Dynamic Modeling and Parameter Optimization of Potato Harvester Under Multi-Source Excitation

Abstract

1. Introduction

2. Materials and Methods

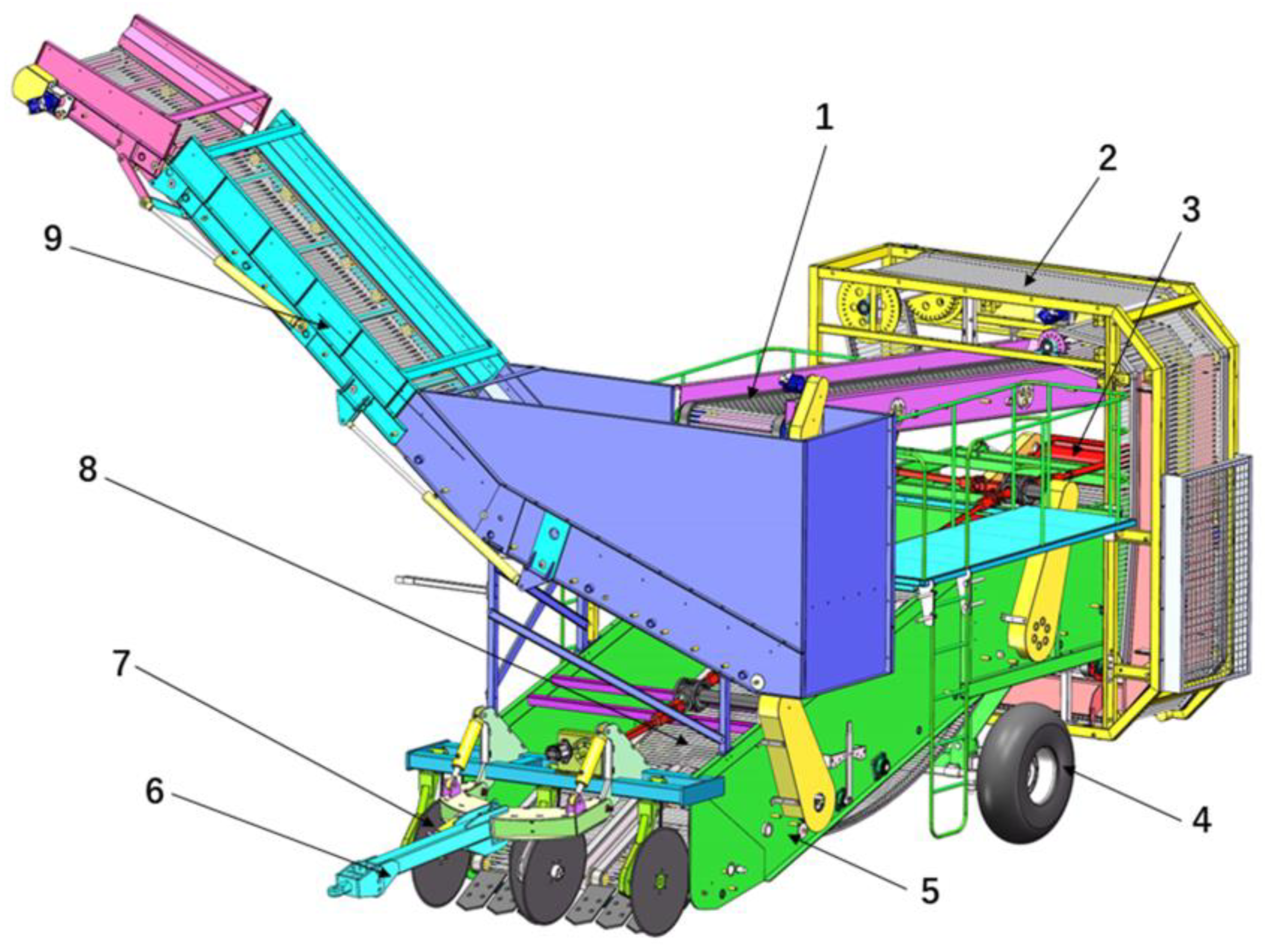

2.1. Potato Harvester Modeling

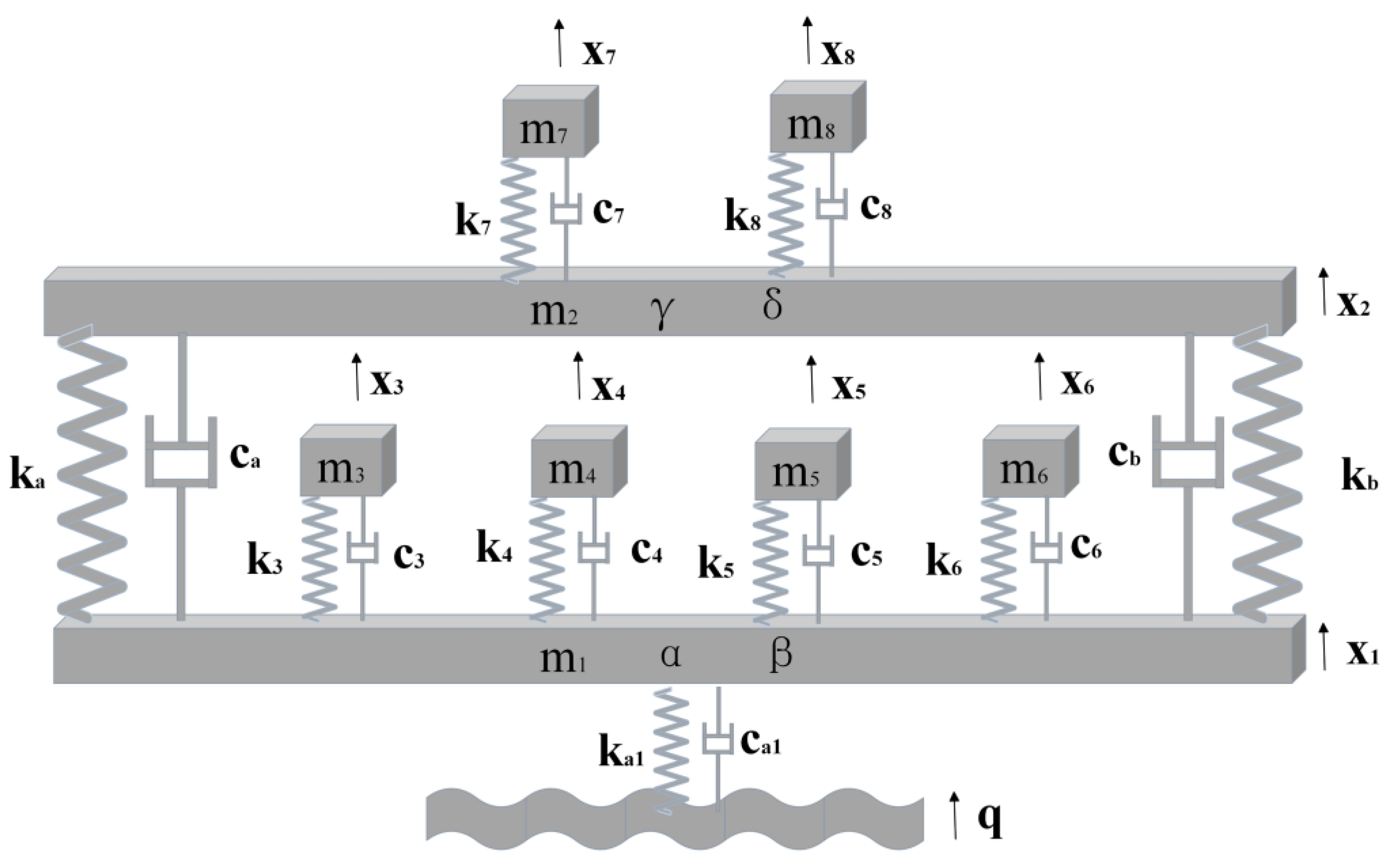

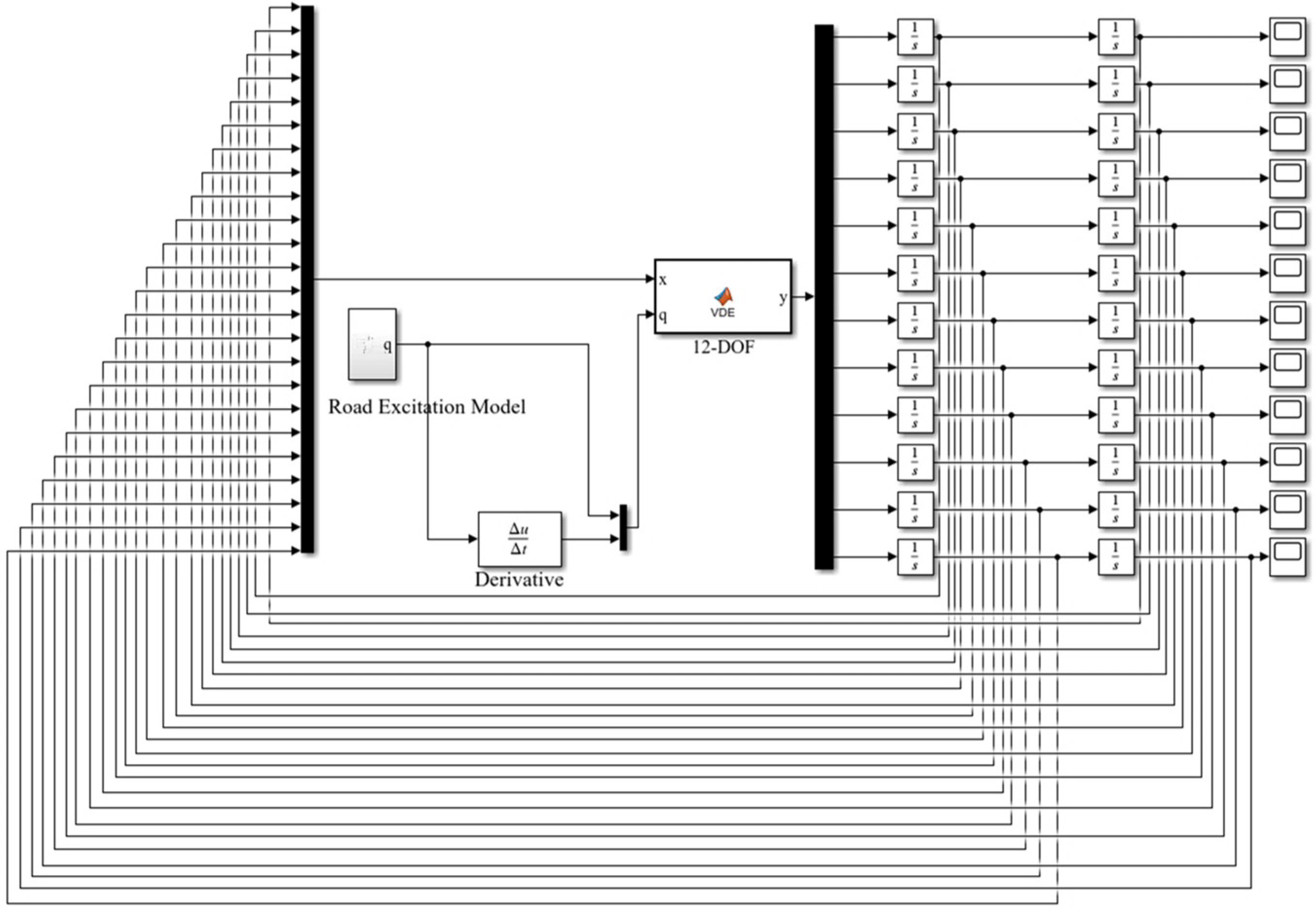

2.1.1. The Harvester Dynamic Model

- (1)

- The dynamics model of the potato harvester is defined with the positive direction being upward, perpendicular to the ground;

- (2)

- The connection between different components is assumed to involve both stiffness and damping interactions;

- (3)

- The excitation effects in the horizontal direction are neglected, and it is assumed that the field surface excitation is the only external excitation.

