Assessment of Quality and Combustion Characteristics of Briquettes Derived from Giant Hogweed Biomass

Abstract

1. Introduction

2. Materials and Methods

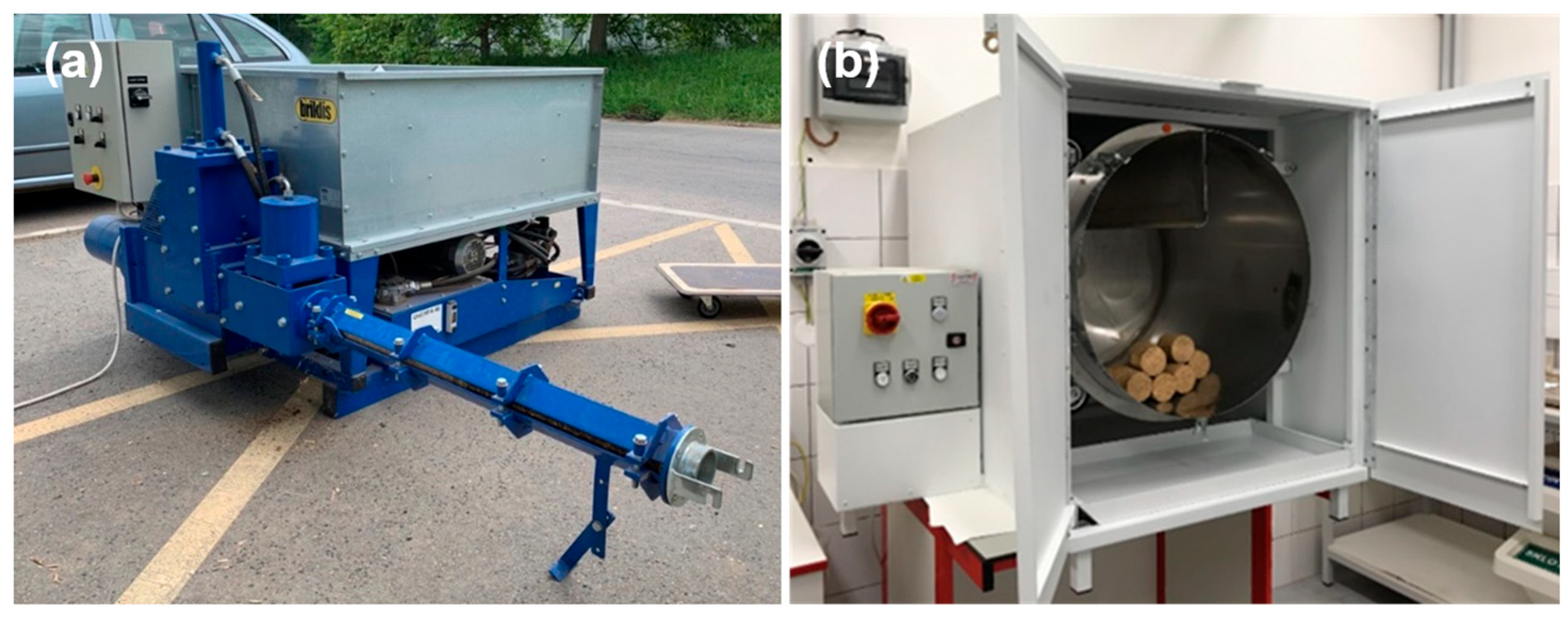

2.1. Sample Collection and Production of Briquettes

2.2. Determination of Mechnical Durability

2.3. Combustion Tests of Briquettes

2.4. Thermogravimetric Analysis and Differential Scanning Calorimetry

3. Results and Discussion

3.1. Mechanical Durability

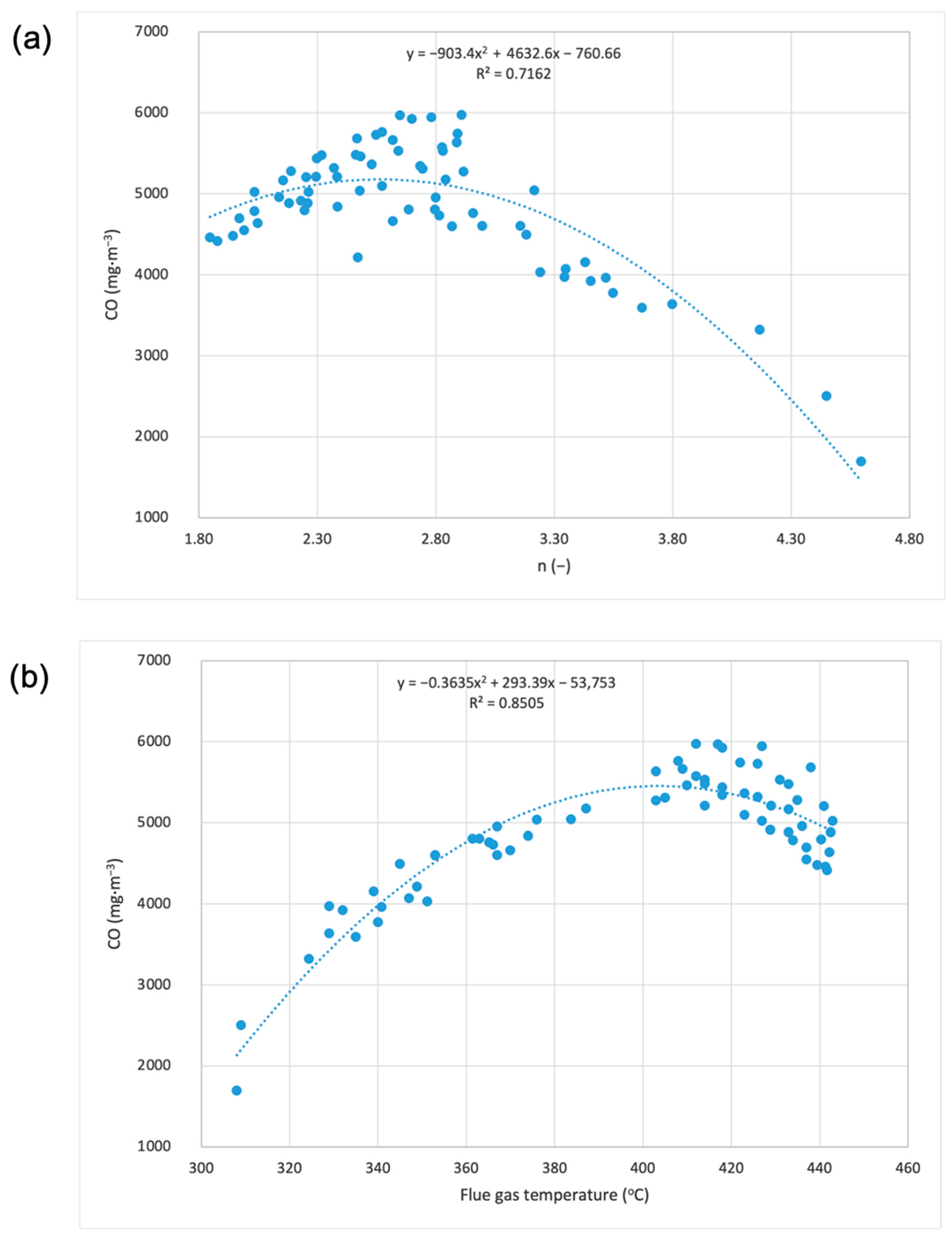

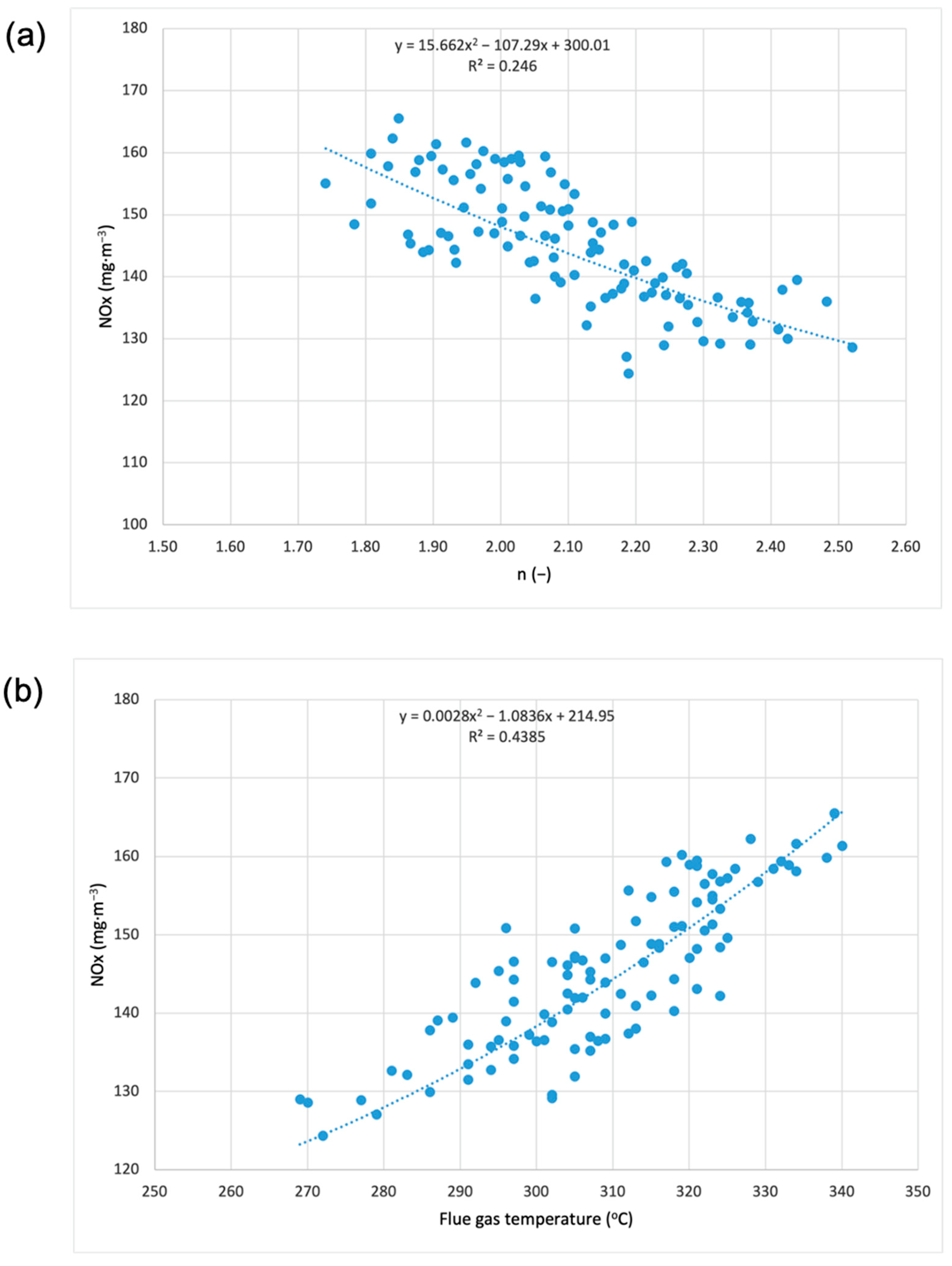

3.2. Assessment of Combustion Behaviour of Briquettes

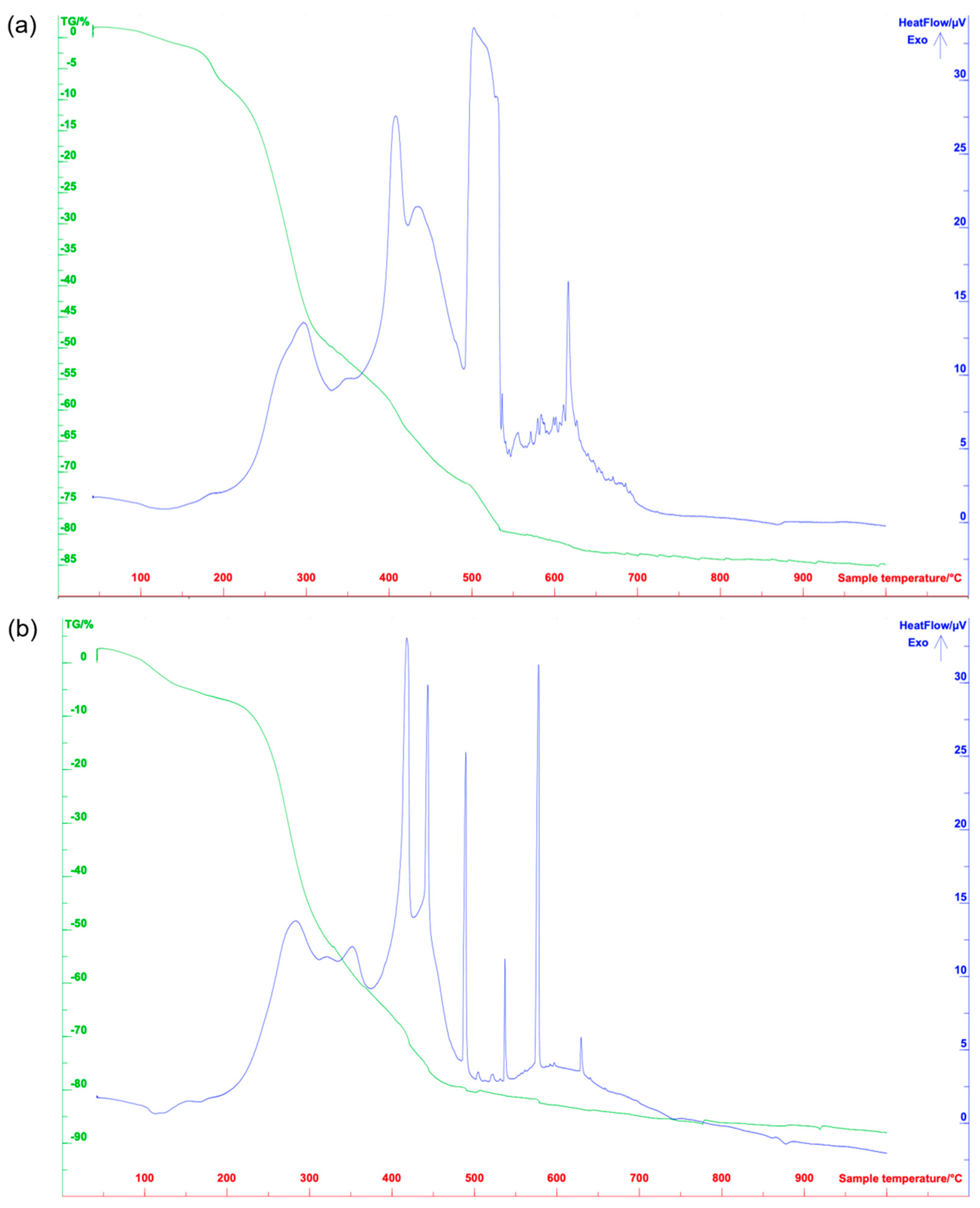

