Environ. Res. Public Health 2019, 16, 832. [Google Scholar] [CrossRef]

- Goyal, P.; Gulia, S.; Goyal, S.K.; Kumar, R. Assessment of the effectiveness of policy interventions for Air Quality Control Regions in Delhi city. Environ. Sci. Pollut. Res. 2019, 26, 30967–30979. [Google Scholar] [CrossRef]

- NPMCR, National Policy for Management of Crop Residues (NPMCR). 2014. Available online: http://agricoop.nic.in/sites/default/files/NPMCR_1.pdf (accessed on 30 July 2022).

- Sood, J. Not a Waste Until Wasted. Down to Earth. 31 January 2013. Available online: https://www.downtoearth.org.in/coverage/not-a-waste-until-wasted-40051 (accessed on 2 June 2022).

- Jain, N.; Bhatia, A.; Pathak, H. Emission of air pollutants from crop residue burning in India. Aerosol Air Qual. Res. 2014, 14, 422–430. [Google Scholar] [CrossRef]

- Koenker, R.; Bassett, G. Regression Quantiles. Econometrica 1978, 46, 33–50. [Google Scholar] [CrossRef]

- Babu, S.C.; Gajanan, S.N.; Hallam, J.A. Chapter 8—Socio Economic Determinants of Nutrition: Application of Quantile Regression. In Nutrition Economics; Academic Press: San Diego, CA, USA, 2017; pp. 145–160. [Google Scholar] [CrossRef]

- Levin, A.; Lin, C.; Chu, C.J. Unit root tests in panel data:asymptotic and finite-sample properties. J. Econom. 2002, 108, 1–24. [Google Scholar] [CrossRef]

- Im, K.S.; Pesaran, M.H.; Shin, Y. Testing for unit roots in heterogeneous panels. J. Econom. 2003, 115, 53–74. [Google Scholar] [CrossRef]

- Pathak, P.; Singh, S.; Sahay, C.; Sharma, R. Recent Approaches in Crop Residue Management and Value Addition for Entrepreneurship Development. 2016. Available online: https://agricoop.nic.in/sites/default/files/Guidelines-2019_%28revised%29_of_Straw_Management_Scheme_0.pdf (accessed on 30 July 2022).

- Shyamsundar, P.; Springer, N.P.; Tallis, H.; Polasky, S.; Jat, M.L.; Sidhu, H.S.; Krishnapriya, P.P.; Skiba, N.; Ginn, W.; Ahuja, V.; et al. Fields on fire: Alternatives to crop residue burning in India. Science 2019, 365, 536–538. [Google Scholar] [CrossRef]

- PTI. Niti Pitches for Financial Support to Farmers not Burning Crop Residues. The Times of India. 2 April 2018. Available online: http://timesofindia.indiatimes.com/articleshow/63584175.cms?utm_source=contentofinterest&utm_medium=text&utm_campaign=cppst (accessed on 30 July 2022).

- Yaashikaa, P.R.; Kumar, P.S.; Varjani, S.; Saravanan, A. A critical review on the biochar production techniques, characterization, stability and applications for circular bioeconomy. Biotechnol. Rep. 2020, 28, e00570. [Google Scholar] [CrossRef]

- Mohammadi, A.; Cowie, A.; Mai, T.L.A.; de la Rosa, R.A.; Kristiansen, P.; Brandão, M.; Joseph, S. Biochar use for climate-change mitigation in rice cropping systems. J. Clean. Prod. 2016, 116, 61–70. [Google Scholar] [CrossRef]

- Kaur, K.; Kaur, P.; Sharma, S. Management of crop residue through various techniques. J. Pharmacogn. Phytochem. 2019, SP1, 618–620. [Google Scholar]

- Mookherjee, P. The Implications of India’s Revised Roadmap for Biofuels: A Lifecycle Perspective. 2021. Available online: https://www.orfonline.org/research/the-implications-of-indias-revised-roadmap-for-biofuels/ (accessed on 30 July 2022).

- Bhatti, J. Second-Generation Bioethanol: It Is Time to Launch it Headlong. Down to Earth. 7 August 2021. Available online: https://www.downtoearth.org.in/blog/energy/second-generation-bioethanol-it-is-time-to-launch-it-headlong-78507 (accessed on 24 August 2022).

- Ministry of Petroleum & Natural Gas. India Has Achieved the Target of 10 Percent Ethanol Blending, 5 Months Ahead of Schedule, PIB. 5 June 2022. Available online: https://pib.gov.in/PressReleaseIframePage.aspx?PRID=1831289 (accessed on 24 August 2022).