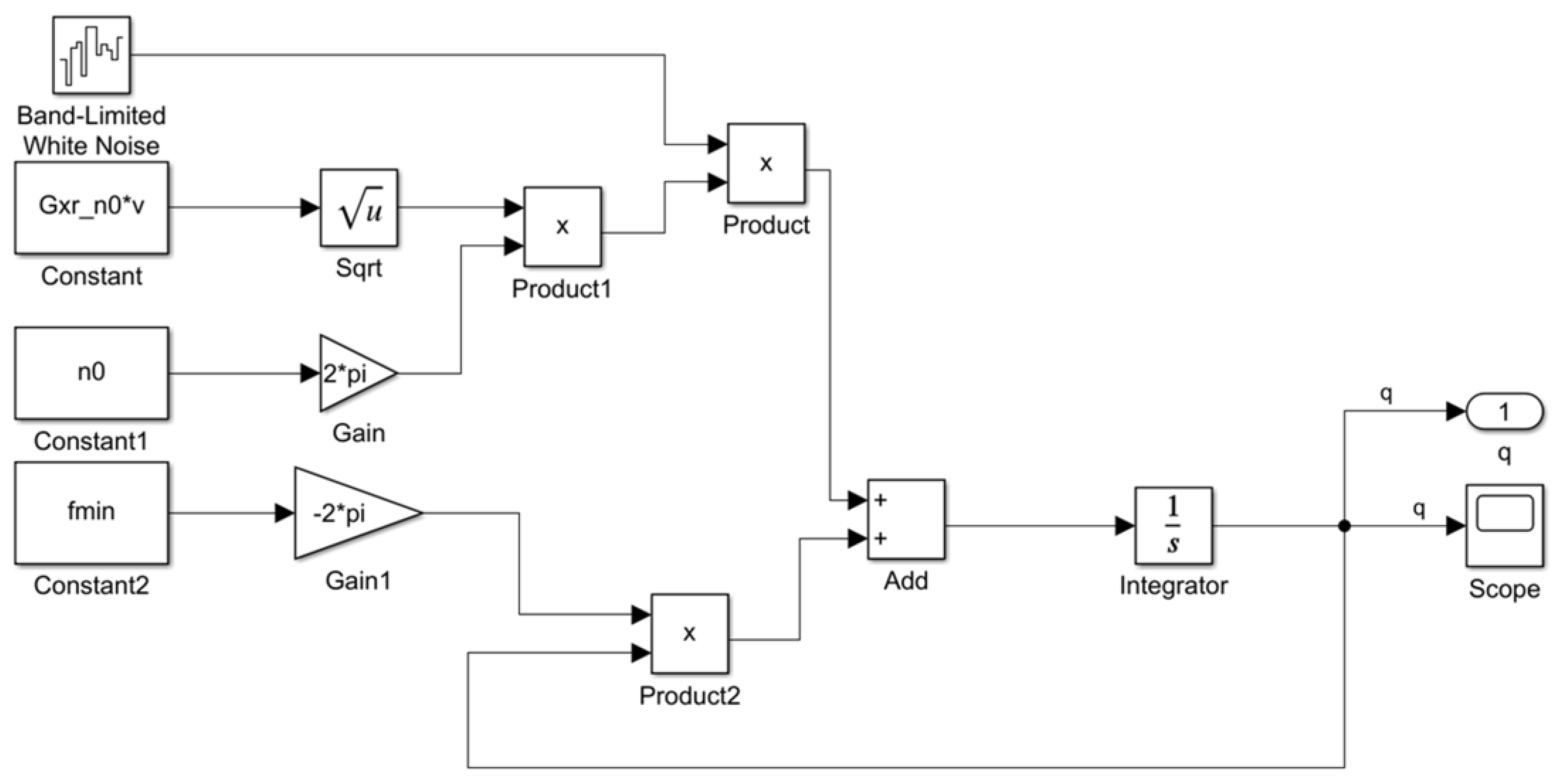

2.1.2. The Field Ground Model

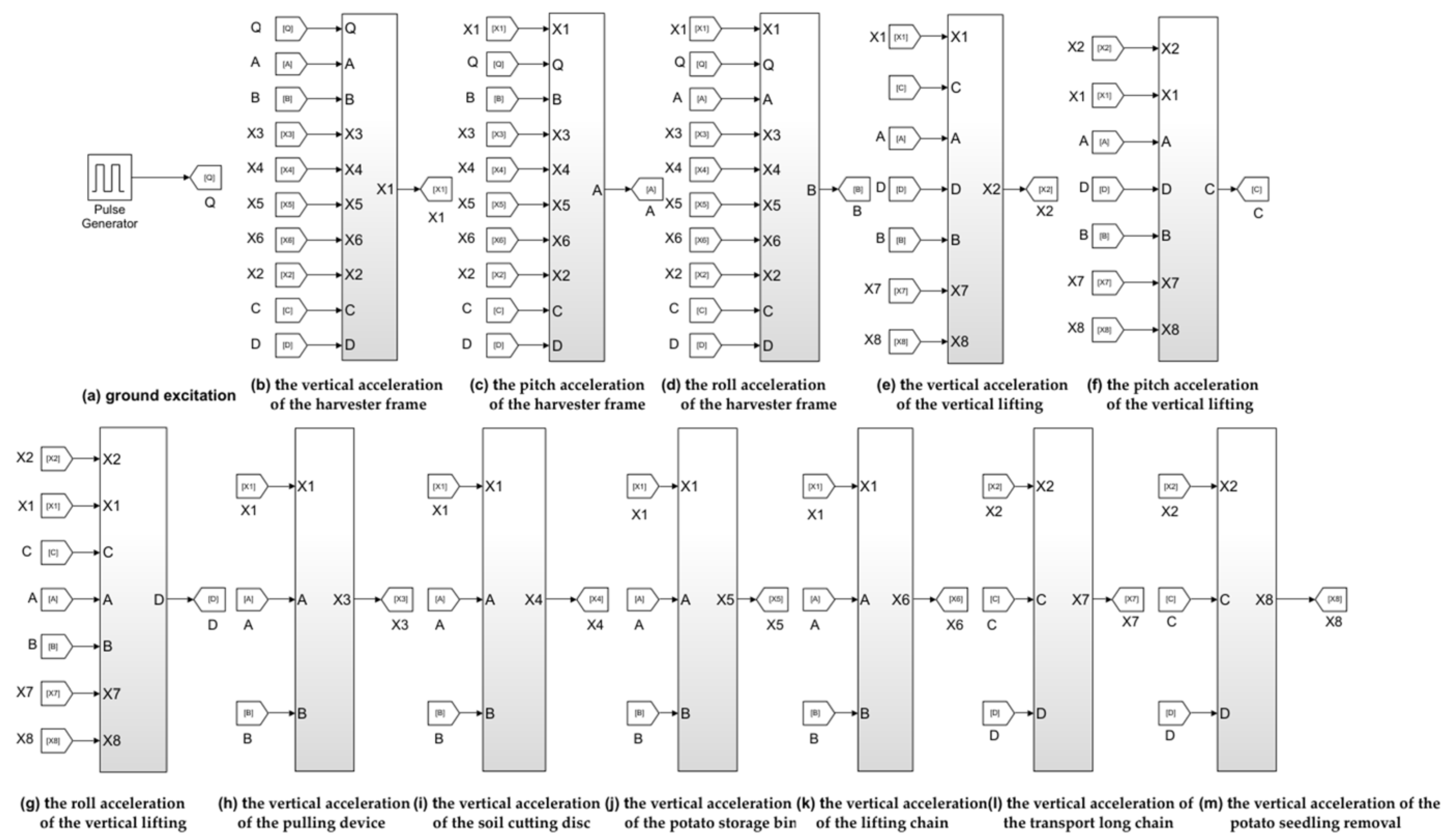

2.2. Collection of Field Vibration Signals

2.3. Bayesian Optimization Algorithm

3. Results

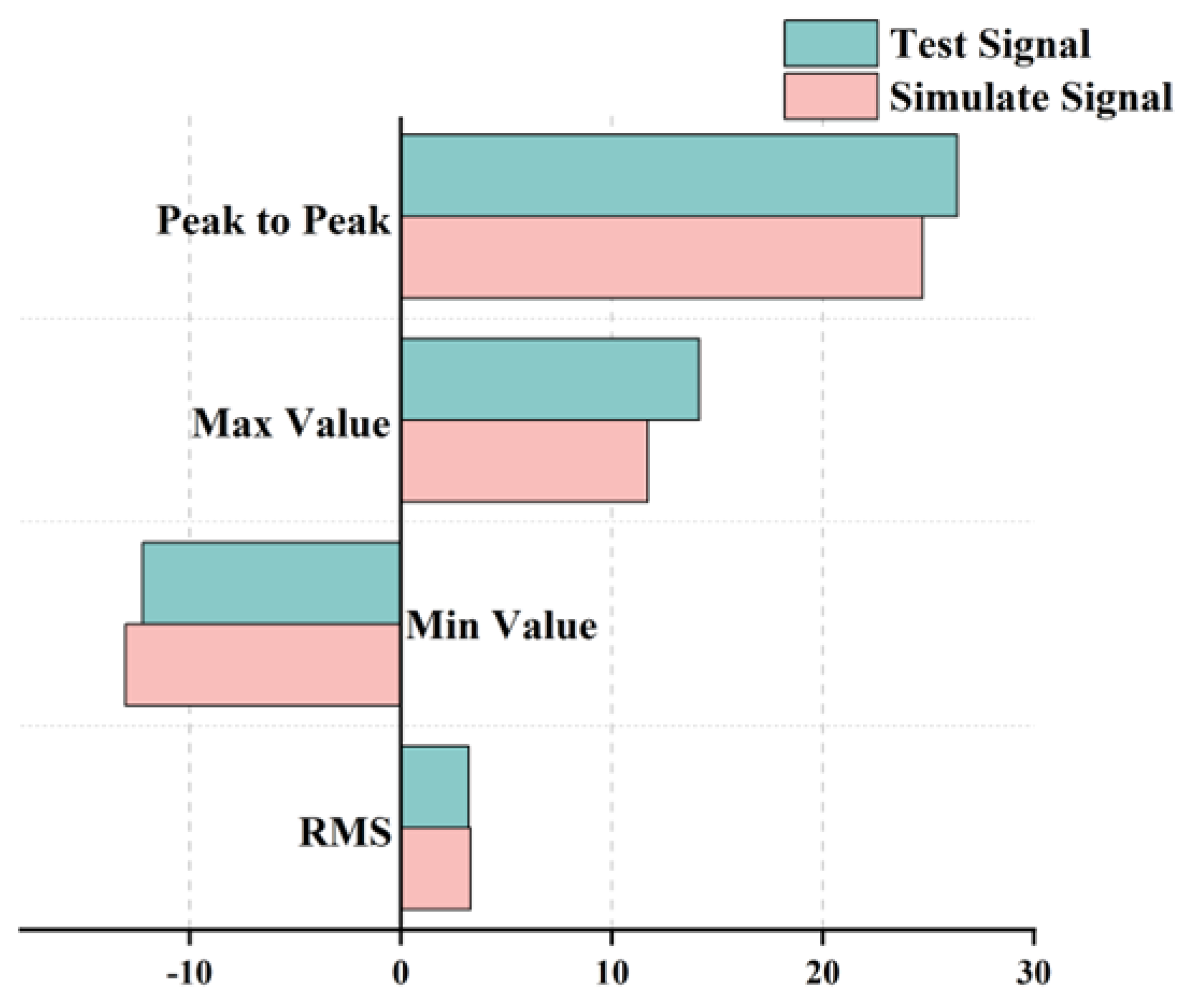

3.1. Comparison of Simulation Results and Experimental Results

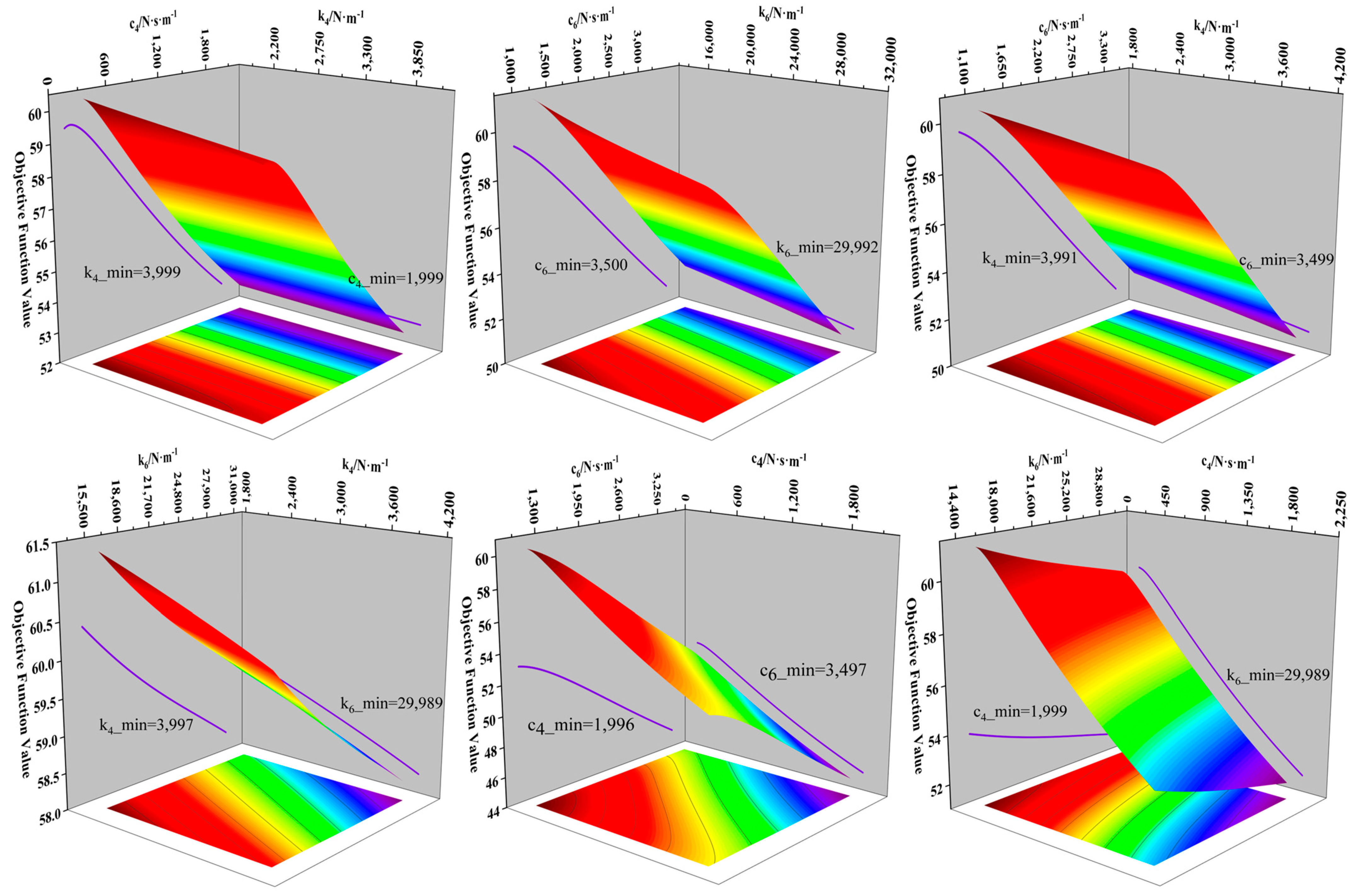

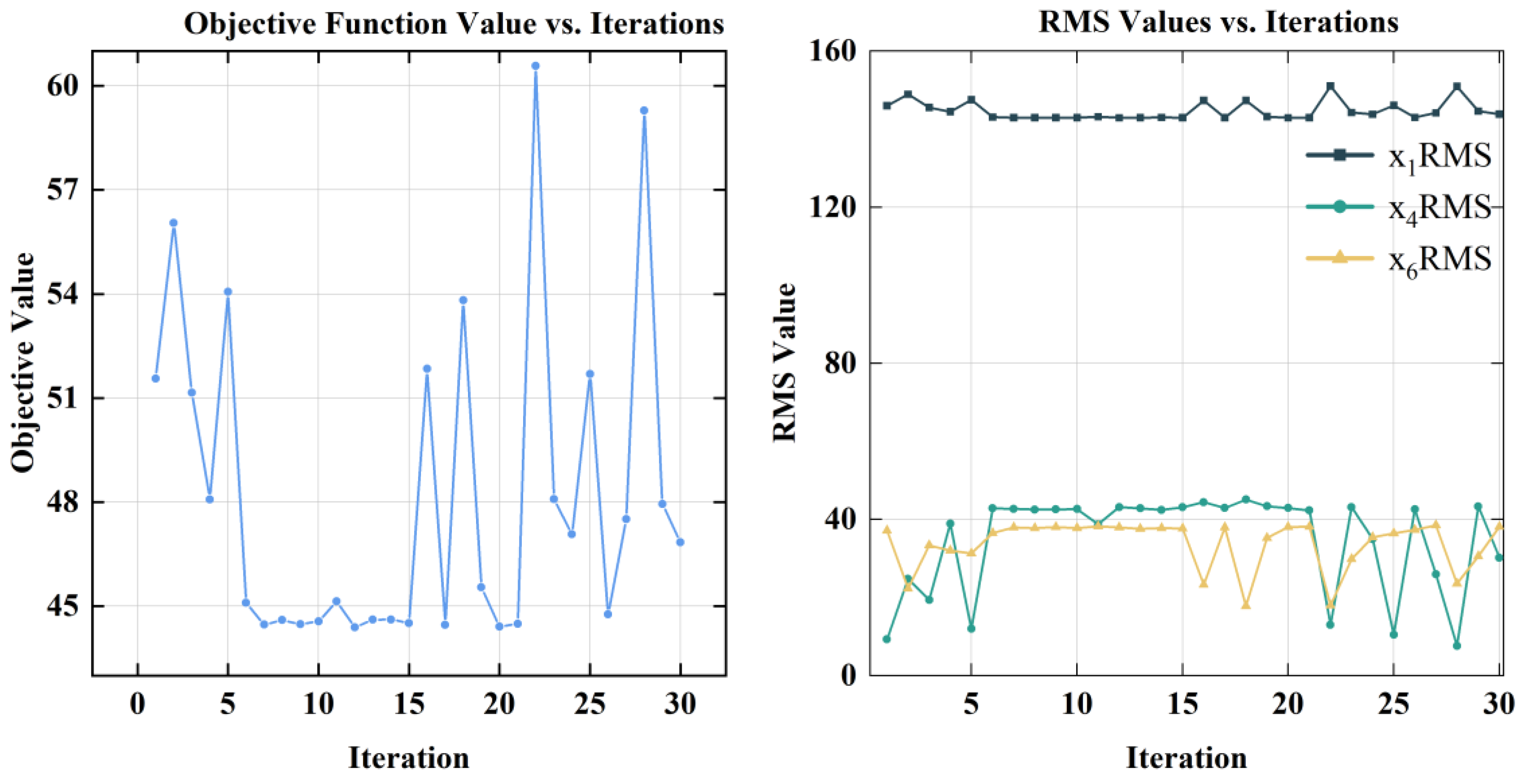

3.2. Analysis of Optimization Results

- (1)

- The combination of and significantly affects the range of the objective function values, with the best overall optimization results achieved in this combination. The surface plot clearly shows that within the given range, the objective function value decreases significantly as the damping parameters increase when only the damping values are adjusted;

- (2)

- In contrast, the optimization results for the and combination are less favorable. Especially when the value of is small, the objective function value is weakly influenced by changes in ;

- (3)

- Comparing the results of the and , and and experiments with the results of the and , and and experiments, it can be observed that experiments where was set as the optimization parameter yield better results compared to those where was set as the optimization parameter.

