Abstract

The aim of this paper is to quantify the amounts of volatile organic compounds (VOCs) emitted from a coke oven in a steel plant in Taiwan and estimate the emission factors of VOCs using an innovative sampling technique. The identification of VOCs emissions was referred to in the AP-42 report issued by the USEPA and the field measurement data of fugitive emissions. VOCs were sampled using a self-designed closed sampling system. A total of six emission points, including quenching emissions, charge lid emissions, combustion stack emissions, door emissions, charging emissions, and coke pushing emissions, were identified in the coking process after comparing with the report of AP-42, and the emission factor of VOCs was 0.030 kg/ton-coke. It showed that the emission factor of VOCs via field measurement was approximately 56% of that reported by Taiwan EPA. Therefore, VOCs emissions estimated by the Taiwan EPA would be highly overestimated than those from the coke oven in the site.

1. Introduction

There is a wide range of waste gases emitted from large industrial processes, in which volatile organic compounds (VOCs) have been recognized as a major health concern in recent years. VOCs could not only cause detrimental effects on human health but also result in photochemical smog, odors, and other environmental issues [1,2]. Among all VOCs, benzene, toluene, ethylbenzene, xylene (BTEX), and other monocyclic aromatic hydrocarbons are under particularly great concern for their human health effects [3]. Short-term exposure to BTEX will cause adverse reactions, including acute eye and lung irritation, headaches, and adverse respiratory system complications. On the other hand, long-term exposure to BTEX involves leukemia, congenital disabilities, allergies, and other cancers and may cause damage to the central nervous system [4].

In addition to health effects, the adverse impact of VOCs on the atmosphere has also been a major public health issue. In recent years, the main pollutants leading to poor ambient air quality in Taiwan have shifted from SO2 and NOX to PM2.5 and O3. VOCs are the precursors of PM2.5, O3, and other secondary pollutants chemically formed in the atmosphere [5,6,7] and have been the main focus of competent authorities [8]. The Taiwan Environmental Protection Administration (Taiwan EPA) published the “Rates of Air Pollution Control Fee of Stationary Sources” in 2006 [9] to charge VOCs air pollution control fees and promulgated the “Regulations for the Emission Factors of Volatile Organic Compounds from Industrial Processes and Operating Units (Including Equipment Components), Control Efficiency and Measurements With Respect to Public and Private Premises’ Reporting of Stationary Sources for Air Pollution Control Fees” [10] in 2007 for unified calculation of VOCs and emission factors (kg/activity intensity). The emission factors of coking processes in the integrated steel plants are 0.054 kg/ton coke, according to the “AP-42: Compilation of Air Emission Factors” issued by the US Environmental Protection Agency (USEPA) [11]. The AP-42 classifies emission factors by industry, nature, and process and distinguishes different procedures in the processes for sampling, analysis, and gathering statistics. After the accumulation and revision of long-term monitoring data, the emission factors of VOCs were established. However, as the data are numerous and complex, there has been a lack of updated data. As a result, the emission factors of VOCs from coking processes have not been updated for a long time and have been calculated only based on the measured BSO (benzene soluble organics) values.

In order to obtain appropriate emission factors, the development of innovative methodologies shall be submitted beforehand to the local EPA for review and approval pursuant to the “Directions for Development of the Emission Factors (Including Control Efficiency) of Volatile Organic Compounds from Stationary Sources in Plants” [12] promulgated in 2009 by the Taiwan EPA. The developed emission factors can be used to calculate the emissions of VOCs only upon the review and approval of the local EPA.

Coking technology has been developed for over a century, and there have been no significant changes in the types of coke ovens. However, the introduction of new materials, control techniques, and pollution control measures has been a great contribution to prevent from the escape of VOCs [13]. It is well known that VOCs are the main pollutants emitted from the coking process. There have been very few accurate VOCs measurement methods for fugitive emission sources, owing to the irregular shapes of the large-area. If the emission factors are not correctly estimated, it would be difficult to evaluate the reduced VOCs emissions, which results in unreasonably overestimated emissions. In view of this, the study aims at developing the emission factors of VOCs from the coking processes through direct measurement and chemical analysis of VOCs with reference to the coking process data from the AP-42.

2. Materials and Methods

2.1. Sampling Protocol

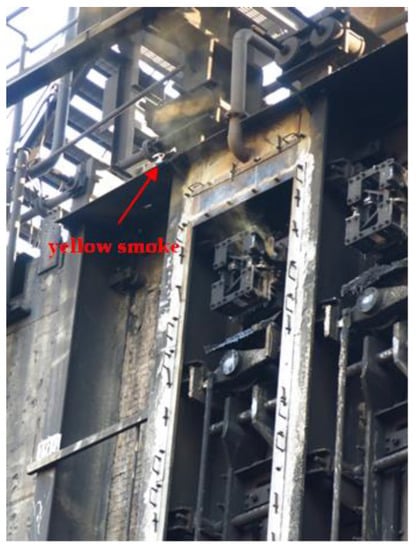

In the past, the research on gaseous exhaustions from coking processes has mainly focused on hazardous air pollutants (HAPs) [14,15,16,17,18]. The study mainly focuses on the field measurement of VOCs from coking processes in order to exactly quantify the emissions and emission factors of the coking processes. The research subject is the coking process of an integrated steel plant in Taiwan. There are four coke oven batteries, two sets of wet quenching equipment, and two sets of dry quenching equipment in the coking process of the steel plant. The sampling of VOCs was conducted mainly at the No. 4 coke oven battery and No. 4 coke dry quenching equipment. The coke oven battery consists of 100 coke ovens, and each of them is 7 m in height and 0.4 m in width. The coke oven battery is capable of producing 1,410,360 metric tons of coke at maximum capacity per year.

