Abstract

To address the lack of specialized seeding equipment and low manual seeding efficiency in rice plot breeding, this study developed an air suction precision seed-metering device for rice plot breeding, featuring automatic seed-switching and seed-clearing functions controlled by an STM32 microcontroller. Firstly, based on morphological analysis and MATLAB image processing, an active contour method was used to construct a suction hole model. Secondly, to meet the non-contaminated switching requirements between rice varieties, an electrically controlled seed-switching and seed-clearing mechanism was developed based on QR code-based precise recognition and positioning. Using 10 rice varieties as experimental materials, performance tests were conducted. The results showed that the seed-switching mechanism had single and cumulative errors under 0.4°, and the seed-clearing rate reached 100% with an average clearing time below 0.88 s. At a rotational speed of 20 r·min−1 and negative pressure of 3200 Pa, seed-filling performance was optimal for all rice varieties. Among them, the rice variety Nayou 6388 exhibited the best seed-filling performance, with a 0.8% missing seed rate, 97.6% single and double seed rate, and 1.6% multiple seed rate. In double-row coordinated tests, each seed-metering device independently completed seed switching and maintained synchronized operation, meeting agronomic requirements for accurate seed switching/clearing and precision seed filling in rice plot breeding.

1. Introduction

Rice (Oryza sativa L.), an annual to biennial herbaceous plant in the Poaceae family, ranks among China’s three staple crops. The promotion of improved varieties can enhance rice yield by at least 20% [1,2]. Plot breeding filed trials serve as indispensable tools for developing new cultivars and permeate all stages of breeding programs [3]. Seeding is the most fundamental operation in plot breeding field trials, and also the most critical, labor-intensive, and time-consuming stage. At present, due to the lack of specialized machinery, rice plot breeding still relies heavily on manual seeding operations, which are time consuming and labor intensive, with low automation and poor operational stability, thereby seriously affecting the accuracy of trial results [4,5]. Therefore, the development of a specialized rice plot seeding machine that closely integrates agronomic requirements with agricultural machinery is of great significance for improving the quality of rice plot breeding operations and expanding the scale of trials.

The seed-metering device is the core component for ensuring the operational quality of plot seeding mechanisms, while the seed-switching and clearing process is a critical link for improving seeding efficiency in plot breeding. With increasingly stringent purity requirements for test varieties during the seeding stage of plot breeding filed trials, the development of a high-precision seed-metering system equipped with an automated seed-switching and clearing mechanism has become an urgent necessity. In Europe and North America, several agricultural machinery manufacturers have developed specialized plot seeders equipped with automatic seed-switching systems. Wintersteiger AG [6] has introduced a plot seeding machine featuring the Smart Feed system, which enables sequential replacement of seed varieties via a 1.7 × 0.8 m magazine-style platform, precise single-seed delivery is achieved through dynamic seed control using a grooved seed-metering disc. Zurn [7] developed the D96 transverse plot seeder, which performs automatic seed switching by laterally conveying seed boxes based on electronic control instructions, ensuring uniform seed delivery through drill seeding. Almaco’s [8] PowerPlant automatic planting system, compatible with tractors, enables unmanned operations and utilizes a combination of vertical compression and horizontal progressive conveying for sequential seed switching, supporting continuous seeding of up to 5760 plots. Haldrup [9] launched the SR-30 plot drill, equipped with an automatic seeding control system that actively switches varieties using a standardized magazine driven by electronic control commands. In China, Wang [4] developed an air suction precision seed-metering device for rice plot breeding, driven by a motor to actuate seed-switching disc along cam type groove slides, achieving high-precision sequential seed switching with zero cross-contamination. Dun et al. [10] designed a manual seed-switching/clearing device for soybean plot breeding, utilizing double seed-metering discs for alternating operations with rapid seed-switching cycles. Hao et al. [11] developed a spoon clip single seed peanut plot seeder controlled by an STM32 microcontroller, achieving coordinated automatic seed clearing and precision seed metering. Yang et al. [12] devised a self-clearing pneumatic maize plot seeder with isolated seed filling and clearing chambers, utilizing air suction gates and negative pressure adsorption for independent operations.

In summary, most plot seeders produced in Europe and North America are now equipped with mature automatic seed-switching and seed-clearing systems, and have already been widely applied in commercial settings. However, the seed-switching mechanisms adopted in these machines typically occupy a large amount of structural space, resulting in increased overall machine width and reduced operational flexibility. Consequently, such equipment is more suitable for large-scale and centralized breeding operations, and is difficult to adapt to the fragmented plots, high variety density, and high-frequency experimental needs commonly seen in breeding environments in China. In contrast, plot seeders developed in China are mostly designed for specific crop varieties. Although some devices have achieved seed-switching and seed-clearing functions to a certain extent, most are still targeted at single crops such as soybean, maize, or peanut, which have relatively large and regularly shaped seeds. There remains a lack of dedicated seeding devices that can accommodate the morphological diversity of rice grains, the high seeding frequency, and the rapid seed-switching requirements typical of rice plot breeding. At present, there is no specialized seeding equipment or control system in China specifically designed for rice plot breeding that integrates seed-switching, seed-metering, and seed-clearing functions into a single unit. As a result, rice plot breeding operations still rely heavily on manual labor, which leads to low efficiency and poor consistency. To address this issue, it is urgently necessary to develop a seeding device based on existing large-scale rice seed-metering systems, utilizing a modular design of functional components to enable flexible switching between large-scale field operations and plot breeding scenarios. On one hand, such a device would ensure precise and specialized operation capabilities for plot breeding field trials; on the other hand, it would help avoid the idle state of large-scale seeders during non-peak farming seasons, thus promoting continuous utilization and improving overall operational efficiency. However, most of the current mechanized seed-metering devices used for plot breeding are not designed with modular structures. Their seed-supplying, -metering, and -clearing components are often highly integrated and tightly coupled, with strong interdependencies among parts. This makes it difficult to disassemble, maintain, or upgrade the system flexibly according to varying operational requirements. Such structural characteristics limit the adaptability and generalizability of seed-metering devices across different crop types, seed characteristics, and field conditions, thereby hindering their broader application in diverse agricultural breeding environments.

To address these challenges, this study considers the agronomic requirements of rice plot breeding and the need for modularization of the functional components within the seed-metering device. In response to technical difficulties such as frequent seed switching, precision seeding, and rapid seed clearing during plot sowing operations, an air suction precision seed-metering device for rice plot breeding was developed. This system is controlled by an STM32 microcontroller, powered by motors and servos, and operates through a human–machine interaction (HMI) platform to perform automated seed-switching and clearing tasks. The design aims to achieve coordinated execution among the microcontroller command system, the seed-metering device, and all control components, thereby fulfilling the operational requirements of precise and orderly seed switching, high-accuracy seeding, and rapid seed clearing in rice plot breeding trials. Ultimately, the goal is to realize modularized functional components, enhanced operational precision, and improved overall seeding efficiency for rice plot breeding applications.

2. Materials and Methods

2.1. Overall Structure of the Seed-Metering Device

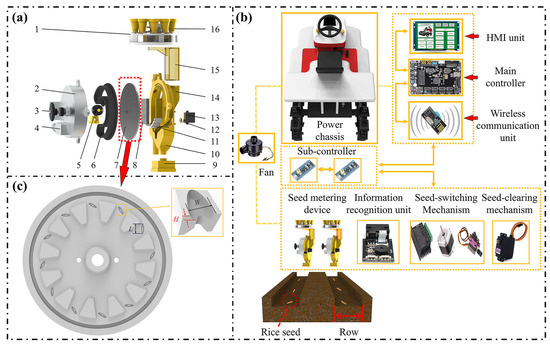

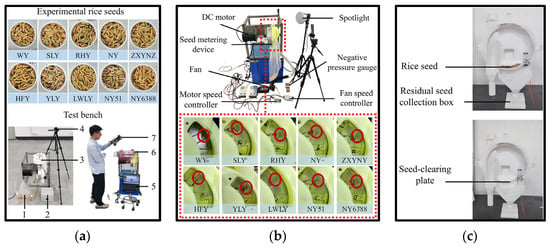

The air suction precision seed-metering device for rice plot breeding is primarily composed of a horizontal rotary seed-switching mechanism, a negative pressure chamber shell, a horizontally shallow bowl-type seed-metering disc, a residual seed collection box, an open–close-type seed-clearing plate, a seed-filling shell, and seed supply box, as shown in Figure 1a. Among them, the horizontal rotary seed-switching mechanism used in plot operations can be replaced with a conventional seed box for field scale seeding, depending on the operational scenario of the seed-metering device, thereby meeting the multifunctional requirement of one device serving multiple purposes.

Figure 1.

Overall structure of the air suction precision seed-metering device for rice seed plot breeding. (a) Overall structure of seed-metering device; (b) key electronic components of control systems; (c) seed-metering disc structure. 1. Horizontal rotary seed-switching mechanism; 2. negative pressure air chamber shell; 3. seed-metering shaft; 4. negative pressure exhaust port; 5. seed-clearing roller; 6. air chamber sealing ring; 7. seed-metering disk; 8. seed-clearing brush; 9. residual seed collection box; 10. seed-clearing channel; 11. open–close-type seed-clearing plate; 12. servo drive flange; 13. servo MG996R; 14. seed-filling shell; 15. seed supply channel; 16. seed supply box.

