Overview of Agricultural Machinery Automation Technology for Sustainable Agriculture

Abstract

:1. Introduction

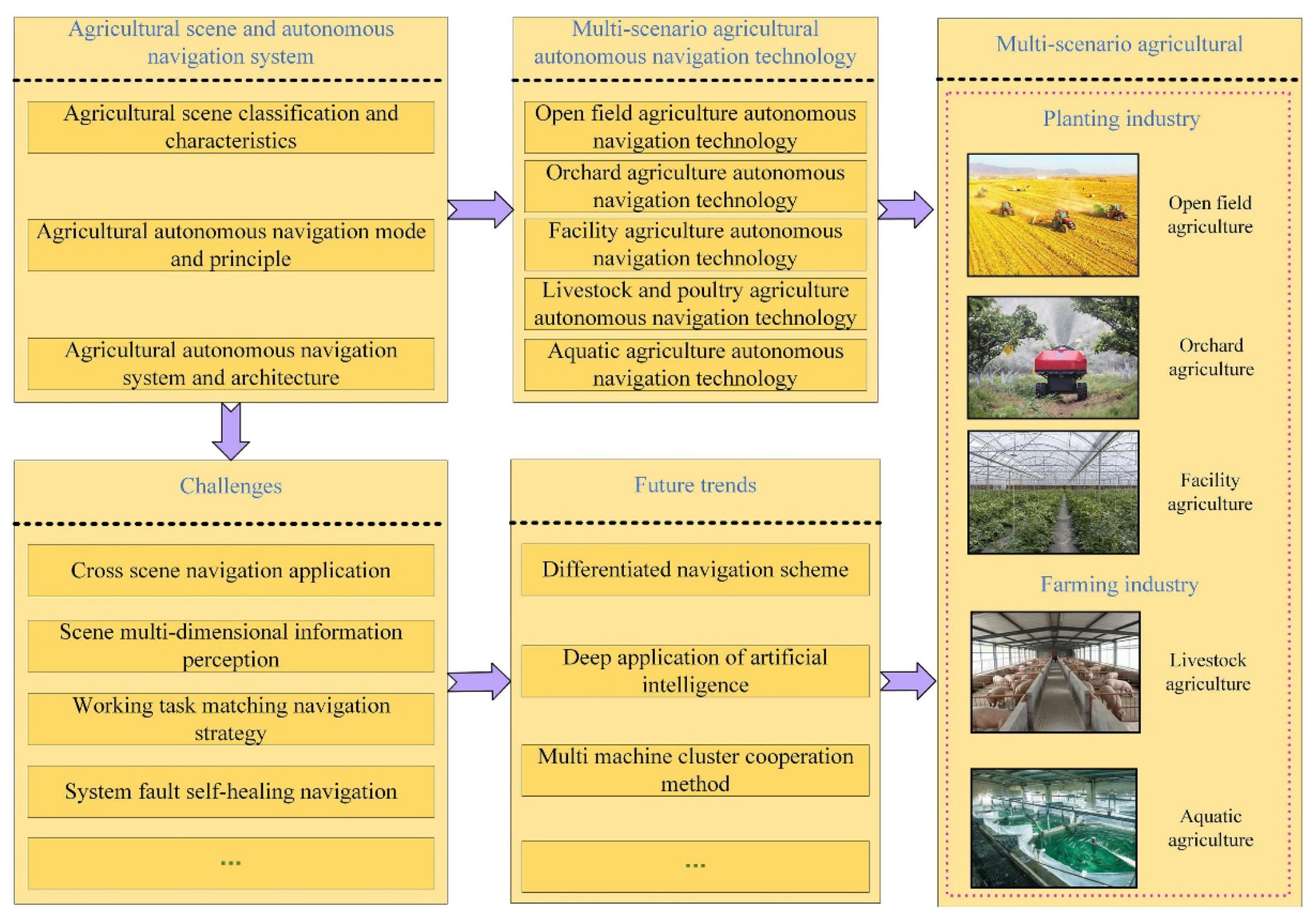

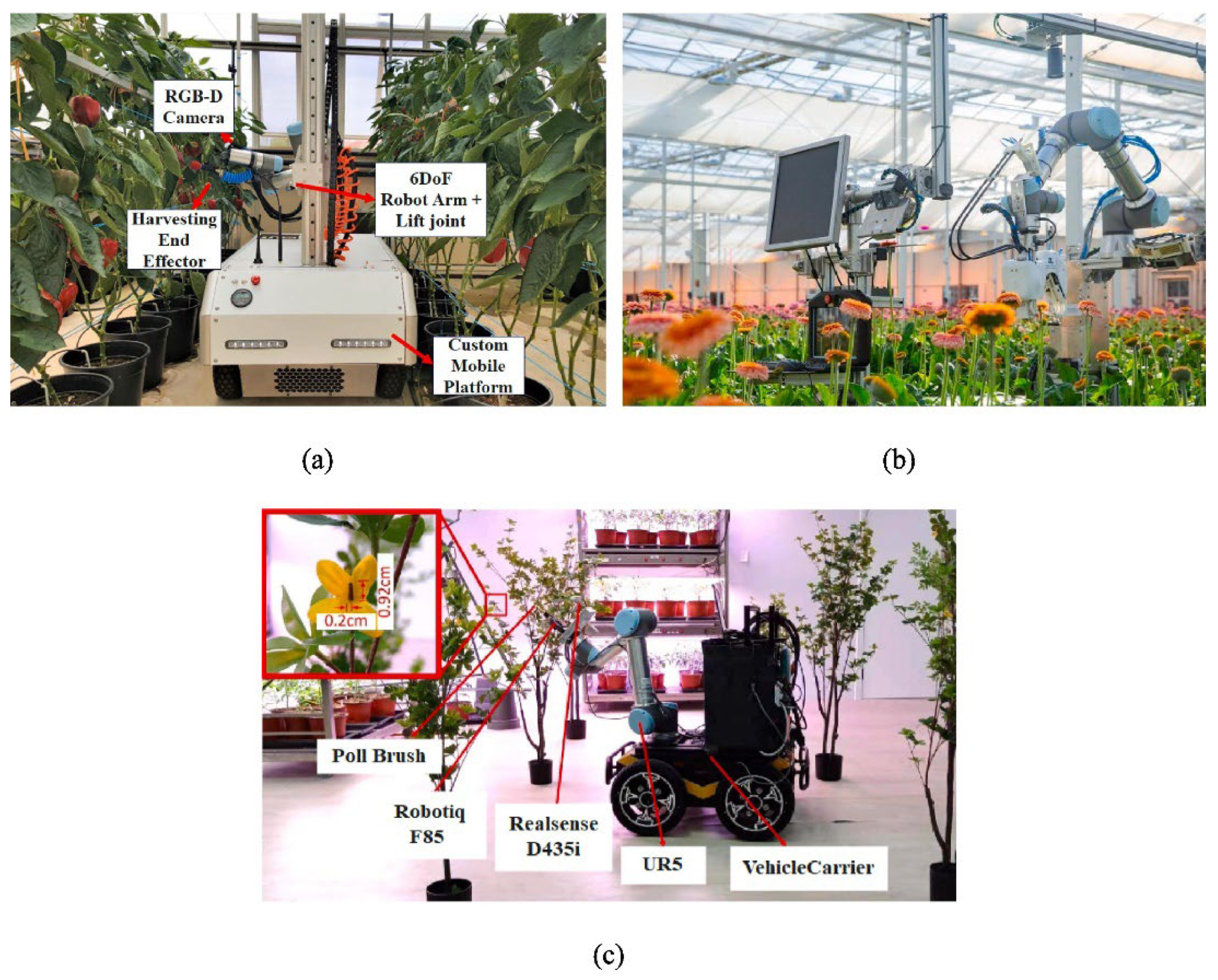

2. Key Technologies for Agricultural Machinery Automation

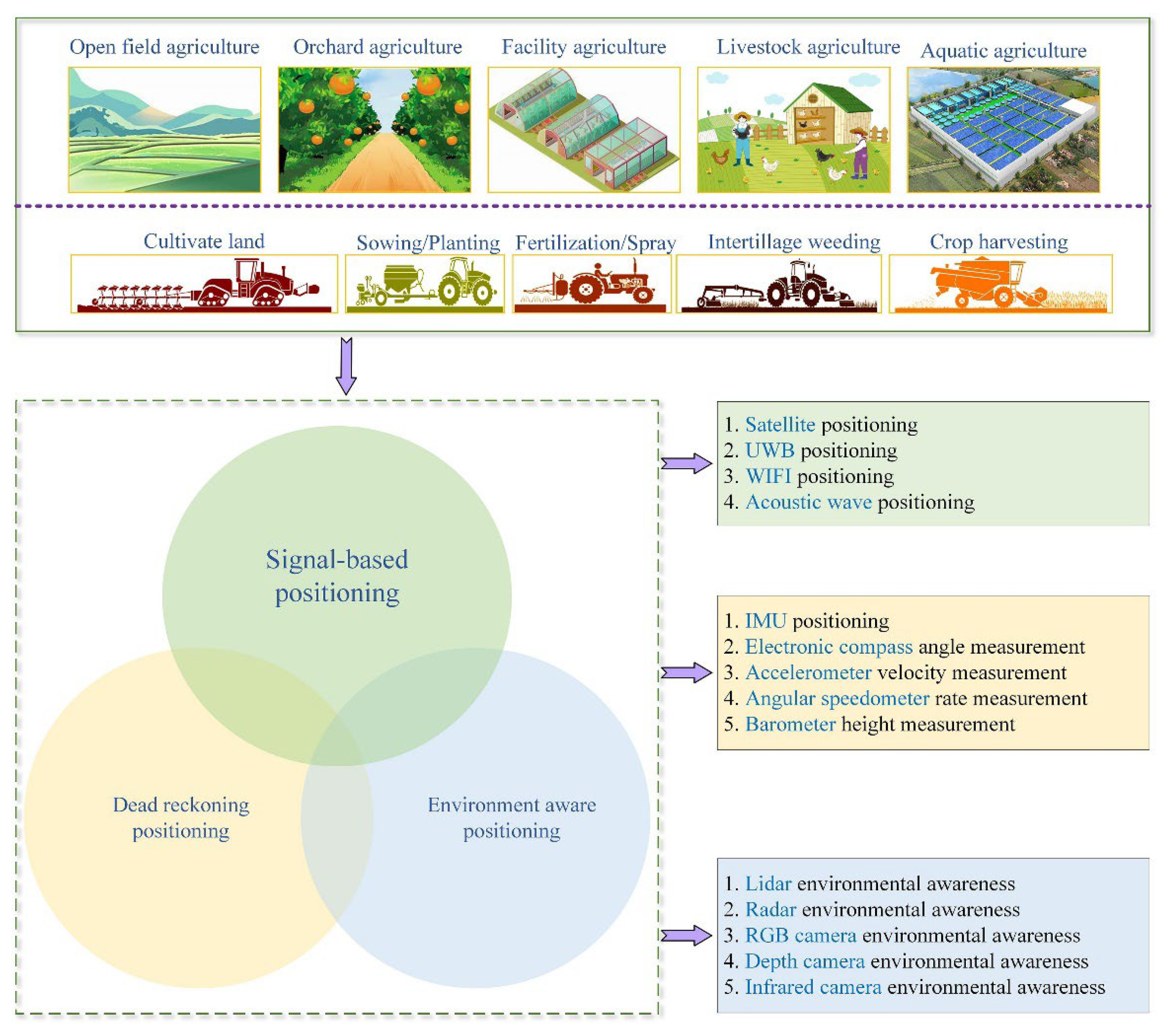

2.1. Positioning Technology

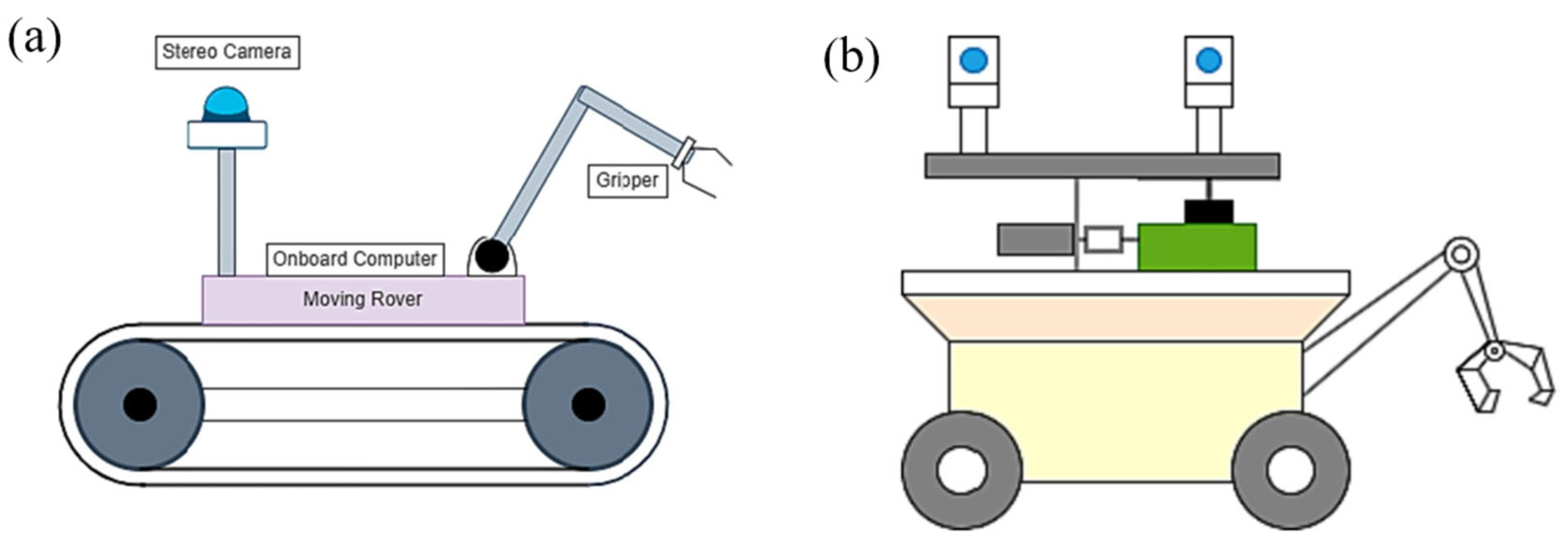

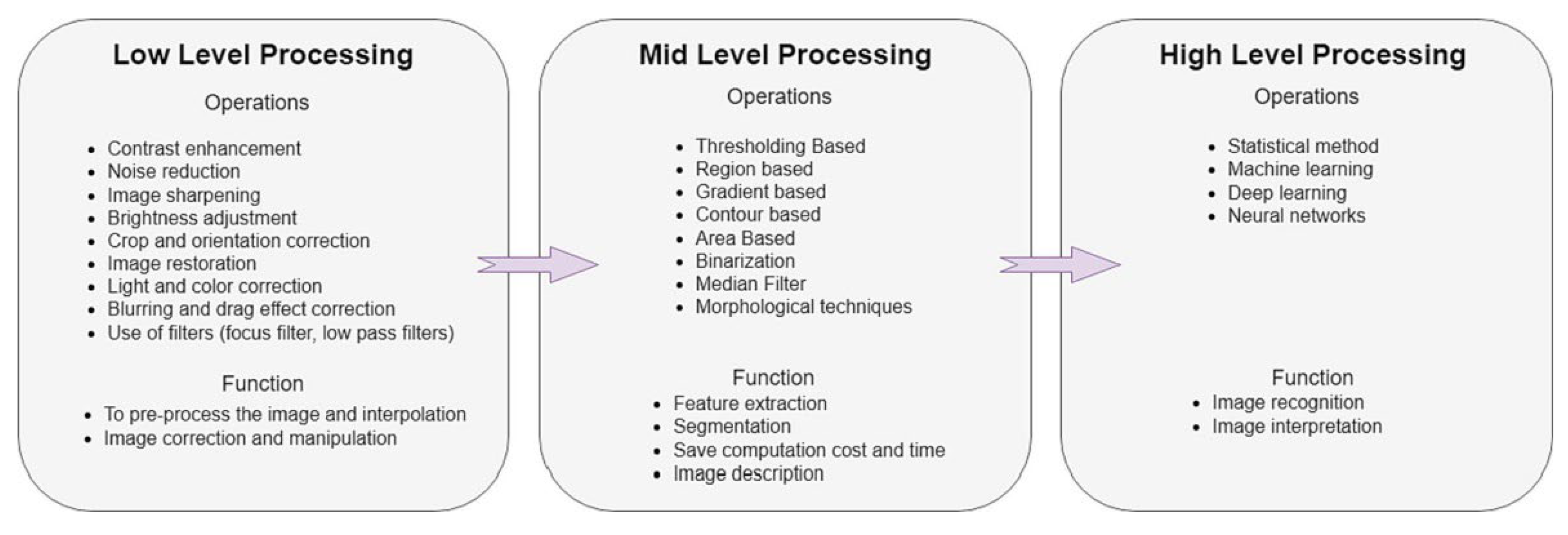

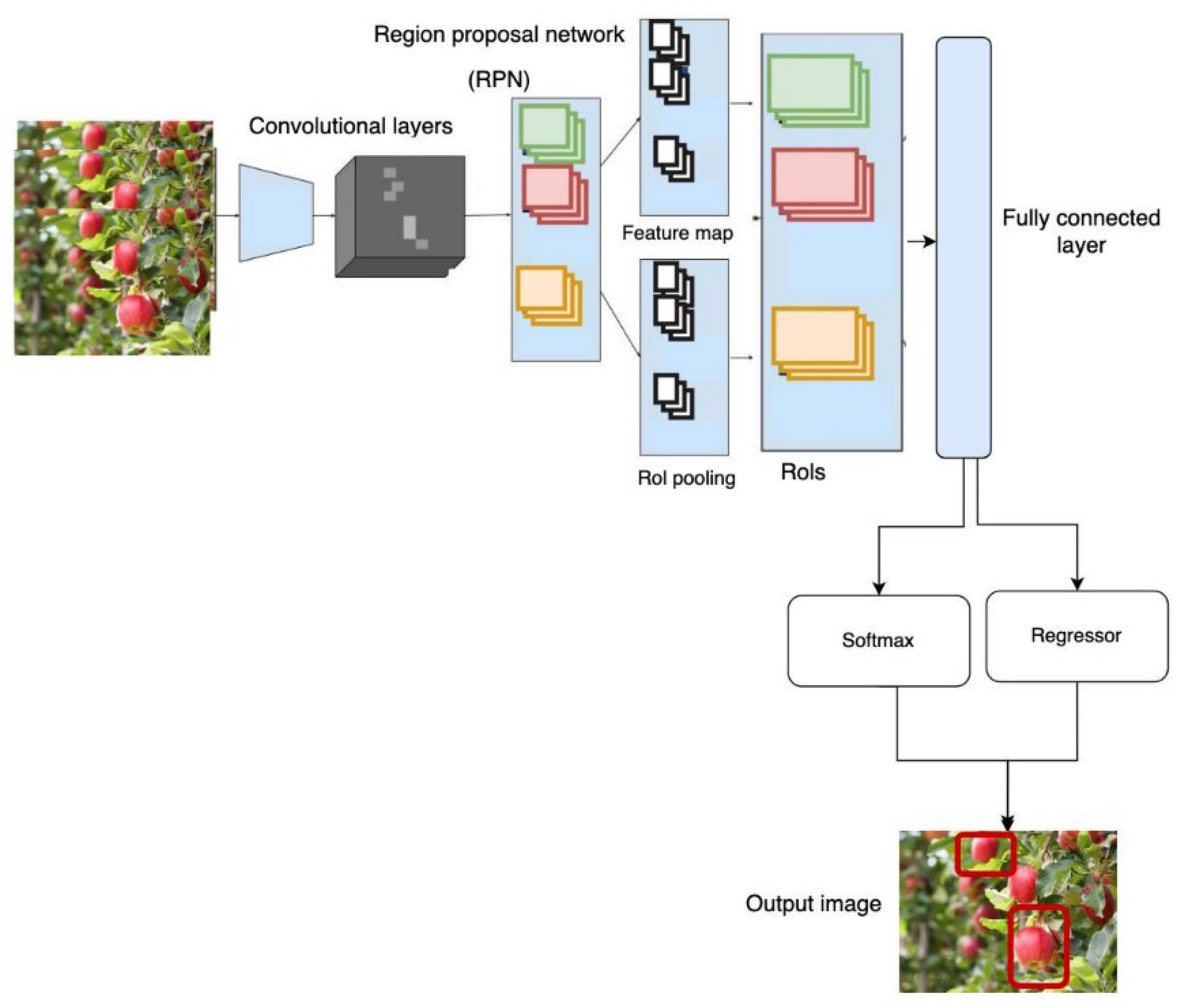

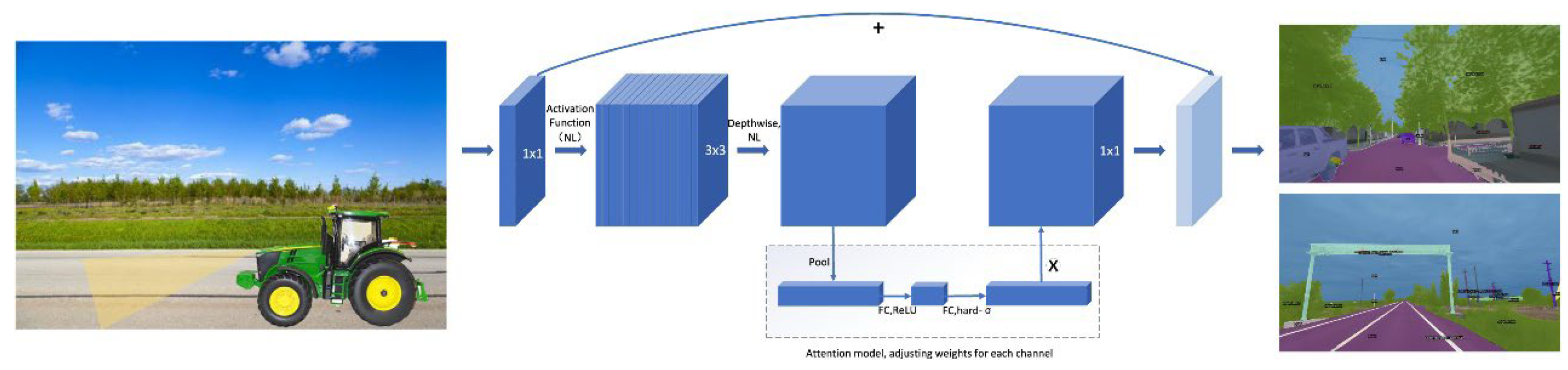

2.2. Perceptive Technology

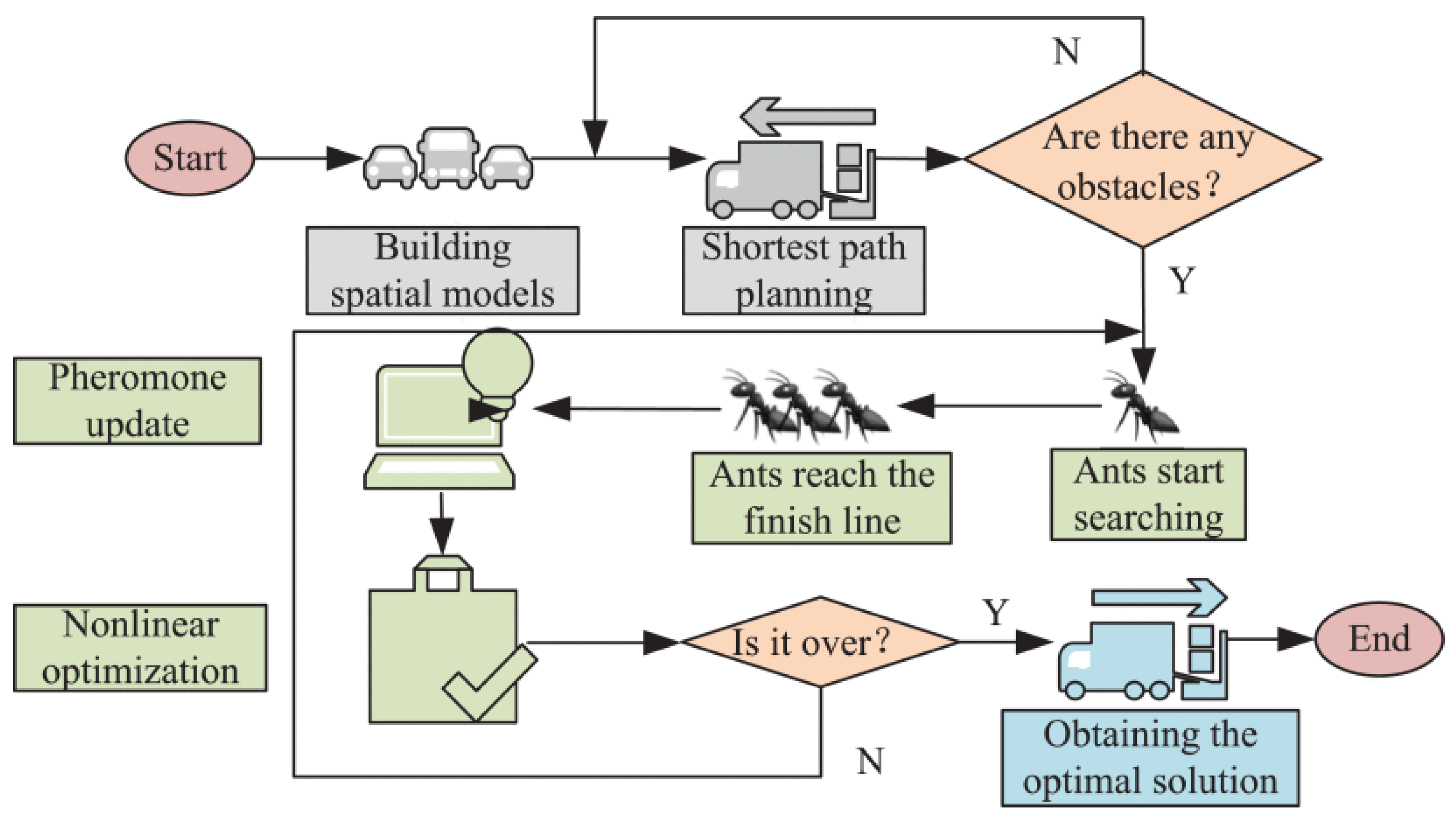

2.3. Control and Execution Technology

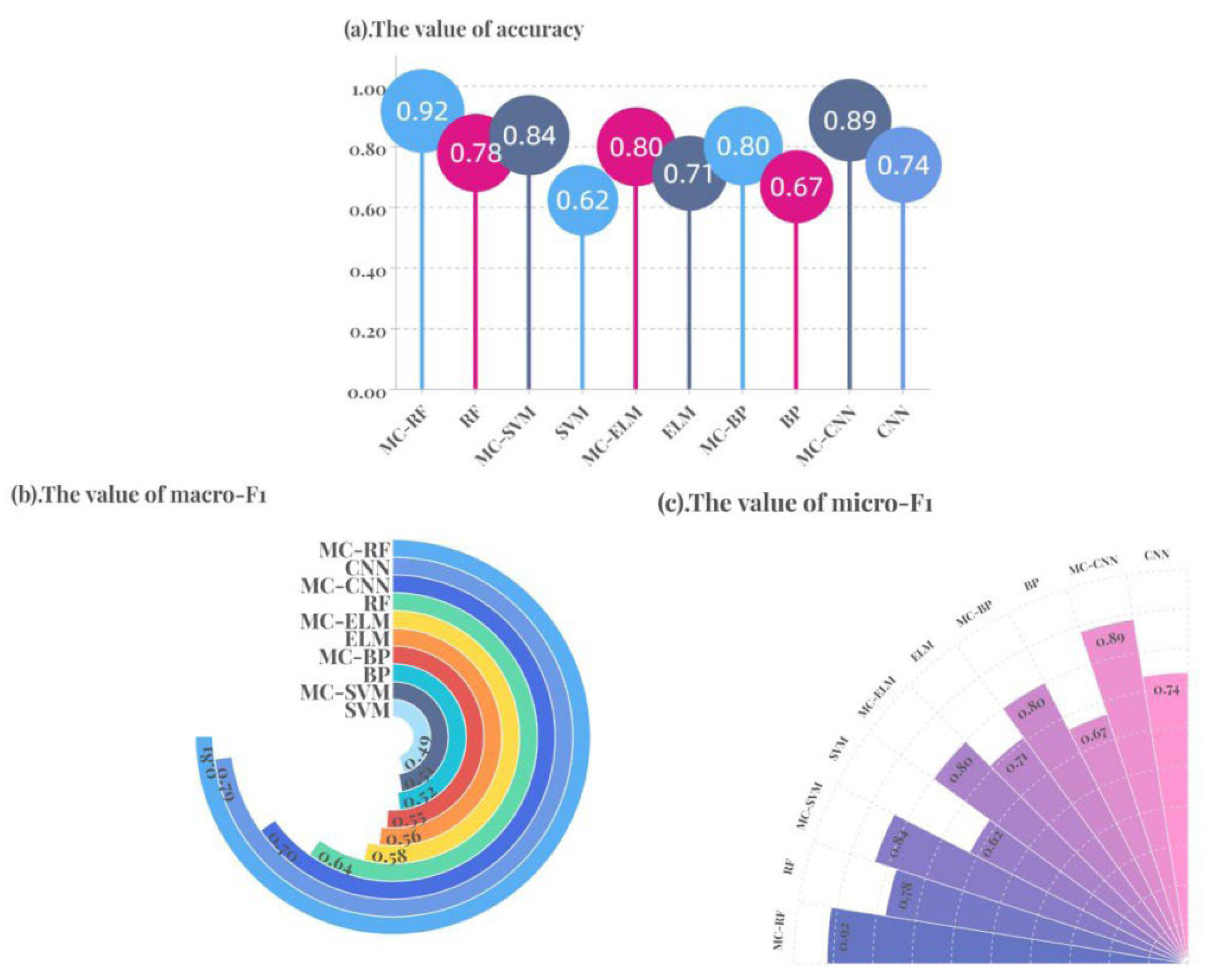

2.4. Artificial Intelligence and Data Analysis Technology

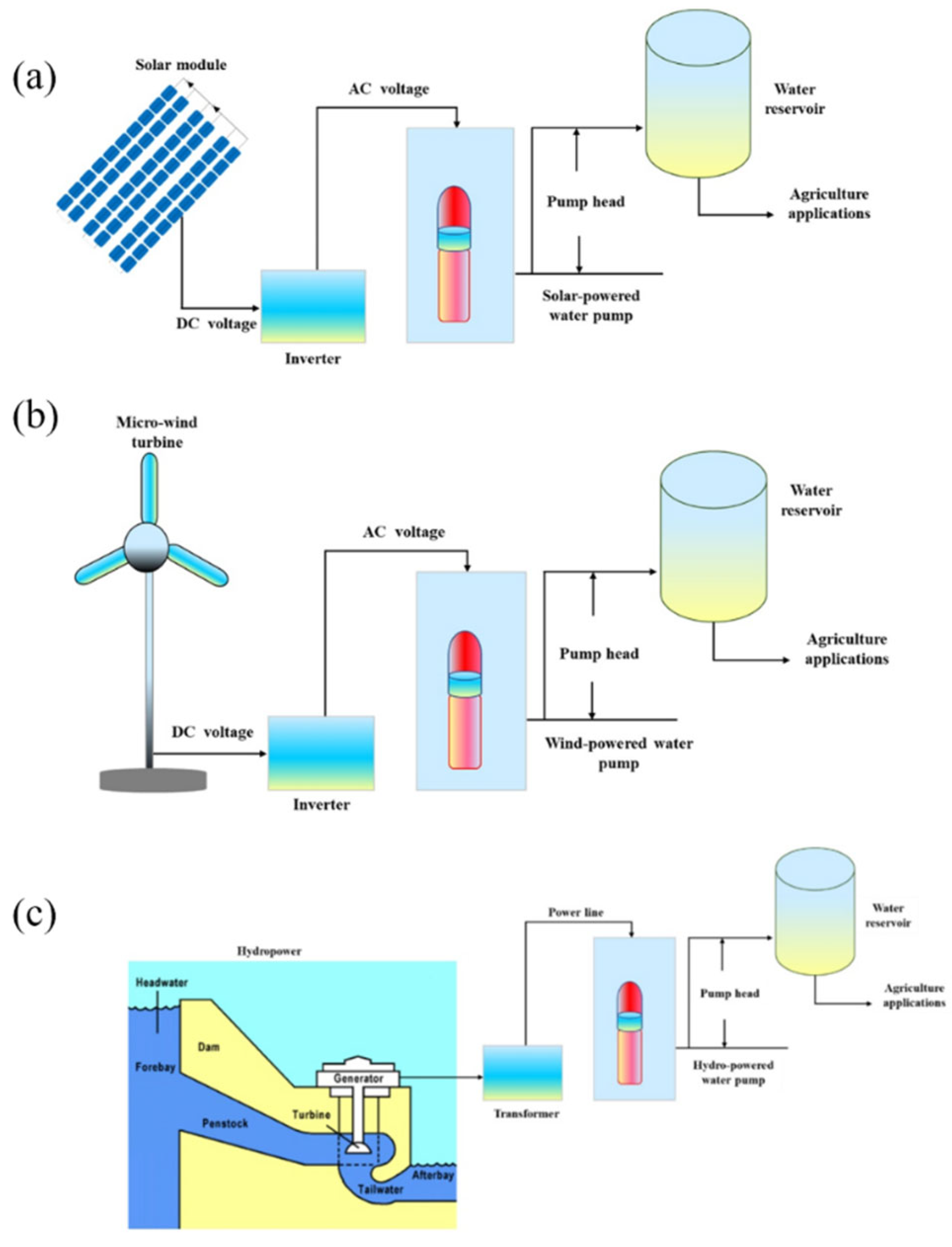

2.5. Green Energy Technology

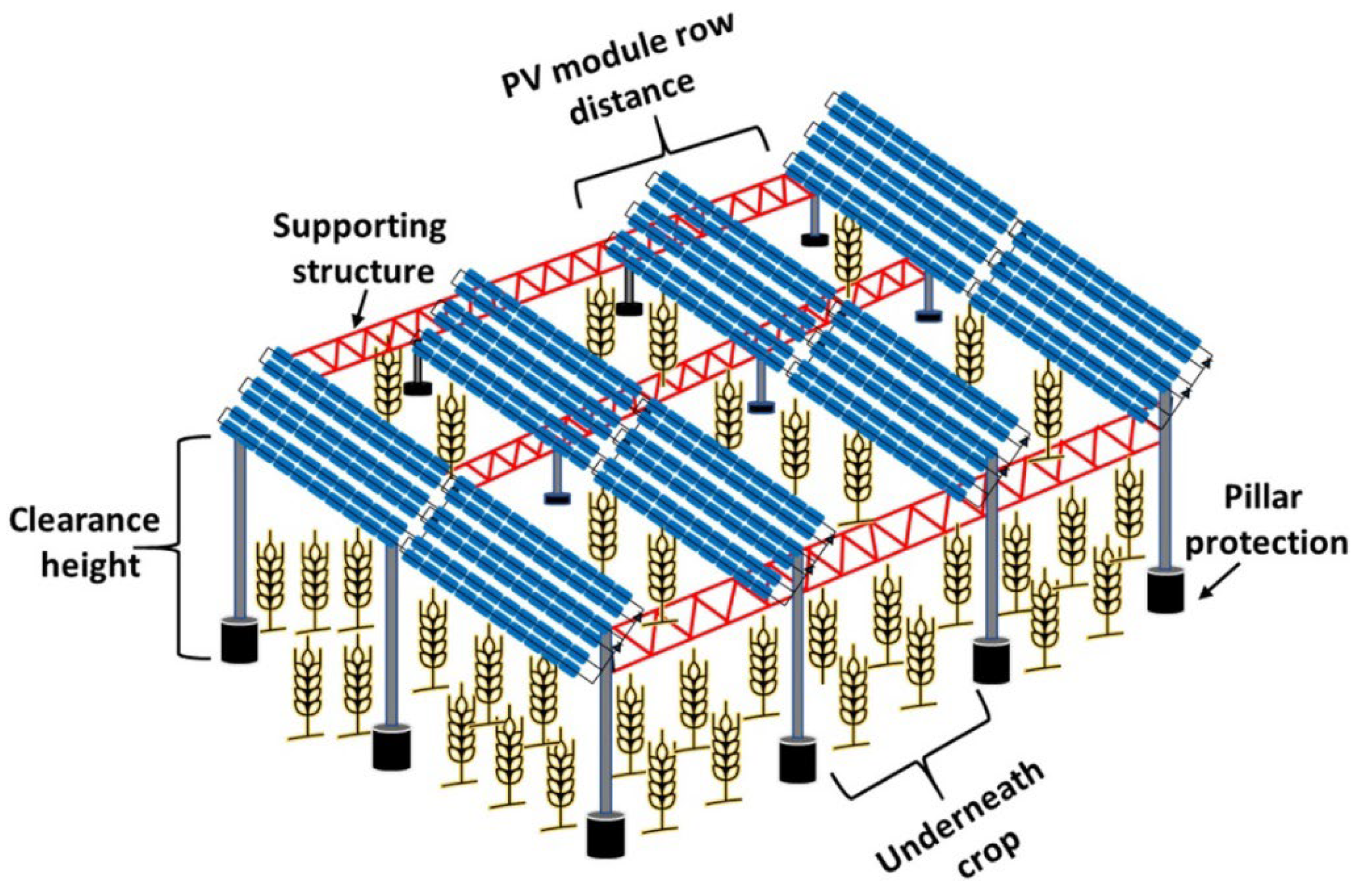

2.5.1. Solar Technology

2.5.2. Wind Energy Technology

2.5.3. Hydroelectric Technology

3. Application Scenarios and Cases

3.1. Autonomous Driving Agricultural Machinery

3.2. Drones and Aerial Operations

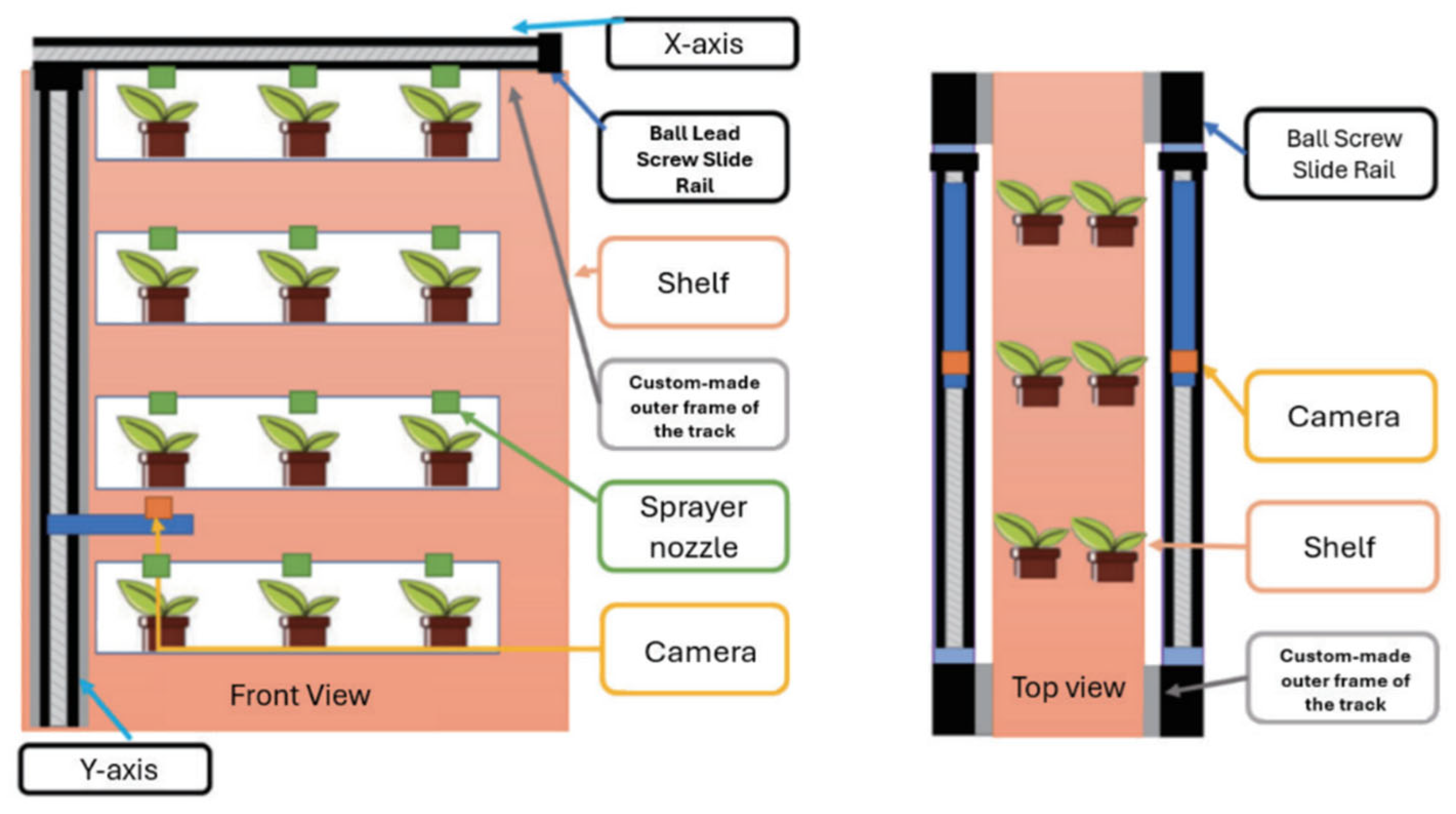

3.3. Precision Homework System

3.4. Intelligent Greenhouses and Vertical Agriculture

4. Advantages and Benefits

4.1. Efficiency Enhancement

4.2. Resource Optimization

4.3. Economic Viability

4.4. Data-Driven Decision-Making

4.5. Addressing Labor Shortages

5. Challenges and Issues

5.1. Positioning Technologies

5.2. Perception Technologies

5.3. Execution Technologies

5.4. Artificial Intelligence Technologies

5.5. Green Energy Technology

5.6. Synthesis of Key Cross-Cutting Challenges

6. Future Development Trends

6.1. Intelligence and Autonomy