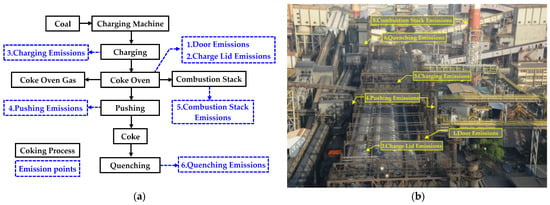

Figure 1 illustrates the major emission points of a coke oven those are listed in the Section 12.2: Coke Production of the AP-42 [11] and the aerial photograph of the target plant. We measured the emissions from six operation units, including the quenching process, combustion stack, charging process and pushing process, doors, and charge lids on the top of coke ovens.

Figure 1.

Emission points specified in AP-42 and the photograph of specific emission points at the target plant. (a) Emission points of the coking process; (b) aerial photograph of the target plant.

Offtake emissions include the emissions from the transport of coke and coke oven gas pipelines. Coke remains at 1050 °C when being transported, and thus most VOCs are burned out. Moreover, the transport time is extremely short (approximately 30 s). A portable toxic vapor analyzer (TVA) for VOCs was used to measure the emissions during transport. The emission concentration of VOCs (indicated as non-methane hydrocarbons, NMHCs) was about 0.28 ppm. A TVA was also used for the multi-point measurement of emissions from the coke oven gas pipelines. The test data ranged from non-detectable to 2 ppm (from which the ambient concentration was deducted), indicating that the offtake VOC emissions in the study were relatively small that could be ignored. Thus, it was suggested that offtake emissions should not be included as a measurement item.

Table 1 presents the sampling points where VOCs species and concentrations were measured herein, including the sampling hole of the stack. In addition, a closed sampling system was designed for measuring door emissions, charge lid emissions, and the charging emissions from the charging telescope. The VOCs sampling devices and calculation processes used in this study were reviewed and approved by the local EPA before the implementation of VOCs sampling at each point.

Table 1.

Emission points and sampling methods applied in this study.

2.2. Sampling Methods

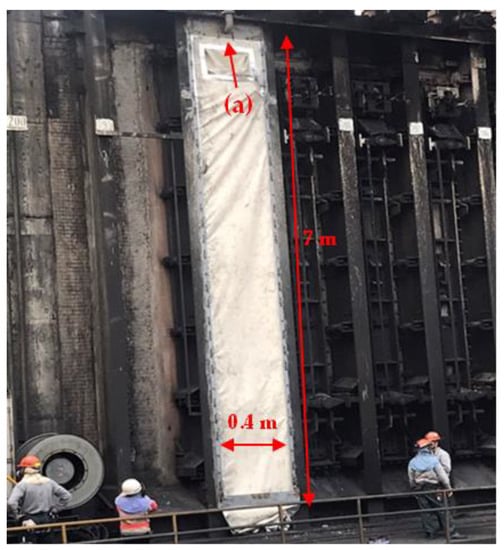

2.2.1. Door Leakage Emissions

As shown in Figure 2, each chamber has one door on its pushing side and another door on its coke side. The two doors are identical in their dimensions. Therefore, it is assumed that the emissions from both sides were equal. However, as the peripheral equipment for both sides was slightly different, we performed VOCs sampling for the pushing side, where a closed sampling device might be used after sealing the door on that side with fire-resistant aluminized fiberglass fabrics and fire-resistant mortar. According to the VOC analysis data in the samples, the calculated VOC emission rates should be doubled to be the real emission rates from the doors of each chamber.

Figure 2.

Self-designed closed sampling system for the door emissions. Site (a) indicates the sampling pipe.

During the coking process, VOCs can be escaped from the coke oven through its door gap. When detecting such leakage, an operator will apply fire-resistant mortar to prevent the leakage of VOCs. After the coking is completed, the gap of the door will be sealed. We measured the emissions of VOCs from the doors of the coke oven in two states, such as free of leaks and subject to possible leaks, according to the plant’s operating procedures for a “10% gas leakage for coke oven doors”. Gas leakages of VOCs from doors of coke ovens were estimated as follows: on-site operators check coke oven doors at a regular time to see if there is any gas leakage. Take one coke oven battery consisting of 100 doors as an example. If there are gas leaks from 10 of the 100 doors, the gas leakage rate is counted as 10%. The measured values were then weighted by the gas leak rate of 10% as specified in the operating procedures to obtain the mean emission factors.

For measuring the door free of leakage, the door had undergone a maintenance check by the on-site operators before the measurement was performed. As for the door subject to be under the possibility of leakage, such as the emitted aerosols of yellow smoke in Figure 3, which had been generally identified by the operators, the site measurements were conducted under the situation of leakage.

Figure 3.

Yellow smoke containing VOCs was leaked out of the coke oven through its door gap.

