Design of a Chili Pepper Harvesting Device for Hilly Chili Fields

Abstract

1. Introduction

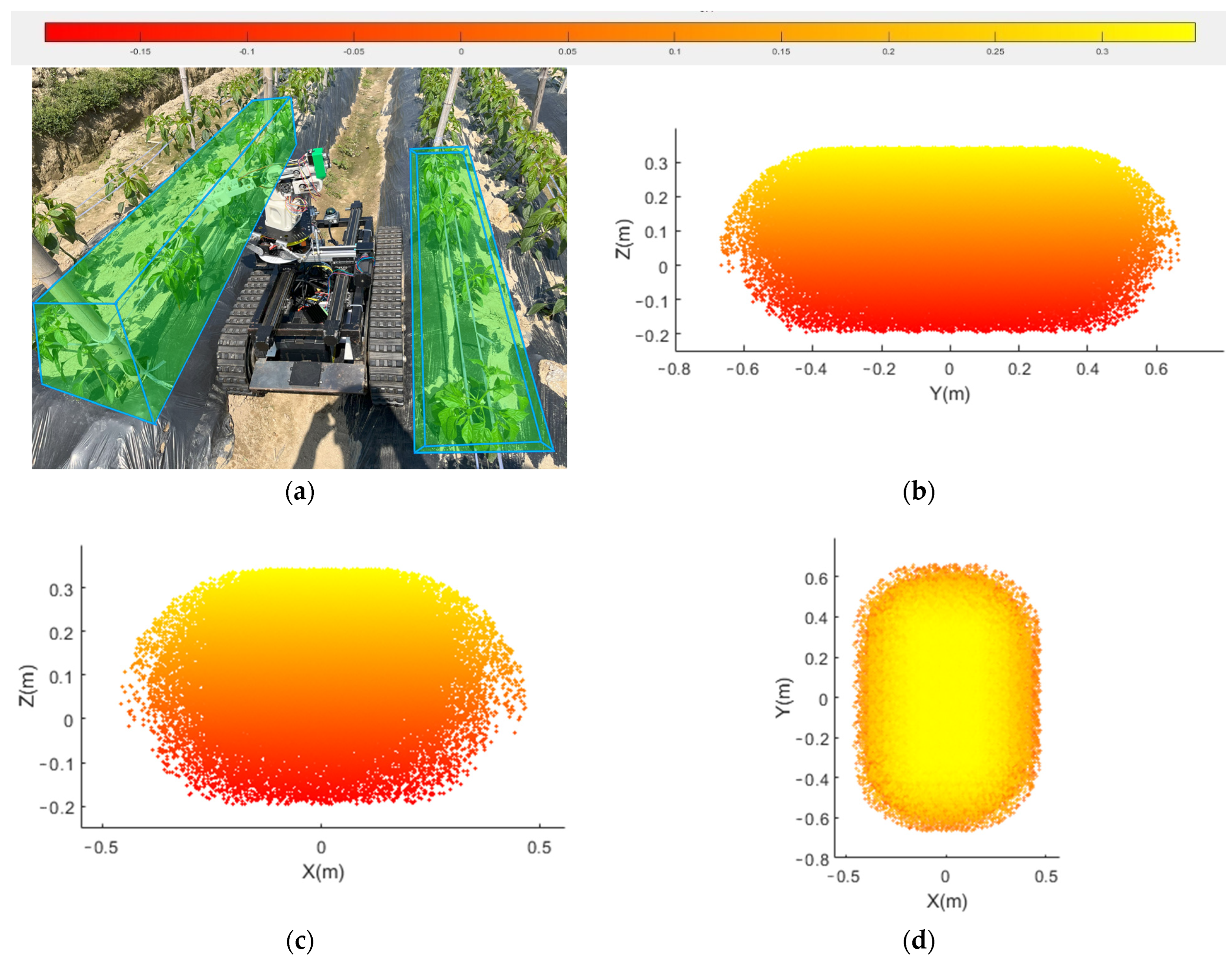

- Using 3D LiDAR-generated point cloud data, combined with point cloud preprocessing, to enable the reconstruction of chili pepper point cloud data.