6.2. Multi-Machine Collaboration and Swarm Operations

6.3. Sustainable Technologies

6.4. Integration of Emerging Technologies

6.5. Localization and Customization

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, X.; Chen, Y.; Liu, Y.; Wang, S.; Jin, J.; Zhao, Y.; Yu, D. A framework combining CENTURY modeling and chronosequences sampling to estimate soil organic carbon stock in an agricultural region with large land use change. Agronomy 2023, 13, 1055. [Google Scholar] [CrossRef]

- Danda, R.R. Innovations in Agricultural Machinery: Assessing the Impact of Advanced Technologies on Farm Efficiency. J. Artific. Intell. Big Data 2022, 3, 29–48. [Google Scholar] [CrossRef]

- Li, H.; Chen, L.; Zhang, Z. A Study on the Utilization Rate and Influencing Factors of Small Agricultural Machinery: Evidence from 10 Hilly and Mountainous Provinces in China. Agriculture 2023, 13, 51. [Google Scholar] [CrossRef]

- Zhu, S.; Wang, B.; Pan, S.; Ye, Y.; Wang, E.; Mao, H. Task allocation of multi-machine collaborative operation for agricultural machinery based on the improved fireworks algorithm. Agronomy 2024, 14, 710. [Google Scholar] [CrossRef]

- Padhiary, M.; Saha, D.; Kumar, R.; Sethi, L.N.; Kumar, A. Enhancing precision agriculture: A comprehensive review of machine learning and AI vision applications in all-terrain vehicle for farm automation. Smart Agric. Technol. 2024, 8, 100483. [Google Scholar] [CrossRef]

- Tang, L.; Syed, A.A.; Otho, A.R.; Junejo, A.R.; Tunio, M.H.; Hao, L.; Ali, M.N.H.A.; Brohi, S.A.; Otho, S.A.; Channa, J.A. Intelligent Rapid Asexual Propagation Technology—A Novel Aeroponics Propagation Approach. Agronomy 2024, 14, 2289. [Google Scholar] [CrossRef]

