Abstract

Biodegradable mulch films not only provide similar field benefits to conventional mulch films but also degrade naturally, rendering them an effective alternative to traditional polyethylene mulch films for mitigating “white pollution”. However, recent studies have focused on the material selection and soil ecological impacts of biodegradable mulch films, while their effects on soil water temperature regulation and root architecture in drip-irrigated rice cultivation remain unclear. To address this research gap, in this study, various treatments including no mulch (NM), conventional plastic mulch (PM), and four types of biodegradable mulch films (BM-W1, BM-B1, BM-B2, and BM-B3) were established, and their effects on the soil hydrothermal flux, root architecture, biomass accumulation, and resource use efficiency of drip-irrigated rice were analyzed at different growth stages. The results indicated the following: (1) Compared with the NM treatment, film mulching increased the soil hydrothermal fluxes and water retention capacity, thereby promoting root growth and biomass accumulation, ultimately increasing the effective panicle number and grain yield. (2) Among the biodegradable film treatments, BM-B3 (with a degradation period of 105 days) maintained relatively higher soil temperature for a longer duration, which increased surface root distribution in the mid-to-late growth stages, further improving fine root growth and biomass accumulation, consequently enhancing both yield and water use efficiency. In contrast, BM-B1 and BM-B2 exhibited excessively rapid degradation rates, leading to significant fluctuations in soil moisture and temperature, thereby negatively affecting water supply and nutrient uptake and ultimately restricting root growth and development. (3) The entropy weight (EW) technique for order of preference by similarity to ideal solution (TOPSIS) model results revealed that although the PM treatment was more advantageous in terms of soil temperature, root dry weight, and soil moisture content, BM-B3 provided a slightly higher yield than the PM treatment did and offered the advantage of biodegradability, making it a preferred alternative to conventional mulch film. In summary, this study revealed the mechanism by which biodegradable mulch films enhanced biomass accumulation and yield formation in drip-irrigated rice production by optimizing soil hydrothermal dynamics and root architecture, thereby exploring their potential as replacements for conventional mulch films. These findings provide a theoretical basis for the efficient and sustainable production of drip-irrigated rice in arid regions.

1. Introduction

Rice (Oryza sativa L.) is an important food crop worldwide that is directly related to the food security of billions of people, and its demand continues to increase [1]. Per one billion people, an additional estimated 100 million tons of rice are produced each year to meet the food demand of the global population [2]. Traditional rice cultivation depends on water-consuming flood irrigation, which is unsustainable in the arid inland regions of northwestern China [3,4]. Therefore, the combination of film mulching and drip irrigation technology and the development of film-mulched cultivation techniques, e.g., drip irrigation under mulch film, have become the main methods for rice cultivation in this region [5]. Statistics indicate that drip irrigation of rice under mulch film can reduce water consumption by 60%, decrease the fertilizer input by 20%, and increase the fertilizer use efficiency by more than 10%, offering significant advantages in alleviating agricultural water pressure and increasing the resource use efficiency [6,7]. However, the polyethylene (PE) films used in traditional film-mulched drip irrigation cultivation are difficult to recycle and reuse and do not degrade naturally in the field [8]. Film has accumulated in oasis farmlands in northwest China for many years, reaching a residual amount of 2 × 106 tons and resulting in destruction of the soil structure, obstruction of crop growth, aggravation of the “white pollution” problem, and occurrence of serious threats to the sustainability of agroecology [9,10].

As an environmentally friendly agricultural material, biodegradable mulch film exhibits the advantages of increasing the temperature, preserving moisture, and degrading naturally, which can reduce field residual pollution while enhancing the soil environment and crop growth [11]. Research has shown that the use of biodegradable mulch film as ground cover can increase the temperature in the 5–25 cm soil layer and reduce water consumption by 30.7–36.8% at the cotton seedling stage [12]. Jia et al. [13] and Li et al. [14] reported that the soil temperature and moisture content under poly(butylene adipate-co-terephthalate) (PBAT)/ethylene-butylene-propylene copolymer (EBP) mulch film were 1.5% and 9.53% higher, respectively, than those in bare land. Chen et al. [15] indicated that soil moisture evaporation under biodegradable mulch film is 30.5% greater than that under traditional plastic mulch film. With respect to root growth, biodegradable mulch film can affect the root architecture and promote root development by optimizing the soil moisture distribution [16]. Mu et al. [17] demonstrated that compared with the use of conventional mulch film, the use of biodegradable mulch film significantly increases root growth. Gu et al. [18] revealed that the use of biodegradable mulch film is beneficial for rapeseed root growth, with the lateral root mass density in the 20–30 cm soil layer at the maturity stage being 18–26 g/m3 greater than that under conventional mulch. Zhou et al. [19] reported that in the 0–100 cm soil layer under polylactic acid (PLA)/starch (50%/30%) biodegradable mulch film, the root length density (RLD) was 16.92% greater than that in nonmulched soil. Zhang et al. [20] indicated that compared with the use of paper mulch film, the use of traditional plastic mulch film resulted in a 31.1% reduction in the root biomass. Moreover, many conclusions have been obtained concerning the promoting effects of biodegradable mulch film on crop growth and yield formation [21,22]. Therefore, clarifying the mechanism underlying the effects of biodegradable mulch film on the soil environment, root architecture, and crop growth is crucial for in-depth investigations of its effectiveness and adaptability under drip irrigation in arid regions.

The application effects of biodegradable mulch film, as a new type of agricultural production material, are influenced by various environmental and management factors, necessitating systematic and comprehensive evaluations [23]. Traditional evaluation methods often focus on single indicators such as the yield, making it difficult to fully reveal multiple mechanisms of action [24]. In recent years, the application of evaluation tools such as the entropy weight (EW) technique for order of preference by similarity to ideal solution (TOPSIS) method in agricultural research has provided notable support for comprehensively analyzing the effects of different mulching treatments [25,26]. The TOPSIS method can be used to quantify and rank the comprehensive benefits of various treatments, providing a basis for systematic decision-making [27]. Therefore, in this study, on the basis of field trials, the TOPSIS evaluation method was employed to investigate the application effects of biodegradable mulch film in drip-irrigated rice production, with a focus on the mechanisms underlying its effects on the soil hydrothermal flux, root architecture, biomass accumulation, and yield. The aims of this study were to provide a systematic basis for the popularization and application of biodegradable mulch films and offer theoretical support for sustainable agricultural development.

2. Materials and Methods

2.1. Test Area

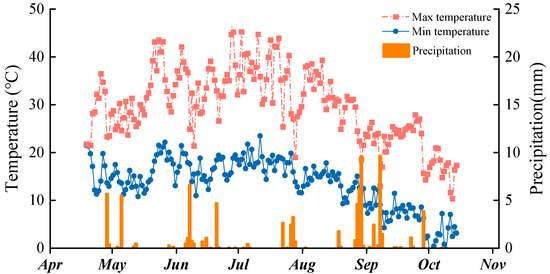

The experiment was conducted during the 2023 rice growing season (May–October) in the experimental field of the College of Agriculture, Shihezi University (44°17′ N, 86°03′ E; 461 m above sea level). The tested soil was irrigated cultivated gray desert soil (calcaric fluvisol), with a pH value of 8.27 in the 0–20 cm soil layer, an organic matter content of 14.53 g·kg−1, a total nitrogen content of 0.46 g·kg−1, an available phosphorus content of 34 mg·kg−1, and an available potassium content of 198 mg·kg−1. Meteorological data (Figure 1) indicated that rainfall was concentrated in early May, mid-June, and early September, and the temperature began to decrease significantly from middle to late September.

