Abstract

Refineries are a major source of atmospheric emissions, which typically include CO, SO2, NOX, particulates, and volatile organic compounds (VOCs). There has been an increasing level of attention toward the emissions of VOCs related to their environmental impact as well as their potential to cause adverse effects on human health and the discomfort associated with their unpleasant odor. In general, an emission factor (EF) represents a model for a first order estimate of emissions, which correlates the quantity of pollutant released into the atmosphere with a so-called “activity index” related to the release of that pollutant. Based on the study of the scientific and technical literature regarding the Italian and European refining scenarios, an attempt was made to verify the existence of a correlation between the size of a refinery and the related total VOC emissions. Once this correlation was evaluated, it was possible to develop an emission factor for VOC emissions considering the plant capacity as the related activity index. After collecting and analyzing data concerning operative capacity and total VOCs emitted from 15 refineries in 2018, the resulting emission factor turned out to be equal to 188 ± 166 g per ton of crude oil processed. This value is in agreement with the range of 50–1000 g/ton reported in the European Best Available Techniques Reference Document for the Refining of Mineral Oil and Gas.

1. Introduction

One of the main environmental impacts of refinery process units is represented by atmospheric emissions [1], which typically consist of CO, CO2, SO2, NOX, CH4, particulates, and volatile organic compounds (VOCs) [2,3].

Under the definition of VOCs, several chemical compounds comprising different functional groups are included. These include hydrocarbons, which contain carbon and hydrogen as constituents and are divided into aliphatic and aromatic, and other compounds containing oxygen, chlorine, or other elements in addition to carbon and hydrogen such as aldehydes, ethers, alcohols, esters, chlorofluorocarbons (CFC), and hydrochlorofluorocarbons (HCFC) [4,5]: all substances classified as VOCs have different physical and chemical behaviors, but are all characterized by a certain volatility.

In recent years, there has been increasing attention toward the emission of VOCs related to their environmental impact [6,7] as well as their potential to produce adverse effects on human health [8,9,10]. Indeed, among the VOCs, there are 187 compounds defined as hazardous air pollutants (HAP) [11], whose potential carcinogenicity and responsibility for other serious damage to human health makes them particularly critical [11].

VOCs, together with NOx and CO, have a high ozone formation potential (OFP), which makes these substances considered as majorly responsible for the formation of ozone in densely populated and industrialized areas [12]. At ground level, the ozone molecule is formed when these pollutants react due to the presence of solar radiation.

Another problem connected with the emissions of VOCs is odor annoyance [13,14,15], since most chemicals with a certain volatility are characterized by a more or less intense and perceptible odor [16].

Despite the problems above-mentioned, no environmental control agency, at the current state of technical and regulatory progress, fixes a specific emission limit for VOCs as a class of substances. In fact, unlike the previously mentioned combustion products [2,17], for which environmental control agencies all over the world have imposed and, over the years, continue to revise the threshold values relevant to annual emissions from refineries [3], for the VOC category, this limit has not been established as yet. Indeed, limits for VOC emissions set at 90,000 tons per year can be found in EPA databases for other sectors [18], but not for the refining sector.

One tool for an easy and immediate estimation of the emission level and the associated impacts related to the release of pollutants from a refinery into the atmosphere is the so-called emission factor (EF). In general, an emission factor is a representative value that relates the amount of a pollutant released to the atmosphere to a given associated activity [19].

This work aims to evaluate an emission factor (EF) relevant to the VOCs emitted by refineries in Europe and, in particular, in Italy [19,20]. The EF provides a first order estimate of emissions based on a limited quantity of information about the examined plant. This is particularly useful due to the fact that the scientific and technical literature lacks these types of data. Indeed, in the scientific literature, it is possible to find data about the concentration of specific pollutants in ambient air [21,22]. By looking into the Integrated Pollution Prevention and Control (IPPC) emission inventory, emission factors for CO2, depending on the type of fuel, can be found by searching in the “petroleum refineries” sector [23]. In the same inventory, in the “oil” section, it is possible to find data relevant to the VOCs emitted from some unit operations such as fluid catalytic cracking (FCC) or storage areas. However, since these data are related to specific sources of the whole plant, they represent only a small fraction of the unit operations that can be found in a refinery, and thus do not allow for an estimation of the overall emissions.

Additionally, in the database of the European Environmental Agency (EEA) regarding large combustion plants (LCP) [24], emission values related to VOC emissions are not mentioned in the “emission to air” section, which merely focuses on NOx, SO2, and dust.

Regarding Italian emission inventories, the database issued by “Istituto Superiore per la Protezione e la Ricerca Ambientale”(ISPRA) [25] includes an annual emission value for VOCs related to industrial plants, however, it is not possible to isolate the emission values related to refineries. Furthermore, in the Italian Greenhouse Gas Inventory [26], some VOC values have been collected for various industrial plants, but are not available for the refining sector.

