Carbon-Negative Policies by Reusing Waste Wood as Material and Energy Resources for Mitigating Greenhouse Gas Emissions in Taiwan

Abstract

:1. Introduction

- -

- Trend analysis of GHG emissions from the energy and the manufacturing and construction industries.

- -

- Environmental policies and regulatory measures for reusing waste wood as material and energy resources.

- -

- Wood-based products for mitigating GHG emissions.

2. Data Mining and Methodology

3. Results and Discussion

3.1. Trend Analysis of GHG Emissions from the Energy and the Manufacturing and Construction Industries

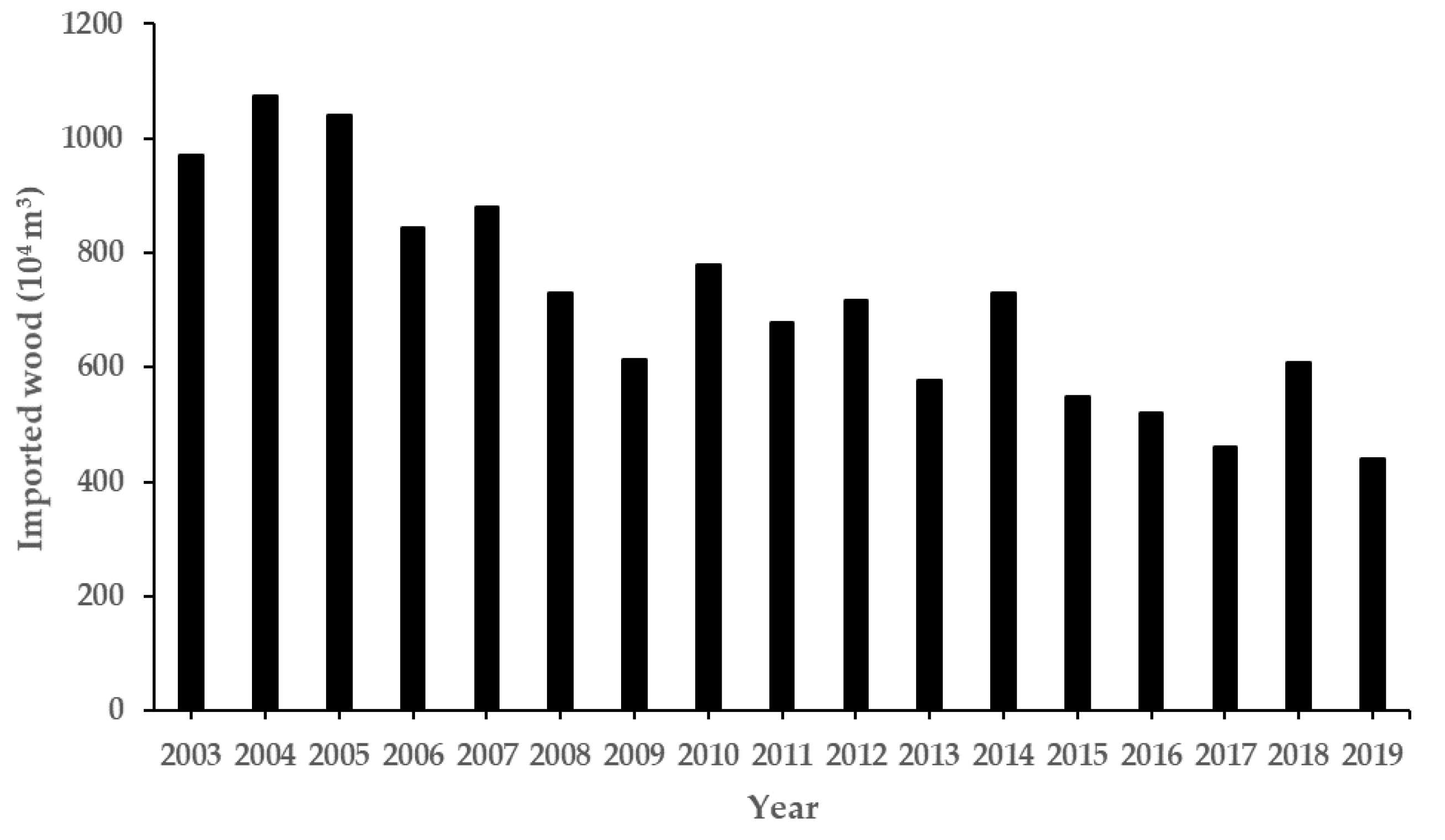

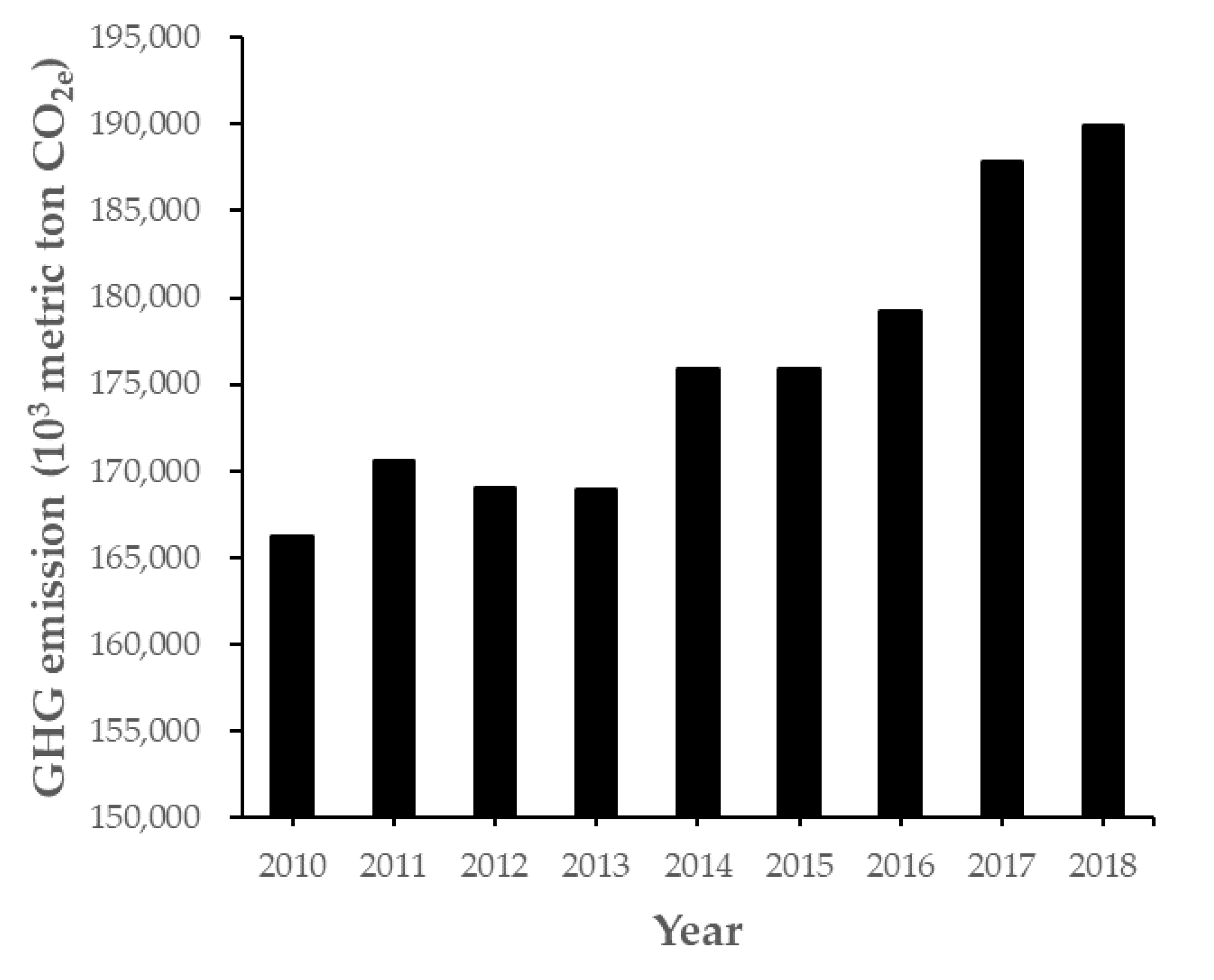

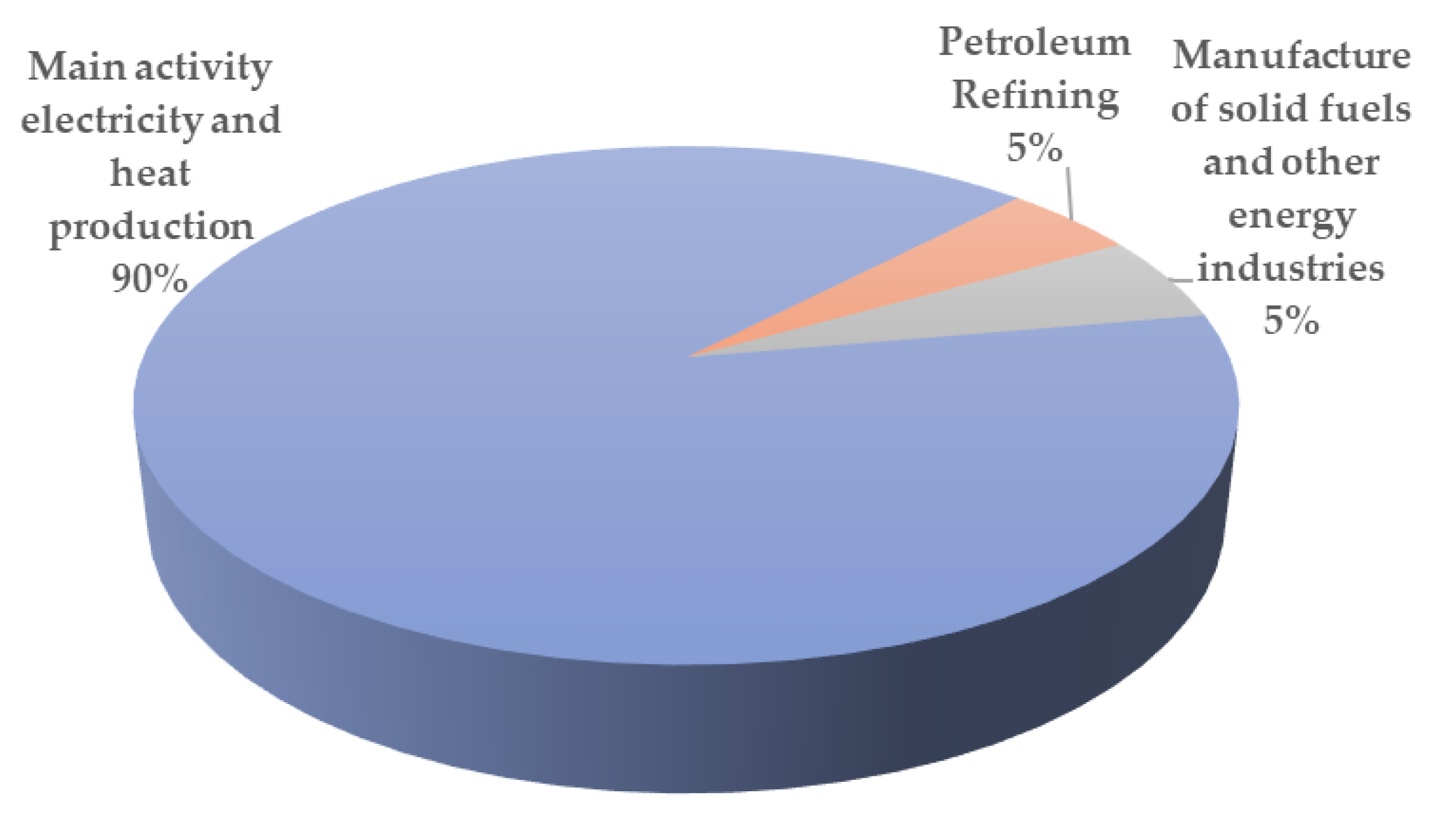

3.1.1. Analysis of GHG Emissions from the Energy Industries

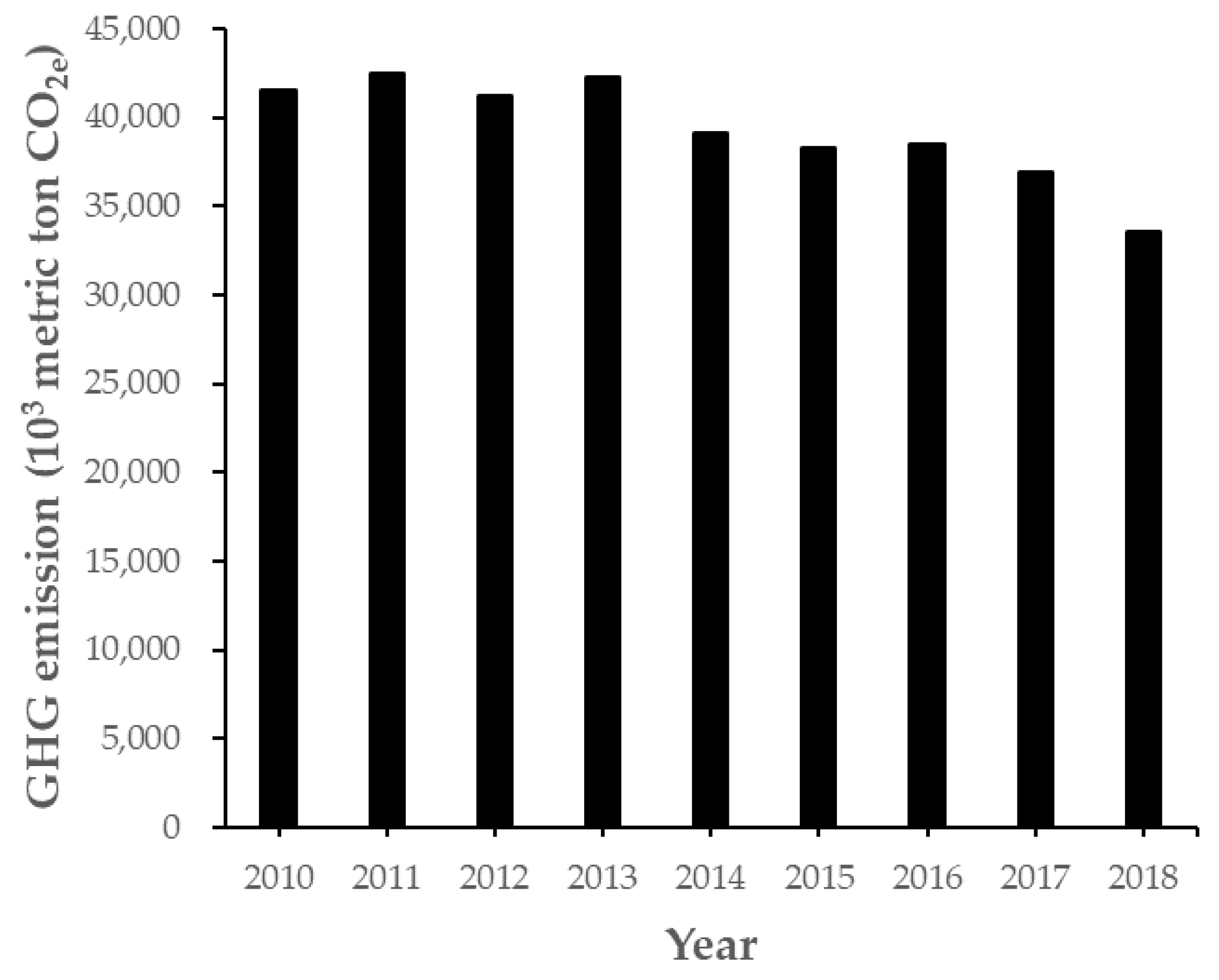

