Effect of Fungicide Application in Combination with Different Growth Regulators on Cotton Boll Quality and Yield in the Northwest Inland of China

Abstract

1. Introduction

2. Materials and Methods

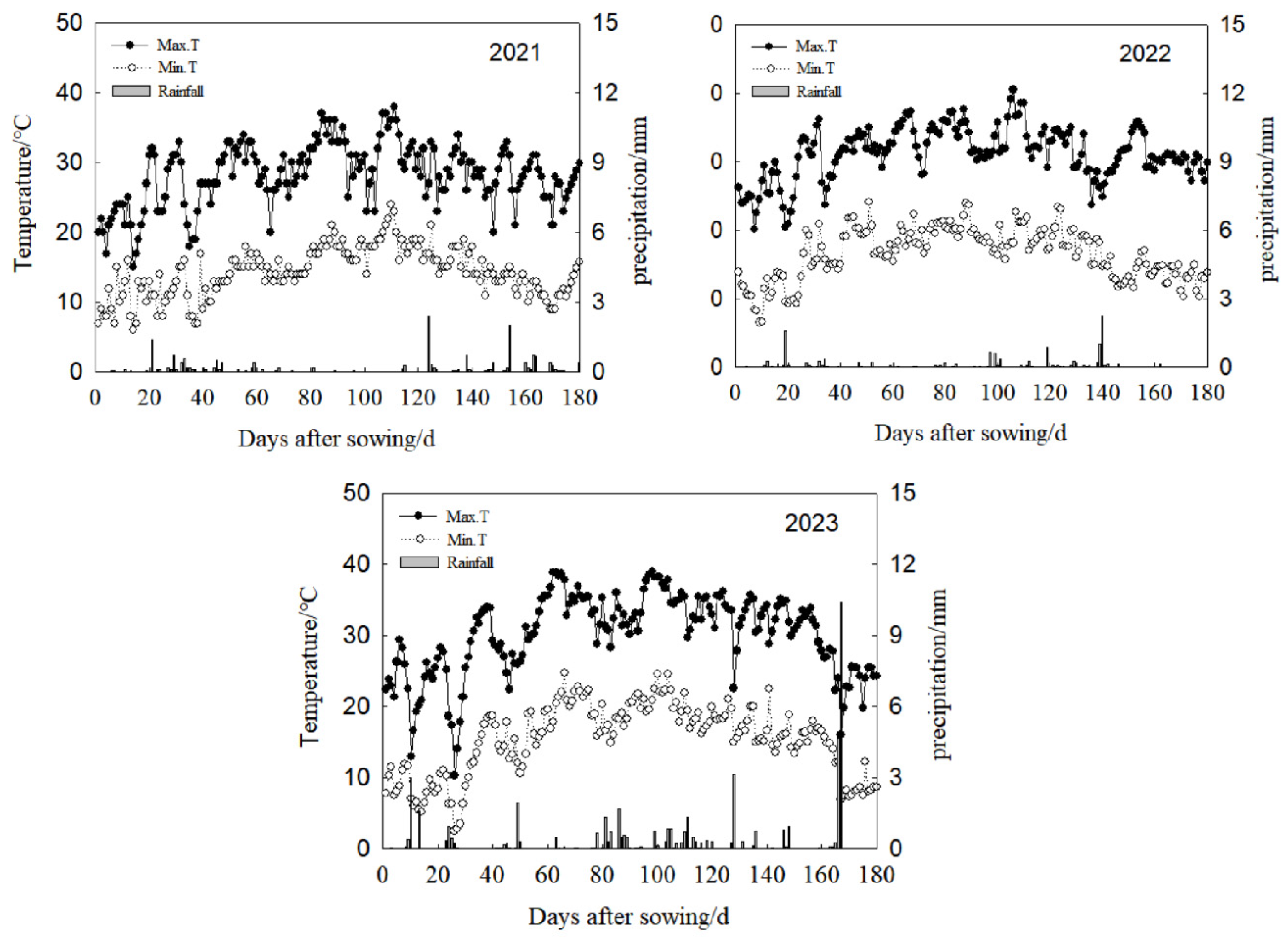

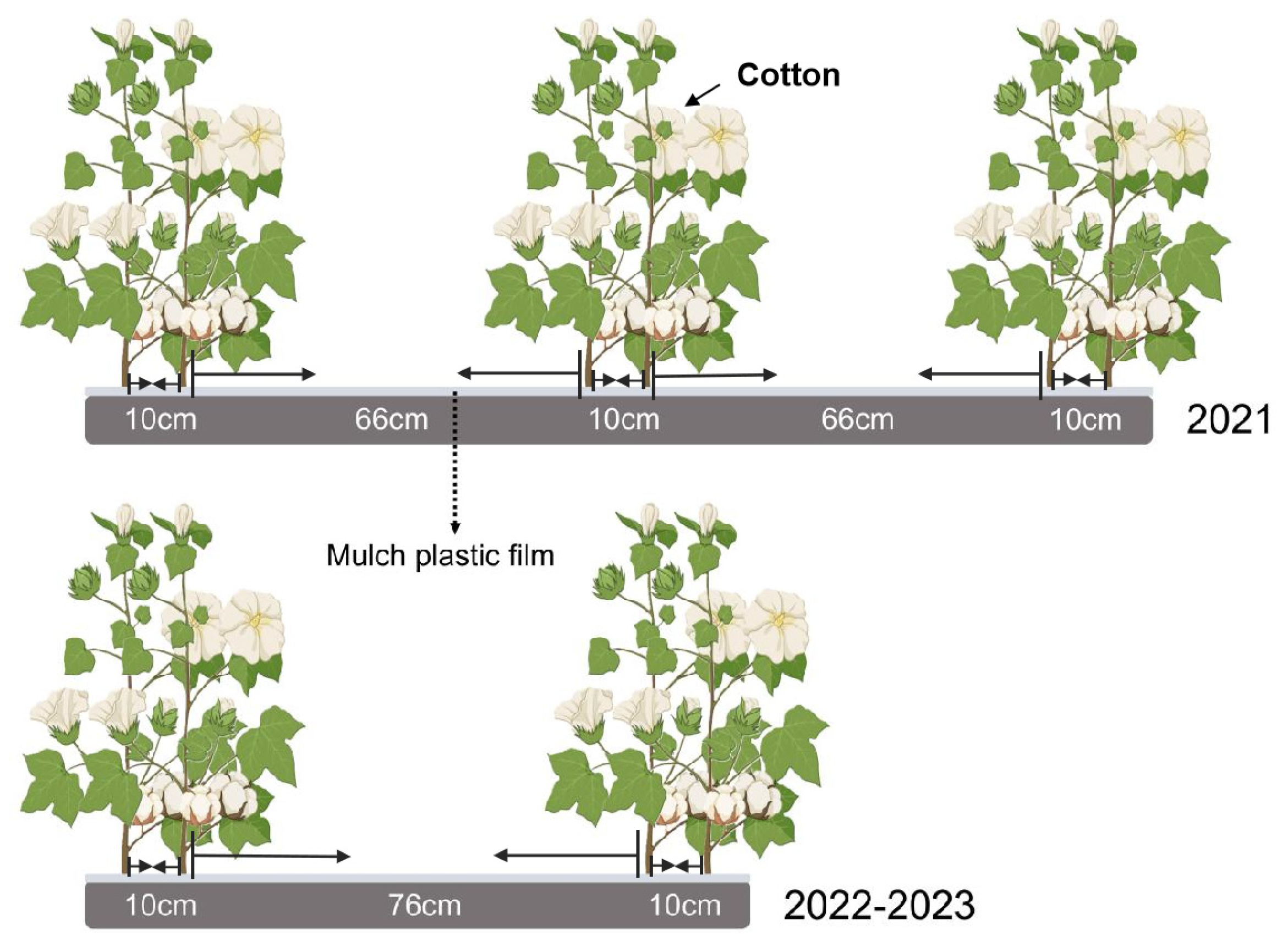

2.1. Experimental Design and Field Management

2.2. Data Collection

2.2.1. Cotton Production and Yield Components

2.2.2. Agronomic Traits Agronomic Traits Determination Indicators