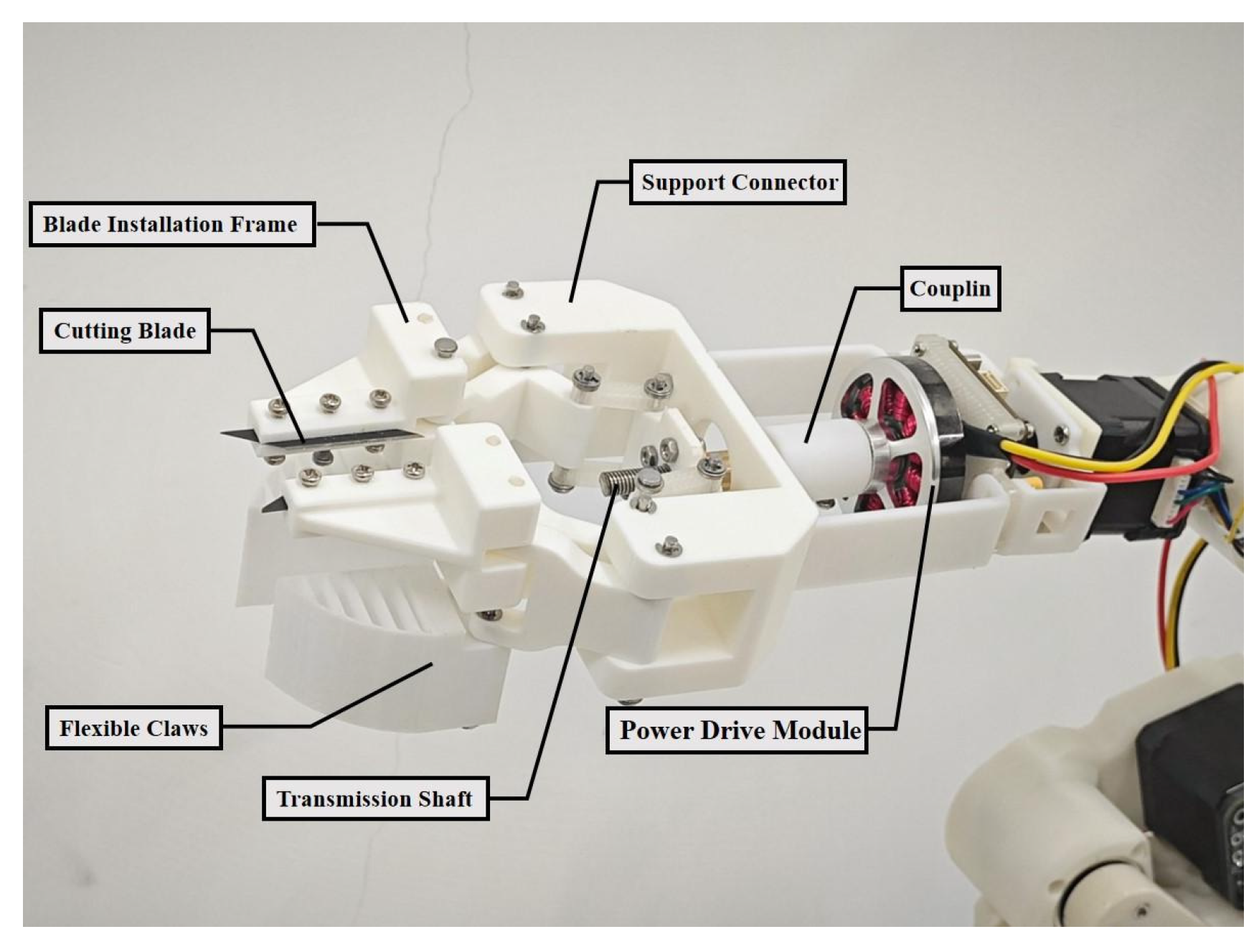

- Applying morphological analysis to identify the chili pepper stem location and precisely determine the cutting position.

