Design and Evaluation of a High-Speed Airflow-Assisted Seeding Device for Pneumatic Drum Type Soybean Precision Seed Metering Device

Abstract

1. Introduction

2. Materials and Methods

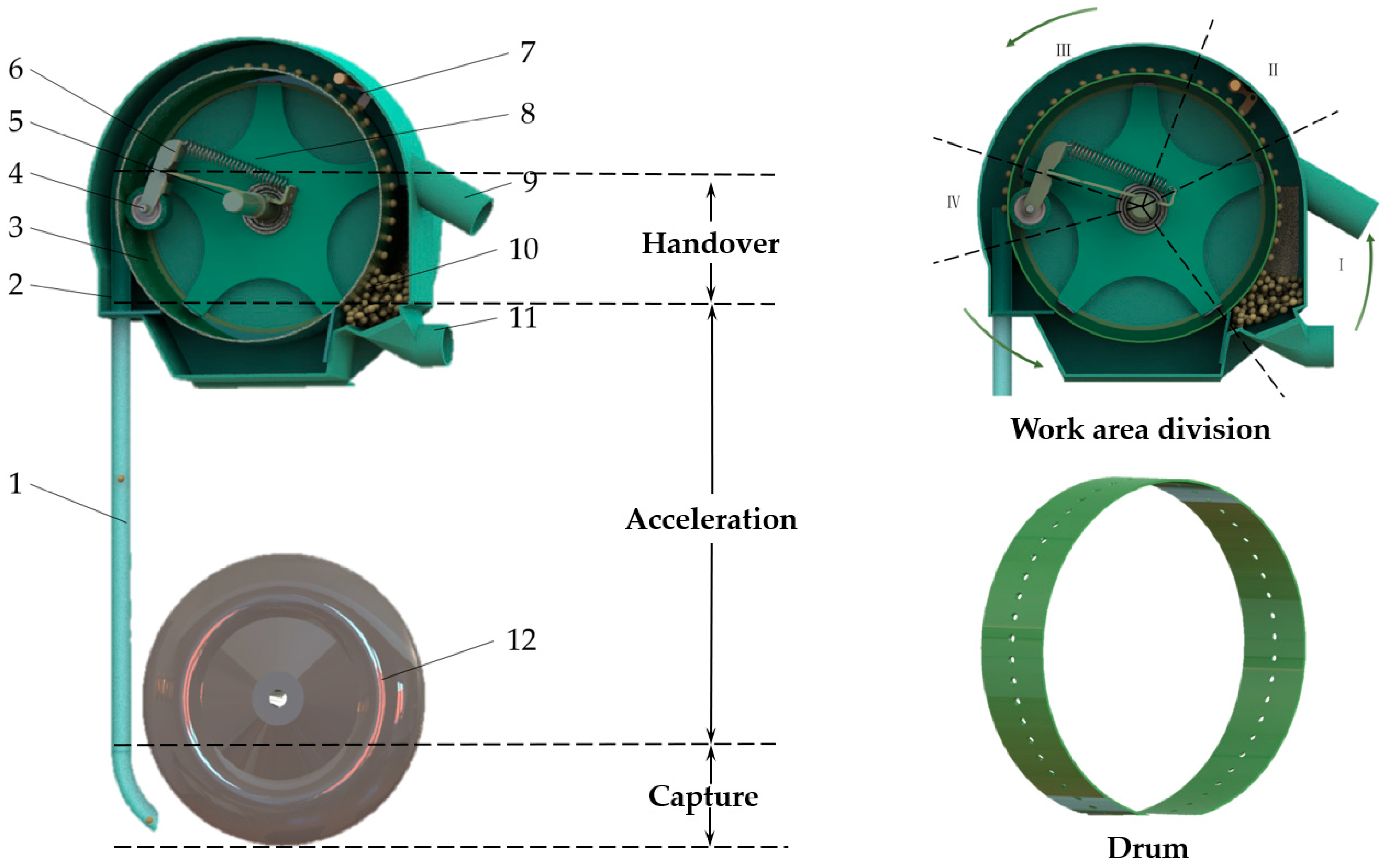

2.1. Structure and Working Principle of the Seeding System

2.2. Kinematic Mechanism Analysis of Soybean Seeds Delivery Process

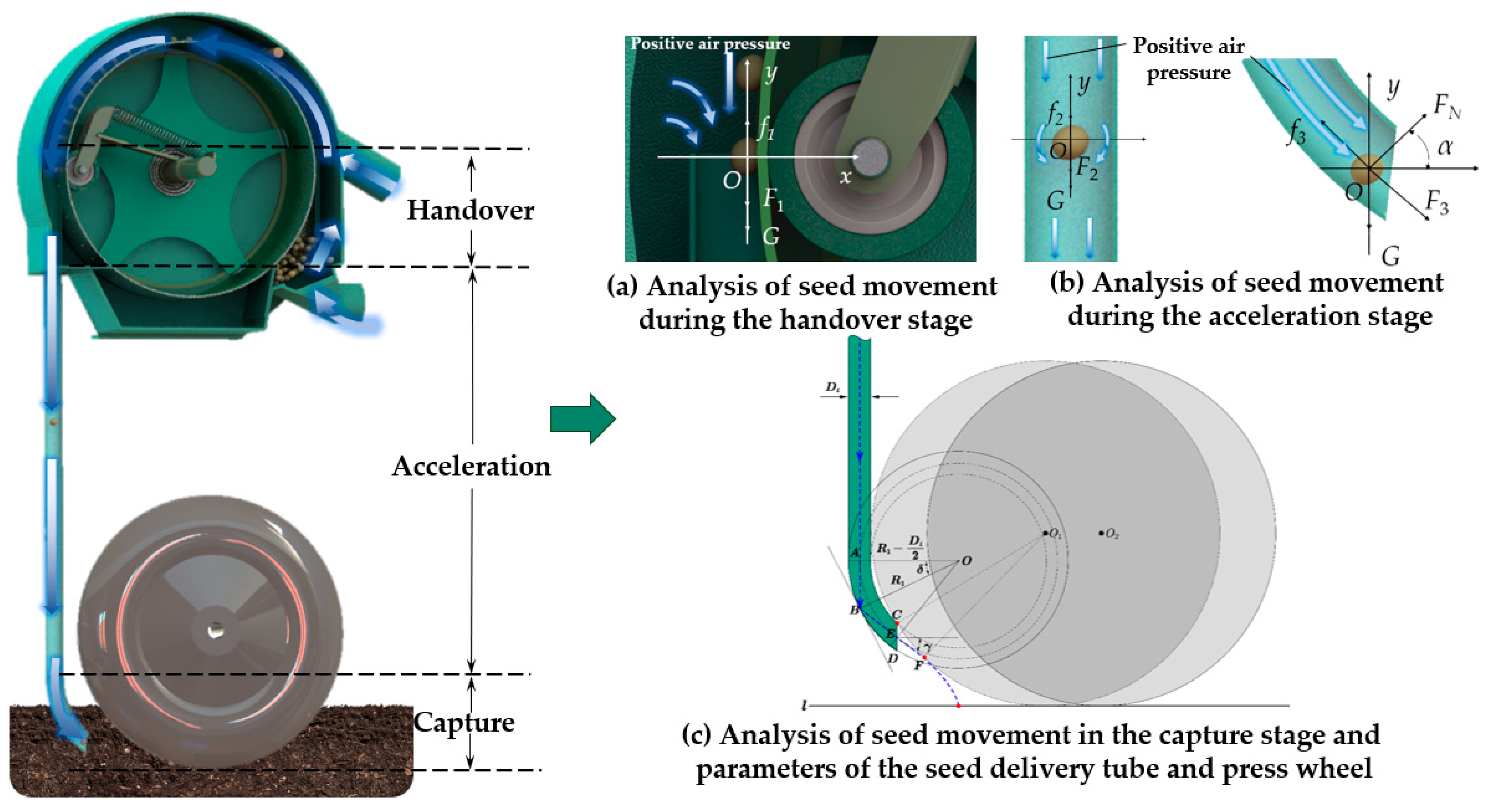

2.2.1. Analysis of the Handover Process When Seeds Leave the Seed Metering Device

2.2.2. Analysis of the Acceleration Process of Seeds in the Seed Delivery Tube

- Analysis of seed movement in the straight section of the seed delivery tube

- 2.