- Chattopadhyay, V. India’s Ethanol Roadmap: The Targets and Challenges. Down to Earth. 9 June 2021. Available online: https://www.downtoearth.org.in/blog/energy/india-s-ethanol-roadmap-the-targets-and-challenges-77360 (accessed on 24 August 2022).

- Pandey, S. How an Agritech Firm is Helping Haryana, Punjab Farmers Use Bio-Decomposer to Curb Stubble Burning. The Print. 10 October 2021. Available online: https://theprint.in/india/how-an-agritech-firm-is-helping-haryana-punjab-farmers-use-bio-decomposer-to-curb-stubble-burning/748295/ (accessed on 20 July 2022).

- PIB. Steps Taken by the Government for Awareness About the New Low-Cost Capsule Which Can Convert the Paddy Stubble into Bio-Manure; Ministry of Agriculture & Farmers Welfare: New Delhi, India, 2021. Available online: https://www.pib.gov.in/PressReleasePage.aspx?PRID=1744517 (accessed on 20 July 2022).

- Korav, S.; Malannavar, A.B.; Sharma, L. A Review-Vermicomposting: An Effective option for Agriculture Waste Management. Biol. Forum 2021, 13, 211–219. [Google Scholar]

- Porichha, G.K.; Hu, Y.; Rao, K.T.V.; Xu, C.C. Crop residue management in india: Stubble burning vs. other utilizations including bioenergy. Energies 2021, 14, 4281. [Google Scholar] [CrossRef]

- Bhatti, J. Can Biomass Co-Firing Offer a Viable Solution to Coal Shortage and Stubble Burning? Down to Earth. 21 October 2021. Available online: https://www.downtoearth.org.in/blog/energy/can-biomass-co-firing-offer-a-viable-solution-to-coal-shortage-and-stubble-burning--79792 (accessed on 20 July 2022).

- Singh, Y.; Gupta, R.K.; Singh, J.; Singh, G.; Singh, G.; Ladha, J.K. Placement effects on rice residue decomposition and nutrient dynamics on two soil types during wheat cropping in rice-wheat system in northwestern India. Nutr. Cycl. Agroecosystems 2010, 88, 471–480. [Google Scholar] [CrossRef]

- Huang, G.B.; Luo, Z.Z.; Li, L.L.; Zhang, R.Z.; Li, G.; Cai, L.Q.; Xie, J.H. Effects of stubble management on soil fertility and crop yield of rainfed area in western loess plateau, China. Appl. Environ. Soil Sci. 2012, 2012, 256312. [Google Scholar] [CrossRef]

- Saini, S.; Kadam, A.A.; Kumar, V.; Gaikwad, K.K.; Singh, S.P.; Dutt, D. Conversion of rice straw into disposable food-serving bowl via refiner mechanical pulping: An environmentally benign approach to mitigate stubble burning and plastic pollution. Biomass Convers. Biorefin. 2021. [Google Scholar] [CrossRef]

- Muzamil, M.; Mani, I.; Kumar, A.; Shukla, L. An Engineering Intervention to Prevent Paddy Straw Burning Through In Situ Microbial Degradation. J. Inst. Eng. Ser. A 2021, 102, 11–17. [Google Scholar] [CrossRef]

- Kumar, S.; Gaind, S. Fermentative production of soluble phosphorus fertilizer using paddy straw: An alternate to biomass burning. Int. J. Environ. Sci. Technol. 2019, 16, 6077–6088. [Google Scholar] [CrossRef]

- Swamy, H.M.; Seidu, M.; Singh, S.B. Issues of paddy stubble burning in Haryana: Current perspective. Paddy Water Environ. 2021, 19, 55–69. [Google Scholar] [CrossRef]

- Kaushal, L.A. Examining the policy-practice gap- The issue of crop burning induced Particulate Matter pollution in Northwest India. Ecosyst. Health Sustain. 2020, 6, 1846460. [Google Scholar] [CrossRef]

| Variables | (1) | (2) | (3) | (4) | Mean | Std.D. | Min | Max | p1 | p99 | Skew. | Kurt. |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (1) CRB | 1.000 | 5.936 | 1.888 | 1.775 | 8.689 | 1.792 | 8.636 | −0.403 | 2.151 | |||

