Effects of Drainage Technology on Waterlogging Reduction and Rice Yield in Mid-Lower Reaches of Yangtze River

Abstract

1. Introduction

- (1)

- The regulatory effects of drainage on groundwater levels and soil moisture;

- (2)

- The methods through which drainage affects rice growth and yield;

- (3)

- The interaction mechanisms between waterlogging alleviation and rice physiology on drainage.

2. Materials and Methods

2.1. Description of the Experimental Site

2.2. Experimental Design

2.3. Crop Planting Scheme

2.4. Monitoring Indicators and Methods

2.5. Data Analysis

3. Results

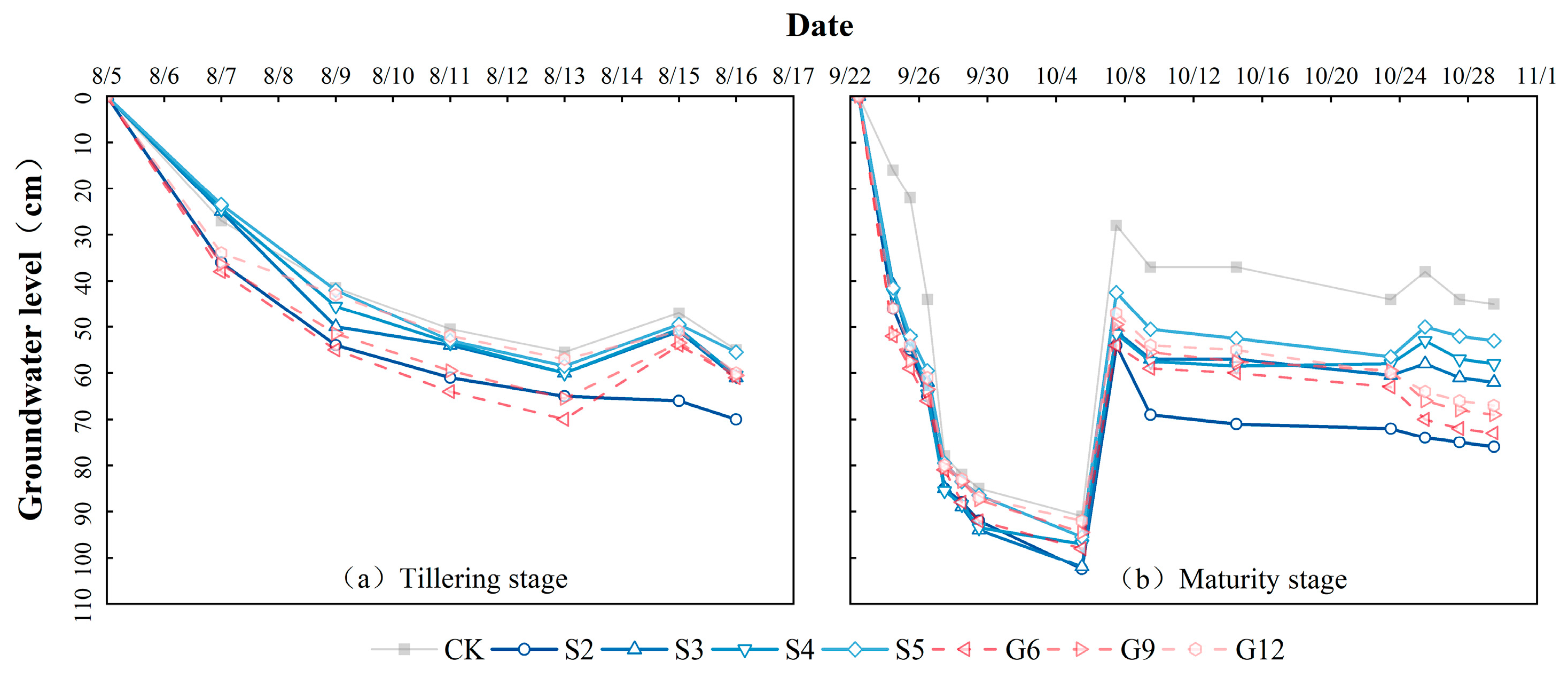

3.1. Comparison of Different Treatment Drainage Effects

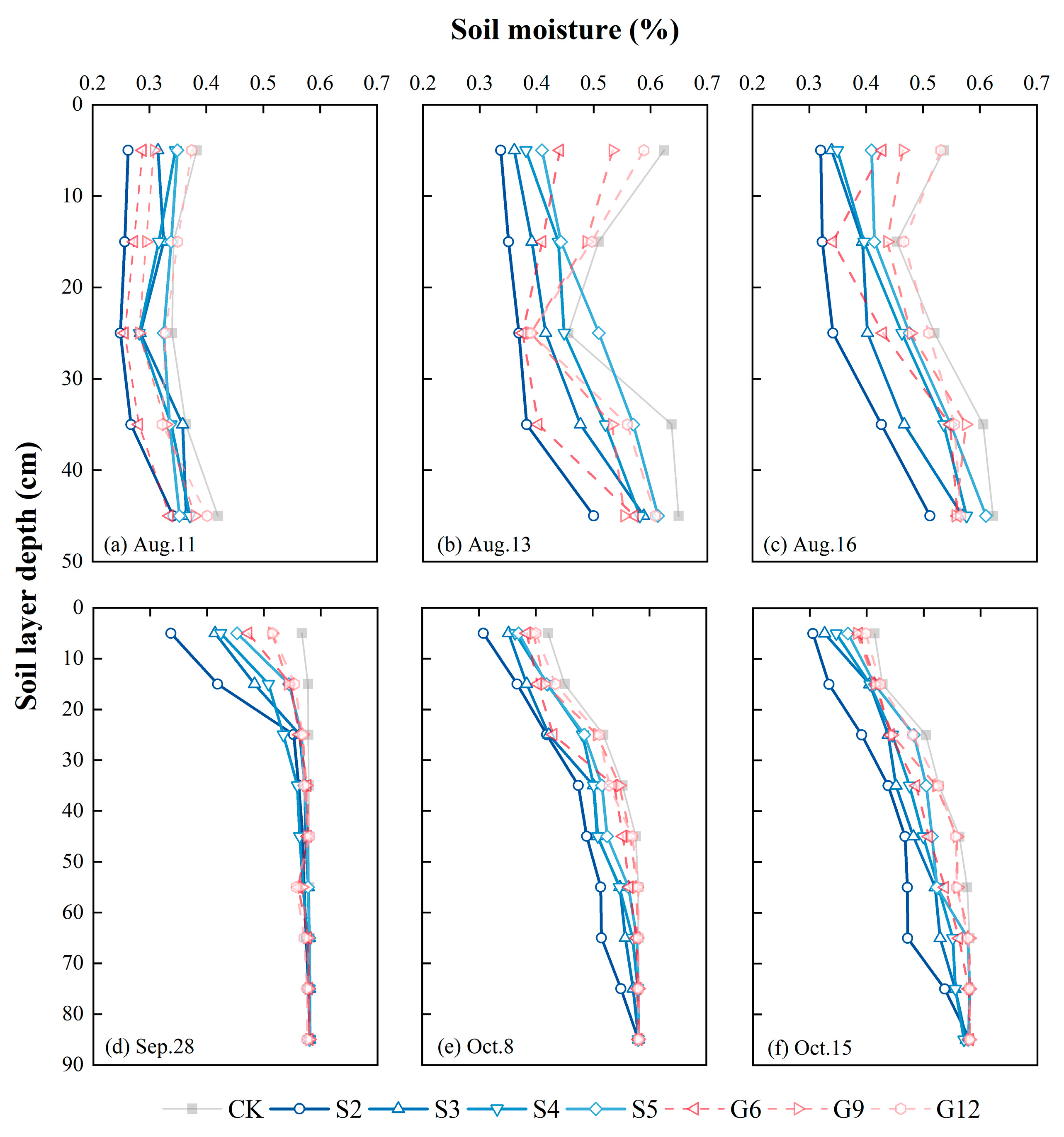

3.2. Effects of Different Treatments on Soil Moisture

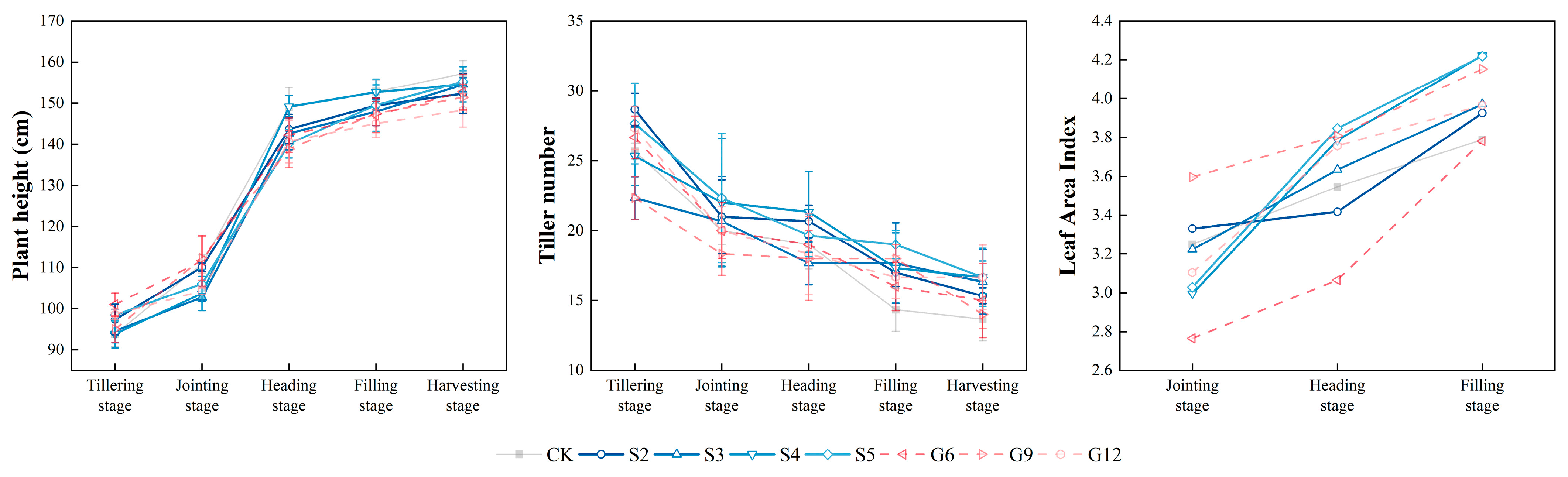

3.3. Effects of Different Treatments on Rice Growth

3.4. Effects of Different Drainage Treatments on Rice Biomass Accumulation

3.5. Effects of Different Treatments on Rice Yield

3.6. Factors Affecting Soil Water Environment Improvement and Rice Yield Through Subsurface Drainage Conditions

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Awad, A.E.; Abuarab, M.E.; Abdelraouf, R.E.; Bakeer, G.A.; El-Shawadfy, M.A.; Ragab, R. Improving Yield and Irrigation Water Productivity of Green Beans under Water Stress with Agricultural Solid Waste-Based Material of Compacted Rice Straw as a Sustainable Organic Soil Mulch. Irrig. Sci. 2024. [Google Scholar] [CrossRef]