- Analysis of seed movement in the curve section of the seed delivery tube

- 3.

- Analysis of the process of seeds leaving the tube and being captured by the seed press wheel

2.3. Numerical Simulation Analysis of the Soybean Precision Seeding System Performance

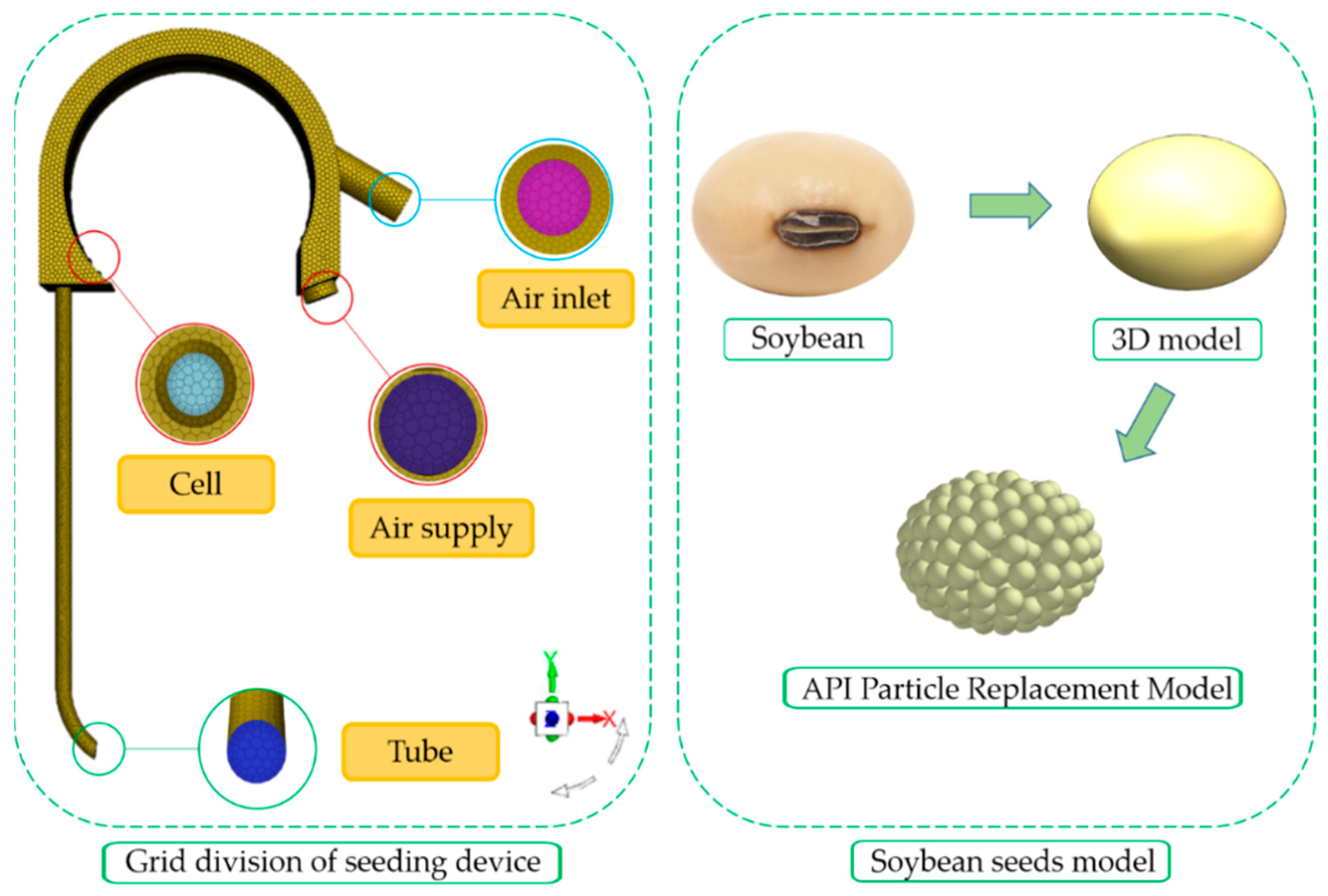

2.3.1. Establishment of the Simulation Model

- Meshing of the precision seeding system

- 2.

- Construction of the soybean seed simulation model

- 3.

- Setting of CFD-DEM simulation parameters

2.3.2. Contents and Methods of Simulation Test

- Setting of test factors for seed delivery tube position and press wheel seed capture simulation

- 2.