The procedure followed in this work to determine an EF for VOCs first involved a comparison of the total emission values collected for different refineries with their operational capacities with the aim to highlight characteristic and repeatable trends, which are needed in order to generalize the statements and to relate the emission levels and the capacity of a single plant through a general trend. Once the relationship between these two quantities is verified, it is then possible to determine a global EF for refineries.

For those who deal with the assessment of emissions, the knowledge of a global EF allows for a preliminary assessment of the emissions related to a plant that has yet to be investigated to be obtained, without knowing the detail of the different operations that are run in the plant. Indeed, by knowing only the operational capacity of the considered refinery, the overall VOC emissions can be estimated simply as the product of the EF by the operational capacity. Furthermore, a more accurate value for the EF may be evaluated based on more detailed data about the refinery unit operations and their emissions, retrieved, for instance, from experimental field measurements.

2. Materials and Methods

2.1. Origin of the Emission Data

All the refineries analyzed in this paper are plants for which we were able to retrieve specific information concerning both total VOC emissions and operative capacity, either from the literature or from technical data provided upon request by the companies that operate the plants [2]. The collected values are representative of the metric tons emitted 2018, and were reported by refineries in their environmental impact document for 2018.

Despite extensive bibliographic research, the number of useful data retrieved for the implementation of the EF are limited, since it is not easy to find information relating to the total VOCs emitted by a plant in order to make it linkable with the plant operational capacity.

In many documents, VOC emissions are reported depending on the sections they are emitted from. This is the case, for instance, for the classification performed within the European Best Available Techniques Reference Document for the Refining of Mineral Oil and Gas (BREF) [2]. According to the aforementioned BREF, the main contributions to VOC emissions are emissions from process plant units, combustion plant units, storage section, loading section, the wastewater treatment plant, and fugitive emissions. Thus, within the BREF, the data relating to the total VOC emissions is divided according to these six emissive “macro” sections. Further detail about the VOCs emitted from other unit operations is not provided. This is the same for the data regarding VOC emissions that can be found in sector-specific scientific and technical literature [27,28,29,30].

In the scientific literature, it is possible to find some studies about the loss of VOCs from the tank parks of refining plants, caused by the handling of the tanks, their respiration, and the loading/unloading operations [22]. Moreover, technical reports exist with regard to the monitoring of fugitive emissions from all sections of a refinery such as pressure pipes and the related components installed on them [31,32], which represent roughly 50% of the total emissions [33] as well as the water treatment lines present within the plants [34].

Although these are the main sources of VOC emissions, each of the unit operations such as vacuum distillation, catalytic and thermal cracking, sweetening and blowdown, which are indicated by the EPA as “significant process emission sources” for Non-Methane Volatile Organic Compounds (NMVOC) at petroleum refineries [35], is able to contribute, to a greater or lower extent according to different factors (age, process configuration, treated material), to the total VOC emissions reported in the environmental documents.

Each plant is different and can include a combination of all of the unit operations foreseen for the refining sector [35,36,37]; in some cases, refineries may include one or more than one version of the same operation, based on the number of production lines and the type of final products they are able to supply. All of these unit operations are sources of VOC emissions; indeed, according to specific emission inventories, typically SRU (sulfur recovery unit) plants and fugitive dust sources in refineries are not accounted as sources of VOC emissions due to their low contribution to this kind of emission [3,38].

Moreover, the data found for the Italian and European case were “non speciated” (i.e., they consider VOC emissions as a whole). There are other types of databases and emission inventories reporting information relating to the different substances emitted. This is, for instance, the case of the National Emission Inventories (NEIs) [39] compiled by the U.S. EPA, which report, for example, the specific HAP issued by each plant, with the possibility of tracing them back to different plant sections and unit operations [40]. These data, which are available only for U.S. refineries, could not be considered within this work, but are being used for developing similar studies referring to the U.S. scenario.

In conclusion, for this work, we considered the total VOC emissions of Italian and European refineries. In detail, the data about VOC emissions were analyzed for plants for which it was possible to obtain information about the quantity of VOCs emitted and the operational capacity, thereby referring 2018. This evaluation was carried out in order to provide a first-order estimate of the VOCs emitted, which can be used for preliminary considerations on the emission levels of a refinery before performing a deeper analysis considering the compounds produced by different processes.

Even though in this work the overall VOC emissions were used for the evaluation of the emission factor, in order to provide a deeper analysis of the plants considered, the unit operations present in the considered Italian and European plants are reported below in Table 1 and Table 2, respectively. For some of the plants, detailed data about the unit operations could not be retrieved and thus were not reported. It is important to highlight that, despite knowing the list of unit operations installed at the considered refineries, emission data from single unit operations were not provided.

Table 1.

Unit operations present in the examined Italian refineries. CDU = Crude Distillation Unit, Vacuum = Vacuum Distillation Unit, FCC = Fluid Catalytic Cracking, CCR = Continuous Catalytic Reforming, Isomer. = Isomerization Section, Desulf. = Desulfurization Section, SRU = Sulfur Recovery Unit, H2 = Hydrogen Plant.

