1. Introduction

Over the last two decades the demand for natural rubber (NR) has risen dramatically, from 6.8 million metric tons in 2000 to over 12.4 million metric tons in 2016 [

1]. The U.S. is one of the biggest importers and consumers of NR and in 2016 it consumed 0.93 million metric tons of NR [

2] for product manufacturing.

NR is obtained from coagulating and refining latex from a plant species. Currently, the world is dependent on a single species,

Hevea brasiliensis, for fulfilling its NR demands. Due to climatic, abiotic, and biotic constraints, such as leaf blight, this crop is almost totally grown in Southeast Asia (~90%) and Africa (~10%). However, with expectations for increased demand for NR and concerns about pathogens that could affect

Hevea production, interest in TK as a domestic source of NR, which was first explored in the 1940s, has resurfaced [

3]. Thus, there is a need to investigate and develop alternative sources of NR.

Although many plants can produce a latex compound, only a few have been studied extensively for commercial production. Two of them are

Parthenium argentatum (guayule) and

Taraxacum kok-saghyz (L.E. Rodin) (TK) [

4]. Guayule is a shrub-like plant grown in semi-arid regions, namely Mexico and the Southwestern U.S. NR is found in guayule’s stem and branches. TK is a relative of the common dandelion (

Taraxacun officinale) and can be grown in temperate zones, such as the U.S. and Canada. TK produces NR in its roots and its rubber has properties similar to

Hevea [

5].

Although much information has been gathered on growing TK, domestication in the U.S. has not occurred because of seed and plant genetics, particularly poor emergence and survival of the plant, and low NR yields per root. After World War II, which provided the impetus for the initial interest in TK as a source of NR, dependence on

Hevea and interest in synthetic rubber took precedence, which unfortunately led to the seed bank for TK from the 1940s being lost. Current research on TK only resumed in the U.S. after the U.S. Department of Agriculture (USDA) returned to Kazakhstan in 2008 and collected seed from TK growing in the wild [

6]. In 2010, studies at the Ohio Agricultural Research and Development Center (OARDC) at the Ohio State University (OSU) were initiated with seed from plants grown from that wild seed lot.

1.1. Literature Review

Taraxacum kok-saghyz (TK), also known as the Russian dandelion, was identified as a potential source of NR in Kazakhstan, Soviet Union in 1931 [

7]. TK was studied extensively by Soviet scientists during the 1930s and 1940s and by U.S. scientists in the 1940s. Reported data from the 1940s indicated actual and projected NR production varied greatly from less than 34 kg/ha to as high as 450 kg/ha. Besides rubber, up to 40% of the TK dry root can be polysaccharides, which have multiple uses [

7,

8].

TK is a perennial plant [

7], but can be grown as an annual for rubber production. Unlike

Hevea brasiliensis, which takes seven years to mature, and guayule, which takes four–five years, TK can be harvested after a single growing season. Rubber accumulation in TK begins at germination, peaks at around one year, and then levels off or decreases due to older root tissues being shed and destroyed by microorganisms [

9]. Kreuzberger et al. [

10] concluded that “the life cycle of TK as a perennial plant makes it a candidate for cultivation as an annual or a biennial crop”. As an annual, it would have a growing period of 180–220 days based on average frost free dates in the temperate zone. TK can tolerate many different soil conditions. Whaley and Bowen [

11] found that satisfactory growth and uniformity were recorded in areas where the surface and subsoils ranged in texture from loam to silty clay. It was grown on soils that ranged from as low as 2% organic matter to as much as 90%; however, the range for best results was found to be 2–8% organic matter [

11].

TK seeds are small, with about 1 million seeds per pound [

10,

12]. Artschwager and McGuire [

13] stated that the TK seeds readily germinate and observed that despite the early development of a strong root system in the seedling, there is a slow expansion of the leaf rosette, which has only minute-sized individual leaves, for two or more months. Another study found that pre-soaking seed between 5 °C and 23 °C for up to four days and then drying the seed increased germination from 50%–~75% [

14]. They also showed that germination at 17 °C or less decreased the rate of germination and the total percentage of germination; whereas, germination at 23 °C gave the highest total germination of >75%. Krotkov [

7] reported that, because of its slow growth, TK seedlings were vulnerable to being outcompeted by native weeds. Slow growth and weed control remain a major problem in successfully growing TK today. To improve germination and growth, high soil moisture is desirable [

14]. Results of earlier research on TK field production as well as more recent studies are summarized in

Table 1.

Direct seeding of TK has been identified by OSU researchers as the preferred method for establishing a TK crop, but limited data exist on this method. European field studies, conducted in 2012 and 2013 [

10], showed that TK emergence first occurred in May and continued through June. The maximum number of seedlings which emerged from viable seed was <5% in 2012 and ~14% in 2013. Alternatively, research at the OARDC found that TK planted in greenhouses in March and transplanted to a field with silt loam and muck soils in June achieved or maintained plant stands of up to 40% through the October/November harvest [

15]. However, using transplants does not appear feasible at large scale due to the high cost of greenhouse growing and transplanting.