Figure 1.

Daily maximum and minimum temperatures and rainfall in the experimental area during the rice growth period.

2.2. Experimental Design

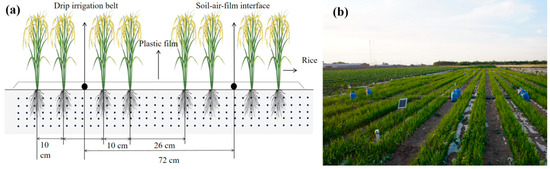

A randomized block design was adopted for this experiment. The tested rice was the high-yield and drought-resistant cultivar T-43. Six treatments were established: no mulch (NM), PE mulch film (PM), Xinjiang Lanshan Tunhe biodegradable mulch film (BM-W1, with a degradation period of 90 days), and Shanghai Hongrui biodegradable mulch film (BM-B1, with a degradation period of 60 days; BM-B2, with a degradation period of 80 days; and BM-B3, with a degradation period of 105 days). Each treatment was replicated three times, and the area of each replicate plot was 60 m2. Sowing occurred on 1 May, and plants were harvested on 30 September. Mechanized hole sowing was employed for direct rice seeding, with pipe laying, mulching, seeding, and soil covering steps completed in one operation. The film width was 1.45 m, with one film covering two drip irrigation pipes and eight rows. The sowing width was 1.65 m, the plant spacing was 10 cm, and an embedded patch-type drip irrigation belt was adopted with a dripper spacing of 30 cm and a dripper flow rate of 2.1 L·h−1. The plant row spacing configuration is shown in Figure 2. The sowing depth was 1.5–2.0 cm, and the covering soil thickness was 1.0–1.5 cm. The used fertilizers were pure nitrogen at 270 kg·ha−1 (urea, N 46%), monoammonium phosphate at 150 kg·ha−1 (P2O5, 52.1%), and potassium sulfate at 135 kg·ha−1 (K2O, 34.6%), all of which were applied via integrated water–fertilizer drip irrigation. The irrigation and nitrogen application rates over the whole growth period are listed in Table 1. The management of diseases, insects, weeds, and pests was consistent with field production practices.

Figure 2.

Schematic illustration of the drip irrigation rice cultivation method. Note: (a): Schematic diagram of field planting. (b): Field actual view photo.

Table 1.

Nitrogen and irrigation application rates for drip irrigation rice.

2.3. Measurement Indicators

2.3.1. Soil Moisture and Temperature

The measurements were conducted using Insentek’s Soil Moisture and Temperature Profile Monitoring System (IST. HRG C-110S). The manufacturer was Dongfang Zhigan (Zhejiang) Technology Co., Ltd. (website, https://www.insentek.com/en/product/smart-moisture.html (accessed on 23 May 2025); address, No. 6 Xinglinwan Road, Cixi, China).

The device was powered by solar panels through the device. This system integrated capacitive soil moisture sensors (range, dry to saturated soil; precision, ±4%) and high-precision temperature sensors (range, −20–60 °C; precision, ±0.5 °C), connected to a data logger with wireless data transmission capabilities. The system automatically recorded the soil temperature and moisture at 10 min intervals across multiple depths (0–100 cm). To ensure accuracy, we manually validated the sensor readings during the first 7 days after installation using gravimetric soil moisture measurements (oven-drying method) and calibrated thermometers.

2.3.2. Root Morphological Characteristics

During the tillering, jointing, heading, and maturity stages of rice, root samples were collected using the root drill method. Specifically, four uniformly growing rice plants were selected as the sampling unit. A cylindrical root drill with an inner diameter of 10 cm and a height of 10 cm was vertically inserted into the geometric center (intersection of the diagonals) of the four plants. Root samples were collected from three soil layers: 0–10 cm, 10–20 cm, and 20–30 cm. The samples were carefully washed with water to remove adhering soil particles while maintaining root integrity and then immediately stored at −4 °C for subsequent analysis. Each treatment was replicated three times at each stage to ensure data accuracy and reliability.

In the laboratory, the roots were scanned at a 300 dpi resolution using an Epson Perfection V800 scanner (Suwa Inc.; Nagano Prefecture, Japan) and dried in an oven at a temperature of 85 °C to a constant weight for dry mass determination. Root morphological analysis was performed using WinRHIZO Pro 2017a software (Regent Instruments Inc., Quebec, QC, Canada), with roots categorized by diameter: >0.8 mm, 0.4–0.8 mm, and ≤0.4 mm [28].

2.3.3. Measurement of Dry Matter Accumulation

At the tillering, jointing, heading, and maturity stages, three rice plants were selected and divided into three parts (stem sheaths, leaves, and panicles), which were then placed in envelope bags, inactivated at 105 °C for 30 min, dried at 80 °C to a constant weight, and weighed using a 1/1000 electronic balance.

2.3.4. Rice Nitrogen and Water Use Efficiency

The dry biomass samples of each treatment at maturity stage were ground and passed through a 0.5 mm sieve. The nitrogen content in the rice plants was measured using an FOSS-8400 automatic Kjeldahl apparatus (FOSS A/S; Hillerød, Denmark) with the semi-micro Kjeldahl method [29]. Then the nitrogen content was multiplied by their dry weight to calculate NMS (kg ha−1), which was then used to calculate nitrogen use efficiency. Each treatment was replicated three times.

Nitrogen use efficiency (NUE, kg·kg−1), evapotranspiration (ET, m3·ha−1), and water use efficiency (WUE, kg·m−3) were calculated for each treatment [30], as follows:

where Y denotes the yield (kg·ha−1), and NMS denotes the total nitrogen accumulation in the whole plant at maturity stage (kg·ha−1). Moreover, ET denotes the total evapotranspiration during the entire growing period (m3·ha−1), P0 denotes the effective precipitation during the entire growing period (mm); TP denotes the total precipitation (mm); i denotes the number of soil layers; γi is the bulk density of the i-th soil layer (g·cm−3); Hi is the thickness of the i-th soil layer (mm); θi1 and θi2 are the initial and final moisture contents, respectively, in the i-th soil layer; I is the irrigation amount (mm·ha−1); and K is the groundwater recharge amount (mm) [31].

2.4. Data Analysis

All the experimental data were statistically analyzed in R software (version 4.3.3, R Core Team, 2024). Duncan’s multiple comparisons analysis was performed using the agricolae package, and plots were generated using the “ggplot2” and “ggpubr” packages along with Origin 2023b (OriginLab, Northampton, MA, USA). The results were expressed as means ± standard errors, with significance achieved at p < 0.05.