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yue, Y.; Zhang, Q.; Dong, B.; Li, J. Application of discrete element method to potato harvesting machinery: A review. Agriculture 2025, 15, 315. [Google Scholar] [CrossRef]

- Yang, X.; Wu, Y.; Wang, L.; Liu, F.; Zhao, X.; Bai, H.; Dong, W.; Kong, X.; Hu, H.; Zhong, W.; et al. Design and performance test of 4UJ-180A potato picking and bagging machine. Agriculture 2024, 14, 454. [Google Scholar] [CrossRef]

- Fan, J.; Li, Y.; Luo, W.; Yang, K.; Yu, Z.; Wang, S.; Hu, Z.; Wang, B.; Gu, F.; Wu, F. An experimental study of stem transported-posture adjustment mechanism in potato harvesting. Agronomy 2023, 13, 234. [Google Scholar] [CrossRef]

- Chen, M.; Liu, X.; Hu, P.; Zhai, X.; Han, Z.; Shi, Y.; Zhu, W.; Wang, D.; He, X.; Shang, S. Study on rotor vibration potato-soil separation device for potato harvester using DEM-MBD coupling simulation. Comput. Electron. Agric. 2024, 218, 108638. [Google Scholar] [CrossRef]

- Jansky, S.; Jin, L.; Xie, K.; Xie, C.; Spooner, D. Potato production and breeding in China. Potato Res. 2009, 52, 57–65. [Google Scholar] [CrossRef]

- Zhou, B.; Li, Y.; Zhang, C.; Cao, L.; Li, C.; Xie, S.; Niu, Q. Potato planter and planting technology: A review of recent developments. Agriculture 2022, 12, 1600. [Google Scholar] [CrossRef]

- Wang, Z.-J.; Liu, H.; Zeng, F.-K.; Yang, C.-H.; Xu, D.; Zhao, Y.-C.; Liu, X.-F.; Kaur, L.; Liu, G.; Singh, J. Potato processing industry in China: Current scenario, future trends and global impact. Potato Res. 2023, 66, 543–562. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, J.; Zhang, C.; Zhao, Y.; Du, X. Design and experimentation of small potato harvester for heavy soil in hilly and mountainous areas. Agronomy 2024, 14, 2131. [Google Scholar] [CrossRef]

- Liang, Z.; Huang, Y.; Li, D.; Wada, M. Parameter determination of a viscoelastic-plastic contact model for potatoes during transient collisions. Biosyst. Eng. 2023, 234, 156–171. [Google Scholar] [CrossRef]

- Li, Z.; Sun, W.; Wang, H.; Wang, J.; Simionescu, P.A. Study on the process of soil clod removal and potato damage in the front harvesting device of potato combine harvester. Agriculture 2024, 14, 1947. [Google Scholar] [CrossRef]

- Min, F.; Li, S.; Hao, Y.; Gao, F. TRIZ aided innovative design of potato soil separating and conveying device for potato harvester. J. Chin. Agric. Mech. 2023, 44, 6–12. [Google Scholar] [CrossRef]

- Wang, W.; Yang, R.; Pan, Z.; Qing, Y.; Zhang, J.; Chen, D.; Guo, X.; Lyu, S. Design and experimental study of single plant harvester for potato breeding experiments. Agriculture 2024, 14, 71. [Google Scholar] [CrossRef]

- Han, Y.; Shen, M.; Gao, Y.; Zhang, Z. Nonlinear vibration characteristics and experimental validation of a human-vehicle-road coupled system. J. Vib. Eng. 2024, 37, 60–70. [Google Scholar] [CrossRef]

- Rong, J.; Zheng, Z.; He, L.; Wang, X.; Yan, X. Time domain simulation and optimization of ride comfort for vehicle active suspension. Trans. Beijing Inst. Technol. 2022, 42, 46–52. [Google Scholar] [CrossRef]

- Dorokhov, A.; Didmanidze, O.; Aksenov, A.; Sibirev, A.; Sazonov, N.; Mosyakov, M.; Godyaeva, M. The results of studies on the assessment of the destruction of soil clods during combine harvesting of potatoes. Agriculture 2022, 12, 2024. [Google Scholar] [CrossRef]

- Jia, B.; Sun, W.; Zhao, Z.; Wang, H.; Zhang, H.; Liu, X.; Li, H. Design and field test of a remotely controlled self-propelled potato harvester with manual sorting platform. Am. J. Potato Res. 2023, 100, 193–209. [Google Scholar] [CrossRef]

- Li, J.; Li, X.; Hu, B.; Gu, T.; Wang, Z.; Wang, H. Analysis of the resistance reduction mechanism of potato bionic digging shovels in clay and heavy soil conditions. Comput. Electron. Agric. 2023, 214, 108315. [Google Scholar] [CrossRef]

- Zhao, X.; Meng, J.; Qu, D.; Wang, K.; Ren, Q.; Yang, G.; Wang, L.; Xie, S. Vibration test and analysis of swing screen of potato excavator. J. Agric. Mech. Res. 2023, 45, 171–176. [Google Scholar] [CrossRef]

- Liu, C.; Wu, N.; Cheng, G.; Wu, F.; Gu, F.; Shi, L.; Wang, B. Design and optimization of a lightweight and simple self-propelled crawler potato combine harvester. Agronomy 2025, 15, 65. [Google Scholar] [CrossRef]

- Wang, Y.; Wei, Z.; Su, G.; Zhang, X.; Wang, X.; Cheng, X.; Wang, F.; Li, X.; Zhou, H.; Yang, Z.; et al. Design and study of anti-blocking type potato stubble disc clamping and pulling device based on MBD-DEM coupled simulation. Comput. Electron. Agric. 2025, 229, 1097339. [Google Scholar] [CrossRef]