- Manik, S.M.N.; Pengilley, G.; Dean, G.; Field, B.; Shabala, S.; Zhou, M. Soil and Crop Management Practices to Minimize the Impact of Waterlogging on Crop Productivity. Front. Plant Sci. 2019, 10, 140. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y.; Ji, Y.; Zhang, M.; Xu, Y.; Li, Z.; Tu, D.; Wu, W. Exploring a Sustainable Rice-Cropping System to Balance Grain Yield, Environmental Footprint and Economic Benefits in the Middle and Lower Reaches of the Yangtze River in China. J. Clean. Prod. 2023, 404, 136988. [Google Scholar] [CrossRef]

- Darzi-Naftchali, A.; Mirlatifi, S.M.; Shahnazari, A.; Ejlali, F.; Mahdian, M.H. Effect of Subsurface Drainage on Water Balance and Water Table in Poorly Drained Paddy Fields. Agric. Water Manag. 2013, 130, 61–68. [Google Scholar] [CrossRef]

- Zhang, R.; Yue, Z.; Chen, X.; Huang, R.; Zhou, Y.; Cao, X. Effects of Waterlogging at Different Growth Stages on the Photosynthetic Characteristics and Grain Yield of Sorghum (Sorghum bicolor L.). Sci. Rep. 2023, 13, 7212. [Google Scholar] [CrossRef]

- Daniel, K.; Hartman, S. How Plant Roots Respond to Waterlogging. J. Exp. Bot. 2024, 75, 511–525. [Google Scholar] [CrossRef]