- Sun, X.; Zhong, K.; Zhang, D.; Shi, B.; Wang, H.; Shi, J.; Battino, M.; Wang, G.; Zou, X.; Zhao, L. The enhancement of the perception of saltiness by umami sensation elicited by flavor enhancers in salt solutions. Food Res. Int. 2022, 157, 111287. [Google Scholar] [CrossRef]

- Sun, X.; Zhong, K.; Zhang, D.; Shi, B.; Wang, H.; Shi, J.; Li, X.; Battino, M.; Zou, X.; Zhao, L. Saltiness enhancement by “má là” umami flavor in NaCl model aqueous and oil-added systems. Food Res. Int. 2023, 173, 113277. [Google Scholar] [CrossRef]

- Paul, K.; Chatterjee, S.S.; Pai, P.; Varshney, A.; Juikar, S.; Prasad, V.; Bhadra, B.; Dasgupta, S. Viable smart sensors and their application in data driven agriculture. Comput. Electron. Agric. 2022, 198, 107096. [Google Scholar] [CrossRef]

- Adewusi, A.O.; Asuzu, O.F.; Olorunsogo, T.; Adaga, E.; Daraojimba, D.O.; Iwuanyanwu, C. AI in precision agriculture: A review of technologies for sustainable farming practices. World J. Adv. Res. Rev. 2024, 21, 2276–2285. [Google Scholar] [CrossRef]

- Tang, Y.; Qiu, J.; Zhang, Y.; Wu, D.; Cao, Y.; Zhao, K.; Zhu, L. Optimization strategies of fruit detection to overcome the challenge of unstructured background in field orchard environment: A review. Precis. Agric. 2023, 24, 1183–1219. [Google Scholar] [CrossRef]

- Alaba, S.Y.; Gurbuz, A.C.; Ball, J.E. Emerging trends in autonomous vehicle perception: Multimodal fusion for 3D object detection. World Electr. Veh. J. 2024, 15, 20. [Google Scholar] [CrossRef]