- Setting of Factors in the Coupling Simulation Test

3. Results and Discussion

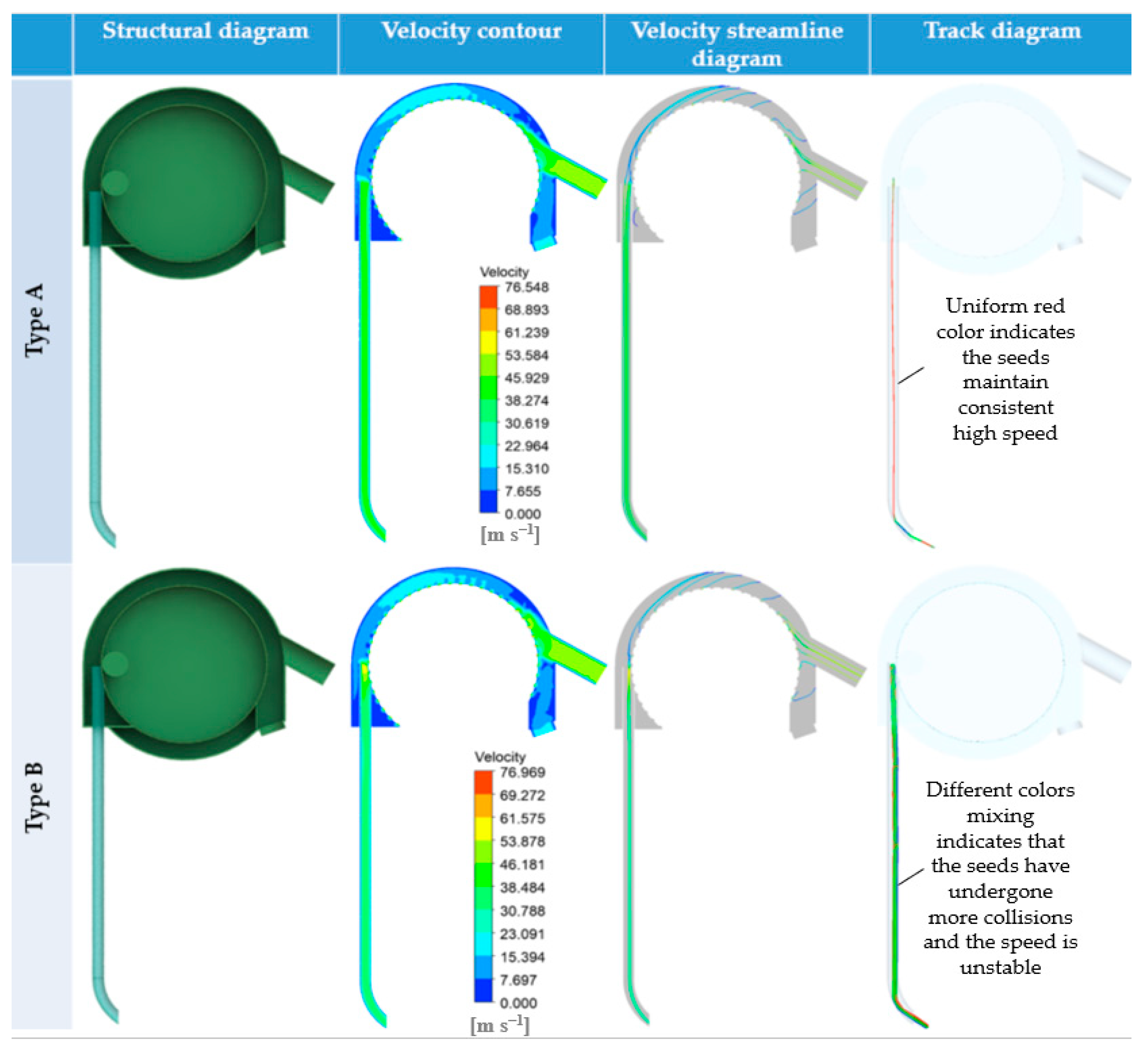

3.1. Analysis of the Influence of Relative Positions of Different Seed Delivery Tubes on Seed Drop Trajectory

3.2. Analysis of Single Factor Coupling Results

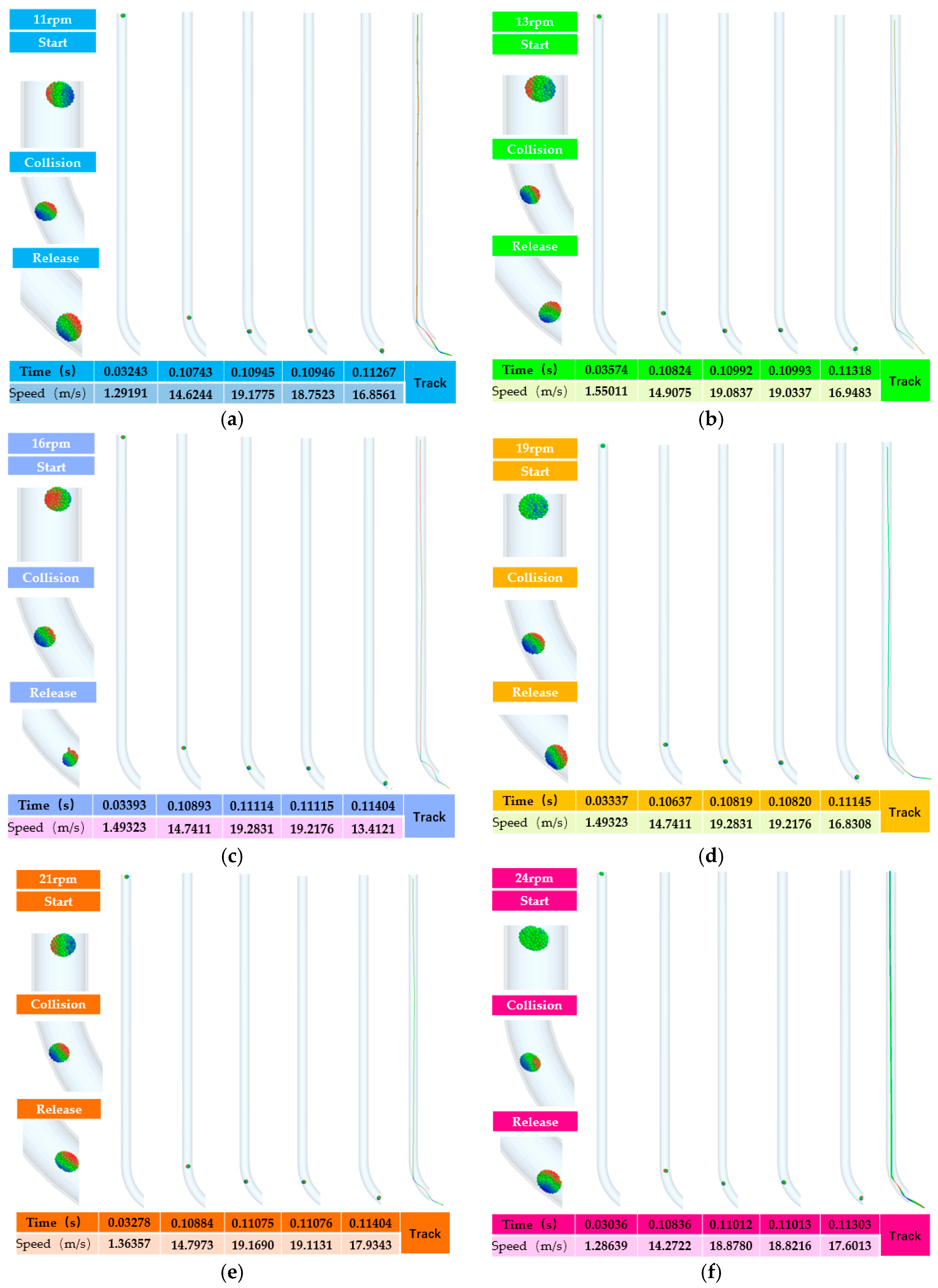

- Analysis of different seed drum rotational speeds at the same inlet pressure

- 2.

