1. Introduction

The rapid expansion of the biogas industry, particularly large-scale biogas projects, has led to a significant increase in the generation of biogas residues. If not managed properly, these residues can cause environmental pollution through foul odors and the contamination of soil and water sources [

1]. This underscores the urgent need for the resourceful and environmentally friendly utilization of biogas residues to ensure the sustainability of the biogas industry. Biogas residue, a solid byproduct of anaerobic digestion of organic materials, is characterized by its high organic content, humus, and beneficial microorganisms, along with satisfactory physical properties such as loose texture and good water-retention capacity [

2,

3,

4]. These attributes make biogas residue a promising material for use in soilless cultivation systems. Moreover, its application as a growth medium can extend the industrial chain of biogas production, offering both ecological and economic benefits.

Strawberries, valued for their high nutritional value, delicious taste, and rich content of vitamins, sugars, organic acids, and essential mineral elements, have become an increasingly popular fruit worldwide [

5,

6]. Over the past decade, the cultivation area for strawberries has significantly expanded [

7]. The majority of strawberry cultivation still relies on traditional soil-based methods that suffer from issues such as soil salinization, continuous cropping obstacles, and severe plant diseases, which have led to low survival rates and significant yield gaps; thus, soilless cultivation has emerged as an effective solution by avoiding these soil-related challenges while also expanding potential cultivation areas and improving overall production efficiency [

8,

9,

10,

11], although the prevalent use of peat as a growing medium poses its own limitations due to its finite nature and prohibitive mining regulations in several countries [

12].

Various materials have been explored as potential alternatives to peat, including coconut bran, composted livestock and poultry manure, olive residue compost, vermicompost, rice husk, volcanic rock, and rock wool [

13,

14,

15,

16,

17,

18,

19]. However, there is a notable absence of research on the utilization of biogas residues in this context. Despite these advancements, the potential of biogas residue as a peat substitute in soilless strawberry cultivation within controlled environments remains largely unexplored. Research on biogas residues has primarily focused on their use as organic fertilizers, particularly in improving soil fertility and enhancing plant growth [

13,

14]. In crop studies, most research has concentrated on the early growth stages of crops such as peppers, tomatoes, and cucumbers, with limited research extending to the entire growth cycle. Specifically, there is a notable lack of studies on the use of biogas residues in strawberry cultivation, especially under controlled environment conditions. Research on its application as a growth medium for strawberries has demonstrated dual benefits. First, it diversified the utilization of biogas industry residues, promoting the development of the biogas industry. When biogas residues are used as a growth medium, integrated with water–fertilizer synergy technology, both agricultural products and the growth medium achieve high-value utilization. Second, it promoted the sustainable utilization of resources by transforming waste into valuable inputs, effectively conserving peat resources, and facilitating the resource-oriented recycling of agricultural waste. This approach yields both ecological and economic benefits.

Therefore, in this study, we aim to optimize a composite growth medium using biogas residues as the primary component, supplemented with vinegar residue, peat, and perlite, for strawberry cultivation in controlled environments. The objectives are to determine the optimal formulation of the composite substrate, assess its physical and chemical properties, and evaluate its effects on strawberry growth, yield, and quality throughout the entire growth cycle. This research not only addresses the environmental challenges associated with biogas residues but also explores their potential to advance circular agriculture and promote sustainable strawberry production.

2. Materials and Methods

2.1. Materials

Biogas residue: The biogas residue utilized in the study was obtained from Jin Feng Green Energy Agricultural Technology Co., Ltd. in Qinbi Village, Dahuaishu Town, Hongtong County, Linfen City, Shanxi Province. It originated from the byproducts of anaerobic fermentation in biogas engineering, which underwent solid–liquid separation before undergoing aerobic composting. The aerobic composting pile was constructed to dimensions of 7 m in length, 5 m in width, and 1.5 m in height, with a total volume of 40 cubic meters. The composting system was enclosed by a high-molecular-weight semi-permeable membrane to facilitate aerobic fermentation and included aeration piping, a data collection system, and a control system. From 4 June 2024, the upper limit of the fan was set to 70 °C, the upper limit of the fan was 50 °C, the cycle opening time was 60 s, and the cycle closing time was 600 s. The temperature climbing time was 48 h, the temperature was 25.7–47.3 °C, the high temperature duration was 576 h, the temperature was 51.6–54.8 °C, and the cooling stage lasted for 72 h, 32.3–42.8 °C. The basic physical and chemical properties and heavy metal content of the biogas residue are shown in

Table 1.