Comprehensive Evaluation Analysis via on Entropy Weight–TOPSIS Method

- (1)

- Data Standardization

On the basis of the analysis results, an evaluation matrix was established for 11 indicators, including the soil temperature, moisture content, and yield, under each treatment, and the data were standardized. The standardized evaluation matrix can be expressed as follows:

where Zij denotes the standardized evaluation matrix, and Yij denotes the standardized data of the j-th indicator in the i-th processing step, with i = 1, 2, …, m and j = 1, 2, …, n.

- (2)

- Calculation of Entropy Weights

After the standardized evaluation matrix was established, the normalized probability of each indicator under the different treatments was calculated. Moreover, information entropy and EW values of each indicator were calculated. The related calculation equations are as follows:

where Pij, ej, and wj denote the normalized probability, information entropy, and EW, respectively; Yij denotes the standardized data of the i-th indicator in the j-th processing step; and N denotes the j-th indicator in the standardized evaluation matrix.

- (3)

- Calculation of the Weighted Normalization Matrix

After the calculation of indicator weights, the weights wj were combined with the matrix Zij for weighting. The weighted normalization matrix can be obtained as follows:

- (4)

- Calculation of the Positive Ideal Solution, Negative Ideal Solution, and Comprehensive Score

The positive ideal solution (Cj+) and negative ideal solution (Cj−) of each indicator in the weighted normalization matrix were obtained, the distance (Si−) between each treatment and the positive ideal solution (Si+) and negative ideal solution was calculated, and the proximity (Di) between the i-th treatment and the ideal solution was determined.

3. Results

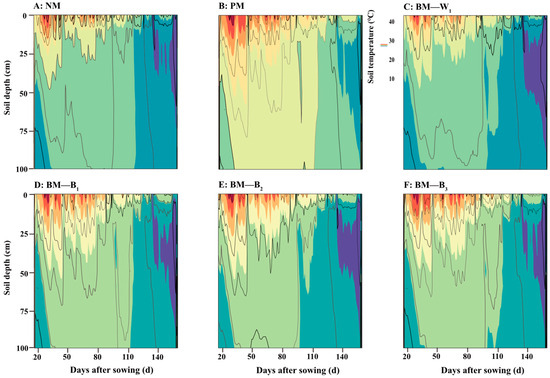

3.1. Effects of Biodegradable Mulch Film on the Soil Temperature

As shown in Figure 3 and Figure S1, the soil temperature under both the mulching and nonmulching treatments decreased significantly with increasing soil depth, and the temperature fluctuations in the deeper soil layers gradually decreased. Compared with the NM treatment, all mulching treatments could increase the surface soil temperature, especially in the middle and late growth stages of rice. Among the plastic mulching treatments, the surface soil temperature under the PM treatment was higher than that under the BM-B1 and BM-B2 treatments in the early growth stage. The temperature change trends of the BM-B3 and BM-W1 treatments were basically consistent in the early growth stage, but the temperature in the 0–40 cm soil layer of BM-B3 was higher than that of BM-W1 in the late growth stage. The temperature change trends of the BM-B1 and BM-B2 treatments were consistent, but the temperature in the 20–40 cm soil layer of BM-B2 was higher than that of BM-B1. In addition, for the deep soil (60–100 cm), the change trends between the mulching and non-mulching treatments were basically consistent during the rice growth period, but the PM and BM-B3 treatments were generally higher than other treatments.

Figure 3.

Effects of the different mulching treatments on the soil temperature in drip-irrigated rice cultivation. Note: The soil temperature values shown are daily averages calculated from measurements recorded at 10 min intervals. For drip-irrigated rice, the tillering, jointing, heading, and maturity stages generally occur at approximately the 45th, 65th, 90th, and 138th days after sowing.

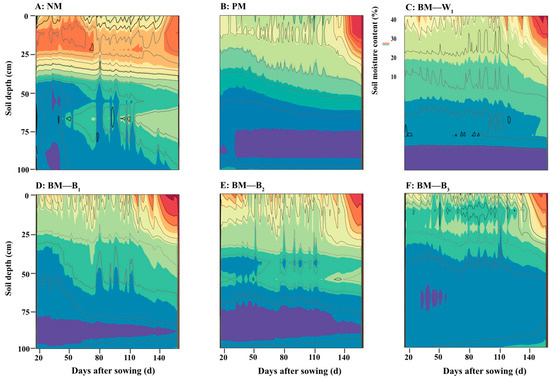

3.2. Effects of Biodegradable Mulch Film on Soil Moisture

As shown in Figure 4 and Figure S2, the soil moisture content under both the mulching and nonmulching treatments exhibited a stratified response with increasing depth, and the stability of the soil moisture content in the deep layer was significantly greater than that in the surface layer. Compared with the NM treatment, plastic film mulching can increase soil moisture content in the 10–40 cm soil layer, and this trend is more obvious in the early growth stage. The soil moisture content of the PM treatment in the 0–40 cm soil layer is higher than that of each degradable plastic film treatment, but the soil moisture content of the PM treatment shows the characteristic that the 20 cm soil layer is lower than the 10 cm soil layer, which is different from the trend of the degradable plastic film treatments. The change trends of soil moisture content of the BM-B3 and BM-W1 treatments are basically consistent in the early growth stage, but in the late growth stage, the moisture content of the 10 cm soil layer of BM-B3 was higher than that of BM-W1. In addition, for the 40–100 cm soil layer, the moisture content under the PM treatment was higher than that of other degradable plastic film treatments, but the moisture content of the BM-B3 treatment in the 40–60 cm soil layer was basically the same as that in the 60–100 cm soil layer, while that of other mulching treatments was generally lower than that in the 80–100 cm soil layer.

Figure 4.

Effects of the different mulching treatments on the soil moisture content in drip-irrigated rice cultivation. Note: In the figure, colors closer to red represent lower soil moisture content, while colors closer to blue represent higher soil moisture content. The soil moisture content values shown represent daily averages calculated from measurements recorded at 10 min intervals. For drip-irrigated rice, the tillering, jointing, heading, and maturity stages generally occur at approximately the 45th, 65th, 90th, and 138th days after sowing.