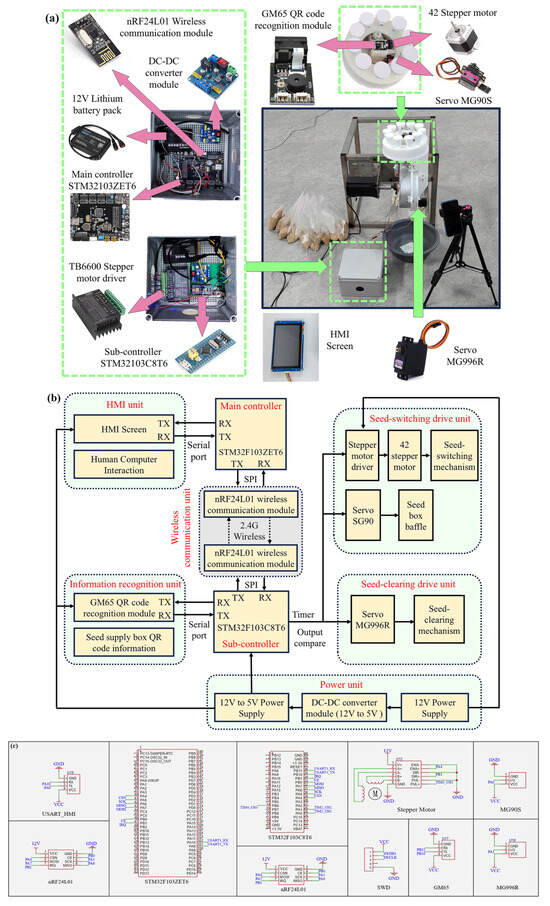

2.1.1. Control Scheme for the Seed-Switching and Clearing System

The key electronic components of the automatic seed-switching and clearing control system are shown in Figure 1b. The system mainly consists of a main controller, an HMI unit, a wireless communication unit, a sub-controller, an information recognition unit, a seed-switching drive unit, and a seed-clearing drive unit. The HMI unit adopts the TJC8048X550_011C serial screen (Shenzhen Taojingchi Electronics Co., Ltd., Shenzhen, China); the main controller is based on the STM32F103ZET6 microcontroller (Dongguan embedfire Technology Co., Ltd., Dongguan, China) [13,14,15,16]; the wireless communication unit utilizes the nRF24L01 wireless transmission module (Nordic Semiconductor, Shenzhen, China) [17]; and the sub-controller is implemented using the STM32F103C8T6 microcontroller (SIMMTECH Co., Ltd., Shenzhen, China) [18,19,20]. The information recognition unit employs a GM65 (Hangzhou Grow Technology Co., Ltd., Hangzhou, China) QR code reader module for seed box identification. The seed-switching drive unit consists of a TB6600 stepper motor driver (Pufeide Electric Co., Ltd., Wenzhou, China), a 42 stepper motor (Pufeide Electric Co., Ltd., Wenzhou, China), and a servo MG90S (Shenzhen Ruixin Hengchuang Electronics Co., Ltd., Shenzhen, China). The seed-clearing drive unit is powered by a servo MG996R (SIMMTECH Co., Ltd., Shenzhen, China).

2.1.2. Working Principle

During operation, the seed-metering device is positioned at the beginning of a plot segment. A negative pressure source draws airflow through the exhaust port, creating a vacuum environment between the negative pressure air chamber shell, sealing ring, and seed-metering disc. The user inputs commands into the HMI based on the rice plot breeding plan, which are transmitted to the main controller via the USART interface. After parsing the instructions, the main controller sends tasks through the nRF24L01 wireless module to sub-controllers, initiating seed-switching and clearing processes. Following “identification-verification-execution”, a 42 stepper motor drives the seed supply box to rotate to the QR code scanning zone. The GM65 module reads the QR code to confirm variety matching. If unmatched, the 42 stepper motor continues rotating until the correct variety is found. Once identified, the MG90S servo opens the seed supply box baffle, allowing seeds to fall into the filling chamber. Seeding begins: rice seeds are adsorbed by negative pressure and transported by the seed-metering disc to the dispensing zone, where they are orderly released into the field under the clearing roller’s action. After completing seeding for the current variety, the device halts, and the MG996R servo opens the seed-clearing plate to clear residual seeds into the residual seed collection box. After clearing, the seed-clearing plate closes rapidly, and the system prepares for the next cycle. This process repeats until all rice varieties on the seed-switching disc are fully seeded.

2.2. Mechanical Structure Design of the Seed-Metering Unit

To enhance the component compatibility between plot specific seed-metering devices and precision hill-drop rice seeders for field production, this study adopts a double-hole air suction precision hill-drop seed-metering device as the foundational unit [21]. The seed-metering disc, seed-switching mechanism, and seed-clearing mechanism were designed as standardized, modular, and rapidly detachable functional components. This modular structure enables flexible adaptation of the seed-metering system to different seeding scenarios, including large scale field production and plot-based rice breeding, thereby improving its operational versatility and utilization efficiency.

2.2.1. Structural Design of the Seed-Metering Disc

The seed-metering disc serves as the core component for achieving precise seed filling of various rice varieties. To expand the seed-filling capability of the disc for long-grain rice varieties, this study selected ten representative irregular rice seed varieties (“Wuyou 1179 (WY), Shenliangyou 1978 (SLY), Ruanhuayou 1179 (RHY), Nayou 6618 (NY), Zengxiangyou Nanzhan (ZXYNZ), Hengfengyou 1179 (HFY), Y Liangyou 1378 (YLY), Longwang Liangyou 889 (LWLY), Nayou 51 (NY51), and Nayou 6388 (NY6388)”) as the research objects. The fundamental physical and mechanical properties of these varieties are listed in Table 1. Based on the contour profiles of the seeds, a morphological analysis was conducted, and a novel seed-metering disc was designed featuring horizontally oriented, shallow bowl-shaped suction holes, as illustrated in Figure 1c.

Table 1.

The three-axis dimensions of the experimental rice seeds.

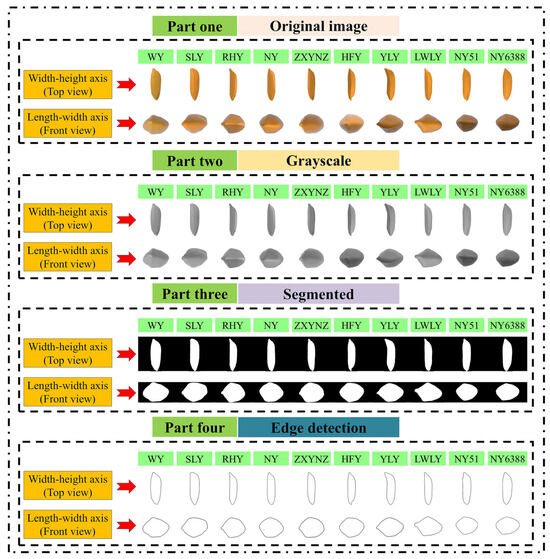

According to the existing literature, seeds are most likely to be adsorbed along their length–width axis, which also results in a more stable seed carrying state post adsorption [22,23]. Therefore, in this study, an ATOS Triple Scan 5M 3D scanner was employed to extract surface features of the rice seeds along both the length–width and width–height axis. Subsequently, using the image processing functions in MATLAB, the active contour model was employed to segment the rice seed images. The edge gradient descent algorithm was then applied for edge detection, and after 500 iterations, the complete seed contours were successfully extracted [24,25,26,27], as illustrated in Figure 2. As observed, the seed edges exhibit complex geometries. Direct extraction of the full contour coordinates would lead to either data redundancy or insufficient accuracy. To address this, the contour curves were horizontally segmented through the centroid, and coordinate points were extracted from the geometrically regular portions of the contour. The contour curve images of each rice seed variety were then imported into the MATLAB App Designer HMI interface [28], from which the actual coordinate points of 50 randomly selected seed feature curves were obtained, as shown in Figure 3. Polynomial fitting was performed on the extracted contours along the length–width and length–height sides, and the resulting polynomial boundary equations are summarized in Table 2 and Figure 3. It was found that a sixth-order polynomial fit along the length–width axis and a second-order polynomial fit along the width–height axis provided the best approximation of the seed boundary features. Based on reference [21], and according to Equation (1) as well as the tri-axial dimensions of each seed variety, the final dimensional parameters of the horizontally oriented shallow bowl-shaped suction holes were determined to be 12 mm (length), 4 mm (width), and 2 mm (height).

where Lmax, Wmax, and Hmax are the maximum dimensions of the rice seed along the length, width, and height axes, respectively, mm; Lmin, Wmin, and Hmin are the corresponding minimum dimensions along the respective axes, mm.

Figure 2.

The external contour curves of various rice seed strain.

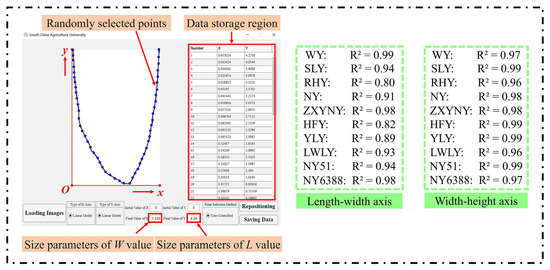

Figure 3.

Coordinate point collection and equation fitting.

Table 2.

Polynomial fitting equation.

Finally, proportional stacking of seed contours along the length–width and width–height axis was performed for multiple rice varieties, as illustrated in Figure 3. Based on the design parameters of the horizontally oriented shallow bowl-shaped suction holes, a secondary acquisition of the contour coordinate points was carried out using the MATLAB App Designer (version R2020a). The fitted polynomial boundary equations of the suction hole profile were ultimately obtained for both the length–width and width–height sides, expressed as follows:

Based on Equation (2) along with the fitted contour parameters of the suction hole, the final geometric design curves of the horizontally oriented shallow bowl-shaped suction hole were obtained.