Vinegar residue: The vinegar residue was a donation from nearby vinegar factories. It had the following nutrient composition: total nitrogen 2.22%, total phosphorus 0.17%, total potassium 0.43%, pH 5.09, and EC 0.46 ms∙cm−1.

Peat and strawberry-specific cultivation substrate: They were obtained from Shandong Sanyi (Shouguang) Agricultural Co., Ltd. (Shandong, China).

Perlite: It was acquired from Puyang Sitong Thermal Insulation Materials Factory in Henan Province.(Henan, China).

The strawberry variety used in the study was Fragaria × ananassa “xiangye”, and the seedlings were purchased from Aishangmei Picking Workshop in Yuci District, Jinzhong City, Shanxi Province. (Shanxi, China).

2.2. Experimental Design

The experiment began in September 2023 and ended in April 2024. The study utilized a single-factor randomized block design comprising 6 treatments, each replicated three times (

Table 2); the total number of plants per treatment was 270. A raised cultivation approach was implemented using troughs measuring 30 cm in diameter and 15 cm in depth. Two drip irrigation belts were laid in each elevated cultivation trough, and the distance between the two adjacent drop holes was 10 cm. Strawberries were grown in the “Z” type with a pitch of 20 cm. During the experiment, a nutrient solution was added to the strawberry plants. The nutrient solution was prepared in a 1 m

3 tank, and the Yamazaki nutrient solution formula [

20] was used (

Table 3). Finally, the pH was adjusted to 5.5–6.0 by the addition of sulfuric acid. Strawberries were supplied with nutrient solution through water and fertilizer equipment; the average irrigation frequency during the strawberry growth period was 2 times a day, and the total irrigation amount was 245 m

3. The research process was shown in

Figure 1.

2.3. Analytical Methods

2.3.1. Physical and Chemical Properties of Growth Medium

Physical properties: The growth medium’s physical properties were assessed following the protocols outlined by Lu et al. [

3] and Meng et al. [

1]. A container with a known volume (V) was initially weighed (W1), then filled with the air-dried growth medium and reweighed to obtain W2. Subsequently, the container, sealed with two layers of gauze, was submerged in water for 24 h and weighed again to determine W3. The weight of the wet gauze (W4) was also documented. After inverting the sealed container to eliminate excess moisture, the final weight was recorded as W5. Each material underwent triplicate testing. The calculations were as follows:

Nutrient content: Total nitrogen was quantified via the Kjeldahl automatic nitrogen analyzer (Foss8410). Effective phosphorus content was determined using the molybdenum-antimony colorimetric method. Fast-acting potassium levels were measured through the ammonium acetate leaching method and analyzed with the 6840 flame spectrophotometer. Organic matter content was evaluated using the potassium dichromate oxidation external heating method.

pH and EC: The air-dried growth medium was mixed with deionized water in a 1:5 mass-to-volume ratio using the saturated leaching method. Following centrifugation and filtration, the pH of the medium was measured using a PHS-3C pH meter, and its electrical conductivity (EC) was determined with a Mettler PC300 desktop conductivity meter. Each sample was measured in triplicate, with the pH and EC values recorded accordingly.