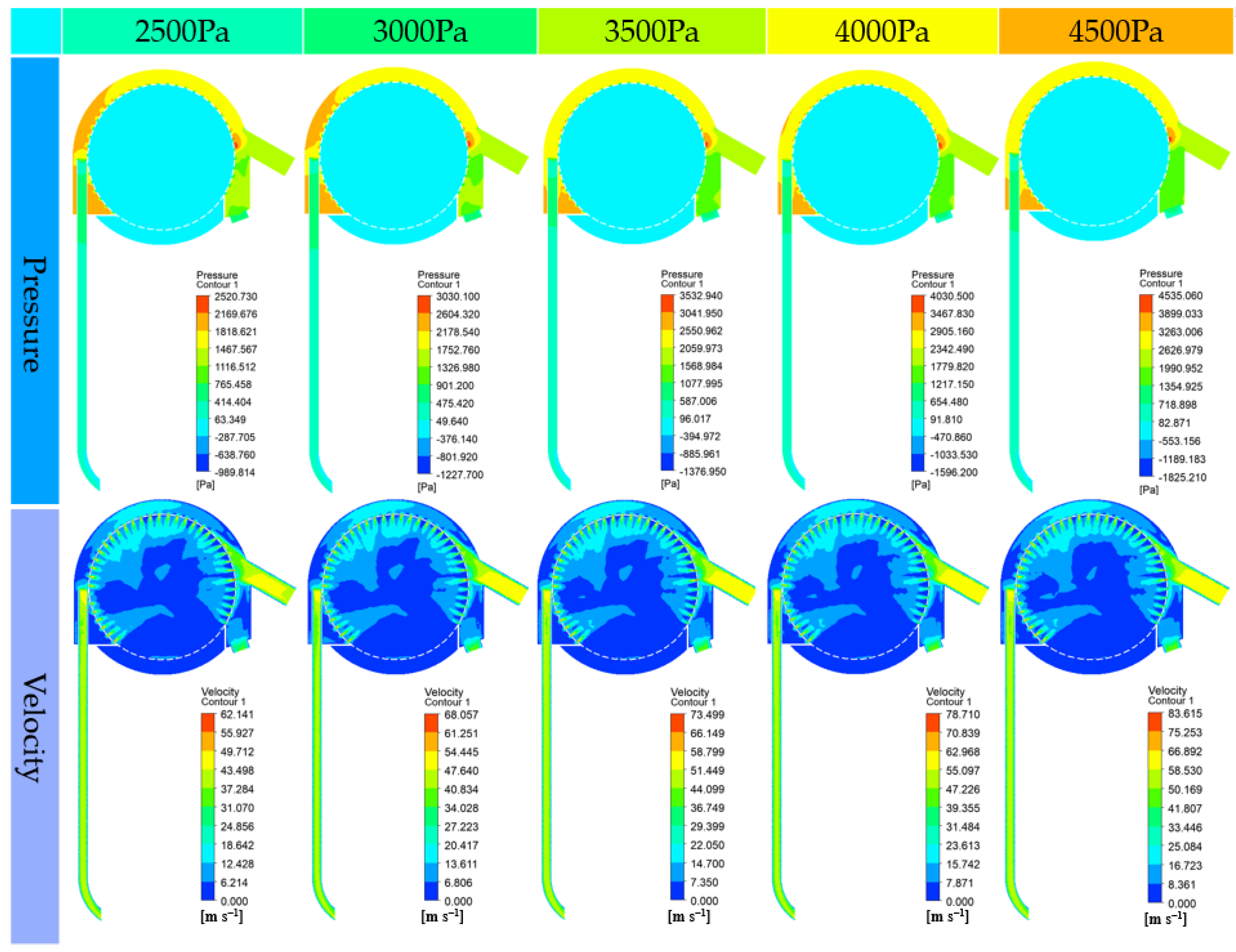

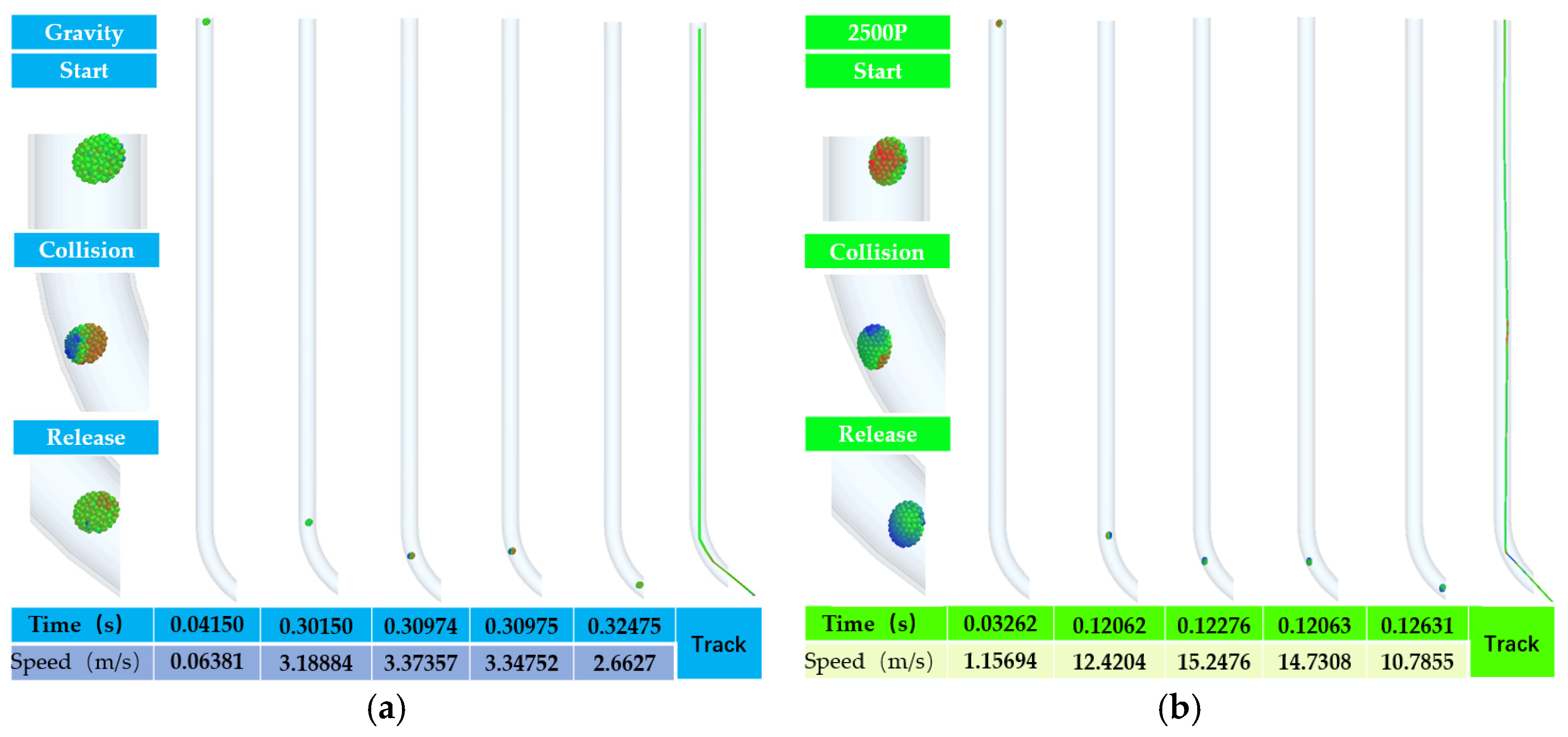