3.3. Effects of Biodegradable Mulch Film on the Rice Root Morphology

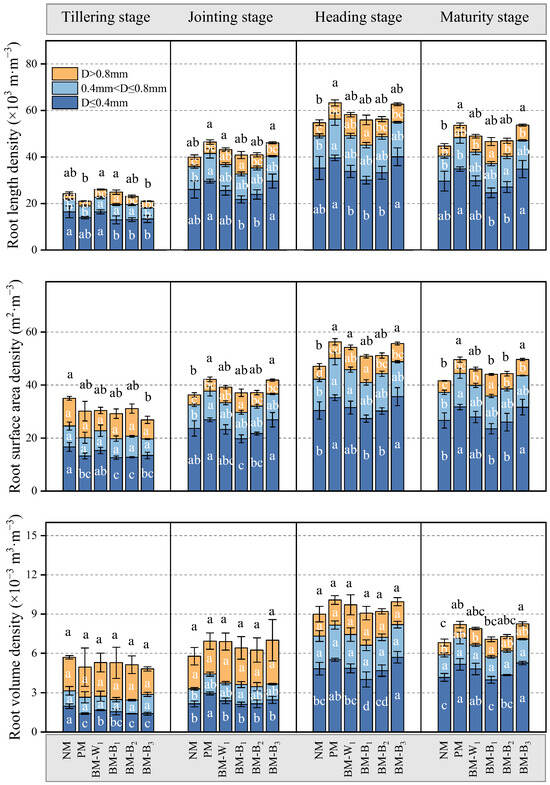

The effects of the different mulching treatments on the root morphology of drip-irrigated rice are shown in Figure 5. The root length density (RLD), root surface area density (SAD), and root volume density (RVD) under each treatment first increased but then decreased with increasing rice growth. The RLD, SAD, and RVD values within the D ≤ 0.4 mm range under each mulching and nonmulching treatment at the different growth stages ranged from 52.09 to 67.69%, 41.07 to 65.17%, and 27.22 to 63.75%, respectively. Among them, the SAD values under the PM treatment at the jointing, heading, and maturity stages, as well as the RLD at the jointing and heading stages, were significantly higher than those under the NM treatment (p < 0.05), but there was no significant difference compared with the biodegradable mulch treatment. Among the degradable mulches, there was no significant difference in the RLD, SAD, and RVD values of the BM-B2 treatment at each growth stage compared with those of the BM-B1. With the increase in the degradation time, the RLD value within the range of D ≤ 0.4 mm under the BM-W1 treatment at the tillering stage increased significantly by 5.79% and 5.58% compared with the BM-B1 and BM-B2, and the RVD values at the heading and maturity stages were also significantly higher than those under the BM-B1 treatment. The RLD, SAD, and RVD values at the heading and maturity stages within the range of D ≤ 0.4 mm under the BM-B3 treatment were significantly higher than those under the BM-B1 and BM-B2 treatments, and the RVD value within the range of D ≤ 0.4 mm at the heading stage was also 17.42% higher than that under the BM-W1 treatment.

Figure 5.

Effects of the different mulching treatments on the root morphology of drip-irrigated rice. Note: Black letters in the figure indicate differences among total values, while white letters indicate significant differences among treatments within the ranges of D > 0.8 mm, 0.4 mm < D ≤ 0.8 mm, and D ≤ 0.4 mm. Within the same period, treatments labeled with the same letter are not significantly different at the p < 0.05 level.

3.4. Effects of Biodegradable Mulch Film on the Vertical Distribution of Rice Roots

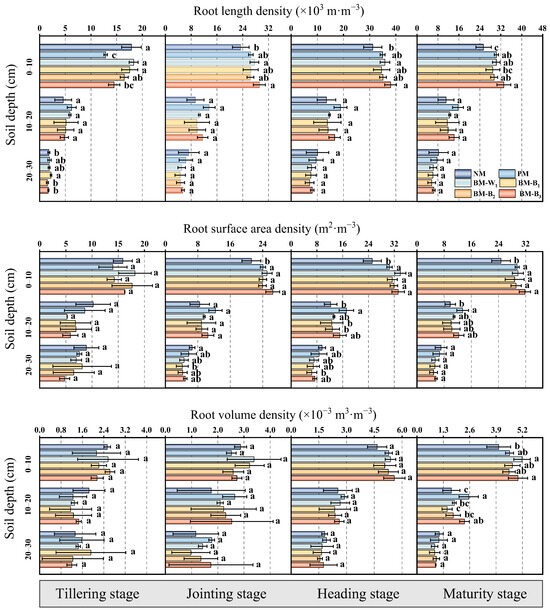

The effects of the different mulching treatments on the vertical distribution of the roots of drip-irrigated rice are shown in Figure 6. The RLD, SAD, and RVD in the 0–10 cm soil layer accounted for 55.13–73.68%, 45.36–65.83%, and 36.31–66.52%, respectively, of the values in the 0–30 cm soil layer at each growth stage. Among them, under the PM treatment, the RLD and SAD values in the 0–10 cm layer at maturity increased by 19.35% and 19.27%, respectively, compared with the NM treatment, and its SAD value in the 10–20 cm layer at heading stage was also significantly higher than that under the BM-B1 and BM-B2 treatments (p < 0.05). Among the degradable mulches, except for the RLD in the 20–30 cm layer at tillering stage and the RVD in the 10–20 cm layer at maturity stage, there were no significant differences in the RLD, SAD, and RVD values in the 10–20 cm and 20–30 cm layers at each growth stage. However, the RLD value in the 0–10 cm layer at maturity under the BM-B3 treatment was 14.49% higher than that under the BM-B2 treatment.

Figure 6.

Effects of the different mulching treatments on the vertical distribution of drip-irrigated rice roots. Note: Within the same period, treatments labeled with the same letter are not significantly different at the p < 0.05 level.

3.5. Effects of Biodegradable Mulch Film on Rice Biomass Accumulation

Table 2 provides a summary of the effects of the different mulching treatments on the accumulation of biomass in drip-irrigated rice. Compared with the NM treatment, the shoot dry weight (SDW) of all mulched treatments increased significantly by 10.60–36.31% at the heading stage, but during the tillering stage, the SDW of the BM-B1 and BM-B2 treatments was significantly lower than that of the NM treatment (p < 0.05). Among them, at the heading stage, the SDW of the PM, BM-W1, and BM-B3 treatments increased by 20.26%, 18.36%, and 23.25%, respectively, compared with the BM-B1 treatment, and the root dry weight (RDW) of the PM and BM-B3 treatments was also significantly higher than that of the BM-B1 and BM-B2 treatments. Moreover, at the maturity stage, the RDW of the PM and BM-B3 treatments increased by 18.18% and 19.09%, respectively, compared with the BM-B1 treatment.

Table 2.

Biomass accumulation of drip-irrigated rice under both the mulching and nonmulching treatments.

3.6. Effects of Biodegradable Mulch Film on the Rice Yield, Yield Components, and Nitrogen and Water Use Efficiency

The effects of different mulching treatments on yield, water use efficiency (WUE), and nitrogen use efficiency (NUE) of drip-irrigated rice are shown in Table 3. In terms of effective panicle number, both BM-B3 treatment (414.40 × 104 ha−1) and PM treatment (406.40 × 104 ha−1) showed significant increases of 13.50% and 11.31%, respectively, compared with NM treatment (p < 0.05). No significant differences were observed among treatments for spikelets per panicle (ranging 111.83–128.88) or grain weight (22.04–23.85 g). For grain yield, PM (10.33 t·ha−1), BM-W1 (9.64 t·ha−1), BM-B2 (9.55 t·ha−1), and BM-B3 (10.39 t·ha−1) treatments all demonstrated significantly higher values than NM treatment (7.04 t·ha−1). Specifically, PM and BM-B3 achieved yield increases of 46.73% and 47.59%, respectively, compared with NM. Regarding nitrogen use efficiency (NUE) and water use efficiency (WUE), all mulching treatments except BM-B1 (for NUE) showed significant improvements over NM. Furthermore, evapotranspiration (ET) was significantly reduced under all mulching treatments, with BM-W1 and BM-B3 exhibiting 10.51% and 8.43% lower ET, respectively, than NM.