2.2.2. Charge Lid Emissions

There are four charge lids on the top of each coke oven, through which coal is loaded down to the coke oven, where the charge lids are identical in size (0.45 m in diameter) (shown in Figure 4). According to the principle of heat transfer, the temperatures of coke ovens were in the range of 1200–1300 °C, causing the buoyancy force to be strong enough to overcome the effect of the friction against the tube wall, enabling relatively even distribution of air flows at the four charge lids. Thus, we could consider that the emissions of VOCs from the charge lids were equivalent to each other. As depicted in Figure 5, a metal closed hood was installed at No. 1 charge lids close to the pushing side for the measurement of VOCs. The measured VOC emissions multiplied by four were determined as the total fugitive emissions of VOCs from the doors of a coke oven.

Figure 4.

Charge lids on the top of coke ovens. Four charge lids are numbering as shown.

Figure 5.

Self-designed closed sampling system for charge lid emissions.

2.2.3. Charging Emissions

During the coal charging process, coal was added down to the coke oven using a charging machine. The charging telescope of the machine was laid onto charge lids (see Figure 6), and coal was added to the chamber through the lids. The escaped emissions of VOCs were collected with a processing device of the charging machine for combustion, destruction, and discharging through the stack.

Figure 6.

A charging telescope on the coal charging machine.

We further measured the VOC emissions from the stack and from the charging telescope during the coal charging process. For collecting the emitted VOCs from a charging telescope, a closed sampling device (shown in Figure 7) made of fire-resistant aluminized fiberglass fabric was used to seal it for VOCs measurement. The measured emissions multiplied by four were considered as the total emissions from the charging telescope. The sum of the emissions from the stack and the fugitive emissions from the charging telescope was the total emissions of VOCs during the coal charging process.

Figure 7.

Self-designed closed sampling system was equipped surrouding the charging telescope, and site (b) is the sampling pipe.

2.2.4. Pushing Emissions

In the integrated steel plants, coal was converted into coke for the iron-making process after undergoing a coking process for a period of 16–24 h. The coke in the oven was pushed out with a pusher ram of a pushing machine through a guiding car into a quenching car. The coke was quenched with water sprayed in a quenching tower. Waste gases generated during the pushing process are discharged through the stacks on the coke side as well as the pushing side. In the study, the emissions of VOCs from the stacks on the coke side and the pushing side were measured. The closed hoods were used to collect waste gases, and the gas collection efficiency shall be taken into account for the calculation of VOCs emissions. According to a report issued by the Taiwan EPA [10], the hoods used for the pushing side are classified as “general hoods” with a gas collection efficiency of 60%; the hoods used for the coke side are recognized as “enclosure hoods” with a gas collection efficiency of 80%. Both of them fall into the category of gas collection facilities.

2.2.5. Stack Emissions

Coke ovens produced heat through the combustion of exhaust gases from multiple sources such as coke oven gas, blast furnace gas and converter gas. in the integrated steel plant to indirectly pyrolyze coal in an oxygen-free chamber for the dry distillation process. Waste gases were then discharged through the stack of coke ovens during the combustion process. VOCs were further sampled and measured at the measurement holes of the stack, as illustrated in Figure 8.

Figure 8.

Stack emissions from the No. 4 coke oven battery during the combustion process.

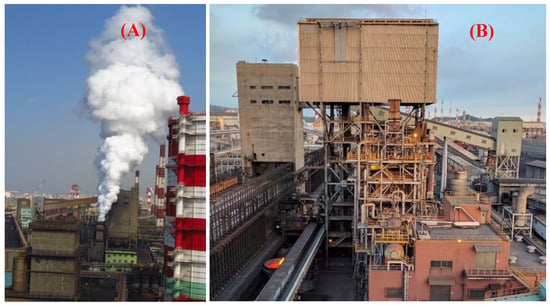

2.2.6. Quenching Emissions

Coke quenching can be conducted in two measures procedures for wet quenching and dry quenching (Figure 9). Wet quenching is implemented by spraying water to quench hot coke directly and is then transported into a wet quenching tower. However, dry quenching is a new quenching process, and hot cokes are then transported to a dry quenching tower and cooled by an inert gas (N2) in a closed environment, in which waste gases are discharged through the stacks. A large amount of high-temperature steam is discharged from the open wet quenching tower during the quenching process, where VOCs cannot be measured correctly. Because the dry quenching tower is closed, VOCs can be collected effectively from the stacks. According to the Taiwan EPA’s report [10], the VOCs removal efficiency of rinsing equipment ranged from 10–80%. It is assumed that there will be at least 10% of VOCs carried away by the steam during the wet quenching process, resulting in the underestimation of VOC emissions. Therefore, the emissions of VOCs in the exhaust pipe from the dry quenching process were then measured for accurate estimating of the VOC emission. Moreover, this suggested that the emission factor of VOCs emitted from the wet quenching process would be approximately 90% of the emission factor for the dry quenching process.

Figure 9.

Coke oven battery’s quenching equipment: Photo (A) indicates the steam from a wet coke quenching, and Photo (B) indicates the dry coke quenching system.

2.3. Measurement Methods

2.3.1. Hydrocarbons in Exhaust Pipes

The total hydrocarbon (THC) emitted from the exhaust pipes was measured based on the “Method for Determination of Total Hydrocarbon and Total Non-methane Hydrocarbon Concentration Using Online Flame Ionization Detector Method” (NIEA A723.74B) [19]. The method involves the continuous extraction of gas samples in the exhaust pipes by using a sampling device. The gas samples directly enter a flame ionization detector (FID) through an air tube for the measurement of total hydrocarbon content in the exhaust pipes. The gas samples are also guided into another channel to measure the methane content. There are two methods for measuring the methane content: (1) molecular sieving method (MSM): The NMHCs in the gas samples are separated with a molecular sieve, and the gas samples then enter the FID for measurement; (2) backflush GC method (BGCM): After the methane in the samples is separated using a chromatography column, the NMHCs are back flushed to enable the methane to enter the FID for THC measurement. The NMHC content equals the THC content from which the methane content is deducted, and the measured hydrocarbon concentration can be expressed in methane equivalent concentration.