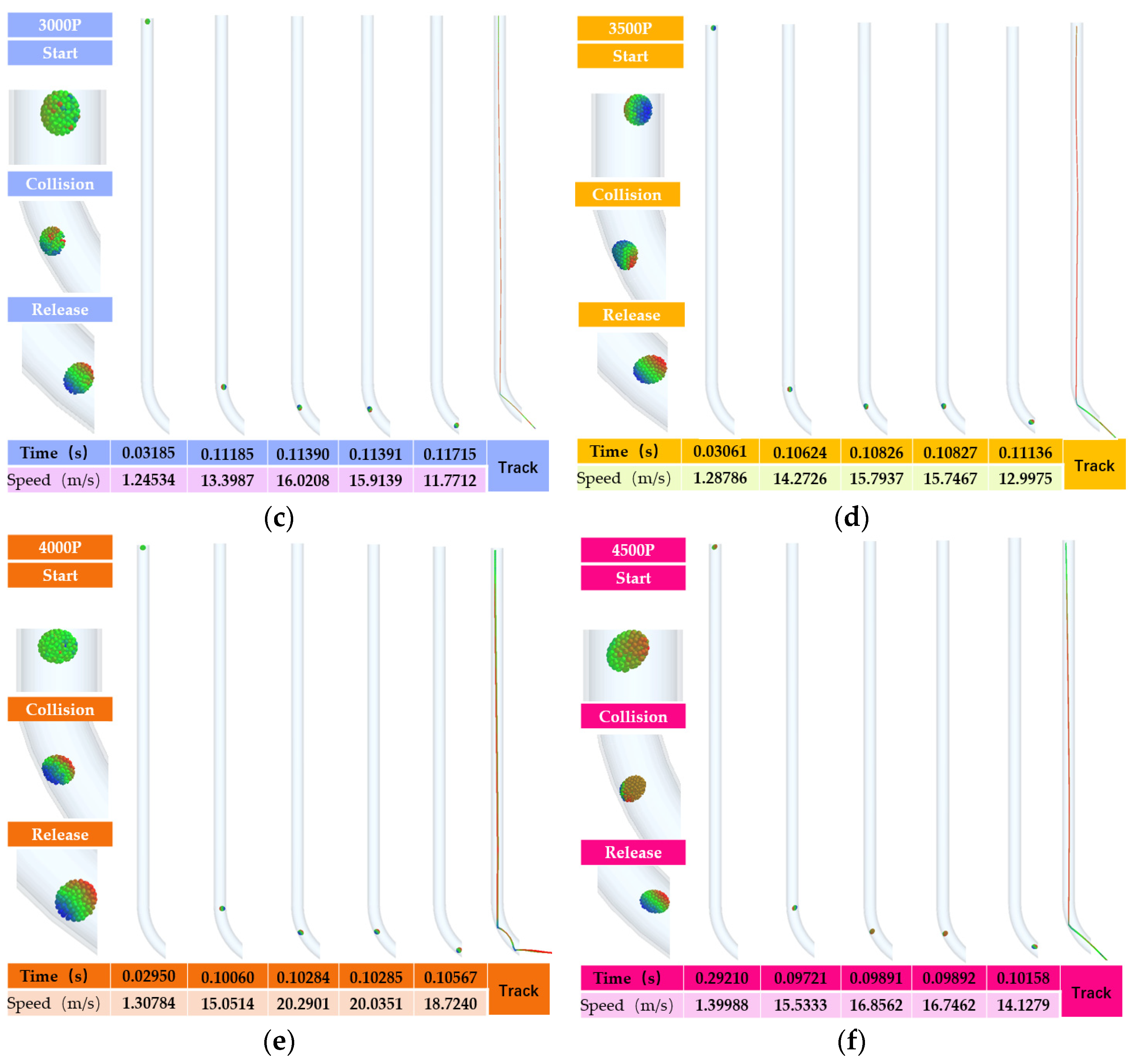

- Analysis of different inlet pressures at the same seed drum speed

- 3.