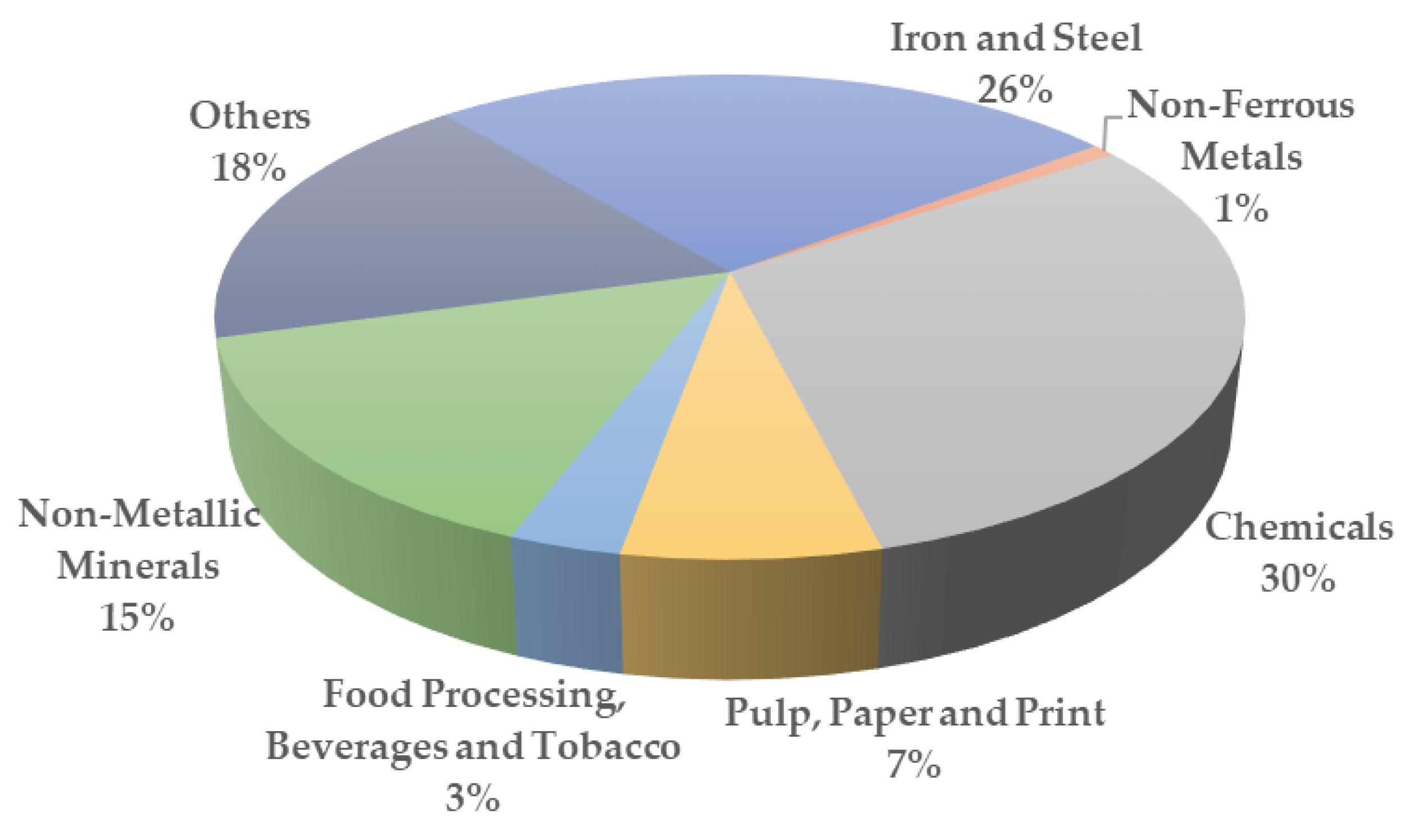

3.1.2. Analysis of GHG Emissions from the Manufacturing and Construction Industries

3.2. Environmental Policies and Regulatory Measures Relevant to the Material and Energy Resources from Waste Wood

3.2.1. Environmental Protection Administration

Basic Environment Act

- -

- Government entities (policymakers)

- -

- Enterprises (manufacturers)

- -

- Citizens (consumers)

Greenhouse Gas Reduction and Management Act

- -

- Development of renewable energy technology in the use of waste wood as an energy source.

- -

- Reduction in and management of GHG emissions from buildings in the use of wood-based building materials.

- -

- Reuse (or recycling) of waste wood as fuels or materials.

- -

- Forest resource management in the forest’s carbon sequestration.