2.3.2. BTEX in Exhaust Pipes

The BTEX in the exhaust pipes was measured based on the “Method for the Determination of Gaseous Organic Compound Emissions by GC/FID” (NIEA A722.76B) [20]. The method conducts the sampling of gaseous organic compounds in the exhaust pipes with Tedlar bags and the separation of organic compounds with a gas chromatography separation column to allow an FID to measure the gaseous organic compounds in the gas samples.

2.3.3. Ambient NMHCs

The ambient NMHCs in the air were measured using the “Method for Determination of Total Hydrocarbons in Air (NIEA A740.10C),” issued by Taiwan EPA [21]. The method uses an online FID to measure the species and concentrations of THCs in the ambient air. The gas sample is also guided into a selective combustion system (e.g., a catalytic converter) that decomposes NMHCs, and then enters the FID for the measurement of methane content in the ambient air. The NMHC content equals the THC content, and the measurement is expressed in methane equivalent concentration.

2.3.4. Ambient BTEX

The ambient BTEX in the air was measured based on the “Method for Determination of Volatile Organic Compounds (VOCs) in Air Collected in Canisters and Analyzed by Gas Chromatography/Mass Spectrometry (GC/MS)” (NIEA A715.15B) [22]. This method uses a vacuum canister made of stainless steel to collect air samples through instant sampling or on a fixed volume sampling basis, concentrates a certain volume of ambient air samples by using cryogenic trapping, and then injects the air samples into a GC/MS by a thermal desorption unit (TDU) to determine the species and concentrations of VOCs in the ambient air samples.

2.4. Data Analysis Methods

2.4.1. Concentration Conversion

The measured VOCs and NMHC concentrations were converted from ppm to mg/Nm3 using the following formula,

where a refers to the conversion factor for emission concentrations (mg/Nm3) as announced in the “Calculation of the Emissions of Air Pollutants from Stationary Sources in Public and Private Premises,” which was issued in 2012 by the Taiwan EPA (Table 2) [23]. Cmg refers to the measured concentration expressed in mg/Nm3 (as methane); Cppm refers to the measured concentration expressed in ppm (as methane).

Table 2.

The values of conversion factor a for NMHCs and BTEX used in Equation (1).

2.4.2. Stack Emission Factor

The emission factors can be calculated by dividing the measured emissions by the activity intensity for the coking process during the measurement. The formula for the emissions can be expressed as follows:

where Ev refers to the measured emissions (kg/h); Q refers to the stack emissions (Nm3/h)

The emission factor formula can be expressed as follows:

where Ef refers to the emission factor (kg/ton); Ac refers to the activity intensity for the coking process (ton/h).

2.4.3. Fugitive Emission Factor Formula

The formula for the fugitive emission factor of the coke oven doors is the same as that for charge lids. However, the ambient concentration of VOCs shall be deducted from the measured VOC concentration. The formula for the emissions of VOCs per unit time can be expressed as follows,

where Cp refers to the measured concentration of ambient VOCs (mg/Nm3) (as methane).

2.4.4. Formula for the Emission Factor of Cooking Process

We performed the measurement of VOCs at six emission points/sites during the coking process, which can be used to calculate the emission factor of VOCs at each emission point/site. The sum of all the emission factors reflects the total emissions of VOCs from the coking process:

where EFco refers to the total emission factor of the coke oven; EFq refers to the emission factor of the quenching process; EFs refers to the emission factor of the combustion stack; EFc refers to the emission factor of the charging process; EFp refers to the emission factor of the pushing process; EFd refers to the emission factor of door leakage; and EFcl refers to the emission factor of the charge lids.

EFco = EFq + EFs + EFc + EFp + EFd + EFcl

2.4.5. QA/QC of Measurement

According to the Taiwan EPA’s documents [6], the coefficient of variation (CV) of three VOC emission factors, which are measured at three different operating times, should be less than 20%. If the CV value exceeds 20%, the measurements must be taken at least five different operating times and their CV re-calculated for less than 20%. The coefficient of variation formula can be expressed as follows,

where CV refers to the coefficient of variation; S refers to the standard deviation; refers to the average; n refers to the number of samples; Xi is the ith measured value.