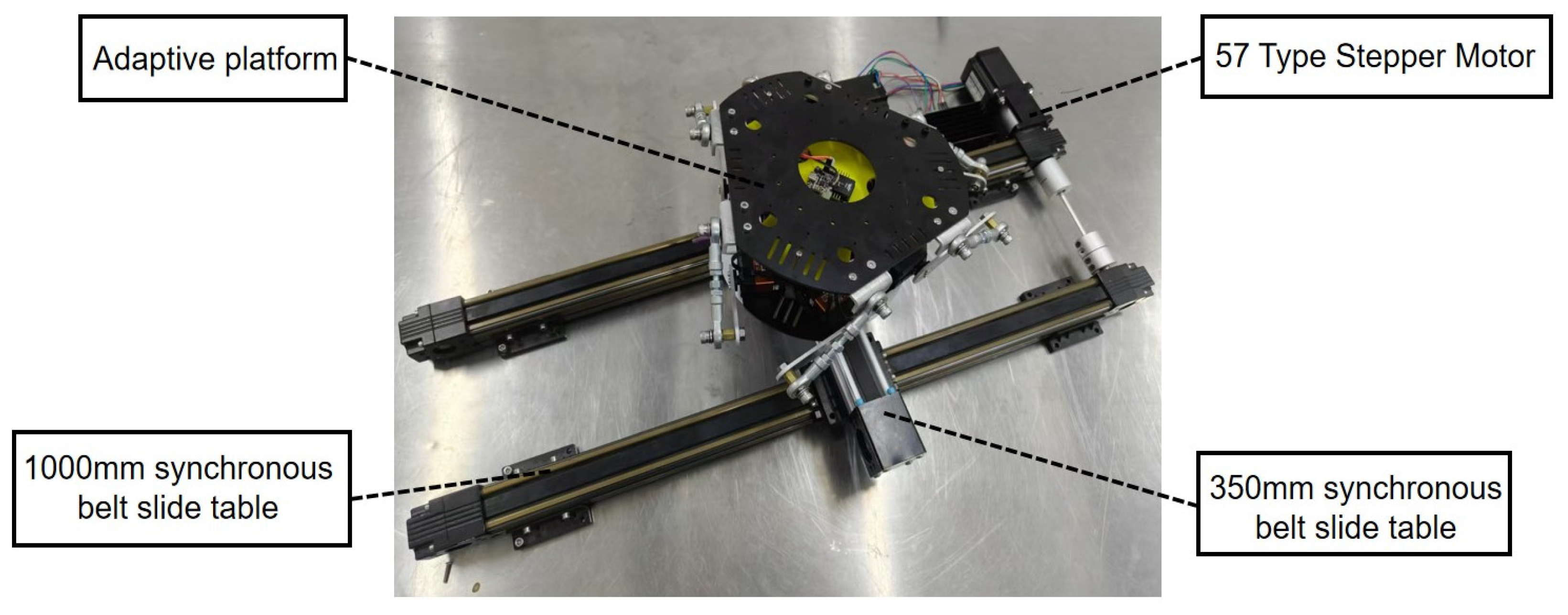

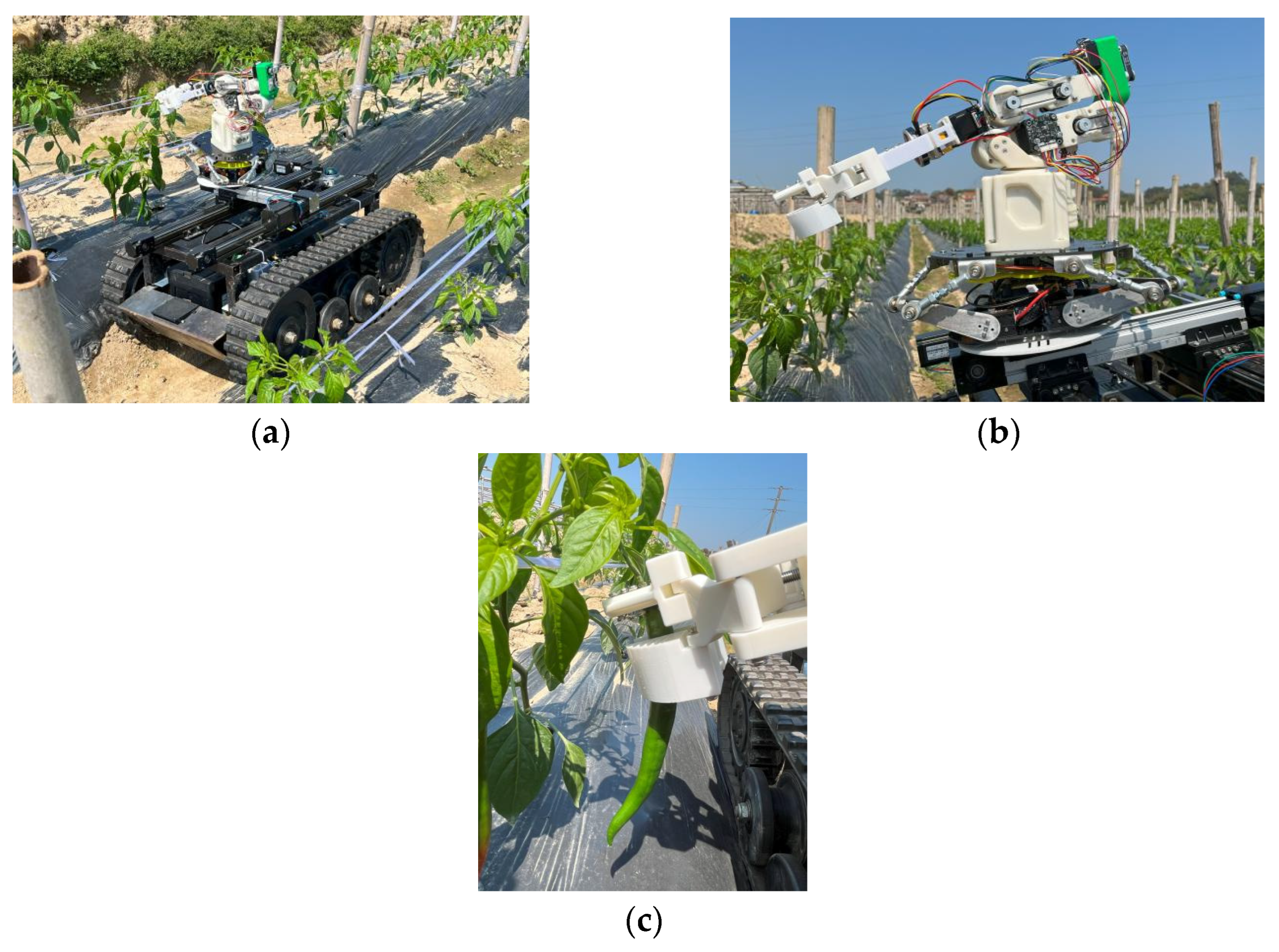

- Achieving dynamic balancing of the robotic arm through an adaptive leveling platform and positioning the arm at the optimal harvesting location using the H-shaped planar slide, accurately completing the cutting, gripping, and collection processes.

