Experimental Research on the Atomization Characteristics of Air-Induction Spray Based on Oil-Based Emulsion

Abstract

1. Introduction

2. Materials and Methods

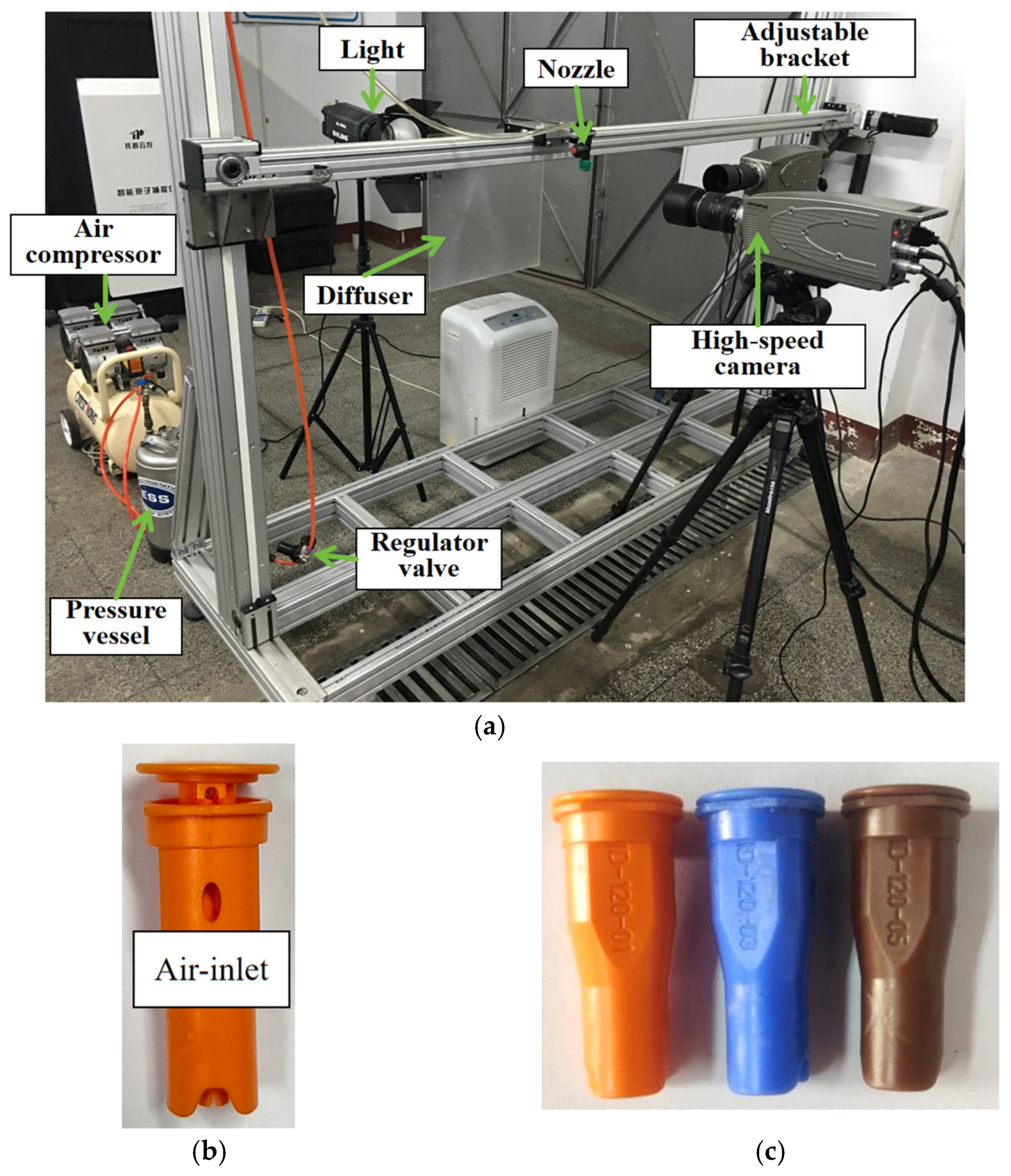

2.1. Experimental Equipment and Method

