End-Effectors for Fruit and Vegetable Harvesting Robots: A Review of Key Technologies, Challenges, and Future Prospects

Abstract

1. Introduction

- Review Principles

- 2.

- Search Strings

- 3.

- Methodology

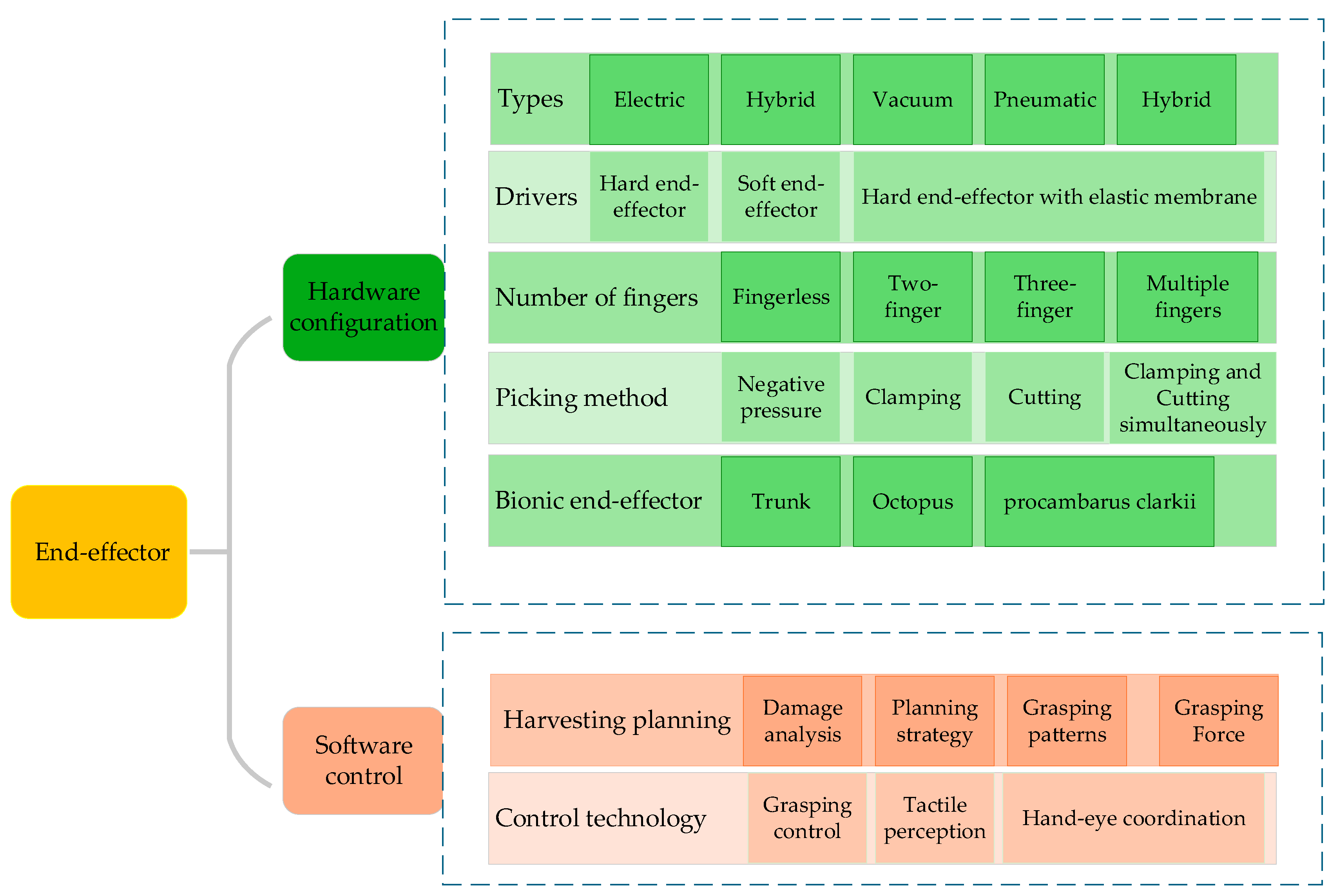

2. Key Technologies of End-Effectors

2.1. End-Effector Configuration Design

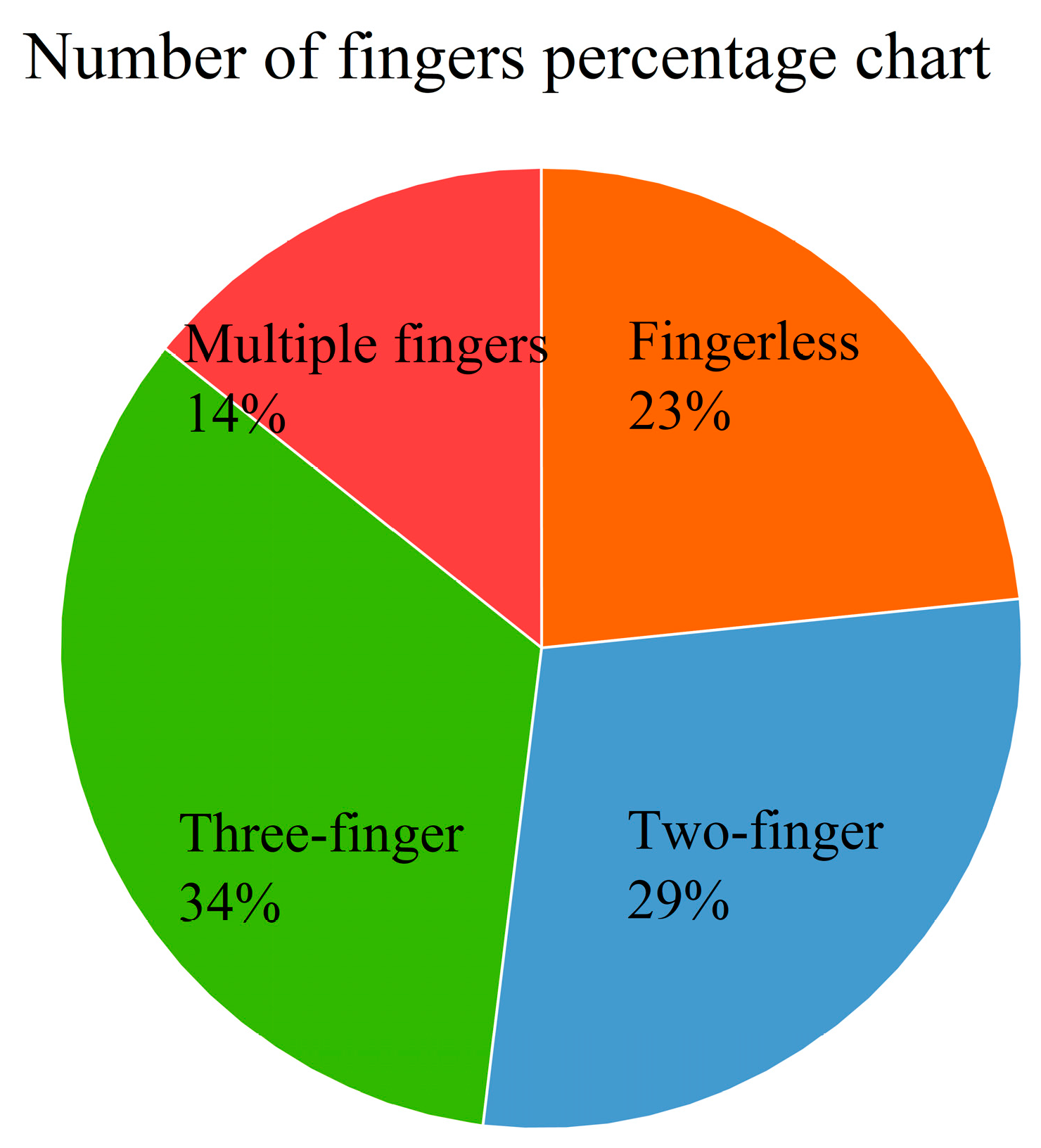

2.1.1. The Number of Fingers on an End-Effector

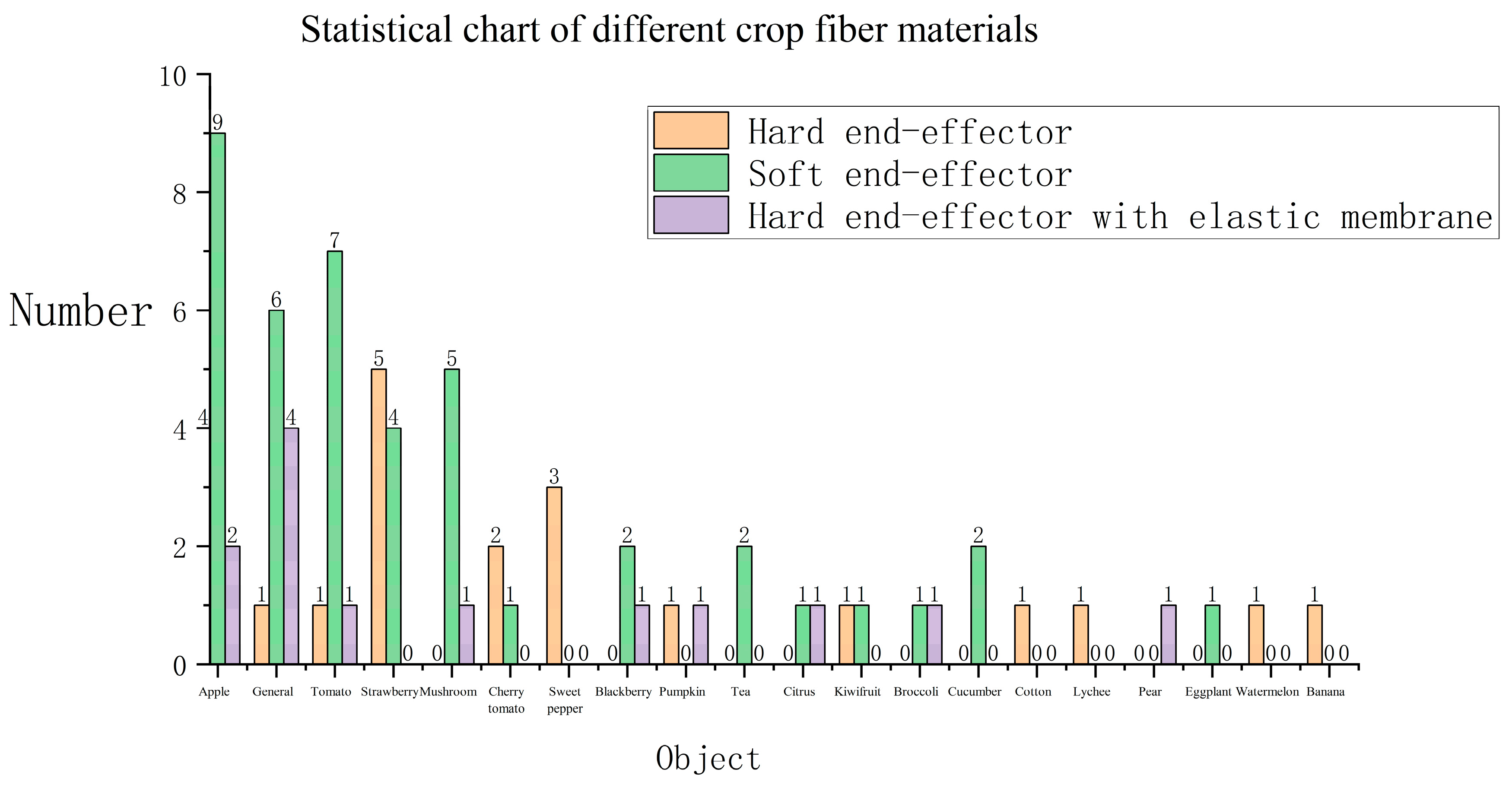

2.1.2. End-Effector Finger Materials