- Takeshima, R.; Murakami, S.; Fujiwara, Y.; Nakano, K.; Fuchiyama, R.; Hara, T.; Shima, T.; Koyama, T. Subsurface Drainage and Raised-Bed Planting Reduce Excess Water Stress and Increase Yield in Common Buckwheat (Fagopyrum esculentum Moench). Field Crops Res. 2023, 297, 108935. [Google Scholar] [CrossRef]

- Huang, W.; Yu, X.; Liang, H.; Wu, Y.; Xin, P.; Zhou, F. Subsurface Fluxes Dominate the Dissolved Nitrogen Losses from Rice Paddies in Central China. Agric. Ecosyst. Environ. 2024, 363, 108881. [Google Scholar] [CrossRef]

- Halbac-Cotoara-Zamfir, R.; Farias-Ramirez, A.J.; De Miranda, J.H.; Moreno-Pizani, M.A.; Duarte, S.N.; Paredes-Trejo, F.J.; Salvati, L.; Halbac-Cotoara-Zamfir, C. Simulation of Subsurface Drainage in the Sugarcane Crop under Different Spacing and Drain Depths. Land 2022, 11, 626. [Google Scholar] [CrossRef]

- Jafari Talukolaee, M.; Darzi Naftchali, A.; Zare Parvariji, L.; Ahmadi, M.Z. Investigating Long-Term Effects of Subsurface Drainage on Soil Structure in Paddy Fields. Soil Tillage Res. 2018, 177, 155–160. [Google Scholar] [CrossRef]

- Askri, B.; Khodmi, S.; Bouhlila, R. Impact of Subsurface Drainage System on Waterlogged and Saline Soils in a Saharan Palm Grove. Catena 2022, 212, 106070. [Google Scholar] [CrossRef]

- Darzi-Naftchali, A.; Ritzema, H.; Karandish, F.; Mokhtassi-Bidgoli, A.; Ghasemi-Nasr, M. Alternate Wetting and Drying for Different Subsurface Drainage Systems to Improve Paddy Yield and Water Productivity in Iran. Agric. Water Manag. 2017, 193, 221–231. [Google Scholar] [CrossRef]