| (2) ASCB | 0.190 * | 1.000 | 8.504 | 2.201 | 4.605 | 12.007 | 4.605 | 11.729 | −0.419 | 1.911 | ||

| (0.000) | ||||||||||||

| (3) AIR | 0.385 * | 0.317 * | 1.000 | 12.877 | 1.587 | 9.670 | 15.864 | 9.88 | 15.645 | −0.195 | 1.935 | |

| (0.000) | (0.000) | |||||||||||

| (4) AVA | 0.618 * | 0.324 * | 0.660 * | 1.000 | 13.947 | 1.739 | 10.173 | 16.549 | 10.492 | 16.41 | −0.393 | 1.875 |

| (0.000) | (0.000) | (0.000) |

| LLC Test | IPS Test | |||

|---|---|---|---|---|

| Variables | Intercept | Trend | Intercept | Trend |

| CBR | −13.526 *** | −12.500 *** | −7.162 *** | −7.245 *** |

| ASCB | −2.52 ** | −6.733 *** | −5.162 *** | −5.162 *** |

| AIR | −11.317 *** | −12.274 *** | −6.701 *** | −7.245 *** |

| AVA | −6.493 *** | −7.893 *** | −6.218 *** | −6.607 *** |

| Group 1 | Group 2 | |||||||

|---|---|---|---|---|---|---|---|---|

| CRB | 0.884 *** | 0.716 * | −1.061 *** | 0.845 *** | 1.386 ** | 0.257 | ||

| (39.30) | (2.52) | (−5.91) | (23.48) | (2.60) | (1.12) | |||

| AVA | 1.108 *** | −0.386 | 0.969 *** | 1.020 *** | −0.327 | 0.654 ** | ||

| (39.30) | (−1.20) | (4.64) | (23.48) | (−0.55) | (2.67) | |||

| ASCB | 0.103 * | −0.0445 | 0.580 *** | 0.0618 ** | −0.0121 | −0.255 *** | ||

| (2.52) | (−1.20) | (10.86) | (2.60) | (−0.55) | (−4.86) | |||

| ARI | −0.334 *** | 0.243 *** | 1.263 *** | 0.0489 | 0.103 ** | −1.087 *** | ||

| (−5.91) | (4.64) | (10.86) | (1.12) | (2.67) | (−4.86) | |||

| Cons. | −5.145 *** | 5.139 *** | −7.852 ** | 1.991 | −8.589 *** | 7.030 *** | 17.35 *** | 3.791 |

| (−7.16) | (8.82) | (−3.00) | (1.16) | (−16.77) | (16.07) | (3.65) | (1.81) | |

| Group 3 | Group 4 | |||||||

| CRB | 0.788 *** | 1.775 *** | 0.475 *** | 0.749 *** | −0.364 * | −0.283 *** | ||

| (15.51) | (3.34) | (3.88) | (24.38) | (−2.38) | (−3.98) | |||

| AVA | 0.858 *** | −1.354 * | 0.379 ** | 1.197 *** | 0.0534 | 0.637 *** | ||

| (15.51) | (−2.41) | (2.92) | (24.38) | (0.29) | (8.76) | |||

| ASCB | 0.0810 *** | −0.0567 * | −0.0683 * | −0.120 * | 0.0110 | 0.379 *** | ||

| (3.34) | (−2.41) | (−1.96) | (−2.38) | (0.29) | (11.60) | |||

| ARI | 0.238 *** | 0.175 ** | −0.751 * | −0.362 *** | 0.509 *** | 1.478 *** | ||

| (3.88) | (2.92) | (−1.96) | (−3.98) | (8.76) | (11.60) | |||

| Cons. | −9.711 *** | 7.510 *** | 26.82 *** | 5.152 *** | −5.969 *** | 3.410 *** | −10.19 *** | 2.622 *** |