1.2. Study Objectives

This study focused on addressing the challenge of establishing a TK crop through direct seeding. It included field production studies on the impact of planting methods (broadcast and drilled), seed treatments (raw and pelleted), planting dates, and field treatments (companion crops and compost mulch) for TK planted in rows. The overall goal for this project was to develop methods for establishing TK in the field via direct seeding. Specific objectives were to:

Determine a practical seed/planter strategy for direct seeding.

Determine the effect of companion crops and compost mulch on seed emergence and survivability.

Determine the effect of planting date, i.e., soil temperature, on the emergence of TK in the field.

This paper reports on progress in achieving these objectives based on field studies conducted in 2014 and 2015.

2. Materials and Methods

Field studies were conducted in 2014 and 2015.

Table 2 summarizes the parameters evaluated in each year.

2.1. Field Locations and Preparations

2.1.1. Field Study 2014

Studies were conducted on Field 6, Horticulture Unit 1 at the OARDC in Wooster, Ohio. The previous crop (2013) in this field was soybean. Soil samples for Field 6 were analyzed at CLC Labs (Westerville, OH, USA) and results were 2.9% organic matter (OM); 197 kg/ha of phosphorus (P, P1test); 348 kg/ha of potassium (K); and a pH of 6.95. Prior to planting TK, the field was sprayed for weed control using glyphosate at 4.5 kg/ha. Two weeks later, on 25 April, a cover crop of oats (62 kg/ha) was planted using a no-till drill, and concurrently, TK seed was broadcast (11.2 kg/ha) using a Valmar 1255 Twin Rotor air seeder (Valmar Airflo, Inc., Elie, MB, Canada). On 5 May, the same planting procedure was repeated.

2.1.2. Field Study 2015

Studies were conducted on the Moomaw Farm, Smithville, Ohio. The previous crop (2014) in this field was no-till soybean. Soil analyses (CLC Labs, Westerville, OH, USA) for the field were: 2.4% OM; 53 kg/ha of P; 173 kg/ha of K; and a pH of 7.0. Before planting TK, the field was prepared using an offset disk, which was followed by two passes (i.e., traverse from field edge to field edge) with a Brillion cultimulcher (Landoll, Marysville, KS, USA). Each tillage pass was perpendicular to the previous operation to improve field leveling. Planting was in the same direction as the last pass with the cultimulcher.

The 2015 field preparations and planting were based on greenhouse tests conducted to evaluate the effectiveness of planting seeds into/below a thin layer (~0.6–1.2 cm) of mulch. These preliminary tests used the field soil from Moomaw Farm and compost mulches from Barnes Nursery Inc., Huron, OH, USA and Bull Country Compost, Dundee, OH, USA. Observations on seed emergence from soil with and without mulch treatments indicated that the mulch benefited TK emergence with no phytotoxic effects (

Figure 1). Based on this result, it was decided to use compost mulch for field planting. The compost (

Figure 2) used was made from yard trimmings and food scraps and had been trommel screened using a 1.6 cm (5/8 inch) opening. Compost properties were as follows: moisture of 38.9% (wb); C/N ratio of 10; OM of 38.7% (db); and NPK of 2.1%, 0.52%, and 0.55% (db), respectively. A prototype Subsurfer applicator, which was developed by the USDA Agricultural Research Service (ARS) to inject broiler litter as a way to prevent nutrient migration off-site with surface water movement [

16], was adapted to surface apply a 0.64–1.27 cm layer of the compost (

Figure 3) in 10–15 cm wide bands in rows 38.1 cm apart, on center, prior to seeding TK. Test plots were planted on 4 May and 15 May.

2.2. Seeding

Both seeding methods and seeding rates were evaluated. Research studies at OSU indicate that a seeding rate of 1.5–2.5 million TK seeds/ha would be needed to produce a commercially viable TK crop [

17]. This range was used to determine seed spacing in this study. For broadcast seeding, a rate of 2.5 million TK seeds/ha was used. For planting with a drill seeder, a theoretical between row spacing of 17.78 cm was used to calculate the in row seed spacings needed to achieve 1.5 and 2.5 million TK seeds/ha. The in-row spacings selected were 1.91 cm and 3.81 cm, respectively.

