1. Introduction

The global agricultural sector is under pressure to meet the demands of a rapidly growing population. By 2050, food production will need to increase by approximately 60% to sustain an additional 2 billion people, primarily in developing countries [

1]. However, achieving this growth is becoming increasingly complex due to climate variability and environmental challenges. Climate change is having a significant impact on agricultural productivity and food security [

2,

3], leading to extreme weather events such as droughts, floods, and pest outbreaks that threaten crop stability [

4].

To address these challenges, technological advancements in precision agriculture offer promising solutions. Innovations in digital agriculture and precision planting systems are essential to enhancing resource efficiency and improving crop resilience [

5]. Variable rate seeding (VRS) and hybrid switching have emerged as key technologies that enable more precise seed placement, ensuring that plant populations are optimized for varying soil conditions and terrain characteristics. While previous research has explored the impact of VRS on yield optimization [

6], there have been limited studies examining the accuracy of hybrid switching and its implications for field management.

The present study focuses on hybrid switching accuracy in precision planting, specifically analyzing how terrain variability influences its implementation and effectiveness in maize production. A comprehensive understanding of the precision of hybrid transitions is critical for improving site-specific crop management and ensuring that hybrid selection strategies align with variable field conditions.

Digitalization has revolutionized various industries, and the agricultural sector is no exception [

7]. With the advancements in modern and digital technologies, farmers now have access to various tools and techniques to improve the quality and quantity of corn. These technologies include genetic engineering, precision agriculture, and advanced harvesting and storage methods [

8]. Precision agriculture is an innovative approach to farming that utilizes advanced technologies, geospatial techniques, and sensors to optimize crop production [

9].

Corn (

Zea mays L.) is one of the world’s largest cultivated and one of the most versatile crops, which is of great importance in the food industry, animal feed, and in the biofuel industry [

10]. Its production plays a crucial role in food security and global agricultural economy. Corn is a vital crop in world agriculture today. Many farmers are transitioning from conventional planting systems to precision planting, which enables higher planting speeds to improve productivity and reduce the time spent in the field, especially in response to the growing labor shortage [

11,

12]. The genetic variability within maize hybrids plays a crucial role in the adaptability and resilience of the crop. Different maize hybrids exhibit variation in traits such as spike density and plant density tolerance, which can influence their performance in different environmental conditions. Furthermore, genetic analyses have shown that complex traits in maize, such as yield potential and stress tolerance, are controlled by multiple genes of small effect that may interact with each other and the environment. In most studies, traditional linear regression or machine learning methods were used to establish the relationship among soil indicators, seeding rate, and yield, which did not consider the impact of climatic conditions and management factors on yield [

13,

14,

15].

In today’s agricultural landscape, many farmers are making the shift from conventional planting systems to precision planting. This transition is driven by the need to improve productivity and reduce the time spent in the field, especially due to the increasing lack of labor force. Precision planting is a farming technique that utilizes advanced technologies to optimize the planting process [

7]. These technologies include hybrid changing, yield monitor, satellites, drones, GPS systems, variable rate application, remote sensing, and computer simulation models.

The first step of precision planting is the application of variable rate seeding (VRS). It has drawn interest with the early precision agriculture pioneers of the mid-1990s [

16]. Variable rate seeding (VRS) is known for at least 20 years and it is an important component of precision agriculture that has had a significant impact on agricultural production by varying the seeding rate according to field conditions, which can save seeds and increase yield and net farm returns [

17]. For implementing VRS, there are two different approaches, namely, the sensor-based approach and the map-based approach [

18]. In the first approach, soil properties are measured by utilizing real-time sensors. This approach is also called an “on-the-go” solution. The variable-rate applicator is then immediately controlled in order to adjust the seeding rate. The second approach requires a different approach: first, grid sampling has to be carried out on the field, which is followed by a laboratory analysis of soil samples; based on the data a site-specific map is generated and using this map a variable-rate applicator is carrying out the task. A map-based VRS control system is easier to implement and has been widely studied for use with technologies such as GPS, remote sensing, yield monitoring, and soil sampling [

19].

For variable rate seeding, the seeding rate determination requires different strategies; however, the strategic analysis is very similar in every situation: first, the soil and environmental conditions have to be analyzed; second, the economic potential of the seed has to be calculated; and finally, based on the breeder’s recommendation, the seed rates have to be decided. Variable rate seeding aims for an economic benefit for the whole field based on potential in each yield zone [

17].

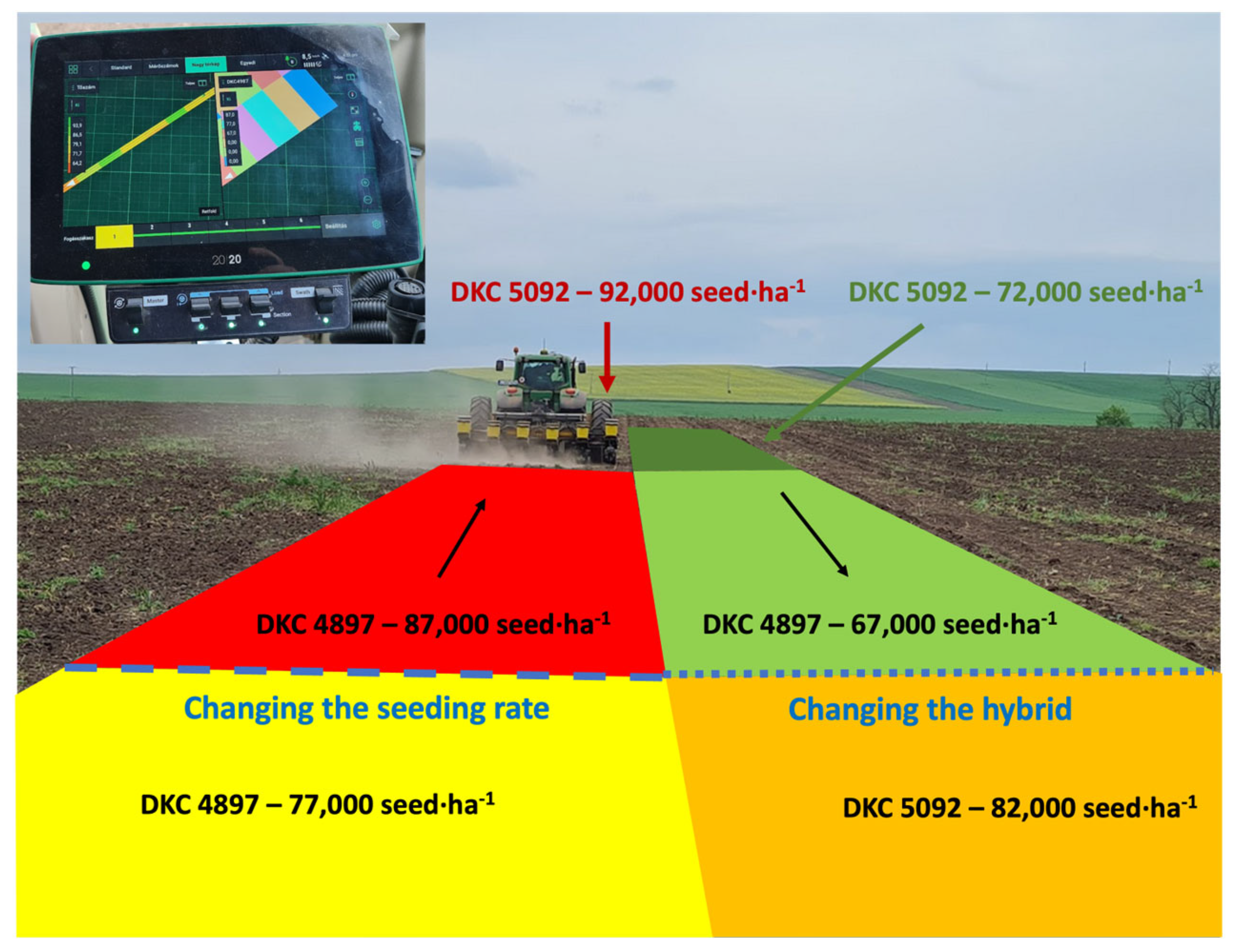

The next step in site-specific management in VRS technology is the hybrid switching for a field. This approach refers to the process of selecting and implementing different varieties or hybrids of corn crops in a specific agricultural field. This change can be driven by various factors, such as the need for higher yields, resistance to pests and diseases, improved adaptability to local climate conditions, or the desire to meet specific market demands [

20].

This hybrid switching approach combines the use of geospatial technologies, computer sciences, and digitalization in order to achieve precise seeding rates. By incorporating machine learning and computer vision, the hybrid approach can accurately identify areas areas of the field that require either higher or lower seeding rates or hybrid differentiation based on changing soil conditions. This not only maximizes crop yield, but also minimizes input costs and environmental impact.