3.2.2. Ministry of Economic Affairs

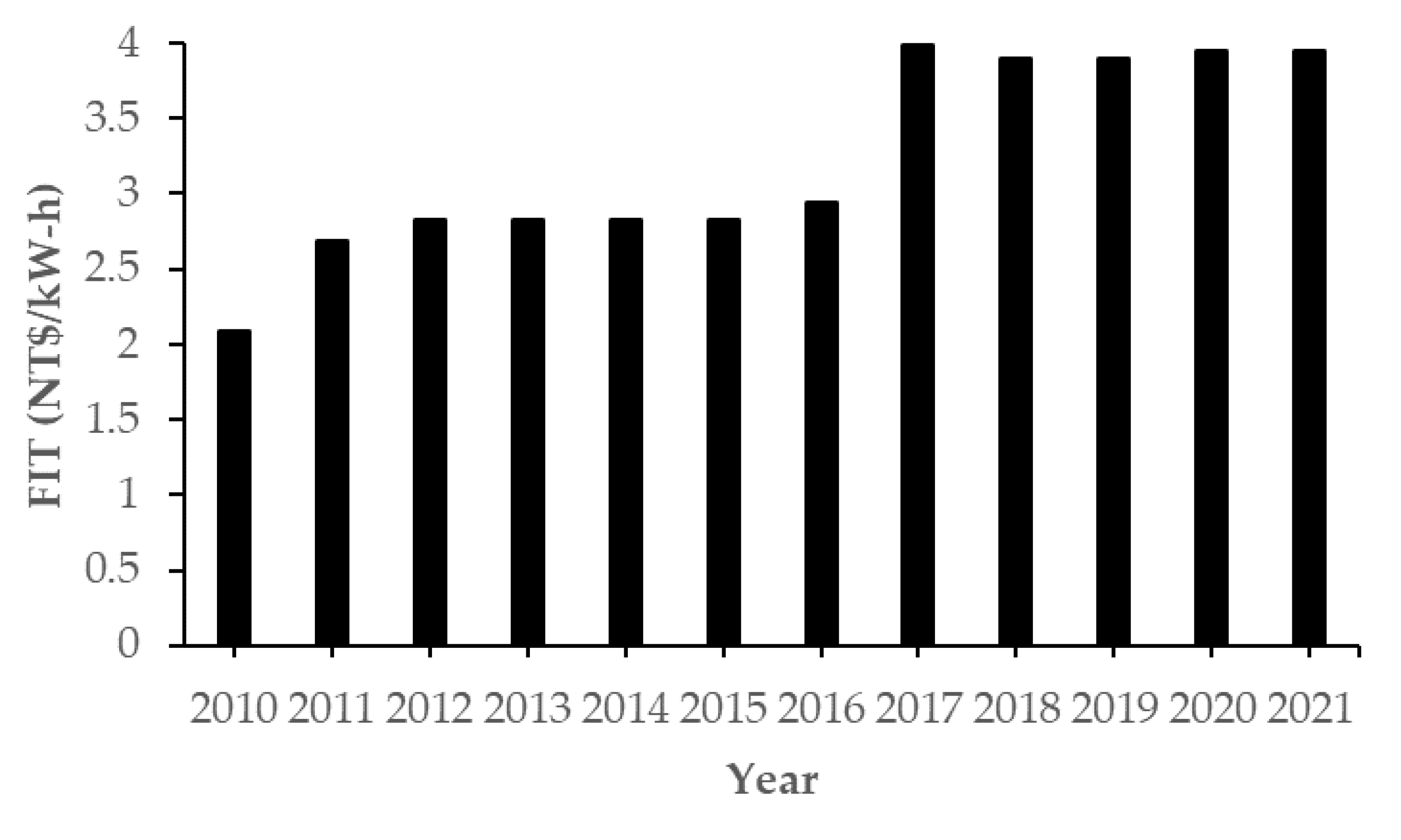

Renewable Energy Development Act

Energy Management Act

3.2.3. Ministry of Interior

3.2.4. Council of Agriculture

Forestry Act

- -

- In order to increase the transfer of carbon from forest biomass to other wood products such as building materials and/or biomass fuels, harvesting of national forest yields shall be carried out according to the annual logging plan and national forest yield management code.

- -

- Forestry enterprises may receive an award if they meet one of the relevant criteria, including large-scale cultivation of forests as a commodity to supply industry, national defense, ship building, road engineering, or other important applications, as well as those who invent or improve tree species, or who undertake bamboo and wood applications and crafts.

Organic Agriculture Promotion Act

3.3. Wood-Based Products for Mitigating the GHG Emissions

3.3.1. Wood-to-Biochar

3.3.2. Wood-to-Building Material

- Ecological GBMs

- Recycled GBMs

3.3.3. Wood-to-Energy

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Food and Agricultural Organization, FAO. Carbon Storage and Climate Change Mitigation Potential of Harvested Wood Products. Available online: http://www.fao.org/forestry/49800-0812a13ea85265539335c760f45630d3d.pdf (accessed on 5 August 2021).

- Januszewicz, K.; Kazimierski, P.; Klein, M.; Kardaś, D.; Łuczak, J. Activated carbon produced by pyrolysis of waste wood and straw for potential wastewater adsorption. Materials 2020, 13, 2047. [Google Scholar] [CrossRef] [PubMed]

- Kosakowski, W.; Bryszewska, M.A.; Dziugan, P. Biochars from post-production biomass and waste from wood management: Analysis of carbonization products. Materials 2020, 13, 4971. [Google Scholar] [CrossRef] [PubMed]

- Haryanto, A.; Hidayat, W.; Hasanudin, U.; Iryani, D.A.; Kim, S.; Lee, S.; Yoo, J. Valorization of Indonesian wood wastes through pyrolysis: A review. Energies 2021, 14, 1407. [Google Scholar] [CrossRef]

- Rodriguez-Franco, C.; Page-Dumroese, D.S. Woody biochar potential for abandoned mine land restoration in the US: A review. Biochar 2021, 3, 7–22. [Google Scholar] [CrossRef]

- Bergman, R.; Puettmann, M.E.; Taylor, A.; Skog, K.E. The carbon impacts of wood products. For. Prod. J. 2014, 64, 220–231. [Google Scholar] [CrossRef]

- European Parliamentary Research Service. Biomass for Electricity and Heating: Opportunities and Challenges. 2015. Available online: https://www.europarl.europa.eu/RegData/etudes/BRIE/2015/568329/EPRS_BRI(2015)568329_EN.PDF (accessed on 5 September 2021).