2.2.2. Seed-Switching Mechanism

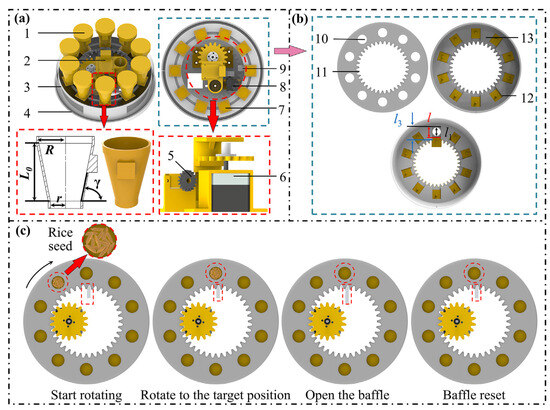

Rice plot breeding requires precise seed switching and quantified seed supply during the seeding process. To reduce the time span of seed switching and avoid cross-contamination among different rice varieties during the switching process, a horizontally rotary seed-switching mechanism with independently partitioned seed supply box was designed in this study, as shown in Figure 4a. This mechanism is capable of rapidly identifying variety information and, based on the operational state of the seed-metering device, utilizes sensor feedback in conjunction with coordinated actuation of motors and servos to achieve fast and accurate seed switching and supply, thereby improving breeding efficiency.

Figure 4.

Overall schematic diagram of the seed-switching mechanism. (a) Seed-switching mechanism structure; (b) schematic diagram of the action of the seed-switching mechanism. (c) Operating principle of the seed-switching mechanism. 1. Seed supply box; 2. GM65 QR code recognition module; 3. seed-switching disc; 4. seed-switching base; 5. seed box baffle drive gear; 6. 42 stepper motor; 7. seed box baffle; 8. servo MG90S; 9. gear rack; 10. seed supply box groove; 11. internal gear; 12. guide slot; 13. seed supply box baffle.

- (1)

- Structural design of the seed supply box

To further reduce variety switching errors, this study proposes a switching strategy based on QR code sequential indexing and demand-driven variety selection. The GM65 QR code recognition module is employed to automatically identify and verify different rice seed varieties, thereby enabling precise variety switching. Given the small seed quantity required per plot during rice plot seeding, the seed volume stored in the seed supply box must exceed the amount needed for the seed-metering device to perform a complete seeding operation. In typical rice plot breeding, the length of a single plot row is approximately 5 m, with hill spacing ranging from 140 mm to 200 mm. Therefore, the seed quantity required for single-row plot seeding can be calculated as follows:

where S is the expected number of seeds required; d represents the hill spacing, mm; n is the number of seeds adsorbed per suction hole.

When the hill spacing is 140 mm and each suction hole adsorbs 3 rice seeds, the maximum number of seeds required for single-row plot operation are 108. Based on this, a seed-filling performance bench test was conducted using multiple rice varieties as test materials, with the missing seed rate as the evaluation index. A total of 300 rice seeds were used as the initial test quantity in each trial. For each test group, 50 hills were evaluated, and each test was repeated five times. According to preliminary trials, the working negative pressure of the seed-metering device was set at 2800 Pa, and the seed-metering disc rotation speed was maintained at 20 r·min−1 during testing. The average values of the test results are presented in Table 3. The results show that when the number of seeds within the seed-filling zone of the seed-metering device was below 400, the seed adsorption performance was generally poor, with most rice varieties exhibiting a missing seed rate greater than 10%. Therefore, the minimum seed quantity for effective seeding in rice plot breeding operations must exceed 500 seeds. Based on this requirement and with reference to [4], the structural dimensions of the seed supply box were determined, as shown in Equation (4) and Figure 4a.

where γ represents the inclined angle of the seed supply box sidewall, °; L0 represents the height of the seed supply box, mm; R represents the radius of the top surface of the seed supply box, mm; r represents the radius of the bottom surface of the seed supply box, mm; γ1 and γ2 represent the maximum friction forces of each rice seed variety along the L-H axis and W-H axis, respectively, °; Vx is the volume of the seed supply box, mm3; N is the seed capacity of the seed supply box; p is the porosity of the rice seeds; and Vz is the average volume of a single rice seed, mm3.

Table 3.

Minimum seed supply test of the seed supply box.

The calculation results show that the maximum seed capacity of the seed supply box is 600 grains, which meets the minimum seed-filling requirement of the seed-metering device.

- (2)

- Structural design of the seed-switching disc

To avoid complex horizontal and vertical intersecting movement paths during the seed-switching process, a cylindrical-shaped seed-switching disc was designed in this study, as shown in Figure 4b. The seed-switching disc enables automatic seed supply box switching through rotational motion driven by a motor, while the seed box baffle performs seed dropping via linear motion transmitted by a servo motor.

Integrating agronomic requirements of rice plot breeding and dimensional parameters of field seed-metering devices [21], ten seed supply boxes were preliminarily determined to be evenly distributed on the seed-switching disc, as shown in Figure 4b. Therefore, for each single operation, the motor needs to rotate 36°, aligning the seed supply box slot with the seed dropping port. Then, a servo MG90S drives the seed supply box baffle to translate linearly along the rack slot track to release the seeds. Finally, the seed supply box baffle resets, completing the seed-switching process, as illustrated in Figure 4c. Based on the number of seed supply boxes and the dimensional parameters of seed supply box covers, the minimum circumference of the seed-switching disc should satisfy [11]:

where D is the diameter of the seed-switching disc, mm; n0 is the number of seed supply box; and C is the perimeter of a seed supply box cover, mm.

To ensure adequate spacing between adjacent seed supply boxes and in consideration of the structural dimensions of the precision hill-drop rice seed-metering device and the overall seeder configuration [21,29], the final design dimensions of the seed-switching disc were determined to be 200 mm in outer diameter and 45 mm in height.

Based on the structural parameters of the seed-switching disc and seed supply boxes, the motion distance l of the seed supply box baffle must be greater than the diameter of the seed supply box groove (l1) and less than the distance from the upper edge of the seed supply box groove to the internal gear (l2), that is:

Therefore, the movement distance of the seed supply box baffle is 25 mm.

- (3)

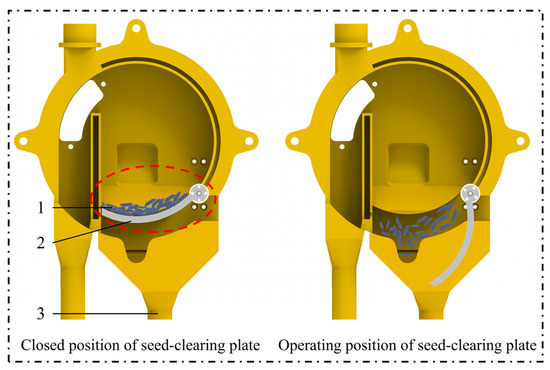

- Seed-clearing mechanism design

To enable rapid seed clearing and prevent cross-contamination between varieties in the seed-filling zone of the seed-metering device, an open–close-type seed-clearing mechanism driven by a servo MG996R was developed, as illustrated in Figure 5. The seed-clearing plate, seed-filling shell, and seed-metering disc together form the seed-filling chamber. After the completion of seeding for a single plot, the seed-clearing plate opens, allowing all residual seeds in the seed-filling chamber to be expelled through the seed-clearing channel. The servo motor then actuates the seed-clearing plate to return to its original position, thereby completing a full seed-clearing cycle. Based on the static friction coefficients of various rice varieties, the rotation angle of the servo motor for controlling the seed-clearing plate was determined to be 60°.

Figure 5.

Principle diagram of seed-clearing mechanism action. 1. Rice seeds; 2. seed-clearing plate; 3. seed-clearing channel.

2.3. Hardware Design of the Control System

2.3.1. Main Controller

The hardware connection diagram and the functional block diagram of the control system for the air suction precision seed-metering device used in rice plot breeding are shown in Figure 6a,b, respectively. The main controller is based on the STM32F103ZET6 microcontroller, which features a maximum operating frequency of 72 MHz, 512 KB of Flash memory, 64 KB of static SRAM, four general purpose 16-bit timers, and two advanced control timers. In terms of communication interfaces, it is equipped with 2 I2C interfaces, 3 SPI interfaces, 5 USART interfaces, and 1 CAN interface. These specifications fulfill the transmission and processing requirements for data storage, motor control, and HMI during breeding seeding operations.

Figure 6.

Schematic diagram of the control system hardware structure. (a) control system hardware connection diagram; (b) control system hardware block diagram; (c) control system circuit diagram.

2.3.2. Human–Machine Interface Unit

The TJC8048X550_011C serial display module was selected to implement the HMI for parameter configuration and information display. The module features a resolution of 800 × 480 pixels, a brightness of 300 nits, an operating voltage range of 4.65 V to 6.5 V, and a typical operating current of 350 mA. It supports an operating temperature range from −20 °C to 70 °C, and is equipped with 512 KB of runtime memory and a main control frequency of 200 MHz. These specifications meet the communication and interaction requirements of HMI systems for rice plot breeding operations under field conditions.