The seeder achieves the desired plant density by increasing or decreasing the rotation speed of a wide-spectrum maize seed disc. The discs are driven by an electric motor. The seed tank of the drill is divided into two compartments. A switch mechanism at the bottom of the seed tank allows the machine to control the output of one or the other hybrid [

21].

The aim of this paper is to evaluate the accuracy of the seeder in implementing variable rate seeding (VRS) and hybrid switching strategies. This evaluation is crucial for the validation of subsequent agronomic and soil experiments, as the accuracy of seed and hybrid placement has a direct impact on the reliability of the results. By ensuring the accuracy of the seeder, we can confidently analyze the influence of different seeding rates and hybrid types on crop yield, soil health, and other key parameters under different environmental and management conditions. This will help provide a solid foundation for future studies and technological improvements in precision agriculture.

2. Materials and Methods

2.1. Location of the Research Area

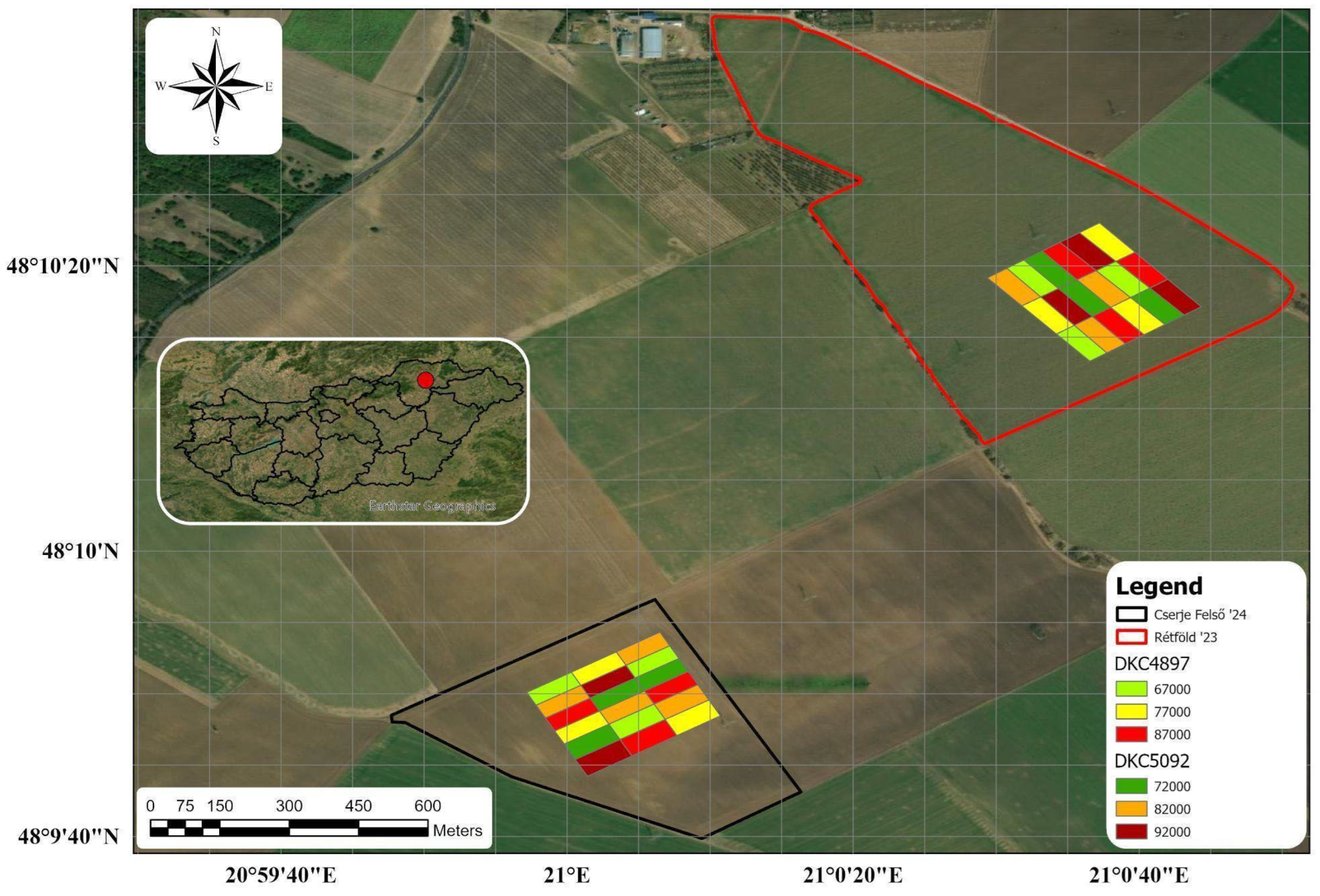

The research field is located in the Northeast of Hungary in Borsod-Abaúj-Zemplén county near a small village named Alsódobsza (

Figure 1). The experiments were established in two different fields for the two different years, located close to each other. The agricultural land belongs to Agro-Tár Ltd. (Alsódobsza, Hungary).

The majority of the area of Alsódobsza, where the Agro-Tár Ltd. agricultural farm is located, is classified as brown forest soil, which covers 34.6% of the total area of Hungary. The soil of “Rétföld” is clay loam where the organic matter content varies between 1.84 and 5.19%, while “Cserje felső” is mainly clay loam, with two areas in the northern and southern parts of the field changing to clay. The organic matter content in this field varies between 2.08 and 4.69%. In addition to intensive arable farming, the area is also used for horticulture and viticulture. The main arable crops are winter wheat, spring barley, maize, sunflower, and winter oilseed rape.

2.2. Seeding Equipment, Seeding Depth and Speed

Seeding equipment was a uniquely built seeder based on “Busa” chassis and a Precision Planting (Precision Planting LLC., Tremont, IL, USA) seeding unit supplied with a 20/20 monitor system. The seed tank was divided into two parts, each controlled by an mSet unit, which managed the separation and transition between different hybrids. This system regulated the opening and closing mechanisms to ensure seamless hybrid switching. Unlike conventional planters, which do not support on-the-go hybrid transitions, the mSet system enables the planting of two hybrids within a single field using a divided hopper and a Precision Planting vSet meter. Additionally, the mSet unit is integrated with SpeedTube technology, allowing for efficient high-speed multi-hybrid planting while maintaining precision (

Figure 2). Seeding depth was a standard 5 cm, and seeding speed varied between 9.59 and 11.61 km/h.

2.3. Maize Hybrids and Seeding Rates

In the research area, two maize hybrids were applied. For DKC 5092, the seeding rate varied between 72 and 92 thousand seeds per hectare with three steps resulting in seeding rates of 72,000, 82,000, and 92,000, respectively. The other hybrid was DKC 4897, which was applied in 67,000, 77,000, and 87,000 seeding rates per hectare (

Table 1). In order to ensure the comparison between various years, the hybrids were the same in the two investigated years, 2023 and 2024. Seeding in 2023 was carried out on 12 May, in 2024 on 29 and 30 May.

Both hybrids are in the medium-to-early maturity group and according to the breeding house trials, they have high scores on yield and drought tolerance characteristics. The hybrids have also received high scores for site stability and vintage effect. For plant height and flowering time, both hybrids received average scores within the maturity group (FAO 390–410), while for water release, DKC 5092 shows fast and DKC 4897 average scores. The experiment was organized in a random block design (

Figure 1 and

Figure 3).