Table 2.

Unit Operations present in the examined European refineries. CDU = Crude Distillation Unit, Vacuum = Vacuum Distillation Unit, FCC = Fluid Catalytic Cracking, CCR = Continuous Catalytic Reforming, Isomer. = Isomerization Section, Desulf. = Desulfurization Section, SRU = Sulfur Recovery Unit, H2 = Hydrogen Plant).

The category defined as “Other” in Table 1 and Table 2 refers to processes such as visbreaking, hydrocracking, alkylation, and naphtha and asphalt treatments.

As already mentioned, in the emission database prepared by IPPC, some EF values relevant to VOC emissions have been proposed for some specific refinery sections. However, it is not possible to compare them with the data presented in this manuscript, as they are presented without the details related to the specific emissions of each unit operation.

2.2. Emission Data Regression through R2 Estimation

In order to first verify the opportunity to use the plant capacity as an activity index for the evaluation of the EF, all data collected were preliminarily analyzed with the aim of verifying the existence of a trend relating the emissions of VOCs with the selected activity index.

To evaluate this relationship, the capacity and emissions of each plant were reported in graphs from which the trend line for each considered scenario and the relative coefficient of determination were evaluated.

In statistics, the coefficient of determination (more commonly R2 [41]) is a proportion between the variability of the data and the correctness of the statistical model used. It measures the fraction of the variance of the dependent variable expressed by the regression. There is no agreed definition of R2. In simple linear regressions, it is the square of the correlation coefficient:

where ESS represents the deviance explained by the model; TSS represents the total deviance of the system; and RSS represents the residual deviance, and they are calculated as follows:

where is the observed data; is the mean value of observed data; and is the data estimated by the employment of a regression model.

R2 varies between 0 and 1: if the value is close to 1, it means that the regression model is able to well predict the value of the dependent variable in the sample, whereas if it is close to 0, it means that the model is not reliable.

2.3. Calculation of the Emission Factors

As stated before, the calculation of the EF for this work was proposed by comparing the ratio of the two quantities examined, which were the total VOC emissions and the operational capacity of the plants (considered as the activity index). The data were represented in graphs and the trend line was traced in order to evaluate the existence of a correlation between these two quantities.

The illustrated data represent the emissions expressed in ton/y, and the operational capacity reported in millions of ton/y. The EF is then presented in grams of VOC per tons of crude oil processed (g/ton), and its value is estimated as shown later in the “Discussion” section.

3. Results

Graphs Analysis and R2 Evaluation

The analysis of the data relevant to Italian and European refineries, used for the evaluation of trend lines and R2 values, showed that there was a trend that correlates the production capacity of a plant with the amount of VOC emissions, thus making it possible to affirm that there is a proportionality between refinery size and emissions in terms of total VOC.

The following section illustrates how the values of the parameter R2, which expresses the proximity to a linear model for the relationship between production capacity and emissions, vary according to the different scenarios considered.

The names of the plants are not reported in this paper, since data are confidential and not open access.

Table 3 reports the list of the refineries (Italian and European) considered in this study, for which it was possible to retrieve data about the operational capacity and total VOC emissions. Usually, data relating to operational capacity are reported in millions of tons per year, but in this work, to obtain an immediate comparison with the emission data, they were reported in ton/y.

Table 3.

Operational capacities and volatile organic compound (VOC) emissions of the Italian and European refineries considered for this study.

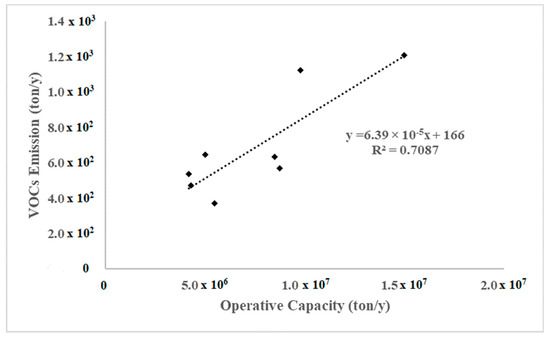

After collecting the data, these were reported in graphs to evaluate the R2 value. In Figure 1, the Italian refineries are analyzed and it is possible to observe that the resulting R2 value was equal to 0.71. The significance of this value will be discussed later.

Figure 1.

Scenario 1: Total VOC emissions vs. operational capacity for Italian refineries.

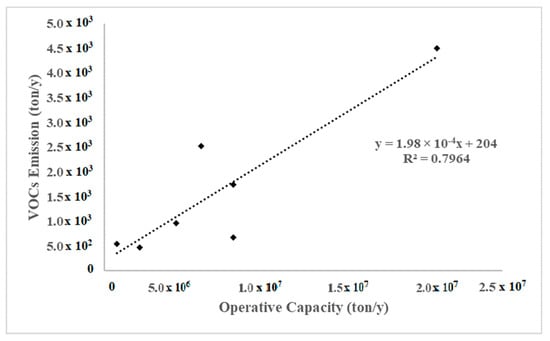

In addition, for the European scenario (setting aside the Italian plants), data concerning the operational capacity and VOC emissions for European refineries were collected, and their trend is illustrated in Figure 2. The resulting value of R2 value was equal to 0.79.