- Brack, D. Sustainable Consumption and Production of Forest Products. In Proceedings of the Thirteenth Session of the United Nations Forum on Forests, New York, NY, USA, 7–11 May 2018; Available online: https://www.un.org/esa/forests/wp-content/uploads/2018/04/UNFF13_BkgdStudy_ForestsSCP.PDF (accessed on 5 September 2021).

- Besserer, A.; Troilo, S.; Girods, P.; Rogaume, Y.; Brosse, N. Cascading recycling of wood waste: A review. Polymers 2021, 13, 1752. [Google Scholar] [CrossRef]

- World Resources Institute, WRI. 4 Charts Explain Greenhouse Gas Emissions by Countries and Sectors. Available online: https://www.wri.org/insights/4-charts-explain-greenhouse-gas-emissions-countries-and-sectors (accessed on 5 August 2021).

- Intergovernmental Panel on Climate Change (IPCC). 2006 IPCC Guidelines for National Greenhouse Gas Inventories; IPCC: Geneva, Switzerland, 2007. [Google Scholar]

- Tsai, W.T.; Lin, Y.Q. Trend analysis of air quality index (AQI) and greenhouse gas (GHG) emissions in Taiwan and their regulatory countermeasures. Environments 2021, 8, 29. [Google Scholar] [CrossRef]

- Chen, L.C.; Lin, J.C.; Wu, C.S.; Huang, G.M.; Chen, Y.H. The current status of the wood product in Taiwan. Q. J. Forest Res. 2012, 34, 287–296. (In Chinese) [Google Scholar]

- Taiwan Forestry Research Institute, Council of Agriculture. Taiwan Forestry Knowledge Planform—Forestry Information. Available online: https://woodsearch.tfri.gov.tw/information_statistics_search.php (accessed on 5 September 2021).

- Sanchez, D.; Kammen, D. A commercialization strategy for carbon-negative energy. Nat. Energy 2016, 1, 15002. [Google Scholar] [CrossRef]

- Goswami, M.; Pant, G.; Mansotra, D.K.; Sharma, S.; Joshi, P.C. Biochar: A carbon negative technology for combating climate change. In Advances in Carbon Capture and Utilization; Pant, D., Nadda, A.K., Pant, K.K., Agarwal, A.K., Eds.; Springer Nature: Singapore, 2021; pp. 251–272. [Google Scholar]

- Vinci, G.; Ruggieri, R.; Billi, A.; Pagnozzi, C.; Di Loreto, M.V.; Ruggeri, M. Sustainable management of organic waste and recycling for bioplastics: A LCA approach for the Italian case study. Sustainability 2021, 13, 6385. [Google Scholar] [CrossRef]

- Environmental Protection Administration (EPA). Taiwan Greenhouse Gases Inventory; EPA: Taipei, Taiwan, 2020.

- Ministry of Justice, Taiwan. Laws and Regulation Retrieving System. Available online: https://law.moj.gov.tw/Eng/index.aspx (accessed on 3 August 2021).

- Council for Sustainable Development. Annual Review Report on the Taiwan’s Sustainable Development Goals; Environmental Protection Administration: Taipei, Taiwan, 2020. (In Chinese)

- Das, S.K.; Avasthe, R.K.; Singh, R.; Babu, S. Biochar as carbon negative in carbon credit under changing climate. Curr. Sci. 2014, 107, 1090–1091. [Google Scholar]

- Basu, P. Biomass Gasification, Pyrolysis and Torrefaction: Practical Design and Theory, 2nd ed.; Academic Press: San Diego, CA, USA, 2013; pp. 47–86. [Google Scholar]

- Lehmann, J.; Joseph, S. Biochar for environmental management: An introduction. In Biochar for Environmental Management, 2nd ed.; Lehmann, J., Joseph, S., Eds.; Routledge: New York, NY, USA, 2015; pp. 1–13. [Google Scholar]

- Tsai, W.T. Forest resource management and its climate-change mitigation policies in Taiwan. Climate 2021, 9, 3. [Google Scholar] [CrossRef]

- Ministry of Economic Affairs (MOEA). Energy Statistics Handbook; MOEA: Taipei, Taiwan, 2021.

- Hsieh, T.T.; Chiang, C.M.; Ho, M.C.; Lai, K.P. The application of green building materials to sustainable building for environmental protection in Taiwan. Adv. Mater. Res. 2012, 343, 267–272. [Google Scholar] [CrossRef]

- Tsai, W.T. Overview of green building material (GBM) policies and guidelines with relevance to indoor air quality management in Taiwan. Environments 2018, 5, 4. [Google Scholar] [CrossRef] [Green Version]

- Taiwan Architecture and Building Center, TABC. Green Building Materials. Available online: https://www.tabc.org.tw/tw/modules/about/gbm (accessed on 13 June 2021).

- EPA, Taiwan. Industrial Waste Reporting and Management Information System. Available online: https://waste.epa.gov.tw/RWD/Statistics/?page=Month1 (accessed on 16 July 2021).