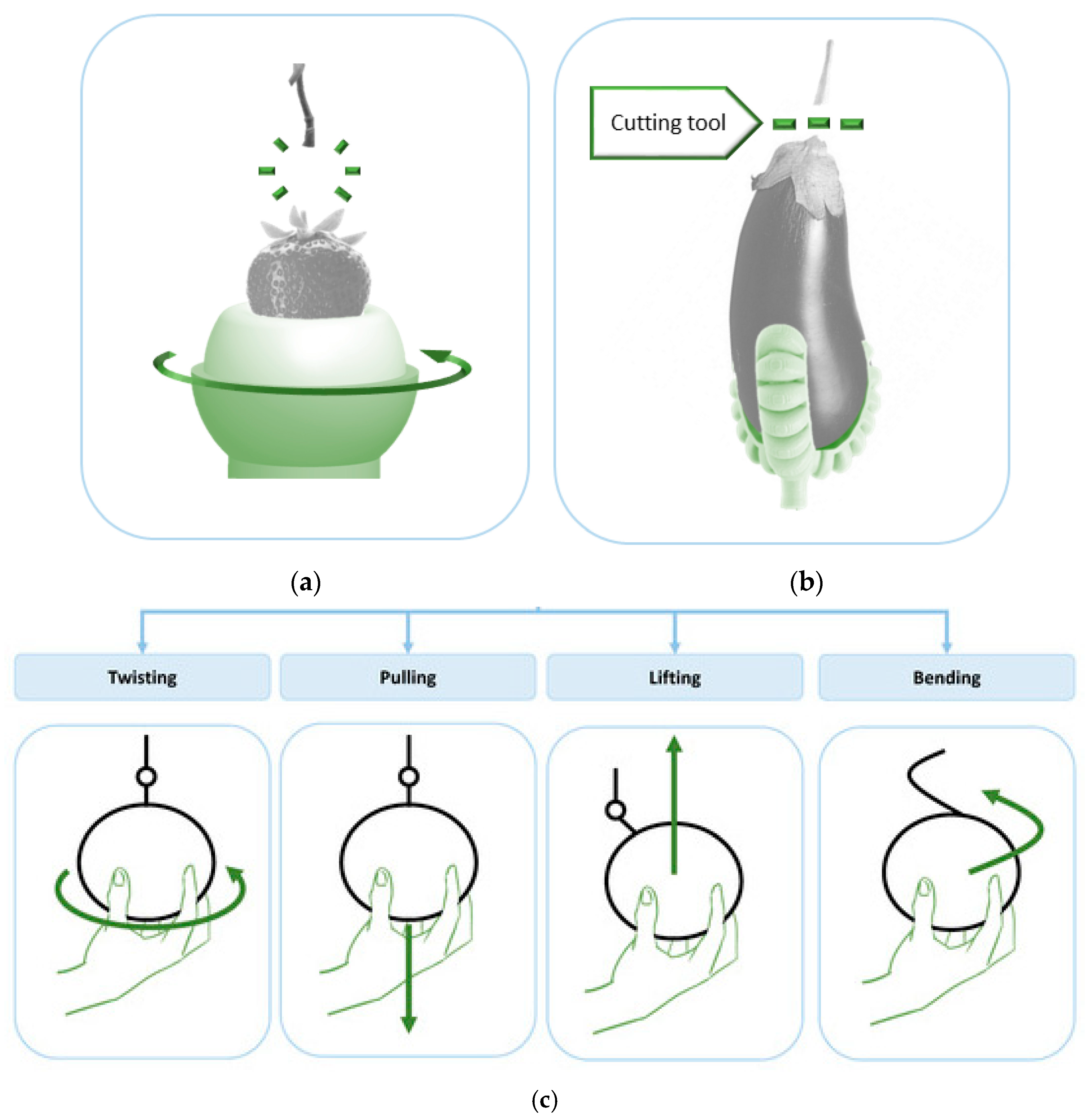

2.1.3. Picking Methods of End-Effectors

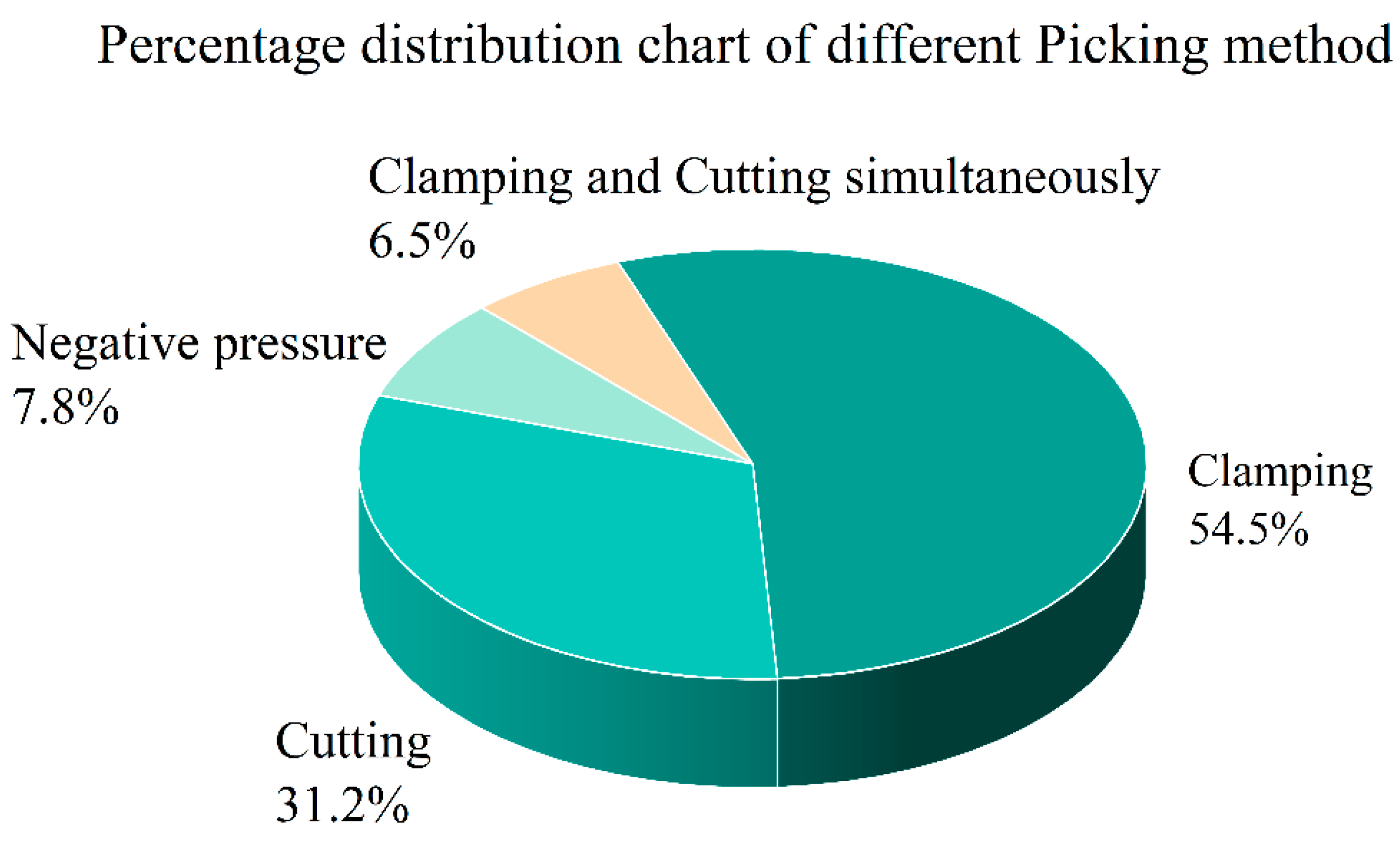

2.1.4. Driver Mechanism of the End-Effector

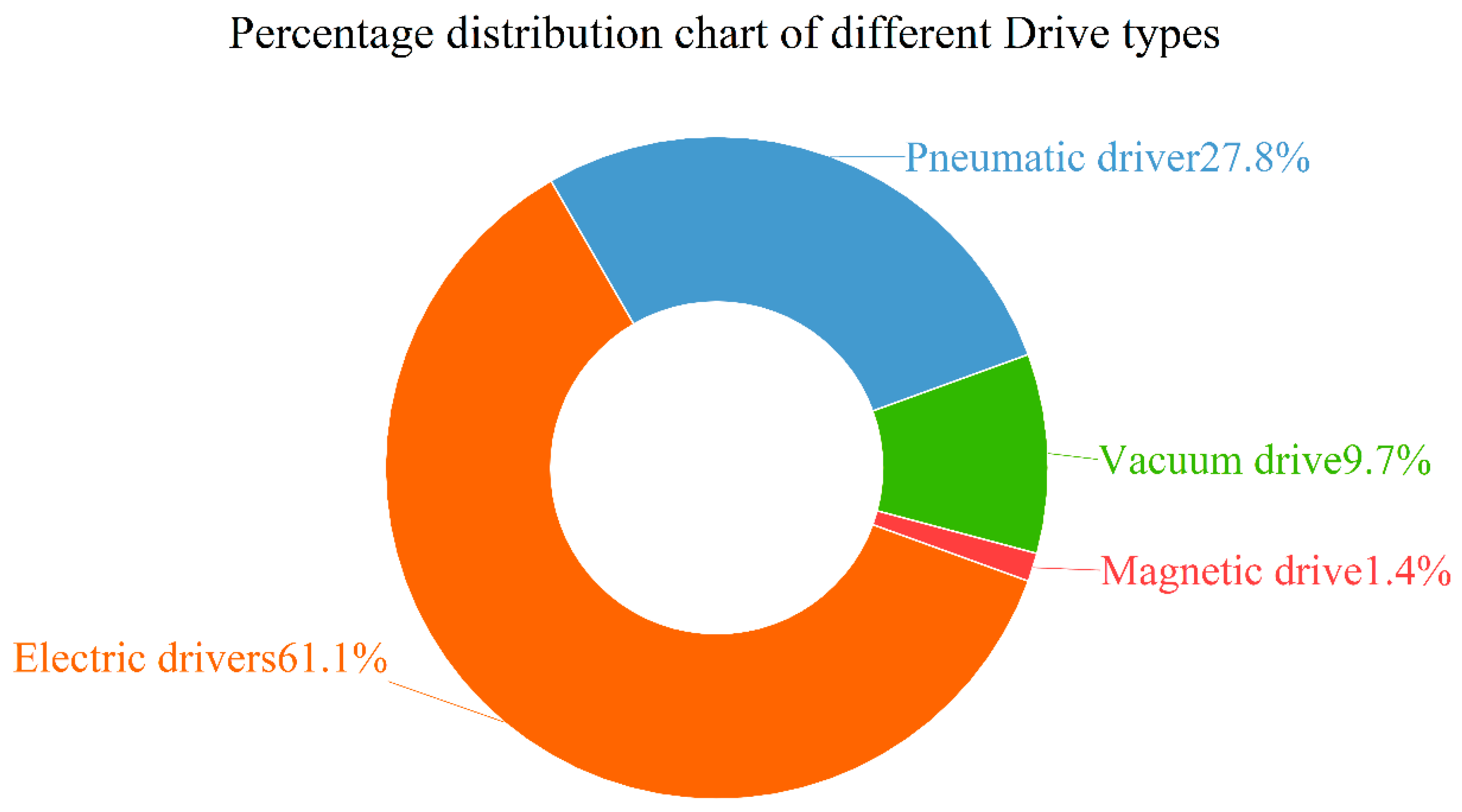

2.1.5. Bionic End-Effector

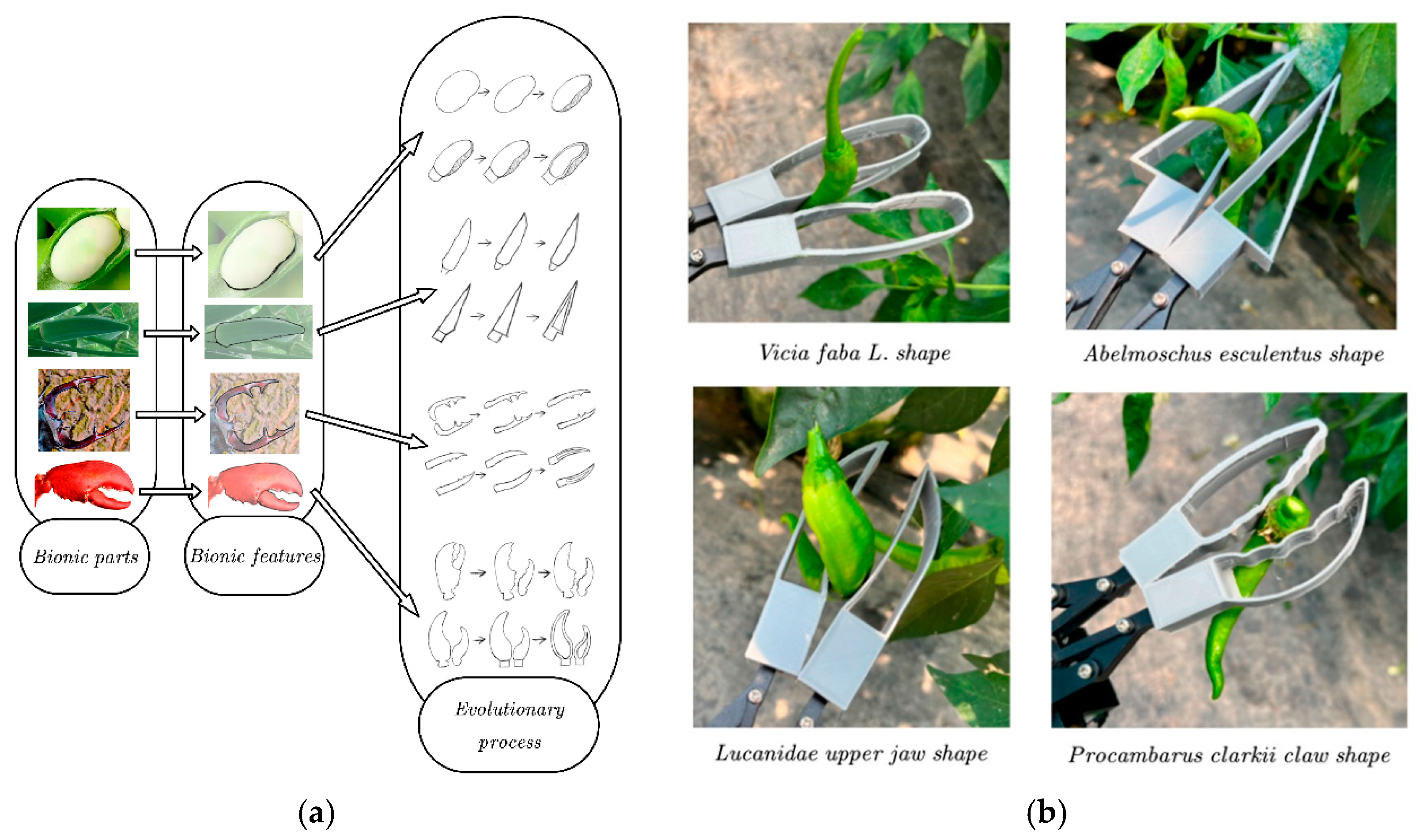

2.2. End-Effector Harvesting Planning Technology

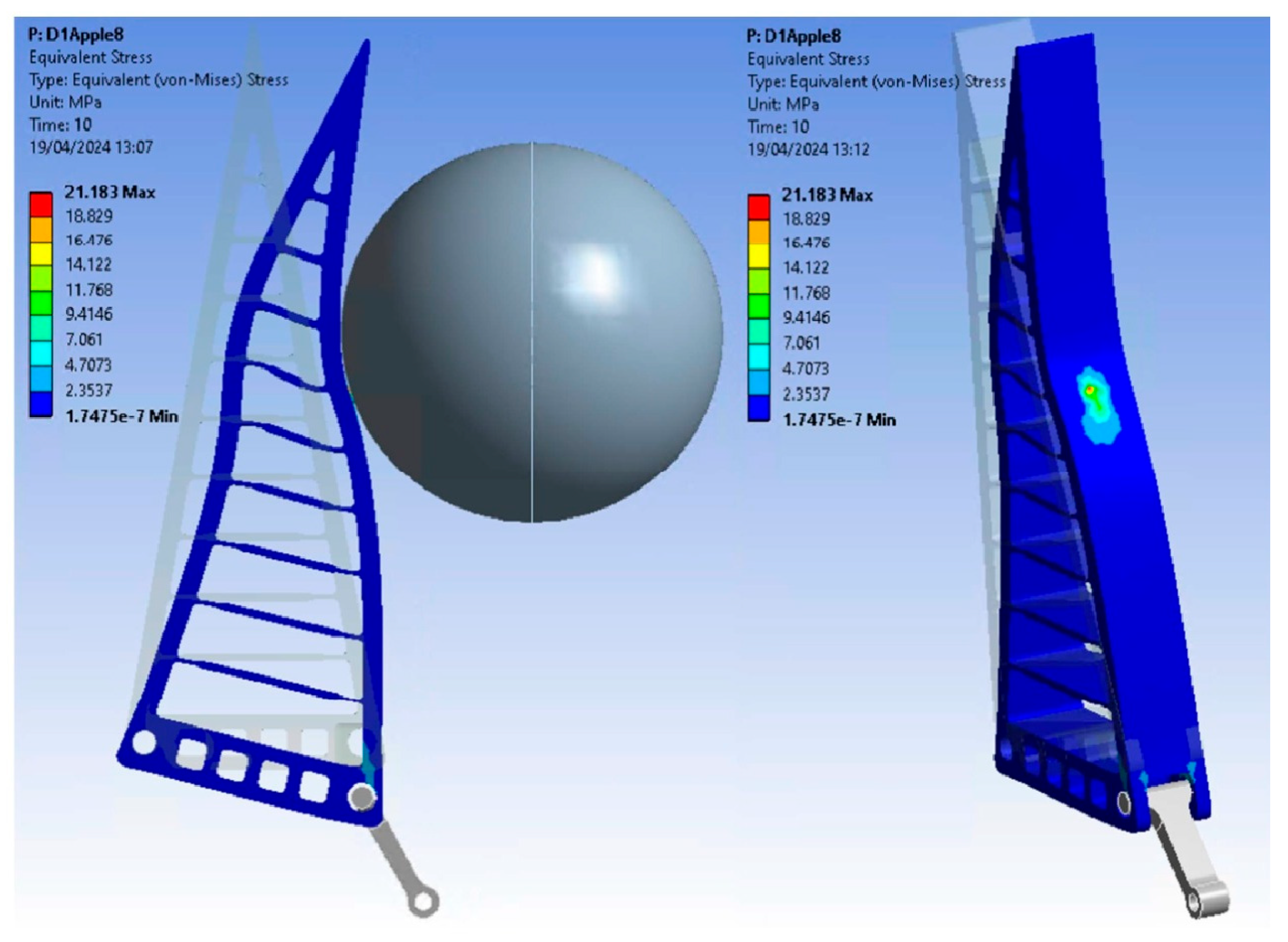

2.2.1. Analysis of Mechanical Damage in Fruit and Vegetable Grasping by End-Effectors