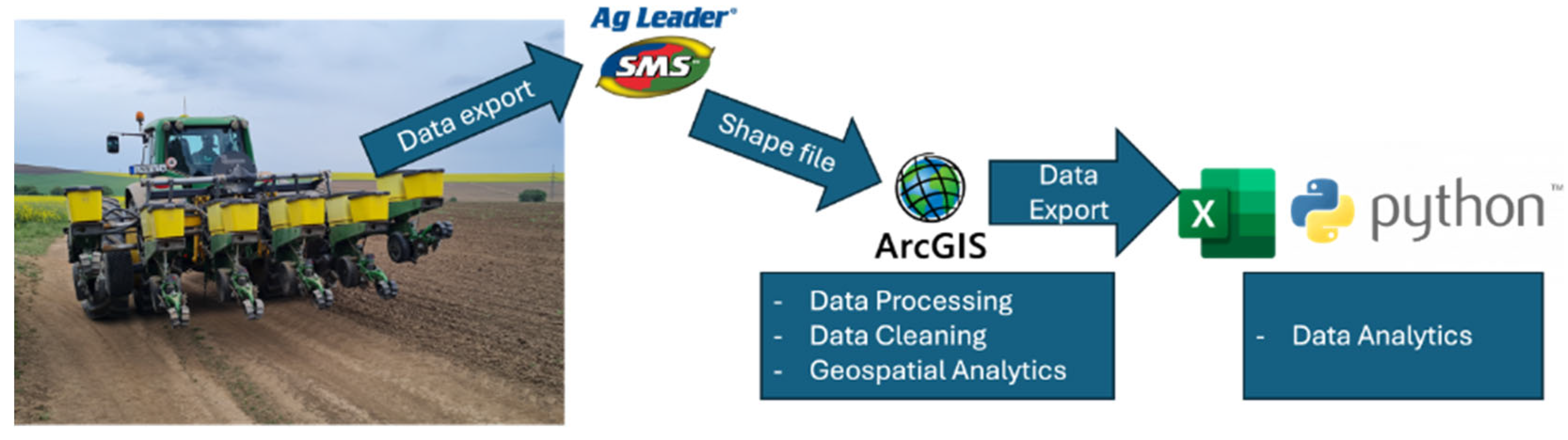

2.4. Data Flow and the Process of Data Analytics

As shown in

Figure 4, the data collection and analysis were a multi-phase process. The data were collected by the various sensors located on the seeder, which were integrated into the tractor’s monitor. At the end of the field work, the measured data were exported from the tractor system to a USB drive.

Once the data have been exported from the tractor’s USB drive and in the Ag Leader SMS software (v. 25, Spatial Management System, Ag Leader Technology, Inc., 2202 South Riverside Drive, Ames, IA, USA, V24.00), the dataset was imported into ArcGIS Pro (v. 3.4, ESRI, Redlands, CA, USA) as an ESRI shape file for further analysis. At this stage, the data were cleaned to remove any inconsistencies or errors, such as missing data points or outliers, to ensure the accuracy and reliability of the dataset.

ArcGIS is a key tool for the spatial analysis of measured data, which can be displayed and analyzed on maps. This includes visualizing the performance of each individual seed drill in the field, such as measuring seed placement, hybrid rotation efficiency, and changes in seeding rates.

One of the key features of ArcGIS is the ability to perform seeder analysis by spatially separating the data recorded for each individual seeder. This allows for the performance to be examined on an individual seeder basis, helping to identify any specific problems with seed placement, hybrid transitions or seeding rates that may occur during the operation. By mapping these variables across the field, it is possible to identify trends and inconsistencies, providing valuable insight into the performance of the seeding system.

After processing and analyzing the data in ArcGIS, we were able to create visualizations showing the variation across the field. These maps provide a better understanding of how different parts of the field were seeded, how accurately the hybrid changes occurred, and how the terrain affected the seeding rates. Analyzing spatial data in this way helps to identify areas for improvement and optimize the use of variable rate seeding as a technological solution for precision farming.

For further detailed statistical analysis, the data were processed using Microsoft Excel (v. 16.92, Spreadsheet software, Microsoft Corporation, One Microsoft Way, Redmond, WA, USA) and Google Colab Jupyter Notebook service (cloud-based platform for writing and executing Python codes, Google LLC., 1600 Amphitheatre Parkway, Mountain View, CA, USA), providing a robust analytical framework to assess the effectiveness of variable rate seeding and hybrid switching technology. This integrated approach ensured a comprehensive analysis and interpretation of the data, supporting the conclusions of the study.

2.5. Data Separation and Data Cleaning

The incoming data from both hybrids were separated based on seeding rate data. As part of the data cleaning process, each seeding rate value was matched to the corresponding hybrid type, ensuring an accurate match between the seeding rate and the specific hybrid for further analysis.

2.6. Seeding Method in 2023

In 2023, it was assumed that the machine measurements for the prescribed seeding rate and hybrid switching were accurate and reliable. This assumption was based on the well-calibrated precision planting system, which was expected to correctly measure and execute the transition between hybrids according to the prescribed seeding rates. The machine’s ability to seamlessly switch between hybrids was verified by the system’s internal monitoring, with the assumption that the equipment’s GPS and other sensing mechanisms ensured the correct operation. In 2023, the experimental field was located in a flat area. The minimum height above sea level was 179.8 m, while the maximum height above sea level was 183.8 m.

2.7. Seeding Method in 2024

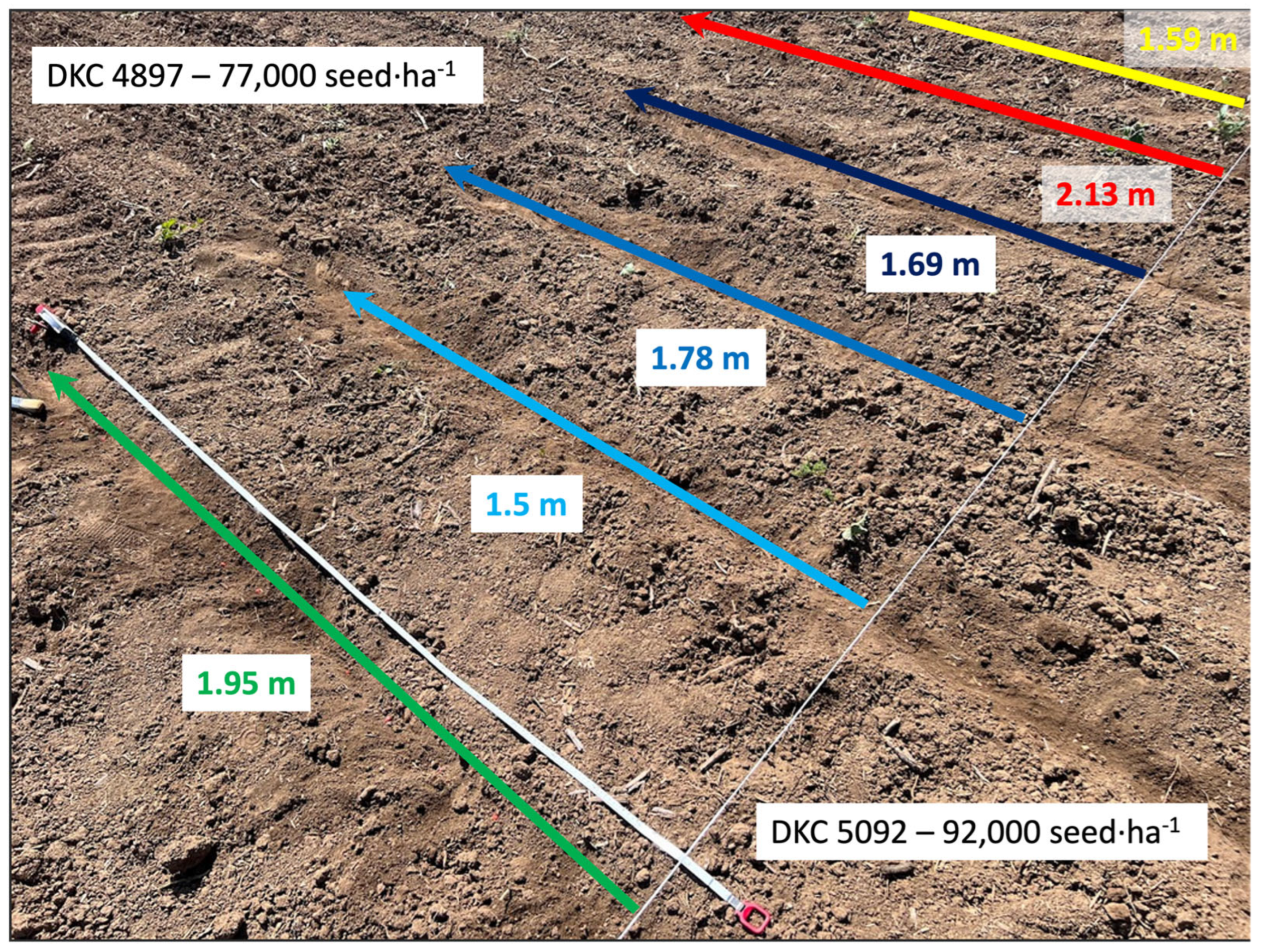

To verify the accuracy of hybrid switching and seeding rate transitions in 2024, we implemented a procedure for marking and excavating individual seeds. Before planting, the selected seeds were painted in distinct colors to visually track the precise point where the hybrid transition occurred. This approach allowed for a clear differentiation between hybrids and facilitated a more accurate assessment of transition length in field conditions. After the seeding process, a manual excavation was performed systematically in every 8th row (downhill) and 9th row (uphill) to determine the exact placement of the hybrid switch relative to the theoretical transition line stored in the ArcGIS system. The excavation process involved carefully removing soil to expose the seeds without disturbing their original position, ensuring accurate distance measurements. Each identified transition point was compared with the expected switching location to quantify any deviations. Given the hilly nature of the experimental field in 2024, with elevations ranging from 206.1 m to 228.34 m above sea level, variations in transition accuracy were expected.