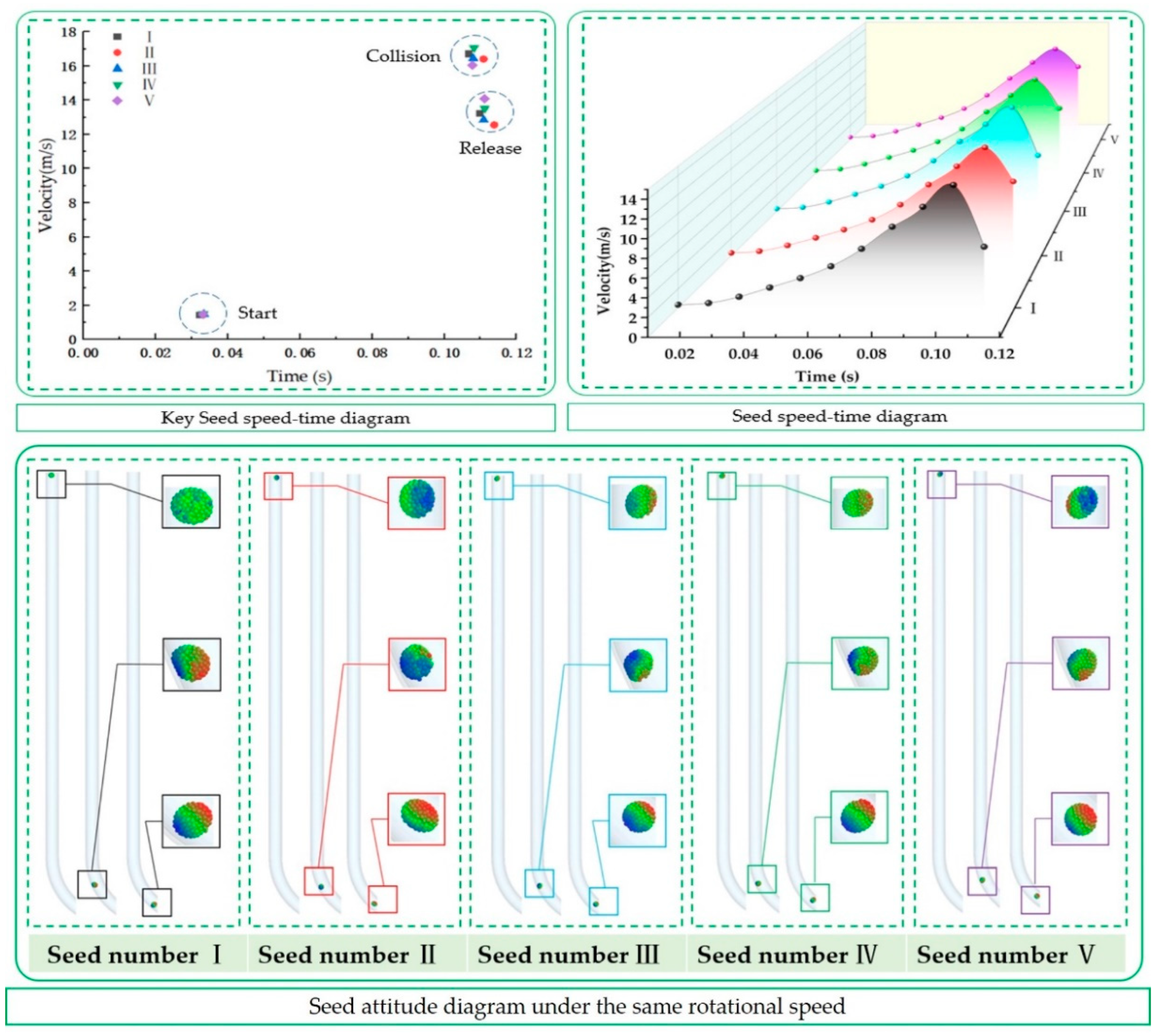

- Analysis of the movement states of different seeds under the same pressure and drum rotational speed

- 4.

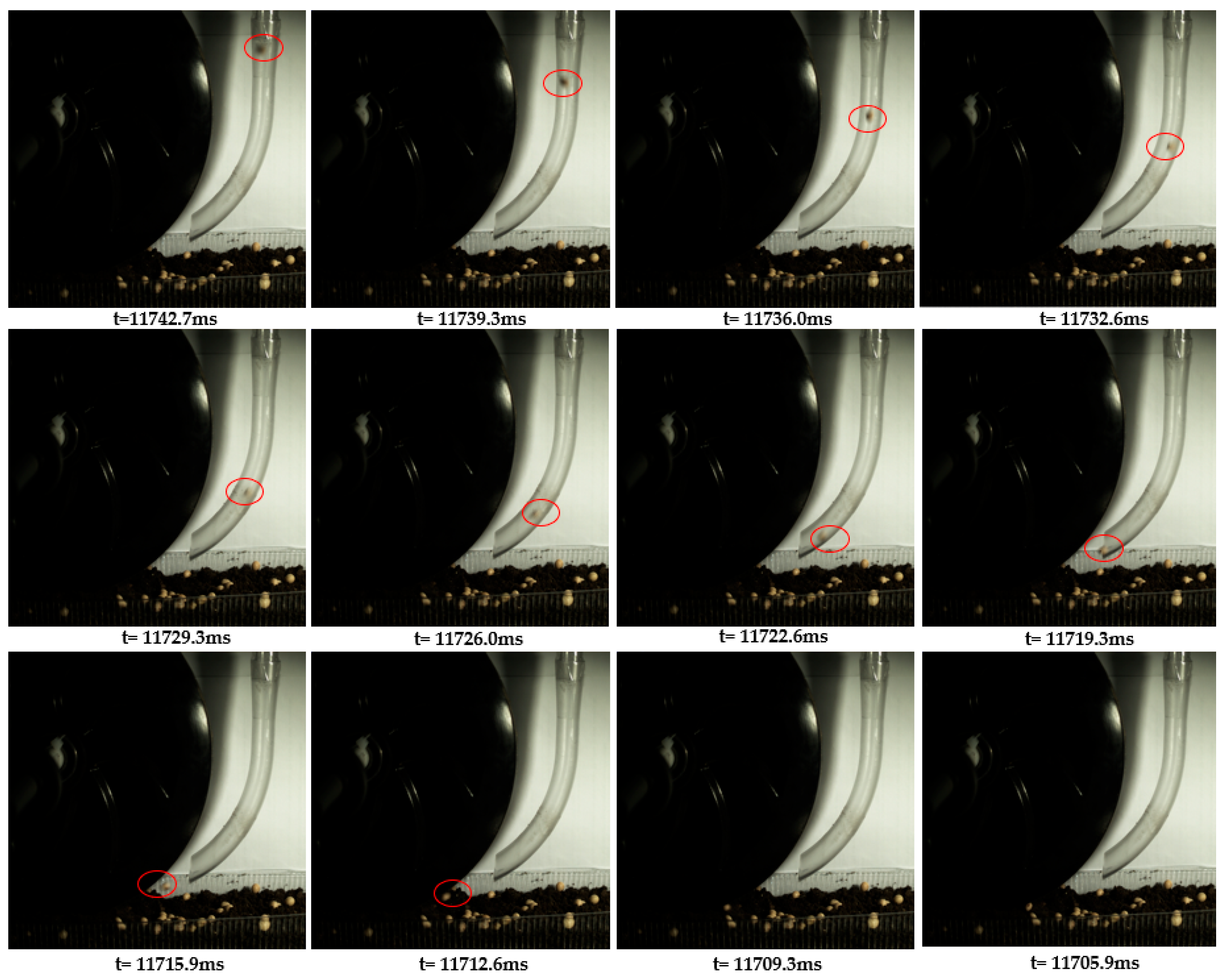

- Analysis of the seed capture process

3.3. Bench Test

3.3.1. Bench Test Conditions and Experimental Arrangements

3.3.2. Results and Discussion of the Bench Tests

4. Conclusions

- (1)

- Optimized Airflow-Assisted Seed Delivery Device: Key structural parameters were determined, including a seed tube diameter of 16 mm, a curved section radius of 80 mm, a seed delivery angle γ of 33.65°, and a press wheel diameter of 254 mm. The Type A structure, which aligns the tube outlet with the seed velocity direction, minimized collisions and improved seeding uniformity during high-speed operation.