2.2.2. End-Effector Harvesting Obstacle-Avoidance Path Planning Strategy

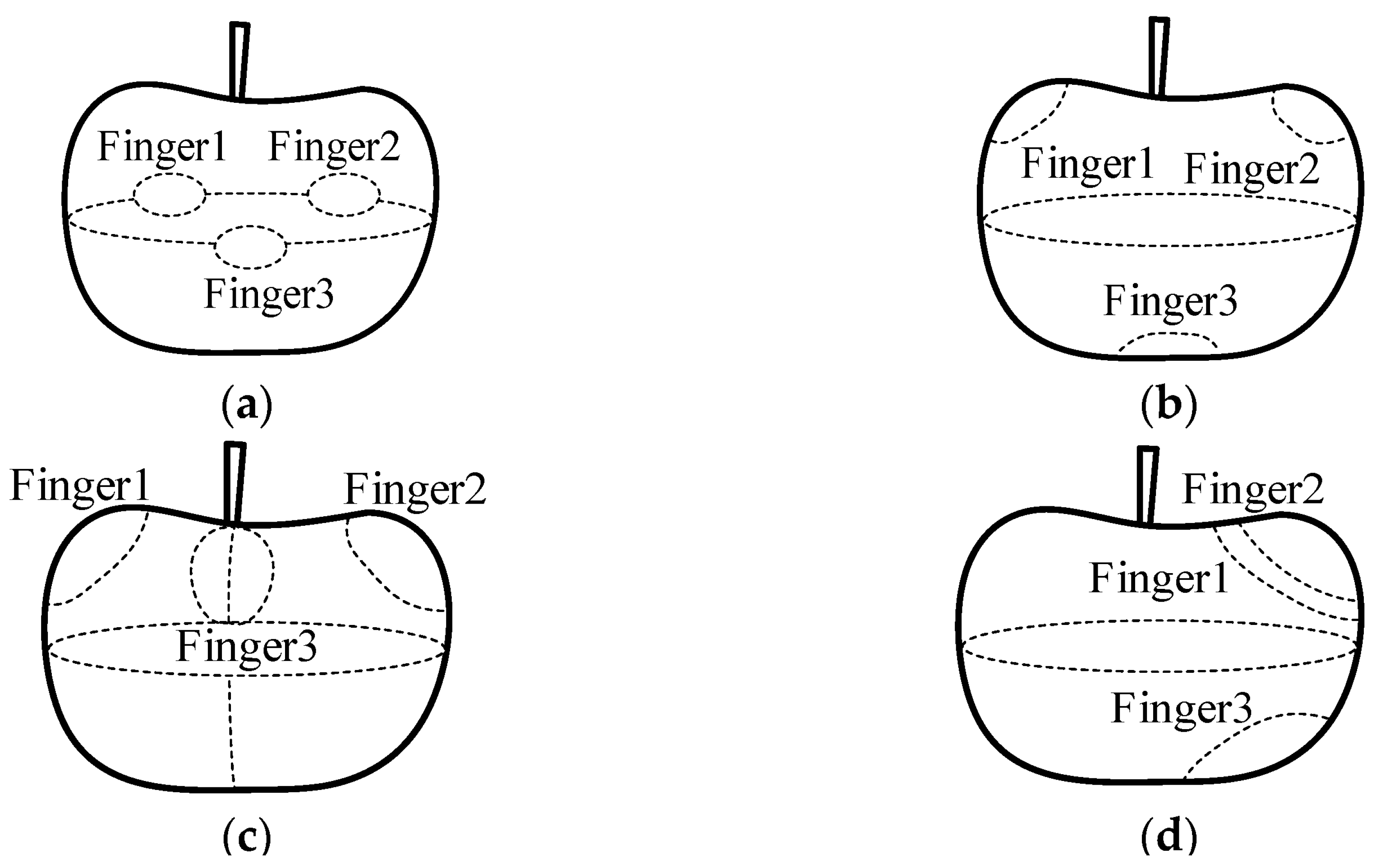

2.2.3. End-Effector Grasping Patterns Design

2.2.4. Modeling and Analysis of Grasping Force in End-Effector

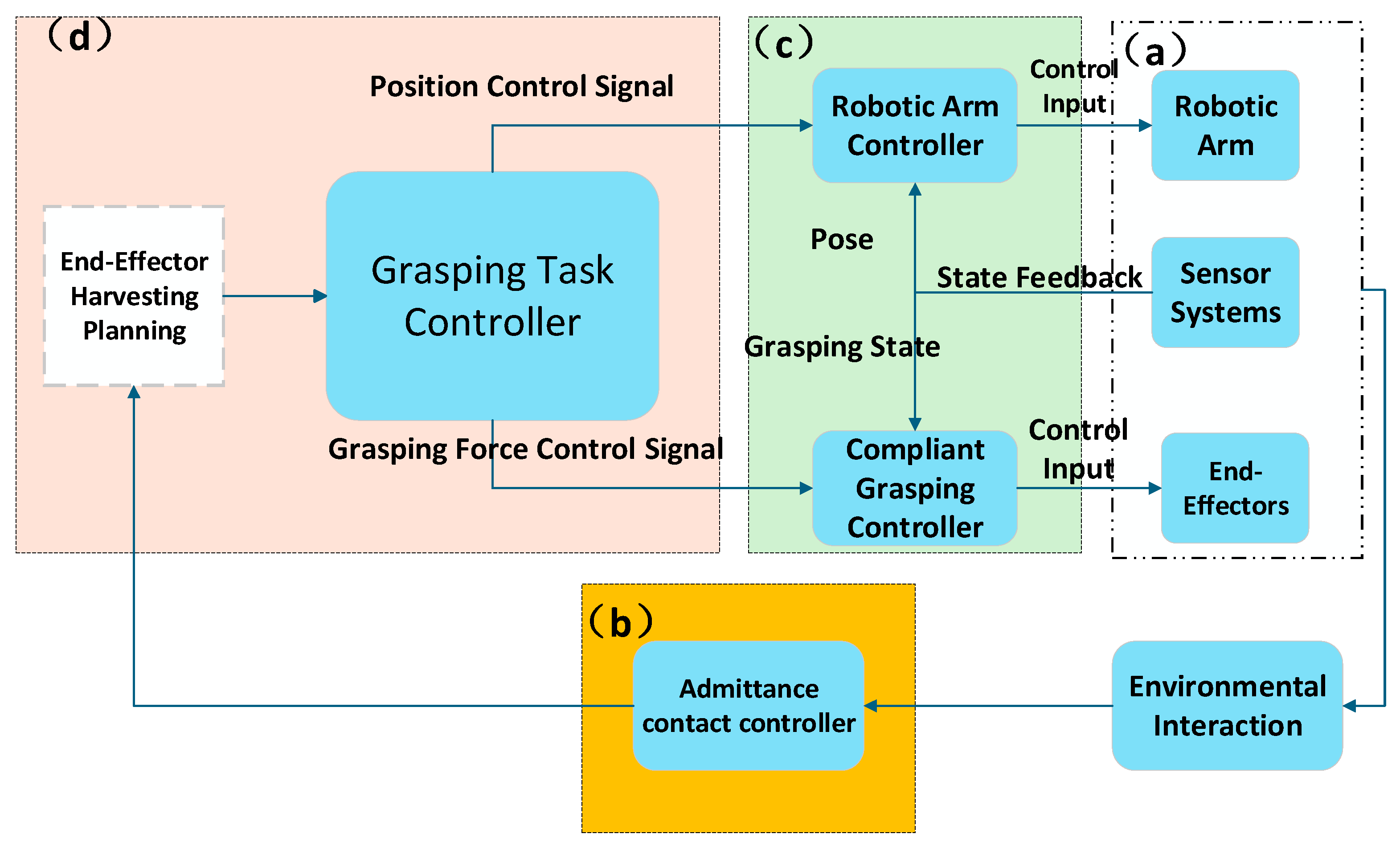

2.3. End-Effector Harvesting Control Technology

2.3.1. End-Effector Grasping Control

2.3.2. Tactile Perception for End-Effectors

2.3.3. Hand–Eye Coordination for End-Effectors

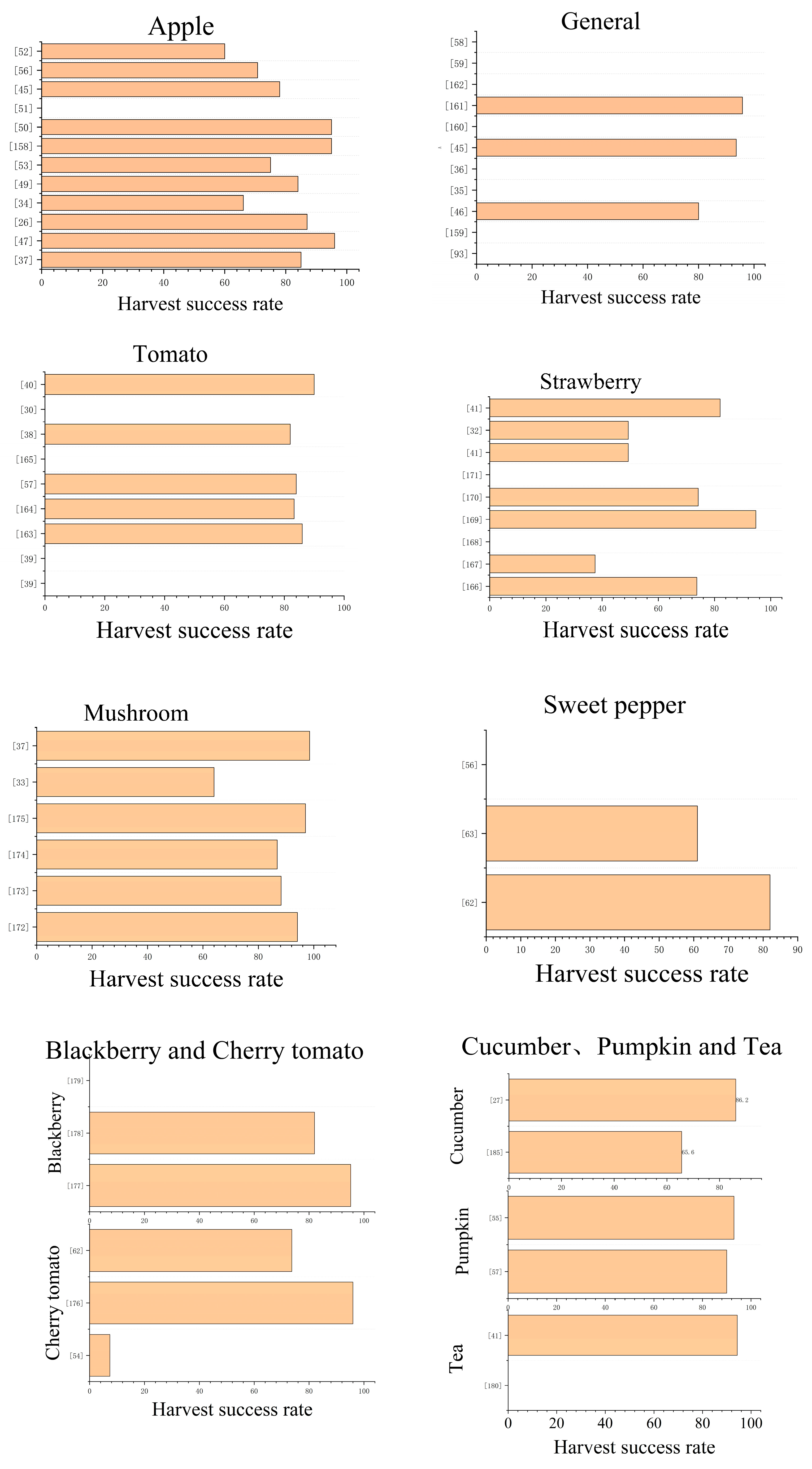

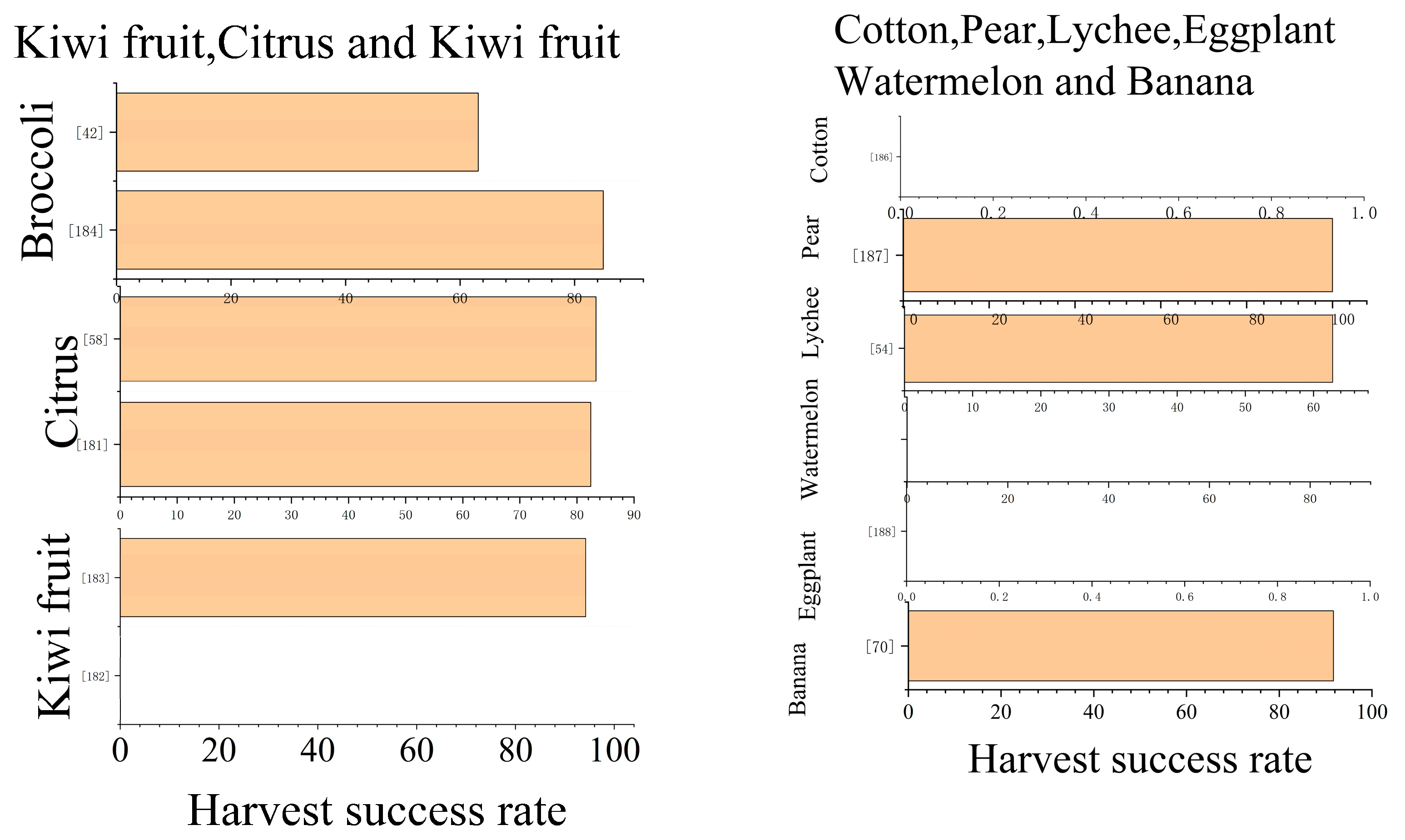

2.4. Unified Comparative Framework for End-Effectors

2.5. End-Effector Performance Evaluation Criteria

3. Challenges and Future Prospects

3.1. Challenges in End-Effector Design and Implementation

- Low Harvest Success Rate

- 2.

- Poor Control, Precision and Flexibility

- 3.

- Limited Versatility and Adaptability

- 4.

- High Manufacturing Cost

3.2. Emerging Technologies Offering Viable Solutions for End-Effector Challenges

- Enhancing End-Effector Harvesting Success Rate through Bionics and Hand–Eye Coordination Technology

- 2.

- Application of Multi-modal Sensor Fusion and Digital Twin Technology to Improve Control Accuracy and Flexibility of End-Effectors

- 3.

- Expanded Versatility and Adaptability via UAV-Integrated Systems

- 4.

- Utilizing the development of simulation platforms and metamorphic mechanism technologies to reduce the manufacturing cost of end-effectors.

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| FAO | Food and Agriculture Organization |