This method enabled us to compare the actual seed placement with the machine-recorded data. In cases where deviations were observed, further investigation was conducted on the sensor-based digital data, analyzing possible influencing factors such as terrain slope and boundary effects. The combination of physical verification and digital data analysis provided a comprehensive evaluation of hybrid switching precision.

2.8. Variable Rate Seeding Accuracy Measurements

There are two ways to determine the accuracy of precision seeding, one is to analyze the data received from the sensors built into the seeding equipment. The sensors record the number and spacing of the seeds. The number of seeds is measured by a photocell and the distance between the placed seeds can be calculated from the number and speed of rotations. The accuracy of the application can be influenced by the unevenness of the seed, the momentary load on the machine, the direction of the shifts, i.e., increasing or decreasing the rate of the seeds, the angle of the slope, and the speed of the seeding machine. The change in the seeding rate can be monitored on the basis of the data recorded during seeding. The occurrence of a hybrid change can be checked from the database obtained from the seeding equipment, as the application of different hybrids is recorded in a different database.

The accuracy of the application can be checked by manual measurement; however, this is time consuming and labor intensive. Manual checking relies on painting different hybrids different colors to distinguish them. Immediately after seeding, the seed trench is reopened, taking care to leave the seeds in place. The painting makes it possible to identify the different hybrids and check the position of the seeds. The accuracy of the number of seeds can then be determined by manual measurement. During the experiment, the manual measurements were applied only in the year 2024. After germination, the hybrid change cannot be measured; however, the precision of the number of seeds can be measured. It should be noted that the number of seeds sown and the number of seeds germinated are not the same.

In our study, we conducted an experiment to evaluate the effectiveness of changes in hybrid and plant density in a seeding process on different terrains. In 2023, the experiment was conducted on flat terrain, while in 2024, it was extended to hilly terrain. To assess the accuracy of the hybrid and plant density adjustments, we measured the distance between the theoretical hybrid change and the actual plant density values. Seeding was carried out using the RTK accuracy GPS system; therefore, we assumed that row spacing is standard 76.2 cm. The seeding machine recorded the row spacing accuracy. The values varied between 0 and 15%; however, we did not calculate with this variable as it has no influence on hybrid and seeding rate changes. In addition, we manually verified the hybrid change by marking specific seeds and monitoring how long it took for the change to occur in the field. This hands-on approach allowed us to closely track the performance of the seeding adjustments and understand the impact of terrain variations on the overall process accurately and individually for each seeding unit.

2.9. Assessing Yield Performance Through Variable Rate Seeding and Spatial Analysis

The yield measurement was carried out using a John Deere S770i combine harvester (John Deere Corporation, 1 John Deere Pl, Moline, Illinois, USA) equipped with an integrated yield and moisture mapping system. Yield data were collected in real-time and later processed to ensure accuracy. To minimize potential measurement errors, data filtering was applied to remove anomalies. The processed yield data were then analyzed in ArcGIS Pro, where experimental units were spatially selected, and yield values were calculated.

3. Results

The switching rate was examined on the basis of the “actual implementation map” of the seeding carried out according to the previously defined application map. This has the advantage that each individual machine line provides data. In SMS software, the data occur in an averaged form; however, when exporting the database into ESRI ArcGIS Pro, the data appear for each individual seeding unit in a separate column. Therefore, the analysis is possible for each unit in the 6th row.

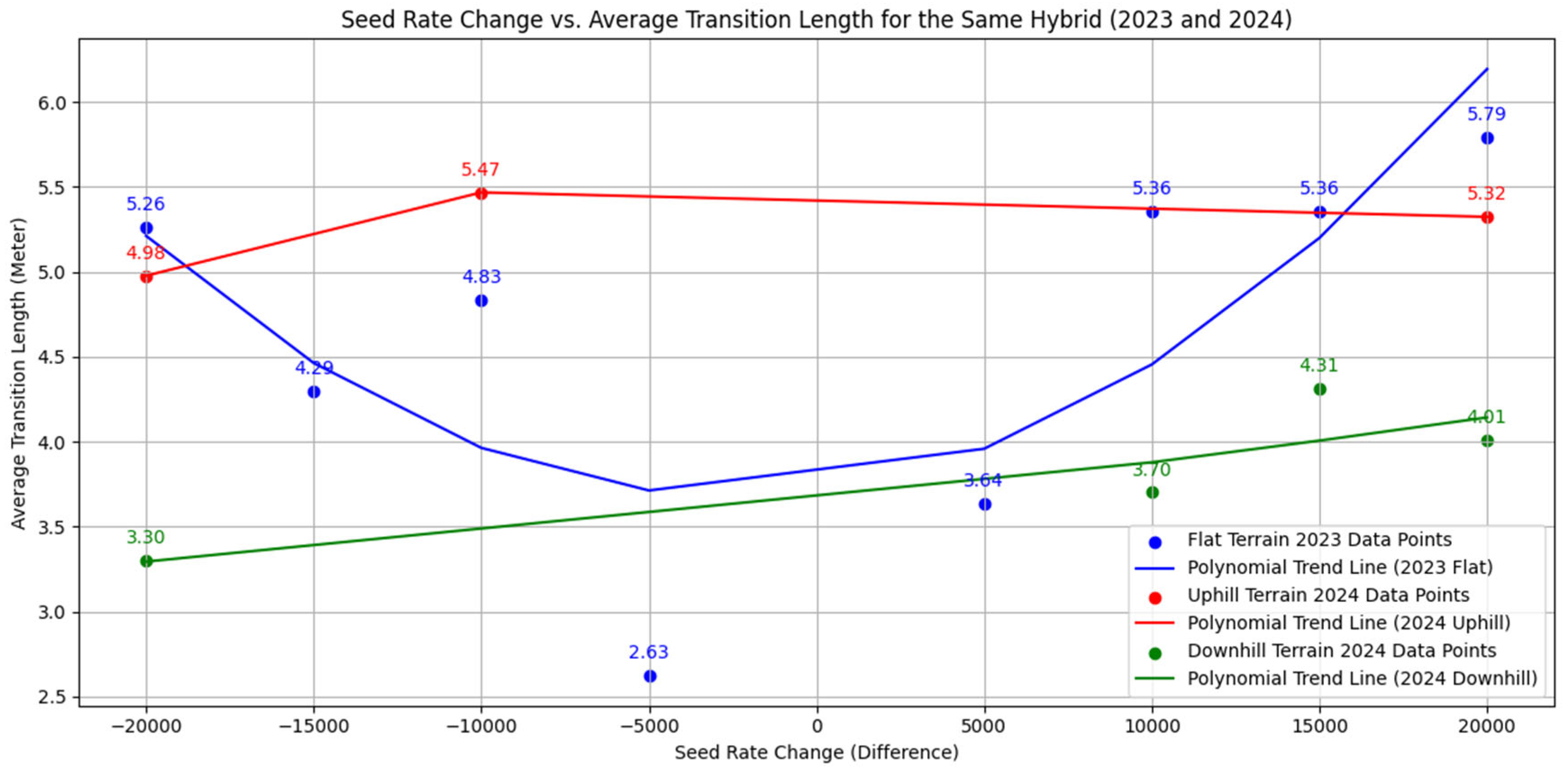

3.1. Speed of Variable Rate Switching—Same Hybrids

The accuracy of the variable rate switching within the same hybrid was investigated for the two hybrids separately. All data obtained were determined from the average of at least nine samples based on the average seed rate collected and calculated from the seeding machine. The allocation of the experimental space allowed 9-9 trails to be investigated. It has been found that in 2023, for the hybrid DKC 4897, when changing the seeding rate from 67,000 to 87,000 seed ha

−1, the distance was slightly lower (5.43 m) than changing from 87,000 to 67,000 seed ha

−1 (5.89 m). This means that when changing for a higher seed rate, it takes an average 46 cm longer for the machine to respond (

Table 2).

In 2023, for the hybrid DKC 5092, when changing the seeding rate from 72,000 to 82,000 seed ha−1, the distance was 5.36 m and from 72,000 to 92,000 seed ha−1, the distance was 5.98 m. This means the higher the difference between the seed rates, the higher the distance from the theoretical changing line. The same applies when calculating the differences for the seed rate from 77,000 to 82,000 and 92,000 seed ha−1. The 77,000 seeds ha−1 occurred only in the edge of the experimental field, which was circum-seeded by the same (DKC 5092) hybrid. When the seed rate is changed for a lower rate, the distances are shorter from the theoretical changing line. In the case that the seed rates are changing only by 5000 seed ha−1, the distance for changing was only 2.63 m, which is within the accuracy expectations.