- Sojka, M.; Kozłowski, M.; Stasik, R.; Napierała, M.; Kęsicka, B.; Wróżyński, R.; Jaskuła, J.; Liberacki, D.; Bykowski, J. Sustainable Water Management in Agriculture—The Impact of Drainage Water Management on Groundwater Table Dynamics and Subsurface Outflow. Sustainability 2019, 11, 4201. [Google Scholar] [CrossRef]

- Darzi-Naftchali, A.; Motevali, A.; Keikha, M. The Life Cycle Assessment of Subsurface Drainage Performance under Rice-Canola Cropping System. Agric. Water Manag. 2022, 266, 107579. [Google Scholar] [CrossRef]

- Darzi-Naftchali, A.; Shahnazari, A. Influence of Subsurface Drainage on the Productivity of Poorly Drained Paddy Fields. Eur. J. Agron. 2014, 56, 1–8. [Google Scholar] [CrossRef]

- Han, Y.; Ma, W.; Zhou, B.; Yang, X.; Salah, A.; Li, C.; Cao, C.; Zhan, M.; Zhao, M. Effects of Straw-Return Method for the Maize–Rice Rotation System on Soil Properties and Crop Yields. Agronomy 2020, 10, 461. [Google Scholar] [CrossRef]

- Hu, N.; Wang, B.; Gu, Z.; Tao, B.; Zhang, Z.; Hu, S.; Zhu, L.; Meng, Y. Effects of Different Straw Returning Modes on Greenhouse Gas Emissions and Crop Yields in a Rice–Wheat Rotation System. Agric. Ecosyst. Environ. 2016, 223, 115–122. [Google Scholar] [CrossRef]

- Islam, M.N.; Bell, R.W.; Barrett-Lennard, E.G.; Maniruzzaman, M. Shallow Drains and Straw Mulch Alleviate Multiple Constraints to Increase Sunflower Yield on a Clay-Textured Saline Soil I. Effects of Decreased Soil Salinity, Waterlogging and End-of-Season Drought. Eur. J. Agron. 2025, 162, 127416. [Google Scholar] [CrossRef]

- Jia, Z.; Terasaki, H.; Fukuhara, T.; Zhou, B. Efficient Desalination Method Using a Subsurface Drainage Pipe with Rice Husk in Paddy Fields. Geoderma Reg. 2023, 35, e00725. [Google Scholar] [CrossRef]

- Lu, P.; Zhang, Z.; Feng, G.; Huang, M.; Shi, X. Experimental Study on the Potential Use of Bundled Crop Straws as Subsurface Drainage Material in the Newly Reclaimed Coastal Land in Eastern China. Water 2018, 10, 31. [Google Scholar] [CrossRef]

- Yang, H.; Zhai, S.; Li, Y.; Zhou, J.; He, R.; Liu, J.; Xue, Y.; Meng, Y. Waterlogging Reduction and Wheat Yield Increase through Long-Term Ditch-Buried Straw Return in a Rice—Wheat Rotation System. Field Crops Res. 2017, 209, 189–197. [Google Scholar] [CrossRef]

- Yang, H.; Feng, J.; Zhai, S.; Dai, Y.; Xu, M.; Wu, J.; Shen, M.; Bian, X.; Koide, R.T.; Liu, J. Long-Term Ditch-Buried Straw Return Alters Soil Water Potential, Temperature, and Microbial Communities in a Rice-Wheat Rotation System. Soil Tillage Res. 2016, 163, 21–31. [Google Scholar] [CrossRef]

- Qian, Y.; Zhu, Y.; Ye, M.; Huang, J.; Wu, J. Experiment and Numerical Simulation for Designing Layout Parameters of Subsurface Drainage Pipes in Arid Agricultural Areas. Agric. Water Manag. 2021, 243, 106455. [Google Scholar] [CrossRef]

- Tian, Y.; Li, D.; Wang, Y.; Zhao, Q.; Li, Z.; Jing, R.; Zhou, X. Effect of Subsurface Drainage Combined with Biochar on the Bacterial Community Composition of Coastal Saline Soil. Water 2023, 15, 2701. [Google Scholar] [CrossRef]

- Chen, L.; Zhang, Z.; Tang, Z.; Liu, Y.; Sui, Q.; Huang, W.; Liu, S.; Feng, P.; Guo, Z.; He, H. Existent Forms and Ecological Risk Assessment of Uranium and Heavy Metals in Soil at a Uranium Mining Area in Northern Guangdong, China. J. Radioanal. Nucl. Chem. 2023, 332, 1805–1814. [Google Scholar] [CrossRef]

- Sun, N.; Zhang, W.; Liao, S.; Li, H. Divergent Changes in Bacterial Functionality as Affected by Root-Zone Ecological Restoration in an Aged Peach Orchard. Microorganisms 2022, 10, 2127. [Google Scholar] [CrossRef]