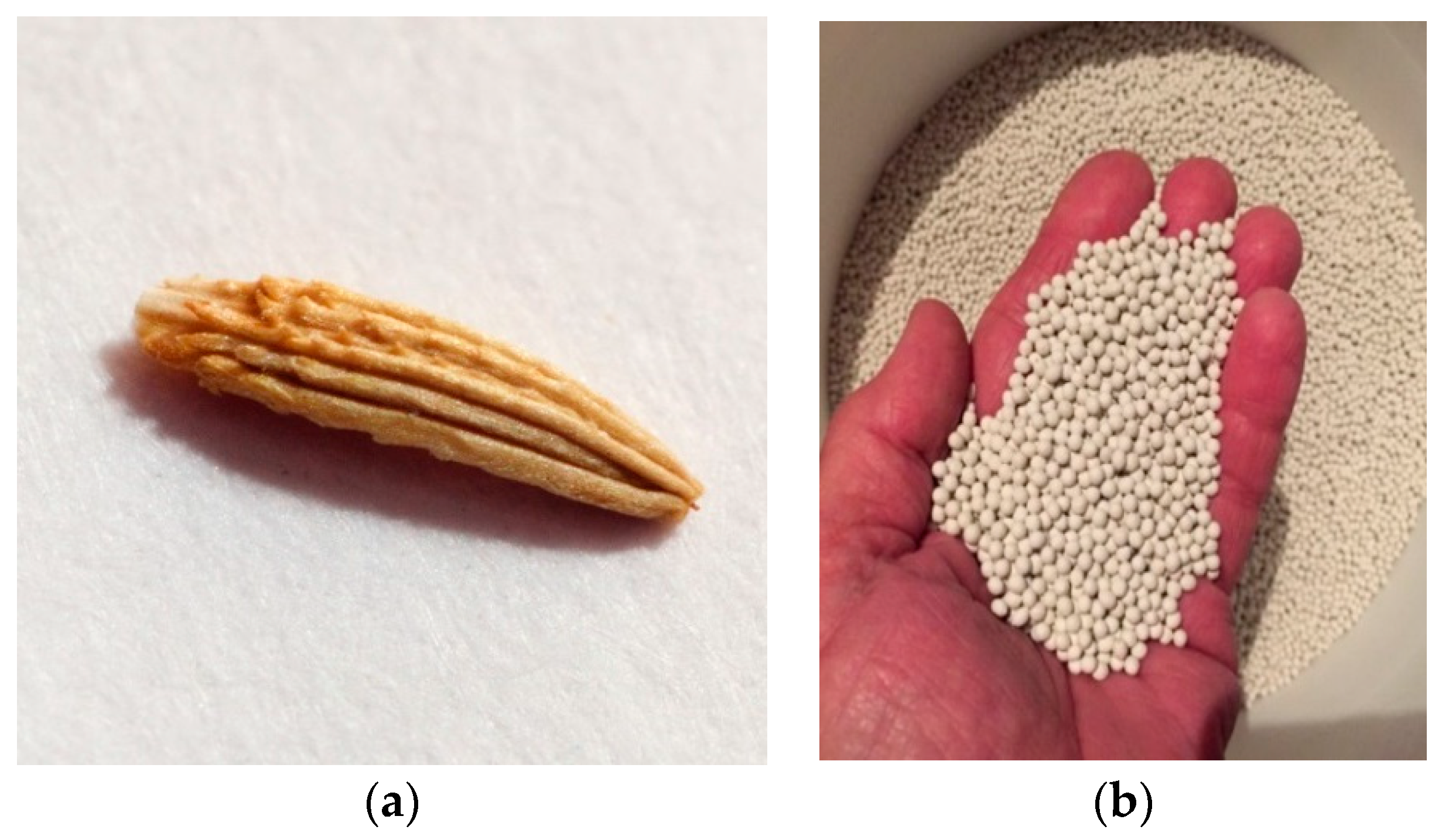

2.2.1. Seed Preparation and Planting in 2014

The study field was planted with raw seed (

Figure 4a) harvested from plants grown from the USDA ARS National Plant Germplasm System seed accessions collected in Kazakhstan in 2008 (accession numbers: KAZ08-001, -004, -005, -007, -009, -010, -011, -013, -014, -015, -017, -018, -021, -022, -023, -024, -025, -026, -027, -028). The seed from thee accessions were planted at the OARDC/OSU Wooster campus. The obtained plants were interbred and then cloned and planted in high tunnels. The seed used for the 2014 study was collected from the high tunnel plants.

Germination tests were conducted on the raw seed just prior to planting using the following procedure: (1) Fit the bottom 8 petri dishes with Whatman Grade 1 filter paper and moistened with 2–3 mL of DI water; (2) use sterilized forceps to place 25 seeds on the filer paper; (3) place the petri dishes in a single layer in a zip top bag and place in germination chamber at 22 °C with 10 h of light for 14 days; (4) add 1–2 mL of DI water as needed; (5) count and record the number of germinated seeds (seeds with root emergence and/or shoot emergence). Germination of 76 ± 15% was achieved.