- Tsai, W.T.; Chou, Y.H. Overview of environmental impacts, prospects and policies for renewable energy in Taiwan. Renew. Sustain. Energy Rev. 2005, 9, 119–147. [Google Scholar] [CrossRef]

- Tzou, L.; Liu, K.H.; Hu, A.H. The development of sustainable materials management (SMM) and circular economy in Taiwan. In Waste Management and Resource Efficiency; Ghosh, S., Ed.; Springer: Singapore, 2019; pp. 209–217. [Google Scholar]

- Makarichi, L.; Jutidamrongphan, W.; Techato, K. The evolution of waste-to-energy incineration: A review. Renew. Sustain. Energy Rev. 2018, 91, 812–821. [Google Scholar] [CrossRef]

- Lorber, K.E.; Sarc, R.; Aldrian, A. Design and quality assurance of solid recovered fuel. Waste Manag. Res. 2012, 30, 370–380. [Google Scholar] [CrossRef] [PubMed]

- Flamme, S.; Geiping, J. Quality standards and requirements for solid recovered fuels: A review. Waste Manag. Res. 2012, 30, 335–353. [Google Scholar] [CrossRef] [PubMed]

| GHG Category | Year | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 2010 | 2011 | 2012 | 2013 | 2014 | 2015 | 2016 | 2017 | 2018 | |

| Carbon dioxide (CO2) | 165,522 | 169,884 | 168,333 | 168,271 | 175,180 | 175,198 | 178,569 | 187,135 | 189,212 |

| Methane (CH4) | 86 | 86 | 86 | 85 | 88 | 91 | 92 | 94 | 94 |

| Nitrous oxide (N2O) | 603 | 607 | 603 | 595 | 599 | 585 | 595 | 621 | 633 |

| Total emission | 166,211 | 170,577 | 169,022 | 168,951 | 175,867 | 175,874 | 179,256 | 187,850 | 189,939 |

| GHG Source | Year | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 2010 | 2011 | 2012 | 2013 | 2014 | 2015 | 2016 | 2017 | 2018 | |

| Main activity electricity and heat production | 150,322 | 154,552 | 152,693 | 151,134 | 156,577 | 156,724 | 160,101 | 169,289 | 170,833 |

| Petroleum refining | 7841 | 7171 | 7838 | 7553 | 8671 | 8710 | 8529 | 8314 | 8862 |

| Manufacture of solid fuels and other energy industries | 8048 | 8854 | 8491 | 10,264 | 10,621 | 10,437 | 10,626 | 10,247 | 10,244 |

| Total emission | 166,211 | 170,577 | 169,022 | 168,951 | 175,867 | 175,874 | 179,256 | 187,850 | 189,939 |

| GHG Category | Year | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 2010 | 2011 | 2012 | 2013 | 2014 | 2015 | 2016 | 2017 | 2018 | |

| Carbon dioxide (CO2) | 41,360 | 42,298 | 41,000 | 42,019 | 38,953 | 38,074 | 38,296 | 36,741 | 33,401 |

| Methane (CH4) | 74 | 79 | 76 | 78 | 74 | 74 | 74 | 69 | 59 |

| Nitrous oxide (N2O) | 135 | 144 | 137 | 140 | 133 | 131 | 131 | 123 | 103 |

| Total emission | 41,569 | 42,521 | 41,213 | 42,237 | 39,160 | 38,279 | 38,501 | 36,933 | 33,563 |

| GHG Source | Year | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 2010 | 2011 | 2012 | 2013 | 2014 | 2015 | 2016 | 2017 | 2018 | |

| Iron and steel | 9546 | 9452 | 9472 | 10,447 | 8810 | 8661 | 8883 | 8557 | 8700 |

| Non-ferrous metals | 296 | 300 | 278 | 287 | 294 | 276 | 259 | 219 | 290 |

| Chemicals | 13,978 | 13,338 | 12,035 | 12,154 | 12,044 | 11,990 | 12,968 | 12,227 | 10,189 |

| Pulp, paper, and print | 2175 | 2544 | 2627 | 2530 | 2397 | 2097 | 2044 | 1951 | 2285 |

| Food processing, beverages, and tobacco | 1062 | 1057 | 1070 | 1005 | 1015 | 993 | 984 | 946 | 997 |

| Nonmetallic minerals | 7222 | 8468 | 8114 | 8237 | 7016 | 6969 | 6428 | 5922 | 4993 |

| Others | 7290 | 7362 | 7617 | 7577 | 7584 | 7293 | 6933 | 7111 | 6109 |

| Total emission | 41,569 | 42,521 | 41,213 | 42,237 | 39,160 | 38,279 | 38,501 | 36,933 | 33,563 |