3. Results and Discussion

3.1. Concentration Distribution

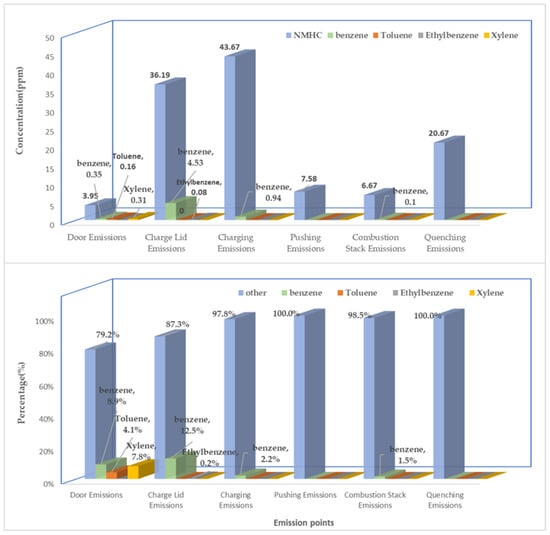

The emission concentrations of NMHC and BTEX are illustrated in Table 3 and Figure 10. The charging emissions (charging telescope and stack) exhausted the highest concentrations of NMHC (8 ppm + 35.67 ppm = 43.67 ppm), which was followed by the charging lid emissions (36.19 ppm). Emissions from the pushing side contained the lowest NMHC concentration (2.00 ppm). The highest NMHC concentration at the charging emissions might result from the instant vaporization of organic compounds during the period of the rejection of coal into the high-temperature chamber. Most of the NMHCs, which were discharged through the stack, were then collected by the gas sampling equipment rather than those emitted through the telescope. During the coking process, the emission concentrations in the charge lid emissions were apparently higher than those from the door leakage, which might be due to clustering at the top of the chamber. Thus, when operating a coke oven, further charge lid repair works shall be carried out to prevent leakage.

Table 3.

The concentrations of VOCs emitted from the coking oven.

Figure 10.

Distribution of BTEX concentrations at six emission sites/points. Door emissions are calculated as the VOC concentrations of [0.9 × (non-leakage concentration) + 0.1 × (leakage concentration)].

For BTEX, the highest benzene concentration (4.53 ppm) was found at the charge lid emissions, and benzene was not detected in the pushing emissions and quenching emissions. Toluene was detected only at the door leakage emissions: for non-leakage door emissions, the toluene concentration was 0.17 ppm; for leakage door emissions, toluene was 0.02 ppm, and there was no obvious difference between the two types of door emissions due to the relatively low toluene emissions. Ethylbenzene was detected only at the door leakage emissions and charge lid emissions. The ethylbenzene concentration at the charge lid emissions was 0.08 ppm.

The BTEX emissions from the coke oven battery are calculated and shown in Table 4. Based on the total NMHCs emission concentration (118.73 ppm), the benzene, toluene, ethylbenzene, and xylene ratio accounted for 5.0%, 0.1%, 0.1%, and 0.3%. The BTEX ratios in this study were obviously lower than what had been measured and reported by the Taiwan EPA: benzene 12.4%; toluene: 2.03%; ethylbenzene: 0.87%; and xylene: 1.35%.

Table 4.

Distribution of BTEX emissions from the coke oven.

3.2. Emission Factors of NMHCs

3.2.1. Door Emissions

The coke oven doors had two states, including free of leaks and subject to possible leaks. We used our self-designed sampling equipment to perform the sampling and measurement of VOCs at the doors on the pushing side and weighted the measured values by the gas leak rate of 10% as specified in the operating procedure to obtain the weighted average emission factors. The measurement results are compiled in Table 5. The measurement data of three samplings for the free of leak state showed a coefficient of variation of 100%, which was higher than 20%. Thus, extra two samplings were further performed to obtain the average of five VOC measurements, which was taken as the emission factor of 0.0002 kg VOCs/ton. Furthermore, the measurement data of three samplings at the doors subject to possible leaks showed a coefficient of variation of 33.3%, which was higher than 20%. Thus, two extra samplings were further performed to obtain the average of five VOC measurements, which was taken as the emission factor of 0.0004 (kg VOCs/ton). Overall, the weighted emission factor of coke oven doors was obtained by the following calculation of (0.0002 × 0.9) + (0.0004 × 0.1) = 0.0002 kg VOCs/ton.

Table 5.

Emission factors of VOCs and QA/QC results for the assessment of door emissions.

3.2.2. Charge Lid Emissions

The samplings for the VOC emissions through the charge lids from the coke oven chamber were implemented by using self-made sampling equipment. The ambient interference was deducted in the sampling procedure. Table 6 displays the VOC measurement results, and the coefficient of variation for three samplings was 67%, which was higher than 20%. Thus, the average of five VOC measurements was taken as the emission factor, which was 0.0016 kg VOCs/ton.

Table 6.

Emission factor of VOCs and QA/QC results for the assessment of charge lid emission.

3.2.3. Charging Emissions

The VOC emissions from the coal charging process were sampled at the exhaust stack sampling platform of the charging machine and the charge lids of the coke oven chamber. The measurement results for charging stacks are shown in Table 7. The coefficient of variation of three samplings was 19%, which did not exceed 20%. Thus, the average of three VOC measurements was the emission factor of 0.0079 kg VOCs/ton.

Table 7.

Emission factor of VOCs and QA/QC results for the assessment of charging stack emissions.

The emissions through the charge lids of the coke oven chamber were sampled by using self-made equipment, and the ambient interference was deducted. The VOC measurement results are shown in Table 8. The coefficient of variation of three samplings was 125%, which was higher than 20%. Thus, the average of five VOC measurements was taken as the emission factor of 0.0004 kg VOCs/ton. The total emission factor of charging emissions (EFc) was calculated as 0.0079 + 0.0004 = 0.0083 kg VOCs/ton.

Table 8.

Emission factor of VOCs and QA/QC results for the assessment of charging telescope emissions.