- (2)

- Impact of Inlet Air Pressure: Increasing inlet air pressure enhanced seed distribution uniformity by accelerating seeds and reducing travel time. A 500 Pa increase in pressure raised the maximum airflow velocity by approximately 5 m/s. However, seed acceleration exhibited diminishing returns: a pressure increase from 2.5 kPa to 3.5 kPa increased seed speed by 2.1 m/s, while a further increase to 4.5 kPa only added 1.1 m/s. The optimal inlet pressure for efficient energy transfer and seed acceleration was approximately 3.5 kPa.

- (3)

- Performance of the Press Wheel: The press wheel significantly improved seeding uniformity by reducing seed rebound upon soil contact. It achieved high and consistent capture rates, ranging from 94.0% to 96.0% across operational speeds of 11 to 19 rpm, ensuring stable seed spacing and uniform crop emergence.

- (4)

- Validation of Simulations: Bench tests using high-speed cameras confirmed the accuracy of the CFD-DEM coupling simulations, as seed movement trajectories and collision patterns closely matched predictions. This validates the model’s reliability for predicting seed behavior under various operational conditions.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| G | Gravitational force acting on soybean seeds (N) |

| F1 | Pressure acting on soybean seeds at the seed discharge port (N) |

| f1 | Resistance of the soybean seed (N) |

| Q | Volumetric airflow rate through any given equipotential surface (m3/s) |

| R | Distance between the equipotential surface and the center of the flow field (m) |

| uR | Velocity of the airflow (m/s) |

| Δp | Static pressure difference between the flow field center and the flow field edge (Pa) |

| ρ | Air density (kg/m3) |

| Cd | Dimensionless drag coefficient (1) |

| dh | Diameter of the seed drum’s holes (m) |

| ds | Diameter of the seed (m) |

| ρ1 | Density of soybean seeds (kg/m3) |

| v0 | Seed speed (m/s) |

| ω | Angular velocity of the seed drum (rad/s) |

| r | Radius of the seed drum (m) |

| a | Acceleration of the seed (m/s2) |

| n | Rotational speed of the seed drum (r/s) |

| vk | Airflow velocity after positive pressure acceleration (m/s) |

| l | Movement distance of the seed (m) |

| F3 | Thrust force of the airflow (N) |

| u | Coefficient of friction between the seeds and the tube wall (1) |

| Normal pressure exerted by the seeds on the tube wall (N) | |

| Trajectory radius of seeds in the curved section (m) | |

| α | Angle between the seed velocity direction line and the horizontal line (°) |

| Dt | Diameter of the seed tube (m) |

| dmax | Maximum size of the seed’s long axis (m) |

| γ | Seed delivery angle (°) |

| D | Horizontal distance from the seed delivery tube to the point where the seed press wheel touches down (m) |

| H | Vertical distance from the end of the seed delivery tube to the ground (m) |

| Dw | Diameter of the press wheel (m) |

References

- Dun, G.; Mao, N.; Gao, Z.; Wu, X.; Liu, W.; Zhou, C. Model construction of soybean average diameter and hole parameters of seed-metering wheel based on DEM. Int. J. Agric. Biol. Eng. 2022, 15, 101–110. [Google Scholar] [CrossRef]

- Xu, J.; Wang, X.; Zhang, Z.; Wu, W. Discrete Element Modeling and Simulation of Soybean Seed Using Multi-Spheres and Super-Ellipsoids. IEEE Access 2020, 8, 222672–222683. [Google Scholar] [CrossRef]

- National Bureau of Statistics. The 2024 National Economic and Social Development Statistical Bulletin of the People’s Republic of China. Available online: https://www.stats.gov.cn/sj/zxfb/202502/t20250228_1958817.html (accessed on 16 July 2025).

- Ma, J.; Zhao, P.; Li, M.; Niu, J. The evolution of global soybean trade network pattern based on complex network. Appl. Econ. 2024, 56, 3133–3149. [Google Scholar] [CrossRef]

- Wang, M.; Liu, D.; Wang, Z.; Li, Y. Structural Evolution of Global Soybean Trade Network and the Implications to China. Foods 2023, 12, 1550. [Google Scholar] [CrossRef]

- Laber, M.; Klimek, P.; Bruckner, M.; Yang, L.; Thurner, S. Shock propagation from the Russia–Ukraine conflict on international multilayer food production network determines global food availability. Nat. Food 2023, 4, 508–517. [Google Scholar] [CrossRef]

- Ding, Y.; Yang, L.; Zhang, D.; Cui, T.; He, X.; Zhong, X. Control System of Motor-driving Maize Precision Planter Based on GPS Speed Measurement. Nongye Jixie Xuebao/Trans. Chin. Soc. Agric. Mach. 2018, 49, 42–49. [Google Scholar] [CrossRef]

- Ding, Y.; Yang, L.; Zhang, D.; Cui, T.; Li, Y.; Zhong, X.; Xie, C.; Ding, Z. Novel low-cost control system for large high-speed corn precision planters. Int. J. Agric. Biol. Eng. 2021, 14, 151–158. [Google Scholar] [CrossRef]

- Yang, L.; Yan, B.; Zhang, D.; Zhang, T.; Wang, Y.; Cui, T. Research progress on precision planting technology of maize. Nongye Jixie Xuebao/Trans. Chin. Soc. Agric. Mach. 2016, 47, 38–48. [Google Scholar] [CrossRef]

- Xue, P.; Xia, X.; Gao, P.; Ren, D.; Hao, Y.; Zheng, Z.; Zhang, J.; Zhu, R.; Hu, B.; Huang, Y.; et al. Double-Setting seed-metering device for precision planting of soybean at high speeds. Trans. ASABE 2019, 62, 187–196. [Google Scholar] [CrossRef]

- Liu, Q.; Cui, T.; Zhang, D.; Yang, L.; Wang, Y.; He, X.; Wang, M. Design and experimental study of seed precise delivery mechanism for high-speed maize planter. Int. J. Agric. Biol. Eng. 2018, 11, 81–87. [Google Scholar] [CrossRef]

- Carpes, D.P.; Alonço, A.D.S.; Rossato, F.P.; Veit, A.A.; De Souza, L.B.; Francetto, T.R. Effect of different conductor tubes on the longitudinal distribution of corn seeds. Rev. Bras. Eng. Agrícola E Ambient. 2017, 21, 657–662. [Google Scholar] [CrossRef][Green Version]

- Wang, B.; Liao, Q.; Wang, L.; Shu, C.; Cao, M.; Du, W. Design and Test of Air-Assisted Seed-Guiding Device of Precision Hill-Seeding Centralized Seed-Metering Device for Sesame. Agriculture 2023, 13, 393. [Google Scholar] [CrossRef]

- Yazgi, A. Effect of seed tubes on corn planter performance. Appl. Eng. Agric. 2016, 32, 783–790. [Google Scholar] [CrossRef]

- Precision Planting LLC SpeedTube-Highspeed Seed Delivery System. Available online: https://www.precisionplanting.com/products/planters/speedtube (accessed on 17 July 2025).