2.2.3. Population Canopy Structure and Photosynthetic Characteristics

2.3. Statistical Analysis

3. Results

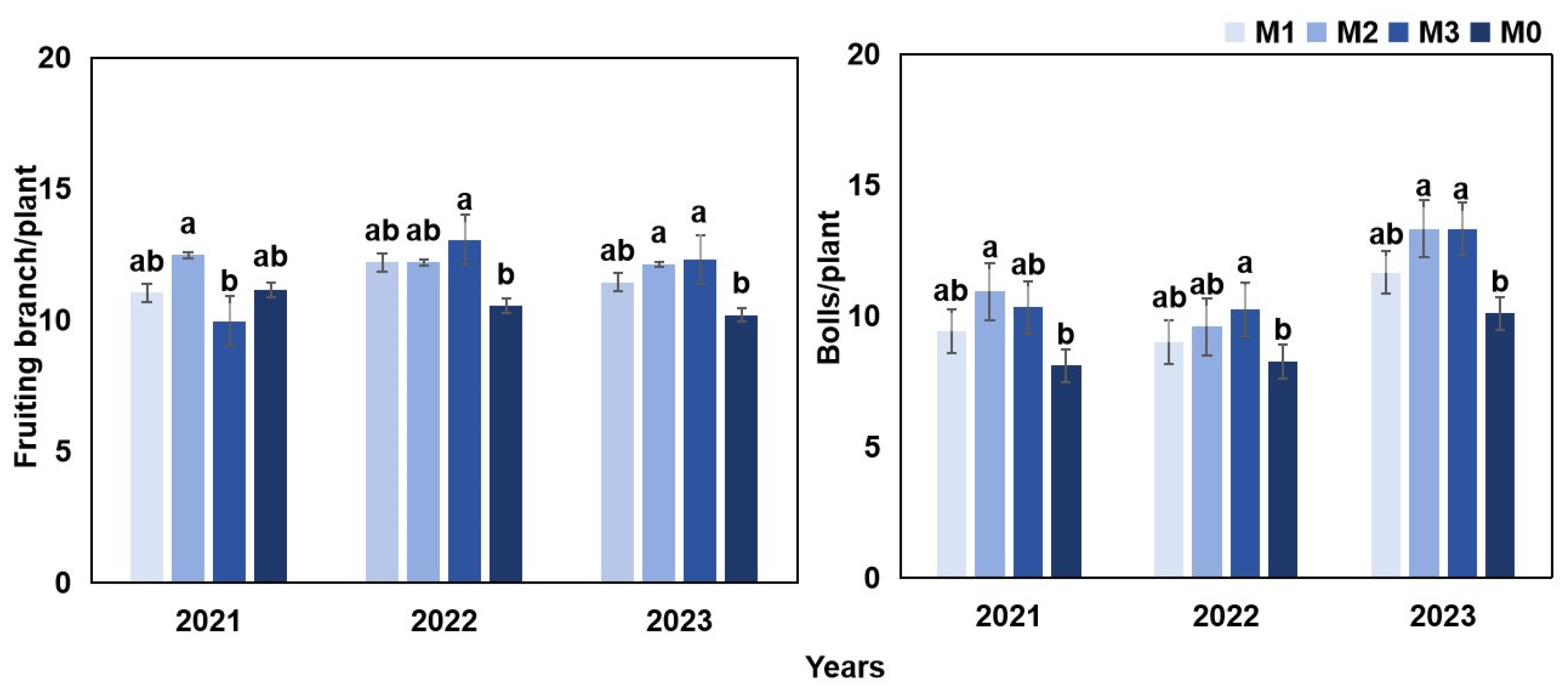

3.1. Yield and Yield Components

3.2. Agronomic Traits

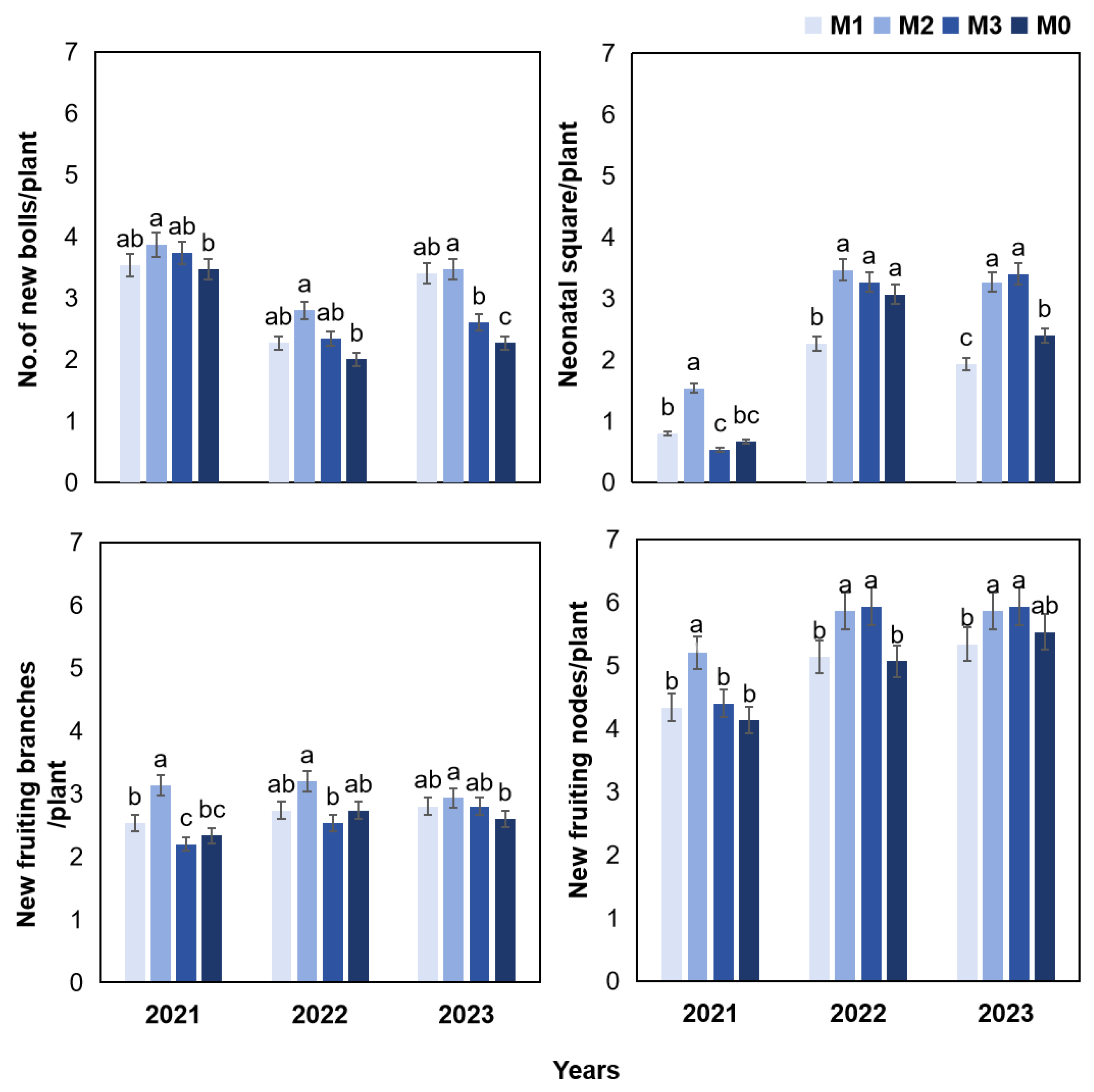

3.2.1. Effect of Combination Treatments on the New Parts

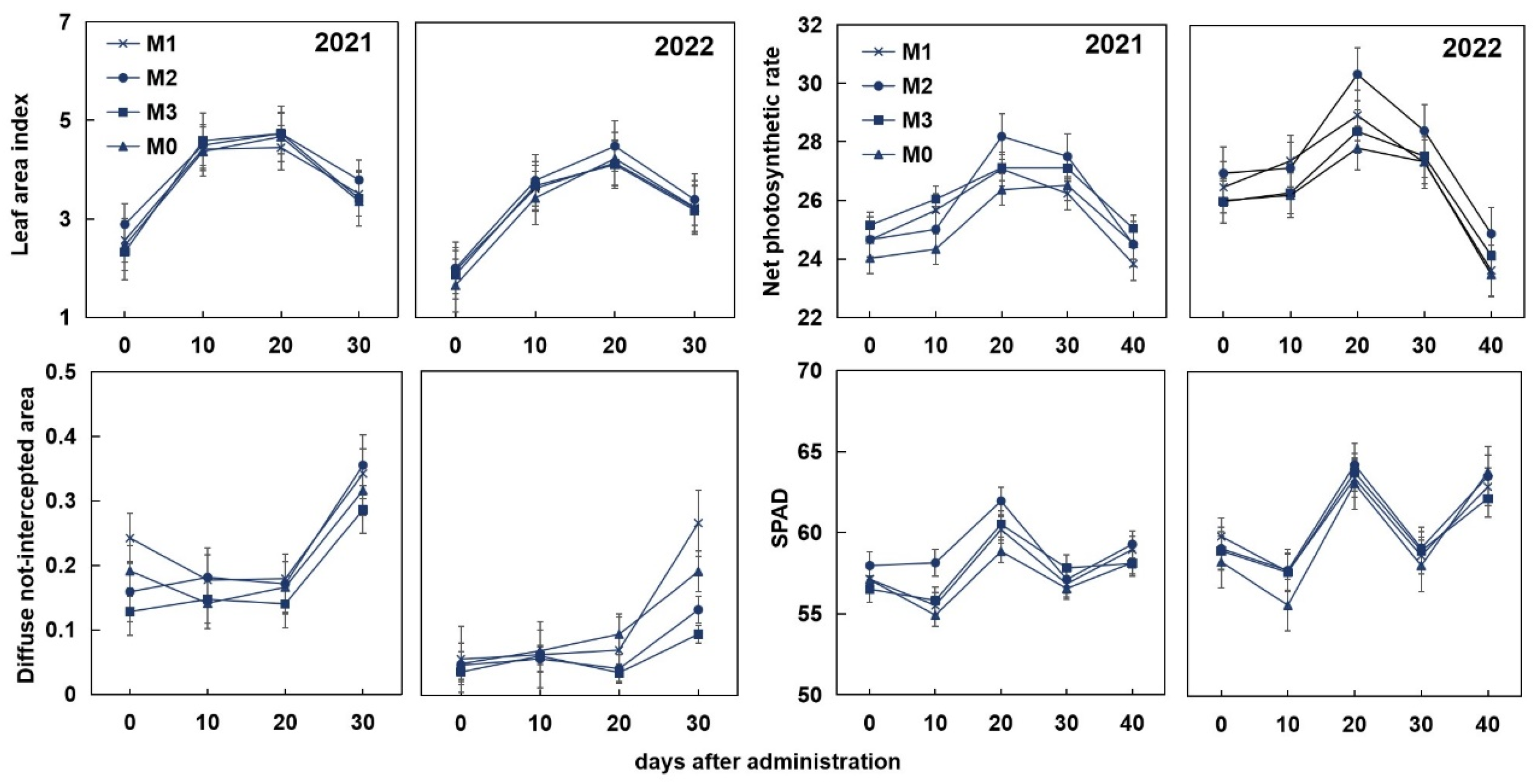

3.2.2. Canopy Structure and Photosynthetic Characteristics

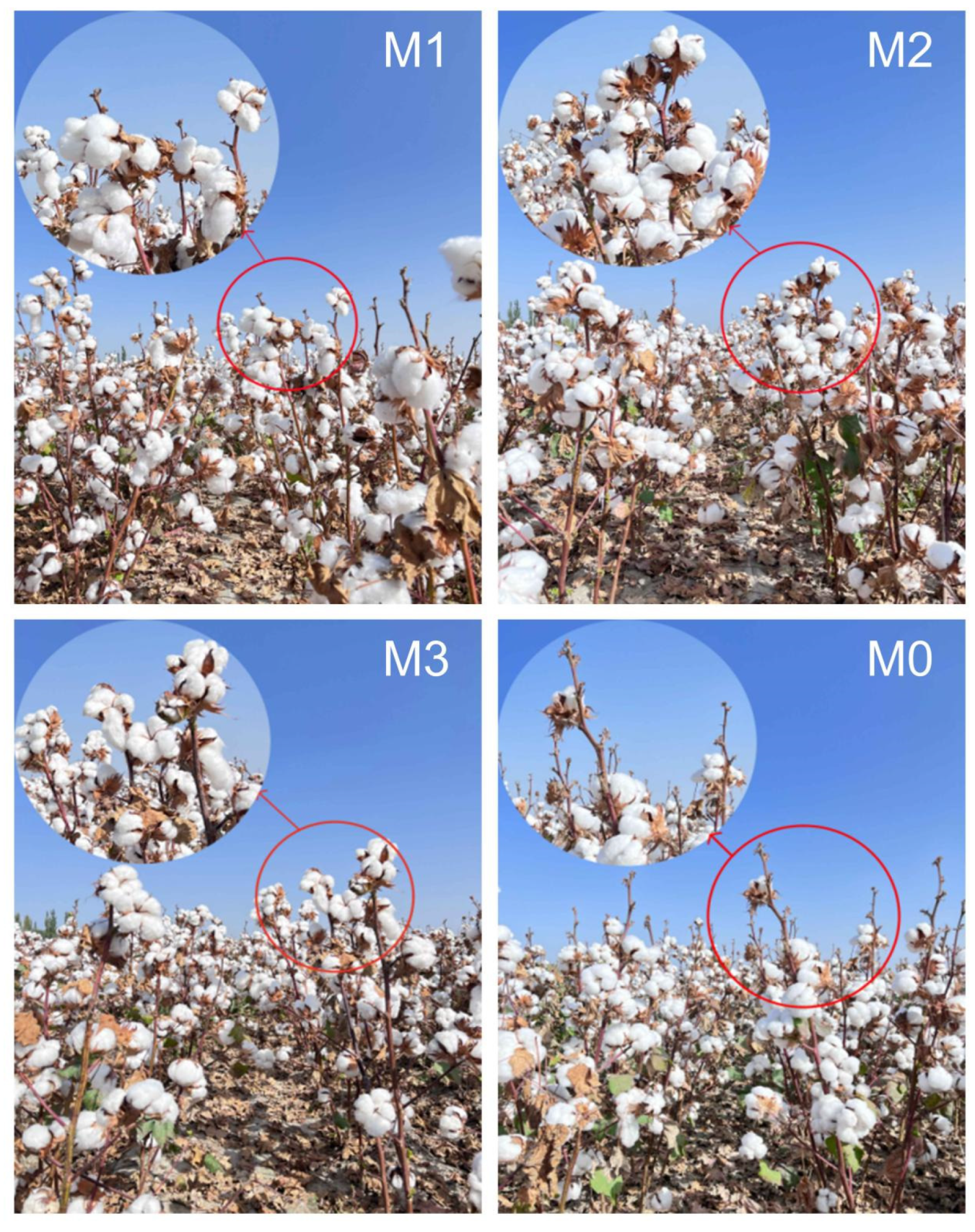

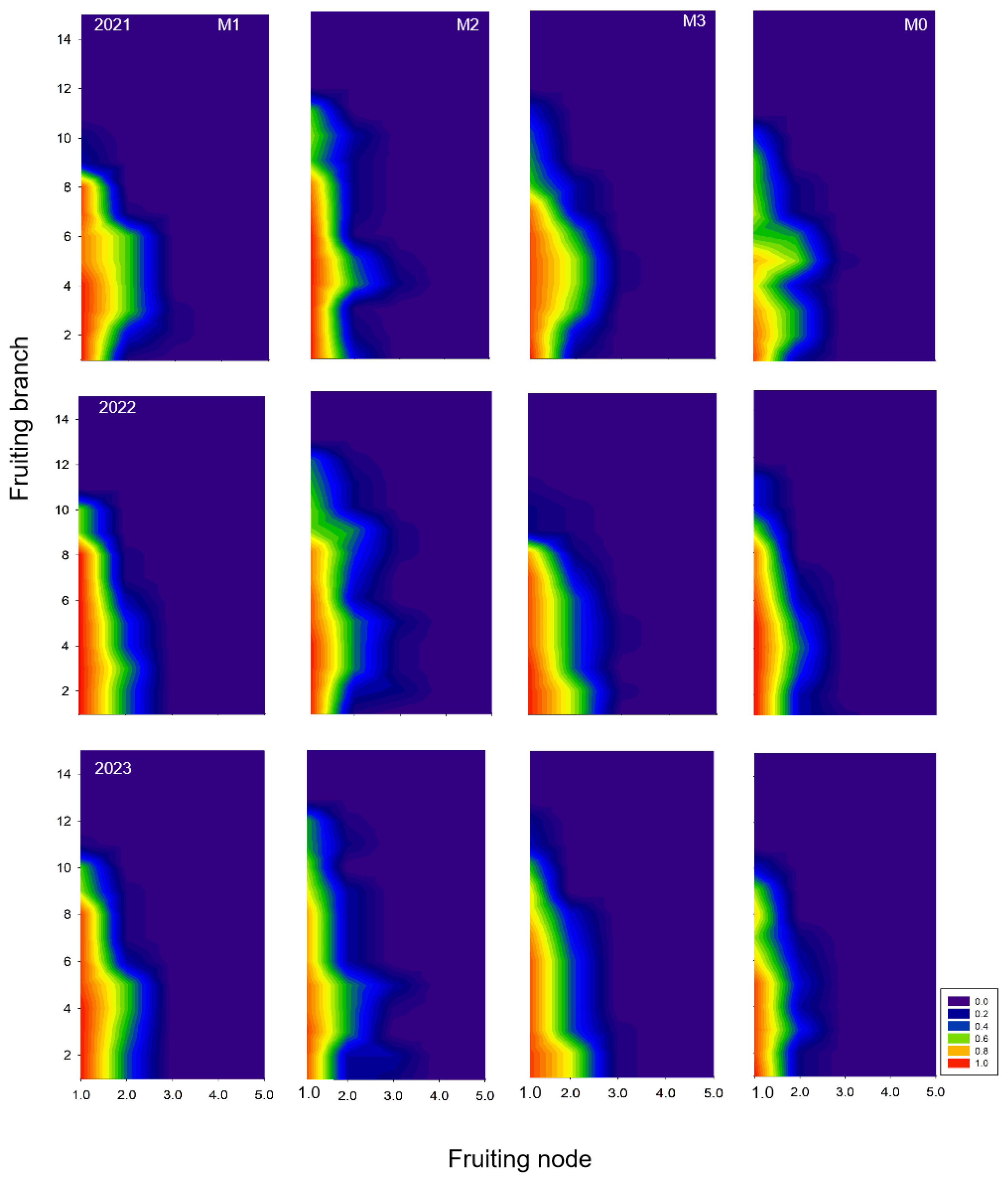

3.2.3. Spatial Distribution of Cotton Bolls