2.3.2. Growth Morphological Indicators

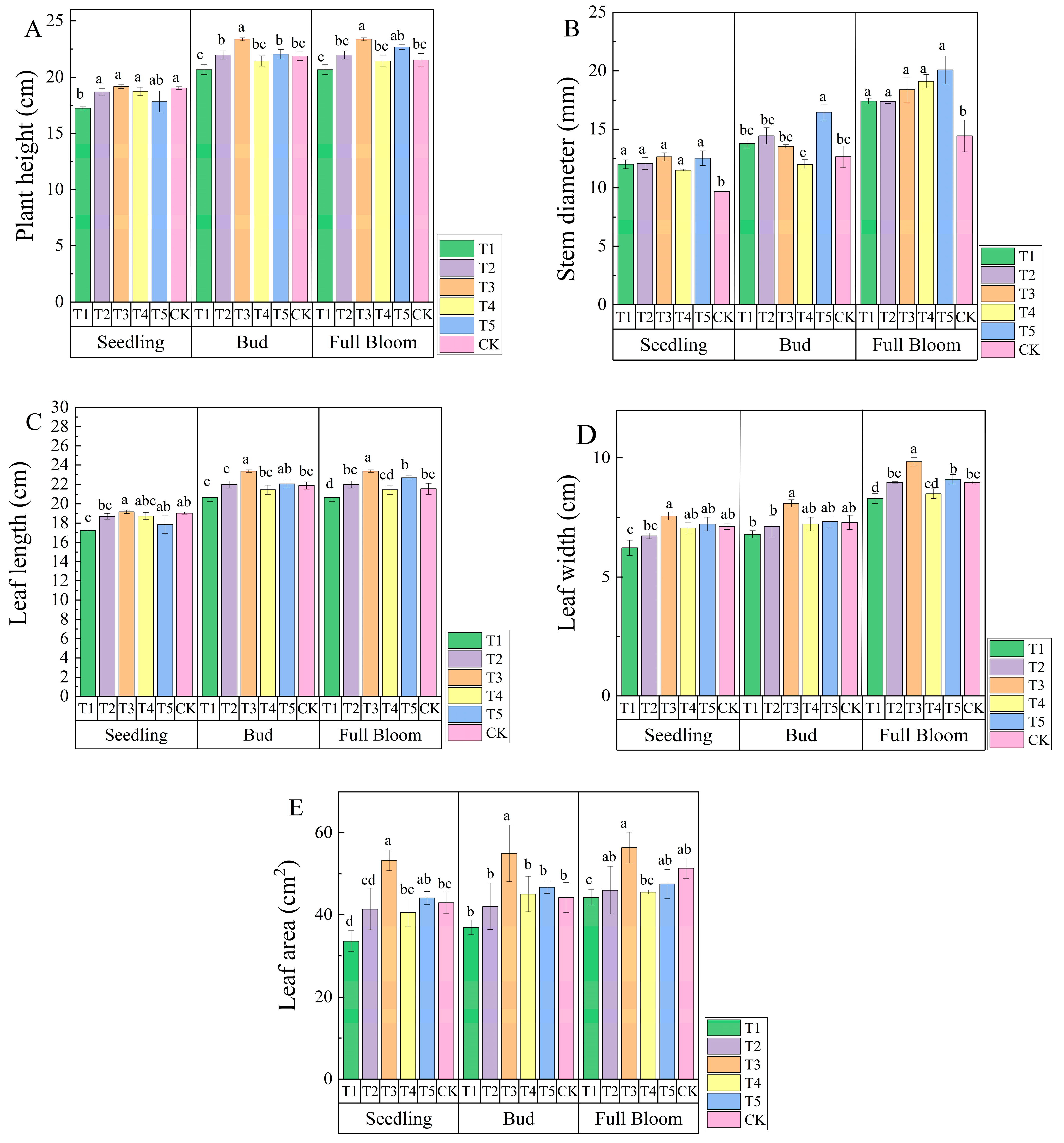

Plant growth index: After establishing seedlings at a fixed density, we assessed the morphological characteristics of strawberry plants at each growth stage, including plant height, stem diameter, and leaf area. Measurements were discontinued once the plants developed eight leaves to facilitate flower and fruit thinning and the removal of senescent leaves. Plant height was measured with a ruler from the ground to the apex of the majority of leaves. Stem diameter was determined using a caliper along the North–South axis of the root stem. Leaf area was calculated using the method proposed by Chen et al. (2009) [

21], where Leaf Area = Leaf Length × Leaf Width × 0.73.