In order to evaluate the effect of broadcasting raw seed on crop establishment, a Valmar air seeder (

Figure 5) was used. It was calibrated indoors using dyed Kentucky bluegrass seed, which is similar in size and shape to TK seed. One-foot plastic squares were coated with spray adhesive and placed on the ground to collect the seed during a single pass of the seeder. Squares were photographed and the number of seeds counted to determine seeding rate. Various seeder settings were used during calibration. Prior to planting, the TK seed was mixed with killed dyed Kentucky bluegrass seed, which increased the total seed volume for improved seeder accuracy to achieve the desired TK seeding rate of 248 TK seeds/m

2. Squares were also used in the field during seeding (one square per test plot) to confirm the seeding rate (

Figure 5) by counting undyed seed per square.

2.2.2. Seed Preparation and Planting in 2015

The TK seed used in 2015 was the seed harvested in 2014 from TK transplants planted in 2013 in a field at OSU’s Muck Crops Research Station in Willard, Ohio. The 2013 transplants were planted using the seeds collected from the high tunnel plants as described previously. The 2013 transplants were culled to remove small plants and then over-wintered, with seeds collected in June 2014. These seeds were stratified and then pelleted (

Figure 4b) in February 2015 by Germains Seed Technology (Gilroy, CA, USA), which used a proprietary priming technique that controls moisture and temperature to help regulate germination but did not include a fungicide. Germination tests, described previously, were conducted on the pelleted seed in May 2015 and gave germination values of 77 ± 7%.

Prior to field planting, a Stanhay belt drill seeder and a Stanhay air drill seeder (Stanhay Precision Seeders, Bourne, UK) were laboratory tested to evaluate their precision for delivery of both raw and pelleted TK seed to the planter drop tube. Seeding rates were calculated from seeding rate tables and confirmed by counts. Based on those studies, it was determined that the Stanhay air drill seeder with pelleted seed would provide the best singulation of seed at the desired seed spacing. The coefficient of variation of seed drop for each rotation of the planter wheel in the lab was 2.3% for a seed spacing of 1.3 cm.

In preparation for direct seeding of seed into a compost using the Stanhay air drill seeder, the Subsurfer unit, discussed earlier, was used to surface apply compost mulch. The Subsurfer had a walking floor system with auger fed drop tubes and no-till disc openers spaced on 38 cm centers. Surface banding of compost was accomplished by operating the Subsurfer with the no-till openers in a raised position, just above the soil surface.

Preliminary field tests with the USDA-ARS in Booneville, Arkansas (USA) showed that the Subsurfer could successfully surface apply the desired yard trimmings/food scrap compost. However, flowability issues were of concern due to the moisture content of the chosen compost; the drier the compost, the better the expected performance. At Moomaw Farm, compost was received and stored in fabric covered piles to minimize rain infiltration. Initially the Subsurfer performed well, with uniform compost banded rows; however, as anticipated, the moisture content of the compost proved to be a challenge. Over time, higher moisture pockets of compost caked and built-up at the auger-fed drop tubes. As a result, at the conclusion of compost application to the soil surface, the plot area had compost mulch bands, the depth and width of which varied with the degree of compost moisture during application (

Figure 3). Future work with the Subsurfer would need to identify dryer compost or Subsurfer modifications to improve flow ability of higher moisture materials.

The pelleted TK seed was directly seeded using the Stanhay air drill seeder shown in

Figure 6a. Row spacing was 76.2 cm. Planting depth was set for 0.64 cm, but was not precisely achieved due to placement of the gage wheel on the planter shoe. Seed spacing was set at 1.91 cm and 3.81 cm for the trials. Observation of this planting system during field trials showed greater variability in seed spacing (

Figure 3c and

Figure 6b) than lab results, but no data were collected.

2.3. Experimental Design

2.3.1. Field Plot Design for 2014

Treatments consisted of two planting dates (28 April and 5 May), with and without a companion crop (CC) of oats, on plots 12.2 m × 2.4 m each with three replications for each. The seeding rate was 248 seeds/m2 or 2.47 million seeds per ha. For each replication, stand establishment data were gathered using a 30 cm × 30 cm quadrat seven times along a transect line, approximately 1.52 m apart. For analysis, stands per treatment was calculated using n = 21. Data was collected on 16 and 26 June, and on 3, 11, and 17 July.

2.3.2. Field Plot Design for 2015

Treatments consisted of two planting dates (4 May and 15 May), row spacing of 76.2 cm, with and without mulch applied, and at seeding rates of 1.91 cm and 3.81 cm between seeds within a row. On 4 May, with no compost applied, planting consisted of a seed spacing of 1.91 cm (5 passes) and 3.81 cm (9 passes). Each pass covered ~0.029 ha. On 15 May, with compost being used, planting consisted of a seed spacing of 1.91 cm (12 passes) and 3.81 cm (27 passes) and, with no compost, seed spacing was 1.91 cm (4 passes). Due to the 76.2 cm row spacing of the planter, only half of the rows with compost were planted. For each treatment, 10 plots were flagged, with each plot being 1.52 m in length. Test plots were randomized using a random number generator (RANDOM.ORG, Dublin, Ireland). Stand counts were performed every week for the first four weeks and then approximately monthly thereafter.