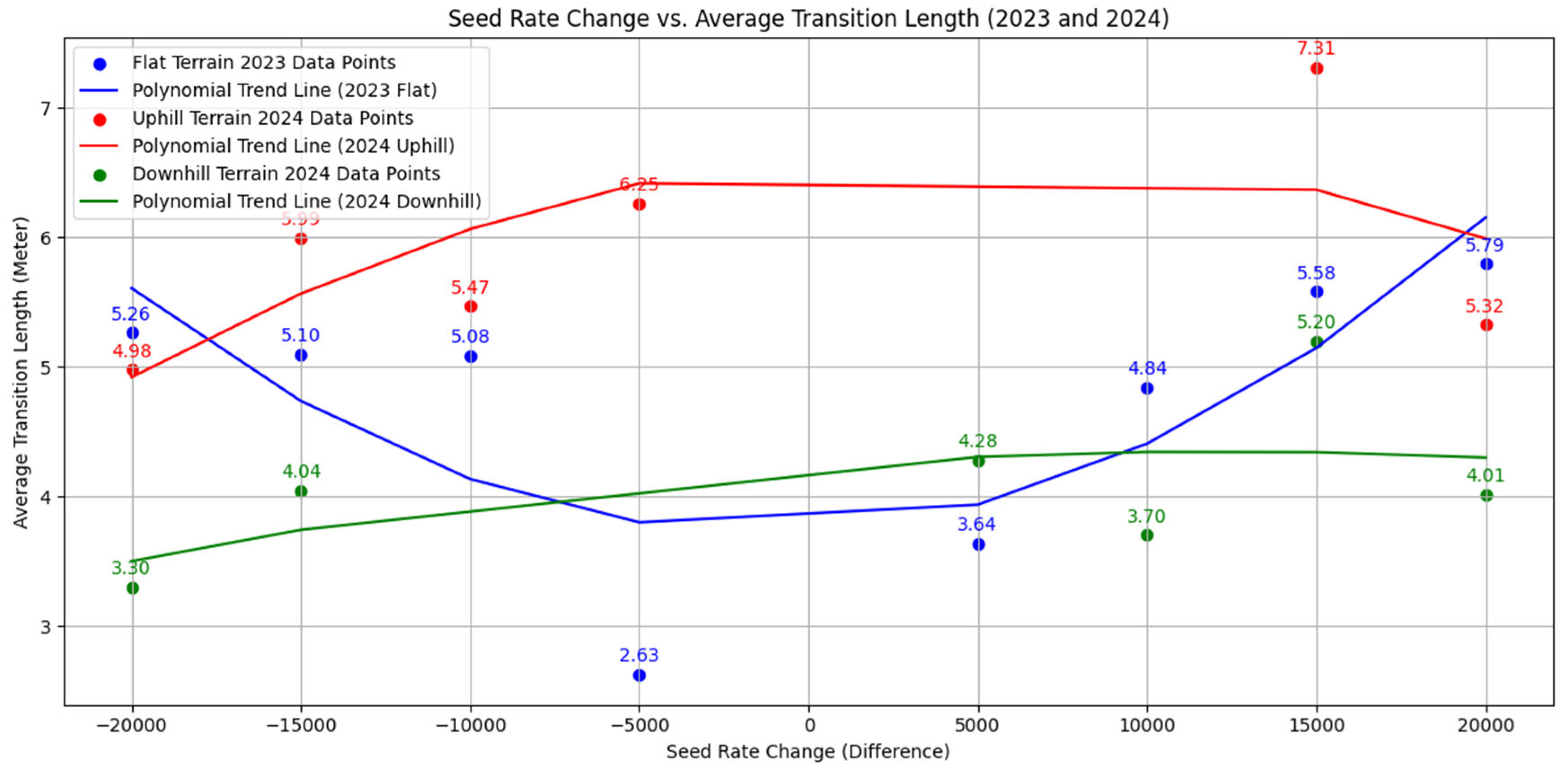

Comparing the two investigated years, it is visible that in 2024 the measured distances are lower than in 2023.

For the same comparison between the years for the hybrid DKC 5092, the distances for changing between the hybrids are generally lower in 2024, except for changing from 82,000 to 72,000 seed ha−1, where the distances for changing the seed rate were 4.83 in 2023 and 5.47 in 2024.

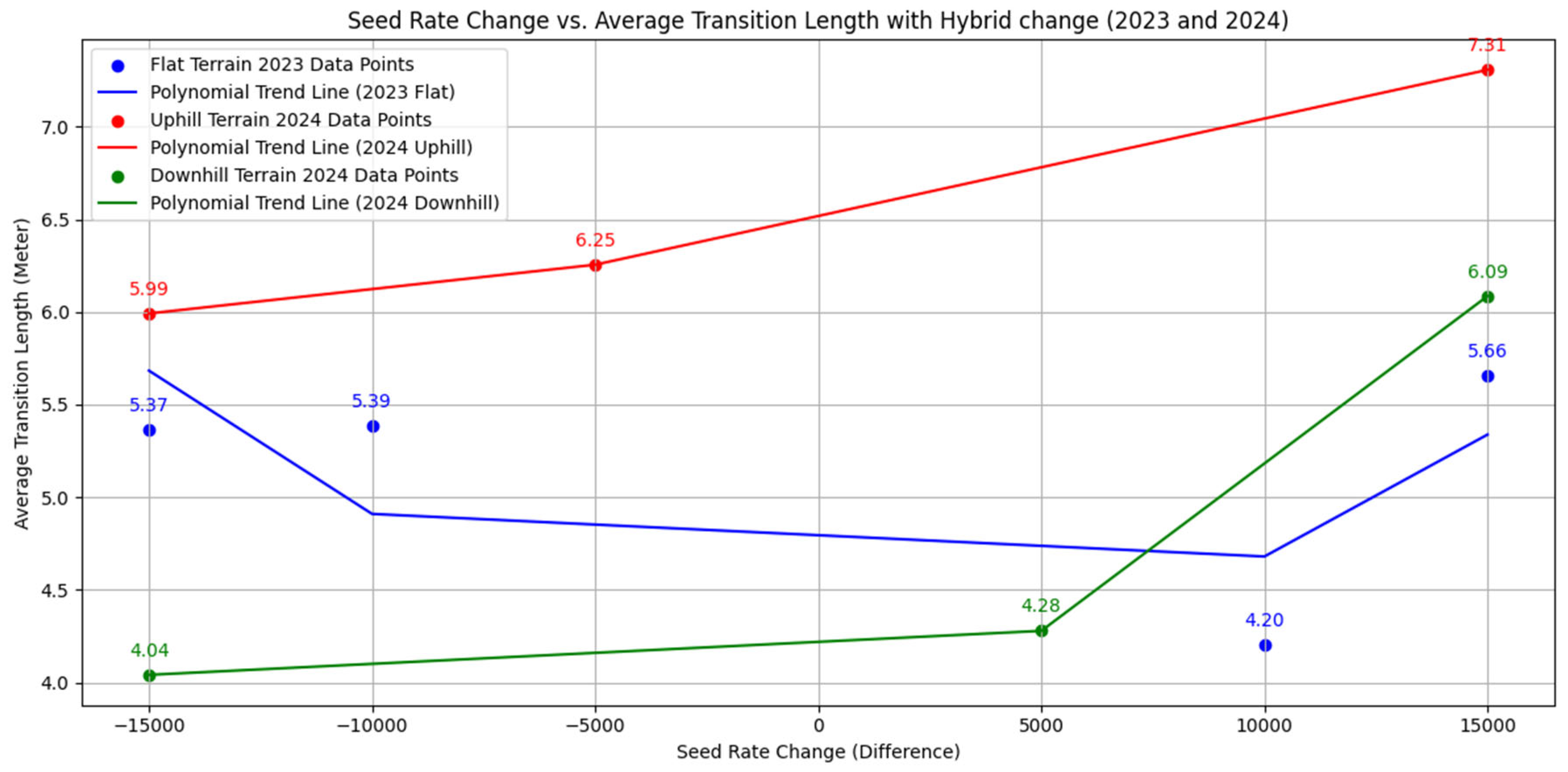

3.2. Speed of Variable Rate Switching—Different Hybrids

This section presents the results the measurement of variable rate seeding when combined with hybrid switching, as well as the results of different seeding rate adjustments. The measured distances from the theoretical hybrid transition line are summarized in

Table 3. The key findings indicate that the measured data differ across years. Moreover, when hybrid switching occurs, the transition distances are longer compared to cases where only the variable seeding rate is applied within the same hybrid.