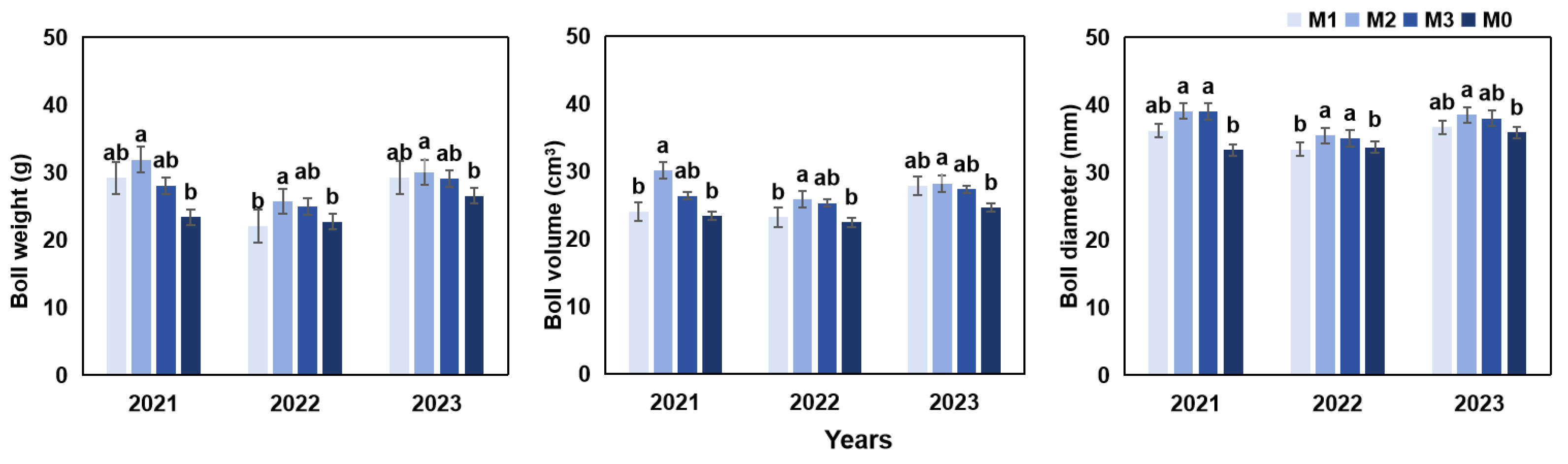

3.2.4. Cotton Boll Morphology

3.3. Correlation Analysis

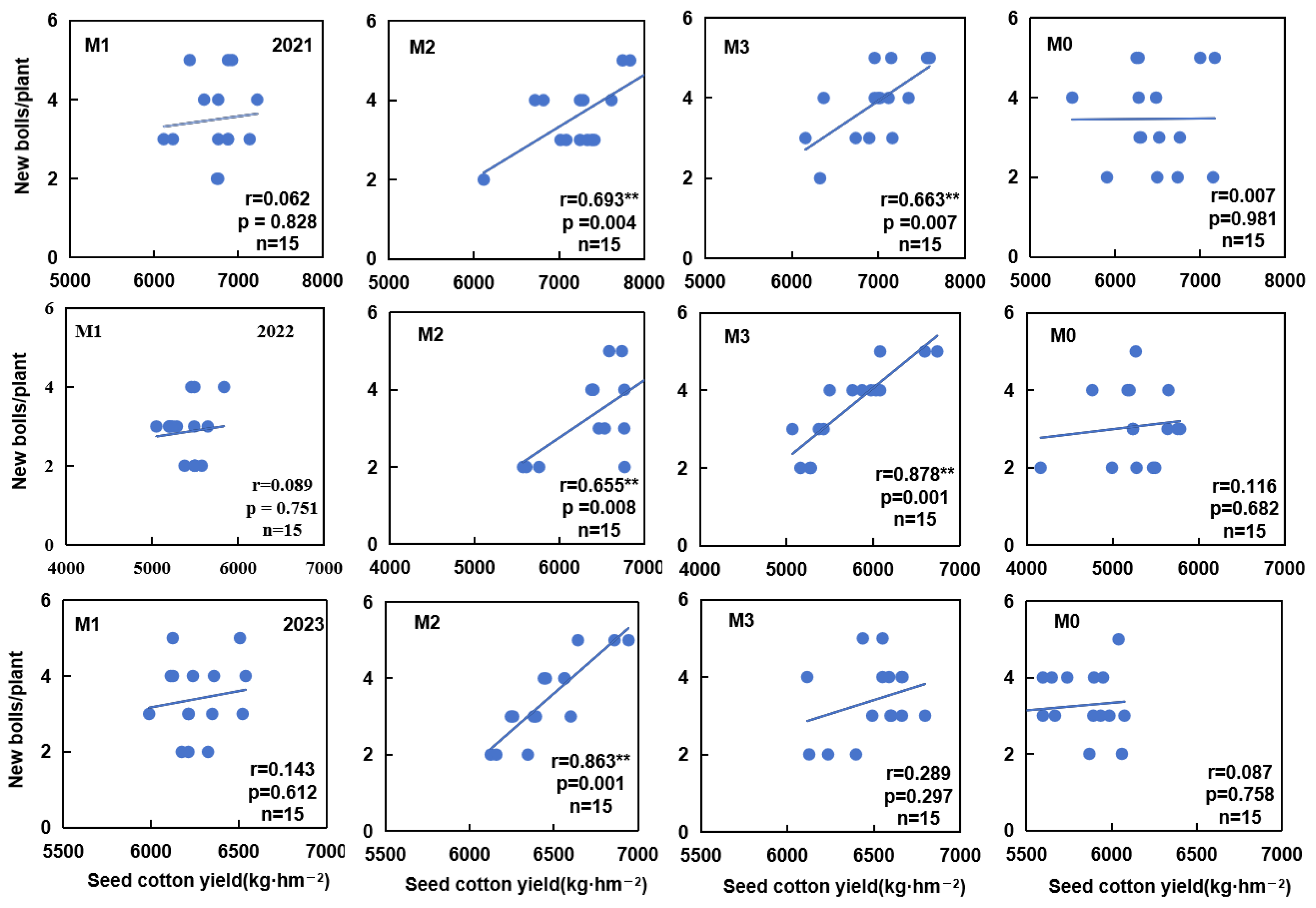

3.3.1. Correlation Between New Bolls and Seed Cotton Yield

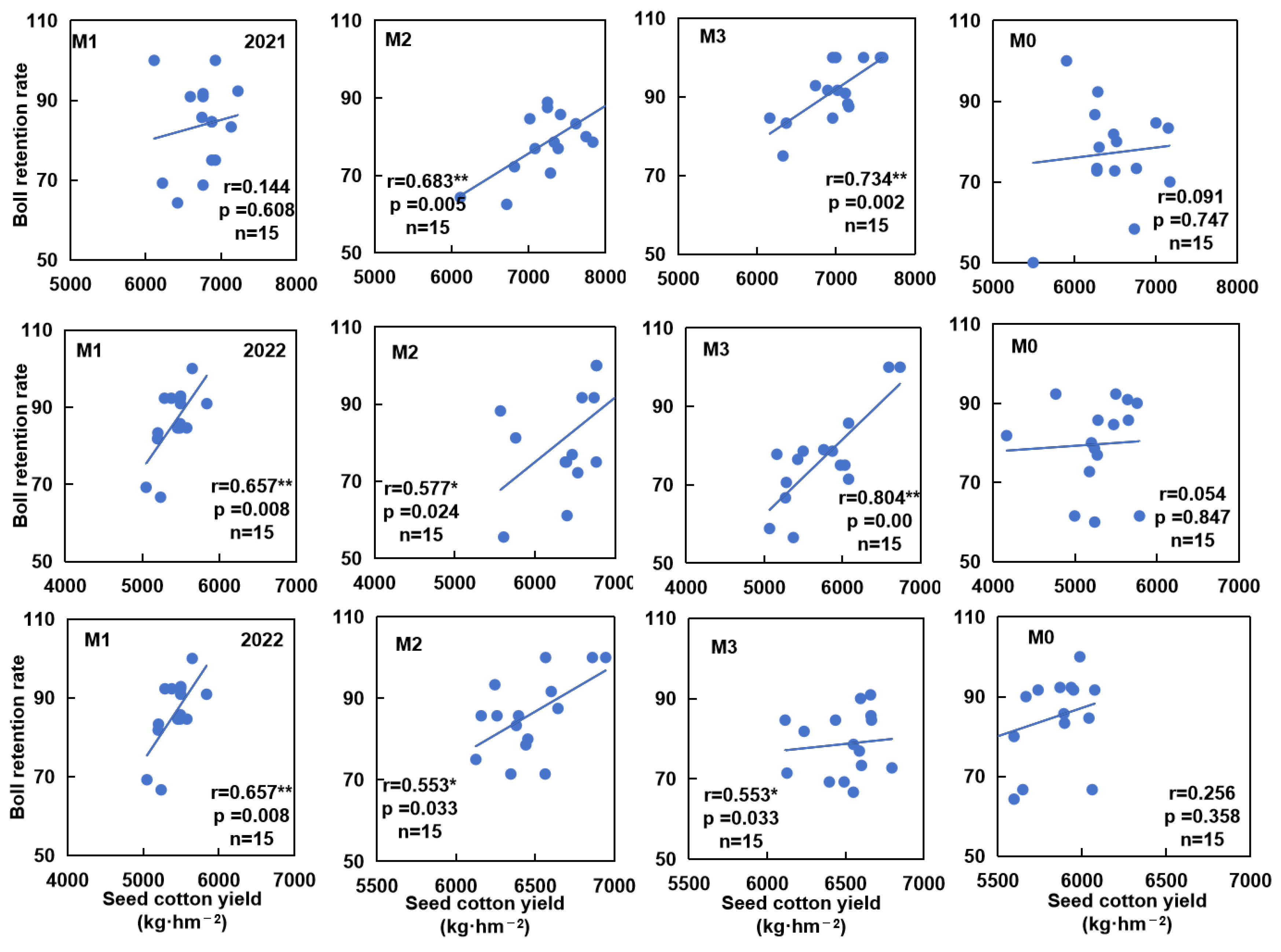

3.3.2. Correlation Between Boll Retention and Seed Cotton Yield

3.3.3. Correlations Among Boll Weight, Volume, Diameter and Seed Cotton Yield

3.4. Cotton Fiber Quality

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ergin, N.; Kulan, E.G.; Harmanci, P.; Kaya, M.D. The