2.4. Stand Counts

2.4.1. Stand Count Procedure in 2014

Stand counts were performed by running a tape measure through the center of the plots and placing a 30.4 cm square every 1.52 m and counting the TK within the square (i.e., the center point of the TK was within the square—if only the tip of a leaf lay within the square it was not counted). This method resulted in seven counts per plot. Since each treatment was replicated three times per planting date, there were a total of 21 counts per treatment per date. Stand counts were conducted on 17 and 26 June; 3, 11 and 17 July; and 26 August.

2.4.2. Stand Count Procedure in 2015

Stand counts were conducted by marking 10 random 30.4 cm plots within each treatment area. There were 5 treatment areas: (1) 4 May seeded at 1.91 cm seed spacing without compost; (2) 4 May seeded at 3.81 cm seed spacing without compost; (3) 15 May seeded at 3.81 cm seed spacing with compost; (4) 15 May seeded at 1.91 cm seed spacing with compost; and (5) 15 May seeded at 1.91 cm seed spacing without compost. Plot location was determined using a random number generator to choose a random row of TK within each treatment area, as well as a random distance from the edge of the field. Plots were marked using flags and were hand weeded at the time each stand count was taken. Stand counts were conducted in 2015 on 11, 18, 22, 26, and 28 May; 1, 5, 11, and 29 June; 3 August; 1 October; and 3 November, and in 2016 on 4 May and 3 June.

2.5. Metrics

The metrics developed to evaluate and compare the effectiveness of the planting methods studied are given in Equations (1) and (2). Statistical significance was assessed using the matched pairs t-test (α = 0.05).

3. Results

3.1. Findings from the 2014 Field Study

Stands for seeds planted via broadcasting on 28 April and 5 May are shown in

Table 3.

Figure 7 shows TK plants on 4 June for a small section of the field planted on 28 April where no weeds were present. Results indicated that for the 28 April and 5 May planting dates, the maximum stands for the plantings with a companion crop (CC) were 28.7% on day 59 and 20.9% on day 52, respectively. For plots planted with no CC (nCC), the maximum stands for the 28 April and 5 May planting dates occurred on day 59 at 27.5% and day 52 at 18.0%, respectively. The calendar date was 26 June. Results showed that TK emergence from broadcasting seed occurred over a long period of time, lasting longer than 50 days.

Estimated 2014 temperatures for air and bare soil at a depth of 10.16 cm [

18] are given in

Figure 8, along with average stands (all treatments combined for a given planting date). The delayed and/or continued emergence of the TK crop (>50 days) was likely impacted by planting date, i.e., soil temperature, as well as seed/soil contact and moisture due to surface broadcasting. Air and soil temperatures did not have sustained levels above 16 °C till 21 May. By 17 July, stands had dropped to 8.8% for the 28 April CC treatment and 6.7% for the 5 May CC treatment (

Table 3). Similarly, stands were 5.7% for the 28 April nCC treatment and 3.9% for the 5 May nCC treatment.

Although stands varied over time for the two planting dates, no statistical difference was found between CC planting dates for stands on 17 July (

Table 3, days 80 and 73 after planting). Similarly, no statistical difference (α > 0.05) was found for nCC planting dates due to the large differences in stands between replicates. For example, for the 28 April CC planting, 19% of the replicates had a 0% stand and one had a maximum of 29.3% stand on 17 July. For the same planting date with nCC, 48% of the replicates had 0% stand, while one replicate had a stand of 29.3%. For the 5 May planting date with CC, 43% of the replications had 0% stand on 17 July, with one sample having a stand of 22.7%, while nCC had 52% of the replicates with 0% stand and one replicate having a maximum stand of 17.3%. Much of the stand loss in 2014 was attributed to weed competition as no herbicides were available for weed control and hand weeding was not practical. Additional factors, such as diseases, pests, or moisture stress, that likely contributed to stand loss, were not evaluated in this study.

3.2. Findings from the 2015 Field Study

Stands for pelleted TK seed planted via drilling on 4 May are shown in

Table 4. For the 4 May planting, no compost (nCp) was used. Results showed decreases in stand for day 28 (1 June) compared to day 22 (26 May) for both treatments, suggesting miscounts (over counting) occurred on day 22. Comparison of data on day 22 to day 28 showed that 40% of the count plots with 1.91 cm seed spacing, and 50% of the count plots with 3.81 cm seed spacing, were over counted by one–five plants. As the counts on both days were made by a highly trained researcher, this discrepancy is probably due to the extreme difficulty of differentiating between TK and some weed plants at first emergence. The highest average stand (average of the two seeding rates) for the 4 May planting was 9.9% on day 57 (29 June). Because no counts were taken between day 28 and day 57, the maximum stand for 4 May was not determined. By 1 October (day 151) the average stand was only 5.1%. Results showed that TK emergence from drilling seed in early May occurred over a long period of time, lasting longer than 50 days.