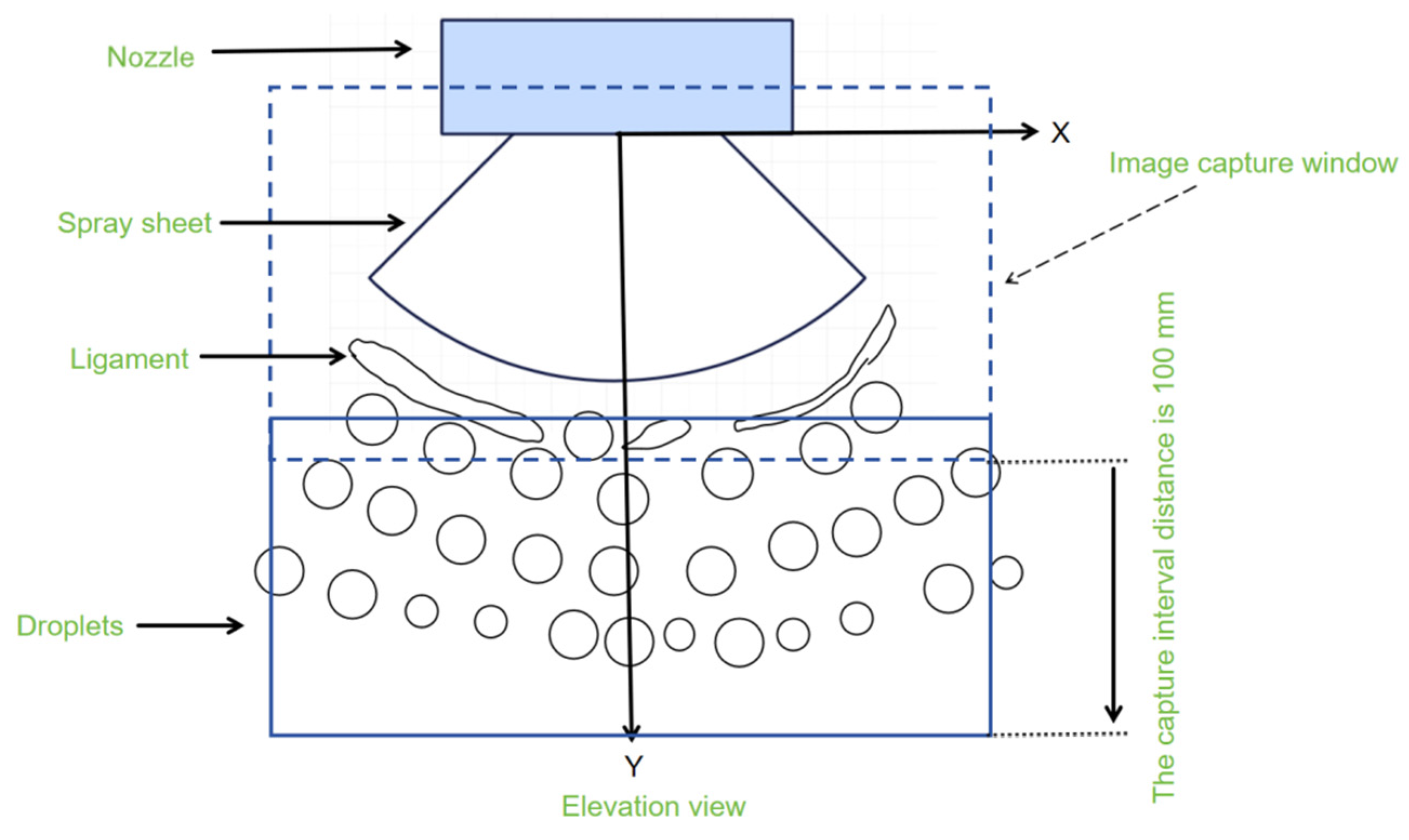

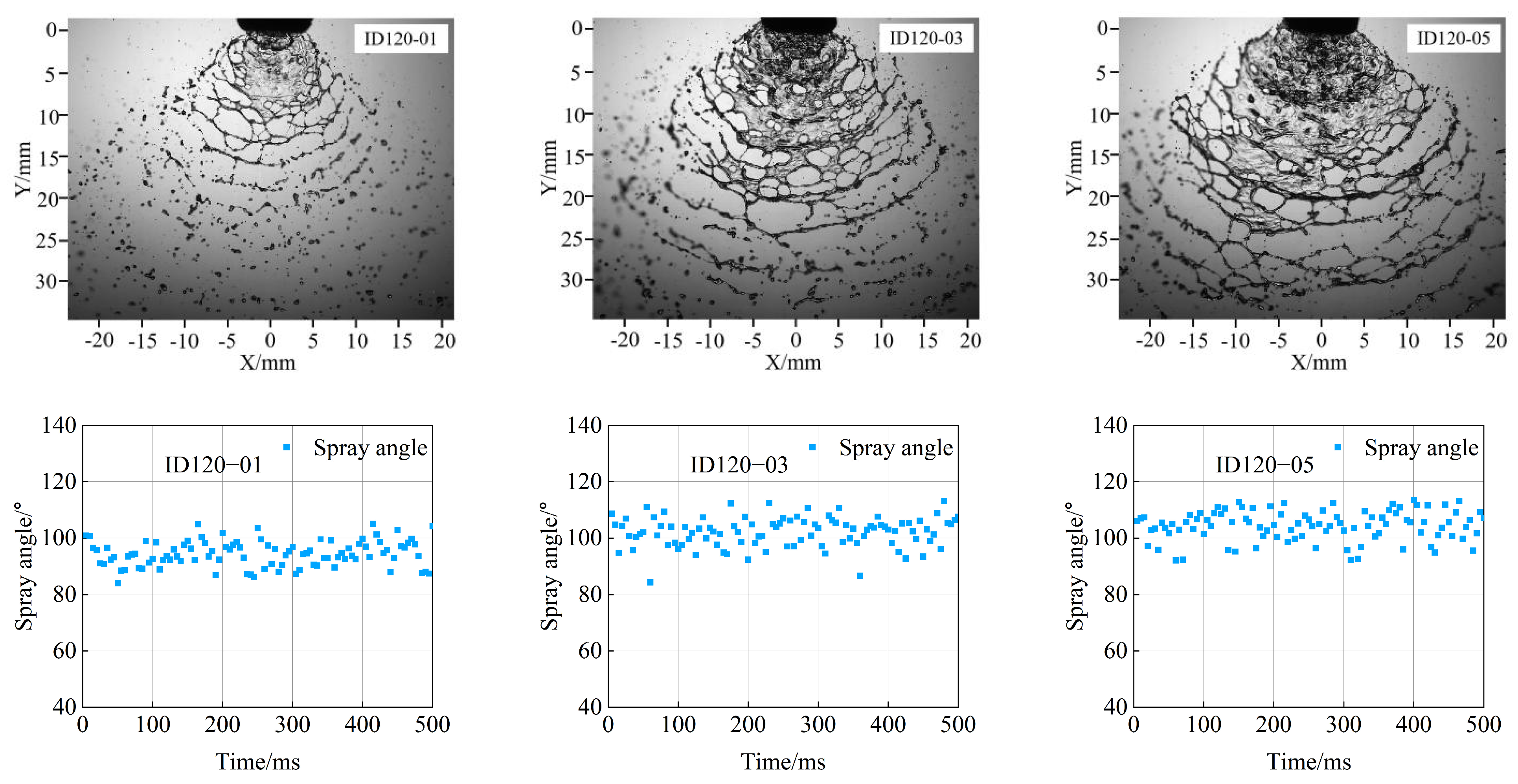

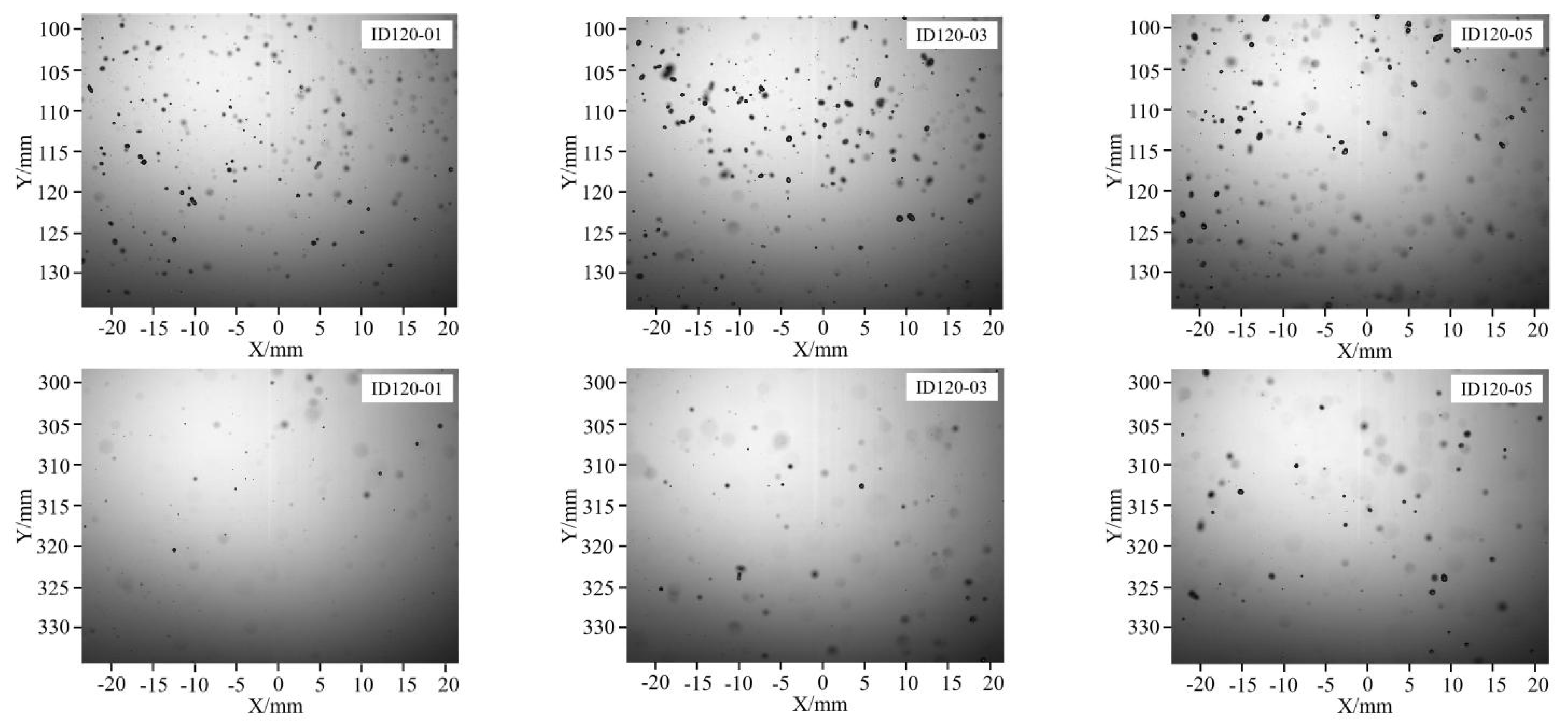

2.2. Capturing of Liquid Sheet and Spray Droplets

2.3. Measurement of Spray Angles