Figure 2.

Scenario 2: Total VOC emissions vs. operational capacity for European refineries.

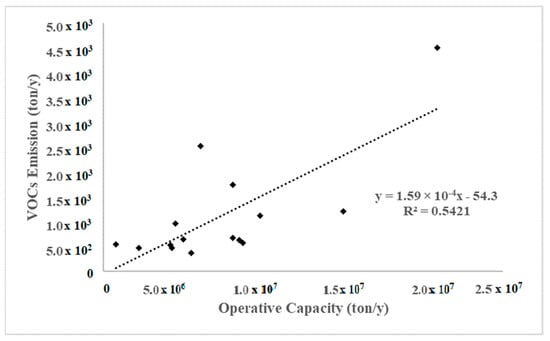

The last step of this investigation involved the unified evaluation of the two previously illustrated datasets, thus putting together the information about the Italian and European refineries considered in this study.

Figure 3 reports the trend and the R2 value for this third scenario, which was equal to 0.54.

Figure 3.

Scenario 3: Total VOC emissions vs. operative capacity for Italian and European refineries.

4. Discussion

4.1. Comparison of R2 Values

Table 4 summarizes the R2 values determined for the three scenarios considered in this study.

Table 4.

R2 values for the three scenarios considered.

In each scenario analyzed, the resulting R2 values were above 0.5, thus pointing out the existence of a correlation between the quantity of VOCs emitted and the refinery treatment capacity: the bigger the refinery, the more its VOC emissions.

The correlation highlighted above supports the choice of the operational capacity as an activity index for the estimation of the EF. This consideration may appear obvious, but is not. Indeed, it is important to highlight that other parameters besides the plant capacity may influence the emissions of an installation such as a lack of controls or poor maintenance of old and deteriorated equipment, which may lead small plants to have much higher emissions than bigger plants, but are properly maintained and operated.

Regarding the values of R2 obtained in this study, according to what can be found in the literature [42,43,44], a value of 0.7 for R2 can be assumed as marking the transition from a modest to a strong linear correlation while considering the linear behavior of a dataset. This means that a strong linear correlation between the operational capacity of the refinery and total VOC emissions exists for the plants considered in scenarios 1 and 2, separately.

The R2 value obtained for scenario 3, which considered Italian and European refineries together, was lower. Nonetheless, a R2 value of 0.5 is representative of the existence of a modest linear correlation [45]. This is important for the purpose of this work, since it proves that data relevant to Italian and European refineries are comparable, and thus can numerically be considered as part of the same context.

4.2. Estimation of An Emission Factor (EF) for Total VOC Emissions

Based on the analysis of the emission and capacity data analyzed in the previous paragraphs, it was finally possible to define a numerical value for the EF expressing the total VOC emitted by a refinery as a function of its capacity.

Despite the third scenario being the one with the lowest value of R2, it was selected for the evaluation of the EF, which was therefore obtained by putting together the data relevant to the Italian and European refineries. This choice is related to the scarcity of data available; to increase the significance of the EF, it was decided to base its calculation on the data of all refineries available for the year 2018 (i.e., 15 plants).

The value of the EF for each refinery was calculated as the ratio between the quantity of VOC emitted by the plant, and its operational capacity.

Once this calculation was performed on each of the plants considered, an average EF (µ) was calculated, together with the median and the standard deviation of the considered data sample. It was not possible to pursue a deeper statistical analysis due to the limited number of data available.

Table 5 reports the mean, median, and standard deviation values for the considered dataset, represented by the ratios of the total VOC emissions and the operative capacity of each plant. All the data reported were expressed in grams of VOC per ton of crude oil processed [g/ton].

Table 5.

Mean, median, and standard deviation of the EF of the evaluated assuming a normal distribution of the dataset.

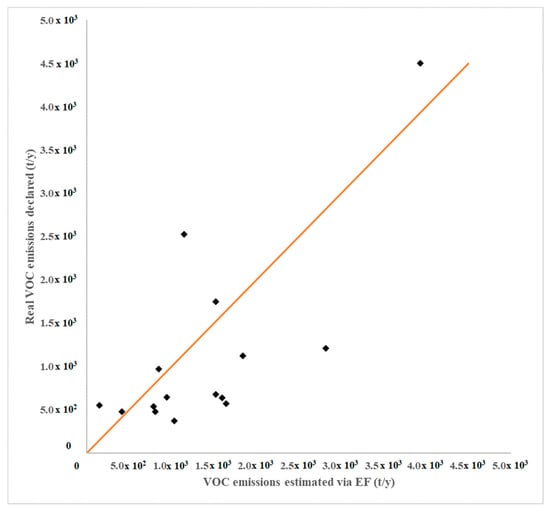

The average value (µ) relevant to the analyzed sample was equal to 188 g of VOC emitted per ton of oil treated, which can be considered as the EF for the total VOC emissions relevant to Italian and European refineries. Under this assumption, it is possible to re-calculate the total VOC emissions of the plants considered for this study by using this EF and multiplying it by the operational capacity of each refinery. The total VOC emissions re-calculated based on the EF estimated in this study and the real VOC emissions declared by the plant operators were then compared by means of a Q–Q (Quantile–Quantile) plot test [46] (Figure 4).