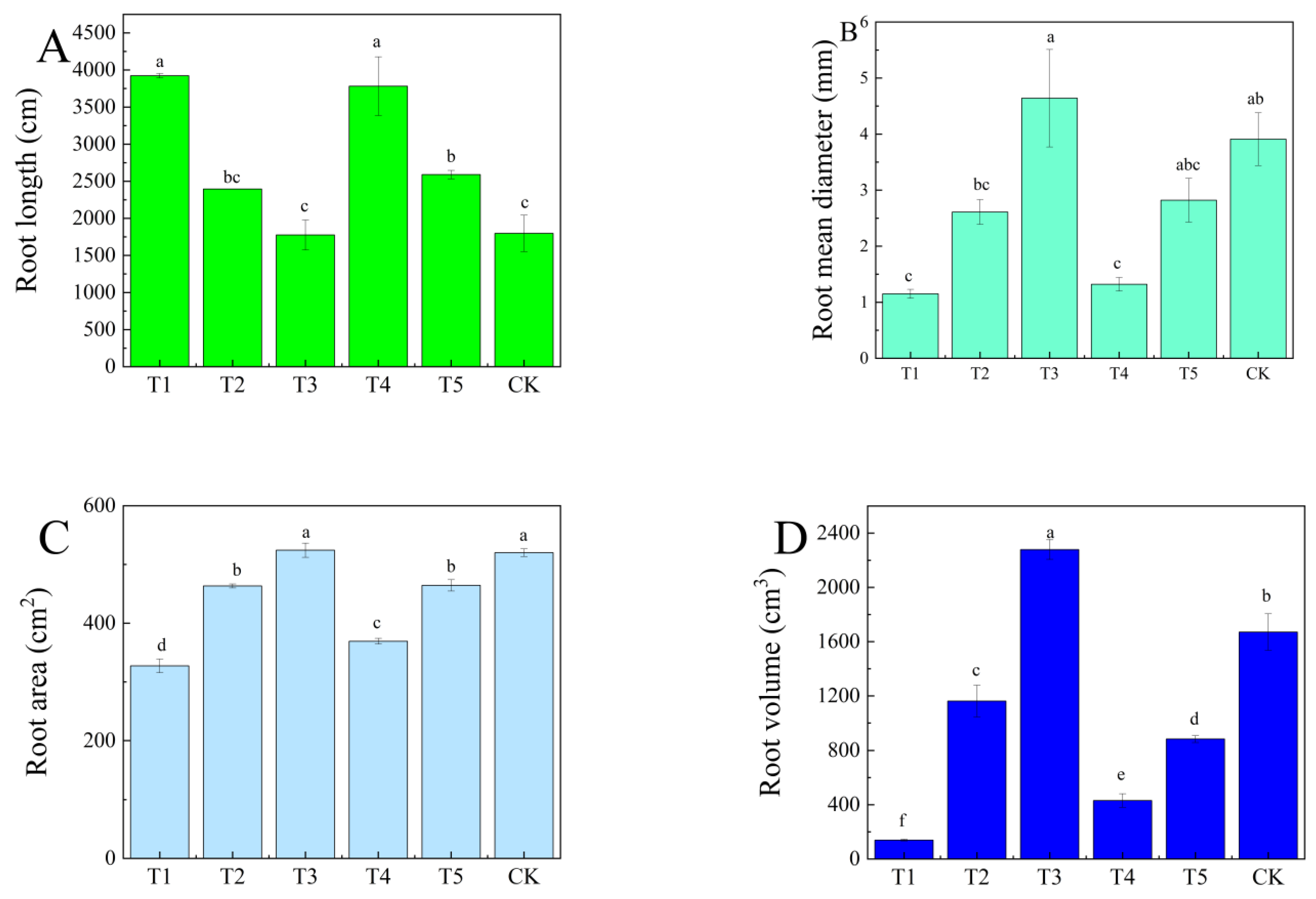

Root measurement: In the later stages of strawberry growth, three complete root systems were randomly selected from each treatment and placed in sealed bags for transport back to the laboratory. The root length, average diameter, and other root characteristics of the facility-grown strawberries were measured using the LA-S plant image analysis system, through root scanning and image software analysis. During the root washing process, a 100-mesh sieve was placed beneath the roots to prevent any detached roots from being washed away by the water.

Yield and quality: Mature fruits were harvested and weighed to determine average fruit weight and plant yield. Soluble sugar content was analyzed using the sulfuric acid anthrone method, titratable acidity was assessed through NaOH neutralization titration, vitamin C content was measured using the ammonium molybdate colorimetric method, and soluble solid content was evaluated with a refractometer (PAL-1) by ATAGO (Tokyo, Japan).