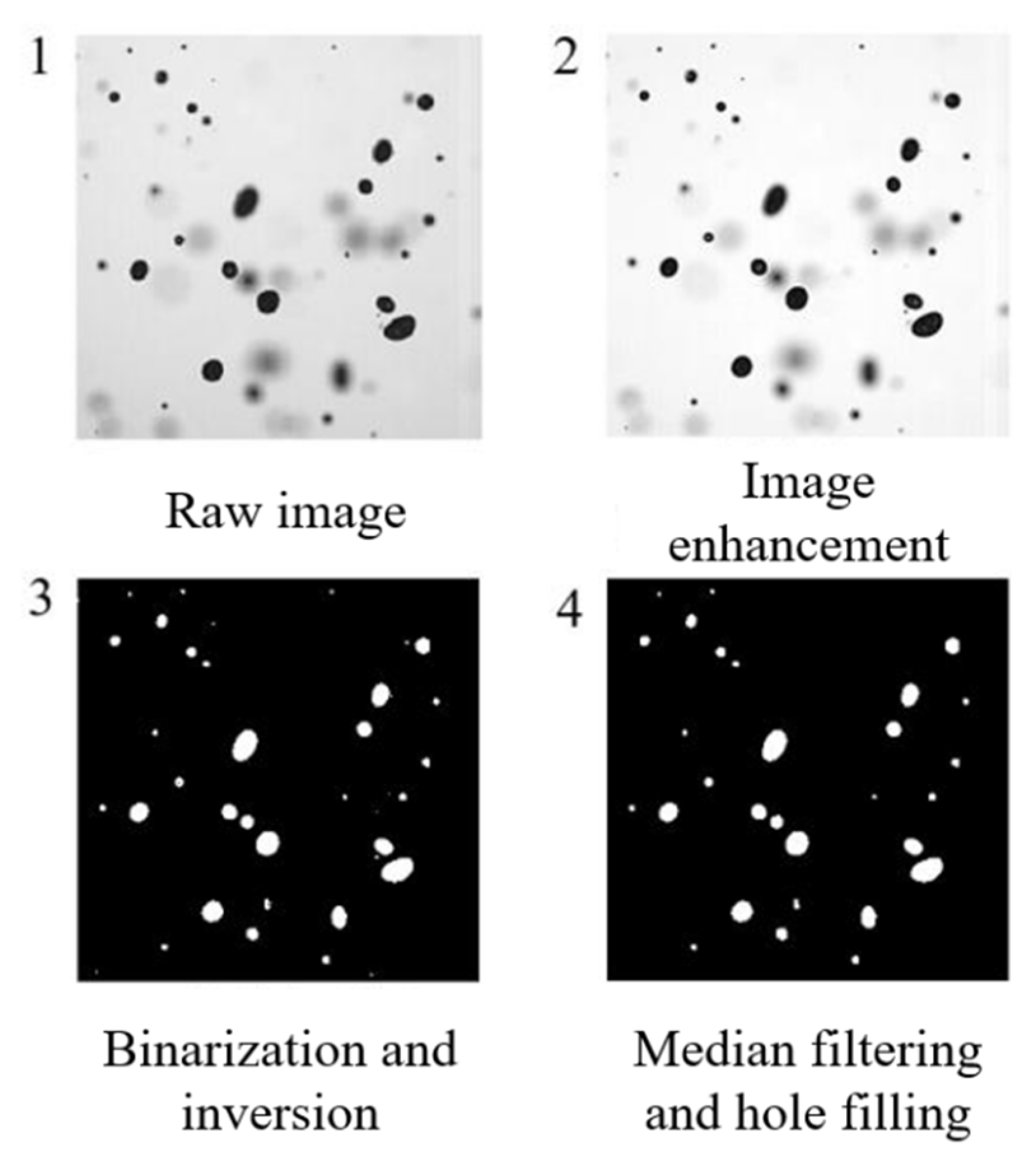

2.4. Measurement of Droplet Size

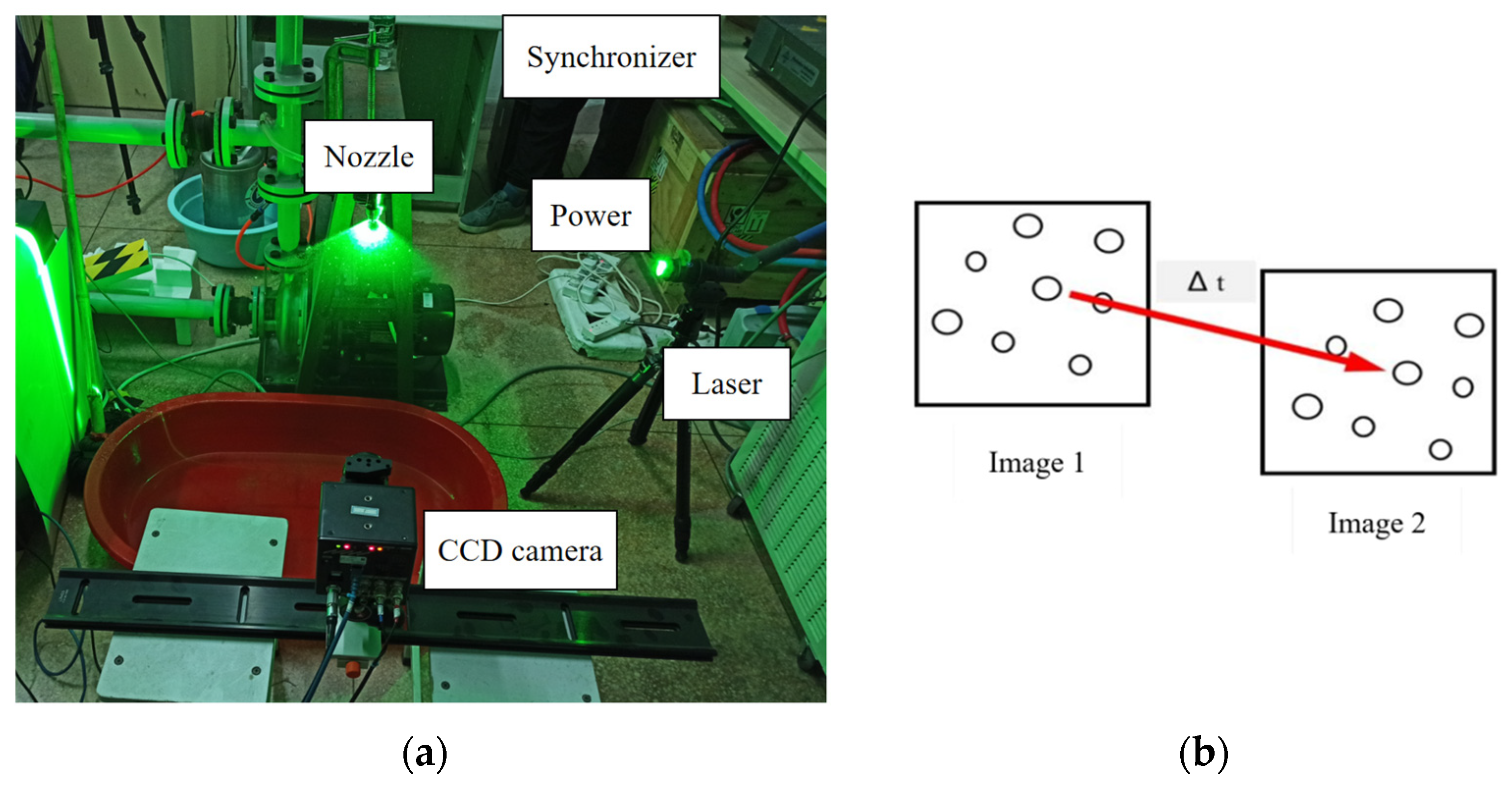

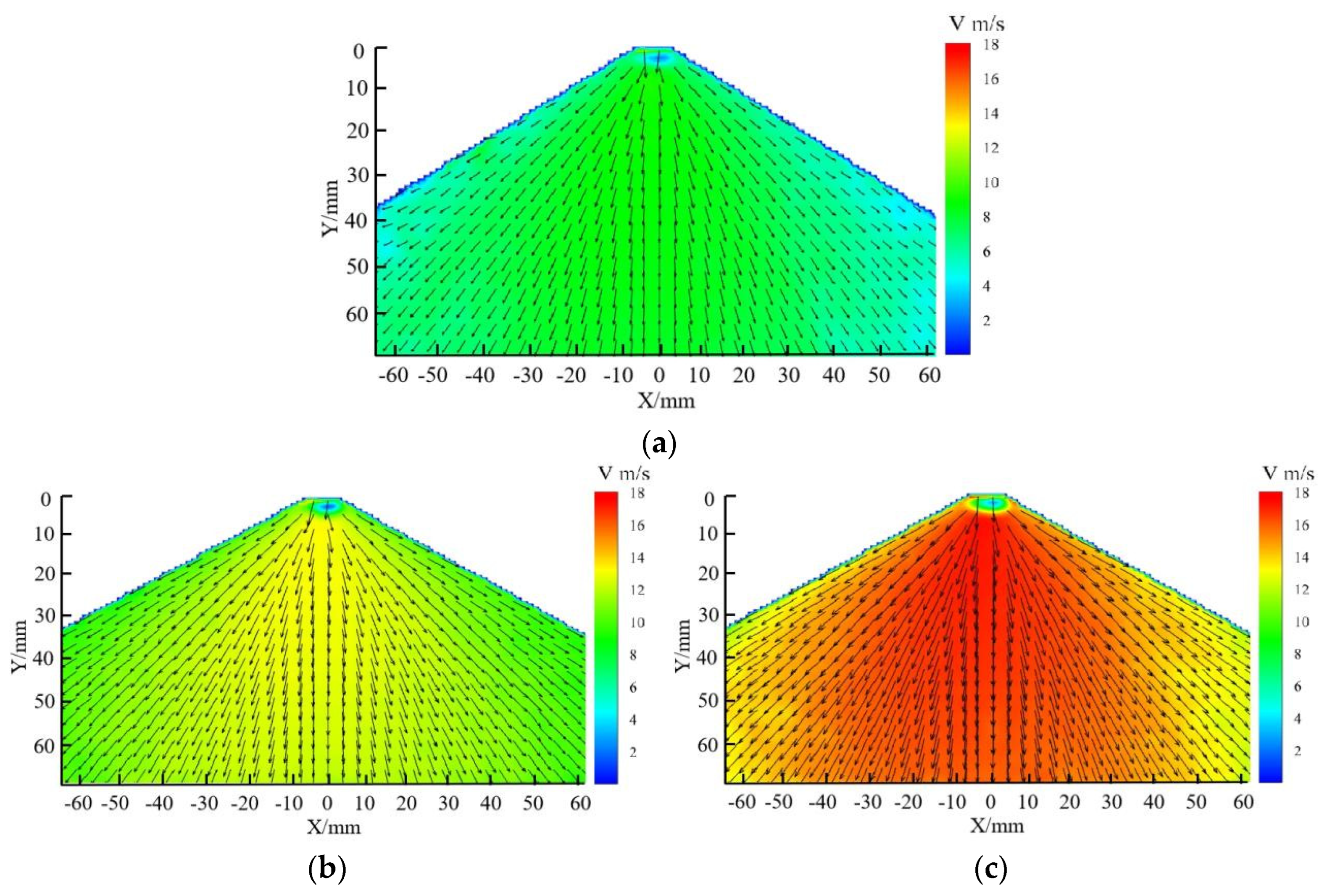

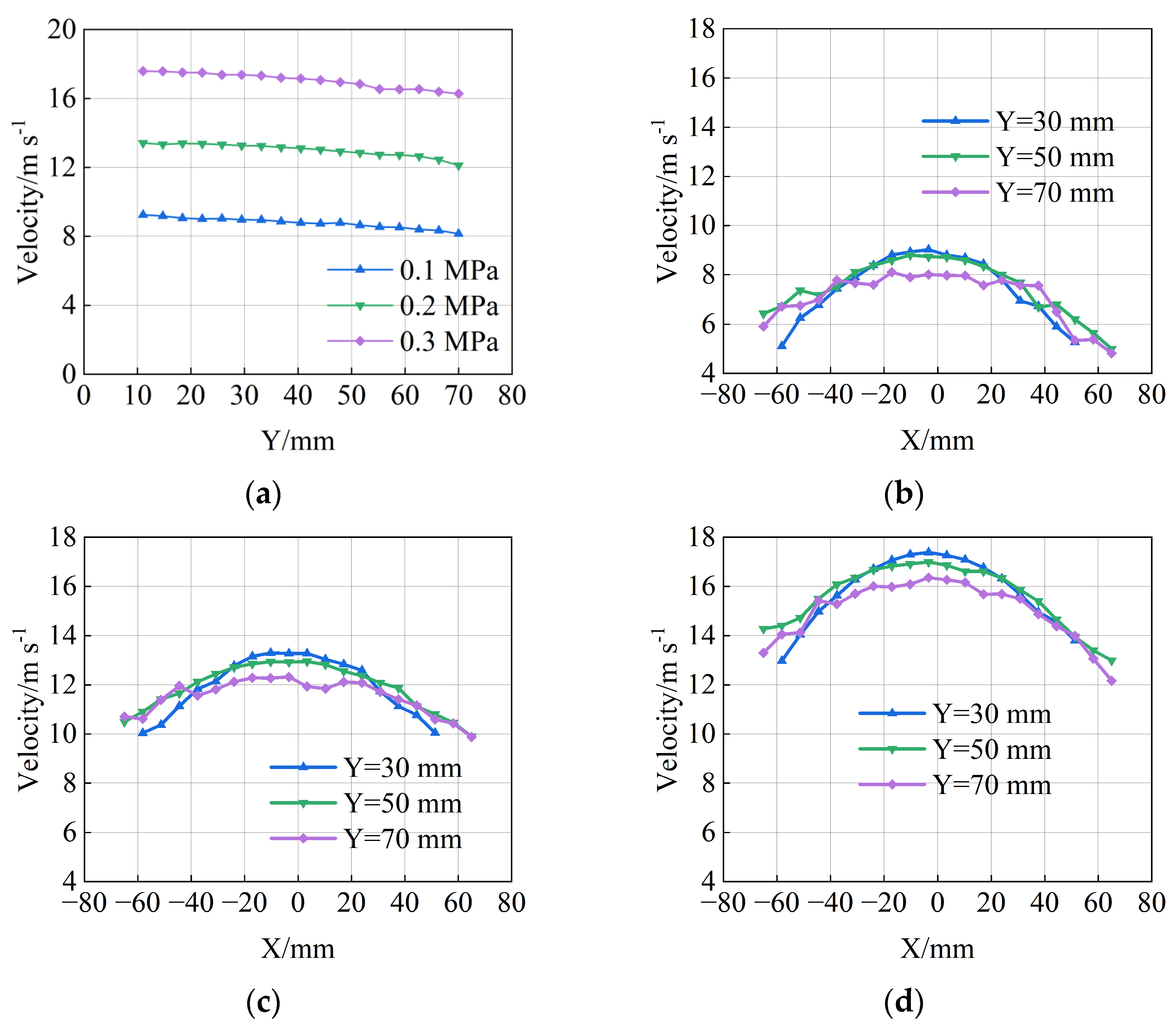

2.5. Measurement of Droplet Mean Velocity