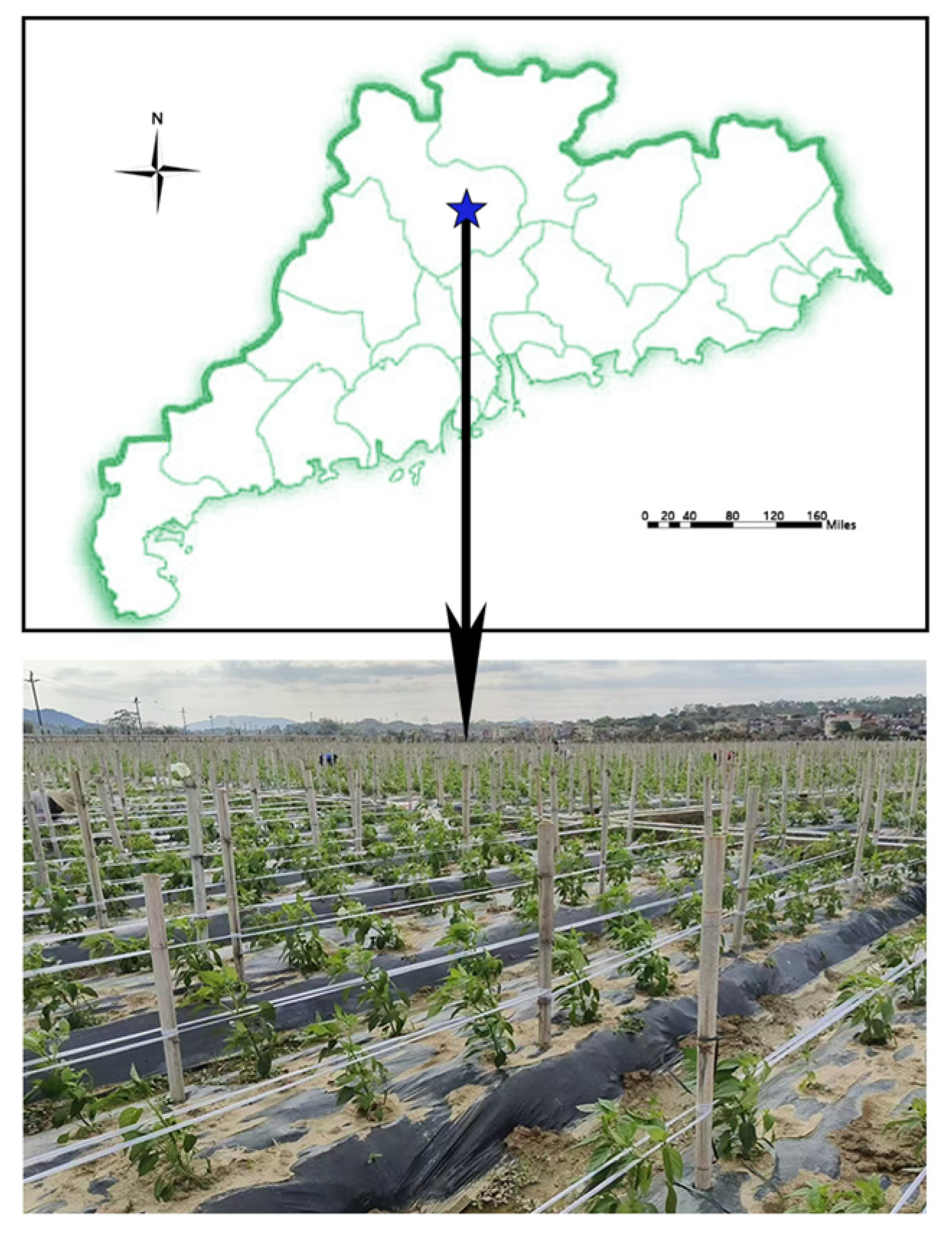

2. Materials and Methods

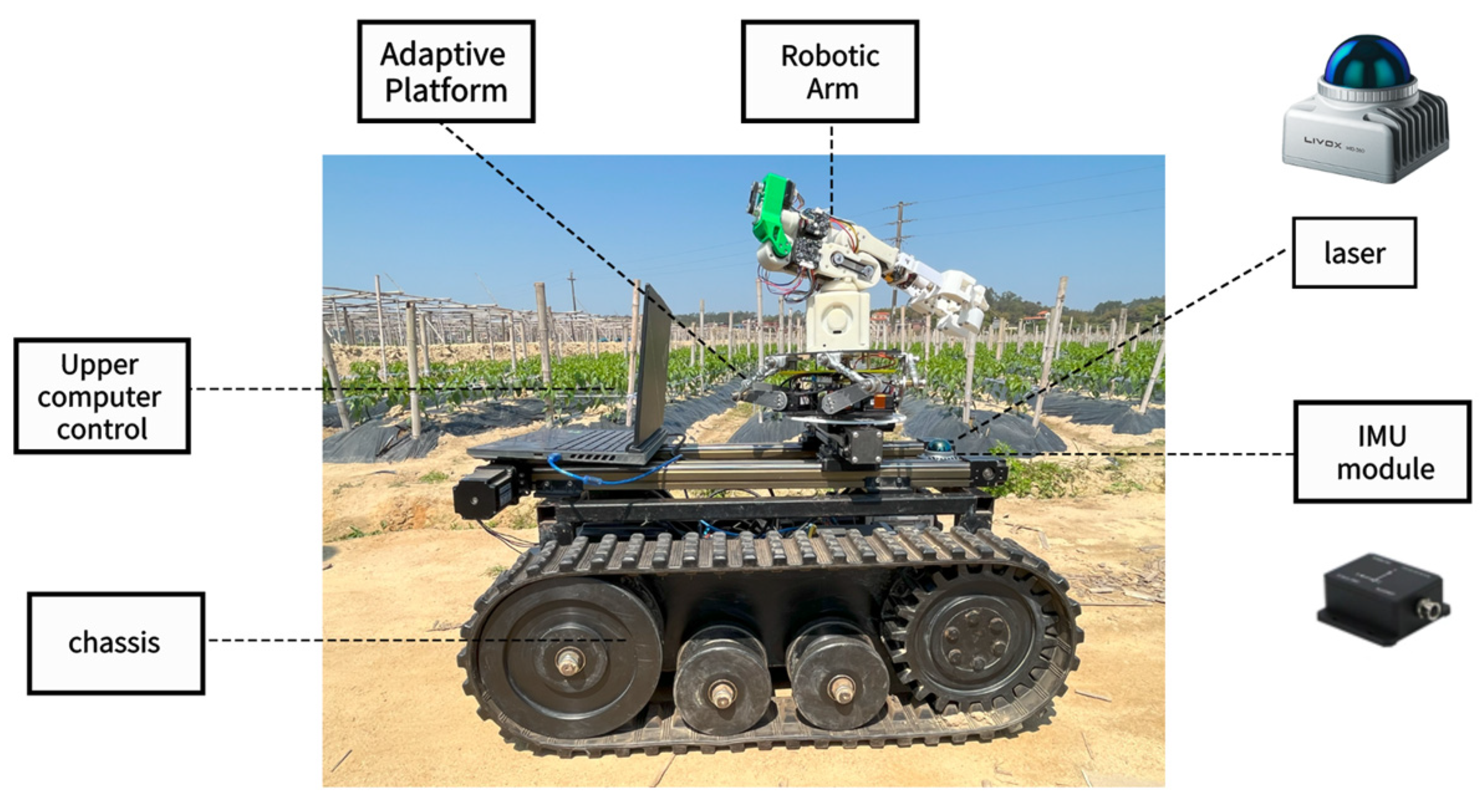

2.1. Overall Design of the Chili Pepper Harvesting System

2.1.1. Design of the Harvesting Platform

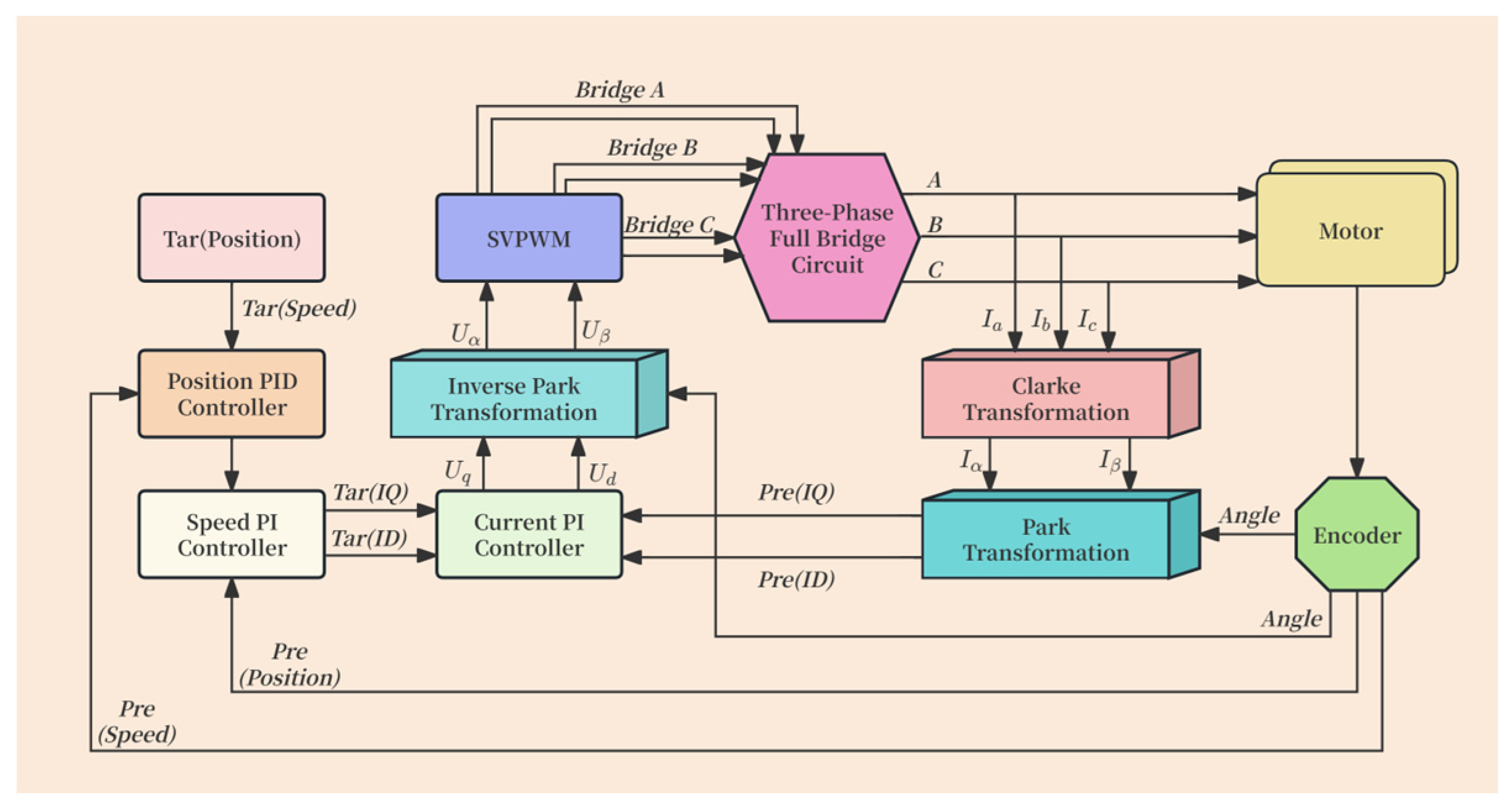

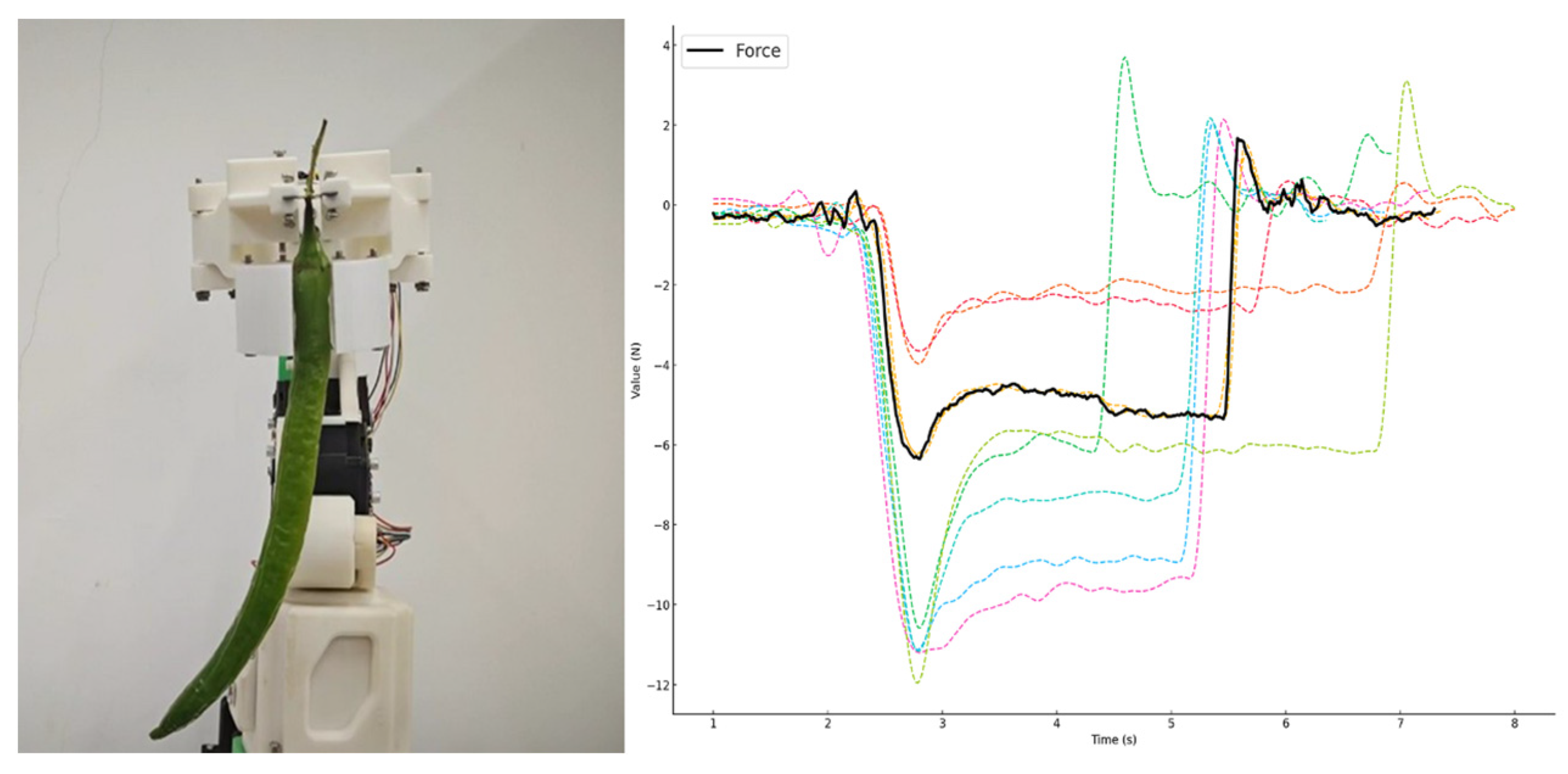

2.1.2. Design of the End Effector