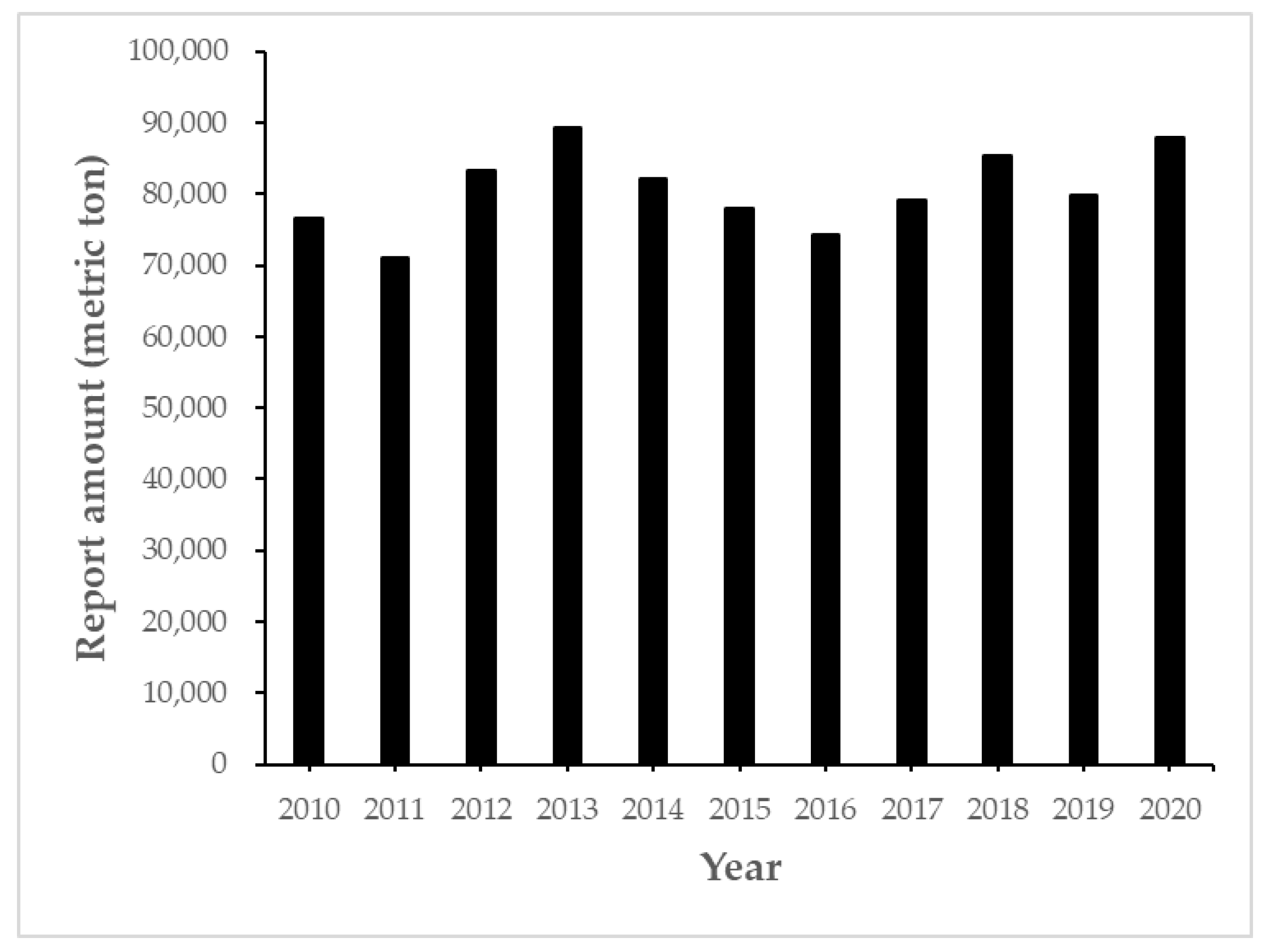

| Waste Wood Category | Year | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 2010 | 2011 | 2012 | 2013 | 2014 | 2015 | 2016 | 2017 | 2018 | 2019 | 2020 | |

| Waste wood (R-0701) | 52,191 | 45,494 | 58,184 | 64,639 | 56,331 | 53,783 | 52,012 | 60,728 | 67,121 | 65,197 | 71,855 |

| Waste wood pallet (D-0701) | 3501 | 3782 | 3493 | 3587 | 3741 | 3807 | 3632 | 3537 | 2915 | 2238 | 2196 |

| Waste mixed wood (D-0799) | 20,988 | 21,860 | 21,702 | 21,113 | 22,061 | 20,377 | 18,610 | 14,902 | 15,369 | 12,480 | 13,911 |

| Total | 76,680 | 71,136 | 83,379 | 89,339 | 82,133 | 77,967 | 74,254 | 79,167 | 85,405 | 79,915 | 87,962 |

| Quality Item | Limit | Unit | Standard Method | Sample Basis | |

|---|---|---|---|---|---|

| Net calorific value | ≥2392 | kcal/kg | Average | CNS 10835 | As received 1 |

| Clorine content | ≤3 | % | Average | EN 15408 | db 2 |

| Mercury content | ≤5 | mg/kg (db) | Average | EN 15411 | As received 1 |

| Lead content | ≤150 | mg/kg (db) | Average | EN 15411 | As received 1 |

| Cadmiun content | ≤5 | mg/kg (db) | Average | EN 15411 | As received 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tsai, W.-T. Carbon-Negative Policies by Reusing Waste Wood as Material and Energy Resources for Mitigating Greenhouse Gas Emissions in Taiwan. Atmosphere 2021, 12, 1220. https://doi.org/10.3390/atmos12091220

Tsai W-T. Carbon-Negative Policies by Reusing Waste Wood as Material and Energy Resources for Mitigating Greenhouse Gas Emissions in Taiwan. Atmosphere. 2021; 12(9):1220. https://doi.org/10.3390/atmos12091220

Chicago/Turabian StyleTsai, Wen-Tien. 2021. "Carbon-Negative Policies by Reusing Waste Wood as Material and Energy Resources for Mitigating Greenhouse Gas Emissions in Taiwan" Atmosphere 12, no. 9: 1220. https://doi.org/10.3390/atmos12091220

APA StyleTsai, W.-T. (2021). Carbon-Negative Policies by Reusing Waste Wood as Material and Energy Resources for Mitigating Greenhouse Gas Emissions in Taiwan. Atmosphere, 12(9), 1220. https://doi.org/10.3390/atmos12091220