Figure 4.

Quantile–Quantile (Q–Q) plot comparing the real VOC emissions vs. VOC emissions estimated with the proposed EF (in t/y).

Furthermore, the EF value proposed here can be compared with other emission values reported in the scientific and technical literature.

As stated before in the “origin of emission data” section, the IPPC proposes an emission factor database (EFDB) that collects EFs for industrial processes [47]. By selecting the “oil” section in the database, it is possible to find some EFs proposed for the refinery sector. In detail, EF values are proposed for fugitive emissions (0.53 kg/m3 of feedstock, e.g., crude oil), the FCC (0.6 kg/m3 of oil), and for the storage sections (0.2, 0.7, and 4.9 g/kg oil throughput, depending on the roof type of the considered tank). By converting the unit of measurements, it is possible to highlight that these values represent an emission range of 200–5000 grams of VOC per ton of crude oil processed. Thus, these values are considerably higher than the EF obtained in this study, especially in consideration of the fact that they only referred to a few sections of the plant, and thus do not represent the overall VOC emissions of the refinery. This difference could be explained by the fact that the data collected in the IPPC database are related to the years 1991–1996 (i.e. 25–30 years ago), when equipment and process configurations had lower efficiencies in the containment of atmospheric emissions. Additionally, the analytical techniques used for VOC measurement and estimation of EFs have been subject to improvements and revisions over the years.

The Best Available Techniques (BAT) Reference Document for the Refining of Mineral Oil and Gas published by the European Integrated Pollution Prevention and Control Bureau [2] reports values for VOC emissions ranging from 50 to 1000 g of VOC emitted per ton of crude oil processed. Thus, it is possible to observe that the EF calculated in this study, being equal to 188 g/ton, falls within the range proposed in the BAT document. This is supposed to be an average value for ordinary operations, thus does not account for extraordinary situations or emission peaks following incidental events. Based on the emission values reported in Figure 3.16 on page 145 of the above-cited BAT reference document [2], it is possible to extrapolate a mean EF value, relevant to the emissions of 39 European refineries in 2015, equal to 241 ± 170 grams of VOC emitted per ton of crude oil processed. This value was only 20% higher than the EF evaluated in this paper. The difference between the values may be due to the year in which the data were collected, and the number of data used to calculate the average value.

As a general rule, the use of an EF for the rough estimation of emissions is easier than searching in emission inventories. As an example, the IPPC provides specific software for searching the database, which collects emissions data from different industrial processes [1,47]. In this database, it is possible to search for the emission factors relevant to the petroleum refining sector. However, the only information that can be found concerns CO2 emissions related to the different fuels employed to run the plant, whereas no emission factors related to VOC emission factors are provided for this industrial sector.

Besides the technical documentation, we also explored the scientific literature in search of similar data, in order to provide a comparison of the EF proposed in this work with some literature data. However, the quantity of similar data available in the scientific literature is very scarce.

A study carried out on a refinery in Texas in 2015 [48] described a plant with an operational capacity of 17.3 million tons of crude oil per year having an overall VOC emission of 3027 tons per year, which corresponded to an EF of 174 g/ton of crude. This value is indeed very close the EF proposed in the present paper, which was less than 10% higher.

Moreover, in a paper about the U.S. refining scenario from 2014 [49], an EF for VOCs was evaluated in a range of 80–110 g/ton (this value was obtained after conversion of the data proposed, which were reported as g/MJ of energy consumed), which in turn is also very similar to the EF proposed here.

5. Conclusions

The aim of this paper was to provide an emission factor (EF) for the overall VOC emissions from Italian and European refineries.

For our evaluation, we first verified that by choosing the operational capacity of a plant as the activity index for estimating an emission factor, a linear trend with a good approximation could be obtained.

The purpose of this work was to provide a tool for a first order estimation of refinery emissions, which will be representative of an average emissive situation, thereby excluding peak conditions and incidental releases. For those who deal with the assessments of emissions, the knowledge of a global EF allows a preliminary assessment of the emissions related to a refinery to be obtained, needing only the datum relevant to the operational capacity of the considered plant.

The EF for VOCs emitted from European refineries evaluated in this study was equal 188 ± 166 g per ton of crude oil processed. This value is in agreement with the range of 50–1000 g/ton that can be found in the Best Available Techniques (BAT) Reference Document for the Refining of Mineral Oil and Gas [2] published by the European Integrated Pollution Prevention and Control (IPPC) Bureau.