3.2.4. Emission Factor from Pushing Emissions

The VOC emission factor of pushing emissions was determined on the base of the samplings performed at the sampling platform on the exhaust stack of the pushing side and the coke side of the coke battery. The measurement results for the stacks on the coke side and pushing side are displayed in Table 9 and Table 10. The coefficient of variation for the stacks on the coke side of three VOC samplings was 34%, which was higher than 20%. Thus, the average of five measurements was taken as the emission factor of 0.0049 kg VOCs/ton. For the stacks on the pushing side, the coefficient of variation was 0%, which did not exceed 20%. Thus, the average of three measurements was taken as the emission factor of 0.0005 kg VOCs/ton. The total emission factor of pushing emissions (EFp) was 0.0054 (=0.0049 + 0.0005) kg VOCs/ton.

Table 9.

Emission factor of VOCs and QA/QC results for the assessment of coke side emissions.

Table 10.

Emission factor of VOCs and QA/QC results for the assessment of pushing side emissions.

3.2.5. Combustion Stack Emissions

The VOC emissions of the combustion stack were sampled on the sampling platform of the exhaust stack. Table 11 summarizes the three VOC measurements. The coefficient of variation was 19%, which did not exceed 20%. Thus, the average of three measurements was taken as the emission factor of 0.0083 kg VOCs/ton.

Table 11.

Emission factor of VOCs and QA/QC results for the assessment of combustion stack emissions.

3.2.6. Quenching Emissions

The quenching emissions were mainly sampled at the dry quenching stack sampling platform. The measurement results are shown in Table 12. The coefficient of variation of three samplings was 18%, which did not exceed 20%. Thus, the average of three measurements was taken as the emission factor, which was 0.0061 kg VOCs/ton.

Table 12.

Emission factor of VOCs and QA/QC results for the assessment of quenching emissions.

3.2.7. Emission Factor for the Coke Oven Battery

The total emission factor for the six emission points/sites was 0.0299 kg VOCs/ton. An emission factor of the coke oven battery, 0.030 kg VOCs/ton, was declared by the Taiwan EPA as the VOC payment base of air pollution fee with the value of three digits below the decimal. The emission factor of VOCs from the coke oven battery obtained in this study has been reviewed and approved by the local EPA and is currently adopted by the integrated steel plants for reporting their VOC emissions from coke oven batteries.

3.3. Comparisons of VOC Emission Factors of Coke Oven Batteries

The emission factor of VOCs in this study was further compared with those published in the AP-42 and obtained from a coke oven battery of an integrated steel plant in China [24] (Table 13). The VOC emission factor published in AP-42 is 0.1857 kg VOCs/ton, while the emission factor of VOCs obtained from China is 0.5978 kg VOCs/ton. The emission factor of VOCs obtained from on-site samplings in this study was 0.0299 kg VOCs/ton, which was as low as 16% and 5% of the other two VOC emission factors. The reasons for such differences were probably due to the usage of an innovative sampling technique which was firstly applied for the measurement of VOC emissions from the coking process in an integrated steel plant.

Table 13.

Comparison of VOCs’ emission factors for different coking plants.

In this study, NMHCs were directly measured through stacks and in a closed and sealed manner; however, the AP-42 was conducted along with the conversion of BSO data based on indirect measurements. Additionally, Cheng et al. [24] estimated the fugitive VOC emission factors from the coke oven battery of an integrated steel plant in China using stainless steel canisters for collecting grab air samples near the doors and the charging lids, which might be highly interfered with by the mixture of ambient air, causing over- or under-estimation of VOC emissions. Additionally, all species of emitted organic compounds in the air samples were analyzed as a single component concentration and then merged into TVOCs, which are different from those measured using the direct analysis of TVOCs in this study. Therefore, the VOCs emission factors could be measured directly based on the technique of the closed sampling systems, which is developed in this study. Additionally, the equipment of the closed sampling system is detachable, and it can be applied to the other process units to measure the emission factors.

3.4. Recommendations on VOC Sampling for the Coke Oven Batteries in the Future

Based on our unique experiences in this study, the following improvements are recommended for the accurate measurements of VOC emissions from the coke oven batteries.

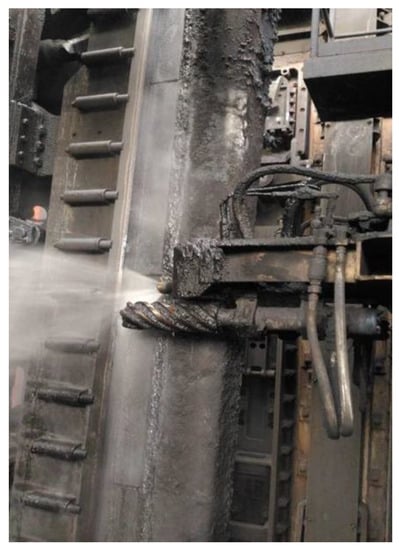

- For the cleaning of the airways of doors, high-pressure water jet machines must be installed on the pushing machine and guiding car. The cleaning should be performed each time to enhance the air tightness of the oven doors and the oven door frames, which could reasonably reduce the potential contamination caused by fugitive emissions from the doors (Figure 11).

Figure 11. Coke oven door cleaned with a high-pressure water jet machine.

Figure 11. Coke oven door cleaned with a high-pressure water jet machine. - All of the oven door frames must be replaced prior to sampling to reduce leakages caused by fugitive emissions.

- The top bricks of coke ovens, riser pipes, and other metal components must be fully renovated to limit the pollution for preventing fugitive emissions from the top of coke ovens (Figure 12).

Figure 12. Renovation of coke oven bricks and riser pipes.