3.3. Evaluation of Thermogravimetric Analysis and Differential Scanning Calorimetry

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gao, W.T.; Su, W.H. Weed Management Methods for Herbaceous Field Crops: A Review. Agronomy 2024, 14, 486. [Google Scholar] [CrossRef]

- Peter, A.; Žlabur, J.Š.; Šurić, J.; Voća, S.; Purgar, D.D.; Pezo, L.; Voća, N. Invasive Plant Species Biomass—Evaluation of Functional Value. Molecules 2021, 26, 3814. [Google Scholar] [CrossRef]

- Guil-Guerrero, J.L.; Guil-Laynez, J.L.; Guil-Laynez, A. Assessment of Several Weeds for Bioenergy Production. J. Biobased Mater. Bioenergy 2014, 8, 358–362. [Google Scholar] [CrossRef]

- Sharma, V.; Pant, S. Weed as Underutilized Bio-Resource and Management Tool: A Comprehensive Review. Waste Biomass Valorization 2019, 10, 1795–1810. [Google Scholar] [CrossRef]

- Halmová, D.; Fehér, A. Possibilities of Utilization of Invasive Plant Phytomass for Biofuel and Heat Production. Acta Reg. Environ. 2009, 6, 49–53. [Google Scholar]

- Brunerova, A.; Muller, M.; Brozek, M. Potential of Wild Growing Japanese Knotweed (Reynoutria japonica) for Briquette Production. In Proceedings of the Engineering for Rural Development, Jelgava, Latvia, 24–26 May 2017; Volume 16. [Google Scholar]

- Jezerska, L.; Zegzulka, J.; Palkovska, B.; Kucerova, R.; Zadrapa, F. Pelletization of Invasive Reynoutria Japonica with Spruce Sawdust for Energy Recovery. Wood Res. 2018, 63, 1045–1058. [Google Scholar]

- Alexiou Ivanova, T.; Paramonova, K.; Talipov, O.; Tanyrbergenov, N.; Zhakupov, T.; Akayev, A. Assessment of Common Reed (Phragmites australis (Cav.) Trin. Ex Steud.) Biomass Suitability for Solid Biofuels Production. Sustainability 2024, 16, 7378. [Google Scholar] [CrossRef]

- Demko, J.; Machava, J.; Saniga, M. Energy Production Analysis of Common Reed—Phragmites Australis (Cav.) Trin. Folia Oecologica 2017, 44, 107–113. [Google Scholar] [CrossRef]