- Jin, Y.; Liu, J.; Xu, Z.; Yuan, S.; Li, P.; Wang, J. Development status and trend of agricultural robot technology. Int. J. Agric. Biol. Eng. 2021, 14, 1–19. [Google Scholar] [CrossRef]

- Talwani, S.; Rakhra, M.; Sarkar, T. Perspectives on the Future of Agriculture and Recent Developments in Agricultural Technology. In Proceedings of the 2024 11th International Conference on Reliability, Infocom Technologies and Optimization (Trends and Future Directions) (ICRITO), Noida, India, 14–15 March 2024; pp. 1–6. [Google Scholar]

- Xie, B.; Jin, Y.; Faheem, M.; Gao, W.; Liu, J.; Jiang, H.; Cai, L.; Li, Y. Research progress of autonomous navigation technology for multi-agricultural scenes. Comput. Electron. Agric. 2023, 211, 107963. [Google Scholar] [CrossRef]

- Zhang, X.; Wu, F.; Gu, N.; Yan, X.; Wang, K.; Dhanasekaran, S.; Gu, X.; Zhao, L.; Zhang, H. Postharvest biological control of Rhizopus rot and the mechanisms involved in induced disease resistance of peaches by Pichia membranefaciens. Postharvest Biol. Technol. 2020, 163, 111146. [Google Scholar] [CrossRef]

- Huang, Y.; Fu, J.; Xu, S.; Han, T.; Liu, Y. Research on integrated navigation system of agricultural machinery based on RTK-BDS/INS. Agriculture 2022, 12, 1169. [Google Scholar] [CrossRef]

- Lipiński, A.J.; Markowski, P.; Lipiński, S.; Pyra, P. Precision of tractor operations with soil cultivation implements using manual and automatic steering modes. Biosyst. Eng. 2016, 145, 22–28. [Google Scholar] [CrossRef]

- Zhang, L.; Zhu, X.; Huang, J.; Huang, J.; Xie, J.; Xiao, X.; Yin, G.; Wang, X.; Li, M.; Fang, K. BDS/IMU integrated auto-navigation system of orchard spraying robot. Appl. Sci. 2022, 12, 8173. [Google Scholar] [CrossRef]