ability of biostimulants and copper-containing fungicide to protect cotton against chilling stress. J. Cotton Res. 2024, 7, 21. [Google Scholar] [CrossRef]

- Cook, D.R.; Kennedy, C.W. Early flower bud loss and mepiquat chloride effects on cotton yield distribution. Crop Sci. 2000, 40, 1678–1684. [Google Scholar] [CrossRef]

- Echer, F.R.; Oosterhuis, D.M.; Loka, D.A.; Rosolem, C.A. High night temperatures during the floral bud stage increase the abscission of reproductive structures in cotton. J. Agron. Crop Sci. 2014, 200, 191–198. [Google Scholar] [CrossRef]

- Shu, H.; Sun, S.; Wang, X.; Chen, J.; Yang, C.; Zhang, G.; Liu, R. Thidiazuron combined with cyclanilide modulates hormone pathways and ROS systems in cotton, increasing defoliation at low temperatures. Front. Plant Sci. 2024, 15, 1333816. [Google Scholar] [CrossRef]

- Heitholt, J.J.; Sassenrath-Cole, G.F. Inter-plant competition: Growth responses to plant density and row spacing. Physiol. Cotton 2010, 17, 179–186. [Google Scholar]

- Liao, B.; Li, F.; Yi, F.; Du, M.; Tian, X.; Li, Z. Comparative physiological and transcriptomic mechanisms of defoliation in cotton in response to thidiazuron versus ethephon. Int. J. Mol. Sci. 2023, 24, 7590. [Google Scholar] [CrossRef] [PubMed]

- Song, X.; Zhang, L.; Zhao, W.; Xu, D.; Eneji, A.E.; Zhang, X.; Li, Z. The relationship between boll retention and defoliation of cotton at the fruiting site level. Crop Sci. 2022, 62, 1333–1347. [Google Scholar] [CrossRef]