- Nackley, L.L. Good Intentions vs. Good Ideas: Evaluating Bioenergy Projects That Utilize Invasive Plant Feedstocks. In Bioenergy and Biological Invasions: Ecological, Agronomic and Policy Perspectives on Minimising Risk; CABI Publishing: Wallingford, UK, 2015. [Google Scholar]

- Nasadiuk, P.; Mamchur, Z. Review of Modern Approaches to the Management of Invasive Species of the Genus Heracleum in Europe. Visnyk Lviv Univ. Biol. Ser. 2024, 67–89. [Google Scholar] [CrossRef]

- Dumitrescu, C.G.; Jîjie, A.-R.; Manea, H.C.; Moacă, E.-A.; Iftode, A.; Minda, D.; Chioibaş, R.; Dehelean, C.-A.; Vlad, C.S. New Insights Concerning Phytophotodermatitis Induced by Phototoxic Plants. Life 2024, 14, 1019. [Google Scholar] [CrossRef]

- Pauková, Ž.; Kaprálová, R.; Hauptvogl, M. Mapping of Occurrence and Population Dynamics of Invasive Plant Species Heracleum Mantegazzianum in the Agricultural Landscape. J. Cent. Eur. Agric. 2019, 20, 671–677. [Google Scholar] [CrossRef]

- Olszewski, P.; Grabowski, J.; Stalmachová, B.; Švehláková, H.; Nováková, J. Risks Concerning Invasive Plant Species in an Industrial-Agricultural Community. In Proceedings of the International Multidisciplinary Scientific GeoConference Surveying Geology and Mining Ecology Management, SGEM, Albena, Bulgaria, 2–8 July 2018; Volume 18. [Google Scholar]

- Müllerová, J. Heracleum Mantegazzianum (Giant Hogweed); CABI Compendium: Wallingford, UK, 2024. [Google Scholar]

- Grzędzicka, E. Invasion of the Giant Hogweed and the Sosnowsky’s Hogweed as a Multidisciplinary Problem with Unknown Future—A Review. Earth 2022, 3, 287–312. [Google Scholar] [CrossRef]

- Tanke, A.; Müller, J.; De Mol, F. Seed Viability of Heracleum Mantegazzianum (Apiaceae) Is Quickly Reduced at Temperatures Prevailing in Biogas Plants. Agronomy 2019, 9, 332. [Google Scholar] [CrossRef]

- de Almeida Moreira, B.R.; Punde, S.; Hine, D.; Yadav, S. From Environmental Invasive Weeds to Solid Biofuels: Assessing Bioenergy Potential through Pelletisation and Operational Optimisation. Sustain. Energy Technol. Assess. 2025, 80, 104396. [Google Scholar] [CrossRef]

- Malaťák, J.; Velebil, J.; Bradna, J.; Kučera, M.; Gendek, A.; Aniszewska, M.; Alexiou Ivanova, T. Comparative Experimental Assessment of Pollutant Emission Behavior in Combustion of Untreated and Thermally Treated Solid Biofuels from Spruce Chips and Rapeseed Straw. Atmosphere 2024, 15, 452. [Google Scholar] [CrossRef]

- Gramauskas, G.; Jasinskas, A.; Kleiza, V.; Mieldažys, R.; Blažauskas, E.; Souček, J. Evaluation of Invasive Herbaceous Plants Utilization for the Production of Pressed Biofuel. Processes 2023, 11, 2097. [Google Scholar] [CrossRef]

- Priedniece, V.; Sturmane, A.; Eglitis, R.; Juhnevica, I.; Krigers, G.; Kirsanovs, V. A Preliminary Evaluation of Alternative Raw Materials for Pellet Production. In Proceedings of the International Scientific Conference of Environmental and Climate Technologies (CONECT), Riga, Latvia, 15–17 May 2024; pp. 72–73. [Google Scholar] [CrossRef]

- Zihare, L.; Soloha, R.; Blumberga, D. The Potential Use of Invasive Plant Species as Solid Biofuel by Using Binders. Agron. Res. 2018, 16, 923–935. [Google Scholar] [CrossRef]

- Polina, I.N.; Mironov, M.V.; Belyy, V.A.; Brovarova, O.V. Investigation of the Component Composition of the Oxidative Thermal Degradation Products of Fuel Pellets from the Heracleum Sosnowskyi Manden Biomass by Chromatography-Mass-Spectrometry. ChemChemTech 2022, 65, 68–76. [Google Scholar] [CrossRef]