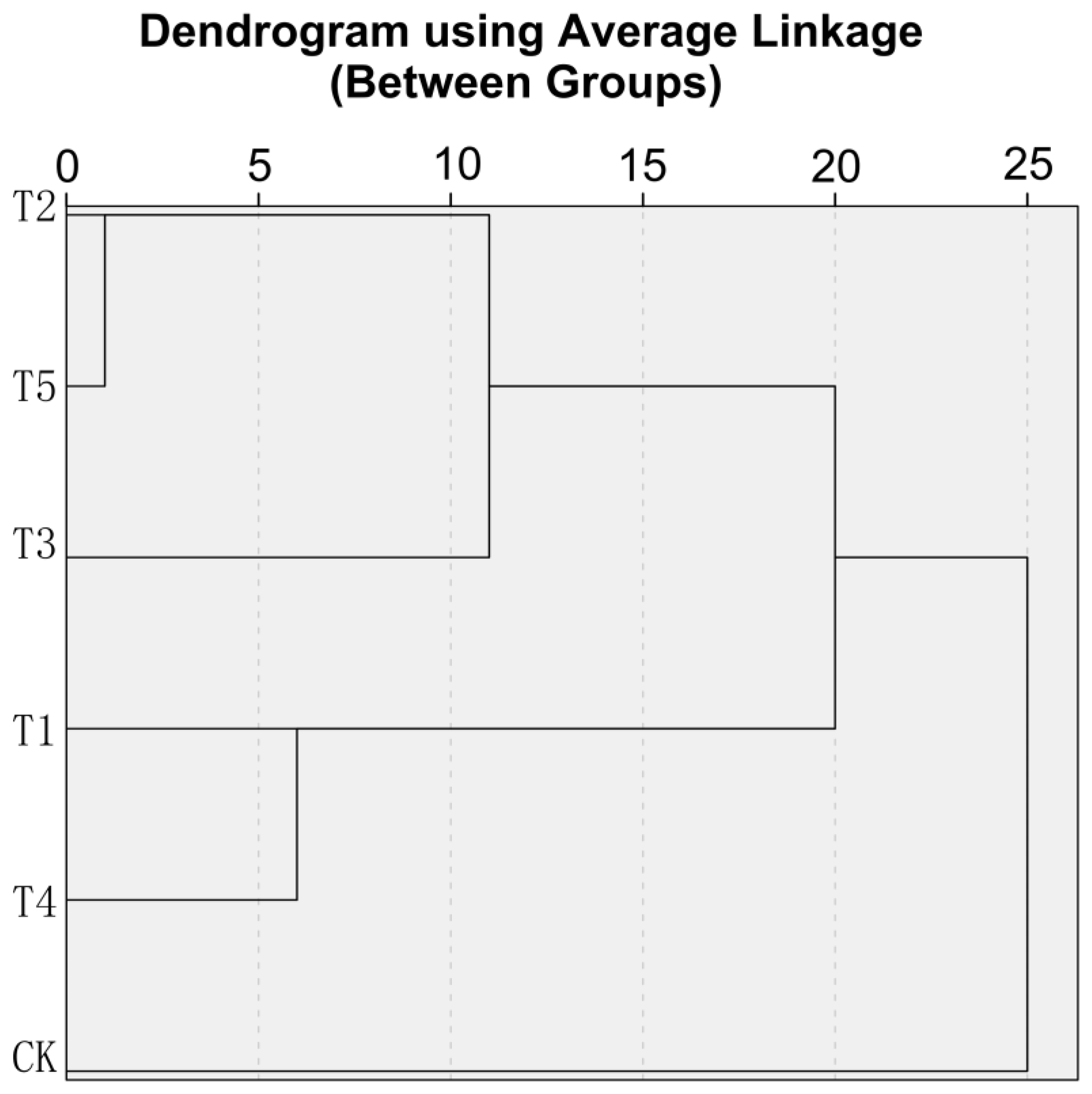

2.4. Statistical Analysis

Data were collected and organized using Microsoft Excel 2017. A one-way ANOVA was employed to evaluate the effects of various treatments on the physicochemical properties and growth of strawberries. Duncan’s multiple range test was applied at a significance level of

p ≤ 0.05 when significant differences were identified. Strawberry growth indicators and quality index were comprehensively assessed using the fuzzy mathematics membership function method [

1]. Redundancy analysis, conducted with Canoco 5, examined the relationships between yield and growth medium physicochemical properties, as well as quality and growth medium properties. Cluster analysis and multiple regression analysis were performed using SPSS 18.0. The “plspm” package in the R language was used to explore the relationship between the basic physicochemical properties of the growth medium, the strawberry plant growth index, and strawberry quality. Graphs were generated using Origin 2019.