- Xiao, R.; Ma, X.; Li, H.; Cao, X.; Wei, Y.; Wang, C.; Zhao, X. Design and experiment of agricultural machinery auxiliary navigation system based on UWB positioning. J. South China Agric. Univ. 2022, 43, 116–123. [Google Scholar]

- Zhao, Z.; Jin, M.; Tian, C.; Yang, S.X. Prediction of seed distribution in rectangular vibrating tray using grey model and artificial neural network. Biosyst. Eng. 2018, 175, 194–205. [Google Scholar] [CrossRef]

- Cui, H.; Hu, C.; Aziz, T.; Albekairi, T.H.; Alshammari, A.; Lin, L. Application and Evaluation of Precision in Food Ink Pattern Printing Utilizing Image-Guided Non-Planar Slicing Technology. Food Bioprocess Technol. 2025, 18, 3504–3520. [Google Scholar] [CrossRef]

- Wu, S.; Liu, J.; Lei, X.; Zhao, S.; Lu, J.; Jiang, Y.; Xie, B.; Wang, M. Research progress on efficient pollination technology of crops. Agronomy 2022, 12, 2872. [Google Scholar] [CrossRef]

- Zhang, Q.; Shaojie Chen, M.E.; Li, B. A visual navigation algorithm for paddy field weeding robot based on image understanding. Comput. Electron. Agric. 2017, 143, 66–78. [Google Scholar] [CrossRef]

- Guan, Z.; Chen, K.; Ding, Y.; Wu, C.; Liao, Q. Visual navigation path extraction method in rice harvesting. Nongye Jixie Xuebao/Trans. Chin. Soc. Agric. Mach. 2020, 51, 19–28. [Google Scholar]

- Durand-Petiteville, A.; Flecher, E.L.; Cadenat, V.; Sentenac, T.; Vougioukas, S. Tree Detection With Low-Cost Three-Dimensional Sensors for Autonomous Navigation in Orchards. IEEE Robot. Autom. Lett. 2018, 3, 3876–3883. [Google Scholar] [CrossRef]

- Wang, B.; Zhang, Y.; Venkitasamy, C.; Wu, B.; Pan, Z.; Ma, H. Effect of pulsed light on activity and structural changes of horseradish peroxidase. Food Chem. 2017, 234, 20–25. [Google Scholar] [CrossRef]

- Jones, M.H.; Bell, J.; Dredge, D.; Seabright, M.; Scarfe, A.; Duke, M.; MacDonald, B. Design and testing of a heavy-duty platform for autonomous navigation in kiwifruit orchards. Biosyst. Eng. 2019, 187, 129–146. [Google Scholar] [CrossRef]

- Liu, L.; Liu, Y.; He, X.; Liu, W. Precision variable-rate spraying robot by using single 3D LIDAR in orchards. Agronomy 2022, 12, 2509. [Google Scholar] [CrossRef]

- Lin, X.; Wang, X.; Lin, C.; Geng, J.; Xue, J.; Zheng, E. Location information collection and optimization for agricultural vehicle based on UWB. Nongye Jixie Xuebao/Trans. Chin. Soc. Agric. Mach. 2018, 49, 23–29. [Google Scholar]

- Ju, J.; Liu, J.; Li, N.; Li, P. Curb-following detection and navigation of greenhouse vehicle based on arc array of photoelectric switches. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2017, 33, 180–187. [Google Scholar]

- Baillie, C.P.; Lobsey, C.R.; Antille, D.L.; McCarthy, C.L.; Thomasson, J.A. A review of the state of the art in agricultural automation. Part III: Agricultural machinery navigation systems. In Proceedings of the 2018 ASABE Annual International Meeting, American Society of Agricultural and Biological Engineers, Detroit, MI, USA, 29 July–1 August 2018; Volume 1. [Google Scholar]

- Bakker, T.; van Asselt, K.; Bontsema, J.; Müller, J.; van Straten, G. Autonomous navigation using a robot platform in a sugar beet field. Biosyst. Eng. 2011, 109, 357–368. [Google Scholar] [CrossRef]

- Wei, X.; Zhang, M.; Liu, Q.; Li, L. Extraction of Crop Height and Cut-edge Information Based on Binocular Vision. Trans. Chin. Soc. Agric. Mach. 2022, 53, 225–233. [Google Scholar]

- Chanprakon, P.; Sae-Oung, T.; Treebupachatsakul, T.; Hannanta-Anan, P.; Piyawattanametha, W. An Ultra-violet sterilization robot for disinfection. In Proceedings of the 5th International Conference on Engineering, Applied Sciences and Technology (ICEAST), Luang Prabang, Laos, 2–5 July 2019; pp. 1–4. [Google Scholar]

- Lakhiar, I.; Yan, H.; Zhang, C.; Wang, G.; He, B.; Hao, B.; Han, Y.; Wang, B.; Bao, R.; Syed, T.N.; et al. A Review of Precision Irrigation Water-Saving Technology under Changing Climate for Enhancing Water Use Efficiency, Crop Yield, and Environmental Footprints. Agriculture 2024, 14, 1141. [Google Scholar] [CrossRef]

- Ji, Y.; Li, S.; Peng, C.; Xu, H.; Cao, R.; Zhang, M. Obstacle detection and recognition in farmland based on fusion point cloud data. Comput. Electron. Agric. 2021, 189, 106409. [Google Scholar] [CrossRef]

- Xie, B.; Liu, J.; Cai, L.; Xu, Z.; Hou, G.; Wang, J.; Li, Y. Design of the UWB navigation system for tracked agricultural machinery in small land and analysis of base station layout. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2022, 38, 48–58. [Google Scholar]

- Radočaj, D.; Plaščak, I.; Heffer, G.; Jurišić, M. A low-cost global navigation satellite system positioning accuracy assessment method for agricultural machinery. Appl. Sci. 2022, 12, 693. [Google Scholar] [CrossRef]

- Li, D.; Li, Z. System Analysis and Development Prospect of Unmanned Farming. Trans. Chin. Soc. Agric. Mach. 2020, 51, 1–12. [Google Scholar]

- Mao, W.; Liu, H.; Wang, X.; Yang, F.; Liu, Z.; Wang, Z. Design and Experiment of Dual Navigation Mode Orchard Transport Robot. Trans. Chin. Soc. Agric. Mach. 2022, 53, 27–39, 49. [Google Scholar]

- Wang, J.; Zhang, Y.; Gu, R. Research status and prospects on plant canopy structure measurement using visual sensors based on three-dimensional reconstruction. Agriculture 2020, 10, 462. [Google Scholar] [CrossRef]

- Xiao, L.; Liu, J.; Ge, J. Dynamic game in agriculture and industry cross-sectoral water pollution governance in developing countries. Agric. Water Manag. 2021, 243, 106417. [Google Scholar] [CrossRef]

- Caffaro, F.; Bisaglia, C.; Cutini, M.; Micheletti Cremasco, M.; Cavallo, E. A method to evaluate the perceived ease of use of Human Machine Interface in agricultural tractors equipped with technological innovations. Span. J. Agric. Res. 2017, 15, e0210. [Google Scholar] [CrossRef]

- Shi, J.; Hu, X.; Zou, X.; Zhao, J.; Zhang, W.; Holmes, M.; Huang, X.; Zhu, Y.; Li, Z.; Shen, T.; et al. A rapid and nondestructive method to determine the distribution map of protein, carbohydrate and sialic acid on Edible bird’s nest by hyper-spectral imaging and chemometrics. Food Chem. 2017, 229, 235–241. [Google Scholar] [CrossRef] [PubMed]

- Wei, L.; Yang, H.; Niu, Y.; Zhang, Y.; Xu, L.; Chai, X. Wheat biomass, yield, and straw-grain ratio estimation from multi-temporal UAV-based RGB and multispectral images. Biosyst. Eng. 2023, 234, 187–205. [Google Scholar] [CrossRef]

- Yuan, L.-m.; Cai, J.-r.; Sun, L.; Ye, C. A Preliminary Discrimination of Cluster Disqualified Shape for Table Grape by Mono-Camera Multi-Perspective Simultaneously Imaging Approach. Food Anal. Methods 2016, 9, 758–767. [Google Scholar] [CrossRef]

- Roy, P.; Isler, V. Surveying apple orchards with a monocular vision system. In Proceedings of the 2016 IEEE International Conference on Automation Science and Engineering (CASE), Fort Worth, TX, USA, 21–25 August 2016; pp. 916–921. [Google Scholar]

- Naser, F.; Rabiei, V.; Razavi, F.; Khademi, O. Effect of calcium lactate in combination with hot water treatment on the nutritional quality of persimmon fruit during cold storage. Sci. Hortic. 2018, 233, 114–123. [Google Scholar] [CrossRef]

- Honrado, J.L.E.; Solpico, D.B.; Favila, C.M.; Tongson, E.; Tangonan, G.L.; Libatique, N.J.C. UAV imaging with low-cost multispectral imaging system for precision agriculture applications. In Proceedings of the 2017 IEEE Global Humanitarian Technology Conference (GHTC), San Jose, CA, USA, 19–22 October 2017; pp. 1–7. [Google Scholar]

- Kumar, J.; Vashisth, A.; Sehgal, V.K.; Gupta, V.K. Assessment of Aphid Infestation in Mustard by Hyperspectral Remote Sensing. J. Indian Soc. Remote Sens. 2013, 41, 83–90. [Google Scholar] [CrossRef]

- Bulanon, D.M.; Burks, T.F.; Alchanatis, V. Image fusion of visible and thermal images for fruit detection. Biosyst. Eng. 2009, 103, 12–22. [Google Scholar] [CrossRef]

- Åstrand, B.; Baerveldt, A.J. An agricultural mobile robot with vision-based perception for mechanical weed control. Auton. Robot. 2002, 13, 21–35. [Google Scholar] [CrossRef]

- Feng, G.; Wang, C.; Wang, A.; Gao, Y.; Zhou, Y.; Huang, S.; Luo, B. Segmentation of Wheat Lodging Areas from UAV Imagery Using an Ultra-Lightweight Network. Agriculture 2024, 14, 244. [Google Scholar] [CrossRef]

- Senni, L.; Ricci, M.; Palazzi, A.; Burrascano, P.; Pennisi, P.; Ghirelli, F. On-line automatic detection of foreign bodies in biscuits by infrared thermography and image processing. J. Food Eng. 2014, 128, 146–156. [Google Scholar] [CrossRef]

- Mustafa, N.B.A.; Fuad, N.A.; Ahmed, S.K.; Abidin, A.A.Z.; Ali, Z.; Yit, W.B.; Sharrif, Z.A.M. Image processing of an agriculture produce: Determination of size and ripeness of a banana. In Proceedings of the 2008 International Symposium on Information Technology, Kuala Lumpur, Malaysia, 26–29 August 2008; Volume 1, pp. 1–7. [Google Scholar]

- Li, H.; Lee, W.S.; Wang, K. Identifying blueberry fruit of different growth stages using natural outdoor color images. Comput. Electron. Agric. 2014, 106, 91–101. [Google Scholar] [CrossRef]

- Meng, Q.; Qiu, R.; He, J.; Zhang, M.; Ma, X.; Liu, G. Development of agricultural implement system based on machine vision and fuzzy control. Comput. Electron. Agric. 2015, 112, 128–138. [Google Scholar] [CrossRef]

- Pan, L.; Zhang, Q.; Zhang, W.; Sun, Y.; Hu, P.; Tu, K. Detection of cold injury in peaches by hyperspectral reflectance imaging and artificial neural network. Food Chem. 2016, 192, 134–141. [Google Scholar] [CrossRef] [PubMed]

- Williams, H.A.M.; Jones, M.H.; Nejati, M.; Seabright, M.J.; Bell, J.; Penhall, N.D.; Barnett, J.J.; Duke, M.D.; Scarfe, A.J.; Ahn, H.S.; et al. Robotic kiwifruit harvesting using machine vision, convolutional neural networks, and robotic arms. Biosyst. Eng. 2019, 181, 140–156. [Google Scholar] [CrossRef]

- Jiao, Y.; Luo, R.; Li, Q.; Deng, X.; Yin, X.; Ruan, C.; Jia, W. Detection and localization of overlapped fruits application in an apple harvesting robot. Electronics 2020, 9, 1023. [Google Scholar] [CrossRef]