Stands for pelleted TK seed planted via drilling on 15 May are shown in

Table 5. For this planting both Cp and nCp were used. Peak stands occurred on 5–11 June (days 21–27 after planting), with peak values of 31.7%, 20.8%, and 21.2% for planting with Cp at 3.81 cm spacing, Cp at 1.91 cm spacing, and nCp at 1.91 cm spacing, respectively. By 1 October (day 140), the average stand for Cp was 16.8% or two times higher than for nCp. Even so, there was no statistical difference (α > 0.05) between stands for Cp and nCp plantings. The time to reach the maximum stand for the 4 May and the 15 May planting dates was 56 days (29 June) and 27 days (11 June), respectively. However, the peak stand for the 4 May planting likely occurred before 29 June (day 56) but after 1 June, although no data to support this supposition was recorded in this time interval. It should be noted that the stand after emergence for the nCp treatment (1.91cm spacing) for the 15 May planting date was higher than the stand for the 4 May planting date for all count dates, suggesting an advantage to the later planting date (15 May) in 2015.

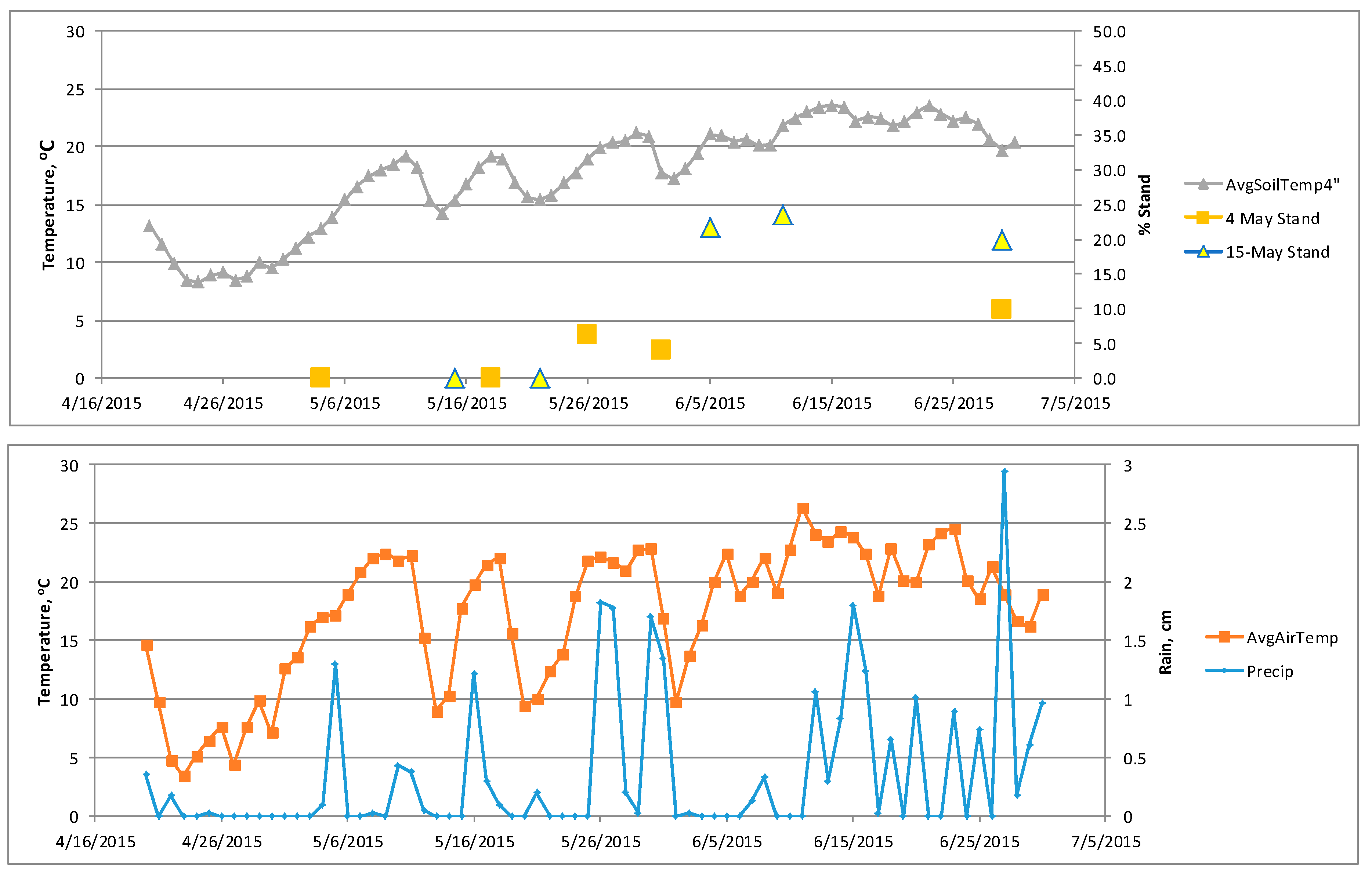

Estimated 2015 temperatures for air and bare soil at a depth of 10.16 cm [

18] are given in

Figure 9, along with average stands (all treatments combined for a given planting date). The delayed emergence of the TK crop (>28 days) for the 4 May planting was most likely impacted by soil temperature in 2015, which did not have sustained levels above 16 °C till 16 May.

3.3. Summary

For the 2014 field study, accurate delivery and spatial distribution of raw TK seed broadcast with a Valmar air seeder at a rate of 248 seeds/m2, or 2.47 million seeds /ha, was achieved. Overall, the average stand count peaked in mid-late June, 50–60 days after planting, with a maximum count of 28.7% achieved on day 59 (26 June) for the CC treatment planted on 28 April. By day 80, the stand was <10% for all treatments.

For the 2015 field study, the Stanhay belt drill seeder did not achieve reliable seed distribution in laboratory trials for either the raw seed or the pelleted seed. In comparison, the Stanhay vacuum air drill seeder achieved good spacing using pelleted TK seed in the laboratory trials, with a coefficient of variation of 2.3% on spacing. Observations on in-row seed spacing in the field indicated seed spacing was not uniform but that singulation was being achieved. Compared to the 4 May planting of TK with nCp, the 15 May nCp planting resulted in higher stands by and after 5 June with peak stand around 11 June. Field data for planting into Cp mulch gave mixed results on stands. For the seed spacing of 3.81 cm in Cp mulch, the maximum stand was 31.7% at 27 days, while at 1.91 cm it was 20.8% at 21 days, which was similar to the 21.2% for the nCp treatment at 27 days. On 1 October (day 140), stands were 21.3% for 3.81 cm in Cp, 12.1% for 1.91 cm in Cp, and 8.4% for 1.91 cm with nCp. The average stand for the 4 May for seeding with nCp was 5.1% on 1 October (151 days), which was lower than the 15 May stand for nCp planting.