3.3. Speed of Variable Rate Switching—Different Seed Rates, Switching Hybrids, and Geographical Location

From the measurements, it can be concluded that seed rate changing and hybrid switching are different in a flat (2023) and a hilly (2024) area. The data are shown in

Table 4,

Table 5 and

Table 6 and

Figure 5,

Figure 6 and

Figure 7.

3.4. Analysis of Variance (ANOVA) and Tukey’s Test for the Effect of Terrain Conditions on Transition Length

3.4.1. Analysis of Variance (ANOVA) Analysis

In order to determine whether terrain conditions have a significant effect on the transition length, we used the Analysis of Variance (ANOVA) and Tukey’s HSD post-hoc test. These statistical tests allow us to assess whether there are significant differences in transition length between different terrain types, and if this is the case, which specific terrain types differ from each other.

Based on the results of both ANOVA and Tukey’s HSD test, we can conclude that the terrain conditions have a statistically significant effect on the transition length. Specifically, the transition length differs significantly between downhill, flat, and uphill terrain types.

First, we conducted a one-way ANOVA to assess whether the mean transition length differed significantly between the three terrain types: flat, uphill, and downhill. The ANOVA test showed that there are significant differences between the terrain types in terms of transition length.

Table 7 summarizes the results of the test performed to examine whether there are statistically significant differences in transition length (seeding rate change) across three different terrain types.

As the p-value (5.5 × 10−13) is much smaller than the standard significance level of 0.05, we reject the null hypothesis (that there is no difference between terrain types). This indicates that there are statistically significant differences in the transition length between the terrain types.

The F-value is 30.91, indicating that the variance between terrain conditions is significantly larger than the variance within groups. The higher the F-value, the greater the probability that there is a statistically significant difference between groups.

In other words, the terrain conditions do have a significant impact on the transition length.

3.4.2. Tukey’s HSD Post-Hoc Test

As the ANOVA confirmed that there were significant differences, we used Tukey’s HSD post-hoc test to identify which specific terrain types differed from each other. Tukey’s test allows us to compare each pair of terrain types and determine whether the differences between their means are statistically significant.

All three pairwise comparisons (downhill vs. flat, downhill vs. uphill, flat vs. uphill) show statistically significant differences in transition length.

This suggests that terrain type plays an important role in how much the seed rate changes.

3.4.3. Hybrid Switching Accuracy by Terrain Type

All measurements were made at least three times within the experimental field to ensure statistical reliability. The number of replicates varied depending on the type of measurement, but no data point was recorded from a single observation. The calculated standard deviations and confidence intervals provide a more accurate representation of the variability within the data set.

The precision of hybrid switching was significantly affected by terrain type, as confirmed by the ANOVA test (

Table 7), which showed a highly significant effect (F = 30.91,

p < 0.001). Tukey’s HSD test (

Table 8) further demonstrated significant differences between all terrain categories, indicating that the hybrid switching length was longest on the uphill terrain, followed by the flat terrain, and shortest on downhill.

The mean hybrid switching lengths for each terrain type were as follows:

Downhill: 0.00 ± 1.17 m (95% CI: [−0.22, 0.22] m)

Flat: 0.87 ± 1.17 m (95% CI: [0.65, 1.09] m)

Uphill: 1.57 ± 1.17 m (95% CI: [1.35, 1.79] m)

The statistically significant differences across all terrain types (Tukey’s HSD,

p < 0.001) confirm that terrain adaptation is a crucial factor in hybrid switching accuracy. The confidence intervals were calculated using the standard formula:

where

represents the mean hybrid switching length for each terrain type,

SD is the standard deviation,

n is the number of observations, and

tα/2 is the critical

t-value for a 95% confidence level.

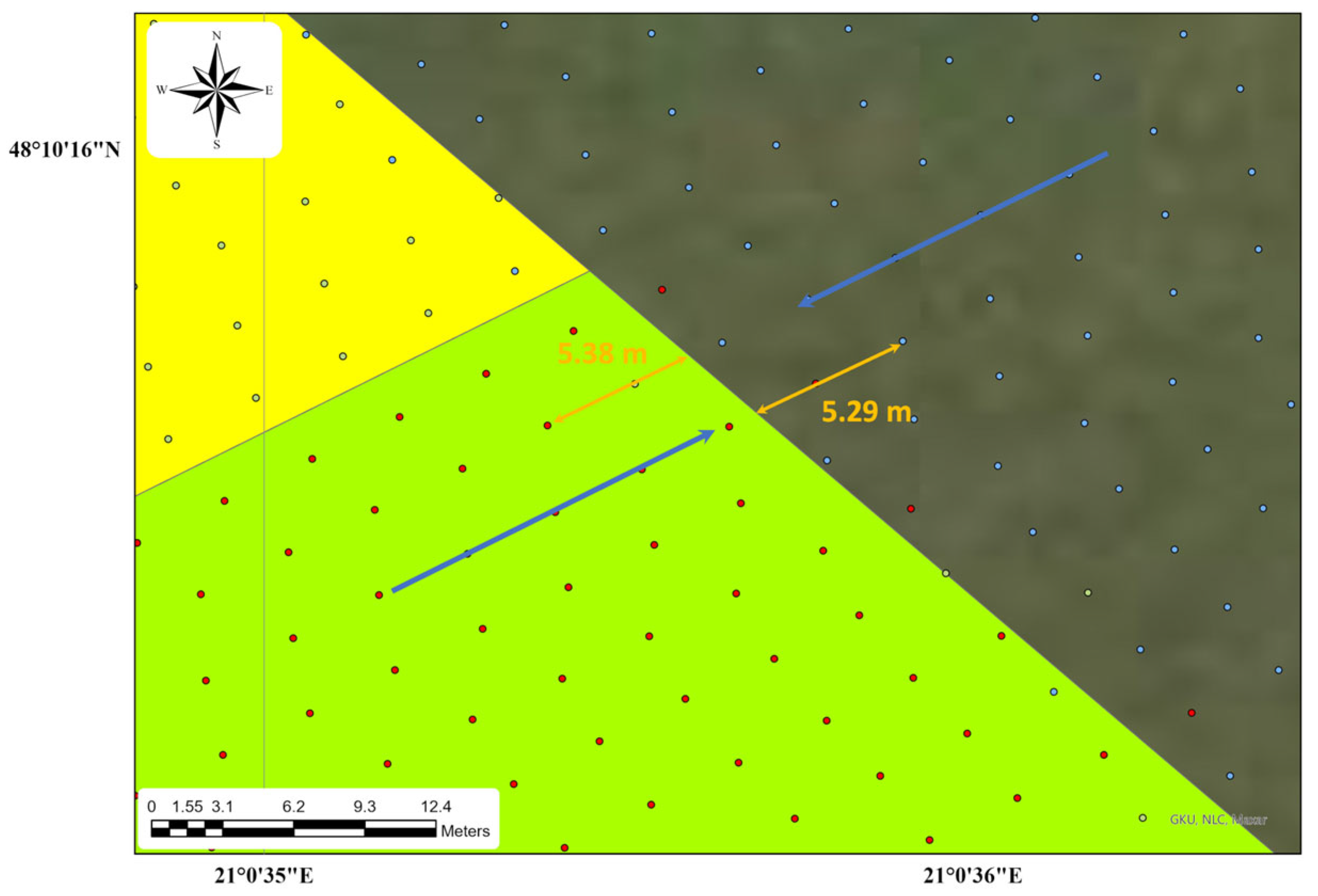

3.5. Comparison of Machine-Measured and Manually Verified Data for Hybrid Switching in 2024

In 2024, we compared machine-measured data with manually verified data to assess the accuracy of hybrid switching and seed placement. Specifically, we focused on the 8th and 9th seeder-lines where we manually inspected marked seeds in designated areas to determine how many meters after the seed was planted the hybrid switch occurred.

These manually measured distances were compared with the recorded data and analyzed in ArcGIS to determine the distance at which the seeder recorded the correct seed rate value. The machine data indicated the seeding rate adjustments and hybrid transitions, while the manual data provided a direct physical verification of how accurate the machine was in actual field conditions.

The results of the comparison are as follows:

These deviations were assessed by manual measurements, which confirmed that the machine’s accuracy was within a 10% margin.

The values are relatively close, indicating that the machine’s performance is generally in line with the manual observations, with some minor discrepancies.

However, this means that it may be necessary to define a buffer zone of 10 meters at the hybrid switching zone boundaries.

3.6. The Importance of the Seeder Settings

When performing yield analysis based on data from precision equipment, it is important to understand the specific characteristics of the equipment, especially when changing seed types or making adjustments to the machine. Precision equipment, such as a seeder, can show significant variability in performance depending on how it is set up and operated. Understanding how the machine performs during hybrid switching, its accuracy in seed placement and the potential errors that can occur are therefore essential for accurate seeding analysis, and as a consequence, this knowledge is important for yield analysis, as well.