- Peng, Q.; Xie, Z.; Tang, G.; Jiang, H.; Guo, J.; Mao, Y.; Wang, B.; Meng, Q.; Yang, J.; Jia, S.; et al. Fungal Community Composition and Function in Different Spring Rapeseeds on the Qinghai-Tibet Plateau, China. Plant Soil 2024, 503, 659–675. [Google Scholar] [CrossRef]

- Tian, H.; Wang, Y.; Xie, J.; Li, H.; Zhu, Y. Effects of Soil Properties and Land Use Types on the Bioaccessibility of Cd, Pb, Cr, and Cu in Dongguan City, China. Bull. Environ. Contam. Toxicol. 2020, 104, 64–70. [Google Scholar] [CrossRef]

- Cuiyun, Y.; Yihang, L.; Jing, Y.; Hongyou, Z.; Zhaoyou, D.; Deying, T.; Oo, A.K.; Lixia, Z. Correlation between Soil Environment and Yield and Quality of Sharen (Amomi Fructus) under Different Planting Patterns. Digit. Chin. Med. 2023, 6, 221–233. [Google Scholar] [CrossRef]

- Zhang, R.; Zhou, Z.; Luo, W.; Wang, Y.; Feng, Z. Effects of Nitrogen Deposition on Growth and Phosphate Efficiency of Schima Superba of Different Provenances Grown in Phosphorus-Barren Soil. Plant Soil 2013, 370, 435–445. [Google Scholar] [CrossRef]

- Yan, Y.; Chen, Z.; Zhu, F.; Zhu, C.; Wang, C.; Gu, C. Effect of Polyvinyl Chloride Microplastics on Bacterial Community and Nutrient Status in Two Agricultural Soils. Bull. Environ. Contam. Toxicol. 2021, 107, 602–609. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Niu, D.; Ren, Y.; Fu, H. Extractability of Nutrients Using Mehlich 3 and Ammonium Bicarbonate-DTPA Methods for Selected Grassland Soils of China. Plant Soil Environ. 2018, 64, 448–454. [Google Scholar] [CrossRef]

- Huang, D.; Guo, Y.; Chen, S.; Wang, Z.; Sun, B.; Niu, Y.; Dong, S. Different Straw Lengths and Burial Modes Affect the Salt Distribution in Coastal Saline Soil and the Regulation of Salt Stress Resistance in Tomato. Plant Soil 2025. [Google Scholar] [CrossRef]

- Mukhopadhyay, R.; Fagodiya, R.K.; Narjary, B.; Barman, A.; Prajapat, K.; Kumar, S.; Bundela, D.S.; Sharma, P.C. Restoring Soil Quality and Carbon Sequestration Potential of Waterlogged Saline Land Using Subsurface Drainage Technology to Achieve Land Degradation Neutrality in India. Sci. Total Environ. 2023, 885, 163959. [Google Scholar] [CrossRef]

- Wu, G.; Ling, J.; Zhao, D.-Q.; Liu, Z.-X.; Xu, Y.-P.; Kuzyakov, Y.; Marsden, K.; Wen, Y.; Zhou, S.-L. Straw Return Counteracts the Negative Effects of Warming on Microbial Community and Soil Multifunctionality. Agric. Ecosyst. Environ. 2023, 352, 108508. [Google Scholar] [CrossRef]

- Liu, L.; Ouyang, W.; Liu, H.; Zhu, J.; Ma, Y.; Wu, Q.; Chen, J.; Zhang, D. Potential of Paddy Drainage Optimization to Water and Food Security in China. Resour. Conserv. Recycl. 2021, 171, 105624. [Google Scholar] [CrossRef]

- Akhtar, K.; Wang, W.; Khan, A.; Ren, G.; Afridi, M.Z.; Feng, Y.; Yang, G. Wheat Straw Mulching with Fertilizer Nitrogen: An Approach for Improving Soil Water Storage and Maize Crop Productivity. Plant Soil Environ. 2018, 64, 330–337. [Google Scholar] [CrossRef]

- Deininger, A.; Tamm, M.; Krause, R.; Sonnenberg, H. SE—Structures and Environment. J. Agric. Eng. Res. 2000, 77, 335–342. [Google Scholar] [CrossRef]

- Bagheri Novair, S.; Mirseyed Hosseini, H.; Etesami, H.; Pirmoradian, N.; Asgari Lajayer, B.; Price, G.W. Straw Application Improved Soil Biological Properties and the Growth of Rice Plant under Low Water Irrigation. Environ. Res. 2024, 255, 119138. [Google Scholar] [CrossRef]

- Shao, G.-C.; Deng, S.; Liu, N.; Yu, S.-E.; Wang, M.-H.; She, D.-L. Effects of Controlled Irrigation and Drainage on Growth, Grain Yield and Water Use in Paddy Rice. Eur. J. Agron. 2014, 53, 1–9. [Google Scholar] [CrossRef]

- Schultz, B.; Zimmer, D.; Vlotman, W.F. Drainage under Increasing and Changing Requirements. Irrig. Drain. 2007, 56, S3–S22. [Google Scholar] [CrossRef]