- Li, Z.K.; Jiang, X.L.; Peng, T.; Shi, C.L.; Han, S.X.; Tian, B.; Zhu, Z.L.; Tian, J.C. Mapping quantitative trait loci with additive effects and additive x additive epistatic interactions for biomass yield, grain yield, and straw yield using a doubled haploid population of wheat (Triticum aestivum L.). Genet. Mol. Res. 2014, 13, 1412–1424. [Google Scholar] [CrossRef] [PubMed]

- Shu, H.; Ni, W.; Guo, S.; Gong, Y.; Shen, X.; Zhang, X.; Guo, Q. Root-applied brassinolide can alleviate the NaCl injuries on cotton. Acta Physiol. Plant. 2015, 37, 75. [Google Scholar] [CrossRef]

- Zhou, H.; Wang, L.; Su, J.; Xu, P.; Liu, D.; Hao, Y.; Fan, H. Combined application of silica nanoparticles and brassinolide promoted the growth of sugar beets under deficit irrigation. Plant Physiol. Biochem. 2024, 216, 109165. [Google Scholar] [CrossRef] [PubMed]

- Siebert, J.D.; Stewart, A.M.; Leonard, B.R. Comparative growth and yield of cotton planted at various densities and configurations. Agron. J. 2006, 98, 562–568. [Google Scholar] [CrossRef]

- Wang, L.; Mu, C.; Du, M.W.; Chen, Y.; Tian, X.L.; Zhang, M.C.; Li, Z.H. The effect of mepiquat chloride on elongation of cotton (Gossypium hirsutum L.) internode is associated with low concentration of gibberellic acid. Plant Sci. 2014, 225, 15–23. [Google Scholar] [CrossRef] [PubMed]

- Huang, C.; Liu, X.; Ma, S.; Qin, A.; Zhang, Y.; Liu, Z. Enhancement of Waterlogging Tolerance and Improvement of Grain Quality in Waxy Maize With Exogenous EDAH: A Mixture of Ethephon and Diethyl Aminoethyl Hexanoate. J. Agron. Crop Sci. 2024, 210, 12729. [Google Scholar] [CrossRef]

- Ren, J.; Tang, Q.; Niu, S.; Liu, S.; Wei, D.; Zhang, Y.; Gao, Z. High dose of plant growth regulator enhanced lodging resistance without grain yield reduction of maize under high density. Int. J. Plant Prod. 2022, 16, 329–339. [Google Scholar] [CrossRef]

- Chen, Y.; Li, Y.B.; Chen, Y.; Ming, Y.; Hu, D.P.; Li, Y.; Zhang, X.; Chen, D.H. Planting density and leaf—Square regulation affected square size and number contributing to altered insecticidal protein content in Bt cotton. J. Crop Res. 2017, 205, 14–22. [Google Scholar] [CrossRef]

- Liu, J.; Guo, W.; Wang, X.; Li, Y.; Lu, F. Influence of high temperature on Bt protein expression in transgenic Bt cotton. Field Crops Res. 2011, 124, 236–241. [Google Scholar]

- Wang, Y.; Shao, Y.; Zhao, X.; Pei, Q.; Nan, N.; Zhang, F.; Li, X. High-efficiency fungicide screening and field control efficacy of maize southern corn rust. Crop Prot. 2025, 187, 106997. [Google Scholar] [CrossRef]

- Liu, J.; Meng, Y.; Lv, F.; Chen, J.; Ma, Y.; Wang, Y.; Chen, B.; Zhang, L.; Zhou, Z. Photosynthetic characteristics of the subtending leaf of cotton boll at different fruiting branch nodes and their relationships with lint yield and fiber quality. Front. Plant Sci. 2015, 6, 747. [Google Scholar] [CrossRef]

- Zhang, Q.; Luo, D.; Sun, Y.; Li, P.; Xiang, D.; Zhang, Y.; Yang, M.; Gou, L.; Tian, J.; Zhang, W. Cotton harvest aids promote the translocation of bur-stored photoassimilates to enhance single boll weight. Ind. Crops Prod. 2023, 195, 116375. [Google Scholar] [CrossRef]

- Wang, P.; Chen, X.P.; Tian, C.Y.; Zhang, F.S. Effect of Different Irrigation and Fertilization Strategies on Yield, Fiber Quality and Nitrogen Balance of High-Yield Cotton System. Sci. Agric. Sin. 2005, 38, 761–769. [Google Scholar]

- Peloso, A.F.; Tatagiba, S.D.; Amaral, F.J.; Cavatte, P.C.; Pezzopane, J.E. Pyraclostrobin Preserves Photosynthesis In Arabica Coffee Plants Subjected To Water Deficit. Rev. Eng. Agric.-REVENG 2020, 28, 109–119. [Google Scholar] [CrossRef]

- Zhao, D.; Oosterhuis, D.M. Cotton responses to shade at different growth stages: Growth, lint yield and fibre quality. Exp. Agric. 2000, 36, 27–39. [Google Scholar] [CrossRef]

- Zhai, M.; Wei, X.; Pan, Z.; Xu, Q.; Qin, D.; Li, J.; Zhang, J.; Wang, L.; Wang, K.; Duan, X.; et al. Optimizing plant density and canopy structure to improve light use efficiency and cotton productivity: Two years of field evidence from two locations. Ind. Crops Prod. 2024, 222, 119946. [Google Scholar] [CrossRef]

| Years | Treatments | No. of Bolls (m2) | Boll Weight (g) | Seed Cotton Yield (kg/ha) | Lint Percentage (%) |

|---|---|---|---|---|---|

| 2021 | M1 | 127.32 ab | 5.30 b | 6745.89 b | 49.44 a |

| M2 | 141.33 a | 5.83 a | 8239.19 a | 44.96 bc | |

| M3 | 121.45 b | 5.73 a | 6959.08 b | 46.62 b | |

| M0 | 116.52 b | 5.37 b | 6242.42 b | 44.51 c | |

| Average | 126.65 A | 5.55 C | 7046.64 A | 46.38 C | |

| 2022 | M1 | 94.73 b | 5.78 ab | 5477.15 b | 50.98 ab |

| M2 | 107.63 a | 5.97 a | 6436.84 a | 46.56 b | |

| M3 | 99.67 ab | 5.79 ab | 5774.62 ab | 48.58 ab | |

| M0 | 90.88 b | 5.71 b | 5184.48 b | 52.57 a | |

| Average | 98.22 C | 5.81 B | 5718.27 C | 49.67 B | |

| 2023 | M1 | 103.04 ab | 6.16 ba | 6349.81 ab | 55.47 ab |

| M2 | 104.87 a | 6.34 a | 6656.46 a | 57.79 ab | |

| M3 | 108.32 a | 6.09 c | 6601.40 a | 54.51 b | |

| M0 | 95.91 b | 6.23 b | 5979.11 b | 59.63 a | |

| Average | 103.03 B | 6.20 A | 6396.69 B | 56.85 A | |

| Source of variance | p | ||||

| Years (Y) | <0.0001 | <0.0001 | <0.0001 | <0.0001 | |

| Treatments (T) | <0.0001 | <0.0001 | <0.0001 | 0.0301 | |

| Y × T | 0.0333 | 0.0090 | 0.0333 | 0.0041 | |

| Years | Treatments | Boll Volume (cm3) | Boll Diameter (mm) | Boll Weight (g) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| n | r | p | n | r | p | n | r | p | ||