On the basis of the data measured, it is possible to draw the following conclusions:

The analysis shows that in 3.84% of cases, there is a noticeable difference in seed distribution between the seeders, i.e., a difference of more than 10,000 seed/ha between the doses applied on the six seeders and the prescribed dose, including the measurement errors.

3.7. Variable Rate Seeding—Optimal Seed Rate Determination

According to the measured data, optimal seed rates are different for each individual hybrid.

An interesting observation from the data is that seeders tend to achieve better seed placement uniformity when operating downhill than when travelling uphill (

Figure 8). For seeding equipment, achieving uniformity is critical to optimizing crop growth and ensuring consistent yields.

The analysis shows that when the seeder travels downhill, it achieves a slightly higher average seed placement uniformity score (99.26) with less variability compared to when it travels uphill, where the average score drops slightly to 98.79 with greater variability. This suggests that the downhill direction allows for more uniform seed placement.

This finding highlights the importance of taking field orientation into account when seeding, as small differences in orientation can affect the overall performance, including achieving optimum seed uniformity.

The seeders respond to the prescription map with a slight delay for the following reason:

The response time of mechanical systems is limited. The seed disc cannot change speed immediately as it requires some time when the speed is changing to a higher or lower rotation.

The RTK system that controls the tractor has an accuracy of ±2 cm and includes tilt compensation. This is one of the most accurate systems available; however, it is not perfect—when changing seeding rates, delays and inaccuracies occur due to the discrepancy between the machine’s movement and the GPS coordinates or changes in slope angle.

The mechanical flow of seed takes time. Neither the speed of the seed discs nor the seed flow can be changed instantaneously, as the seeds already inside the speed tube are not able to react immediately.

3.8. Furrow Quality

The analysis of the furrow quality in relation to the direction of operation shows a significant trend in seed placement performance. When the seeder operates in the down direction, the furrow quality is significantly higher with an average score of approximately 97.77. In addition, the consistency of the furrow quality is better, as indicated by the lower standard deviation of 1.47. On the other hand, when the drill moves uphill, the average furrow quality drops to 92.25, with a higher variability of 4.38. This suggests that the downhill direction produces more uniform and higher quality furrows, probably due to the natural assistance of gravity, which helps to stabilize the drill and improve the accuracy of seed placement (

Figure 9).

3.9. Seed Skipping Analysis—Directional Differences

The analysis of the average seed skipping percentage shows a significant directional difference between uphill and downhill operations. When the seeder is travelling upwards, the average seed skipping percentage is approximately 0.99%, with a relatively high standard deviation of 1.07%, indicating considerable variability in seed placement. The maximum seed skipping percentage observed during the upward operation can be as high as 7.52%, indicating instances where seed skipping is much more pronounced.

On the other hand, the average seed skipping percentage during the downward operation is much lower at 0.50% with a much smaller standard deviation of 0.41%. The maximum seed skipping observed in the downhill direction is also much lower at 1.96%. This suggests that the seeder tends to place the seed more evenly in the down direction, with less variation in seed skipping across the rows. The more consistent and lower percentages of seed skipping in the downhill direction suggest that terrain orientation plays a critical role in seed placement performance.

3.10. The Influence of Seeder 6 and Data Cleaning

It is important to note that during the data cleaning process, Seeder 6 was excluded from the analysis due to a significant deviation in the percentage of missed seeds compared to the other seeders. The missing seed percentages for this seeder were significantly higher, skewing the overall results.

This discrepancy is probably due to the seed roller brush settings on the 6th seed drill. The incorrect adjustment of these components can result in uneven seed distribution, leading to much higher missed seed percentages. In particular, the seed skipping values for the 6th seeder were many times higher than those observed for the other seeders, suggesting that this issue requires particular attention during data pre-processing.

This serves as a reminder of the importance of thoroughly checking raw data before undertaking any analysis. Relying solely on calculated averages or machine-recorded data can lead to misleading conclusions if outliers or biases are not identified and corrected. It is important to note that most analytical tools, such as the Ag Leader SMS system, also use the calculated average.

In this case, the exclusion of the 6th drill allowed for a more accurate representation of the overall drill performance. The high variance introduced by the faulty 6th drill would otherwise have skewed the analysis, leading to potentially incorrect conclusions.

3.11. The Importance of Data Quality

The discrepancies observed in the 6th seeder underline a critical point: it is essential not to rely solely on calculated averages or automated data outputs, but to carefully inspect the raw measurements before proceeding with any analysis. While tools such as Ag Leader SMS and other similar platforms can provide valuable insights through calculated averages, they may not be able to highlight individual anomalies or calibration issues that significantly affect the quality of the data. Ensuring the accuracy of measurements by identifying outliers and addressing potential errors is critical to making informed decisions based on the data.

This analysis highlights the importance of manually reviewing the data for outliers or unusual patterns that may indicate equipment problems or other anomalies.

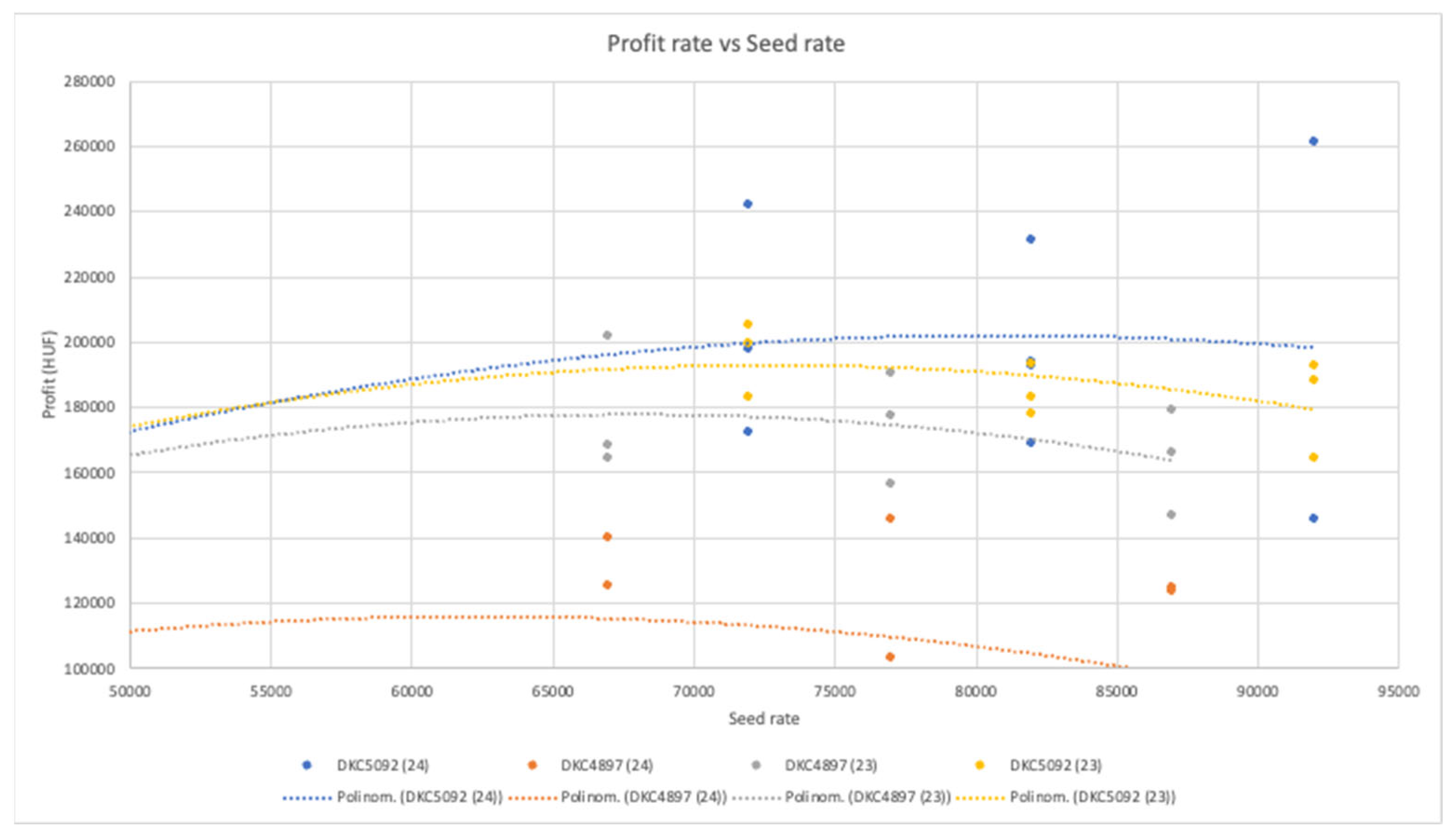

3.12. The Effect of Variable Rate Seeding on Yield

The effects of variable rate seeding on yield in our measurements were as follows: in 2023, the average yield of DKC 4897 was 12.56 t ha

−1 while of DKC 5092 was 12.95 t ha

−1; in 2024, the average yield of DKC 4897 was 7.25 t ha

−1 while of DKC 5092 was 7.45 t ha

−1 (

Figure 10). Considering the potential measurement uncertainty, yield data were aggregated across experimental units to reduce variability, and the values presented reflect the mean productivity per hectare. While minor variations in measurement precision are inherent in yield monitoring systems, the applied data validation process ensured reliable comparisons between experimental units. Additionally, differences between the two years are influenced not only by variable rate seeding effects, but also by weather conditions and field-specific soil and slope characteristics. The 2023 growing season had more favorable climatic conditions, while the 2024 experimental field had a more pronounced terrain variation, which likely contributed to differences in yield. Despite these factors, the comparative analysis remains valid for assessing the impact of variable rate seeding under different environmental conditions.