3. Results and Analysis

3.1. Comparison of Atomization Characteristics Between Water and Oil-Based Emulsion Air-Induction Spray

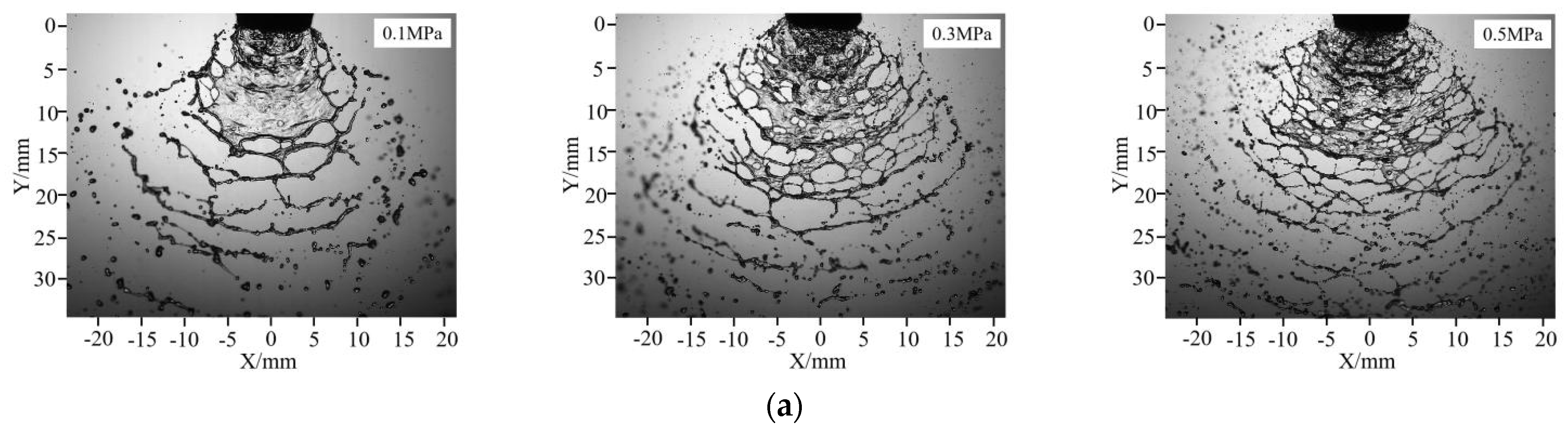

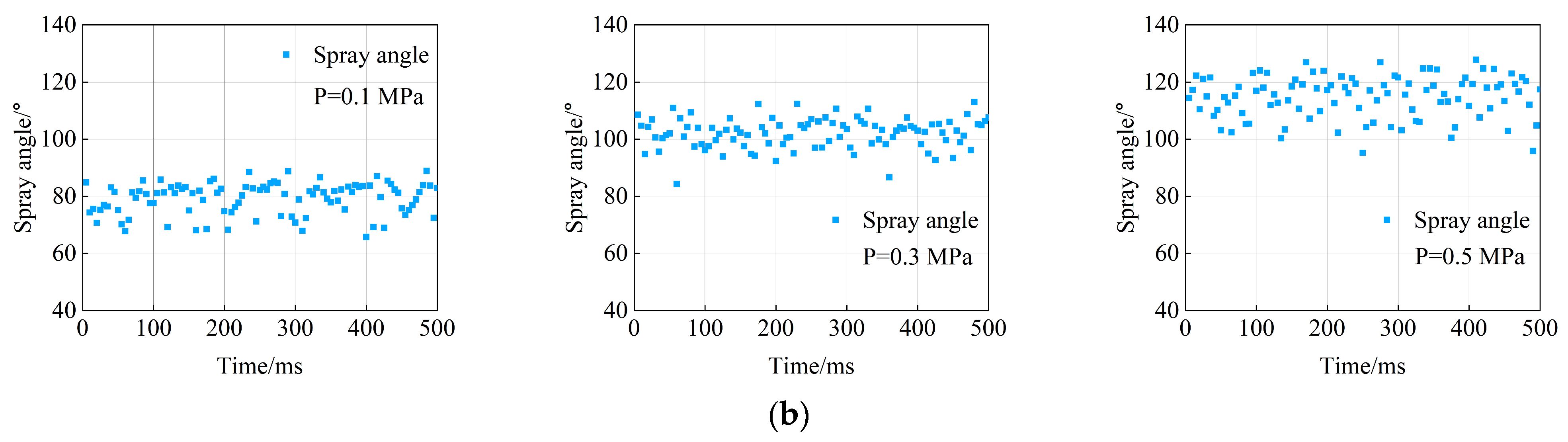

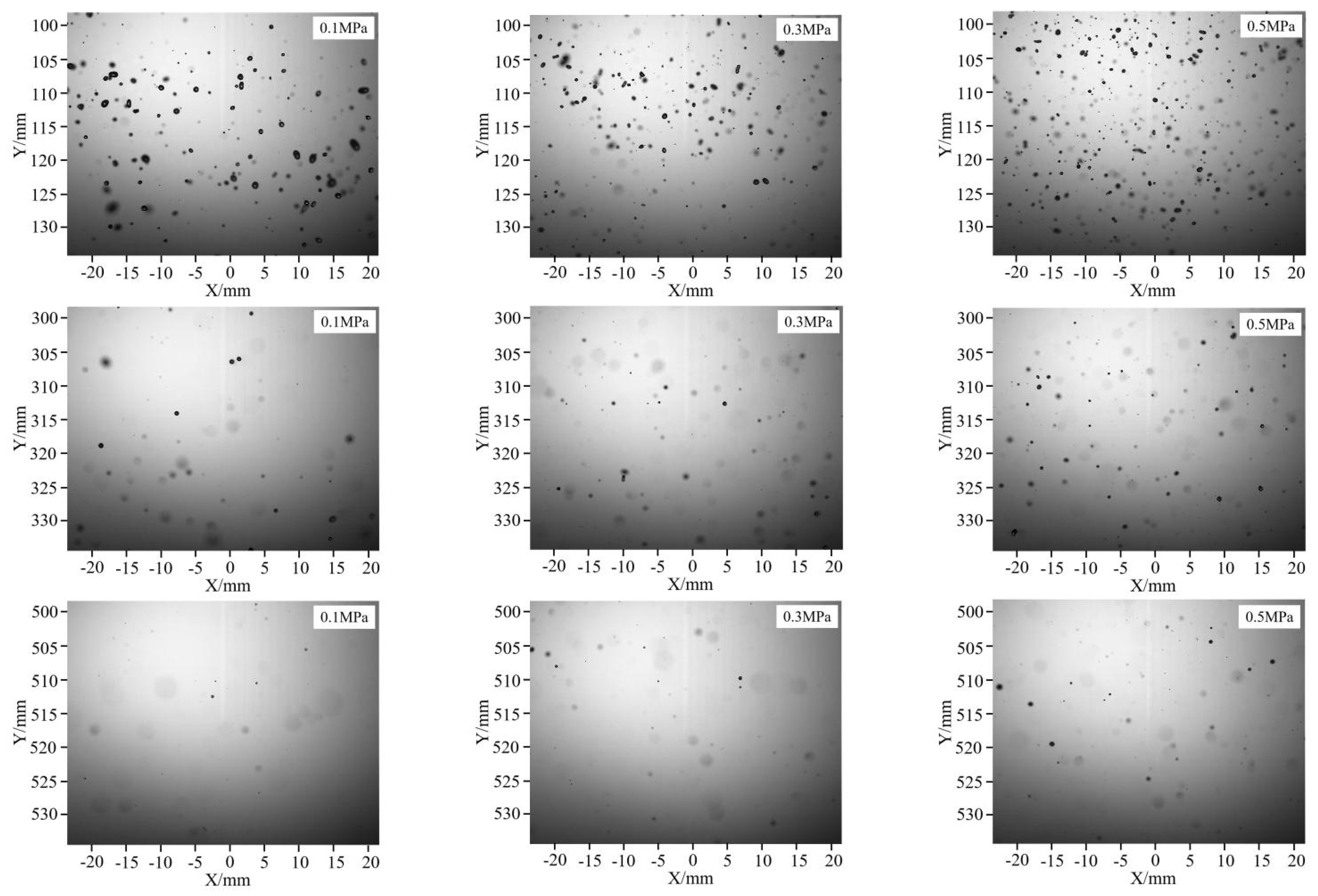