| BDA | Big Data Analytics |

| AI | Artificial Intelligence |

| EE | End-Effector |

| CU | Controlling Unit |

| MCM | Monte Carlo Method |

| FEA | Finite Element Analysis |

| APSO | Adaptive Weight Particle Swarm Optimization |

| MPC | Model Predictive Control |

| PID | Proportional-Integral-Derivative |

| UAVs | Unmanned aerial vehicles |

| SOFA | Simulation Open Framework Architecture |

Appendix A

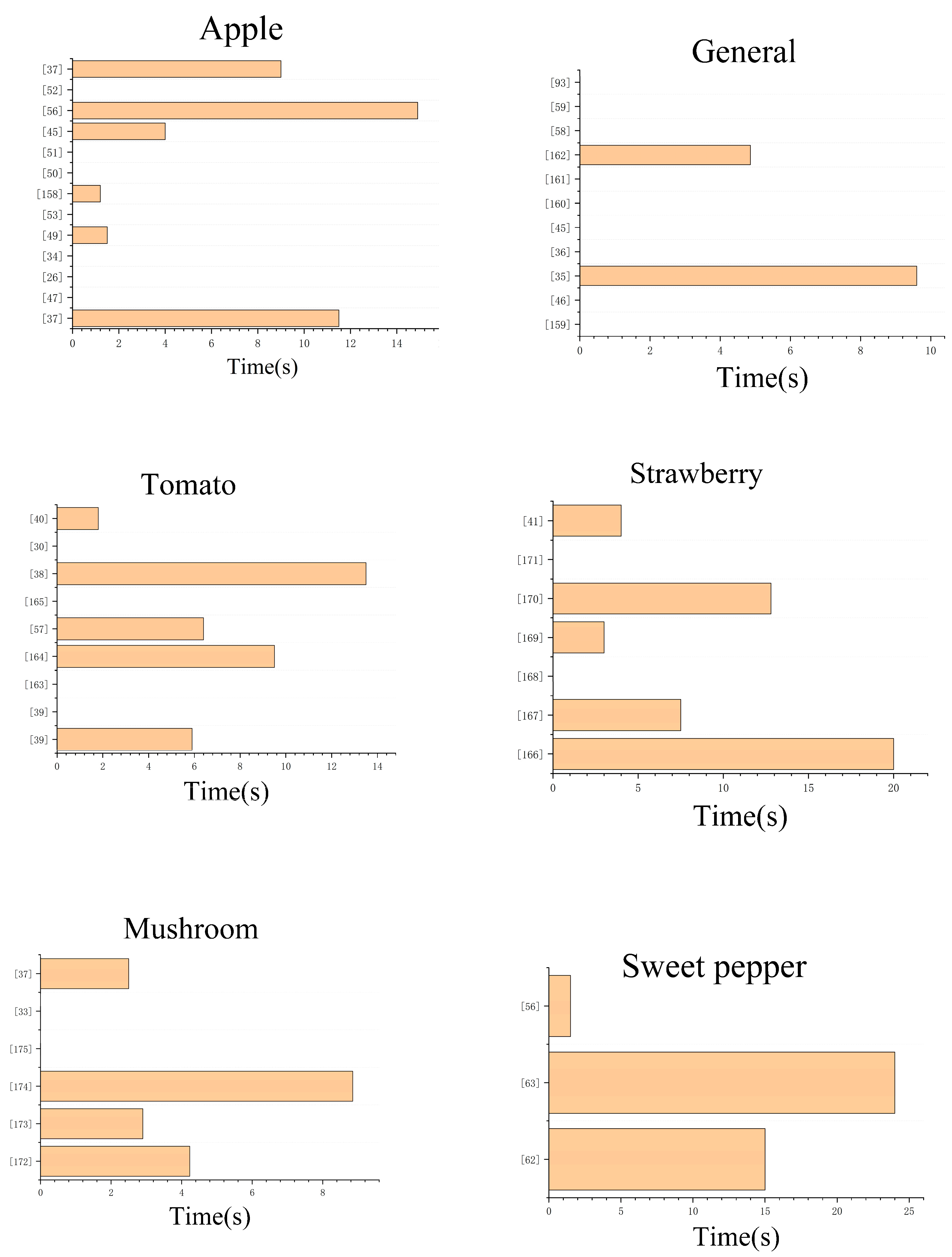

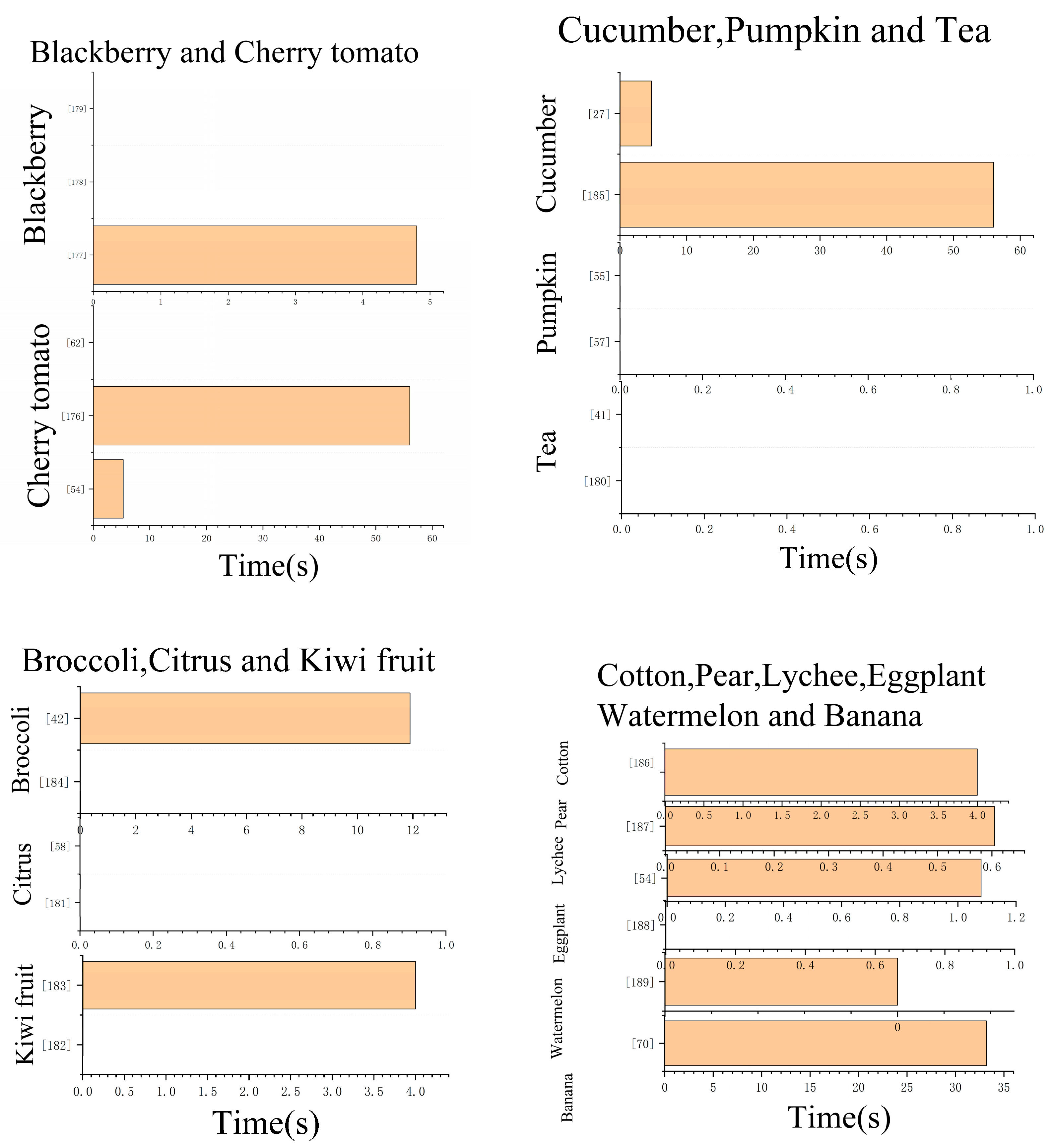

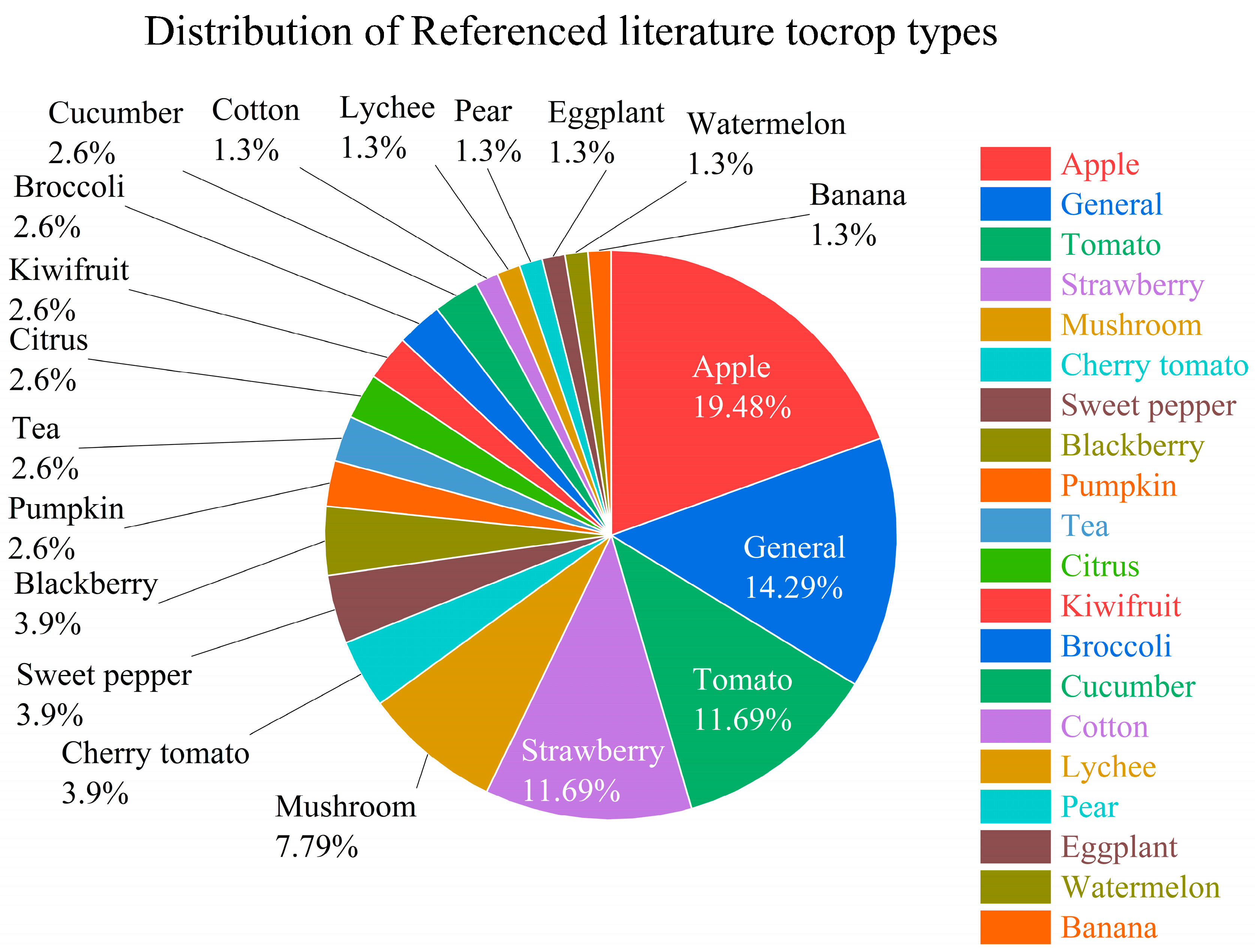

| Object | Drivers | Types | Number of Fingers | Picking Method | Time | Harvest Rate | Damage Rate | References |

|---|---|---|---|---|---|---|---|---|

| apple | Electric drivers | Hard end-effector | Three-finger | Clamping | 11.5 s | 85% | [37] | |

| apple | Hybrid drivers | Soft end-effector | Fingerless | Negative pressure | 96% | [47] | ||

| apple | Vacuum drive | Soft end-effector | Fingerless | Negative pressure | 95%% | [26] | ||

| apple | Vacuum drive | Soft end-effector | Fingerless | Negative pressure | 66.1% | [34] | ||

| apple | Pneumatic drivers | Hard end-effector with elastic membrane | Three-finger | Clamping | 1.5 s | 84% | [49] | |

| apple | Electric drivers | Hard end-effector | Multiple fingers | Cutting | 75% | [53] | ||

| apple | Electric drivers | Soft end-effector | Three-finger | Clamping | 1.2 s | 95% | [158] | |