In the scientific literature as well as in the databases collecting emission factors, different EF values can be found, which are calculated for different unit operations or for entire plant sections (among the most common are those relating to storage, water treatment, and fugitive emissions). However, EFs related to single unit operations are lacking, while the contribution of the main emission sections covers rather wide ranges that may vary on a case-by-case basis. A possible interesting future development could be the improvement of the evaluation of the EF for individual plant units in order to develop a more accurate correlation, allowing for a better estimate of the VOC emissions from different plant sections.

Author Contributions

Conceptualization, M.I., L.C. and S.S.; Data curation, L.R. and E.P.; Formal analysis, M.I.; Writing—original draft, L.R.; Writing—review & editing, L.C. and S.S. All authors have read and agreed to the published version of the manuscript.

Funding

This project has received funding from the European Union’s HORIZON 2020 research and innovation programme under grant agreement No 789315.

Conflicts of Interest

The authors declare no conflict of interest.

References

- European Commission. Integrated Pollution Prevention and Control Reference Document on Best Available Techniques in the Slaughterhouses and Animal By-Products Industries May 2005. Available online: https://eippcb.jrc.ec.europa.eu/sites/default/files/2020-01/sa_bref_0505.pdf (accessed on 28 May 2020).

- Barthe, P.; Chaugny, M.; Roudier, S.; Delgado Sancho, L. Best Available Techniques (BAT) Reference Document for the Refining of Mineral Oil and Gas; Publications Office of the European Union: Brussels, Belgium, 2015. [Google Scholar]

- US Environment Protetion Agency. Emission Estimation Protocol for Petroleum Refineries; US Environment Protetion Agency: Washington, DC, USA, 2015; Volume 3, p. 250. [Google Scholar]

- US Environment Protetion Agency. Tennessee Air Pollution Control Regulations—Chapter 1200-3-18—VOLATILE ORGANIC COMPOUNDS; US Environment Protetion Agency: Atlanta, GA, USA, 2017; ISBN 1200-3-18-290. [Google Scholar]

- Ministero della Salute. Composti Organici Volatili (COV) Direzione generale della prevenzione sanitaria Direzione generale della comunicazione e dei rapporti europei e internazionali. Available online: http://www.salute.gov.it/imgs/C_17_opuscoliPoster_283_ulterioriallegati_ulterioreallegato_3_alleg.pdf. (accessed on 27 May 2020).

- Hakami, A.; Bergin, M.S.; Russell, A.G. Ozone formation potential of organic compounds in the Eastern United States: A comparison of episodes, inventories, and domains. Environ. Sci. Technol. 2004, 38, 6748–6759. [Google Scholar] [CrossRef]

- Duan, J.; Tan, J.; Yang, L.; Wu, S.; Hao, J. Concentration, sources and ozone formation potential of volatile organic compounds (VOC) during ozone episode in Beijing. Atmos. Res. 2008, 88, 25–35. [Google Scholar]

- Wu, C.; Liu, J.; Liu, S.; Li, W.; Yan, L.; Shu, M.; Zhao, P.; Peng Zhou, P.; Cao, W. Assessment of the health risks and odor concentration of volatile compounds from a municipal solid waste landfill in China. Chemosphere 2018, 202, 1–8. [Google Scholar] [PubMed]

- Zhang, Z.; Yan, X.; Gao, F.; Thai, P.; Wang, H.; Chen, D.; Zhou, L.; Gong, D..; Li, Q.; Morawska, L.; et al. Supplementary information: Emission and health risk assessment of volatile organic compounds in various processes of a petroleum re fi nery in the Pearl River Delta. Environ. Pollut. 2018, 238, 452–461. [Google Scholar] [CrossRef] [PubMed]

- Volatile Organic Compuounds (VOC): Your Environment, Your Health|National Library of Medicine. Available online: https://toxtown.nlm.nih.gov/chemicals-and-contaminants/volatile-organic-compounds-VOC (accessed on 11 December 2019).

- US Environment Protetion Agency. Health and Environmental Effects of Hazardous Air Pollutants|Hazardous Air Pollutants. Available online: https://www.epa.gov/haps/health-and-environmental-effects-hazardous-air-pollutants (accessed on 15 May 2020).

- EMEP/EEA Air Pollutant Emission Inventory Guidebook. 2016 Fugitive Emissions oil-Refining/Storage. Available online: https://webcache.googleusercontent.com/search?q=cache:bFzVb5fu0UYJ:https://www.eea.europa.eu/publications/emep-eea-guidebook-2016/download+&cd=1&hl=it&ct=clnk&gl=it (accessed on 27 May 2020).