2.3.3. Wireless Communication Unit

Two nRF24L01 wireless communication modules were selected to facilitate data transmission between the main controller and the sub-controllers. The nRF24L01 is a single-chip transceiver produced by NORDIC Semiconductor, operating within the 2.4 GHz to 2.5 GHz ISM band. The module allows configuration of output power, channel selection, and communication protocols via an SPI interface, and supports a maximum transmission distance of 520 m at a data rate of 2 Mbps, thus meeting the communication requirements of rice plot breeding operations under field conditions. In this system, the signal lines of the nRF24L01 module “CE, CSN, SCK, MOSI, MISO, and IRQ” are connected to the following pins of the STM32 microcontroller: PB0, PA4, PA5, PA7, PA6, and PB1, respectively. The functions of each signal line are as follows: (1) CSN: when set to a low logic level, the nRF24L01 enters active mode and is ready to communicate with the microcontroller; (2) SCK: provides the SPI clock signal to synchronize data transmission and is connected to the STM32 microcontroller; (3) MISO: transfers data from the nRF24L01 module to the microcontroller; (4) MOSI: transfers data from the microcontroller to the nRF24L01 module; (5) IRQ: sends an interrupt signal to the microcontroller when the nRF24L01′s internal status changes; (6) CE: in combination with register configurations and a low CSN level, this pin determines the module’s working mode.

2.3.4. Sub-Controller

The sub-controller is designed based on the STM32F103C8T6 microcontroller, which features 128 KB of flash memory, 20 KB of SRAM, a 32-byte EEPROM, and four general-purpose 16-bit timers/counters. The microcontroller operates at a maximum frequency of 72 MHz. In terms of communication interfaces, it includes 2 SPI interfaces, 1 CAN interface, 3 USART interfaces, and 2 I2C interfaces, fully meeting the control requirements for seed-clearing and seed-switching operations in rice plot breeding under field conditions.

- (1)

- Seed-switching drive unit

This unit primarily consists of an information recognition module and a seed-switching drive module. The information recognition module employs the GM65 QR code recognition module, which features a minimum reading time of 0.1 s and a minimum scanning interval of 0.1 s. The module maintains consistent recognition performance under conditions of variable lighting and large temperature fluctuations, making it suitable for field environments.

The seed-switching drive module is composed of a 42 stepper motor, a servo MG90S, a 12 V power supply, and a voltage step down module. The 42 stepper motor offers stable performance and high positioning accuracy, while the servo MG90S provides high torque, stable rotational speed, and excellent resistance to wear and corrosion. These characteristics enable reliable and precise seed switching under the demanding conditions of rice breeding operations.

- (2)

- Seed-clearing drive unit

The seed-clearing drive unit consists of an open–close-type seed-clearing plate and a servo MG996R motor. Upon completion of seeding in a single plot, the sub-controller triggers the MG996R to actuate. The servo motor then drives the seed-clearing plate to rotate, enabling rapid removal of residual seeds from the seed-filling zone.

2.4. Control System Software Design

The control system software is primarily composed of four modules: the main control program, wireless communication program, sub-controller program, and the HMI program, as illustrated in Figure 6c. Among them, the main control program, wireless communication program, and sub-controller program were developed in C programming language using the Keil uVision5 integrated development environment. The HMI program was developed using USART HMI V1.66.3 and consists of the display hardware and a graphical user interface designed for real-time interaction and control.

2.4.1. Main Controller Software Design

The main controller program is responsible for coordinating and scheduling the entire system by receiving and processing information from the sub-controllers and managing operations such as seed switching, seed metering, and seed clearing. During system operation, the main program performs an initialization routine to ensure the proper functioning of peripherals including SPI, GPIO, and USART, and to establish stable communication links. Once initialization is complete, the user inputs operational commands via the HMI interface, which are then parsed by the main controller to generate corresponding control signals. These signals are transmitted to the sub-controllers via the nRF24L01 wireless communication module, triggering the execution of specific tasks. Meanwhile, the sub-controllers send status updates or operational data back to the main controller through the same wireless module. Upon receiving this feedback, the main control program analyzes the data and updates the HMI interface based on the actual operating conditions. This enables real-time monitoring and information feedback, ensuring that the user can intuitively track the operational status of the system throughout the seeding process.

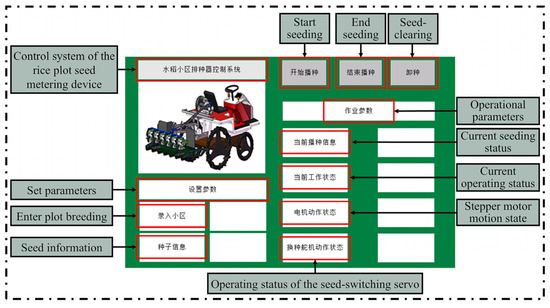

2.4.2. Human–Machine Interface Design

The HMI interface is shown in Figure 7. Its design process is as follows: (1) The interface is designed using a reasonable combination of colors; (2) Touch buttons such as “Enter breeding plot, Seed information, Start seeding, End seeding, and Seed-clearing” are sequentially configured within designated areas. Additionally, data display components such as “Current seeding status, Current operating status, Stepper motor motion state, and Operating status of seed-switching servo” are configured. Input information, such as “Enter breeding plot and Seed information”, are mapped to corresponding key values during interface operations and recorded in specified variable storage spaces; (3) After completing the interface design, the generated configuration file is transmitted via serial communication to the HMI screen; (4) The HMI screen receiving the configuration file can then perform data interactions with the main controller using the USART protocol, ensuring real-time updating of operational parameters. At this point, the HMI interface design is completed.

Figure 7.

HMI interface.

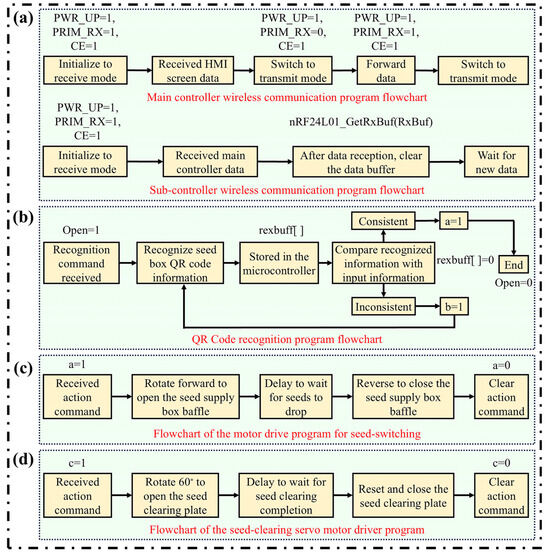

2.4.3. Wireless Communication Program Design

The wireless communication program flow is illustrated in Figure 8a. The nRF24L01 module communicates with the STM32 microcontroller via the SPI interface. Upon system startup, the wireless communication program initializes the module by setting the CSN pin to a low level and writing data into the Tx_FIFO buffer. By configuring the CE, PWR_UP, and PRIM_RX parameters, the nRF24L01 module switches between transmission and reception modes as required.

Figure 8.

Schematic diagram of the control system software design. (a) Wireless communication program design; (b) information recognition program design; (c) seed-switching servo drive program design; (d) seed-clearing drive program design.

2.4.4. Sub-Controller Software Design

The sub-controller program is primarily responsible for executing and monitoring operations such as seed switching and seed clearing. As shown in Figure 6c, TIM4 and TIM2 are configured in timer mode. CH1 of TIM4 outputs PWM pulses to the PUL+ signal terminal of the TB6600 stepper motor driver, which is used to control the motor speed. The PB4 and PB5 pins serve as the ENA- (enable signal) and DIR- (direction signal) terminals of the driver, respectively. CH2 of TIM2 is used to output PWM pulses to the servo MG90S and MG996R, which control seed release and clearing actions. The RX and TX ports of USART3 are connected to the GM65 QR code recognition module, enabling serial communication between the sub-controller and the GM65 for seed variety identification.

- (1)

- Information recognition program design

The program design for the information recognition unit is illustrated in Figure 8b. As shown in the Figure 8b, the GM65 QR code recognition module communicates with the sub-controller via a TTL-232 serial communication interface. Through this interface, the sub-controller can not only receive QR code data transmitted by the GM65 module but also send command instructions to control its operation.

- (2)

- Seed-switching drive program design

The sub-controller adjusts the motor speed by varying the pulse frequency, and through gear transmission, the rotational speed of the seed-switching disc is also controlled by the PWM frequency output from the sub-controller. To prevent step loss, which may affect switching accuracy, this study optimizes motor acceleration during start up and braking phases using a trapezoidal acceleration–deceleration algorithm. Considering the structural dimensions and spatial layout of the seed-switching disc and 42 stepper motor, the gear ratio between the motor pinion and the internal gear of the seed-switching disc is set to 1:2. According to Equation (7), the rotational speed of the seed-switching disc can be calculated as follows [11]:

where n1 is the rotational speed of the seed-switching disc, r·min−1; f is the PWM pulse frequency, Hz; N0 is the internal subdivisions value of the stepper motor driver; j is the gear transmission ratio; Z is the gear reduction ratio; NT is the timer frequency, Hz; Npsc is the prescaler value; and Narr is the auto reload register value.

In addition, during seed-switching operations, the single-step rotation angle of the seed-switching disc is directly related to the number of revolutions of the stepper motor. Therefore, the microcontroller program can control the rotational angle of the seed-switching disc by regulating the number of output pulses, which in turn determines the number of motor revolutions. The relationship can be expressed as follows [11]:

where N1 represents the number of PWM pulses; Q denotes the number of motor revolutions; θ is the step angle, °; and F is the number of subdivisions.

- (3)

- Seed-clearing servo drive program design

The program flowchart for the seed-clearing drive unit is shown in Figure 8d. In the microcontroller program, an integer variable c is defined and initially assigned a value of 0. Upon receiving the seed-clearing command, c is set to 1, triggering the servo motor to perform the clearing action. Once the clearing operation is completed, c is reset to 0.