- Thakur, A.; Venu, S.; Gurusamy, M. An extensive review on agricultural robots with a focus on their perception systems. Comput. Electron. Agric. 2023, 212, 108146. [Google Scholar] [CrossRef]

- Chang, C.L.; Xie, B.X.; Chung, S.C. Mechanical control with a deep learning method for precise weeding on a farm. Agriculture 2021, 11, 1049. [Google Scholar] [CrossRef]

- Wu, Z.; Chen, Y.; Zhao, B.; Kang, X.; Ding, Y. Review of weed detection methods based on computer vision. Sensors 2021, 21, 3647. [Google Scholar] [CrossRef]

- Blok, P.M.; Barth, R.; van den Berg, W. Machine vision for a selective broccoli harvesting robot. IFAC-PapersOnLine 2016, 49, 66–71. [Google Scholar] [CrossRef]

- Zhang, L.; Jia, J.; Gui, G.; Hao, X.; Gao, W.; Wang, M. Deep Learning Based Improved Classification System for Designing Tomato Harvesting Robot. IEEE Access 2018, 6, 67940–67950. [Google Scholar] [CrossRef]

- Rahimi-Ajdadi, F.; Abbaspour-Gilandeh, Y.; Mollazade, K.; Hasanzadeh, R.P.R. Development of a novel machine vision procedure for rapid and non-contact measurement of soil moisture content. Measurement 2018, 121, 179–189. [Google Scholar] [CrossRef]

- Zhou, Z.; Majeed, Y.; Diverres Naranjo, G.; Gambacorta, E.M.T. Assessment for crop water stress with infrared thermal imagery in precision agriculture: A review and future prospects for deep learning applications. Comput. Electron. Agric. 2021, 182, 106019. [Google Scholar] [CrossRef]

- Cravero, A.; Pardo, S.; Sepúlveda, S.; Muñoz, L. Challenges to use machine learning in agricultural big data: A systematic literature review. Agronomy 2022, 12, 748. [Google Scholar] [CrossRef]

- Sun, J.; Wu, M.; Hang, Y.; Lu, B.; Wu, X.; Chen, Q. Estimating cadmium content in lettuce leaves based on deep brief network and hyperspectral imaging technology. J. Food Process Eng. 2019, 42, e13293. [Google Scholar] [CrossRef]

- Lin, L.; Wang, X.; He, R.; Cui, H. Action mechanism of pulsed magnetic field against E. coli O157:H7 and its application in vegetable juice. Food Control 2019, 95, 150–156. [Google Scholar] [CrossRef]

- Scarlett, A.J. Integrated control of agricultural tractors and implements: A review of potential opportunities relating to cultivation and crop establishment machinery. Comput. Electron. Agric. 2001, 30, 167–191. [Google Scholar] [CrossRef]

- Solairaj, D.; Yang, Q.; Guillaume Legrand, N.N.; Routledge, M.N.; Zhang, H. Molecular explication of grape berry-fungal infections and their potential application in recent postharvest infection control strategies. Trends Food Sci. Technol. 2021, 116, 903–917. [Google Scholar] [CrossRef]

- Jararweh, Y.; Fatima, S.; Jarrah, M.; AlZu’bi, S. Smart and sustainable agriculture: Fundamentals, enabling technologies, and future directions. Comput. Electr. Eng. 2023, 110, 108799. [Google Scholar] [CrossRef]

- Chen, J.; Zhang, M.; Xu, B.; Sun, J.; Mujumdar, A.S. Artificial intelligence assisted technologies for controlling the drying of fruits and vegetables using physical fields: A review. Trends Food Sci. Technol. 2020, 105, 251–260. [Google Scholar] [CrossRef]

- Jia, W.; Zheng, Y.; Zhao, D.; Yin, X.; Liu, X.; Du, R. Preprocessing method of night vision image application in apple harvesting robot. Int. J. Agric. Biol. Eng. 2018, 11, 158–163. [Google Scholar] [CrossRef]

- Lu, E.; Ma, Z.; Li, Y.; Xu, L.; Tang, Z. Adaptive backstepping control of tracked robot running trajectory based on real-time slip parameter estimation. Int. J. Agric. Biol. Eng. 2020, 13, 178–187. [Google Scholar] [CrossRef]

- Kvalsund, M.; Glette, K.; Veenstra, F. Centralized and Decentralized Control in Modular Robots and Their Effect on Morphology. In Proceedings of the ALIFE 2022: The 2022 Conference on Artificial Life, Virtual, 18–22 July 2022; p. 49. [Google Scholar]

- Cortez, W.S.; Verginis, C.K.; Dimarogonas, D.V. A Distributed, Event-Triggered, Adaptive Controller for Cooperative Manipulation With Rolling Contacts. IEEE Trans. Robot. 2023, 39, 3120–3133. [Google Scholar] [CrossRef]

- Zhang, H.; Apaliya, M.T.; Mahunu, G.K.; Chen, L.; Li, W. Control of ochratoxin A-producing fungi in grape berry by microbial antagonists: A review. Trends Food Sci. Technol. 2016, 51, 88–97. [Google Scholar] [CrossRef]

- Yan, Y.; Zhang, X.; Zheng, X.; Apaliya, M.T.; Yang, Q.; Zhao, L.; Gu, X.; Zhang, H. Control of postharvest blue mold decay in pears by Meyerozyma guilliermondii and it’s effects on the protein expression profile of pears. Postharvest Biol. Technol. 2018, 136, 124–131. [Google Scholar] [CrossRef]

- Stroppa, F.; Selvaggio, M.; Agharese, N.; Luo, M.; Blumenschein, L.H.; Hawkes, E.W.; Okamura, A.M. Shared-Control Teleoperation Paradigms on a Soft-Growing Robot Manipulator. J. Intell. Robot. Syst. 2023, 109, 30. [Google Scholar] [CrossRef]

- Lee, H.J.; Kim, M.S.; Lee, M.C. Path Planning Based on Artificial Potential Field with an Enhanced Virtual Hill Algorithm. Appl. Sci. 2024, 14, 8292. [Google Scholar] [CrossRef]

- Puente-Castro, A.; Rivero, D.; Pazos, A.; Fernandez-Blanco, E. UAV swarm path planning with reinforcement learning for field prospecting. Appl. Intell. 2022, 52, 14101–14118. [Google Scholar] [CrossRef]

- Zeng, K.; Chen, B.; Li, Y.; Meng, H.; Wu, Q.; Yang, J.; Liang, H. Gold nanoparticle-carbon nanotube nanohybrids with peroxidase-like activity for the highly-sensitive immunoassay of kanamycin in milk. Int. J. Food Sci. Technol. 2022, 57, 6028–6037. [Google Scholar] [CrossRef]

- Qenawy, M.; Ali, M.; El-Mesery, H.S.; Hu, Z. Analysis and control of hybrid convection-radiation drying systems toward energy saving strategy. J. Food Sci. 2024, 89, 9559–9576. [Google Scholar] [CrossRef]

- Wu, Q.; Chen, H.; Liu, B. Path Planning of Agricultural Information Collection Robot Integrating Ant Colony Algorithm and Particle Swarm Algorithm. IEEE Access 2024, 12, 50821–50833. [Google Scholar] [CrossRef]

- Hernández, H.A.; Mondragón, I.F.; González, S.R.; Pedraza, L.F. Reconfigurable agricultural robotics: Control strategies, communication, and applications. Comput. Electron. Agric. 2025, 234, 110161. [Google Scholar] [CrossRef]

- Nisser, M.; Cheng, L.; Makaram, Y.; Suzuki, R.; Mueller, S. ElectroVoxel: Electromagnetically Actuated Pivoting for Scalable Modular Self-Reconfigurable Robots. In Proceedings of the ICRA 2022, Philadelphia, PA, USA, 23–27 May 2022; pp. 4254–4260. [Google Scholar]

- Kaneishi, D.; Takijo, K. Module-W: Reconfigurable Modular Robots Forming Compliant Structures. In Proceedings of the 2022 IEEE 5th International Conference on Soft Robotics (RoboSoft), Edinburgh, UK, 4–8 April 2022; pp. 595–600. [Google Scholar]

- Liang, Z.; Xu, L.; De Baerdemaeker, J.; Li, Y.; Saeys, W. Optimisation of a multi-duct cleaning device for rice combine harvesters utilising CFD and experiments. Biosyst. Eng. 2020, 190, 25–40. [Google Scholar] [CrossRef]

- Peck, R.H.; Timmis, J.; Tyrrell, A.M. Self-assembly and self-repair during motion with modular robots. Electronics 2022, 11, 1595. [Google Scholar] [CrossRef]

- Cassotta, M.; Forbes-Hernández, T.Y.; Calderón Iglesias, R.; Ruiz, R.; Zabaleta, M.E.; Giampieri, F.; Battino, M. Links between nutrition, infectious diseases, and microbiota: Emerging technologies and opportunities for human-focused research. Nutrients 2020, 12, 1827. [Google Scholar] [CrossRef]

- Fayek, N.M.; Xiao, J.; Farag, M.A. A multifunctional study of naturally occurring pyrazines in biological systems; formation mechanisms, metabolism, food applications and functional properties. Crit. Rev. Food Sci. 2023, 63, 5322–5338. [Google Scholar] [CrossRef]

- Rossides, G.; Metcalfe, B.; Hunter, A. Particle swarm optimization—An adaptation for the control of robotic swarms. Robotics 2021, 10, 58. [Google Scholar] [CrossRef]

- Parada, I.; Sacristán, V.; Silveira, R.I. A new meta-module design for efficient reconfiguration of modular robots. Auton. Robot. 2021, 45, 457–472. [Google Scholar] [CrossRef]

- Khulal, U.; Zhao, J.; Hu, W.; Chen, Q. Nondestructive quantifying total volatile basic nitrogen (TVB-N) content in chicken using hyperspectral imaging (HSI) technique combined with different data dimension reduction algorithms. Food Chem. 2016, 197, 1191–1199. [Google Scholar] [CrossRef]

- Kutsanedzie, F.Y.H.; Chen, Q.; Hassan, M.M.; Yang, M.; Sun, H.; Rahman, M.H. Near infrared system coupled chemometric algorithms for enumeration of total fungi count in cocoa beans neat solution. Food Chem. 2018, 240, 231–238. [Google Scholar] [CrossRef]

- Javaid, M.; Haleem, A.; Khan, I.H.; Suman, R. Understanding the potential applications of Artificial Intelligence in Agriculture Sector. Adv. Agrochem 2023, 2, 15–30. [Google Scholar] [CrossRef]

- El-Mesery, H.S.; Qenawy, M.; Ali, M.; Hu, Z.; Adelusi, O.A.; Njobeh, P.B. Artificial intelligence as a tool for predicting the quality attributes of garlic (Allium sativum L.) slices during continuous infrared-assisted hot air drying. J. Food Sci. 2024, 89, 7693–7712. [Google Scholar] [CrossRef] [PubMed]

- Lu, B.; Jun, S.; Ning, Y.; Wu, X.; Xin, Z. Identification of tea white star disease and anthrax based on hyperspectral image information. J. Food Process Eng. 2021, 44, e13584. [Google Scholar] [CrossRef]

- Zheng, B.; Myint, S.W.; Thenkabail, P.S.; Aggarwal, R.M. A support vector machine to identify irrigated crop types using time-series Landsat NDVI data. Int. J. Appl. Earth Obs. 2015, 34, 103–112. [Google Scholar] [CrossRef]

- Geng, Z.; Duan, X.; Li, J.; Chu, C.; Han, Y. Risk prediction model for food safety based on improved random forest integrating virtual sample. Eng. Appl. Artif. Intell. 2022, 116, 105352. [Google Scholar] [CrossRef]

- Leroux, A.; Boussard, M.; Dés, R. Inducing Readable Oblique Decision Trees. In Proceedings of the 2018 IEEE 30th International Conference on Tools with Artificial Intelligence (ICTAI), Volos, Greece, 5–7 November 2018; pp. 401–408. [Google Scholar]

- Zareef, M.; Chen, Q.; Hassan, M.M.; Arslan, M.; Hashim, M.M.; Ahmad, W.; Kutsanedzie, F.Y.H.; Agyekum, A.A. An Overview on the Applications of Typical Non-linear Algorithms Coupled With NIR Spectroscopy in Food Analysis. Food Eng. Rev. 2020, 12, 173–190. [Google Scholar] [CrossRef]