- Yang, Z.; Sun, W.; Liu, H.; Zhang, Y.; Chen, X.; Wei, Z.; Li, X. Field collaborative recognition method and experiment for thermal infrared imaging of damaged potatoes. Comput. Electron. Agric. 2024, 223, 109096. [Google Scholar] [CrossRef]

- Long, S.; Kang, S.; Xu, S.; Liu, Y.; Fan, J.; Wang, J. Parameter optimization of vibration and crushing combination digging device based on soil-tuber breakage model. Comput. Electron. Agric. 2025, 230, 109861. [Google Scholar] [CrossRef]

- Meng, J.; Li, Z.; Xian, W.; Li, F.; Li, Y. Modal response and vibration characteristics of sugar beet combine harvester frame. Eng. Agrícola 2024, 44, 20240054. [Google Scholar] [CrossRef]

- Zhang, W.; Qu, Y.; Yin, X.; Liu, H.; Mu, G.; Li, D. Experimental study on impact friction damage of sweet potato skin. Agriculture 2024, 14, 93. [Google Scholar] [CrossRef]

- Chen, S.; Zhou, Y.; Tang, Z.; Lu, S. Modal vibration response of rice combine harvester frame under multi-source excitation. Biosyst. Eng. 2020, 194, 177–195. [Google Scholar] [CrossRef]

- Lei, T.; Hou, M.; Li, L.; Cao, H. A state estimation of dynamic parameters of electric drive articulated vehicles based on the forgetting factor of unscented Kalman filter with singular value decomposition. Actuators 2025, 14, 31. [Google Scholar] [CrossRef]

- Banerjee, S.; Balamurugan, V.; Krishnakumar, R. Ride comfort analysis of math ride dynamics model of full tracked vehicle with trailing arm suspension. Procedia Eng. 2016, 144, 1110–1118. [Google Scholar] [CrossRef]

- Li, S.; Yang, S.; Chen, L. Modeling and dynamic analysis for a three-directional coupled no-linear heavy vehicle. J. Vib. Shock 2014, 33, 22. [Google Scholar] [CrossRef]

- Drexler, D.; Hou, Z. Simulation analysis on vertical vehicle dynamics of three in-wheel motor drive configurations. Proc. Inst. Mech. Eng. Part D: J. Automob. Eng. 2024, 238, 8. [Google Scholar] [CrossRef]

- Fang, Z.; Li, Q.; Yao, L.; Hu, X. Stiffness optimization for hybrid electric vehicle powertrain mounting system in the context of NSGA-II for vibration decoupling and dynamic reaction minimization. World Electr. Veh. J. 2025, 16, 131. [Google Scholar] [CrossRef]

- Gao, G.; Wang, J.; Ma, T.; Liu, W.; Lei, T. Multistage estimators for the distributed drive articulated steering vehicle. Math. Probl. Eng. 2020, 5921285, 16. [Google Scholar] [CrossRef]

- Liang, C.; Ma, X.; Zhu, L.; Yan, S.; Yang, J. Model identification and evaluation of vibration isolation platform for atomic interference gravimeter. J. Instrum. Instrum. 2023, 9, 44. [Google Scholar] [CrossRef]

- Pei, X.; Hou, Y.; Huang, H.; Zheng, J. A multi-objective sensor placement method considering modal identification uncertainty and damage detection sensitivity. Buildings 2025, 15, 821. [Google Scholar] [CrossRef]

- Zhu, X.; Xu, S.; Xiao, H.; Fu, P.; Fu, J. Performance seeking control of adaptive cycle engine based on Bayesian optimization. J. Aerosp. Power 2024, 40, 112. [Google Scholar] [CrossRef]

- Yuan, Z.; Sun, Y.; Bai, Y. Design and testing of vibratory potato harvester based on EDEM. J. Agric. Mech. Res. 2024, 46, 167–173. [Google Scholar] [CrossRef]

- Singh, A.; Nawayseh, N.; Singh, H.; Dhabi, Y.; Samuel, S. Internet of agriculture: Analyzing and predicting tractor ride comfort through supervised machine learning. Eng. Appl. Artif. Intell. 2023, 125, 106720. [Google Scholar] [CrossRef]

- Chen, K.; He, S.; Xu, E.; Tang, R.; Wang, Y. Research on ride comfort analysis and hierarchical optimization of heavy vehicles with coupled nonlinear dynamics of suspension. Measurement 2020, 165, 108142. [Google Scholar] [CrossRef]

- Mo, R.; Wang, Q.; Xu, E.; Lin, C. Dynamic modeling method of truck car based on multibody system transfer matrix method. Mach. Des. Manuf. 2019, 8, 66. [Google Scholar] [CrossRef]

- Ibarrola-Chamizo, J.; Agirre-Olabide, I.; Merino, M.; Aginaga, J. Modal complexity factors as indexes for modal parameter identification in operational modal analysis of coupled dynamic systems. J. Sound Vib. 2025, 600, 118860. [Google Scholar] [CrossRef]

- Wang, H.; Wang, Q.; Rui, Q.; Li, R.; Zhang, J.; Luo, T. Research on digitized modeling method of riding road of vehicle. Acta Armamentarii 2016, 37, 1153–1160. [Google Scholar] [CrossRef]

- Zhang, Y.; Duan, J.; Liu, Y.; Chen, Z.; Su, Y.; Liu, S. Dynamic analysis of a vehicle–bridge system under excitation of random road irregularities. Buildings 2024, 14, 3413. [Google Scholar] [CrossRef]

- Zhang, N.; Xia, H. Dynamic analysis of coupled vehicle-bridge system based on inter-system iteration method. Comput. Struct. 2013, 114, 26–34. [Google Scholar] [CrossRef]

- Su, M.; Li, S.; Huang, H.; Liu, Y. Design and experimental study of 7-DOF vehicle-road coupling model. Mach. Des. Manuf. 2021, 4, 88–96. [Google Scholar] [CrossRef]

- Liu, H.; Liu, X.; Wei, A.; Cai, Y. Dynamic response analysis of asphalt pavement under pavement-unevenness excitation. Appl. Sci. 2024, 14, 8822. [Google Scholar] [CrossRef]