Table 3.

Yield, yield components, NUE, and WUE of drip-irrigated rice under both the mulching and nonmulching treatments.

3.7. Comprehensive Evaluation of the Effects of the Different Mulching Treatments

3.7.1. Determination of Indicator Weights via the Entropy Weight Method

A comprehensive evaluation matrix was constructed on the basis of the data for 11 indicators, i.e., ST, ET, SW, RLD, SAD, RVD, RDW, SDW, WUE, NUE, and yield, under the different mulching treatments. After standardizing the matrix, the EW method was employed to calculate the proportion of each indicator, and entropy and weight values were then obtained. Table 4 provides the analysis results for the normalized probability, information entropy, and EW of each indicator. The results revealed that the ST exhibited the highest EW value (0.399), which was significantly greater than those of the other indicators, indicating that the soil temperature was the most critical factor influencing the mulching drip irrigation rice system. The EW value of the RDW (0.076) was greater than that of the SDW (0.038), indicating that the promotion effects of the mulching and nonmulching treatments on root growth were greater than those on the growth of aboveground parts. The EW values of the WUE (0.047) and NUE (0.039) were relatively low and lower than that of the yield (0.040), indicating that the impact of each treatment on the yield may depend more on the optimization of the soil water and heat environment rather than on simply increasing the resource utilization efficiency. In addition, the normalized probability of the ST was 0.000, with an information entropy value of 1.000, indicating that the information of this indicator was highly concentrated.

Table 4.

Normalized probability, information entropy, and entropy weight values for each indicator.

3.7.2. Ideal Solutions Under the Different Mulching Treatments

According to the entropy weight of each indicator in Table 4, the distance was calculated between each treatment and the positive (Si+) and negative (Si−) ideal solutions, and then the final ranking was obtained (Table 5). As shown in Table 5, the comprehensive ranking of the treatments was PM > BM-B3 > BM-W1 > BM-B2 > BM-B1 > NM. Among them, PM showed the best performance with a proximity closeness coefficient (Di) of 0.8494, confirming its comprehensive advantages in maintaining soil water and heat conditions and promoting rice growth. It is worth noting that the biodegradable film BM-B3 (Di = 0.7852) achieved 78.5% of the traditional film effect, demonstrating good potential for substitution. And NM performed the worst (Si+ = 0.4892), highlighting the superiority of mulching cultivation.

Table 5.

Comprehensive evaluation of the different mulching treatments for drip-irrigated rice.

4. Discussion and Conclusion

4.1. Effects of Biodegradable Mulch Film on the Soil Hydrothermal Flux and Root Architecture of Drip-Irrigated Rice

The soil temperature and moisture are key environmental variables in farmland habitats and play a central role in shaping material cycling and energy flow [32]. Studies have shown that mulching can suppress soil moisture loss and hinder root–soil–air heat exchange, thereby regulating the hydrothermal flux [33]. Thidar et al. [34] reported that film mulching can increase the soil moisture content by 0.60–11.10%, and Wang et al. [35] revealed that film mulching can increase the temperature of the tillage layer by 1.40–2.60 °C. In this study, compared with NM, film mulching increased soil moisture content in the 10–40 cm soil layer, and this trend was more evident in the early growth stage, which was consistent with previous research findings [34]. In particular, PM provided a significantly greater moisture content in the 0–10 cm and 30–100 cm soil layers than did the other treatments, while the moisture content in the 10–20 cm layer under PM was lower than that under BM-B3. Moreover, the soil temperature under the PM treatment was higher than that under the biodegradable mulch film treatments, indicating that PE mulch completely blocked water–air exchange, resulting in an increase in the surface soil temperature, whereas moisture accumulated in the 0–10 cm soil layer through condensation and reflux [11,36]. Compared with PE mulch film, biodegradable films regulated the soil hydrothermal flux differently on spatial and temporal scales because of their varying biodegradation properties. BM-W1 provided a greater soil moisture content in the 70–100 cm layer than did BM-B1 and BM-B2. The temperature difference between the 0 cm and 100 cm layers under BM-W1 was greater than that under the other biodegradable mulch film treatments, and it provided smaller fluctuations in the moisture content during the growth period, indicating its advantage in maintaining soil moisture stability but a smaller warming effect on deep soil. Under BM-B3, the soil temperature was higher than that under BM-B1, BM-B2, and BM-W1, and the soil moisture content in the 10–70 cm layer was higher than that under the other biodegradable mulch film treatments. At the maturity stage, the moisture content in the 40–100 cm soil layer was higher under BM-B3 than that under PM, and the moisture content was the highest in the 70–80 cm soil layer. This slow degradation strategy aligns with the growth cycle of drip-irrigated rice and enables the maintenance of a stable soil temperature, reduces evaporation loss, and promotes water infiltration to achieve an effective balance between moisture retention and water infiltration [11].

As the frontier organ that senses and responds to environmental heterogeneity, plant roots are precisely regulated in terms of their morphology, plasticity, and interactions within their physiological metabolic networks to maximize resource acquisition and adapt to the changing ecological environment [37]. Gu et al. [18] reported that the lateral root density of rapeseed in the 20–30 cm soil layer under biodegradable mulch film was 18–26 g·m−3 greater than that under PM. Zhou et al. [19] indicated that PLA/starch mulch film increased the RLD by 16.92% compared with that without mulching. The results of this study indicate that the SAD value of the NM treatment in the 0–10 cm soil layer at maturity was significantly lower than that of the mulching treatment, suggesting that higher soil evaporation under non-film mulching reduces the surface root surface area density in the late growth stage [38]. During the middle and late growth stages (heading stage), the SAD value of the PM in the 10–20 cm soil layer was higher than those of the BM-B1 and BM-B2. Additionally, the RVD value of the PM within the range of D ≤ 0.4 mm was higher than those of other treatments, suggesting that the complete coverage measure of PM can increase the contact area of plant roots in the 10–20 cm soil layer and promote the increase in the proportion of fine roots. For biodegradable plastic films, the RLD value of BM-W1 during the jointing stage was higher than those of the BM-B1 and BM-B2. From the vertical distribution perspective, it was mainly concentrated in the 0–10 cm layer, indicating that compared with the BM-B1 and BM-B2, BM-W1 was more conducive to promoting the growth of surface roots in the pre-middle growth stages [18]. The BM-B3 had significantly higher RLD in the 0–10 cm soil layer at maturity and RVD in the 10–20 cm soil layer than the BM-B1 treatment. Its RLD, SAD, and RVD within the range of D ≤ 0.4 mm were also higher than those of the BM-B1 and BM-B2. This further demonstrates that under its longer degradation strategy, the stable changes in soil moisture and temperature promote the increase in the length and volume of rice surface roots, which further enhances the number of fine roots and increases the potential for water and nutrient absorption [11].