2.2. Chili Pepper Harvesting Point Localization

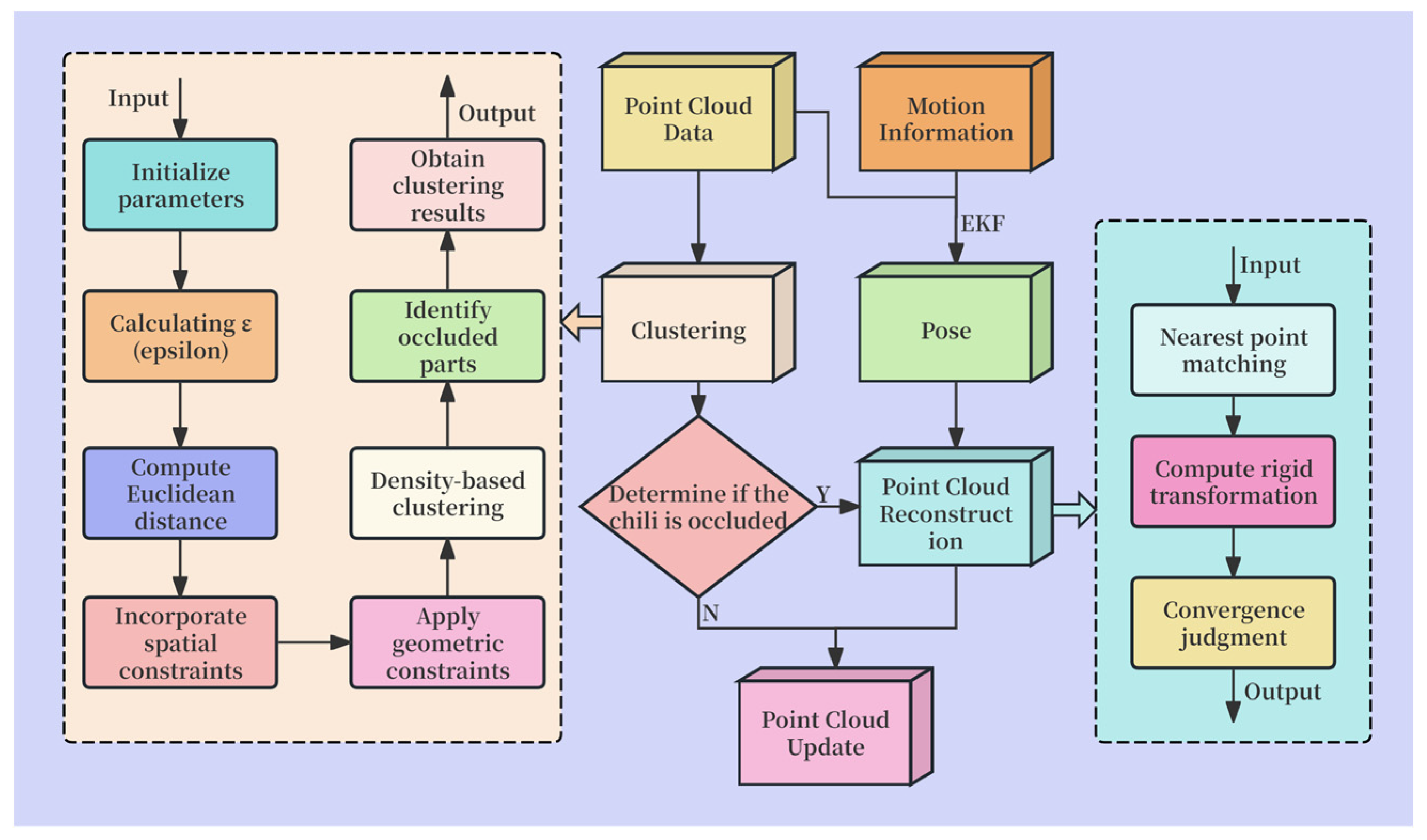

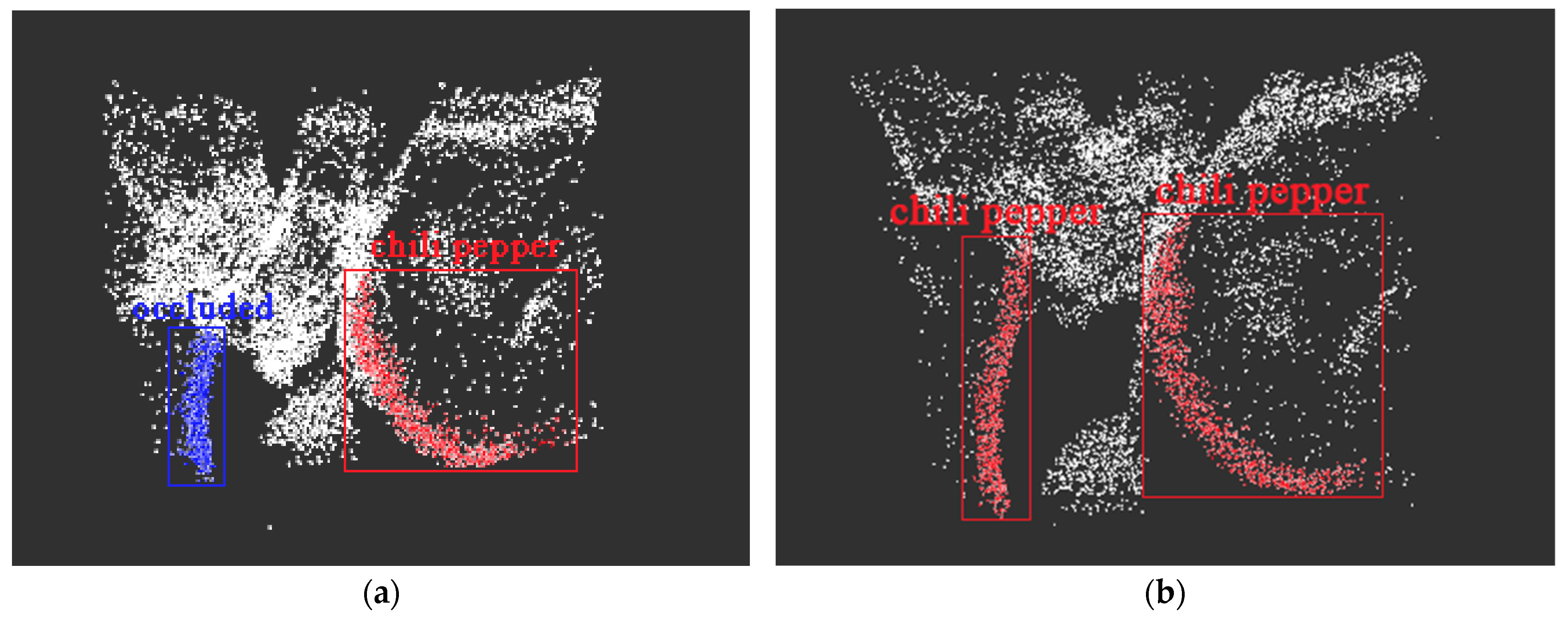

2.2.1. Point Cloud Preprocessing

2.2.2. Point Cloud Reconstruction and Localization

2.3. Experimental Design

2.3.1. Comparative Experiment

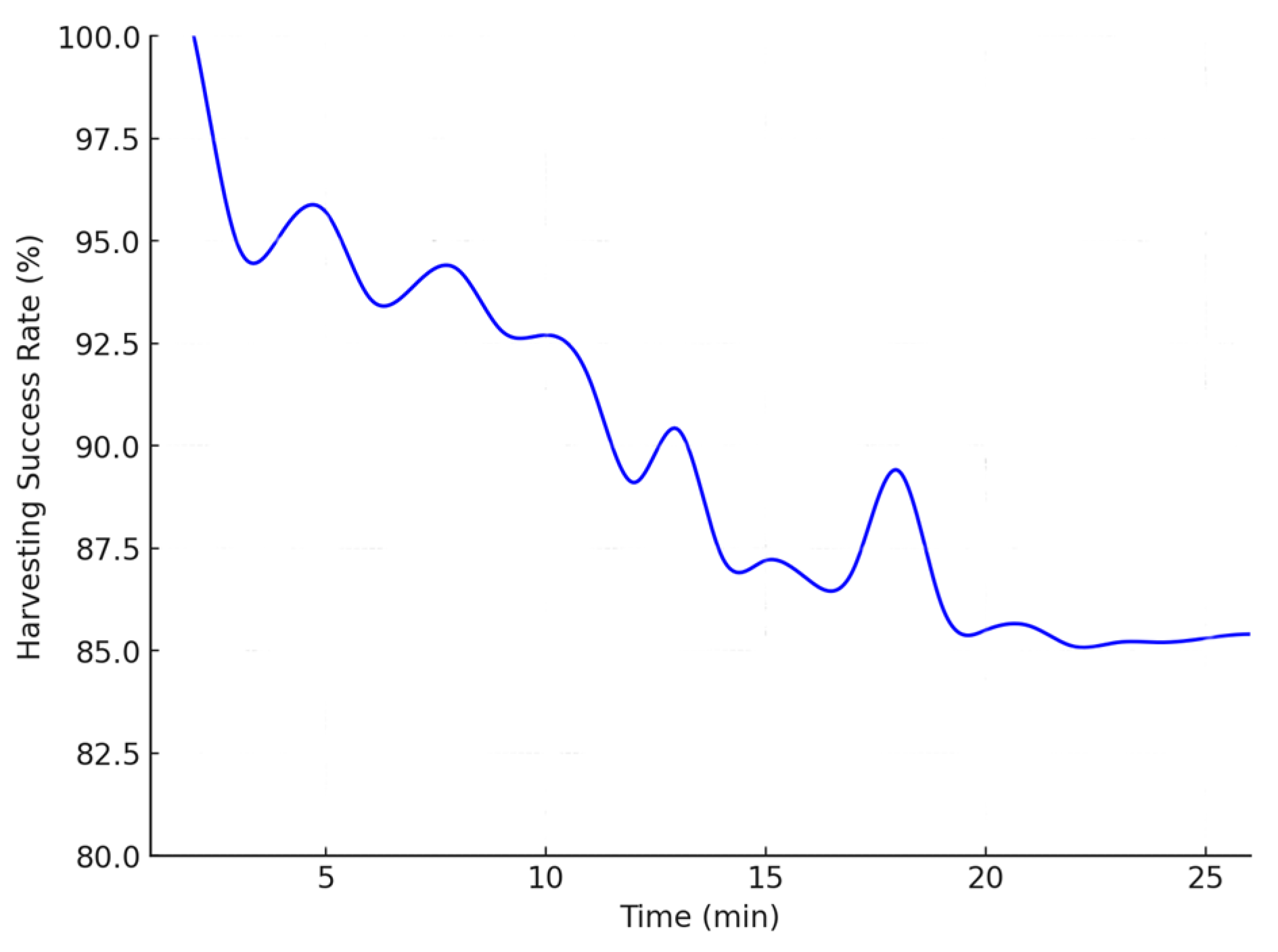

2.3.2. Continuous Experiment

3. Results

3.1. Comparative Experimental Results

3.2. Continuous Experimental Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Qiao, L.J.; Zhao, B.H.; Zong, Y.X.; Kou, C.Y.; Dong, Y.H. Development status, trend and countermeasures of chili industry in China. Chin. Veg. 2023, 11, 9–15. [Google Scholar]