| apple | Electric drivers | Hard end-effector | Three-finger | Clamping | 95% | [50] | ||

| apple | Electric drivers | Hard end-effector | Three-finger | Negative pressure | [51] | |||

| apple | Vacuum drive | Soft end-effector | Fingerless | Negative pressure | 4 s | 78% | [45] | |

| apple | Pneumatic drivers | Soft end-effector | Multiple fingers | Clamping | 14.9 s | 70.77% | 4.55% | [56] |

| apple | Electric drivers | Hard end-effector with elastic membrane | Three-finger | Clamping | 60% | [52] | ||

| apple | Vacuum drive | Soft end-effector | Fingerless | Negative pressure | 9 s | [37] | ||

| apple | Pneumatic drivers | Soft end-effector | Multiple fingers | Clamping | [60] | |||

| apple | Pneumatic drivers | Soft end-effector | Three-finger | Clamping | [93] | |||

| general | Pneumatic drivers | Soft end-effector | Three-finger | Clamping | [159] | |||

| general | Hybrid drivers | Hard end-effector with elastic membrane | Three-finger | Clamping | [46] | |||

| general | Electric drivers | Hard end-effector with elastic membrane | Two-finger | Cutting | 9.6 s | 80% | [35] | |

| general | Electric drivers | Soft end-effector | Two-finger | Clamping | [36] | |||

| general | Electric drivers | Hard end-effector with elastic membrane | Two-finger | Clamping | [45] | |||