4.2. Effects of Biodegradable Mulch Film on the Biomass Accumulation, Yield, and Resource Utilization of Drip-Irrigated Rice

Roots are the key organs through which plants absorb water and nutrients, directly affecting aboveground growth, yield formation, and use efficiency [39]. In this study, film mulching significantly increased the SDW of rice at the heading stage (10.60–36.31%), while the RDW of PM and BM-B3 treatments at maturity was also significantly higher than that of NM. Specifically, the SDW of PM at the heading stage was 20.26% higher than that of BM-B1, and its RDW was significantly higher than those of BM-B1 and BM-B2. However, SDW and RDW at the heading and maturity stages showed characteristics of being lower than those of BM-B3 (with no significant difference), indicating that the low air permeability of PE film mulching may limit its further accumulation [40]. Among biodegradable films, BM-B3 had significantly higher SDW at the heading stage than BM-B1, and its RDW was also significantly higher than those of BM-B1 and BM-B2. Additionally, its SDW and RDW at maturity were higher than those of other biodegradable film treatments (although there was no significant difference among groups). This suggests that a longer degradation period can provide a stable water and temperature environment for late-stage rice growth, promoting biomass accumulation [41]. The RDW of BM-W1 at the tillering stage was higher than that of other biodegradable film treatments, but its RDW at heading and maturity stages was lower than that of BM-B3, indicating that although it promoted early root growth, its rapid degradation in later stages led to soil water loss, which was insufficient to maintain root growth and aboveground biomass accumulation. Therefore, when using biodegradable films, selecting films with appropriate degradation rates to balance soil water–heat flux and increase biomass accumulation is crucial [11].

The crop yield and resource use efficiency are important indicators for evaluating the effects of mulching [42]. In this study, compared with NM, the BM-B3 and PM treatments significantly increased the effective panicle number by 13.50% and 11.31% and the yield by 46.73% and 47.59%, respectively. However, no significant differences were observed among treatments in spikelet per panicle, grain weight, or filled grain rate. This indicates that for drip-irrigated rice, film mulching improves soil hydrothermal conditions, thereby promoting tillering and panicle formation rather than influencing grain traits [43]. Among the mulching treatments, both PM and BM-B3 achieved yields exceeding 10 t·ha−1, while other biodegradable film treatments yielded between 9 and 10 t·ha−1. Given the absence of significant differences in the effective panicle number and spikelets per panicle, the yield advantage of BM-B3 and PM likely stemmed from their slow degradation characteristics, which regulated soil hydrothermal fluxes to create a microclimate similar to PE film, optimizing root architecture and dry matter accumulation, thereby enhancing yield. Additionally, all mulching treatments significantly improved WUE and NUE while reducing ET. Notably, BM-W1 and BM-B3 reduced ET by 10.51% and 8.43%, respectively. These results demonstrate that biodegradable films with an appropriate degradation rate (e.g., BM-B3) not only maintain high yield levels but also enhance resource use efficiency, providing a viable alternative to conventional PE mulch [24].

4.3. Comprehensive Assessment of the Impacts of Biodegradable Mulch Film

As an agricultural production material, biodegradable mulch films require comprehensive evaluation for their agricultural application. The TOPSIS model can be used to evaluate their application in the cultivation of crops such as maize and processing tomatoes [24,44]. In this study, the EW–TOPSIS method was employed to evaluate the following four aspects of cultivation under biodegradable mulch films: soil hydrothermal flux, roots, growth, and yield. The comprehensive ranking was as follows: PM > BM-B3 > BM-W1 > BM-B2 > BM-B1 > NM (Table 5). PE mulch film could completely block water and heat exchange at the root–soil–air interface, which was conducive to aboveground biomass accumulation. However, the excessively high soil temperature at the latter growth stage inhibited root growth, affecting the final yield formation. After degradation at the later growth stages under BM-B3, water and heat exchange at the root–soil–air interface increased, which promoted root growth and root architectural development, resulting in increased yield, WUE, and NUE levels. Although BM-W1 provided both water retention ability and biodegradability, it was still insufficient for soil hydrothermal regulation, thus affecting its biomass accumulation capacity. In contrast, BM-B1 and BM-B2 provided excessively fast degradation, resulting in prolonged soil exposure, affecting water storage and root growth, and in turn leading to lower comprehensive scores. In addition, the EW–TOPSIS model reduced the subjective bias through weight calculation [45]. The soil temperature, root dry mass, soil moisture content, and SAD exhibited the highest weights, whereas the NUE contributed less, indicating that biodegradable films regulated growth mainly by increasing the soil hydrothermal flux and optimizing the root morphology. This study confirmed that drip-irrigated rice requires a stable soil hydrothermal flux at the midgrowth stage, necessitating mulch films with extended degradation periods. However, the field degradation rate of biodegradable plastic films depends not only on the material properties but also on the soil–film interface contact, microbial activity, and spatiotemporal soil moisture distribution. Therefore, future research should aim to optimize the performance of plastic films through soil management practices to provide a reference for the sustainable development of agriculture [46].

Supplementary Materials

The following supporting information can be downloaded at https://www.mdpi.com/article/10.3390/agronomy15061292/s1, Figure S1. Effects of the different mulching treatments on the soil temperature in drip-irrigated rice cultivation. Figure S2. Effects of the different mulching treatments on the soil moisture content in drip-irrigated rice cultivation.

Author Contributions

Conceptualization, Z.S., G.W., Q.W. and Y.L.; methodology, G.W., Q.H., X.Z., Q.W. and Y.L.; software, Z.S.; validation, G.W., Q.H., L.Z., Q.W. and Y.L.; formal analysis, Z.S.; investigation, Z.S., Q.H., X.Z., Q.T. and L.Z.; resources, G.W., X.Z. and Q.T.; data curation, Z.S., Q.H., X.Z., Q.T. and L.Z.; writing—original draft, Z.S.; writing—review and editing, Z.S., G.W., Q.W. and Y.L.; visualization, Z.S.; supervision, G.W., Q.H., Q.W. and Y.L.; project administration, Z.S., G.W., Q.W. and Y.L.; funding acquisition, G.W., Q.W. and Y.L. All authors have read and agreed to the published version of the manuscript.

Funding

This study was supported by the National Natural Science Foundation of China (32360527 and 31460541).