Comparison of two planting methods showed the 2015 stand counts at ~80 days for seeding in rows (vacuum air drill) to be higher than for 2014 broadcast seeding. No statistical differences (at α = 0.05) were found between treatments in this study because of large standard errors for stand counts.

4. Discussion

This study identified some practices that may improve plant stands for TK crops grown via direct seeding. Soil temperature and moisture appear to affect seed germination, while the slow growth rate and fragile root system of the young plant affects its establishment. Planting methods can address some of these limitations, but there is a need for germplasm improvements that lead to a faster growing and hardier TK plant.

For un-pelleted TK seed, the Valmar air seeder could be adapted to achieve desired planting densities for direct seeding by broadcasting. However, surface broadcasting of seed in late April and early May delayed peak stands of TK to over 50 days in Ohio for the TK seed used in this study. For broadcast seeding, use of a CC gave higher stands than nCC, but were not statistically different. All stands at days 73 and 80 after seeding were less than 10%.

For pelleted TK seed, the Stanhay air seeder was found to accurately meter seed. Field observations showed that singulation of seed drop was achieved for this particular seeder, but that seed spacing was not uniform. Results suggest that, over the long term, stands were improved by planting TK seed at a depth of 0.6 cm into Cp mulch at <1.27 cm depth. For the current pelleted TK seed, observations indicated that soil temperature >16 °C at seeding is critical for rapid (<4 weeks) germination and maximum stand establishment, and that a weed free field is essential for the crop to survive to maturity.

Currently, the main challenges to direct seeding of TK, whether broadcast or seeded in rows, include plant emergence, seedling vigor, growth rate, and weed control. Achieving weed control is a major challenge because no herbicides are currently available for TK production, cultivation of TK planted in rows is impractical due to the morphology of the plant, weeds out-compete the TK crop, and unchecked weed pressure reduces crop survival and plant growth rate. These limitations are being addressed at OARDC/OSU through studies of the plant genome to identify genetic markers, development of weed resistance through traditional plant breeding techniques, and other research to improve the TK germplasm.

Author Contributions

Contributions of authors is as follows: Conceptualization, H.M.K. and A.S.; Methodology, H.M.K., A.S., M.K. and S.W.; Validation, H.M.K.; Formal Analysis, H.M.K. and A.S.; Investigation, H.M.K., A.S., S.W. and M.K.; Resources, H.M.K., R.F. and D.P.; Data Curation, H.M.K. and S.W.; Writing—Original Draft Preparation, H.M.K. and A.S.; Writing—Review & Editing, H.M.K., A.S., M.K. and S.W.; Visualization, H.M.K. and A.S.; Supervision, H.M.K., A.S. and M.K.; Project Administration, H.M.K. and R.F.; Funding Acquisition, H.M.K., R.F. and D.P.