- Wei, X.; Zhou, Q.; Cai, M.; Wang, Y. Effects of Vegetation Restoration on Regional Soil Moisture Content in the Humid Karst Areas—A Case Study of Southwest China. Water 2021, 13, 321. [Google Scholar] [CrossRef]

- Tang, H.; Xu, C.; Xu, W.; Xu, Y.; Xiang, Y.; Wang, J. Method of Straw Ditch-Buried Returning, Development of Supporting Machine and Analysis of Influencing Factors. Front. Plant Sci. 2022, 13, 967838. [Google Scholar] [CrossRef] [PubMed]

- Zhou, L.-Y.; Zhu, Y.; Kan, Z.-R.; Li, F.-M.; Zhang, F. The Impact of Crop Residue Return on the Food–Carbon–Water–Energy Nexus in a Rice–Wheat Rotation System under Climate Warming. Sci. Total Environ. 2023, 894, 164675. [Google Scholar] [CrossRef]

- Ren, X.; Wang, S.; Yang, P.; Tao, Y.; Chen, H. Performance Evaluation of Different Combined Drainage Forms on Flooding and Waterlogging Removal. Water 2021, 13, 2968. [Google Scholar] [CrossRef]

- Xu, H.; Wang, H.; Zhang, Y.; Yang, X.; Lv, S.; Hou, D.; Mo, C.; Wassie, M.; Yu, B.; Hu, T. A Synthetic Light-Inducible Photorespiratory Bypass Enhances Photosynthesis to Improve Rice Growth and Grain Yield. Plant Commun. 2023, 4, 100641. [Google Scholar] [CrossRef]

- Misra, V.; Solomon, S.; Mall, A.K.; Prajapati, C.P.; Hashem, A.; Abd_Allah, E.F.; Ansari, M.I. Morphological Assessment of Water Stressed Sugarcane: A Comparison of Waterlogged and Drought Affected Crop. Saudi J. Biol. Sci. 2020, 27, 1228–1236. [Google Scholar] [CrossRef]

- Zhen, B.; Zhou, X.; Lu, H.; Li, H. Effects of Waterlogging on Rice Growth at Jointing–Booting Stage. Water 2024, 16, 1981. [Google Scholar] [CrossRef]

- Nishiuchi, S.; Yamauchi, T.; Takahashi, H.; Kotula, L.; Nakazono, M. Mechanisms for Coping with Submergence and Waterlogging in Rice. Rice 2012, 5, 2. [Google Scholar] [CrossRef]

- Lafitte, H.; Yongsheng, G.; Yan, S.; Li, Z.-K. Whole Plant Responses, Key Processes, and Adaptation to Drought Stress: The Case of Rice. J. Exp. Bot. 2006, 58, 169–175. [Google Scholar] [CrossRef]

- Pan, J.; Sharif, R.; Xu, X.; Chen, X. Mechanisms of Waterlogging Tolerance in Plants: Research Progress and Prospects. Front. Plant Sci. 2021, 11, 627331. [Google Scholar] [CrossRef]

- Singh, P.; Jaiswal, S.; Kushwaha, A.; Gahlowt, P.; Mishra, V.; Tripathi, D.K.; Singh, S.P.; Gupta, R.; Singh, V.P. Peroxynitrite Is Essential for Aerenchyma Formation in Rice Roots under Waterlogging Conditions. Planta 2023, 258, 2. [Google Scholar] [CrossRef] [PubMed]

- Chen, M.; Wang, G.; Jing, Y.; Zhou, J.; Song, J.; Chang, F.; Yu, R.; Wang, J.; Wang, W.; Sun, X.; et al. Straw Interlayer Improves Sunflower Root Growth: Evidence from Moisture and Salt Migration and the Microbial Community in Saline-Alkali Soil. J. Integr. Agric. 2024, 23, 3870–3881. [Google Scholar] [CrossRef]

- Marcaida, M.; Li, T.; Angeles, O.; Evangelista, G.K.; Fontanilla, M.A.; Xu, J.; Gao, Y.; Li, Z.; Ali, J. Biomass Accumulation and Partitioning of Newly Developed Green Super Rice (GSR) Cultivars under Drought Stress during the Reproductive Stage. Field Crops Res. 2014, 162, 30–38. [Google Scholar] [CrossRef]

- Katsura, K.; Okami, M.; Mizunuma, H.; Kato, Y. Radiation Use Efficiency, N Accumulation and Biomass Production of High-Yielding Rice in Aerobic Culture. Field Crops Res. 2010, 117, 81–89. [Google Scholar] [CrossRef]

- Cheng, J.; Lin, B.-J.; Chen, J.-S.; Duan, H.-X.; Sun, Y.-F.; Zhao, X.; Dang, Y.P.; Xu, Z.-Y.; Zhang, H.-L. Strategies for Crop Straw Management in China’s Major Grain Regions: Yield-Driven Conditions and Factors Influencing the Effectiveness of Straw Return. Resour. Conserv. Recycl. 2025, 212, 107941. [Google Scholar] [CrossRef]