- Cao, H.; Gu, Y.; Fang, J.; Hu, Y.; Ding, W.; He, H.; Chen, G. Application of stacking ensemble learning model in quantitative analysis of biomaterial activity. Microchem. J. 2022, 183, 108075. [Google Scholar] [CrossRef]

- Huang, J.; Zhou, J.; Zheng, L. Support Vector Machine Classification Algorithm Based on Relief-F Feature Weighting. In Proceedings of the 2020 International Conference on Computer Engineering and Application (ICCEA), Guangzhou, China, 18–20 March 2020; pp. 547–553. [Google Scholar]

- Misra, N.N.; Dixit, Y.; Al-Mallahi, A.; Bhullar, M.S.; Upadhyay, R.; Martynenko, A. IoT, big data, and artificial intelligence in agriculture and food industry. IEEE Internet Things J. 2020, 9, 6305–6324. [Google Scholar] [CrossRef]

- Zhou, X.; Sun, J.; Tian, Y.; Lu, B.; Hang, Y.; Chen, Q. Hyperspectral technique combined with deep learning algorithm for detection of compound heavy metals in lettuce. Food Chem. 2020, 321, 126503. [Google Scholar] [CrossRef]

- Chen, C.; Zhu, W.; Steibel, J.; Siegford, J.; Han, J.; Norton, T. Classification of drinking and drinker-playing in pigs by a video-based deep learning method. Biosyst. Eng. 2020, 196, 1–14. [Google Scholar] [CrossRef]

- Suruliandi, A.; Mariammal, G.; Raja, S.P. Crop prediction based on soil and environmental characteristics using feature selection techniques. Math. Comput. Model. Dyn. Syst. 2021, 27, 117–140. [Google Scholar] [CrossRef]

- Amirian, M.; Schwenker, F. Radial Basis Function Networks for Convolutional Neural Networks to Learn Similarity Distance Metric and Improve Interpretability. IEEE Access 2020, 8, 123087–123097. [Google Scholar] [CrossRef]

- Pallathadka, H.; Ravipati, P.; Sekhar Sajja, G.; Phasinam, K.; Kassanuk, T.; Sanchez, D.T.; Prabhu, P. Application of machine learning techniques in rice leaf disease detection. Mater. Today Proc. 2022, 51, 2277–2280. [Google Scholar] [CrossRef]

- Ouafiq, E.M.; Saadane, R.; Chehri, A. Data management and integration of low power consumption embedded devices IoT for transforming smart agriculture into actionable knowledge. Agriculture 2022, 12, 329. [Google Scholar] [CrossRef]

- Apolo-Apolo, O.E.; Martínez-Guanter, J.; Egea, G.; Raja, P.; Pérez-Ruiz, M. Deep learning techniques for estimation of the yield and size of citrus fruits using a UAV. Eur. J. Agron. 2020, 115, 126030. [Google Scholar] [CrossRef]

- Wang, J.; Lu, S.; Wang, S.-H.; Zhang, Y.-D. A review on extreme learning machine. Multimed. Tools Appl. 2022, 81, 41611–41660. [Google Scholar] [CrossRef]

- Purnama, S.; Sejati, W. Internet of things, big data, and artificial intelligence in the food and agriculture sector. Int. Trans. Artif. Intell. 2023, 1, 156–174. [Google Scholar] [CrossRef]

- Jha, K.; Doshi, A.; Patel, P.; Shah, M. A comprehensive review on automation in agriculture using artificial intelligence. Artif. Intell. Agric. 2019, 2, 1–12. [Google Scholar] [CrossRef]

- Padhan, P.C.; Sciences, S. Application of ARIMA model for forecasting agricultural productivity in India. J. Agric. Soc. Sci. 2012, 8, 50–56. [Google Scholar]

- Xu, M.; Sun, J.; Cheng, J.; Yao, K.; Wu, X.; Zhou, X. Non-destructive prediction of total soluble solids and titratable acidity in Kyoho grape using hyperspectral imaging and deep learning algorithm. Int. J. Food Sci. Technol. 2023, 58, 9–21. [Google Scholar] [CrossRef]

- Hewamalage, H.; Bergmeir, C.; Bandara, K. Recurrent Neural Networks for Time Series Forecasting: Current status and future directions. Int. J. Forecast. 2021, 37, 388–427. [Google Scholar] [CrossRef]

- Badmus, M.A.; Ariyo, O.S. Forecasting cultivated areas and production of maize in Nigerian using ARIMA Model. Asian J. Agric. Sci. 2011, 3, 171–176. [Google Scholar]

- Sanches Silva, A.; Reboredo-Rodríguez, P.; Sanchez-Machado, D.I.; López-Cervantes, J.; Barreca, D.; Pittala, V.; Samec, D.; Orhan, I.E.; Gulcan, H.O.; Forbes-Hernandez, T.Y.; et al. Evaluation of the status quo of polyphenols analysis: Part II—Analysis methods and food processing effects. Compr. Rev. Food Sci. Food Saf. 2020, 19, 3219–3240. [Google Scholar] [CrossRef]

- Yan, H.; Acquah, S.J.; Zhang, C.; Wang, G.; Huang, S.; Zhang, H.; Zhao, B.; Wu, H. Energy partitioning of greenhouse cucumber based on the application of Penman-Monteith and Bulk Transfer models. Agric. Water Manag. 2019, 217, 201–211. [Google Scholar] [CrossRef]

- Huang, S.; Yan, H.; Zhang, C.; Wang, G.; Acquah, S.J.; Yu, J.; Li, L.; Ma, J.; Darko, R.O. Modeling evapotranspiration for cucumber plants based on the Shuttleworth-Wallace model in a Venlo-type greenhouse. Agric. Water Manag. 2020, 228, 105861. [Google Scholar] [CrossRef]

- Lin, J.; Ma, J.; Liu, K.; Huang, X.; Xiao, L.; Ahmed, S.; Dong, X.; Qiu, B. Development and test of an autonomous air-assisted sprayer based on single hanging track for solar greenhouse. Crop Prot. 2021, 142, 105502. [Google Scholar] [CrossRef]

- Rahman, M.M.; Khan, I.; Field, D.L.; Techato, K.; Alameh, K. Powering agriculture: Present status, future potential, and challenges of renewable energy applications. Renew. Energy 2022, 188, 731–749. [Google Scholar] [CrossRef]

- Zhang, L.; Yang, Z.; Wu, X.; Wang, W.; Yang, C.; Xu, G.; Wu, C.; Bao, E. Open-Field Agrivoltaic System Impacts on Photothermal Environment and Light Environment Simulation Analysis in Eastern China. Agronomy 2023, 13, 1820. [Google Scholar] [CrossRef]

- Liao, J.; Hewitt, A.J.; Wang, P.; Luo, X.; Zang, Y.; Zhou, Z.; Lan, Y.; O’Donnell, C. Development of droplet characteristics prediction models for air induction nozzles based on wind tunnel tests. Int. J. Agric. Biol. Eng. 2019, 12, 1–6. [Google Scholar] [CrossRef]

- Xiang, Q.; Qureshi, W.A.; Tunio, M.H.; Solangi, K.A.; Xu, Z.; Lakhiar, I.A. low-pressure drop size distribution characterization of impact sprinkler jet nozzles with and without aeration. Agric. Water Manag. 2021, 243, 106458. [Google Scholar] [CrossRef]

- Yüksel, I. Hydropower for sustainable water and energy development. Renew. Sustain. Energy Rev. 2010, 14, 462–469. [Google Scholar] [CrossRef]

- Zakaria, I.; Hong, L.; Yue, J.; Pan, T.; Chao, C.; Ransford Opoku, D. Hydraulic performance characteristics of impact sprinkler with a fixed water dispersion device. Int. J. Agric. Biol. Eng. 2018, 11, 104–112. [Google Scholar]

- Garcia-Perez, P.; Cassani, L.; Garcia-Oliveira, P.; Xiao, J.; Simal-Gandara, J.; Prieto, M.A.; Lucini, L. Algal nutraceuticals: A perspective on metabolic diversity, current food applications, and prospects in the field of metabolomics. Food Chem. 2023, 409, 135295. [Google Scholar] [CrossRef]

- Lin, L.; Mao, X.; Sun, Y.; Rajivgandhi, G.; Cui, H. Antibacterial properties of nanofibers containing chrysanthemum essential oil and their application as beef packaging. Int. J. Food Microbiol. 2019, 292, 21–30. [Google Scholar] [CrossRef]

- Cui, B.; Cui, X.; Wei, X.; Zhu, Y.; Ma, Z.; Zhao, Y.; Liu, Y. Design and Testing of a Tractor Automatic Navigation System Based on Dynamic Path Search and a Fuzzy Stanley Model. Agriculture 2024, 14, 2136. [Google Scholar] [CrossRef]

- Kise, M.; Noguchi, N.; Ishii, K.; Terao, H. Development of the Agricultural Autonomous Tractor with an RTK-GPS and a Fog. IFAC Proc. Vol. 2001, 34, 99–104. [Google Scholar] [CrossRef]

- Zhang, C.; Noguchi, N.; Yang, L. Leader–follower system using two robot tractors to improve work efficiency. Comput. Electron. Agric. 2016, 121, 269–281. [Google Scholar] [CrossRef]

- Ahmed, S.; Qiu, B.; Ahmad, F.; Kong, C.-W.; Xin, H. A state-of-the-art analysis of obstacle avoidance methods from the perspective of an agricultural sprayer UAV’s operation scenario. Agronomy 2021, 11, 1069. [Google Scholar] [CrossRef]

- Yao, Z.; Zhao, C.; Zhang, T. Agricultural machinery automatic navigation technology. iScience 2024, 27, 108714. [Google Scholar] [CrossRef]

- Kong, F.; Qiu, B.; Dong, X.; Yi, K.; Wang, Q.; Jiang, C.; Zhang, X.; Huang, X. Design and Development of a Side Spray Device for UAVs to Improve Spray Coverage in Obstacle Neighborhoods. Agronomy 2024, 14, 2002. [Google Scholar] [CrossRef]

- Souvanhnakhoomman, S. Review on application of drone in spraying pesticides and fertilizers. arXiv 2024, arXiv:2402.00020. [Google Scholar]

- Kumar, E.; Saini, A.; Prajapati, A.; Garhwali, S.; Kumar, A. A comparative study on agriculture drone for monitoring and spraying pesticides. Pharma Innov. J. 2023, SP-12, 263–267. [Google Scholar]

- Zhu, C.; Hao, S.; Liu, C.; Wang, Y.; Jia, X.; Xu, J.; Guo, S.; Huo, J.; Wang, W. An Efficient Computer Vision-Based Dual-Face Target Precision Variable Spraying Robotic System for Foliar Fertilisers. Agronomy 2024, 14, 2770. [Google Scholar] [CrossRef]

- Qiu, A.; Young, C.; Gunderman, A.L.; Azizkhani, M.; Chen, Y.; Hu, A.P. Tendon-Driven Soft Robotic Gripper with Integrated Ripeness Sensing for Blackberry Harvesting. In Proceedings of the 2023 IEEE International Conference on Robotics and Automation (ICRA), London, UK, 29 May–2 June 2023; pp. 11831–11837. [Google Scholar]

- Liu, J.; Abbas, I.; Noor, R.S. Development of deep learning-based variable rate agrochemical spraying system for targeted weeds control in strawberry crop. Agronomy 2021, 11, 1480. [Google Scholar] [CrossRef]

- Silwal, A.; Yandun, F.; Nellithimaru, A.; Bates, T.; Kantor, G. Bumblebee: A Path Towards Fully Autonomous Robotic Vine Pruning. Field Robot. 2022, 2, 1661–1696. [Google Scholar] [CrossRef]

- Li, T.; Xie, F.; Zhao, Z.; Zhao, H.; Guo, X.; Feng, Q. A multi-arm robot system for efficient apple harvesting: Perception, task plan and control. Comput. Electron. Agric. 2023, 1, 107979. [Google Scholar] [CrossRef]

- Liu, J.; Gull, U.; Putnam, D.H.; Kisekka, I. Variable-Rate Irrigation Uniformity Model for Linear-Move Sprinkler Systems. Trans. ASABE 2021, 64, 1295–1302. [Google Scholar] [CrossRef]