Figure 12. Renovation of coke oven bricks and riser pipes. - The combustion chamber of the charging machine must be upgraded for the complete burning of VOCs generated during the charging process.

4. Conclusions

The site sampling and analysis of VOCs were conducted for six emission points of the coking process with reference to the AP-42 report and confirmed, through actual application, that self-designed closed sampling equipment for VOC sampling was feasible for the measurement of door emissions, charge lid emissions, and charging telescope emissions. The emission factors, which were calculated by the concentrations directly measured using the closed sampling systems, were more realistic than those estimated emission factors using the existing parameters. A new or existing coking plant that is revamped can be re-evaluated to obtain updated emission factors by following the technique which has been established herein.

The charging lid emissions exhausted a very high concentration of NMHCs (36.19 ppm) and also stacked emissions during charging (35.67 ppm). Thus, when operating a coke oven, further repair works for charge lids shall be carried out to prevent the emissions of VOCs from potential leaks. Benzene, toluene, ethylbenzene, and xylene (BTEX) accounted for 5.0%, 0.1%, 0.1%, and 0.3%, respectively, of the VOC emissions from the coke oven battery. In the past, there were only some data on BTEX ratios of VOCs fugitively emitted from coke oven batteries in the integrated steel plants. The findings of this study showed that the BTEX ratio was about 50:1:1:3, and benzene was recognized as the dominant aromatic hydrocarbon component, which was similar to the results of Wang et al. [25] and Zhang et al. [26]. In general, the BTEX ratio of vehicular emissions is about 3:4:1:4 or 3:7:1:5 [27]. However, the BTEX ratio of the coking process was 50:1:1:3, which implied the fingerprint characteristics of BTEX emissions from the coal coking process. According to the recent 3-year (2018–2020) study by Yuan et al. [2], the BTEX ratios of two ambient air quality monitoring stations around the industrial complex where this integrated steel plant is located are about 0.3:(6.7–9.2):1:6. Therefore, the BTEX ratio of the coking oven in the integrated steel plant is evidentially different from those of the industrial complex. It can be reasonably inferred that the coking process has not made many contributions to VOC concentrations in the ambient air of a nearby industrial complex.

Author Contributions

Conceptualization, C.-T.S. and C.-S.Y.; Methodologies, C.-T.S., W.-H.C., Y.-C.L., K.-L.C. and K.-S.C.; Experimental and Analysis, C.-T.S.; Resources, C.-S.Y.; Writing, W.-H.C. and C.-T.S.; Supervision, C.-T.S.; Project Administration, C.-T.S.; Funding Acquisition, C.-T.S. and C.-S.Y. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The statement should be excluded. All data are shown in the tables of the text.

Acknowledgments

Ming-Chang Wu and Chi-Shu Huang are appreciated for their kind assistance in the on-site sampling arrangement. Ai-Lin Shen is appreciated for her assistance in the instrumental analysis.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Hu, R.Y.; Liu, G.J.; Zhang, H.; Xue, H.Q.; Wang, X. Levels, characteristics and health risk assessment of VOCs in different functional zones of Hefei. Ecotox. Environ. Saf. 2018, 160, 301–307. [Google Scholar] [CrossRef] [PubMed]

- Tohid, L.; Sabeti, Z.; Sarbakhsh, P.; Benis, K.Z.; Shakerkhatibi, M.; Rasoulzadeh, Y.; Rahimian, R.; Darvishali, S. Spatiotemporal variation, ozone formation potential and health risk assessment of ambient air VOCs in an industrialized city in Iran. Atmos. Pollut. Res. 2019, 10, 556–563. [Google Scholar] [CrossRef]

- Abbasi, F.; Pasalari, H.; Delgado-Saborit, J.M.; Rafiee, A.; Abbasi, A.; Hoseini, M. Characterization and risk assessment of BTEX in ambient air of a Middle Eastern City. Process. Saf. Environ. Prot. 2020, 139, 98–105. [Google Scholar] [CrossRef]

- Cerón Bretón, J.G.; Cerón Bretón, R.M.; Ucan, F.V.; Baeza, C.B.; Espinosa Fuentes, M.L.; Ramírez Lara, E.; Rangel Marrón, M.; Pacheco, J.A.M.; Rodríguez Guzmán, U.; Chi, M.P. Characterization and sources of aromatic hydrocarbons (BTEX) in the atmosphere of two urban sites located in Yucatan Peninsula in Mexico. Atmosphere 2017, 8, 107. [Google Scholar] [CrossRef]

- Zhan, J.L.; Feng, Z.M.; Liu, P.F.; He, X.W.; He, Z.M.; Chen, T.Z.; Wang, Y.F.; He, H.; Mu, Y.J.; Liu, Y.C. Ozone and SOA formation potential based on photochemical loss of VOCs during the Beijing summer. Environ. Pollut. 2021, 285, 117444. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.F.; Jing Gao, J.; Cai, Y.J.; Wang, J.J.; Pan, J. Real-time tracing VOCs, O3 and PM2.5 emission sources with vehicle-mounted proton transfer reaction mass spectrometry combined differential absorption lidar. Atmos. Pollut. Res. 2021, 12, 146–153. [Google Scholar] [CrossRef]

- Liu, Y.F.; Qiu, P.P.; Li, C.L.; Li, X.K.; Ma, W.; Yin, S.J.; Yu, Q.; Li, J.F.; Liu, X.G. Evolution and variations of atmospheric VOCs and O3 photochemistry during a summer O3 event in a county-level city, Southern China. Atmos. Environ. 2022, 272, 118942. [Google Scholar] [CrossRef]

- Yuan, C.S.; Cheng, W.H.; Huang, H.Y. Spatiotemporal distribution characteristics and potential sources of VOCs at an industrial harbor city in southern Taiwan: Three-year VOCs monitoring data analysis. J. Environ. Manag. 2022, 303, 114259. [Google Scholar] [CrossRef] [PubMed]

- Taiwan EPA. Rates of Air Pollution Control Fee of Stationary Sources; Taiwan EPA: Taipei, Taiwan, 2006.