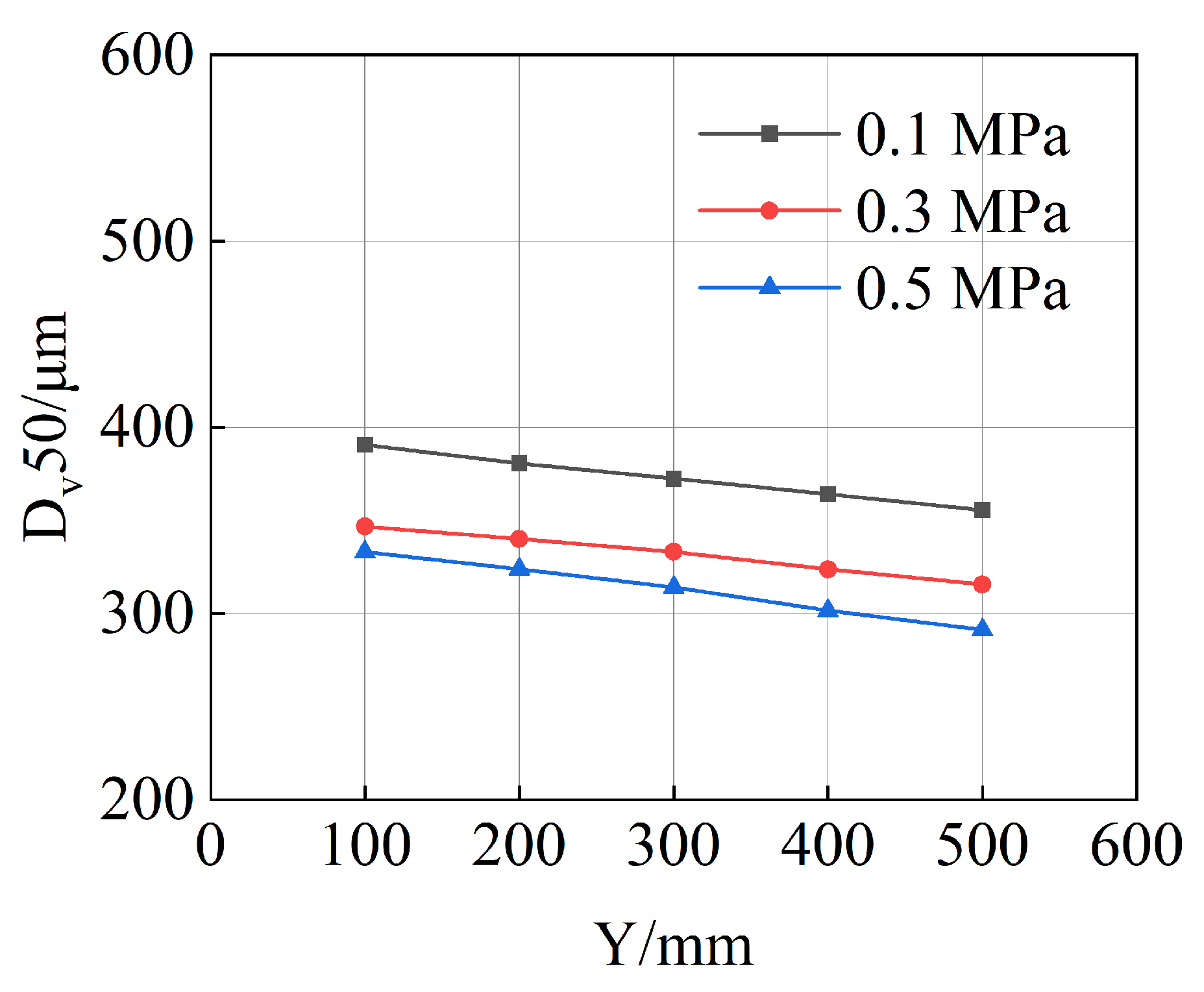

3.2. The Effect of Spray Pressure on the Atomization Characteristics of Oil-Based Emulsion Air-Induction Sprays

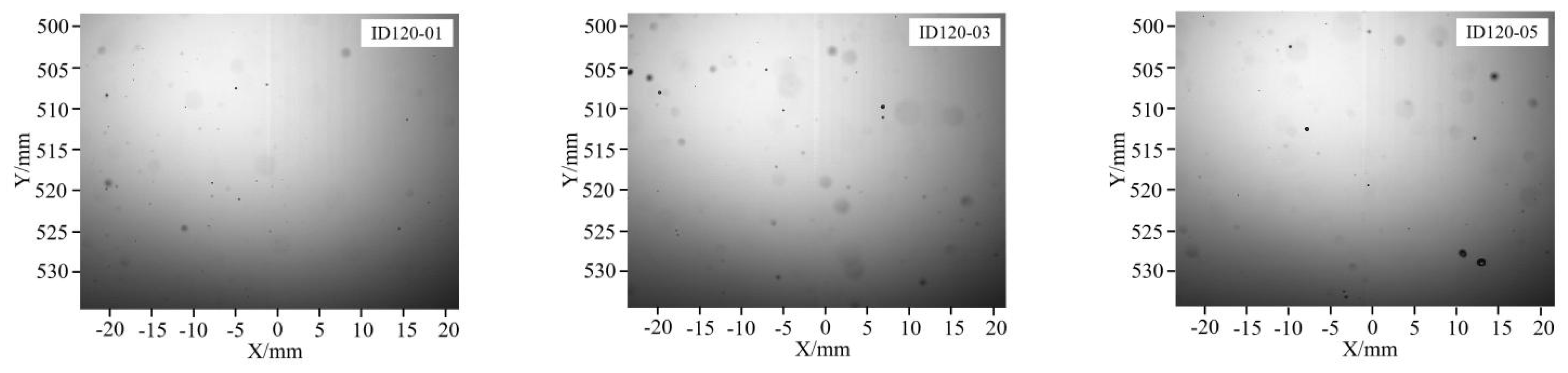

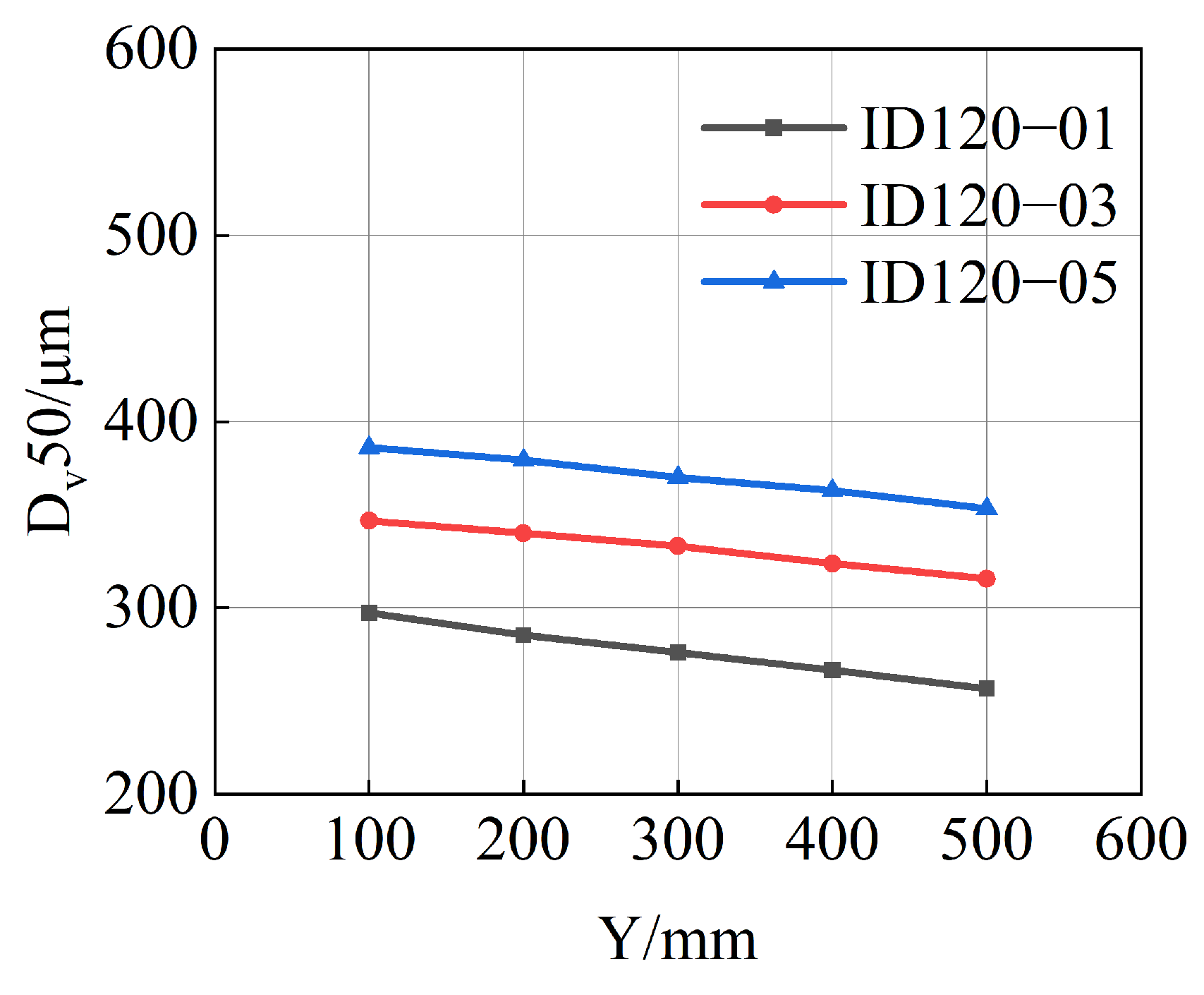