4. Discussion

4.1. Selection and Pretreatment of Growth Medium Materials

In previous studies on the use of biogas as a growth medium, it was not clear whether biogas residue still needs pretreatment after anaerobic fermentation or whether it can be used directly. In the preliminary experiment, we found that the yellow ghost umbrella could grow when uncomposted biogas residue was used as the growth medium. This kind of bacterium competes with strawberries for nutrients, resulting in local dry spots in the growth medium. At the same time, if the biogas residue was not sealed after composting, it would be easy for grubs to grow in it. Through experience, we believe that if biogas residue is used as the growth medium, it needs to be pretreated. Yan Gui et al. (2024) [

22] also observed that well-decomposed digestate was more beneficial for ginseng growth.

Biogas residue is considered to be a high-quality material that can replace peat resources in strawberry growth media. In this study, we successfully utilized vinegar residue in the preparation of a biogas residue-based growth medium. Studies by Wang et al. [

23] (2022) have demonstrated that vinegar residue is a valuable source of organic matter and acidic functional groups. Zahra Mirfattahi et al. [

24] (2020) induced salt tolerance in strawberry

(Fragaria × ananassa Duch) plants by acetate application. The application of organic materials such as vinegar residue effectively modulated nutrient efficacy and balanced nutrient provision. A small quantity of peat was incorporated to address the inadequate buffering capacity of biogas and vinegar residues. Similar results have been obtained in studies using other agricultural wastes to prepare strawberry substrates [

10,

16,

25].

4.2. Physicochemical Properties of Growth Medium

An ideal growth medium for strawberries should possess a low salinity, a slightly acidic pH, good aeration, and high water and nutrient retention capacities [

26,

27]. In this study, the compounded biogas growth medium exhibited a bulk density ranging from 0.21 to 0.25 g cm

−3, with total porosity ranging from 85.25% to 98.39%. The air/water ratio ranged from 1:1.8 to 1:2.7, pH levels varied from 5.45 to 5.97, and the electrical conductivity (EC) ranged from 0.91 to 1.13 ms·cm

−1, meeting the requirements for crop growth [

8,

28,

29,

30,

31]. Strawberry is a fruit of high economic value, but it has poor salt tolerance [

29]. The physicochemical characteristics of growth media play a crucial role in determining their suitability for cultivating strawberries [

3,

32]. In this study, the T3 (biogas residue/peat/perlite/vinegar residue = 2:3:1:4) had a better effect.

The total porosity in this study differed from previous studies, which suggests an optimal total porosity range of 70–90%. The total porosity of the biogas growth medium in this study was relatively high. This may be related to the particle size composition of the growth medium material. Endo et al. and Nguyen et al. [

30,

33] identified the optimal growth medium aeration porosity as 20–30% and water-holding capacity (WHC) as 50–60%, consistent with the results of this study.

Elevated water-holding porosity levels can induce hypoxia in plants. High-density growth media may compromise aeration and drainage, causing anoxia and stunting strawberry growth. Conversely, an excessively low unit weight impedes root anchorage during watering, resulting in water and nutrient loss and weak plant growth. In this experiment, although the organic matter content of T1 was higher than that of CK, and EC and pH were in the ideal range of strawberry growth, its water-holding porosity was significantly lower than that of CK, and its growth and yield were not as good as those of CK.

4.3. Influence of the Growing Medium on Strawberry Growth Parameters

A suitable compound biogas residue growth medium can effectively promote strawberry growth. In T1, a high total porosity was observed, suggesting that the growing medium’s particles were relatively loose, making it difficult for strawberry seedling roots to anchor and accelerating water flow during irrigation. The average root diameter of T3 was 4.04 times that of T1. Strong root development contributed greatly to the nutrient uptake of strawberries, which may also explain why T3 plants grew better than T1. Eyheraguibel et al. [

29] found that root development led to an increase in root surface area and improved the absorption and utilization of mineral nutrients. Robust roots were noted to better support plant growth, aiding strawberries in effectively absorbing nutrients and water, and providing sufficient materials and energy for the growth of aboveground stems and leaves, thereby promoting an increase in plant biomass [

25].