The effect of variable rate seeding on the profit was calculated for both of the hybrids and the variable rate seeding. It is clearly visible that while the highest yield in 2023 was achievable around 12.5 t ha

−1 and in 2024 around 7.3 t ha

−1 at the 82,000 seeds ha−1, if the seed rate is compared to the profit rate, the seed rate figures are 67,000 seed ha

−1 for DKC 4897 in 2023 and 67,000 seed ha

−1 in 2024. For DKC 5092, the most profitable seed rate was 72,000 seed ha

−1 in both 2023 and 2024. To interpret the relationship between yield and seeding density shown in (

Figure 11), it is important to clarify that the experiment prescription map was created to the part of the field which produced homogenous yields in the previous years; therefore, soil properties were the same, indicating that it will not affect the experiment with a new variable. The crop mapping methodology is described in detail in the

Section 2. (Materials and Methods). The purpose of the figure is to show how each seeding density affected the yield, thus providing an opportunity for optimization. The results confirm that the appropriate adjustment of the seeding rate has a significant effect on yield and profitability. It is important to emphasize that maximum yield does not mean maximum profitability and that hybrid selection and correct spacing also have an impact on profitability and yield levels.

4. Discussion

Variable rate seeding is a well-known practice in precision agriculture. Moreover, choosing the appropriate hybrid for maize production is crucial for successful farming practices. Soil variability occurs within-field in most agricultural lands in Hungary; therefore, within-field hybrid switching is a new perspective for precision agriculture. Changing the seed rate within a field highly depends on the hybrid and the effect of the climatic conditions of the growing season; therefore, generalized, exact figures can be misleading. As it can be found in the literature, an average of 67,000–87,000 seeds ha

−1 are published, which corresponds to our measurements. However, these studies do not address the relationship between terrain slope conditions and seeding accuracy, which is one of the aspects that our research addressed. There are literatures available on how the seed rate change affects the yield, but the accuracy of the change has not been addressed, although it does affect the actual zone boundaries. Combined with the accessibility of precision technologies and services to farmers, there has been increased interest and ability to make site-specific crop management decisions. In [

22], the authors published research on developing procedures to optimize maize seeding rates and maximize yield using soil and topographic parameters. The experimental treatments included five seeding rates (61,750; 74,100; 86,450; 98,800; and 111,150 seeds ha

−1) in a randomized complete block design in three central Iowa fields from 2012 to 2014 (nine site-years). They have concluded that an average of 86.450 seeds ha

−1 was the optimum rate for seeding.

In this research, we have found that the optimum seed rate for yield was achievable at 82,000 seeds ha−1; however, if the seed rate is compared to the profit, the acceptable seeding rates are much lower than 82,000 seeds ha−1.

In this study, we have applied a unique seeding machine. For this reason, the comparison with any other seeding equipment is not possible precisely. The ability to plant two or more hybrids during a single planting operation (i.e., multi-hybrid planting) has been studied recently [

23]. However, the authors were not focusing on the accuracy of the seeder, rather their focus was on the potential to mitigate the in-field yield variation caused by soil, disease pressures, environmental and water conditions. They have utilized a multi-hybrid planting platform to conduct on-farm research trials in ten eastern Nebraska fields. Their focus was on the placement of an offensive versus defensive (i.e., drought tolerant) maize hybrid, largely based on soil type and water availability interactions. The study did not focus on the precision of the seeding equipment, rather the present research specifically evaluated the influence of terrain on the accuracy of hybrid switching and adjustments to seed rate.

The results shown in this study have investigated the seeding equipment from another perspective, namely, the accuracy of the machine in various circumstances, such as varying the seed rate with the same hybrid and varying the seed rate, as well as switching two similar hybrids (DKC 4897 and DKC 5092). The data analysis so far has shown that correlations between various factors occur and the worst case scenario for hybrid switching or changing seed rate was within 8 m, which is acceptable for the practitioner farmers.

This study demonstrates the effectiveness of precision farming techniques, particularly variable rate seeding (VRS) and hybrid switching, in improving seed placement and productivity. Our results show that terrain significantly affects the accuracy of these systems, with downhill operations yielding more uniform seed placement and fewer instances of seed skipping compared to uphill operations. This is consistent with previous studies on the role of terrain in precision agriculture [

3,

6], which highlighted the challenges posed by varying environmental conditions.

The positive correlation between prescribed and applied doses further supports the findings of [

9], which showed that VRS can optimize seed distribution and increase productivity. Furthermore, hybrid switching was found to be effective in improving crop resilience and yield, especially when combined with VRS technology, confirming the importance of selecting the right hybrids for varying field conditions [

20].

Recent research has emphasized the need for advanced analytical approaches to better understand the interactions between soil properties, terrain variability, and planting accuracy. Ref. [

22] analyzed 92 different VRS methods and demonstrated that adjusting seeding rates based on soil texture, electrical conductivity (ECa), and yield potential can significantly improve resource efficiency. However, their study did not account for the precision of seed rate transitions within management zones, an aspect directly investigated in our research.

Additionally, NARMAX-based modeling approaches, as highlighted by [

15], have shown that traditional linear regression methods may not fully capture the complex interactions between soil variability, planting precision, and yield potential. These findings suggest that a more granular analysis of hybrid transition accuracy is necessary for optimizing precision planting strategies. Our study contributes to this effort by quantifying hybrid switching accuracy in real-field conditions, demonstrating that transition lengths can vary up to 8 m in the worst-case scenario, yet remain within an acceptable range for practitioners.

These results emphasize the need for real-time seed metering adjustments in precision agriculture. Future research should explore the integration of machine learning models to refine hybrid switching algorithms and enhance VRS efficiency under varying terrain conditions. Ensuring precise hybrid transitions will be essential for optimizing site-specific crop management and maximizing the benefits of multi-hybrid planting systems.

Our results also highlight the importance of data quality and equipment calibration. The exclusion of Seeder 6 due to anomalies emphasizes the need for thorough data cleaning to avoid misleading results. These findings highlight a broader issue in precision agriculture—ensuring reliable and validated input data is critical for achieving optimal outcomes.

In future research, integrating machine learning algorithms could enhance hybrid selection and optimize VRS recommendations based on real-time field conditions. Additionally, long-term studies should assess how these technologies influence soil health and sustainability over multiple growing seasons. Advancing these approaches will play a pivotal role in making precision agriculture more adaptive and profitable for modern farming systems.

5. Conclusions

The study highlights the effectiveness of precision farming technologies in improving seed placement, hybrid switching accuracy, and overall productivity. The knowledge gained from this research provides a foundation for future advances in the field, particularly as agriculture continues to adapt to the challenges of climate change and a growing global population.

The study highlights the importance of terrain and hybrid switching in precision farming, particularly in optimizing seed placement and seed rate adjustments. When switching hybrids, a buffer zone of 10 m on either side of the switch is required due to potential inaccuracies in seed placement. In cases where similar hybrids are used, this buffer zone helps to ensure that the seed rate stabilizes and maintains its accuracy within the transition zone.

The results of the study provide valuable insights into the challenges and opportunities of hybrid switching in different terrain conditions. As precision farming technologies advance, this knowledge will help improve the accuracy of hybrid switching and seed placement, ultimately leading to better crop yields and more sustainable farming practices.

The results of this research provide a solid foundation for future advances in the field, especially as agriculture continues to evolve to meet the demands of a growing global population and the effects of climate change. By improving hybrid precision and seeding efficiency, the agricultural industry can better respond to these challenges and achieve greater productivity in the long term.