- Nóia Júnior, R.D.S.; Asseng, S.; García-Vila, M.; Liu, K.; Stocca, V.; Dos Santos Vianna, M.; Weber, T.K.D.; Zhao, J.; Palosuo, T.; Harrison, M.T. A Call to Action for Global Research on the Implications of Waterlogging for Wheat Growth and Yield. Agric. Water Manag. 2023, 284, 108334. [Google Scholar] [CrossRef]

- Alam, M.S.; Sasaki, N.; Datta, A. Waterlogging, Crop Damage and Adaptation Interventions in the Coastal Region of Bangladesh: A Perception Analysis of Local People. Environ. Dev. 2017, 23, 22–32. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, S.; Cheng, M.; Jiang, H.; Zhang, X.; Peng, C.; Lu, X.; Zhang, M.; Jin, J. Effect of Drought on Agronomic Traits of Rice and Wheat: A Meta-Analysis. Int. J. Environ. Res. Public Health 2018, 15, 839. [Google Scholar] [CrossRef]

- Somaweera, K.A.T.N.; Suriyagoda, L.D.B.; Sirisena, D.N.; De Costa, W.A.J.M. Accumulation and Partitioning of Biomass, Nitrogen, Phosphorus and Potassium among Different Tissues during the Life Cycle of Rice Grown under Different Water Management Regimes. Plant Soil 2016, 401, 169–183. [Google Scholar] [CrossRef]

- Tang, H.; Wang, D.; Zhao, J.; Xu, C.; Wang, J. Mode and Experiments of a Straw Ditch-Burying Returning and Maturing in Cold Region of Northeast China. Eur. J. Agron. 2023, 151, 127006. [Google Scholar] [CrossRef]

- Su, Y.; Lv, J.L.; Yu, M.; Ma, Z.H.; Xi, H.; Kou, C.L.; He, Z.C.; Shen, A.L. Long-term Decomposed Straw Return Positively Affects the Soil Microbial Community. J. Appl. Microbiol. 2020, 128, 138–150. [Google Scholar] [CrossRef] [PubMed]

- Liang, F.; Li, B.; Vogt, R.D.; Mulder, J.; Song, H.; Chen, J.; Guo, J. Straw Return Exacerbates Soil Acidification in Major Chinese Croplands. Resour. Conserv. Recycl. 2023, 198, 107176. [Google Scholar] [CrossRef]

- Cheng, Z.; Li, A.; Wang, R.; Hu, Q.; Zhou, J.; Li, M.; Wang, T.; He, D.; Zhu, L. Long-Term Straw Return Promotes Accumulation of Stable Soil Dissolved Organic Matter by Driving Molecular-Level Activity and Diversity. Agric. Ecosyst. Environ. 2024, 374, 109155. [Google Scholar] [CrossRef]

| Soil Layer Depth (cm) | HC (cm·d−1) | P (%) | PC (%) | BD (g·cm−3) | FC (%) | EC (µS·cm−1) |

|---|---|---|---|---|---|---|

| 0–20 | 0.73 | 50 | 45 | 1.3 | 35 | 0.97 |

| Soil Layer Depth (cm) | pH | OM (g·kg−1) | TN (g·kg−1) | TP (g·kg−1) | TK (g·kg−1) | HN (g·kg−1) | AP (g·kg−1) | AK (g·kg−1) |

|---|---|---|---|---|---|---|---|---|

| 0–20 | 5.92 | 24.56 | 2.38 | 0.49 | 19.97 | 160.5 | 14.97 | 195.4 |

| Treatment | Yield (Mg·ha−1) | Seed Setting Rate | 1000-grain Weight (g) | Harvest Index |

|---|---|---|---|---|

| CK | 6.425 ± 0.522 b | 0.78 ± 0.04 a | 20.14 ± 0.38 a | 0.32 ± 0.04 c |

| S2 | 6.558 ± 0.216 b | 0.80 ± 0.04 a | 20.13 ± 0.25 a | 0.40 ± 0.05 abc |

| S3 | 7.501 ± 0.300 a | 0.83 ± 0.03 a | 21.79 ± 2.30 a | 0.48 ± 0.02 a |

| S4 | 6.910 ± 0.479 ab | 0.81 ± 0.04 a | 20.15 ± 0.17 a | 0.42 ± 0.03 ab |

| S5 | 6.775 ± 0.240 ab | 0.82 ± 0.02 a | 20.59 ± 0.75 a | 0.42 ± 0.02 ab |

| G6 | 6.865 ± 0.386 ab | 0.79 ± 0.01 a | 20.27 ± 0.82 a | 0.38 ± 0.01 bc |

| G9 | 7.115 ± 0.366 ab | 0.83 ± 0.02 a | 20.18 ± 0.70 a | 0.48 ± 0.03 a |

| G12 | 6.443 ± 0.068 ab | 0.78 ± 0.06 a | 20.96 ± 0.63 a | 0.35 ± 0.06 bc |

| Items | Price (CNY·ha−1) | |||||||

|---|---|---|---|---|---|---|---|---|

| CK | S2 | S3 | S4 | S5 | G6 | G9 | G12 | |

| Excavate the earth in the trench | 3600 | 12,600 | 9600 | 8100 | 7200 | 6600 | 5600 | 4600 |