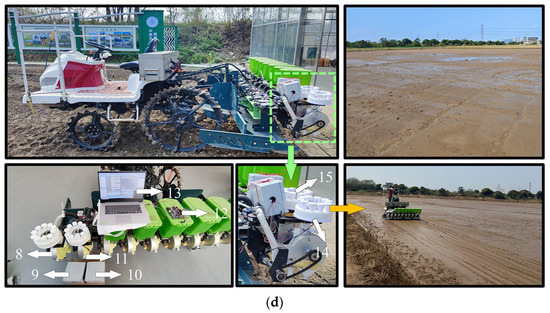

2.5. Performance Evaluation Test

To evaluate the operational performance of the seed-switching, seed-metering, and seed-clearing processes of an air suction precision seed-metering device for rice plot breeding, validation experiments were conducted at the Agricultural Machinery Laboratory in the Agricultural Engineering Building of South China Agricultural University and at the Dajisha island rice planting base. Ten rice varieties, including WY, SLY, RHY, NY, ZXYNZ, HFY, YLY, LWLY, NY51, and NY6388, were selected as test samples. Performance evaluation and verification were conducted on parameters such as the seed dropping time and switching accuracy of the horizontal rotary seed-switching mechanism, seed-filling performance of the shallow bowl-shaped suction holes seed-metering disc, seed-clearing time and seed-clearing rate of the open–close-type seed-clearing mechanism, and the multi-controller (one main controller and two sub-controllers) control strategy.

2.5.1. Seed-Switching Performance Evaluation Experiment

To evaluate the operational efficiency and quality of a single seed-switching operation, this experiment randomly selected 600 fully shaped rice seeds from each variety, sequentially loaded them into their corresponding seed supply boxes, and utilized camera equipment to record the entire seed-switching process. The duration from the moment seeds began to show a downward motion in the seed supply box until they completely exited the box was defined as the single seed dropping time. Microsoft Clipchamp software (version 4.3.100020.0; Microsoft Corporation, Redmond, WA, USA) was used to precisely measure the time interval from the initial seed dropping frame to the final frame, thereby assessing the time required for a single seed-switching operation.

Meanwhile, to accurately capture the single and cumulative rotation angles of the seed-switching disc, a Handyscan 300 scanner (Creaform Shanghai Ltd., Shanghai, China; scanning resolution of 0.1 mm, measurement accuracy of 0.04 mm) was used to record the actual rotation angles of the ten seed supply box groove on the seed-switching disc. By comparing these measured angles with the theoretical rotation angle of the stepper motor (36°), the errors in the single and cumulative rotation angles of the seed-switching disc were evaluated. The experimental instruments and equipment are shown in Figure 9a. On this basis, a seed-switching performance evaluation experiment was conducted in December 2024 at the Agricultural Machinery Laboratory in the Agricultural Engineering Building of South China Agricultural University.

Figure 9.

Performance test of the precision seed-metering device for rice plot breeding. (a) Seed-switching mechanism test bench; (b) bench test platform for seed-filling performance evaluation; (c) seed-clearing mechanism test bench; (d) double-row seed-metering device synchronization test. 1. Experimental rice seeds; 2. controller; 3. seed supply box; 4. camera equipment; 5. seed-switching disc; 6. PC data acquisition terminal; 7. Handyscan 300; 8. seed-metering device Ⅰ; 9. sub-controller Ⅰ; 10. sub-controller Ⅱ; 11. seed-metering device Ⅱ; 12. main controller; 13. HMI terminal; 14. seed-switching mechanism Ⅰ; 15. seed-switching mechanism Ⅱ.

2.5.2. Seed-Filling Performance Evaluation Experiment

To evaluate the seed-filling performance of the horizontally oriented shallow bowl-shaped seed-metering disc across multiple rice varieties and to determine the optimal operating parameters of the seed-metering system, a seed-filling performance test was conducted. The test adopted a two-factor experimental design, with negative pressure and seed-metering disc rotation speed as the test factors, and single and double seed rate, multiple seed rate, and missing seed rate as the evaluation indicators. The seed suction negative pressure was set at four levels: 2400 Pa, 2800 Pa, 3200 Pa, and 3600 Pa, while the rotation speed of the seed-metering disc was set at three levels: 20 r·min−1, 40 r·min−1, and 60 r·min−1, as shown in Table 4. The experiments were carried out in accordance with the agricultural industry standard NY/T 1300-2022 [30] and the national standard GB/T 6973-2005 [31]. Camera equipment was used to record the number of seeds adsorbed by the suction holes during continuous operation. For each test group, 250 hills were recorded per trial, and three replicates were performed, with the average values used for analysis. Based on this, a seed-filling performance evaluation experiment of the seed-metering device was conducted in December 2024 at the Agricultural Machinery Laboratory in the Agricultural Engineering Building of South China Agricultural University. The test bench setup is shown in Figure 9b.

Table 4.

Experimental factors and levels.

2.5.3. Seed-Clearing Performance Evaluation Experiment

To evaluate the clearing effectiveness of the seed-clearing mechanism, a single-factor performance test was conducted using different rice varieties as test materials. The number of residual seeds in the seed-filling zone was selected as the test factor, with three levels set at 300, 400, and 500 seeds. The evaluation indicators were seed-clearing time and seed-clearing rate. This single-factor test was designed to assess the clearing performance of the mechanism under varying residual seed loads. Based on this, a seed-clearing performance evaluation experiment of the seed-metering device was conducted in December 2024 at the Agricultural Machinery Laboratory in the Agricultural Engineering Building of South China Agricultural University. The experimental setup is shown in Figure 9c.

2.5.4. Double-Row Seed-Metering Device Synchronization Test

To verify the synchronous execution capability of multiple sub-controllers (each independently operating a seed-metering device) under differentiated working conditions, a double-row seed-metering linkage test was conducted based on a “1 + 2” master-slave control architecture. The objective was to determine whether each sub-controller could operate autonomously and without mutual interference after receiving commands from the central master controller. The test was carried out in February 2025 at the Dajisha Island rice planting base of South China Agricultural University. Before the test, the plots were soaked in water for three days, followed by two rounds of puddling with a rotary tiller. A laser land leveler was then used to level the paddy field, and after waiting for two days, a double-row seed metering device linkage test was carried out. Meanwhile, the seed hoppers of the dual-nozzle air suction precision rice seed-metering devices were modified and replaced with modular units equipped with seed-switching and seed-clearing functions.

The experiment was divided into two groups: a standard operation scenario and a differentiated operation scenario. In the standard scenario, all rice varieties on the seed-switching disc of both seed-metering devices were arranged in an identical fixed order with one-to-one correspondence. In the differentiated scenario, the seed arrangement on the first device followed the standard sequence, while the seed arrangement on the second device was randomized, creating a non-corresponding layout. During the experiment, the main controller simultaneously transmitted identical instructions to both sub-controllers to observe whether the two seed-metering units initiated operations simultaneously and exhibited synchronized actions under both standardized and differentiated operating conditions. Additionally, under differentiated operating conditions, the time required for the seed-switching disc to complete a single cycle of variety identification and seed supply was recorded to evaluate the system’s response time and control stability in multi-unit coordinated operations.

3. Results

3.1. Seed-Switching Performance Evaluation Test Results

The single seed-switching times for each rice variety are presented in Table 5. As shown in Table 5, YLY exhibited the shortest switching time at 0.63 s, while LWLY required the longest switching time at 1.13 s. Although the static friction coefficients of these two rice varieties are relatively similar, the difference in switching time is primarily attributed to their external morphological characteristics. YLY seeds possess a crescent-shaped contour with a streamlined dorsal curve, which makes them difficult to stack stably in confined spaces. As a result, they exhibit lower stacking resistance and are more prone to rotational and rolling motion around their central axis during descent within the seed supply box, facilitating consistent flow direction. In contrast, LWLY seeds are spindle-shaped and tend to form bridging or interlocking structures when stacked in limited space, leading to localized blockage and reduced overall flow rate. Furthermore, during sliding along the inner wall of the seed supply box, LWLY seeds are more likely to align in a stable configuration, which further contributes to reduced local flow velocity.

Table 5.

Seed-switching time and rotation error of seed-switching disc.

Table 5 presents the single-step and cumulative rotational angle errors of the seed-switching disc. As shown in Table 5, both the absolute values of the single rotation error and the cumulative rotation error were less than 0.4°, indicating that the seed-switching mechanism exhibits high control precision and good operational stability. These results demonstrate that the switching system fully meets the requirements for accurate and reliable seeding operations in rice plot breeding.