- John Deere LLC ExactEmerge. Available online: https://www.deere.com/en/planting-equipment/row-units/exactemerge-row-unit/ (accessed on 17 July 2025).

- Du, X.; Liu, C. Design and testing of the filling-plate of inner-filling positive pressure high-speed seed-metering device for maize. Biosyst. Eng. 2023, 228, 1–17. [Google Scholar] [CrossRef]

- Liu, R.; Liu, Y.; Liu, Z.; Liu, L. Research on Positive Pressure Airflow Assisted Blowing and Seed Guiding Device of Corn High-speed Precision Planter. Nongye Jixie Xuebao/Trans. Chin. Soc. Agric. Mach. 2023, 54, 156–166. [Google Scholar] [CrossRef]

- Lau, T.C.W.; Nathan, G.J. Influence of Stokes number on the velocity and concentration distributions in particle-laden jets. J. Fluid Mech. 2014, 757, 432–457. [Google Scholar] [CrossRef]

- Salewski, M.; Fuchs, L. Effects of aerodynamic particle interaction in turbulent non-dilute particle-laden flow. J. Turbul. 2008, 9, 1–23. [Google Scholar] [CrossRef]

- Guzman, L.; Chen, Y.; Landry, H. Coupled CFD-DEM Simulation of Seed Flow in Horizontal-Vertical Tube Transition. Processes 2023, 11, 909. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, W.; Yan, W.; Qi, B. Design and Experiment of Seed Pressing Device for Precision Seeder Based on Air Flow Assisted Seed Delivery. Nongye Jixie Xuebao/Trans. Chin. Soc. Agric. Mach. 2020, 51, 69–76. [Google Scholar] [CrossRef]

- Lei, X.; Liao, Y.; Zhang, Q.; Wang, L.; Liao, Q. Numerical simulation of seed motion characteristics of distribution head for rapeseed and wheat. Comput. Electron. Agric. 2018, 150, 98–109. [Google Scholar] [CrossRef]

- Wang, X.; Hu, H.; Wang, Q.; Li, H.; He, J.; Chen, W. Calibration Method of Soil Contact Characteristic Parameters Based on DEM Theory. Nongye Jixie Xuebao/Trans. Chin. Soc. Agric. Mach. 2017, 48, 78–85. [Google Scholar] [CrossRef]

- Han, D.D.; Wang, Q.; Wang, Y.X.; Li, W.; Tang, C.; Lv, X.R. Determination and parameters calibration of the soybean-bonded particle model based on discrete element method. Comput. Part. Mech. 2025, 12, 231–244. [Google Scholar] [CrossRef]

- Tang, H.; Xu, F.; Xu, C.; Zhao, J.; Wang, Y.J. The influence of a seed drop tube of the inside-filling air-blowing precision seed-metering device on seeding quality. Comput. Electron. Agric. 2023, 204, 107555. [Google Scholar] [CrossRef]

| Types | Characteristics | Picture |

|---|---|---|

| Mechanical belt-type delivery system | Each seed is isolated within the compartments, effectively preventing bouncing, but the structure is relatively complex, and the rotational speed of the seed disc must be precisely synchronized with the mechanical belt. |  |

| Brush belt-type delivery system | Seeds are fixed at specific positions by bristles, effectively preventing bouncing, but the structure is complex too, requiring precise coordination between the seed disc speed and the brush belt to achieve uniform seed distribution. |  |

| Airflow-assisted delivery system | Utilizing airflow to carry seeds at high speeds, reducing collision chances, with a simple structure that does not require additional high-precision motors. However, the downside is that the high speed of the seeds causes them to bounce upon contact with soil. |  |

| Airflow-assisted delivery system + press wheel | The seed delivery process involves minimal collision, has a simple structure, and during the high-speed landing of seeds, they are immediately pressed by the press wheel, resulting in uniform seed spacing. |  |

| Parameters | Soybeans | Soil | Steel | Reference | |

|---|---|---|---|---|---|

| Solid phase | Poisson’s ratio | 0.245 | 0.35 | 0.30 | [24,25] |

| Shear modulus (Pa) | 7.5 × 107 | 1 × 106 | 1.37 × 108 | ||

| Density (kg/m3) | 1220 | 2550 | 7850 | ||

| Restitution coefficient (with particle) | 0.39 | 0.6 | 0.52 | ||

| Static friction coefficient (with particle) | 0.29 | 054 | 0.27 | ||

| Rolling friction coefficient (with particle) | 0.05 | 0.31 | 0.05 | ||

| Gas phase | Fluid | Air | [26] | ||

| Gravitational acceleration (m/s2) | 9.81 | ||||

| Density (kg/m3) | 1.225 |

| Seed Drum Rotational Speeds Speed (rpm) | Replicate | CI (%) | Mean CI (%) |

|---|---|---|---|

| 11 | 1 | 96.0 | 96.0 |

| 2 | 95.0 | ||

| 3 | 97.0 | ||

| 13 | 1 | 95.0 | 94.3 |

| 2 | 95.0 | ||

| 3 | 93.0 | ||

| 16 | 1 | 95.0 | 94.3 |

| 2 | 94.0 | ||

| 3 | 94.0 | ||

| 19 | 1 | 94.0 | 94.0 |

| 2 | 94.0 | ||

| 3 | 94.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ding, Y.; Zheng, G.; Zhang, W.; Qi, B.; Wang, Y.; Xia, Q.; Wang, R.; Zhang, H. Design and Evaluation of a High-Speed Airflow-Assisted Seeding Device for Pneumatic Drum Type Soybean Precision Seed Metering Device. Agronomy 2025, 15, 2202. https://doi.org/10.3390/agronomy15092202

Ding Y, Zheng G, Zhang W, Qi B, Wang Y, Xia Q, Wang R, Zhang H. Design and Evaluation of a High-Speed Airflow-Assisted Seeding Device for Pneumatic Drum Type Soybean Precision Seed Metering Device. Agronomy. 2025; 15(9):2202. https://doi.org/10.3390/agronomy15092202

Chicago/Turabian StyleDing, Youqiang, Gang Zheng, Wenyi Zhang, Bing Qi, Yunxia Wang, Qianqian Xia, Ruzheng Wang, and Haojie Zhang. 2025. "Design and Evaluation of a High-Speed Airflow-Assisted Seeding Device for Pneumatic Drum Type Soybean Precision Seed Metering Device" Agronomy 15, no. 9: 2202. https://doi.org/10.3390/agronomy15092202

APA StyleDing, Y., Zheng, G., Zhang, W., Qi, B., Wang, Y., Xia, Q., Wang, R., & Zhang, H. (2025). Design and Evaluation of a High-Speed Airflow-Assisted Seeding Device for Pneumatic Drum Type Soybean Precision Seed Metering Device. Agronomy, 15(9), 2202. https://doi.org/10.3390/agronomy15092202