| Backfill the earthworks | 0 | 2500 | 2500 | 2000 | 2000 | 1700 | 1334 | 700 |

| Layout of the catchment ditch | 0 | 2000 | 2000 | 2000 | 2000 | 2000 | 2000 | 2000 |

| Process the 110 mm corrugated pipe with non-woven fabric | 0 | 0 | 0 | 0 | 0 | 50 | 38 | 25 |

| 110 mm corrugated pipe with non-woven fabric | 0 | 0 | 0 | 0 | 0 | 7500 | 5000 | 3750 |

| Process the rice straw | 0 | 800 | 534 | 400 | 320 | 0 | 0 | 0 |

| Rice straw | 0 | 2520 | 1680 | 1260 | 1008 | 0 | 0 | 0 |

| 110 mm PVC pipe | 0 | 2900 | 1934 | 1450 | 1160 | 997 | 645 | 484 |

| Artificial management fee | 50 | 400 | 400 | 400 | 400 | 400 | 400 | 400 |

| Transportation fee | 0 | 60 | 60 | 60 | 60 | 1200 | 900 | 600 |

| Engineering cost total | 3650 | 23,780 | 18,708 | 15,670 | 14,148 | 20,447 | 15,917 | 12,559 |

| Independent Variables | Simple Correlation Coefficient with Actual Yield, Y (r) | Unstandardized Regression Coefficient | Standardized Regression Coefficient (Path Coefficient, Direct Action) | Significance | |

|---|---|---|---|---|---|

| B | Standard Error | ||||

| Soil moisture, X1 | −0.228 | 2259.048 | 2092.810 | 2.118 | 0.302 |

| Plant height, X2 | −0.368 | −1.980 | 4.259 | −0.143 | 0.650 |

| Tiller number, X3 | −0.185 | −3.060 | 7.444 | −0.121 | 0.688 |

| Leaf biomass, X4 | −0.127 | −0.807 | 7.554 | −0.043 | 0.917 |

| Drainage volumes, X5 | 0.183 | −0.089 | 0.892 | −0.108 | 0.922 |

| Groundwater level, X6 | 0.226 | 9.209 | 11.037 | 1.818 | 0.420 |

| Leaf area index, X7 | 0.114 | 155.176 | 101.768 | 0.800 | 0.153 |

| Root biomass, X8 | 0.517 | 16.313 | 10.370 | 0.657 | 0.142 |

| Stem biomass, X9 | 0.166 | 30.910 | 11.962 | 1.384 | 0.024 |

| Panicle biomass, X10 | 0.329 | 2.898 | 4.479 | 0.328 | 0.530 |

| i | j | |||||

|---|---|---|---|---|---|---|

| Drainage Volumes, X5 | Groundwater Level, X6 | Leaf Area Index, X7 | Root Biomass, X8 | Stem Biomass, X9 | Panicle Biomass, X10 | |

| Soil moisture, X1 | 0.1137 | 0.8422 | 0.1322 | 0.2640 | 0.6925 | 0.0713 |

| Plant height, X2 | 0.0017 | 0.2507 | 0.2627 | 0.2566 | 0.6281 | 0.0898 |

| Tiller number, X3 | 0.0094 | 0.1650 | 0.1037 | 0.2076 | 0.0220 | 0.0231 |

| Leaf biomass, X4 | 0.0325 | 0.0857 | 0.5106 | 0.0823 | 0.9472 | 0.2393 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qi, B.; Yang, S.; Li, D.; Qin, D.; Zheng, X.; Hu, J.; Zhou, X.; Liu, H. Effects of Drainage Technology on Waterlogging Reduction and Rice Yield in Mid-Lower Reaches of Yangtze River. Agronomy 2025, 15, 905. https://doi.org/10.3390/agronomy15040905

Qi B, Yang S, Li D, Qin D, Zheng X, Hu J, Zhou X, Liu H. Effects of Drainage Technology on Waterlogging Reduction and Rice Yield in Mid-Lower Reaches of Yangtze River. Agronomy. 2025; 15(4):905. https://doi.org/10.3390/agronomy15040905

Chicago/Turabian StyleQi, Bowei, Shenjiao Yang, Dongwei Li, Dandan Qin, Xingfei Zheng, Jianlin Hu, Xinguo Zhou, and Hongquan Liu. 2025. "Effects of Drainage Technology on Waterlogging Reduction and Rice Yield in Mid-Lower Reaches of Yangtze River" Agronomy 15, no. 4: 905. https://doi.org/10.3390/agronomy15040905

APA StyleQi, B., Yang, S., Li, D., Qin, D., Zheng, X., Hu, J., Zhou, X., & Liu, H. (2025). Effects of Drainage Technology on Waterlogging Reduction and Rice Yield in Mid-Lower Reaches of Yangtze River. Agronomy, 15(4), 905. https://doi.org/10.3390/agronomy15040905