- Wang, D.; Liu, D.; Chen, Y.; Zhu, D. Stability analysis of freight AGV driving. Manuf. Autom. 2025, 3, 9–16. [Google Scholar] [CrossRef]

- Liu, Z.; Yang, X.; Han, J. A study on 3D modeling and analysis of uneven road based on geometric features. J. Vib. Shock 2020, 39, 188–195. [Google Scholar] [CrossRef]

- Pang, J.; Lin, Y.; Wang, S.; Du, Z.; Xie, L.; Chen, X. Vibration analysis and structure optimization of grain cleaning screen based on VMD. Trans. Chin. Soc. Agric. Eng. 2023, 39, 1–9. [Google Scholar] [CrossRef]

- Jing, T.; Tang, Z.; Ding, Z.; Liang, Y.; Fang, M.; Wang, T. Paddy soil compaction effect undergoing multi-dimensional dynamic load of combine harvester crawler. Agriculture 2024, 14, 202. [Google Scholar] [CrossRef]

- Duan, L.; Xue, K.; Jiang, T.; Du, Z.; Xu, Z.; Shi, L. A parallel constrained Bayesian optimization algorithm for high-dimensional expensive problems and its application in optimization of VRB structures. Struct. Multidiscip. Optim. 2024, 67, 13. [Google Scholar] [CrossRef]

- Palm, N.; Landerer, M.; Palm, H. Gaussian process regression based multi-objective Bayesian optimization for power system design. Sustainability 2022, 14, 12777. [Google Scholar] [CrossRef]

- Ben Yahya, A.; Ramos Garces, S.; Van Oosterwyck, N.; De Boi, L.; Cuyt, A.; Derammelaere, S. Mechanism design optimization through CAD-based Bayesian optimization and quantified constraints. Discov. Mech. Eng. 2024, 3, 21. [Google Scholar] [CrossRef]

- Aldair, A.A.; Alsaedee, E.B.; Abdalla, T.Y. Design of ABCF control scheme for full vehicle nonlinear active suspension system with passenger seat. Iran. J. Sci. Technol. Trans. Electr. Eng. 2019, 43, 289–302. [Google Scholar] [CrossRef]

- Grotti, E.; Santana, P.B.; Filho, J.G.P.; Gomes, H.M. Multi objective robust optimization framework based on first and second order Taylor expansion applied to a vehicle suspension design. Optim. Eng. 2024, 25, 637–668. [Google Scholar] [CrossRef]

- Wu, B.; Huang, T.; Qiu, X.; Zuo, T.; Wang, X.; Xie, F. Design and experimental study of potato-soil separation device for sticky soils condition. Appl. Sci. 2021, 11, 10959. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, C.; Zhu, C.; Zhu, Y.; Li, Z.; Li, P. Analysis of vibration characteristics of corn no-till seeder and its influence on seed metering performance. J. Chin. Agric. Mech. 2024, 45, 1–8. [Google Scholar] [CrossRef]

- Wang, X.; Cao, Y.; Fang, W.; Sheng, H. Vibration test and analysis of crawler pepper harvester under multiple working conditions. Sustainability 2023, 15, 8112. [Google Scholar] [CrossRef]

- Zheng, G.; Li, Y.; Ji, K.; Liang, Z.; Ma, X.; Cheng, J. Vibration analysis and structural optimization of header frame of millet combine harvester. J. Agric. Mech. Res. 2024, 46, 41–45. [Google Scholar] [CrossRef]

- Wang, M.; Yan, C.; Yu, K. Research on vibration control method of tracked combine harvester. J. Agric. Mech. Res. 2024, 46, 75–79. [Google Scholar] [CrossRef]

- Mo, S.; Chen, K.; Zhang, Y.; Zhang, W. Vertical dynamics analysis and multi-objective optimization of electric vehicle considering the integrated powertrain system. Appl. Math. Model. 2024, 131, 33–48. [Google Scholar] [CrossRef]

- Chen, X.; Chen, L.; Liu, C.; Wang, W. A method for optimising the parameters of connecting parts of a corn no-till planter. Biosyst. Eng. 2024, 245, 177–189. [Google Scholar] [CrossRef]

| Parameters | Name |

|---|---|

| Road Surface Grade | |||

|---|---|---|---|

| A | |||

| B | |||

| C | |||

| D | |||

| E | |||

| F | |||

| G | |||

| H |

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Device Name | Performance Specifications | Parameter Values |

|---|---|---|

| DH5902N dynamic signal acquisition instrument | Channels | 16 |

| Sampling bandwidth | 100 kHz | |

| Distortion | <0.5% | |

| Triaxial accelerometer | Measurement range | ±500 |

| Frequency response | 0.5~7000 Hz | |

| Lateral sensitivity | <5% | |

| Software platform | DHDAS dynamic signal acquisition and analysis system | |

| Parameter | Value | Parameter | Value | Parameter | Value |

|---|---|---|---|---|---|

| Parameter | Actual Test/ ) | Simulation Test/ ) | Difference/ ) |

|---|---|---|---|

| Peak-to-peak value | 26.37 | 24.74 | 1.63 |

| Maximum value | 14.14 | 12.72 | 1.42 |

| Minimum value | −12.23 | −13.03 | 0.80 |

| RMS value of acceleration | 3.22 | 3.30 | 0.08 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meng, J.; Li, Z.; Li, Z.; Li, Y.; Xie, W. Dynamic Modeling and Parameter Optimization of Potato Harvester Under Multi-Source Excitation. Agronomy 2025, 15, 1134. https://doi.org/10.3390/agronomy15051134

Meng J, Li Z, Li Z, Li Y, Xie W. Dynamic Modeling and Parameter Optimization of Potato Harvester Under Multi-Source Excitation. Agronomy. 2025; 15(5):1134. https://doi.org/10.3390/agronomy15051134

Chicago/Turabian StyleMeng, Jianguo, Zhipeng Li, Zheng Li, Yanzhou Li, and Wenxia Xie. 2025. "Dynamic Modeling and Parameter Optimization of Potato Harvester Under Multi-Source Excitation" Agronomy 15, no. 5: 1134. https://doi.org/10.3390/agronomy15051134

APA StyleMeng, J., Li, Z., Li, Z., Li, Y., & Xie, W. (2025). Dynamic Modeling and Parameter Optimization of Potato Harvester Under Multi-Source Excitation. Agronomy, 15(5), 1134. https://doi.org/10.3390/agronomy15051134