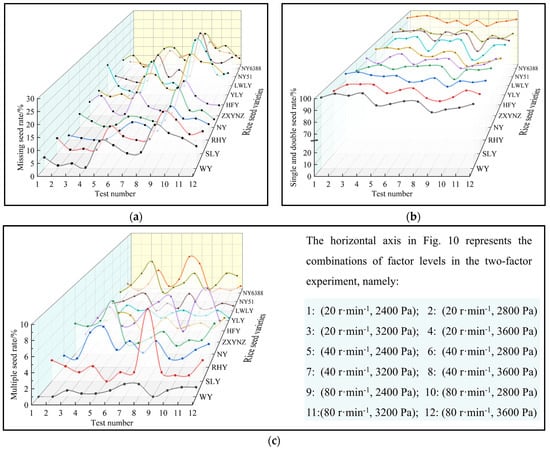

3.2. Seed-Filling Performance Test Results

The results of the two-factor seed-filling performance test are shown in Figure 10 and Table 6. As illustrated in Figure 10a, when the seed-metering disc rotation speed was 20 r·min−1 and the negative pressure was 3200 Pa, the varieties RHY, LWLY, NY, NY51, and NY6388 exhibited the lowest missing seed rates. Under the seed-metering disc rotation speed 20 r·min−1 and the negative pressure was 3600 Pa, the lowest missing seed rates were observed for WY, SLY, ZXYNZ, HFY, and YLY. The primary reason for this phenomenon lies in the fact that rice seeds tend to accumulate horizontally along the length–width axis within the seed-filling zone. Under such stacking conditions, the thousand kernel weight and the static friction force along the L-H (length–height) side become key factors influencing the missing seed rate. Taking NY6388 as an example, Table 1 shows that this variety exhibits a high length–width ratio, and its slender shape increases the likelihood of successfully entering the horizontal shallow-bowl suction holes. Moreover, due to its relatively low static friction angle, NY6388 seeds can more easily adjust their posture to match the contour of the suction holes under the combined effects of mechanical force and negative pressure suction, NY6388 seeds can more easily adjust their posture to conform to the contour of the suction holes, thereby significantly improving seed-filling performance. In contrast, varieties such as WY, SLY, ZXYNZ, HFY, and YLY possess greater thousand kernel weight and higher L-H side static friction, making them more dependent on stronger suction to overcome frictional resistance during stacking and absorption. Therefore, under the combined influence of individual seed weight and L-H side friction, a greater negative pressure is required to ensure sufficient suction force at the seed-metering holes, thereby reducing the missing seed rate. Furthermore, as shown in Table 6, the seed-metering disc rotation speed had a highly significant effect on the missing seed rates of WY, SLY, RHY, HFY, YLY, LWLY, and NY6388, and a significant effect on NY and NY51, while having no significant effect on ZXYNZ. In terms of negative pressure, it had a highly significant effect on SLY and YLY, a significant effect on WY, ZXYNZ, HFY, LWLY, and NY6388, and no significant effect on RHY, NY and NY51.

Figure 10.

Seed-filling performance test results. (a) Missing seed rate; (b) single and double seed rate; (c) multiple seed rate.

Table 6.

Seed-filling performance variance analysis results.

As shown in Figure 10b, when the seed-metering disc rotation speed was 20 r·min−1 and the negative pressure was 2800 Pa, RHY exhibited the highest single and double seed rate. When the negative pressure reached 3200 Pa, the highest single and double seed rates were observed for SLY, LWLY, NY, NY51, and NY6388. When the negative pressure reached 3600 Pa under the same rotation speed, WY, ZXYNZ, HFY, and YLY achieved the highest. According to the data in Table 1 and the seed contour characteristics shown in Figure 1c, the thousand kernel weight and external morphological profile are the primary factors influencing the single and double seed-filling performance. The reason for the observed trends is that RHY, with its relatively low thousand kernel weight, can be reliably adsorbed even at lower negative pressure. Furthermore, the kidney-shaped profile of RHY allows single seeds to be drawn into the horizontally oriented shallow bowl-shaped suction holes along the length–width axis, where they occupy the majority of the hole volume, making it difficult for additional seeds to enter-thus increasing the probability of single seed filling. As the negative pressure increases, the single and double seed rate trends for the other varieties become more similar to those observed for the missing seed rate. As shown in Table 6, the seed-metering disc rotation speed had a highly significant effect on the single and double seed rates of WY, HFY, YLY, and LWLY, and a significant effect on SLY, RHY, ZXYNZ, and NY6388, while showing no significant effect on NY and NY51. The negative pressure had a highly significant effect on YLY, a significant effect on WY, and no significant effect on SLY, RHY, NY, ZXYNZ, HFY, LWLY, NY51, and NY6388.

As shown in Figure 10c, when the seed-metering disc rotation speed was 20 r·min−1 and the negative pressure was 2400 Pa, WY, ZXYNZ, YLY, and NY51 exhibited the lowest multiple seed rates. Under the same speed and a negative pressure of 2800 Pa, the lowest multiple seed rates were observed for RHY and NY6388. When the rotation speed was increased to 40 r·min−1 and the negative pressure remained at 2400 Pa, SLY, HFY, and LWLY showed the lowest multiple seed rates. When the rotation speed was increased 60 r·min−1 and the negative pressure remained at 2400 Pa, NY had the lowest multiple seed rate. According to the data in Table 1 and the contour profiles illustrated in Figure 1c, the length–width ratio of the seeds is the primary factor affecting the likelihood of multiple seeds being adsorbed by a single suction hole. The reason for the above trends is that WY, ZXYNZ, YLY, NY51, RHY, and NY6388 possess relatively lower length–width values and more flattened seed shapes, which favor single or double seed occupancy within the suction hole. Additionally, these varieties have relatively lower thousand kernel weight and lower static friction coefficients along the L-H side, which helps reduce the probability of multiple seed pickup under lower negative pressure and slower rotation speeds. In contrast, SLY, HFY, LWLY, and NY—due to their lower friction and length–width ratios—are more susceptible to multiple seed adsorption along the length–height axis under low pressure and low speed conditions. Therefore, increasing the rotation speed of the seed-metering disc is necessary to reduce the contact time between the seed population and the seed-metering disc surface, thereby lowering the multiple seed rate. As shown in Table 6, rotation speed had a highly significant effect on the multiple seed rates of WY and NY, while it had no significant effect on SLY, RHY, ZXYNZ, HFY, YLY, LWLY, NY51, and NY6388. Negative pressure had a highly significant effect on WY, NY and NY51, a significant effect on ZXYNZ, and no significant effect on SLY, RHY, HFY, YLY, LWLY, and NY6388.

To determine the optimal operating parameters of the seed-metering device, a comprehensive evaluation was conducted based on the experimental results of missing seed rate, single and double seed rate, and multiple seed rate, with the missing seed rate considered the primary performance indicator. Using a comprehensive analysis method, weights were assigned as follows: 40% for missing seed rate, 50% for single and double seed rate, and 10% for multiple seed rate. The optimal scores calculated from this evaluation are presented in Table 7. Based on the results in Table 7, it was concluded that the optimal seed-filling performance across all rice varieties was achieved when the seed-metering disc rotation speed was 20 r·min−1 and the negative suction pressure was 3200 Pa. As shown in the data from Figure 10, under these conditions, the missing seed rate for all rice varieties was below 5.2%, the single and double seed rate exceeded 90%, and the multiple seed rate remained below 4.8%. Among all tested varieties, Nayou 6388 exhibited the best overall performance, with a missing seed rate of 0.8%, a single and double seed rate of 97.6%, and a multiple seed rate of 1.6%, thereby meeting the precision seed-filling requirements for rice plot breeding trials.

Table 7.

Comprehensive evaluation results.

3.3. Seed-Clearing Performance Test Results

The results of seed-clearing performance tests are shown in Table 8. It can be observed that when the residual seed quantities in the seed-filling zone were 300, 400, and 500 grains, the seed-clearing average time is 0.88 s, and each seed-clearing ensured 100% clearing of seeds within the seed chamber. These results indicate that the seed-clearing mechanism can achieve rapid clearing of seeds and effectively prevent cross-contamination among different rice varieties.

Table 8.

Test results of seed-clearing performance.

3.4. Double-Row Seed-Metering Device Synchronization Test Results

Under the standardized operation scenario, both seed-metering devices were activated simultaneously and sequentially performed the seed-switching and seed-clearing operations. The motor and servo actuations were synchronized, and all operations were executed with high accuracy, in accordance with the expected behavior. Visual observation confirmed that when performing identical tasks, both seed-metering devices maintained consistent timing and relative positioning throughout the process. The seed supply boxes were accurately aligned, and the seed-clearing plates opened synchronously. The actions of the two seed-metering units were fully coordinated, and the system was capable of providing real-time feedback to the HMI, displaying the operational progress and current status of each seed-metering device.

Under the differentiated operation scenario, seed-metering unit 1 successfully identified and aligned with seed supply box 1, initiated the seed-switching motor, and completed the task following the opening of the seed-clearing plate. seed-metering unit 2, based on the recognition of a different seed variety, accurately located seed supply box 2 and executed the corresponding seed-switching and seed-clearing operations. Although the two devices followed different action sequences and states, both were able to execute their respective tasks precisely upon receiving the same command. The operations of both seed-metering devices were completed successfully, and each unit independently responded to the recognized seed information, confirming that the control logic enables differentiated execution as intended. Comparative observations verified that the actions of the two seed-metering units followed the programmed differentiated control sequence. As shown in Table 9, the maximum QR code recognition time per switching task was 0.3 s, and the maximum switching time was 1.5 s. Combined with the average data in Table 5, the maximum total time for a single switching operation was 2.63 s, meeting the operational requirements for rapid seed switching and metered seed supply in rice plot breeding field trials.

Table 9.

Test results of double-row seed-metering device linkage.

4. Discussion

With the rapid development of plot breeding technologies, the seeding stage has become crucial for ensuring the authenticity of experimental data and the reliability of variety evaluations. In rice plot breeding, the demand for multi-variety, small-batch, and high-precision seeding has exposed the limitations of traditional manual operations, which cannot meet modern breeding’s high-frequency and automated requirements. Although initial advances have been achieved in air suction seed-metering devices [32,33,34,35], stepwise seed supply [36,37], and STM32-based control systems, most studies have concentrated on large-seed crops [38,39,40]. To date, no universal and high-precision seeding device specifically adapted to the complex morphology of rice grains has been reported. Rice plot seeding still faces challenges such as low system integration, poor variety compatibility, low efficiency, high labor intensity, and frequent cross-contamination, highlighting the urgent need for innovative equipment development.