- Cayambe, J.; Heredia-R, M.; Torres, E.; Puhl, L.; Torres, B.; Barreto, D.; Heredia, B.N.; Vaca-Lucero, A.; Diaz-Ambrona, C.G.H. Evaluation of sustainability in strawberry crops production under greenhouse and open-field systems in the Andes. Int. J. Agric. Sustain. 2023, 21, 2255449. [Google Scholar] [CrossRef]

- Chen, C.-H.; Wu, Y.-C.; Xu, J.-W. Vertical Smart Greenhouse Planting System. Sens. Mater. 2025, 37, 1139–1151. [Google Scholar] [CrossRef]

- Rasool, G.; Guo, X.; Wang, Z.; Hassan, M.; Aleem, M.; Javed, Q.; Chen, S. Effect of Buried Straw Layer Coupled with Fertigation on Florescence and Yield Parameters of Chinese Cabbage Under Greenhouse Environment. J. Soil Sci. Plant Nutr. 2020, 20, 598–609. [Google Scholar] [CrossRef]

- Ullah, I.; Mao, H.; Rasool, G.; Gao, H.; Javed, Q.; Sarwar, A.; Khan, M.I. Effect of deficit irrigation and reduced N fertilization on plant growth, root morphology and water use efficiency of tomato grown in soilless culture. Agronomy 2021, 11, 228. [Google Scholar] [CrossRef]

- Cepeda, P.; Ponce, P.; Molina, A.; Lugo, E. Towards Sustainability of Protected Agriculture: Automatic Control and Structural Technologies Integration of an Intelligent Greenhouse. IFAC Proc. Vol. 2013, 46, 366–371. [Google Scholar] [CrossRef]

- Shabbir, A.; Mao, H.; Ullah, I.; Buttar, N.A.; Ajmal, M.; Solangi, K.A. Improving water use efficiency by optimizing the root distribution patterns under varying drip emitter density and drought stress for cherry tomato. Agronomy 2020, 11, 3. [Google Scholar] [CrossRef]

- Sarr, A.; Soro, Y.M.; Tossa, A.K.; Diop, L. Agrivoltaic, a synergistic co-location of agricultural and energy production in perpetual mutation: A comprehensive review. Processes 2023, 11, 948. [Google Scholar] [CrossRef]

- Wu, H.; Li, X.; Lu, H.; Tong, L.; Kang, S. Crop acreage planning for economy- resource- efficiency coordination: Grey information entropy based uncertain model. Agric. Water Manag. 2023, 9, 108557. [Google Scholar] [CrossRef]

- Rajak, R.K.; Pawar, A.; Pendke, M.; Shinde, P.; Rathod, S.; Devare, A.J. Crop recommendation system to maximize crop yield using machine learning technique. Int. Res. J. Eng. Technol. (IRJET) 2017, 4, 950–953. [Google Scholar]

- Rajeswari, S.; Suthendran, K. C5.0: Advanced Decision Tree (ADT) classification model for agricultural data analysis on cloud. Comput. Electron. Agric. 2019, 156, 530–539. [Google Scholar] [CrossRef]

- Chouhan, S.; Singh, D.; Singh, A. An Improved Feature Selection and Classification using Decision Tree for Crop Datasets. Int. J. Comput. Appl. 2016, 142, 5–8. [Google Scholar] [CrossRef]

- Liang, Z.; Li, Y.; Xu, L.; Zhao, Z. Sensor for monitoring rice grain sieve losses in combine harvesters. Biosyst Eng. 2016, 147, 51–66. [Google Scholar] [CrossRef]

- Zhao, Y.; Gong, L.; Huang, Y.; Liu, C. A review of key techniques of vision-based control for harvesting robot. Comput. Electron. Agric. 2016, 127, 311–323. [Google Scholar] [CrossRef]

- Kim, H.; Lee, J. A study on the possibility of implementing a real-time stereoscopic 3D rendering TV system. Displays 2015, 40, 24–34. [Google Scholar] [CrossRef]

- Azizi, A.; Abbaspour-Gilandeh, Y.; Mesri-Gundoshmian, T.; Farooque, A.A.; Afzaal, H. Estimation of soil surface roughness using stereo vision approach. Sensors 2021, 21, 4386. [Google Scholar] [CrossRef]

- Ravikumar, Y.; Ponpandian, L.N.; Zhang, G.; Yun, J.; Qi, X. Harnessing l-arabinose isomerase for biological production of d-tagatose: Recent advances and its applications. Trends Food Sci. Technol. 2021, 107, 16–30. [Google Scholar] [CrossRef]

- Adade, S.Y.-S.S.; Lin, H.; Johnson, N.A.N.; Nunekpeku, X.; Aheto, J.H.; Ekumah, J.-N.; Kwadzokpui, B.A.; Teye, E.; Ahmad, W.; Chen, Q. Advanced food contaminant detection through multi-source data fusion: Strategies, applications, and future perspectives. Trends Food Sci. Technol. 2025, 156, 104851. [Google Scholar] [CrossRef]

- Ismail, A.; Naeem, I.; Gong, Y.Y.; Routledge, M.N.; Akhtar, S.; Riaz, M.; Ramalho, L.N.Z.; de Oliveira, C.A.F.; Ismail, Z. Early life exposure to dietary aflatoxins, health impact and control perspectives: A review. Trends Food Sci. Technol. 2021, 112, 212–224. [Google Scholar] [CrossRef]

- Khan, I. Impacts of energy decentralization viewed through the lens of the energy cultures framework: Solar home systems in the developing economies. Renew. Sustain. Energy Rev. 2020, 119, 109576. [Google Scholar] [CrossRef]

- Hu, D.; Sun, T.; Yao, L.; Yang, Z.; Wang, A.; Ying, Y. Monte Carlo: A flexible and accurate technique for modeling light transport in food and agricultural products. Trends Food Sci. Technol. 2020, 102, 280–290. [Google Scholar] [CrossRef]

- Ravikumar, Y.; Razack, S.A.; Ponpandian, L.N.; Zhang, G.; Yun, J.; Huang, J.; Lee, D.; Li, X.; Dou, Y.; Qi, X. Microbial hosts for production of D-arabitol: Current state-of-art and future prospects. Trends Food Sci. Technol. 2022, 120, 100–110. [Google Scholar] [CrossRef]

- Guo, Z.; Barimah, A.O.; Shujat, A.; Zhang, Z.; Ouyang, Q.; Shi, J.; El-Seedi, H.R.; Zou, X.; Chen, Q. Simultaneous quantification of active constituents and antioxidant capability of green tea using NIR spectroscopy coupled with swarm intelligence algorithm. LWT 2020, 129, 109510. [Google Scholar] [CrossRef]

- Dash, P.B.; Naik, B.; Nayak, J.; Vimal, S. Socio-economic factor analysis for sustainable and smart precision agriculture: An ensemble learning approach. Comput. Commun. 2022, 182, 72–87. [Google Scholar] [CrossRef]

- Ouafiq, E.M.; Saadane, R.; Chehri, A.; Jeon, S. AI-based modeling and data-driven evaluation for smart farming-oriented big data architecture using IoT with energy harvesting capabilities. Sustain. Energy Technol. Assess. 2022, 52, 102093. [Google Scholar] [CrossRef]

- Otero, P.; Carpena, M.; Garcia-Oliveira, P.; Echave, J.; Soria-Lopez, A.; Garcia-Perez, P.; Fraga-Corral, M.; Cao, H.; Nie, S.; Xiao, J.; et al. Seaweed polysaccharides: Emerging extraction technologies, chemical modifications and bioactive properties. Crit. Rev. Food Sci. Nutr. 2023, 63, 1901–1929. [Google Scholar] [CrossRef]

- Wang, M.Z.; Ding, L.Y.; Wang, C.; Chen, L.M.; Loor, J.J.; Wang, H.R. Short communication: Arginase inhibition reduces the synthesis of casein in bovine mammary epithelial cells. J. Dairy Sci. 2017, 100, 4128–4133. [Google Scholar] [CrossRef]

- Liang, Z.; Li, Y.; De Baerdemaeker, J.; Xu, L.; Saeys, W. Development and testing of a multi-duct cleaning device for tangential-longitudinal flow rice combine harvesters. Biosyst Eng. 2019, 182, 95–106. [Google Scholar] [CrossRef]

- Ullah, H.; De Filippis, A.; Baldi, A.; Dacrema, M.; Esposito, C.; Garzarella, E.U.; Santarcangelo, C.; Tantipongpiradet, A.; Daglia, M. Beneficial effects of plant extracts and bioactive food components in childhood supplementation. Nutrients 2021, 13, 3157. [Google Scholar] [CrossRef]

- Guan, X.; Shi, L.; Yang, W.; Ge, H.; Wei, X.; Ding, Y. Multi-Feature Fusion Recognition and Localization Method for Unmanned Harvesting of Aquatic Vegetables. Agriculture 2024, 14, 971. [Google Scholar] [CrossRef]

- Möller, J. Computer vision—A versatile technology in automation of agricultural machinery. J. Agric. Eng. 2010, 47, 28–36. [Google Scholar]

- Zhao, S.; Adade, S.Y.S.S.; Wang, Z.; Jiao, T.; Ouyang, Q.; Li, H.; Chen, Q. Deep learning and feature reconstruction assisted vis-NIR calibration method for on-line monitoring of key growth indicators during kombucha production. Food Chem. 2025, 463, 141411. [Google Scholar] [CrossRef]

- Aby, G.R.; Issa, S.F. Safety of automated agricultural machineries: A systematic literature review. Safety 2023, 9, 13. [Google Scholar] [CrossRef]

- Hossain, M.S.; Rahman, M.; Rahman, A.; Kabir, M.; Mridha, M.F.; Huang, J.; Shin, J. Automatic navigation and self-driving technology in agricultural machinery: A state-of-the-art systematic review. IEEE Access 2025, 13, 94370–94401. [Google Scholar] [CrossRef]

- Mentsiev, A.U.; Isaev, A.R.; Supaeva, K.S.; Yunaeva, S.M.; Khatuev, U.A. Advancement of mechanical automation in the agriculture sector and overview of IoT. J. Phys. Conf. Ser. 2019, 1399, 044042. [Google Scholar] [CrossRef]

- Ding, C.; Wang, L.; Chen, X.; Yang, H.; Huang, L.; Song, X. A Blockchain-Based Wide-Area Agricultural Machinery Resource Sched-uling System. Appl. Eng. Agric. 2023, 39, 1–12. [Google Scholar] [CrossRef]

- Xue, Y.; Jiang, H. Monitoring of chlorpyrifos residues in corn oil based on Raman spectral deep-learning model. Foods 2023, 12, 2402. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Gao, Z.; Zhang, Y. Real-time detection and location of potted flowers based on a ZED camera and a YOLO V4-tiny deep learning algorithm. Horticulturae 2021, 8, 21. [Google Scholar] [CrossRef]

- Baharudin, M.E.; Zakaria, M.Z.; Nor, A.M.; Saad, M.S.; Hamid, R.A.; Mustafa, A.F.; Rahman, A.S.A. Automation of agricultural machinery: Development and validation of a portable automation module for oil palm plantation machinery. J. Appl. Res. Technol. 2024, 22, 698–705. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, L.; Xu, B.; Husnain, N.; Wang, Q. Overview of Agricultural Machinery Automation Technology for Sustainable Agriculture. Agronomy 2025, 15, 1471. https://doi.org/10.3390/agronomy15061471

Jiang L, Xu B, Husnain N, Wang Q. Overview of Agricultural Machinery Automation Technology for Sustainable Agriculture. Agronomy. 2025; 15(6):1471. https://doi.org/10.3390/agronomy15061471

Chicago/Turabian StyleJiang, Li, Boyan Xu, Naveed Husnain, and Qi Wang. 2025. "Overview of Agricultural Machinery Automation Technology for Sustainable Agriculture" Agronomy 15, no. 6: 1471. https://doi.org/10.3390/agronomy15061471

APA StyleJiang, L., Xu, B., Husnain, N., & Wang, Q. (2025). Overview of Agricultural Machinery Automation Technology for Sustainable Agriculture. Agronomy, 15(6), 1471. https://doi.org/10.3390/agronomy15061471