- Taiwan EPA. Regulations for the Emission Factors of Volatile Organic Compounds from Industrial Processes and Operating Units (Including Equipment Components), Control Efficiency and Measurements with Respect to Public and Private Premises’ Reporting of Stationary Sources for Air Pollution Control Fees; Taiwan EPA: Taipei, Taiwan, 2007.

- U.S. EPA. AP-42: Compilation of Air Emission Factors; U.S. EPA: Washington, DC, USA, 2008.

- Taiwan EPA. Directions for Development of the Emission Factors (Including Control Efficiency) of Volatile Organic Compounds from Stationary Sources in Plants; Taiwan EPA: Taipei, Taiwan, 2009.

- Li, J.; Zhou, Y.; Simayi, M.; Deng, Y.Y.; Xie, S.D. Spatial-temporal variations and reduction potentials of volatile organic compound emissions from the coking industry in China. J. Clean. Prod. 2019, 214, 224–235. [Google Scholar] [CrossRef]

- Amodio, M.; Andriani, E.; Dambruoso, P.R.; Gennaro, G.; Di Gilio, A.; Intini, M.; Palmisani, J.; Tutino, M. A monitoring strategy to assess the fugitive emission from a steel plant. Atmos. Environ. 2013, 79, 455–461. [Google Scholar] [CrossRef]

- Fan, R.F.; Li, J.N.; Chen, L.G.; Xu, Z.C.; He, D.H.; Zhou, Y.X.; Zhu, Y.Y.; Wei, F.H.; Li, J.H. Biomass fuels and coke plants are important sources of human exposure to polycyclic aromatic hydrocarbons, benzene and toluene. Environ. Res. 2014, 135, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Ciaparra, D.; Aries, E.; Booth, M.J.; Anderson, D.R.; Almeida, S.M.; Harrad, S. Characterization of volatile organic compounds and polycyclic aromatic hydrocarbons in the ambient air of steelworks. Atmos. Environ. 2009, 43, 2070–2079. [Google Scholar] [CrossRef]

- Mu, L.; Peng, L.; Liu, X.; Song, C.; Bai, H.; Zhang, J.; Hu, D.; He, Q.; Li, F. Characteristics of polycyclic aromatic hydrocarbons and their gas/particle partitioning from fugitive emissions in coke plants. Atmos. Environ. 2014, 83, 202–210. [Google Scholar] [CrossRef]

- Bigda, R.; Sobolewski, A.; Telenga-Kopyczyńska, J.; Słowik, K. Problems with determination of fugitive emission of polycyclic aromatic hydrocarbons from coke oven battery. J. Ecol. Eng. 2017, 18, 136–149. [Google Scholar] [CrossRef]

- NIEA A723.74B; Method for Determination of Total Hydrocarbon and Total Nonmethane Hydrocarbon Concentration Using Online Flame Ionization Detector Method. Taiwan EPA: Taipei, Taiwan, 2020.

- NIEA A722.76B; Method for the Determination of Gaseous Organic Compound Emissions by GC/FID. Taiwan EPA: Taipei, Taiwan, 2019.

- NIEA A740.10C; Method for Determination of Total Hydrocarbons in Air. Taiwan EPA: Taipei, Taiwan, 2014.

- NIEA A715.15B; Method for Determination of Volatile Organic Compounds (VOCs) in Air Collected in Canisters and Analyzed by Gas Chromatography/Mass Spectrometry (GC/MS). Taiwan EPA: Taipei, Taiwan, 2014.

- Taiwan EPA. Calculation of the Emissions of Air Pollutants from Stationary Sources in Public and Private Premises; Taiwan EPA: Taipei, Taiwan, 2012.

- Cheng, L.; Wei, W.; Zhang, C.Z.; Xu, X.L.; Sha, K.C.; Meng, Q.B.; Jiang, Y.; Cheng, S.Y. Quantitation study on VOC emissions and their reduction potential for coking industry in China: Based on in-situ measurements on treated and untreated plants. Sci. Total Environ. 2022, 836, 155466. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.L.; Hao, R.; Fang, L.; Nie, L.; Zhang, Z.S.; Hao, Z.P. Study on emissions of volatile organic compounds from a typical coking chemical plant in China. Sci. Total Environ. 2021, 752, 141927. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.M.; Wang, D.; Liu, Y.; Cui, Y.F.; Xue, Z.G.; Gao, Z.F.; Du, J.H. Characteristics and ozone formation potential of volatile organic compounds in emissions from a typical Chinese coking plant. J. Environ. Sci. 2020, 95, 183–189. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.C.; Chiu, M.Y.; Ho, K.F.; Zou, S.C.; Wang, X.M. Volatile organic compounds (VOCs) in urban atmosphere of Hong Kong. Chemosphere 2002, 48, 375–382. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).