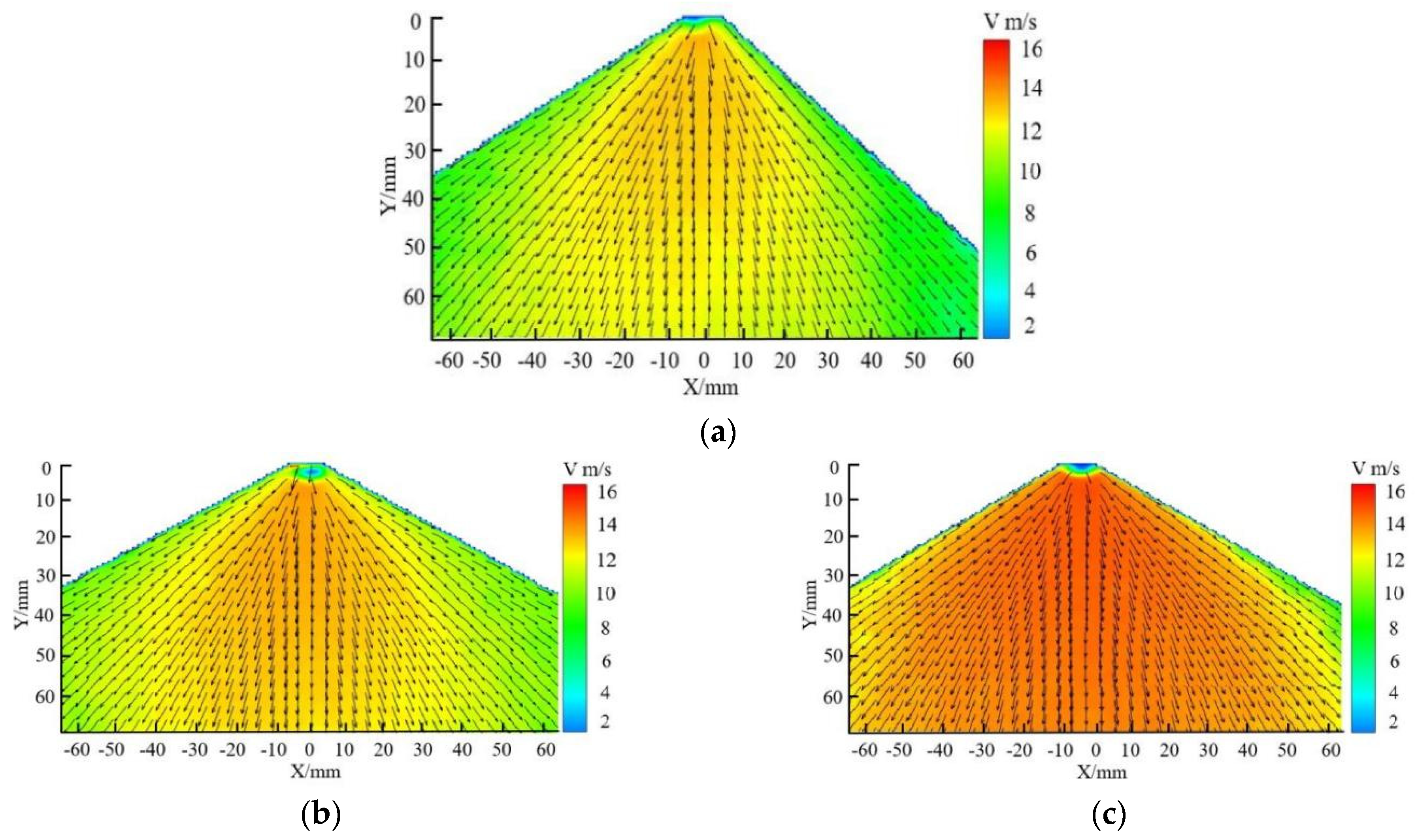

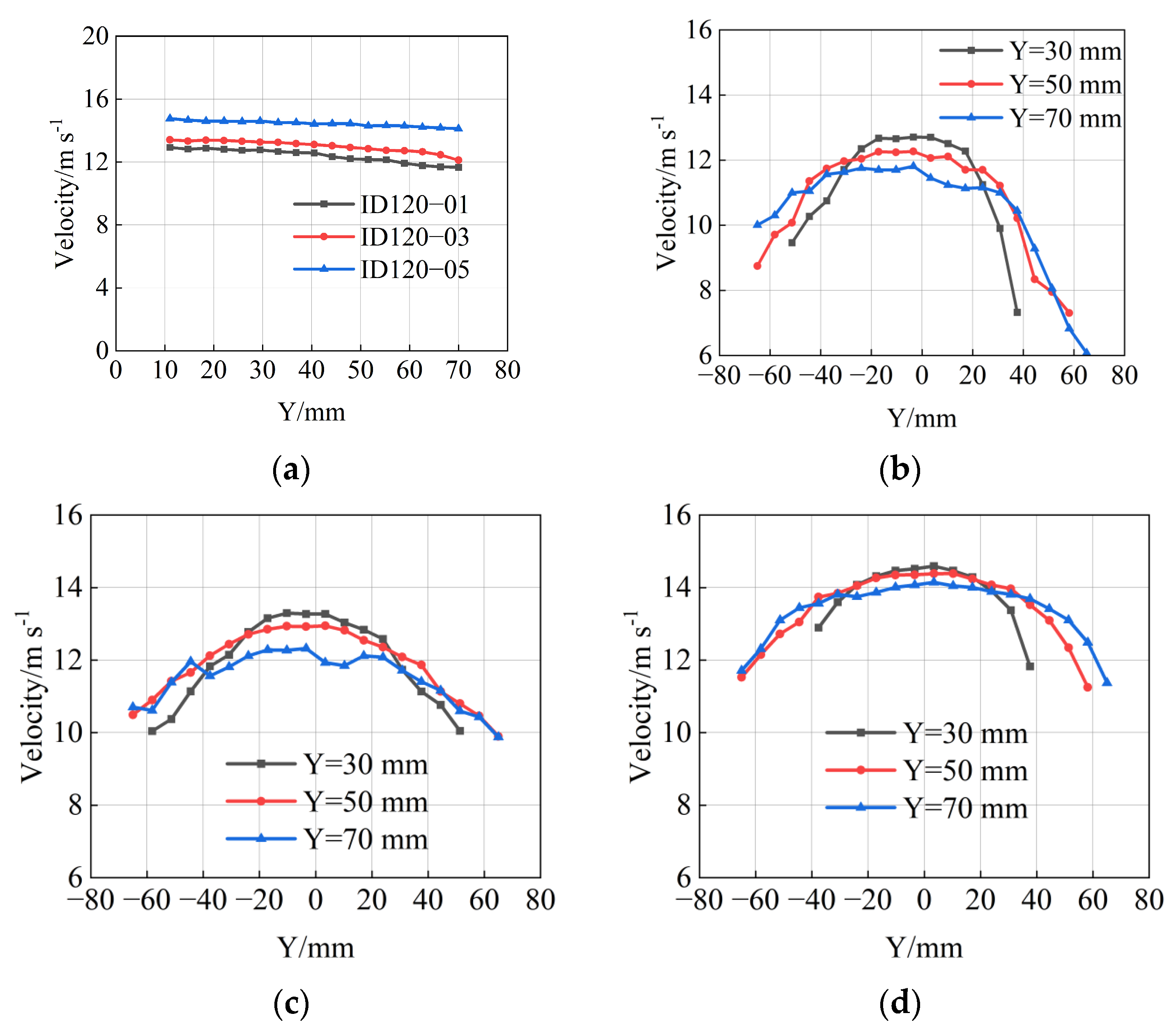

3.3. The Effect of Nozzle Configuration on the Atomization Characteristics of Oil-Based Emulsion Air-Induction Sprays

4. Conclusions

- 1.