In our experiments, we observed an intriguing phenomenon: The length of strawberry roots did not necessarily correlate with the vigor of the strawberry plants. Instead, the growth vigor of strawberry plants was found to be closely related to the average diameter of the strawberry roots. Two reasons were identified for this: Firstly, spatial constraints played a role. In the elevated cultivation method, the substrate was filled to a height of 30 cm and a width of 40 cm on the racks. Within this limited growing space, driven by the roots’ tendency to seek water and nutrients, the roots may have prioritized lateral expansion to occupy more space for water and nutrients, thereby increasing the root diameter. Secondly, the characteristics of the growth medium influenced root development. Different ratios of growth medium resulted in varying bulk densities, porosities, and water-holding porosities, affecting the water retention and aeration of the medium.

4.4. Impact of Growing Medium on Strawberry Yield and Quality

In this study, the single berry weight across treatments ranged from 17.66 to 23.59 g, with a yield per plant ranging from 128.70 to 189.22 g. Treatment T3 exhibited a significant 13.88% increase in single berry weight and a 14.54% increase in yield per plant compared to the control (CK). Ailin Molosag et al. [

34] showed that the weight of a single fruit in earthworm compost was 14.70–16.90 g. In their hydroponic strawberry experiment, S. S. Sahoo, D. Sahoo, and K. K. Sahoo [

25] found that the single fruit weight was between 12.20 and 21.19 g. Azizi Yeganeh et al. [

16] identified Selve as a strawberry variety with a berry weight of 18.5 g, while Pedro Palencia et al. [

10] counted the total yield of strawberries per plant for 5 months and found it to be close to 911 g. In this paper, the single berry weight statistics were slightly higher than the results of these studies, because in the statistical calculation process, strawberries with a single berry weight of less than 8 g were excluded to avoid the masking of the growth medium differences due to the problem of large and small strawberries. In addition, there is a certain relationship with different varieties of strawberries [

10,

16].

The addition of organic materials, such as biogas residue, resulted in higher levels of soluble solids compared to the control group, showing an increase ranging from 12.87% to 29.34%. This observation indicates that the increase in organic materials influenced the synthesis and metabolism of sugar in strawberries [

16]. Soluble sugar content in T3 increased by 29.34%, and the SSC/TA ratio increased by 1.68 times compared with CK. This indicated that T3 optimized the physical properties of the growth medium and made its ventilation and water retention more harmonious; suitable pH activated the available nutrients of the growth medium, improved microbial activity, and caused the strawberry fruit to be fully developed and of a higher quality. This conclusion could also be verified by the redundancy analysis and PLS-PM.

4.5. Significance of This Study and Future Prospects

This study provides new insights and scientific evidence for the application of biogas residues in soilless cultivation. By optimizing biogas residue substrate formulations, we not only improved strawberry growth efficiency and fruit quality but also significantly reduced production costs. This method holds substantial value in resource utilization and environmentally friendly agricultural practices. In the future, researchers should continue to explore the optimization of different biogas residue mixtures and delve deeper into the specific mechanisms by which physicochemical properties influence plant growth to further enhance application effects and economic benefits.

5. Conclusions

In summary, the use of biogas residues as a growth substrate for strawberries is both feasible and effective. By combining biogas residues with peat, acetic acid residues, and perlite in a rational manner, the physical and chemical properties of the growth substrate were improved, leading to significant enhancements in strawberry growth performance, yield, and fruit quality. This study offers new perspectives for agricultural production, particularly in enhancing economic benefits and resource utilization efficiency. The T3 treatment (biogas residue/peat/perlite/vinegar residue = 2:3:1:4) demonstrated optimal cultivation results and superior performance in promoting strawberry growth and improving fruit quality. Economic benefit analysis revealed that compared to high-cost peat substrates, biogas residue-based substrates significantly reduced production costs while maintaining or even surpassing production efficiency. They can thus be utilized as optimal formulations for the next phase of testing.