| (−17.38) | (12.19) | (5.42) | (4.08) | (−8.00) | (6.04) | (−6.91) | (3.94) | |

| Group 1 | Group 2 | |||||||

|---|---|---|---|---|---|---|---|---|

| Equation | RMSE | R2 | chi2 | p | RMSE | R2 | chi2 | p |

| CRB | 0.532235 | 0.9271 | 1875.4 | 0.000 | 0.475908 | 0.9032 | 1007.34 | 0.000 |

| AVA | 0.464716 | 0.9294 | 1768.08 | 0.000 | 0.431051 | 0.907 | 1031.52 | 0.000 |

| ASCB | 1.403704 | 0.4536 | 145.46 | 0.000 | 2.293336 | 0.0483 | 29.89 | 0.003 |

| AIR | 0.984931 | 0.382 | 172.76 | 0.000 | 1.106658 | 0.5436 | 119.3 | 0.000 |

| Group 3 | Group 4 | |||||||

| CRB | 0.430588 | 0.9212 | 1050.95 | 0.000 | 0.869134 | 0.7895 | 812.55 | 0.000 |

| AVA | 0.407448 | 0.9214 | 1014.66 | 0.000 | 0.698099 | 0.8694 | 1328.03 | 0.000 |

| ASCB | 2.00225 | 0.015 | 13.74 | 0.000 | 1.53559 | 0.5307 | 254.49 | 0.000 |

| AIR | 0.595892 | 0.8153 | 340.58 | 0.000 | 0.790781 | 0.7302 | 520.03 | 0.000 |

| Group 1 | Group 2 | |||||||

|---|---|---|---|---|---|---|---|---|

| 20th | 40th | 60th | 80th | 20th | 40th | 60th | 80th | |

| ASCB | −0.124 | −0.0451 | 0.0619 | 0.0639 | −0.0125 | 0.0173 | 0.0518 | 0.0805 ** |

| (−1.02) | (−0.42) | (0.79) | (1.31) | (−0.46) | (0.30) | (1.57) | (2.80) | |

| ARI | −0.00313 | −0.140 | −0.320 | −0.268 * | −0.000870 | 0.0772 | −0.0230 | −0.0494 |

| (−0.03) | (−1.00) | (−1.94) | (−2.57) | (−0.02) | (1.30) | (−0.37) | (−0.73) | |

| AVA | 1.086 *** | 1.092 *** | 1.084 *** | 1.047 *** | 1.050 *** | 0.988 *** | 1.035 *** | 1.083 *** |

| (27.82) | (24.28) | (21.50) | (16.89) | (14.63) | (11.05) | (16.33) | (14.74) | |

| Cons. | −7.752 *** | −6.471 *** | −4.490 * | −4.404 ** | −8.231 *** | −8.317 *** | −7.681 *** | −7.940 *** |

| (−7.33) | (−4.17) | (−2.45) | (−2.66) | (−9.17) | (−8.94) | (−9.50) | (−9.90) | |

| Group 3 | Group 4 | |||||||

| 20th | 40th | 60th | 80th | 20th | 40th | 60th | 80th | |

| ASCB | 0.0499 | 0.0796 | 0.0604 | −0.0425 | −0.247 | 0.0339 | −0.124 * | −0.203 * |

| (1.92) | (1.87) | (0.96) | (−1.17) | (−1.79) | (0.76) | (−1.99) | (−2.25) | |

| ARI | 0.294 | 0.0873 | 0.188 | 0.188 * | 0.399 | −0.350 *** | −0.213 * | −0.287 * |

| (1.49) | (0.37) | (1.57) | (2.41) | (1.13) | (−6.94) | (−2.17) | (−2.45) | |

| AVA | 0.749 ** | 0.940 *** | 0.860 *** | 0.879 *** | 0.780 *** | 1.087 *** | 1.097 *** | 1.239 *** |

| (3.19) | (3.89) | (9.33) | (15.38) | (4.77) | (32.05) | (19.73) | (20.66) | |

| Cons. | −8.957 *** | −9.057 *** | −8.758 *** | −7.822 *** | −10.07 *** | −5.970 *** | −6.216 *** | −6.084 *** |

| (−7.57) | (−11.55) | (−12.65) | (−14.52) | (−5.25) | (−9.97) | (−7.19) | (−5.79) | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Singh, D.; Dhiman, S.K.; Kumar, V.; Babu, R.; Shree, K.; Priyadarshani, A.; Singh, A.; Shakya, L.; Nautiyal, A.; Saluja, S. Crop Residue Burning and Its Relationship between Health, Agriculture Value Addition, and Regional Finance. Atmosphere 2022, 13, 1405. https://doi.org/10.3390/atmos13091405

Singh D, Dhiman SK, Kumar V, Babu R, Shree K, Priyadarshani A, Singh A, Shakya L, Nautiyal A, Saluja S. Crop Residue Burning and Its Relationship between Health, Agriculture Value Addition, and Regional Finance. Atmosphere. 2022; 13(9):1405. https://doi.org/10.3390/atmos13091405

Chicago/Turabian StyleSingh, Devesh, Sunil Kumar Dhiman, Vijay Kumar, Ram Babu, Karuna Shree, Anjali Priyadarshani, Archana Singh, Leena Shakya, Aparna Nautiyal, and Shukla Saluja. 2022. "Crop Residue Burning and Its Relationship between Health, Agriculture Value Addition, and Regional Finance" Atmosphere 13, no. 9: 1405. https://doi.org/10.3390/atmos13091405

APA StyleSingh, D., Dhiman, S. K., Kumar, V., Babu, R., Shree, K., Priyadarshani, A., Singh, A., Shakya, L., Nautiyal, A., & Saluja, S. (2022). Crop Residue Burning and Its Relationship between Health, Agriculture Value Addition, and Regional Finance. Atmosphere, 13(9), 1405. https://doi.org/10.3390/atmos13091405