To address current challenges, this study developed an air suction precision seed-metering device with a seed-switching and clearing control system for rice plot breeding, focusing on seed-switching, precise seeding, and rapid clearing stages, aiming to achieve full-process automation and multi-machine collaborative control through key technological innovations, the device achieves the following technological innovations:

- (1)

- In the seed-switching stage, an innovative variety identification and indexing strategy based on QR code recognition was developed. By coordinating the GM65 recognition module with a stepper motor, the system enables non-contact, contamination-free, and traceable high-efficiency seed switching, effectively reducing the risk of cross-contamination between varieties. The proposed mechanism avoids the response delays and structural complexity associated with traditional manual switching and multi-stage mechanical transmission, significantly improving the accuracy and operational efficiency of the seed-switching process, and providing stable and reliable technical support for continuous multi-variety seeding [10,32]. Furthermore, compared with the 10–15 s switching time required by existing automatic seed supply devices [41], the seed supply mechanism designed in this study achieves a substantial improvement in switching efficiency, further enhancing the system’s practicality and application value in high-frequency rice plot breeding tasks.

- (2)

- In the seed-metering stage, addressing the challenges posed by the varying shapes and sizes of rice grains, a method based on active extraction of seed contours and proportional iterative design was proposed. An optimized horizontal shallow-bowl suction hole structure was developed, which enabled high-precision seed filling at a rate of 1–2 seeds per hole, while also enhancing the device’s adaptability to multiple rice varieties.

- (3)

- In the seed-clearing stage, this study designed and implemented an automatic open–close seed-clearing device controlled by an MG996R servo, featuring rapid response and efficient removal of residual seeds. The device utilizes a servo-driven precise opening and closing mechanism, enabling complete seed clearance within a short period. Compared to existing seed-clearing mechanisms that typically require approximately 9 s to complete the process [42], the proposed device significantly reduces the clearing duration and improves operational efficiency. This effectively lowers the risk of cross-contamination between different seed varieties and provides reliable support for rapid switching between seeding tasks.

- (4)

- Additionally, a double-row seeding collaborative operation platform was developed based on a “1 + 2” master-slave multi-controller architecture. The system was validated to accurately perform seed-switching, seed-metering, and seed-clearing tasks under both standard and non-standard variety arrangements, demonstrating high consistency and stable responsiveness in multi-machine operation scenarios.

The system developed in this study not only improves the level of automation in the seeding stage of rice plot breeding but also demonstrates strong modular scalability. It can be seamlessly integrated with existing precision hill-drop seeding devices for rice, thereby meeting the application requirements for high-frequency, small-batch, and contamination-free seeding in rice plot breeding. However, the range of rice varieties used in the current experiment remains limited, and further testing is required to verify the seed-metering device’s compatibility with a broader spectrum of rice genotypes. Additionally, the frequency of field operations under various application scenarios should be increased to comprehensively evaluate system performance. Moreover, the system still encounters technical challenges during its transition from double-row to multi-row collaborative operations. On one hand, multi-unit synchronous control imposes higher demands on the master controller’s real-time communication capability and data processing efficiency. On the other hand, due to limitations in the spatial layout and mechanical transmission design of the seed-metering mechanism, non-ideal field conditions may lead to increased motion deviation between seed-metering units, thereby affecting synchronization accuracy and variety recognition precision. To address these issues, future work will focus on optimizing the structural layout and spatial coordination of the seed-metering units to enhance mechanical compatibility among modules. Meanwhile, improvements will be made to the control logic and execution precision under multi-row operation to ensure stable and efficient system performance in complex field environments.

In summary, future research will focus on enhancing the practicality and application value of the system under complex field conditions. This will include expanding the variety types tested, optimizing the suction hole structure design, conducting adaptability evaluations across different agronomic environments, and exploring the integration of emerging technologies such as visual recognition to advance seeding operations toward a higher level of intelligence. The outcomes of this study are expected to provide both technical support and theoretical foundations for the development of automated seeding systems in rice plot breeding and to accelerate the transformation of China’s rice plot breeding technology from labor-driven to intelligence-driven.

5. Conclusions

- (1)

- In this study, an air suction precision seed-metering control system for seed switching and seed clearing in rice plot breeding was developed. The system utilizes an HMI screen as the human–machine interaction terminal, with an STM32F103ZET6 microcontroller serving as the main controller and STM32F103C8T6 microcontrollers as sub-controllers. Data communication is achieved through nRF24L01 wireless modules. The control system enables the precise execution of seed-switching, seed-metering, and seed-clearing operations.

- (2)

- A seed-switching mechanism was developed, driven by a 42 stepper motor and an MG90S servo, with precise variety identification achieved through a GM65 QR code recognition module. The seed-switching disc accommodates 10 independently partitioned seed supply boxes, with each switching operation involving a 36° rotation. The average time for a single seed-switching operation was 0.83 s, the maximum absolute rotational error per step was less than 0.4°, and the cumulative absolute rotational error was less than 0.03°.

Based on the agronomic requirements of rice plot breeding and the morphological characteristics of different rice varieties, a horizontally oriented shallow bowl-shaped seed-metering disc was designed using MATLAB R2020a, incorporating active contour extraction and proportional contour iteration. This design aims to accommodate seed-filling operations across multiple rice varieties. The results from a two-factor seed-filling performance test indicated that the disc exhibited good adaptability to all ten tested rice varieties. Under operating conditions of 20 r·min−1 rotational speed and 3200 Pa negative pressure, all varieties demonstrated favorable filling performance. Among them, Nayou 6388 performed the best, with a missing seed rate of 0.8%, a combined single and double seeding rate of 97.6%, and a multiple seeding rate of only 1.6%, meeting the precision seed-filling requirements for rice plot breeding trials.

An open–close-type seed-clearing mechanism driven by an MG996R servo motor was developed. Performance testing showed that when the number of residual seeds in the seed chamber was 300, 400 and 500, the average seed-clearing time was 0.88 s, and the seed-clearing rate reached 100% in all cases, meeting the operational requirements for rapid seed clearing in rice plot breeding trials.

- (3)

- To evaluate the coordinated performance of the seed-metering system, a double-row seed-metering linkage test was conducted. The results showed that the master controller could effectively coordinate with multiple sub-controllers to achieve the precise control of each seed-metering device. In addition, the designed seed-switching and seed-clearing control system, along with its supporting mechanisms, enables rapid connection and replacement with the seed supply boxes and seed-metering discs of air suction precision rice seeders, meeting the flexible deployment requirements of rice plot breeding and field operations.

- (4)

- Although the seed-metering device developed in this study has demonstrated significant achievements in operational precision and coordination performance, further efforts will be made to enhance the adaptability of the seed-metering mechanism to complex field conditions. In future work, seed-metering trials involving a broader range of rice varieties will be conducted to comprehensively verify its operational compatibility with multiple rice varieties. In addition, extensive plot seeding trials for breeding will be carried out in various typical application scenarios, including dryland, paddy fields, and breeding stations, to evaluate the adaptability and stability of the seed-metering mechanism under different working environments.

Author Contributions

Conceptualization, W.Q., Y.L. and Y.Z.; methodology, W.Q. and Y.Z.; software, W.Q.; validation, Y.L. and C.Q.; formal analysis, Y.L.; investigation, Z.F.; resources, Y.Z. and M.Z.; data curation, D.Y.; writing—original draft preparation, W.Q. and Y.Z.; writing—review and editing, W.Q., Z.W., Y.Z. and M.Z.; visualization, G.Z. and S.L.; project administration, Y.Z.; funding acquisition, Y.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Guangdong Province Science and Technology Plan Project, grant number 2021B1212040009, and the earmarked fund for CARS, grant number CARS-01.

Data Availability Statement

Data will be made available on request.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| HFY | Hengfengyou 1179 |

| HMI | human–machine interaction |

| LWLY | Longwang Liangyou 889 |

| L-H | Length–Height |

| NY | Nayou 6618 |

| NY51 | Nayou 51 |

| NY6388 | Nayou 6388 |

| RHY | Ruanhuayou 1179 |

| SLY | Shenliangyou 1978 |

| WY | Wuyou 1179 |

| W-H | Width–Height |

| YLY | Y Liangyou 1378 |

| ZXYNZ | Zengxiangyou Nanzhan |

References

- FAO. Statistical Yearbook 2023—World Food and Agriculture. Available online: https://reliefweb.int/report/world/fao-statistical-yearbook-2023-world-food-and-agriculture (accessed on 5 April 2024).

- China Statistical Yearbook 2023. Available online: https://www.stats.gov.cn/sj/ndsj/2023/indexeh.htm (accessed on 4 March 2025).

- Shang, S.; Wu, X.; Yang, R.; Li, G.; Yang, X.; Chen, D. Research status and prospect of plot-sowing equipment and technology. Trans. Chin. Soc. Agric. Mach. 2021, 52, 1–20. [Google Scholar]

- Wang, X. Study on Air-Suction Precision Seeder for Rice Breeding in Community. Master’s Thesis, South China Agricultural University, Guangzhou, China, 2023. [Google Scholar]

- Zhao, J.; Gao, L.; Wang, J.; Zhang, W.; Qu, M. Design and experiment of a combined machine for returning straw fine powder to field. Tech. Autom. Appl. 2025, 44, 10–13. [Google Scholar]

- Wintersteiger. Smart Feed. Available online: https://www.wintersteiger.com/en/Plant-Breeding-and-Research/Products/Product-range/Plot-drills/590-Smart-Feed (accessed on 5 April 2024).

- Zurn Harvesting. ZÜRN D96. Available online: https://zuern-harvesting.de/feldversuchstechnik/zuern-d96/ (accessed on 5 July 2024).

- Almaco. Row Crop Planting System. Available online: https://www.almaco.com/equipment/planting-systems/row-crop-planting-systems/powerplant-automated-planting-system/ (accessed on 25 October 2023).