| 2021 | M1 | 15 | 0.487 | 0.066 | 15 | 0.301 | 0.276 | 15 | 0.407 | 0.132 |

| M2 | 15 | 0.574 * | 0.025 | 15 | 0.594 * | 0.020 | 15 | 0.515 * | 0.050 | |

| M3 | 15 | 0.099 | 0.725 | 15 | 0.231 | 0.407 | 15 | 0.432 | 0.108 | |

| M0 | 15 | 0.154 | 0.583 | 15 | 0.428 | 0.112 | 15 | 0.402 | 0.137 | |

| 2022 | M1 | 15 | 0.520 * | 0.047 | 15 | 0.297 | 0.282 | 15 | 0.273 | 0.325 |

| M2 | 15 | 0.469 | 0.078 | 15 | 0.506 | 0.054 | 15 | 0.592 * | 0.020 | |

| M3 | 15 | 0.287 | 0.299 | 15 | 0.211 | 0.451 | 15 | 0.580 * | 0.023 | |

| M0 | 15 | −0.031 | 0.914 | 15 | 0.198 | 0.479 | 15 | 0.157 | 0.577 | |

| 2023 | M1 | 15 | 0.364 | 0.182 | 15 | −0.070 | 0.805 | 15 | 0.280 | 0.312 |

| M2 | 15 | 0.642 ** | 0.010 | 15 | 0.768 ** | 0.001 | 15 | 0.733 ** | 0.002 | |

| M3 | 15 | 0.740 ** | 0.002 | 15 | 0.508 | 0.053 | 15 | 0.633 * | 0.011 | |

| M0 | 15 | 0.230 | 0.409 | 15 | 0.043 | 0.880 | 15 | 0.052 | 0.854 | |

| Years | Parts | Treatments | Upper Half Mean Length (mm) | Uniformity Index (%) | Fiber Strength (cN tex−1) | Micronaire |

|---|---|---|---|---|---|---|

| 2022 | Upper | M1 | 29.70 ab | 85.30 a | 29.03 a | 4.76 a |

| M2 | 30.50 a | 85.43 a | 29.30 a | 4.33 a | ||

| M3 | 30.53 a | 84.80 a | 28.73 a | 4.63 a | ||

| M0 | 29.50 b | 85.03 a | 29.73 a | 4.96 a | ||

| Middle | M1 | 30.76 a | 85.23 ab | 29.46 a | 4.86 a | |

| M2 | 30.76 a | 86.10 a | 28.33 b | 4.23 a | ||

| M3 | 30.50 a | 85.73 ab | 28.53 ab | 5.00 a | ||

| M0 | 29.70 b | 84.16 b | 28.56 ab | 5.13 a | ||

| Lower | M1 | 30.40 a | 83.23 b | 29.20 a | 4.86 a | |

| M2 | 30.26 ab | 84.33 a | 29.40 a | 4.80 a | ||

| M3 | 30.10 ab | 84.60 a | 28.93 a | 4.83 a | ||

| M0 | 29.65 b | 83.15 b | 28.60 a | 5.23 a | ||

| 2023 | Upper | M1 | 31.00 ab | 88.60 a | 32.33 a | 4.40 ab |

| M2 | 31.70 a | 89.43 a | 32.86 a | 4.20 a | ||

| M3 | 31.23 ab | 88.33 a | 33.03 a | 4.30 ab | ||

| M0 | 30.16 b | 87.63 a | 31.33 a | 4.53 a | ||

| Middle | M1 | 30.76 a | 87.63 a | 33.63 a | 4.36 a | |

| M2 | 30.83 a | 88.50 a | 35.00 a | 4.20 a | ||

| M3 | 30.40 a | 88.36 a | 33.26 a | 4.26 a | ||

| M0 | 30.30 a | 87.70 a | 33.03 a | 4.66 a | ||

| Lower | M1 | 31.56 a | 89.26 a | 32.80 a | 4.16 a | |

| M2 | 32.20 a | 89.60 a | 35.23 a | 4.10 a | ||

| M3 | 31.33 ab | 89.26 a | 34.30 a | 4.33 a | ||

| M0 | 30.40 b | 88.93 a | 32.00 a | 4.53 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abuduaini, M.; Cheng, H.; Song, X.; Wu, G.; Li, X.; Tian, Y.; Zhang, J.; Wang, W.; Yang, S.; Meng, Z.; et al. Effect of Fungicide Application in Combination with Different Growth Regulators on Cotton Boll Quality and Yield in the Northwest Inland of China. Agronomy 2025, 15, 394. https://doi.org/10.3390/agronomy15020394

Abuduaini M, Cheng H, Song X, Wu G, Li X, Tian Y, Zhang J, Wang W, Yang S, Meng Z, et al. Effect of Fungicide Application in Combination with Different Growth Regulators on Cotton Boll Quality and Yield in the Northwest Inland of China. Agronomy. 2025; 15(2):394. https://doi.org/10.3390/agronomy15020394

Chicago/Turabian StyleAbuduaini, Munire, Hao Cheng, Xinghu Song, Gang Wu, Xinxin Li, Yangqing Tian, Jiahao Zhang, Wenqing Wang, Siqi Yang, Ziyi Meng, and et al. 2025. "Effect of Fungicide Application in Combination with Different Growth Regulators on Cotton Boll Quality and Yield in the Northwest Inland of China" Agronomy 15, no. 2: 394. https://doi.org/10.3390/agronomy15020394

APA StyleAbuduaini, M., Cheng, H., Song, X., Wu, G., Li, X., Tian, Y., Zhang, J., Wang, W., Yang, S., Meng, Z., Zhao, F., Wu, H., & Zhao, Q. (2025). Effect of Fungicide Application in Combination with Different Growth Regulators on Cotton Boll Quality and Yield in the Northwest Inland of China. Agronomy, 15(2), 394. https://doi.org/10.3390/agronomy15020394