- Invernizzi, M.; Ilare, J.; Capelli, L.; Sironi, S. Proposal of a method for evaluating odour emissions from refinery storage tanks. Chem. Eng. Trans. 2018, 68, 49–54. [Google Scholar]

- Axelsson, G.; Stockfelt, L.; Andersson, E.; Gidlof-Gunnarsson, A.; Sallsten, G.; Barregard, L. Annoyance and worry in a petrochemical industrial area—Prevalence, time trends and risk indicators. Int. J. Environ. Res. Public Health 2013, 10, 1418–1438. [Google Scholar]

- Belgiorno Naddeo, Z. Odour Impact Assessment Handbook. Automot. Eng. 2010, 35, 18. [Google Scholar]

- American Industrial Hygiene Association. Odor Thresholds for Chemicals with Established Health Standards, 2nd ed.; AIHA: Falls Church, VA, USA, 2003. [Google Scholar]

- Presidente della Repubblica Italiana. Decreto legislativo n.183, 15 novembre 2017. Gazzetta Ufficiale. 2017, pp. 15–18. Available online: https://www.gazzettaufficiale.it/eli/id/2017/12/16/17G00197/sg (accessed on 28 May 2020).

- Consumer Products: National Volatile Organic Compound Emission Standards | Stationary Sources of Air Pollution|US EPA. Available online: https://www.epa.gov/stationary-sources-air-pollution/consumer-products-national-volatile-organic-compound-emission (accessed on 15 May 2020).

- US Environment Protetion Agency. AP-42: Compilation of Air Emissions Factors|Air Emissions Factors and Quantification|US EPA. Available online: https://www.epa.gov/air-emissions-factors-and-quantification/ap-42-compilation-air-emissions-factors (accessed on 15 May 2020).

- Sims, N.; Palm, B. What is an Emission Factor. Available online: https://www.mecknc.gov/LUESA/AirQuality/PermittingRegulations/Documents/EmissionCalculations.pdf (accessed on 27 May 2020).

- Hsu, C.; Chiang, H.; Shie, R.; Ku, C.; Lin, T.; Chen, M.; Chen, N.; Chen, Y. Ambient VOC in residential areas near a large-scale petrochemical complex: Spatiotemporal variation, source apportionment and health. Environ. Pollut. 2018, 240, 95–104. [Google Scholar] [CrossRef]

- Wei, W.; Cheng, S.; Li, G.; Wang, G.; Wang, H. Characteristics of volatile organic compounds (VOC) emitted from a petroleum refinery in Beijing, China. Atmos. Environ. 2014, 89, 358–366. [Google Scholar]

- Integrated Pollution Prevention and Control (IPPC). Prevenzione e Riduzione Integrate Dell’Inquinamento, Decreto Legislativo 372/99 (art. 3, comma 2). Linea Guida E&CM 2005, 99, 1–243. [Google Scholar]

- European Environment Agency. Plant-by-Plant Emissions (LCP) and Information on Derogations. Available online: https://www.eea.europa.eu/data-and-maps/data/lcp-9/plant-by-plant-emissions-lcp (accessed on 14 May 2020).

- Istituto Superiore per la Protezione e la Ricerca Ambientale. Italian Emission Inventory 1990–2017. 2019. Available online: https://www.isprambiente.gov.it/it/pubblicazioni/rapporti/italian-emission-inventory-1990-2017-informative-inventory-report-2019 (accessed on 27 May 2020).

- Istituto Superiore per la Protezione e la Ricerca Ambientale. Italian Greenhouse Gas Inventory 1990–2018. 2020. Available online: https://www.isprambiente.gov.it/it/pubblicazioni/rapporti/italian-greenhouse-gas-inventory-1990-2018.-national-inventory-report-2020 (accessed on 27 May 2020).

- Lu, C.; Huang, H.; Chang, S.; Hsu, S. Emission characteristics of VOC from three fixed-roof p-xylene liquid storage tanks. Environ. Monit. Assess. 2013, 185, 6819–6830. [Google Scholar] [CrossRef] [PubMed]

- Howari, F.M. Evaporation losses and dispersion of volatile organic compounds from tank farms. Environ. Monit. Assess. 2015, 187, 273. [Google Scholar] [CrossRef]

- Chambers, A.K.; Strosher, M.; Wootton, T.; Moncrieff, J.; McCready, P. Direct measurement of fugitive emissions of hydrocarbons from a refinery. J. Air Waste Manag. Assoc. 2008, 58, 1047–1056. [Google Scholar] [CrossRef] [PubMed]

- Cheng, W.H.; Chou, M.S. VOC emission characteristics of petrochemical wastewater treatment facilities in southern Taiwan. J. Environ. Sci. Health Part A 2003, 38, 521–2535. [Google Scholar] [CrossRef] [PubMed]

- Furry, E.D.W.; Harris, A.G.; Ranum, B.D.; Anderson, B.E.P.; Carlstrom, C.V.M.; Sadik, D.W.A.; Shockley, A.C.E.; Siegell, D.J.H. Evaluation of Instrument Leak Detection Capabilities for smar LDAR Application: Refinery Testing. Environ. Prog. Sustain. Energy 2014, 33, 676–680. [Google Scholar]

- U.S. Enviromental Protection Agency. VOC Fugitive Losses: New Monitors, Emission Losses, and Potential Policy Gaps. 2006. Available online: https://www3.epa.gov/ttn/chief/efpac/documents/wrkshop_fugvocemissions.pdf (accessed on 27 May 2020).