- Ma, Y.X.; Wang, X.W.; Zhang, Y.X.; Kuai, J.L. Response of Yield, Quality, and Blossom-End Rot of Chili Peppers to Calcium Fertilization in Gobi Solar Greenhouses with Substrate Cultivation. North. Hortic. 2024, 24, 29–36. [Google Scholar]

- Zhang, Z.F. Current Status, Major Challenges, and Strategies for the Development of the Chili Pepper Industry in China. North. Hortic. 2023, 14, 153–158. [Google Scholar]

- Bai, L.L.; Hu, W.Z.; Jiang, A.L.; Liu, C.H.; Liu, Y.W. Current Status of Chili Pepper Processing Technology and Equipment. Food Ind. Technol. 2014, 35, 369–372+376. [Google Scholar]

- Zou, X.X.; Ma, Y.Q.; Dai, X.Z.; Li, X.F.; Yang, S. The Spread and Industrial Development of Chili Peppers in China. Acta Hortic. 2020, 47, 1715–1726. [Google Scholar] [CrossRef]

- Zou, X.X.; Yang, S.; Dai, X.Z.; Hu, B.W.; Xu, H.; Zhu, F.; Pei, S.Y.; Yuan, F. A 40-Year Review and Prospect of the Rapid Development of the Chili Pepper Industry in China. Acta Hortic. 2025, 52, 247–258. [Google Scholar] [CrossRef]

- Huang, D.M.; Wei, J.L.; Wu, S.H.; Lin, M. Analysis of the Development Status of the Chili Pepper Processing Industry in Guizhou Province. China Condiments 2019, 44, 187–189+194. [Google Scholar]

- Ren, H.C.; Li, X.L.; Gui, M.; Li, W.F.; Liu, F.W. Development Status and Countermeasures of Yunnan’s Characteristic Chili Pepper Industry. China Veg. 2022, 8, 7–12. [Google Scholar] [CrossRef]

- Wang, L.H.; Zhang, B.X.; Zhang, Z.H.; Cao, Y.C.; Yu, H.L.; Feng, X.G. “The 13th Five-Year Plan” Progress in Chili Pepper Breeding Research, Industry Status, and Prospects in China. China Veg. 2021, 2, 21–29. [Google Scholar] [CrossRef]

- Pi, W. Comprehensive Integration of Artificial Intelligence Technology and Smart Agriculture Development. J. Cotton Sci. 2023, 35, 251. [Google Scholar]

- Liu, C.L.; Gong, L.; Yuan, J.; Li, Y.M. Key Technologies in Agricultural Robots: Current Status and Development Trends. J. Agric. Mech. 2022, 53, 1–22+55. [Google Scholar]

- Roshandel, N.; Scholz, C.; Cao, H.L.; Amighi, M.; Firouzipouyaei, H.; Burkiewicz, A.; Menet, S.; Ballen Moreno, F.; Warawout Sisavath, D.; Imrith, E.; et al. mmPrivPose3D: A Dataset for Pose Estimation and Gesture Command Recognition in Human-Robot Collaboration Using Frequency Modulated Continuous Wave 60Hz RaDAR. Data Brief 2025, 59, 111316. [Google Scholar] [CrossRef]

- Xue, C.W.; Liu, T.; Deng, L.B.; Gu, W.; Zhang, B.W. Improvement of DBSCAN Classification Differential Evolution Algorithm Based on Principal Component Analysis. Mod. Electron. Technol. 2024, 47, 171–179. [Google Scholar]

- Li, C.; Zhou, J.; Du, K.; Tao, M. Enhanced Discontinuity Characterization in Hard Rock Pillars Using Point Cloud Completion and DBSCAN Clustering. Int. J. Rock Mech. Min. Sci. 2025, 186, 106005. [Google Scholar] [CrossRef]

- Hu, J.; Xu, X.; Cao, C.; Tian, Z.; Ma, Y.; Sun, X.; Yang, J. Vibration Position Detection of Robot Arm Based on Feature Extraction of 3D Lidar. Sensors 2024, 24, 6584. [Google Scholar] [CrossRef]

- Qin, J.; Wang, W.B.; Zou, Q.J.; Wang, Z.M.; Ji, C.Q. A Review of 3D Object Detection Methods Based on LiDAR Point Clouds. Comput. Sci. 2023, 50, 259–265. [Google Scholar]

- Li, N.; Gao, X.; Yang, L.; Jiang, H.Y.; Zhang, L.J.; Chen, G.Y. Dynamic Path Planning for Harvesting Robotic Arm Based on Improved Algorithm Fusion and Switching. J. Agric. Mech. 2024, 55, 221–230+272. [Google Scholar]

- Liu, W.H.; He, X.K.; Liu, Y.J.; Wu, Z.M.; Yuan, C.J.; Liu, L.M.; Qi, P.; Li, T. 3D LiDAR Navigation Method for Orchard Aisles. Trans. Agric. Eng. 2021, 37, 165–174. [Google Scholar]

- Wang, Y.; Han, Q.; Habermann, M.; Daniilidis, K.; Theobalt, C.; Liu, L. NeuS2: Fast Learning of Neural Implicit Surfaces for Multi-View Reconstruction. In Proceedings of the 2023 IEEE/CVF International Conference on Computer Vision (ICCV), Paris, France, 2–3 October 2023; pp. 3272–3283. [Google Scholar] [CrossRef]

- Liu, X.P.; Ma, Y.X.; Xu, K.; Wan, J.W.; Guo, Y.L. Multi-Scale Point Cloud Completion Embedded with Transformer Architecture. J. Image Graph. 2022, 27, 538–549. [Google Scholar] [CrossRef]

- Yang, D.; Yang, H.; Liu, D.; Wang, X. Research on Automatic 3D Reconstruction of Plant Phenotype Based on Multi-View Images. Comput. Electron. Agric. 2024, 220, 108866. [Google Scholar] [CrossRef]

- Xue, G.H.; Li, R.X.; Zhang, Z.H.; Liu, R. Research Status and Development Trends of SLAM Algorithms Based on 3D LiDAR. Inf. Control 2023, 52, 18–36. [Google Scholar] [CrossRef]