- Ceriani, A.; Dalle Fratte, M.; Agosto, G.; Montagnoli, A.; Cerabolini, B.E.L. Using Plant Functional Traits to Define the Biomass Energy Potential of Invasive Alien Plant Species. Plants 2023, 12, 3198. [Google Scholar] [CrossRef]

- Pathak, M.; Slade, R.; Shukla, P.R.; Skea, J.; Pichs-Madruga, R.; Ürge-Vorsatz, D. Mitigation of Climate Change Climate Change 2022 Working Group III Contribution to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK, 2022; ISBN 9789291691609. [Google Scholar]

- Nakimuli, C.N.; Kaggwa, F.; De Greef, J.; Okot, D.K.; Blondeau, J.; Kawuma, S. Review of Machine Learning Applications for Predicting the Quality Biomass Briquettes for Sustainable and Low-Carbon Energy Solutions. Green Energy Resour. 2025, 3, 100130. [Google Scholar] [CrossRef]

- Jeníček, L.; Malaťák, J.; Velebil, J.; Neškudla, M. Pyrolyzed Agro-Food By-Products: A Sustainable Alternative to Coal. Materials 2025, 18, 1495. [Google Scholar] [CrossRef]

- Ibitoye, S.E.; Jen, T.C.; Mahamood, R.M.; Akinlabi, E.T. Densification of Agro-Residues for Sustainable Energy Generation: An Overview. Bioresour. Bioprocess. 2021, 8, 75. [Google Scholar] [CrossRef]

- Kabas, O.; Ercan, U.; Dinca, M.N. Prediction of Briquette Deformation Energy via Ensemble Learning Algorithms Using Physico-Mechanical Parameters. Appl. Sci. 2024, 14, 652. [Google Scholar] [CrossRef]

- Gendek, A.; Aniszewska, M.; Malaťák, J.; Velebil, J. Evaluation of Selected Physical and Mechanical Properties of Briquettes Produced from Cones of Three Coniferous Tree Species. Biomass Bioenergy 2018, 117, 173–179. [Google Scholar] [CrossRef]

- Bajwa, D.S.; Peterson, T.; Sharma, N.; Shojaeiarani, J.; Bajwa, S.G. A Review of Densified Solid Biomass for Energy Production. Renew. Sustain. Energy Rev. 2018, 96, 296–305. [Google Scholar] [CrossRef]

- Mao, H.J.; Li, Y.N.; Lin, Y.C.; Wang, T.; Li, W.Z.; Ju, M.T.; Zhu, F.D. Overview of Advances in Emission Control Technologies for Nitric Oxides from Biomass Boilers. Chin. J. Eng. 2019, 41, 1–11. [Google Scholar]

- Boningari, T.; Smirniotis, P.G. Impact of Nitrogen Oxides on the Environment and Human Health: Mn-Based Materials for the NOx Abatement. Curr. Opin. Chem. Eng. 2016, 13, 133–141. [Google Scholar] [CrossRef]

- Siegmund, T.; Gollmer, C.; Scherzinger, M.; Kaltschmitt, M. A Review of CO Emissions during Solid Biofuel Combustion—Formation Mechanisms and Fuel-Related Reduction Measures. J. Energy Inst. 2024, 116, 101762. [Google Scholar] [CrossRef]

- Prochnow, A.; Heiermann, M.; Plöchl, M.; Amon, T.; Hobbs, P.J. Bioenergy from Permanent Grassland—A Review: 2. Combustion. Bioresour. Technol. 2009, 100, 4945–4954. [Google Scholar] [CrossRef]

- ISO 17831-2; Solid Biofuels—Determination of Mechanical Durability of Pellets and Briquettes—Part 2: Briquettes. ISO: Geneva, Switzerland, 2015.

- Malaťák, J.; Gendek, A.; Aniszewska, M.; Velebil, J. Emissions from Combustion of Renewable Solid Biofuels from Coniferous Tree Cones. Fuel 2020, 276, 118001. [Google Scholar] [CrossRef]

- Chaloupková, V. Dependence of Briquettes Quality on Their Structure and Biomass Material Composition. Ph.D. Thesis, Czech University of Life Sciences, Prague, Czech Republic, 2019. [Google Scholar]

- Dyjakon, A.; Sobol, Ł.; Krotowski, M.; Mudryk, K.; Kawa, K. The Impact of Particles Comminution on Mechanical Durability of Wheat Straw Briquettes. Energies 2020, 13, 6186. [Google Scholar] [CrossRef]