Data Availability Statement

The original contributions presented in the study are included in the article; further inquiries can be directed to the corresponding authors.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Ishfaq, J.; Soomar, A.M.; Khalid, F.; Abbasi, Y. Assessing rice (Oryza sativa L.) quality: A comprehensive review of current techniques and future directions. J. Agric. Food Res. 2023, 14, 100843. [Google Scholar] [CrossRef]

- Xiong, D.L. Perspectives of improving rice photosynthesis for higher grain yield. Crop Environ. 2024, 3, 123–137. [Google Scholar] [CrossRef]

- Tang, Q.Y.; Ma, Y.D.; Zhao, L.; Song, Z.W.; Yin, Y.G.; Wang, G.D.; Li, Y.X. Effects of water and nitrogen management on root morphology, nitrogen metabolism enzymes, and yield of rice under drip irrigation. Agronomy 2023, 13, 1118. [Google Scholar] [CrossRef]

- Tuong, T.P.; Bouman, B.A.M.; Mortimer, M. More rice, less water: Integrated approaches for increasing water productivity in irrigated rice-based systems in Asia. Plant Prod. Sci. 2005, 8, 231–241. [Google Scholar] [CrossRef]

- Zhao, L.; Tang, Q.Y.; Song, Z.W.; Yin, Y.G.; Wang, G.D.; Li, Y.X. Increasing the yield of drip-irrigated rice by improving photosynthetic performance and enhancing nitrogen metabolism through optimizing water and nitrogen management. Front. Plant Sci. 2023, 14, 1075625. [Google Scholar] [CrossRef]

- Bai, R.X.; Chen, L.; Zhang, X.J.; Wei, G.H.; Wei, C.Z. Effect of salinity and soil temperature on the growth and physiology of drip-irrigated rice seedlings. Arch. Agron. Soil. Sci. 2016, 63, 513–524. [Google Scholar] [CrossRef]

- Zhang, X.J.; Liu, H.; Meng, C.R.; Zhang, Z.Y.; Wang, M.M.; Wei, C.Z. Ammonium alleviates iron deficiency of drip-irrigated rice seedlings in low soil temperature in calcareous soil. Acta Agric. Scand. B Soil. Plant Sci. 2019, 69, 411–421. [Google Scholar] [CrossRef]

- Othman, N.A.F.; Selambakkannu, S.; Seko, N. Biodegradable dual–layer polyhydroxyalkanoate (pha)/polycaprolactone (pcl) mulch film for agriculture: Preparation and characterization. Energy Nexus. 2022, 8, 100137. [Google Scholar] [CrossRef]

- Song, Z.W.; Zhao, L.; Bi, J.G.; Tang, Q.Y.; Wang, G.D.; Li, Y.X. Classification of Degradable Mulch Films and Their Promotional Effects and Limitations on Agricultural Production. Agriculture 2024, 14, 1235. [Google Scholar] [CrossRef]

- Yang, C.; Zhao, Y.; Long, B.B.; Wang, F.Y.; Li, F.Y.; Xie, D. Biodegradable mulch films improve yield of winter potatoes through effects on soil properties and nutrients. Ecotoxicol. Environ. Saf. 2023, 264, 115402. [Google Scholar] [CrossRef]

- Yin, M.H.; Li, Y.N.; Fang, H.; Chen, P.P. Biodegradable mulching film with an optimum degradation rate improves soil environment and enhances maize growth. Agric. Water Manag. 2019, 216, 127–137. [Google Scholar] [CrossRef]

- Zhao, J.T.; Ma, Y.Z.; Fan, Y.L.; Liu, J.M.; Li, Q.Q. Effects of biodegradable mulch on cotton yield and water use efficiency. J. Irrig. Drain. Eng. 2021, 39, 96–101. [Google Scholar] [CrossRef]

- Jia, H.; Wang, Z.H.; Zhang, J.Z.; Li, W.H.; Ren, Z.L.; Jia, Z.C.; Wang, Q. Effects of biodegradable mulch on soil water and heat conditions, yield and quality of processing tomatoes by drip irrigation. J. Arid. Land. 2020, 12, 819–836. [Google Scholar] [CrossRef]

- Li, Q.; Wang, Q.; Zhang, E.H.; Liu, Q.L. Response of biodegradable film water retention and wanning to the maize grain yields in Hexi irrigation area. Agric. Res. Arid. Areas. 2016, 34, 27–31+50. [Google Scholar] [CrossRef]

- Chen, N.; Li, X.Y.; Šimůnek, J.; Shi, H.B.; Ding, Z.J.; Peng, Z.Y. Evaluating the effects of biodegradable film mulching on soil water dynamics in a drip–irrigated field. Agric. Water Manag. 2019, 226, 105788. [Google Scholar] [CrossRef]

- Fang, H.; Li, Y.N.; Gu, X.B.; Chen, P.P.; Li, Y.P. Root characteristics, utilization of water and nitrogen, and yield of maize under biodegradable film mulching and nitrogen application. Agric. Water Manag. 2022, 262, 107392. [Google Scholar] [CrossRef]

- Mu, X.G.; Gao, H.; Li, M.H.; Zhao, X.R.; Guo, N.; Jin, L.; Li, J.S.; Ye, L. Effects of different types of plastic film mulching on soil quality, root growth, and yield. Environ. Sci. 2023, 44, 3439–3449. [Google Scholar] [CrossRef]

- Gu, X.B.; Li, Y.N.; Du, Y.D. Biodegradable film mulching improves soil temperature, moisture and seed yield of winter oilseed rape (Brassica napus L.). Soil. Till Res. 2017, 171, 42–50. [Google Scholar] [CrossRef]

- Zhou, C.M.; Li, Y.N.; Gu, X.B.; Yin, M.H.; Zhao, X. Effects of biodegradable film mulching planting patterns on soil nutrient and nitrogen use efficiency of summer maize. Trans. Chin. Soc. Agric. Mach. 2016, 47, 133–142+112. [Google Scholar] [CrossRef]

- Zhang, X.Y.; You, S.Y.; Tian, Y.Q.; Li, J.S. Comparison of plastic film, biodegradable paper and bio–based film mulching for summer tomato production: Soil properties, plant growth, fruit yield and fruit quality. Sci. Hortic. 2019, 249, 38–48. [Google Scholar] [CrossRef]

- Abduwaiti, A.; Liu, X.W.; Yan, C.R.; Xue, Y.H.; Jin, T.; Wu, H.Q.; He, P.C.; Bao, Z.; Liu, Q. Testing biodegradable films as alternatives to plastic-film mulching for enhancing the yield and economic benefits of processed tomato in Xinjiang Region. Sustainability 2021, 13, 3093. [Google Scholar] [CrossRef]

- Cozzolino, E.; Di, M.I.; Ottaiano, L.; Bilotto, M.; Petriccione, M.; Ferrara, E.; Mori, M.; Morra, L. Assessing yield and quality of Melon (Cucumis melo L.) improved by biodegradable mulching film. Plants 2023, 12, 219. [Google Scholar] [CrossRef]

- Yang, N.; Feng, L.S.; Li, K.Y.; Feng, C.; Sun, Z.X.; Liu, J.L. The degradable time evaluation of degradable polymer film in agriculture based on polyethylene film experiments. e-Polymers 2021, 21, 821–829. [Google Scholar] [CrossRef]

- Zhang, W.W.; Wang, W.S.; Zhang, Y.Z.; Wang, F.P.; Sun, S.J. Determining the optimal degradation rate of biodegradable films in a maize farmland based on the EWM-TOPSIS model. Agric. Water Manag. 2025, 309, 109359. [Google Scholar] [CrossRef]