- Matsushima, T.; Noguchi, Y.; Arima, J.; Aoki, T.; Okita, Y.; Ikeda, Y.; Ishimoto, K.; Taniguchi, S.; Yamashita, Y.; Seto, S.; et al. World Robot Challenge 2020—Partner Robot: A Data-Driven Approach for Room Tidying with Mobile Manipulator. Adv. Robotics 2022, 36, 850–869. [Google Scholar] [CrossRef]

- Yang, J.; Lu, H.Z.; Li, J.; Zeng, X.Q. Modeling and Simulation of the Orchard Lifting Platform Leveling Mechanism. J. Agric. Mech. 2018, 40, 111–116. [Google Scholar] [CrossRef]

- Peng, Y.X.; Liao, K.; Xu, S.Y.; Chen, F.; Li, L.J.; Tang, G.C.; Luo, H. Development of a Wheeled Camellia Oleifera Fruit Harvesting Integrated Machine for Hilly Areas. Trans. Agric. Eng. 2024, 40, 31–38. [Google Scholar]

- Bao, X.L.; Ma, Z.T.; Ma, X.J.; Li, Y.S.; Ren, M.T.; Li, S.J. Design and Experiment of a Citrus Harvesting Robot for Hilly Orchards’ Natural Environment. J. Agric. Mech. 2024, 55, 124–135. [Google Scholar]

- Cao, X.; Zhong, P.; Huang, Y.; Huang, M.; Huang, Z.; Zou, T.; Xing, H. Research on Lightweight Algorithm Model for Precise Recognition and Detection of Outdoor Strawberries Based on Improved YOLOv5n. Agriculture 2025, 15, 90. [Google Scholar] [CrossRef]

- Wang, Y.Q.; Tang, Y.; Yang, G.Y. Design and Experiment of Control System for Robot Citrus Harvesting. Chin. J. Agric. Mech. 2023, 44, 146–153. [Google Scholar]

- Gong, L.; Wang, W.J.; Wang, T.; Liu, C.L. Robotic Harvesting of the Occluded Fruits with a Precise Shape and Position Reconstruction Approach. J. Field Robot. 2021, 39, 69–84. [Google Scholar] [CrossRef]

- Duan, S.C. Dynamics Data Acquisition System for Harvesting Robotic Arm Based on Three-Axis Gyroscope. J. Agric. Mech. 2022, 44, 37–41. [Google Scholar]

- Yu, Y.C.; Kang, F.; Zheng, Y.J.; Lv, H.T.; Wang, Y.X. Design and Simulation of a High-Level Automatic Leveling Work Platform for Orchards. J. Beijing For. Univ. 2021, 43, 150–159. [Google Scholar]

- Framing, C.-E.; Hedinger, R.; Iglesias, E.S.; Heßeler, F.-J.; Abel, D. EduBal: An Open Balancing Robot Platform for Teaching Control and System Theory. IFAC Pap. Online 2020, 53, 17168–17173. [Google Scholar] [CrossRef]

- Han, W.; Gu, Q.; Gu, H.; Xia, R.; Gao, Y.; Zhou, Z.; Luo, K.; Fang, X.; Zhang, Y. Design of Chili Field Navigation System Based on Multi-Sensor and Optimized TEB Algorithm. Agronomy 2024, 14, 2872. [Google Scholar] [CrossRef]

- Wang, K.; Zhang, J.; Xu, Z.; Xu, Y. Interpretation of Land Use Planning Technical Regulations Based on Integration and Oriented to Transformation—“Urban Land Use Classification and Planning Land Use Standards (GB50137-2011)”. Urban Plan. 2012, 36, 42–48+92. [Google Scholar]

- Chen, T.; Zhang, S.; Chen, J.; Fu, G.; Chen, Y.; Zhu, L. Development, Integration, and Field Experiment Optimization of an Autonomous Banana-Picking Robot. Agriculture 2024, 14, 1389. [Google Scholar] [CrossRef]

- Chen, Z.; Lei, X.; Yuan, Q.; Qi, Y.; Ma, Z.; Qian, S.; Lyu, X. Key Technologies for Autonomous Fruit- and Vegetable-Picking Robots: A Review. Agronomy 2024, 14, 2233. [Google Scholar] [CrossRef]

- Liu, S.; Li, S.; Miao, H.; Chai, Y.; Chen, F.; Wang, J.; Dong, P. Research on Recognition and Localization of Pepper-Picking Robots in Different Scenarios Based on YOLOv3. J. Agric. Mech. Res. 2024, 46, 38–43. [Google Scholar]

| Adaptive Leveling Platform | MID-360 | IMU Inertial Navigation System | Visual System | |

|---|---|---|---|---|

| Scheme 1 | √ | √ | ||

| Scheme 2 | √ | √ | ||

| Scheme 3 | √ | √ | √ | |

| Scheme 4 | √ | √ | √ |

| Scheme | Harvesting Success Rate | Harvesting Time Consumption/s | Occluded Pepper Recognition Success Rate | Unoccluded Pepper Recognition Success Rate | Pepper Damage Rate |

|---|---|---|---|---|---|

| Scheme 1 | 63.67% | 15.72 | 72.27% | 78.94% | 1.84% |

| Scheme 2 | 64.33% | 15.37 | 73.09% | 78.63% | 1.76% |

| Scheme 3 | 86.33% | 13.17 | 81.95% | 89.04% | 0.80% |

| Scheme 4 | 85.96% | 12.93 | 82.16% | 88.60% | 0.82% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, W.; Luo, J.; Wang, J.; Gu, Q.; Lin, L.; Gao, Y.; Chen, H.; Luo, K.; Zeng, Z.; He, J. Design of a Chili Pepper Harvesting Device for Hilly Chili Fields. Agronomy 2025, 15, 1118. https://doi.org/10.3390/agronomy15051118

Han W, Luo J, Wang J, Gu Q, Lin L, Gao Y, Chen H, Luo K, Zeng Z, He J. Design of a Chili Pepper Harvesting Device for Hilly Chili Fields. Agronomy. 2025; 15(5):1118. https://doi.org/10.3390/agronomy15051118

Chicago/Turabian StyleHan, Weikang, Jialong Luo, Jiatao Wang, Qihang Gu, Liujun Lin, Yuan Gao, Hongru Chen, Kangya Luo, Zhixiong Zeng, and Jie He. 2025. "Design of a Chili Pepper Harvesting Device for Hilly Chili Fields" Agronomy 15, no. 5: 1118. https://doi.org/10.3390/agronomy15051118

APA StyleHan, W., Luo, J., Wang, J., Gu, Q., Lin, L., Gao, Y., Chen, H., Luo, K., Zeng, Z., & He, J. (2025). Design of a Chili Pepper Harvesting Device for Hilly Chili Fields. Agronomy, 15(5), 1118. https://doi.org/10.3390/agronomy15051118