- Olugbade, T.; Ojo, O.; Mohammed, T. Influence of Binders on Combustion Properties of Biomass Briquettes: A Recent Review. Bioenergy Res. 2019, 12, 241–259. [Google Scholar] [CrossRef]

- Kpalo, S.Y.; Zainuddin, M.F.; Manaf, L.A.; Roslan, A.M. A Review of Technical and Economic Aspects of Biomass Briquetting. Sustainability 2020, 12, 4609. [Google Scholar] [CrossRef]

- Ivanova, T.; Kolarikova, M.; Havrland, B.; Passian, L. Mechanical Durability of Briquettes Made of Energy Crops and Wood Residues. In Proceedings of the Engineering for Rural Development, Jelgava, Latvia, 29–30 May 2014; Volume 13. [Google Scholar]

- Brožek, M. The Effect of Moisture of the Raw Material on the Properties Briquettes for Energy Use. Acta Univ. Agric. Silvic. Mendel. Brun. 2016, 64, 1453–1458. [Google Scholar] [CrossRef]

- Brunerová, A.; Roubík, H.; Brožek, M. Bamboo Fiber and Sugarcane Skin as a Bio-Briquette Fuel. Energies 2018, 11, 2186. [Google Scholar] [CrossRef]

- Piętka, J.; Gendek, A.; Malaťák, J.; Velebil, J.; Moskalik, T. Effects of Selected White-Rot Fungi on the Calorific Value of Beech Wood (Fagus sylvatica L.). Biomass Bioenergy 2019, 127, 105290. [Google Scholar] [CrossRef]

- Williams, A.; Jones, J.M.; Ma, L.; Pourkashanian, M. Pollutants from the Combustion of Solid Biomass Fuels. Prog. Energy Combust. Sci. 2012, 38, 113–137. [Google Scholar] [CrossRef]

- Huang, H.; Gao, Y.; Chen, H.; Wu, Y.; Wang, J.; Yu, C.; Li, J.; Zou, C. Biomass Briquette Fuel, Boiler Types and Pollutant Emissions of Industrial Biomass Boiler: A Review. Particuology 2023, 77, 79–90. [Google Scholar] [CrossRef]

- European Union. Commission Regulation (EU) 2015/1185 of 24 April 2015 Implementing Directive 2009/125/EC of the European Parliament and of the Council with Regard to Ecodesign Requirements for Solid Fuel Local Space Heaters. Available online: http://data.europa.eu/eli/reg/2015/1185/oj (accessed on 16 May 2025).

- Malaťák, J.; Bradna, J.; Velebil, J. The Dependence of COx and NOx Emission Concentrations on the Excess Air Coefficient during Combustion of Selected Agricultural Briquetted By-Products. Agron. Res. 2017, 15, 1084–1093. [Google Scholar]

- Malaťák, J.; Velebil, J.; Malaťáková, J.; Passian, L.; Bradna, J.; Tamelová, B.; Gendek, A.; Aniszewska, M. Reducing Emissions from Combustion of Grape Residues in Mixtures with Herbaceous Biomass. Materials 2022, 15, 7288. [Google Scholar] [CrossRef]

- Roy, M.M.; Corscadden, K.W. An Experimental Study of Combustion and Emissions of Biomass Briquettes in a Domestic Wood Stove. Appl. Energy 2012, 99, 206–212. [Google Scholar] [CrossRef]

- Win, K.M.; Persson, T.; Bales, C. Particles and Gaseous Emissions from Realistic Operation of Residential Wood Pellet Heating Systems. Atmos. Environ. 2012, 59, 320–327. [Google Scholar] [CrossRef]

- Chandrasekaran, S.R.; Hopke, P.K.; Newtown, M.; Hurlbut, A. Residential-Scale Biomass Boiler Emissions and Efficiency Characterization for Several Fuels. In Proceedings of the Energy and Fuels, New Orleans, LA, USA, 17 January 2013; Volume 27. [Google Scholar]

- Hrdlička, J.; Skopec, P.; Dlouhý, T.; Hrdlička, F. Emission Factors of Gaseous Pollutants from Small Scale Combustion of Biofuels. Fuel 2016, 165, 68–74. [Google Scholar] [CrossRef]