Funding

This research was funded by the PENRA Consortium, Ohio Third Frontier, OARDC, and USDA NIFA Hatch Project 1005665. In-kind contributions of equipment usage and personnel time were provided by the USDA ARS Dale Bumpers Small Farm Research Center in Booneville, Arkansas.

Acknowledgments

Thank you to Mary Wicks, PENRA coordinator, OARDC/OSU, Wooster, OH for her meticulous proofreading and helpful suggestions for improving the document.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Leading Consumers of Natural Rubber Worldwide from 2013 to 2017. Available online: http://www.statista.com/statistics/275392/top-10-consumers-of-natural-rubber/ (accessed on 13 July 2016).

- Natural Rubber Production Worldwide from 2000 to 2017 (in 1000 metric tons). Available online: https://www.statista.com/statistics/275387/global-natural-rubber-production/ (accessed on 1 November 2017).

- Beilen, J.; Poirier, Y. Guayule and Russian Dandelion as Alternative Sources of Natural Rubber. Crit. Rev. Biotechnol. 2007, 27, 217–231. [Google Scholar] [CrossRef] [PubMed]

- Thomas, P. More Acres but Shrinking Yield Worries Rubber Cultivators. The New India Express, 2014. Available online: http://www.newindianexpress.com/business/news/More-Acres-but-Shrinking-Yield-Worries-Rubber-Cultivators/2014/07/24/article2345392.ece (accessed on 8 June 2016).

- Cornish, K. Alternative natural rubber crops: Why should we care? Technol. Innov. 2017, 18, 245–256. [Google Scholar] [CrossRef]

- Hellier, B.C. Collecting in Central Asia and the Caucasus: US national plant germplasm system plant explorations. HortScience 2011, 46, 1438–1439. [Google Scholar]

- Krotkov, G. A review of literature on Taraxacum kok-saghyz rod. Bot. Rev. 1945, 11, 417–461. [Google Scholar] [CrossRef]

- Ujor, V.; Bharathidasan, A.K.; Michel, F.C., Jr.; Ezeji, T.C.; Cornish, K. Butanol production from inulin-rich chicory and Taraxacum kok-saghyz extracts: Determination of sugar utilization profile of Clostridium saccharobutylicum P262. Ind. Crops Prod. 2015, 76, 739–748. [Google Scholar] [CrossRef]

- Bonner, J.; Gadston, A.W. The physiology and biochemistry of rubber formation in plants. Bot. Rev. 1947, 13, 543–596. [Google Scholar] [CrossRef]

- Kreuzberger, M.; Hahn, T.; Zibek, S.; Schiemann, J.; Thiele, K. Seasonal pattern of biomass and rubber and inulin of wild Russian dandelion (Taraxacum kok-saghyz) under experimental conditions. Eur. J. Agron. 2011, 80, 66–77. [Google Scholar] [CrossRef]

- Whaley, W.; Bowen, J. Russian Dandelion (kok-saghyz): An Emergency Source of Natural Rubber; US Department of Agriculture: Washington, DC, USA, 1947.

- Kok-saghyz Production Machinery Progress Report. In Bureau of Plant Industry, Soils, and Agricultural Engineering; US Department of Agriculture: Beltsville, MD, USA, 1943.

- Artschwager, E.; McGuire, R. Contribution to the Morphology and Anatomy of the Russian Dandelion (Taraxacum kok-saghyz); United States Department of Agriculture: Washington, DC, USA, 1943.

- Levitt, J.; Hamm, P.C. A method of increasing the rate of seed germination of Taraxacum Kok-Saghyz. Plant Physiol. 1943, 18, 288–293. [Google Scholar] [CrossRef] [PubMed]

- Keener, H.M.; Shah, S.; Klingman, M.; Wolfe, S.; Pote, D.; Fioritto, R. Field Studies on Establishment of TK in Ohio. Unpublished work. 2015. [Google Scholar]

- Pote, D.H.; Way, T.R.; Kleinman, P.J.A.; Moore, P.A., Jr.; Meisenger, J.J.; Sistani, K.R.; Saprito, L.S.; Allen, A.L.; Feyereisen, G.W. Subsurface application of poultry litter in pasture and no-till soils. J. Environ. Qual. 2011, 40, 402–411. [Google Scholar] [CrossRef] [PubMed]

- Cornish, K. Greenhouse and Planting Box Studies on Growth of TK Plants. Unpublished work. 2014. [Google Scholar]

- OARDC Weather System, Wooster, Ohio, USA. Available online: http://www.oardc.ohio-state.edu/weather1/stationinfo.asp?id=1 (accessed on 15 July 2016).

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).