- Bakker, A.; Benavente, E.; Caamaño, B.; Duclaux, O.; Durand, M.; Fragu, L.; Kangas, P.; Leventos, D.; Ribeiro, N.; Roberts, P.; et al. Air pollutant emission estimation methods for E-PRTR reporting by refineries. Concawe Rep. 2015, 3, 215. [Google Scholar]

- Fatehifar, E.; Kahforoshan, D.; Khazini, L.; Soltanmohammadzadeh, J.S.; Sattar, H.R. Estimation of VOC Emission from Wastewater Treatment Unit in a Petrochemical Plant Using Emission Factors. In Proceedings of the WSEAS Conferences, Cantabria, Spain, 23–25 September 2008; pp. 87–193. [Google Scholar]

- EMEP/EEA. Production processes—Emission Inventory Guidebook. 1999. Available online: https://www.eea.europa.eu/publications/EMEPCORINAIR (accessed on 27 May 2020).

- US Environment Protetion Agency. AP-42: Compilation of Air Emissions Factors - Air Emissions Factors and Quantification: Stationary and Point Sources. 2009. Available online: https://www.epa.gov/air-emissions-factors-and-quantification/ap-42-compilation-air-emissions-factors (accessed on 27 May 2020).

- Malakar, S.; Das Saha, P. Estimation of VOC Emission in Petroleum Refinery ETP and Comparative Analysis with Measured VOC Emission Rate Srikumar Malakar, 2 Papita Das Saha. IJES 2015, 4, 20–29. [Google Scholar]

- RTI International. Compilation of Non-confidential Component 1 Responses to the 2011 Petroleum Refinery Information Collection Request Purpose. RTI Int. Mem. 2010, 69–73. [Google Scholar]

- US Environment Protetion Agency. 2014 National Emissions Inventory 2nd Version: Technical Support Document. 2018. Available online: https://www.epa.gov/air-emissions-inventories/2014-national-emissions-inventory-nei-technical-support-document-tsd (accessed on 27 May 2020).

- Comprehensive Data Collected from the Petroleum Refining Sector|Stationary Sources of Air Pollution|US EPA. Available online: https://www.epa.gov/stationary-sources-air-pollution/comprehensive-data-collected-petroleum-refining-sector (accessed on 12 December 2019).

- Zhang, D. A Coefficient of Determination for Generalized Linear Models. Am. Stat. 2017, 71, 310–316. [Google Scholar] [CrossRef]

- Moore, M.A.; Notz, D.S.; Flinger, W.I. The Basic Practice of Statistics, 6th ed.; W.H. Freeman and Company: New York, NY, USA, 2013. [Google Scholar]

- Zikmund, W.G. Business Research Methods; Harcourt College Publishers: Fort Worth, TX, USA, 2000. [Google Scholar]

- Ratner, B. The Correlation Coefficient: Definition. Available online: http://www.dmstat1.com/res/TheCorrelationCoefficientDefined.html (accessed on 15 May 2020).

- Kenny, D.B.B.; Lipkowitz, B. Reviews in Computational Chemistry. 2003. Available online: https://books.google.it/books?id=IqWXSLz6QE8C&pg=PA230&lpg=PA230&dq=As+a+rule+of+thumb,+typically+R2+values+greater+than+0.5+are+considered+acceptable.&source=bl&ots=4-hljNB9Ma&sig=ACfU3U3nDrJjkcYy9jZX4XQnxQ4qZQmFKg&hl=it&sa=X&ved=2ahUKEwjkpsSGzPboAhVM_Co (accessed on 20 April 2020).

- Garcia, E. (16) (PDF) A Tutorial on Quantile-Quantile Plots. Available online: https://www.researchgate.net/publication/308631899_A_Tutorial_on_Quantile-Quantile_Plots/references (accessed on 27 May 2020).

- IPPC. EFDB, 2019. Available online: https://www.ipcc-nggip.iges.or.jp/EFDB/main.php (accessed on 15 April 2020).

- Hoyt, D.; Raun, L.H. Measured and estimated benzene and volatile organic carbon (VOC) emissions at a major U.S. refinery/chemical plant: Comparison and prioritization. J. Air Waste Manag. Assoc. 2015, 65, 1020–1031. [Google Scholar] [CrossRef]

- Sun, P.; Young, B.; Elgowainy, A.; Lu, Z.; Wang, M.; Morelli, B.; Hawkins, T. Criteria Air Pollutant and Greenhouse Gases Emissions from U.S. Refineries Allocated to Refinery Products. Environ. Sci. Technol. 2019, 53, 6556–6569. [Google Scholar] [CrossRef] [PubMed]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).