- Haldrup. Haldrup SR-30. Available online: https://en.haldrup.net/haldrup-products/haldrup-seeders/haldrup-sr-30/ (accessed on 7 January 2025).

- Dun, G.; Liu, W.; Mao, N.; Wu, X.; Ji, W.; Ma, H. Optimization design and experiment of alternate post changing seed metering device for soybean plot breeding. J. Jilin Univ. (Eng. Technol. Ed.) 2023, 53, 285–296. [Google Scholar]

- Hao, J.; Qin, J.; Yang, S.; Ai, Q.; Ma, Z. Design and experiments of a precision sowing unit with the spoon clip for single peanut seed planting in plot. Trans. Chin. Soc. Agric. Eng. 2023, 39, 33–41. [Google Scholar]

- Yang, W.; Fang, X.; Li, J.; Li, L. Design and experiment of air-suction precision seed meter with self-clearing seed chamber for corn plot test. Trans. Chin. Soc. Agric. Eng. 2019, 50, 64–73. [Google Scholar]

- Zhang, Y.; Tang, Y.; He, D.; Shi, J.; Hao, L.; Li, J.; Sun, D.; Li, H.; Zhang, Z.; Ye, S.; et al. Design and Test of Electromagnetic Vibration Type Fine and Small-Amount Seeder for Millet. Agriculture 2024, 14, 1528. [Google Scholar] [CrossRef]

- Yuan, X.; Huang, C.; Tao, G.; Yi, S.; Li, Y. Design and Experiment of Oil-Electric Hybrid Air-Suction Sorghum Plot Seeder. Agriculture 2024, 14, 432. [Google Scholar] [CrossRef]

- Wang, W.; Shi, W.; Liu, C.; Wang, Y.; Liu, L.; Chen, L. Development of automatic wheat seeding quantity control system based on Doppler radar speed measurement. Artif. Intell. Agric. 2025, 13, 12–25. [Google Scholar] [CrossRef]

- Wang, J.; Liao, M.; Xia, H.; Chen, R.; Li, J.; Li, J.; Yang, J. Study on a Novel Reseeding Device of a Precision Potato Planter. Agriculture 2024, 14, 1824. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, H.; Shi, Z.; Jin, W.; Chen, Y.; Yu, Y. Design and experiments of seed pickup status monitoring system for cotton precision dibblers. Trans. Chin. Soc. Agric. Eng. 2022, 38, 9–19. [Google Scholar]

- Li, Y.; Wan, L.; Xu, Z.; Yuan, H.; Chen, H.; Song, J. Design of automatic control system for plot batch seed cleaning machine. Trans. Chin. Soc. Agric. Eng. 2021, 37, 9–17. [Google Scholar]

- Liao, Q.; Luo, Z.; Yang, H.; Li, M.; Shen, W.; Wang, L. Variable-rate seeding control system based on RTK speed measurement for rapeseed direct seeder. Trans. Chin. Soc. Agric. Mach. 2024, 55, 65–74. [Google Scholar]

- Wang, H.; Yang, L.; Zhang, D.; Cui, T.; He, X.; Xiao, T.; Li, H.; Du, Z.; Xie, C. Comparative investigation and evaluation of electric-drive seed-metering systems across diverse speed ranges for enhanced high-precision seeding applications. Comput. Electron. Agric. 2024, 222, 108976. [Google Scholar] [CrossRef]

- Qian, C.; Qin, W.; Jiang, Y.; Huang, Z.; Zhang, M.; Wang, Z.; Yang, W.; Zang, Y. Parameter optimization and experiment of the vacuum seed meter with double holes for direct seeding of rice. Int. J. Agric. Biol. Eng. 2025, 18, 89–99. [Google Scholar]

- Bao, G.; Zhang, Z.; Liu, L.; Li, J.; Tao, C.; Yang, W. Study on the Adsorption Mechanism of Spherical Particles near the Seed Metering Disk Surface by Narrow Elongated Suction Holes. Agriculture 2025, 15, 657. [Google Scholar] [CrossRef]

- Ding, L.; Yuan, Y.; Dou, Y.; Li, C.; He, Z.; Guo, G.; Zhang, Y.; Chen, B.; Li, H. Design and Experiment of Air-Suction Maize Seed-Metering Device with Auxiliary Guide. Agriculture 2024, 14, 169. [Google Scholar] [CrossRef]

- Chamara, N.; Bai, G.; Ge, Y. AICropCAM: Deploying classification, segmentation, detection, and counting deep-learning models for crop monitoring on the edge. Comput. Electron. Agric. 2023, 215, 108420. [Google Scholar] [CrossRef]

- Ma, J.; Li, Y.; Du, K.; Zheng, F.; Zhang, L.; Gong, Z.; Jiao, W. Segmenting ears of winter wheat at flowering stage using digital images and deep learning. Comput. Electron. Agric. 2020, 168, 105159. [Google Scholar] [CrossRef]

- Nadia, A.; Sharmin, S.R.; Afroz, J.; Muhammad, A.E.R.; Anisur, R. Inspection of paddy seed varietal purity using machine vision and multivariate analysis. J. Agric. Food Res. 2021, 3, 100109. [Google Scholar]

- Suresh, K.R.; Durgaprasad, P.; José, L.D.P.; Abderrahim, W.; Rajue, C.S.K.; Maddina, D.K.; Muneerah, A.N.; Ali, J.C. Contour analysis for heat transfer rate in a wedge geometry with non-uniform shapes nanofluid: Gradient descent machine learning technique. Results Eng. 2024, 23, 102714. [Google Scholar]

- María, C.Z.C.; Servando, D.L.C.R. A MATLAB App for calculating the age-dependent degree of erosion of monogenetic scoria cones from DEM data. MethodsX 2021, 8, 101454. [Google Scholar]

- Zha, X.; Chen, L.; Chen, D.; He, Y.; Yang, R. Design and Testing of a Branched Air-Chamber Type Pneumatic Seed Metering Device for Rice. Agriculture 2024, 14, 1934. [Google Scholar] [CrossRef]

- NY/T 1300-2022; Technical Code of Practice for the Variety Trial and Informatization of Crops—Rice (Oryza sativa L.). Ministry of Agriculture and Rural Affairs of the People’s Republic of China: Beijing, China, 2022.

- GB/T 6973-2005; Testing Methods of Single Seed Drills (Precision Drills). General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China: Beijing, China, 2005.

- Chen, H.; Wang, H.; Wang, Y.; Shi, N.; Wei, Z.; Dou, Y. Design and experiment of three-leaf type air-suction seed meter with automatic clear and replace seeds features for soybean plot test. Trans. Chin. Soc. Agric. Mach. 2020, 51, 75–85. [Google Scholar]

- Deng, S.; Feng, Y.; Cheng, X.; Wang, X.; Zhang, X.; Wei, Z. Disturbance analysis and seeding performance evaluation of a pneumatic-seed spoon interactive precision maize seed-metering device for plot planting. Biosyst. Eng. 2024, 247, 221–240. [Google Scholar] [CrossRef]

- Ma, X.; Gong, Q.; Wang, Q.; Xu, D.; Zhou, Y.; Chen, G.; Cao, X.; Wang, L. Design of an Air Suction Wheel-Hole Single Seed Drill for a Wheat Plot Dibbler. Agriculture 2022, 12, 1735. [Google Scholar] [CrossRef]

- Ma, Y. Design and Experiment of Rice Breeding Fine Quantity Sowing Device. Master’s Thesis, South China Agricultural University, Guangzhou, China, 2016. [Google Scholar]

- Yang, R.; Wang, J.; Shang, S.; Zha, X.; Pan, Z.; Wang, Z. Design and Experiment of Potato Breeding Planter with Rotary Table Grid. Trans. Chin. Soc. Agric. Mach. 2023, 54, 84–93. [Google Scholar]

- Liu, D.; Ma, J.; Qiao, X.; Xin, P.; Zhang, X.; Wang, J.; Zheng, D. The design of and experiments with a double-row seed-metering device for buckwheat breeding in an experimental area. Agronomy 2023, 13, 2857. [Google Scholar] [CrossRef]

- Zhao, H.; Zhang, D.; Yang, L.; Cui, T.; Song, W.; He, X.; Wu, H.; Dong, J. Optimal Design and Experiment of Critical Components of Hand-Pushing Corn Plot Precision Planter. Agriculture 2022, 12, 2103. [Google Scholar] [CrossRef]

- Wang, H.; Tang, Y.; Dong, Z.; Wang, M.; Zhao, J. Self-alignment algorithm of wheat plot breeding path based on Beidou satellite positioning. J. Zhejiang Agric. Univ. 2019, 31, 1709–1716. [Google Scholar]

- Roberto, E.T.; Rossana, M.C.A.; Erwin, Q.; Peralta, E.K. Development of a single-row push type plot seeder with mechatronic seed feeding device for corn (Zea mays L) field breeding experiment. In Proceedings of the 5th International Conference on Agriculture, Environment, and Food Security, Jember, Indonesia, 18 November 2021. [Google Scholar]

- Liu, S.; Shang, S.; Yang, R.; Zheng, Y.; Wang, Y.; Li, Q. Design of Automatic Supplying Seed System for Plot Seeder of Rape. Trans. Chin. Soc. Agric. Mach. 2011, 42, 91–95. [Google Scholar]

- Ran, Y.; Wang, S.; Wang, Y.; Yu, Y.; Li, H. Design of Cleaning Device for Plot Seed Planter in Soybean. Soybean Sci. Technol. 2019, 6, 16–20. [Google Scholar]