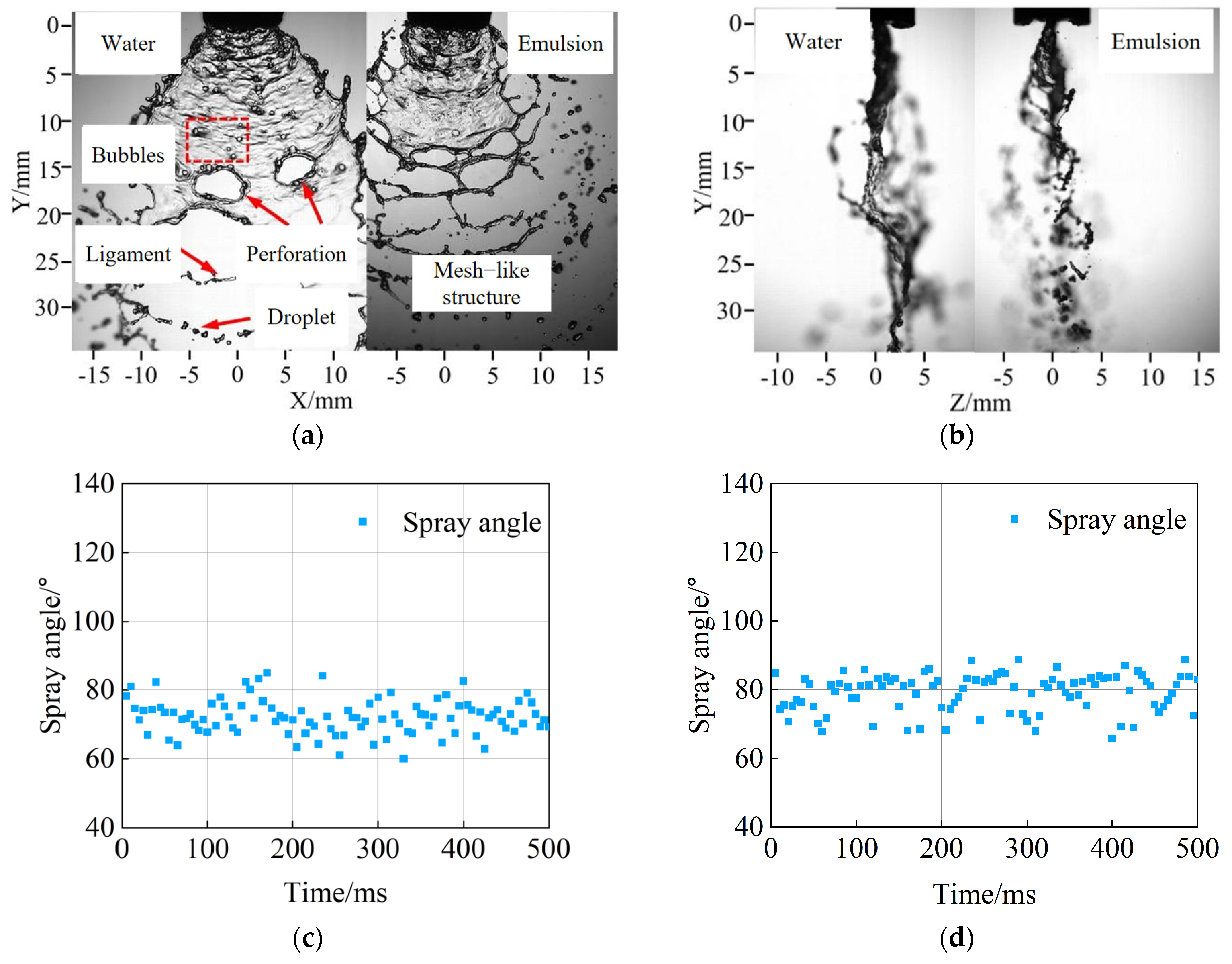

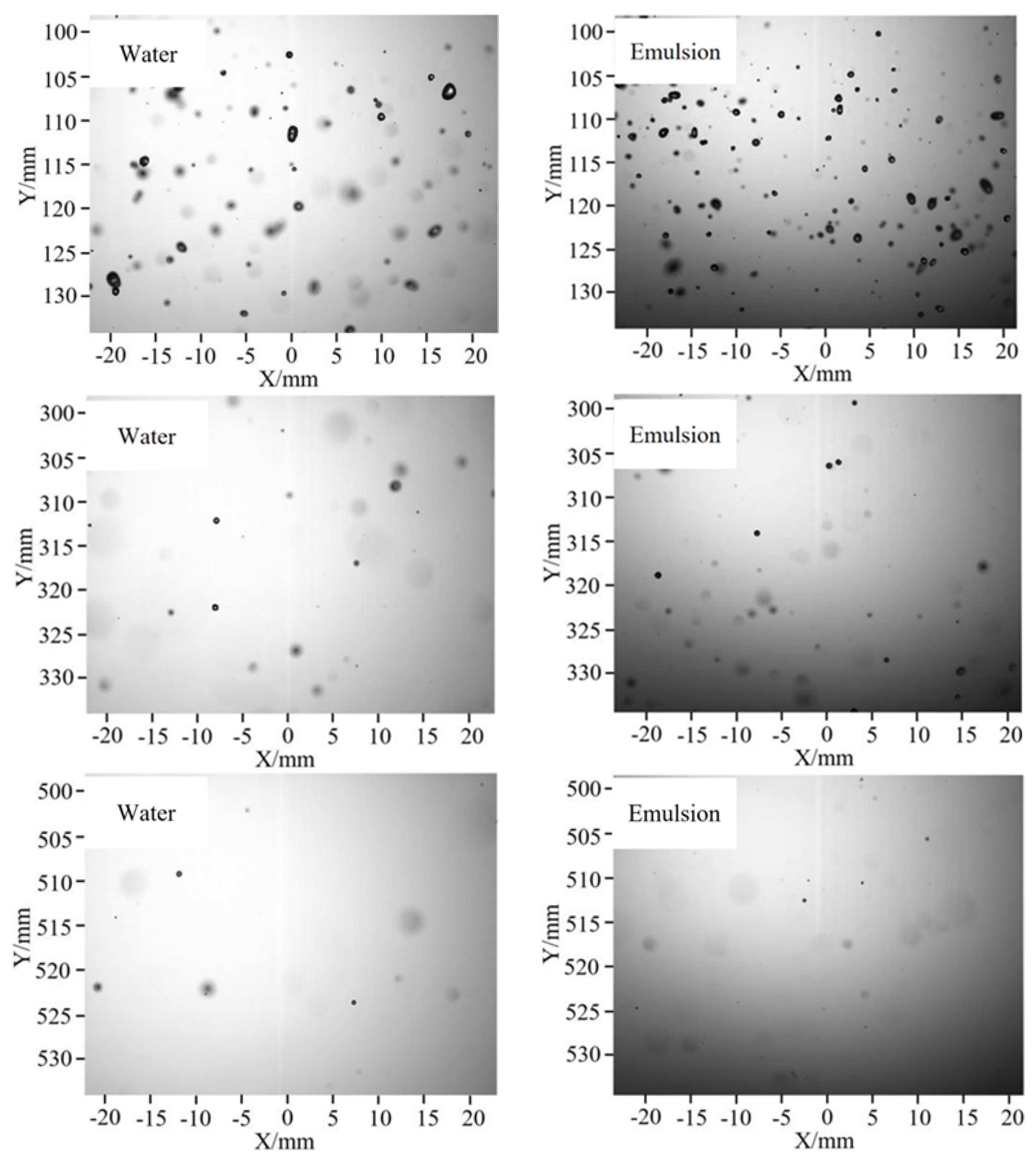

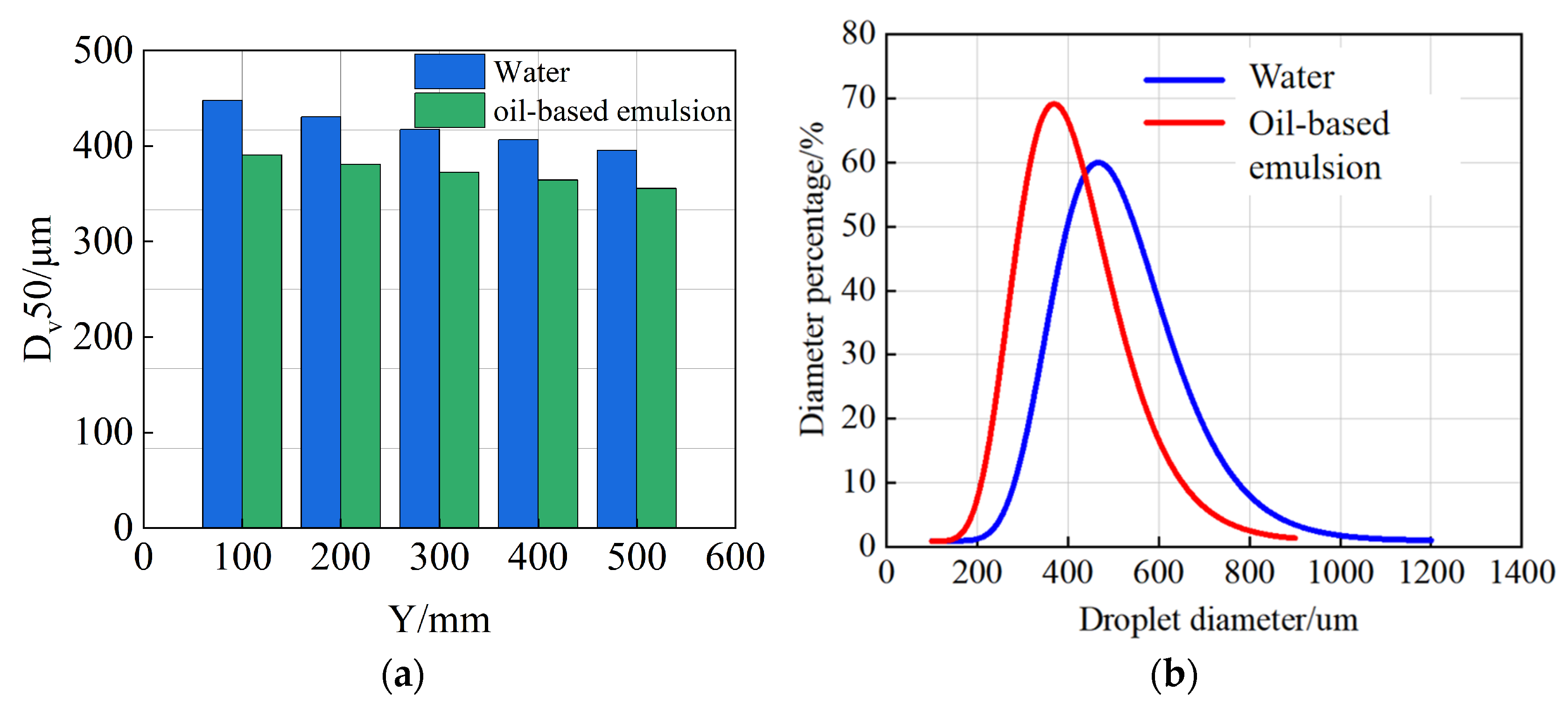

- When the spray liquid changes from water to oil-based emulsion, the atomization characteristics of air-induction spray significantly change. For the water spray, the liquid sheet features relatively bigger bubbles and holes. For the oil-based emulsion spray, the bubble size is significantly reduced, and the presence of oil droplets causes the liquid sheet to break up into a mesh-like structure, promoting the early formation of droplets.

- 2.

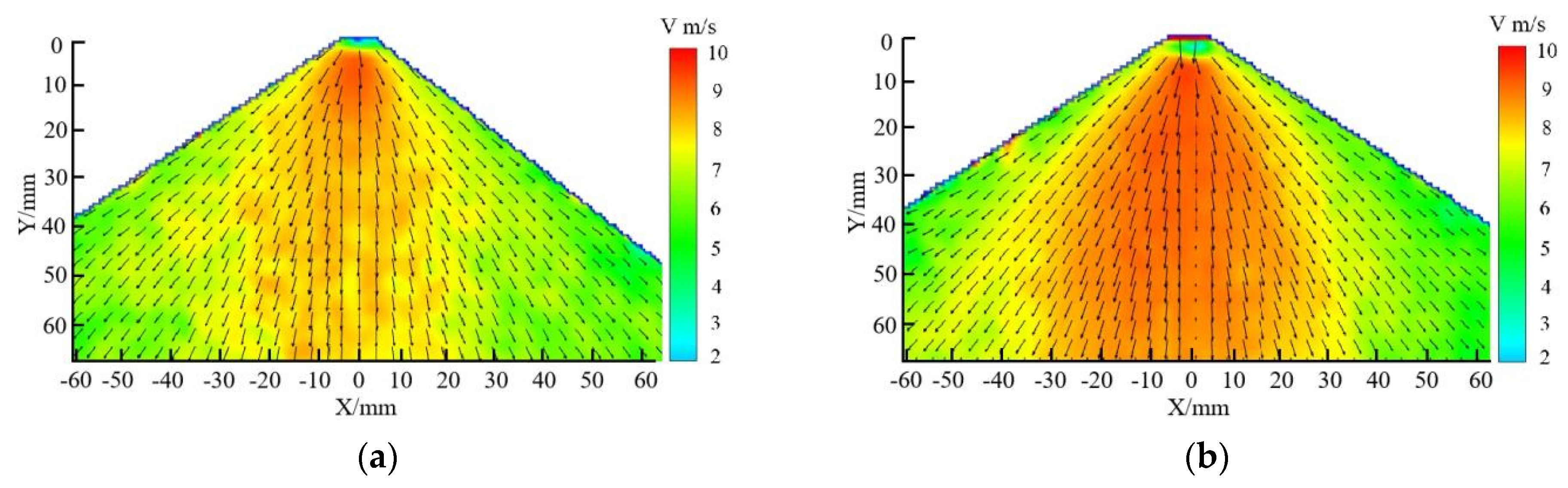

- The oil-based emulsion spray had a larger angle, which was 9.73% larger than that of water spray. Furthermore, the oil-based emulsion spray had a smaller droplet size; the DV50 of oil-based emulsion spray droplets was 12.73% smaller than that of water spray droplets. The droplet velocity of oil-based emulsion spray is larger than water spray, and its velocity distribution is more stable.

- 3.

- The increase in spray pressure intensified the atomization and breakup of the liquid sheet of oil-based emulsion air-induction spray. As the spray pressure increases, the liquid sheet breaks up more severely, with more holes and mesh-like structures generated. When the spray pressure increased from 0.1 MPa to 0.3 MPa and 0.5 MPa, the spray angle increased by 28.91% and 44.94%, respectively, and the DV50 of droplets decreased by 10.56% and 15.67%, respectively. The maximum velocity increased by 46.12% and 91.06%, respectively.

- 4.