- Zhong, Y.X.; Li, J.Z.; Xiong, H. Effect of deficit irrigation on soil CO2 and N2O emissions and winter wheat yield. J. Clean. Prod. 2021, 279, 123718. [Google Scholar] [CrossRef]

- Sun, T.; Li, G.; Ning, T.Y.; Zhang, Z.M.; Mi, Q.H.; Lal, R. Suitability of mulching with biodegradable film to moderate soil temperature and moisture and to increase photosynthesis and yield in peanut. Agric. Water Manag. 2018, 208, 214–223. [Google Scholar] [CrossRef]

- Zyoud, S.H.; Fuchs-Hanusch, D. A bibliometric-based survey on AHP and TOPSIS techniques. Expert. Syst. Appl. 2017, 78, 158–181. [Google Scholar] [CrossRef]

- Tang, Q.Y.; Wang, G.D.; Zhao, L.; Song, Z.W.; Li, Y.X. Response of yield, root traits and plasticity of nitrogen-efficient cultivars of drip-irrigated rice to a nitrogen environment. J. Integr. Agric. 2025, 24, 480–496. [Google Scholar] [CrossRef]

- Jia, Y.; Wang, J.; Qu, Z.; Zou, D.; Sha, H.; Liu, H.; Sun, J.; Zheng, H.; Wang, J.; Yang, L.; et al. Effects of low water temperature during reproductive growth on photosynthetic production and nitrogen accumulation in rice. Field Crops Res. 2019, 242, 107587. [Google Scholar] [CrossRef]

- Wang, Z.Q.; Zhang, W.Y.; Beebout, S.S.; Zhang, H.; Liu, L.J.; Yang, J.C.; Zhang, J.H. Grain yield, water and nitrogen use efficiencies of rice as influenced by irrigation regimes and their interaction with nitrogen rates. Field Crops Res. 2016, 193, 54–69. [Google Scholar] [CrossRef]

- Ministry of Water Resources of the People’s Republic of China. Irrigation Experiment Code of Practice; SL13-2004; China Water & Power Press: Beijing, China, 2005. [Google Scholar]

- Bradford, J.B.; Schlaepfer, D.R.; Lauenroth, W.K.; Yackulic, C.B.; Duniway, M.; Hall, S.; Jia, G.; Jamiyansharav, K.; Munson, S.M.; Wilson, S.D.; et al. Future soil moisture and temperature extremes imply expanding suitability for rainfed agriculture in temperate drylands. Sci. Rep. 2017, 7, 12923. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.H.; Ding, J.L.; Zhang, Y.H.; Wu, J.C.; Zhang, J.M.; Pan, X.Y.; Gao, C.M.; Wang, Y.; He, F. Effects of tillage and mulching measures on soil moisture and temperature, photosynthetic characteristics and yield of winter wheat. Agric. Water Manag. 2018, 201, 299–308. [Google Scholar] [CrossRef]

- Thidar, M.; Gong, D.Z.; Mei, X.R.; Gao, L.L.; Li, H.R.; Hao, W.P.; Gu, F.X. Mulching improved soil water, root distribution and yield of maize in the Loess Plateau of Northwest China. Agric. Water Manag. 2020, 241, 106340. [Google Scholar] [CrossRef]

- Wang, Y.J.; He, K.; Zhang, J.B.; Chang, H.Y. Environmental knowledge, risk attitude, and households’ willingness to accept compensation for the application of degradable agricultural mulch film: Evidence from rural China. Sci. Total Environ. 2020, 744, 140616. [Google Scholar] [CrossRef] [PubMed]

- Guo, B.; Yang, Z.X.; He, W.Q.; Liu, J.L. Application effectiveness and problems of biodegradable mulch. Chin. J. Agrometeorol. 2023, 44, 977–994. [Google Scholar] [CrossRef]

- Dao, J.C.; Xing, Y.J.; Chen, C.Y.; Chen, M.H.; Wang, Z.T.; Chen, Y.L. Changes in shoot and root adaptations of fibrous-root and taproot crops in response to different drought types: A meta-analysis. Agric. Water Manag. 2025, 309, 109320. [Google Scholar] [CrossRef]

- Zhang, W.; Li, S.Q.; Shen, Y.F.; Yue, S.C. Film mulching affects root growth and function in dryland maize-soybean intercropping. Field Crops Res. 2021, 271, 108240. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, J.H.; Yang, J.C. Improving nitrogen use efficiency of rice crop through an optimized root system and agronomic practices. Crop Environ. 2023, 2, 192–201. [Google Scholar] [CrossRef]

- Li, X.Y.; Cheng, X.Y.; Wu, J.L.; Cai, Z.H.; Wang, Z.K.; Zhou, J. Multi-omics reveals different impact patterns of conventional and biodegradable microplastics on the crop rhizosphere in a biofertilizer environment. J. Hazard. Mater. 2024, 467, 133709. [Google Scholar] [CrossRef]

- Li, G.; Long, H.Y.; Zhang, R.L.; Xu, A.G.; Niu, L. Stable soil water shapes the rhizosphere of Solanum lycopersicum L. and improves tomato fruit yield and quality. Sci. Hortic. 2025, 341, 114001. [Google Scholar] [CrossRef]

- Liao, S.; Deng, F.; Zhou, W.; Wang, L.; Li, W.; Hu, H.; Pu, S.L.; Li, S.X.; Chen, Y.; Tao, Y.F.; et al. Polypeptide urea increases rice yield and nitrogen use efficiency through root growth improvement. Field Crops Res. 2024, 313, 109415. [Google Scholar] [CrossRef]

- Li, X.Y.; Guo, Y.; Ding, Z.J.; Leng, X.; Tian, T.; Hu, Q. Influence of different film mulchings on soil temperature at different time scales and maize yield. Trans. Chin. Soc. Agric. Mach. 2018, 49, 247–256. [Google Scholar] [CrossRef]

- Sun, L.; Li, B.; Yao, M.Z.; Niu, D.S.; Gao, M.M.; Mao, L.Z.; Xu, Z.Y.; Wang, T.L.; Wang, J.K. Optimising water and nitrogen management for greenhouse tomatoes in Northeast China using EWM TOPSIS AISM model. Agric. Water Manag. 2023, 290, 108579. [Google Scholar] [CrossRef]

- He, P.R.; Yu, S.E.; Ding, J.H.; Ma, T.; Li, J.G.; Dai, Y.; Chen, K.W.; Peng, S.H.; Zeng, G.Q.; Guo, S.S. Multi-objective optimization of farmland water level and nitrogen fertilization management for winter wheat cultivation under waterlogging conditions based on TOPSIS-Entropy. Agric. Water Manag. 2024, 297, 108840. [Google Scholar] [CrossRef]

- Song, N.N.; Wang, B.; Liu, J.; Wang, F.L.; Wang, X.X.; Zong, H.Y. Is degradable plastic film alternative? Insights from crop productivity enhancement and soil environment improvement. Eur. J. Agron. 2023, 149, 126882. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).