- Ciupek, B.; Judt, W.; Urbaniak, R.; Kłosowiak, R. The Emission of Carbon Monoxide and Nitrogen Oxides from Boilers Supplied by a Pellet under the Influence of Changes in the Air-Fuel Equivalence Ratio. J. Ecol. Eng. 2019, 20, 34–38. [Google Scholar] [CrossRef]

- Chen, W.H.; Kuo, P.C. A Study on Torrefaction of Various Biomass Materials and Its Impact on Lignocellulosic Structure Simulated by a Thermogravimetry. Energy 2010, 35, 2580–2586. [Google Scholar] [CrossRef]

- Krutul, D.; Szadkowski, J.; Výbohová, E.; Kučerová, V.; Čabalová, I.; Antczak, A.; Szadkowska, D.; Drożdżek, M.; Zawadzki, J. Effect of Steam Explosion Pretreatment on Chosen Saccharides Yield and Cellulose Structure from Fast-Growing Poplar (Populus Deltoides × maximowiczii) Wood. Wood Sci. Technol. 2024, 58, 441–458. [Google Scholar] [CrossRef]

- Oladokun, O.; Ahmad, A.; Abdullah, T.A.T.; Nyakuma, B.B.; Bello, A.A.H.; Al-Shatri, A.H. Multicomponent Devolatilization Kinetics and Thermal Conversion of Imperata Cylindrica. Appl. Therm. Eng. 2016, 105, 931–940. [Google Scholar] [CrossRef]

- López-González, D.; Avalos-Ramirez, A.; Giroir-Fendler, A.; Godbout, S.; Fernandez-Lopez, M.; Sanchez-Silva, L.; Valverde, J.L. Combustion Kinetic Study of Woody and Herbaceous Crops by Thermal Analysis Coupled to Mass Spectrometry. Energy 2015, 90, 1626–1635. [Google Scholar] [CrossRef]

- Kok, M.V.; Özgür, E. Thermal Analysis and Kinetics of Biomass Samples. Fuel Process. Technol. 2013, 106, 739–743. [Google Scholar] [CrossRef]

- Kučerová, V.; Lagaňa, R.; Výbohová, E.; Hýrošová, T. The Effect of Chemical Changes during Heat Treatment on the Color and Mechanical Properties of Fir Wood. Bioresources 2016, 11, 9079–9094. [Google Scholar] [CrossRef]

| Tfg | n | CO | NOx | |

|---|---|---|---|---|

| (°C) | (-) | (mg·m−3) | (mg·m−3) | |

| Summer-Harvested Biomass | ||||

| Mean | 396.38 | 2.72 | 4850.46 | 246.11 |

| SD | 9.72 | 0.14 | 188.95 | 13.03 |

| Max | 443.00 | 4.60 | 5970.28 | 363.00 |

| Min | 308.10 | 1.85 | 1696.45 | 163.37 |

| Autumn-Harvested Biomass | ||||

| Mean | 308.69 | 2.10 | 1750.06 | 144.16 |

| SD | 3.00 | 0.03 | 49.91 | 2.76 |

| Max | 340.00 | 2.52 | 2419.83 | 165.49 |

| Min | 269.10 | 1.74 | 1280.06 | 38.47 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Paramonova, K.; Ivanova, T.A.; Muntean, A.; Passian, L.; Malaťák, J.; Hutla, P.; Ribintev, I. Assessment of Quality and Combustion Characteristics of Briquettes Derived from Giant Hogweed Biomass. Agronomy 2025, 15, 2213. https://doi.org/10.3390/agronomy15092213

Paramonova K, Ivanova TA, Muntean A, Passian L, Malaťák J, Hutla P, Ribintev I. Assessment of Quality and Combustion Characteristics of Briquettes Derived from Giant Hogweed Biomass. Agronomy. 2025; 15(9):2213. https://doi.org/10.3390/agronomy15092213

Chicago/Turabian StyleParamonova, Kseniia, Tatiana Alexiou Ivanova, Alexandru Muntean, Luboš Passian, Jan Malaťák, Petr Hutla, and Ion Ribintev. 2025. "Assessment of Quality and Combustion Characteristics of Briquettes Derived from Giant Hogweed Biomass" Agronomy 15, no. 9: 2213. https://doi.org/10.3390/agronomy15092213

APA StyleParamonova, K., Ivanova, T. A., Muntean, A., Passian, L., Malaťák, J., Hutla, P., & Ribintev, I. (2025). Assessment of Quality and Combustion Characteristics of Briquettes Derived from Giant Hogweed Biomass. Agronomy, 15(9), 2213. https://doi.org/10.3390/agronomy15092213