- The change in nozzle configuration had a relatively small impact on the change in spray angle. When the nozzle configuration changed from ID120-01 to ID120-03 and ID120-05, the spray angle increased by 8.09% and 10.79%, respectively. The nozzle configuration did not change the form of atomization and breakup, but it had a significant impact on droplet size and velocity. When the nozzle changed from ID120-01 to ID120-03 and ID120-05, the droplet size increased by 20.64% and 33.99%, respectively, while the droplet velocity increased by 3.71% and 14.15%.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ma, J.; Liu, K.; Dong, X.; Huang, X.; Ahmad, F.; Qiu, B. Force and motion behaviour of crop leaves during spraying. Biosyst. Eng. 2023, 235, 83–99. [Google Scholar] [CrossRef]

- Qin, W.-C.; Qiu, B.-J.; Xue, X.-Y.; Chen, C.; Xu, Z.-F.; Zhou, Q.-Q. Droplet deposition and control effect of insecticides sprayed with an unmanned aerial vehicle against plant hoppers. Crop Prot. 2016, 85, 79–88. [Google Scholar] [CrossRef]

- Shen, Y.; Zhu, H.; Liu, H.; Chen, Y.; Ozkan, E. Development of a laser-guided, embedded-computer-controlled, air-assisted precision sprayer. Trans. Asabe 2017, 60, 1827–1838. [Google Scholar] [CrossRef]

- Szarka, A.Z.; Kruger, G.R.; Golus, J.; Rodgers, C.; Perkins, D.; Brain, R.A. Spray drift deposition comparison of fluorimetry and analytical confirmation techniques. Pest Manag. Sci. 2021, 77, 4192–4199. [Google Scholar] [CrossRef]

- Ahmad, F.; Zhang, S.; Qiu, B.; Ma, J.; Xin, H.; Qiu, W.; Ahmed, S.; Chandio, F.A.; Khaliq, A. Comparison of Water Sensitive Paper and Glass Strip Sampling Approaches to Access Spray Deposit by UAV Sprayers. Agronomy 2022, 12, 1302. [Google Scholar] [CrossRef]

- Li, J.; Nie, Z.; Chen, Y.; Ge, D.; Li, M. Development of Boom Posture Adjustment and Control System for Wide Spray Boom. Agriculture 2023, 13, 2162. [Google Scholar] [CrossRef]

- Liao, J.; Hewitt, A.J.; Wang, P.; Luo, X.; Zang, Y.; Zhou, Z.; Lan, Y.; O’Donnell, C. Development of droplet characteristics prediction models for air induction nozzles based on wind tunnel tests. Int. J. Agric. Biol. Eng. 2019, 12, 1–6. [Google Scholar] [CrossRef]

- Ferguson, J.C.; Chechetto, R.G.; O’Donnell, C.C.; Dorr, G.J.; Moore, J.H.; Baker, G.J.; Powis, K.J.; Hewitt, A.J. Determining the drift potential of Venturi nozzles compared with standard nozzles across three insecticide spray solutions in a wind tunnel. Pest Manag. Sci. 2016, 72, 1460–1466. [Google Scholar] [CrossRef]

- Liao, J.; Luo, X.; Wang, P.; Zhou, Z.; O’Donnell, C.C.; Zang, Y.; Hewitt, A.J. Analysis of the Influence of Different Parameters on Droplet Characteristics and Droplet Size Classification Categories for Air Induction Nozzle. Agronomy 2020, 10, 256. [Google Scholar] [CrossRef]

- Cryer, S.A.; Altieri, A.L.; Schmucker, A.L.; Day, K.M. Minimising atomisation drift potential by exploring the break-up of liquid sheets using multiphase methylated soybean and silicon oil emulsions. Biosyst. Eng. 2021, 202, 142–151. [Google Scholar] [CrossRef]

- Gong, C.; Kang, C.; Jia, W.; Yang, W.; Wang, Y. The effect of spray structure of oil-based emulsion spray on the droplet characteristics. Biosyst. Eng. 2020, 198, 78–90. [Google Scholar] [CrossRef]

- Dafsari, R.A.; Yu, S.; Choi, Y.; Lee, J. Effect of geometrical parameters of air-induction nozzles on droplet characteristics and behaviour. Biosyst. Eng. 2021, 209, 14–29. [Google Scholar] [CrossRef]

- Abdelmotalib, H.M.; Dafsari, R.A.; Seung-Hwa, Y.; Lee, J. Computational study of internal flow characteristics of the air induction nozzle. Int. J. Mech. Sci. 2021, 204, 106578. [Google Scholar] [CrossRef]

- Berger-Neto, A.; Jaccoud-Filho, D.d.S.; Wutzki, C.R.; Tullio, H.E.; Cunha Pierre, M.L.; Manfron, F.; Justino, A. Effect of spray droplet size, spray volume and fungicide on the control of white mold in soybeans. Crop Prot. 2017, 92, 190–197. [Google Scholar] [CrossRef]

- Franca, J.A.L.; da Cunha, J.P.A.R.; Antuniassi, U.R. Spectrum and velocity of droplets of spray nozzles with and without air induction. Eng. Agric. 2018, 38, 232–237. [Google Scholar] [CrossRef]

- Vallet, A.; Tinet, C. Characteristics of droplets from single and twin jet air induction nozzles: A preliminary investigation. Crop Prot. 2013, 48, 63–68. [Google Scholar] [CrossRef]

- McArtney, S.J.; Obermiller, J.D. Comparative performance of air-induction and conventional nozzles on an axial fan sprayer in medium density apple orchards. Horttechnology 2008, 18, 365–371. [Google Scholar] [CrossRef]

- Butts, T.R.; Luck, J.D.; Fritz, B.K.; Hoffmann, W.C.; Kruger, G.R. Evaluation of spray pattern uniformity using three unique analyses as impacted by nozzle, pressure, and pulse-width modulation duty cycle. Pest Manag. Sci. 2019, 75, 1875–1886. [Google Scholar] [CrossRef]

- Yang, W.; Zhong, W.; Jia, W.; Ou, M.; Dong, X.; Zhang, T.; Ding, S.; Yu, P. The effect of oil-in-water emulsion pesticide on the evolution of liquid sheet rim disintegration and the spraying distribution. Crop Prot. 2024, 177, 106547. [Google Scholar] [CrossRef]

- Yang, W.; Jia, W.; Ou, M.; Zhong, W.; Jiang, L.; Wang, X. Effect of Physical Properties of an Emulsion Pesticide on the Atomisation Process and the Spatial Distribution of Droplet Size. Agriculture 2022, 12, 949. [Google Scholar] [CrossRef]

- Gong, C.; Li, D.; Kang, C.; Wang, Y. Visualisation of the evolution of perforations in oil-based emulsion sheets formed by flat-fan spray nozzles. Biosyst. Eng. 2021, 207, 68–80. [Google Scholar] [CrossRef]

- Jiang, Y.; Li, H.; Xiang, Q.; Chen, C. Comparison of PIV Experiment and Numerical Simulation on the Velocity Distribution of Intermediate Pressure Jets with Different Nozzle Parameters. Irrig. Drain. 2017, 66, 510–519. [Google Scholar] [CrossRef]

- Moneib, H.A.; Mahfouz, A.; El-Fatih, A.; Emara, A. Near-field spray characterization of a spill return atomizer using a PIV laser sheet. Fuel 2021, 289, 119792. [Google Scholar] [CrossRef]

- Dorr, G.J.; Hewitt, A.J.; Adkins, S.W.; Hanan, J.; Zhang, H.; Noller, B. A comparison of initial spray characteristics produced by agricultural nozzles. Crop Prot. 2013, 53, 109–117. [Google Scholar] [CrossRef]

- Paap, U.; Kress, B.; Steinrueck, H.-P.; Maier, F. Probing Surface and Interfacial Tension of Ionic Liquids in Vacuum with the Pendant Drop and Sessile Drop Method. Int. J. Mol. Sci. 2022, 23, 3158. [Google Scholar] [CrossRef]

- Ochowiak, M.; Broniarz-Press, L.; Rozanska, S.; Matuszak, M.; Wlodarczak, S. Characteristics of spray angle for effervescent-swirl atomizers. Chem. Eng. Process. Process Intensif. 2015, 98, 52–59. [Google Scholar] [CrossRef]

- Kacar, S.; Bayilmis, C.; Cetin, O. A web laboratory using MATLAB Builder NE for computer image processing. Turk. J. Electr. Eng. Comput. Sci. 2014, 22, 166–175. [Google Scholar] [CrossRef]

- Zhou, A.; Xu, Z.; Chen, Y.; Chen, Y. Application of multi time-interval PIV technique in complex flow field measuremen. J. Hohai Univ. Nat. Sci. 2023, 51, 114–121. [Google Scholar]

| Nozzle Type | Liquid Inlet Diameter Dl/mm | Air Inlet Diameter Da/mm | V-Notch Angle a/° | Long Axis Diameter of Nozzle Outlet DL/mm | Short Axis Diameter of Nozzle Outlet DS/mm |

|---|---|---|---|---|---|

| ID120-01 | 0.72 | 1.41 | 26 | 2.10 | 0.50 |

| ID120-03 | 1.29 | 1.54 | 31 | 2.98 | 0.99 |

| ID120-05 | 1.73 | 1.96 | 34 | 4.12 | 1.19 |

| Test Number | Flat-Fan Nozzle | Pressure/ MPa | Flow Rate/ mL·s−1 | Concentration/ % v/v | Surface Tension/ N m−1 |

|---|---|---|---|---|---|

| ① | ID120-03 | 0.1 | 12.76 ± 0.43 | 0 | 0.07 |

| ② | ID120-03 | 0.1 | 12.76 ± 0.43 | 0.1 | 0.04 |

| ③ | ID120-03 | 0.3 | 22.00 ± 0.13 | 0.1 | 0.04 |

| ④ | ID120-03 | 0.5 | 30.34 ± 0.48 | 0.1 | 0.04 |

| ⑤ | ID120-01 | 0.3 | 7.44 ± 0.19 | 0.1 | 0.04 |

| ⑥ | ID120-05 | 0.3 | 14.37 ± 0.66 | 0.1 | 0.04 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, M.; Chen, F.; Gong, C.; Kang, C. Experimental Research on the Atomization Characteristics of Air-Induction Spray Based on Oil-Based Emulsion. Agronomy 2025, 15, 936. https://doi.org/10.3390/agronomy15040936

Yan M, Chen F, Gong C, Kang C. Experimental Research on the Atomization Characteristics of Air-Induction Spray Based on Oil-Based Emulsion. Agronomy. 2025; 15(4):936. https://doi.org/10.3390/agronomy15040936

Chicago/Turabian StyleYan, Mingzhi, Fujun Chen, Chen Gong, and Can Kang. 2025. "Experimental Research on the Atomization Characteristics of Air-Induction Spray Based on Oil-Based Emulsion" Agronomy 15, no. 4: 936. https://doi.org/10.3390/agronomy15040936

APA StyleYan, M., Chen, F., Gong, C., & Kang, C. (2025). Experimental Research on the Atomization Characteristics of Air-Induction Spray Based on Oil-Based Emulsion. Agronomy, 15(4), 936. https://doi.org/10.3390/agronomy15040936