| general | Electric drivers | Hard end-effector | Fingerless | Clamping | 93.6% | [160] | ||

| general | Pneumatic drivers | Soft end-effector | Three-finger | Clamping | [161] | |||

| general | Electric drivers | Soft end-effector | Three-finger | Clamping | 4.86 s | 95.82% | 2.9% | [162] |

| general | Electric drivers | Hard end-effector with elastic membrane | Three-finger | Clamping | [58] | |||

| general | magnetic drive | Soft end-effector | Two-finger | Clamping | [58] | |||

| tomato | Pneumatic drivers | Soft end-effector | Fingerless | Cutting | 5.9 s | [39] | ||

| tomato | Electric drivers | Hard end-effector with elastic membrane | Two-finger | Clamping | [39] | |||

| tomato | Pneumatic drivers | Soft end-effector | Two-finger | Clamping | 86% | [163] | ||

| tomato | Electric drivers | Soft end-effector | Fingerless | Cutting | 9.5 s | 83.3% | [164] | |

| tomato | Pneumatic drivers | Soft end-effector | Two-finger | Clamping | 6.4 s | 84% | [57] | |

| tomato | electric drivers | Hard end-effector | Three-finger | Clamping | [165] | |||

| tomato | Pneumatic drivers | Soft end-effector | Fingerless | Cutting | 13.5 s | 82% | [38] | |

| tomato | Electric drivers | Soft end-effector | Two-finger | Clamping and Cutting simultaneously | [30] | |||

| tomato | Electric drivers | Soft end-effector | Fingerless | Clamping | 1.8 s | 90% | 1.9 | [40] |

| strawberry | Pneumatic drivers | Soft end-effector | Three-finger | Clamping | 20 s | 73.7% | [166] | |

| strawberry | Electric drivers | Soft end-effector | Multiple fingers | Clamping | 7.5 s | 37.5% | [167] | |

| strawberry | Hybrid drivers | Soft end-effector | two-finger | Cutting | [168] | |||

| strawberry | Pneumatic drivers | Hard end-effector | Multiple fingers | Cutting | 3 s | 94.7% | [169] | |

| strawberry | Electric drivers | Hard end-effector | two-finger | Cutting | 12.8 s | 74.2% | [170] | |

| strawberry | Electric drivers | Hard end-effector | Two-finger | Cutting | [171] | |||

| strawberry | Electric drivers | Hard end-effector | Two-finger | Cutting | 4 s | 49.3% | [41] | |

| strawberry | Electric drivers | Hard end-effector | Fingerless | Cutting | 49.3% | [32] | ||

| strawberry | Electric drivers | Soft end-effector | two-finger | Clamping | 82% | [41] | ||

| mushroom | Pneumatic drivers | Soft end-effector | Fingerless | Negative pressure | 4.23 s | 94.1% | [172] | |

| mushroom | Vacuum drive | Soft end-effector | Fingerless | Negative pressure | 2.9 s | 88.2% | 2.9 | [173] |

| mushroom | Pneumatic drivers | Soft end-effector | Three-finger | Clamping | 8.85 s | 86.8% | [174] | |

| mushroom | hybrid drivers | Soft end-effector | Fingerless | Cutting | 97% | [175] | ||

| mushroom | Electric drivers | Hard end-effector with elastic membrane | Three-finger | Clamping | 100%single/64%clusters | [33] | ||

| mushroom | Vacuum drive | Soft end-effector | Fingerless | Negative pressure | 2.5 s | 98.5% | [37] | |

| cherry tomato | Vacuum drive | Soft end-effector | Multiple fingers | Clamping | 5.3 s | 7.4% | [59] | |

| cherry tomato | Electric drivers | Hard end-effector | Two-finger | Clamping and cutting simultaneously | 56 s | 96% | [54] | |

| cherry tomato | Electric drivers | Hard end-effector | Two-finger | Clamping | 73.7% | [176] | ||

| sweet pepper | Electric drivers | Hard end-effector | Two-finger | Cutting | 15 s | 82% | [63] | |

| sweet pepper | Electric drivers | Hard end-effector | Multiple fingers | Cutting | 24 s | 61% | [64] | |

| sweet pepper | Electric drivers | Hard end-effector | Two-finger | Cutting | 1.5 s | [56] | ||

| blackberry | Electric drivers | Soft end-effector | Three-finger | Clamping | 4.8 s | 95.2% | [177] | |

| blackberry | Electric drivers | Soft end-effector | Fingerless | Clamping | 82% | [178] | ||

| blackberry | Electric drivers | Hard end-effector with elastic membrane | Three-finger | Clamping | [179] | |||

| pumpkin | Electric drivers | Hard end-effector with elastic membrane | Multiple fingers | Clamping and cutting simultaneously | 90% | [57] | ||

| pumpkin | Electric drivers | Hard end-effector | Multiple fingers | Cutting | 93% | [55] | ||

| tea | Electric drivers | Soft end-effector | Two-finger | Cutting | [180] | |||

| tea | Electric drivers | Soft end-effector | Two-finger | Clamping | 94.33% | [41] | ||

| citrus | Electric drivers | Soft end-effector | Multiple fingers | Cutting | 82.4% | [181] | ||

| citrus | Electric drivers | Hard end-effector with elastic membrane | Multiple fingers | Cutting | 83.33% | [58] | ||

| kiwifruit | Electric drivers | Soft end-effector | Two-finger | Clamping | [182] | |||

| kiwifruit | Electric drivers | Hard end-effector | Two-finger | Clamping | 4 s | 94.2% | [183] | |

| broccoli | Pneumatic drivers | Soft end-effector | Three-finger | Cutting | 85% | [184] | ||

| broccoli | electric drivers | Hard end-effector with elastic membrane | Three-finger | Clamping and cutting simultaneously | 11.9 s | 63.16% | [42] | |

| cucumber | Pneumatic drivers | Soft end-effector | Fingerless | Cutting | 56 s | 65.6% | [185] | |

| cucumber | Pneumatic drivers | Soft end-effector | Fingerless | Cutting | 4.7 s | 86.2% | [27] | |

| cotton | Electric drivers | Hard end-effector | Three-finger | Clamping | 4 s | [186] | ||

| lychee | Pneumatic drivers | Hard end-effector | Multiple fingers | Cutting | 1.08 | 62.86% | [54] | |

| pear | Electric drivers | Hard end-effector with elastic membrane | Three-finger | Clamping | 0.60 s | 100% | 0 | [187] |

| eggplant | Pneumatic drivers | Soft end-effector | Three-finger | Clamping | [188] | |||

| watermelon | Electric drivers | Soft end-effector | Three-finger | Cutting | 85% | [189] | ||

| banana | Hydraulic drive | Hard end-effector | Two-finger | Clamping and cutting simultaneously | 33.2 s | 91.69% | [67] |

References

- Powell, N.; Ji, X.; Ravash, R.; Edlington, J.; Dolferus, R. Yield stability for cereals in a changing climate. Funct. Plant Biol. 2012, 39, 539–552. [Google Scholar] [CrossRef]

- Food and Agriculture Organization. The State of Food and Agriculture. Climate Change, Agriculture and Food Security; Food and Agriculture Organization of the United Nations: Rome, Italy, 2016. [Google Scholar]

- Mitchell, E.; Walker, R. Global ageing: Successes, challenges and opportunities. Br. J. Hosp. Med. 2020, 81, 1–9. [Google Scholar] [CrossRef]

- Zhou, K.; Liu, T.; Zhou, L. Industry 4.0: Towards future industrial opportunities and challenges. In Proceedings of the 2015 12th International Conference on Fuzzy Systems and Knowledge Discovery (FSKD), Zhangjiajie, China, 15–17 August 2015; IEEE: Piscataway, NJ, USA, 2015; pp. 2147–2152. [Google Scholar]

- Jin, Y.; Liu, J.; Xu, Z.; Yuan, S.; Li, P.; Wang, J. Development status and trend of agricultural robot technology. Int. J. Agric. Biol. Eng. 2021, 14, 1–19. [Google Scholar] [CrossRef]

- Hurst, Z.M.; Spiegal, S. Design thinking for responsible agriculture 4.0 innovations in rangelands. Rangelands 2023, 45, 68–78. [Google Scholar] [CrossRef]

- Araújo, S.O.; Peres, R.S.; Barata, J. Characterising the agriculture 4.0 landscape—Emerging trends, challenges and opportunities. Agronomy 2021, 1, 667. [Google Scholar] [CrossRef]

- Mukhopadhay, S.C. Smart sensing technology for agriculture and environmental monitoring. In Smart Sensing Technology for Agriculture and Environmental Monitoring; Mukhopadhyay, S.C., Ed.; Lecture Notes in Electrical Engineering; Springer: Berlin/Heidelberg, Germany, 2012; Volume 146, pp. 1–10. [Google Scholar]

- Yu, Y.; Hao, S.; Guo, S. Motor torque distribution strategy for different tillage modes of agricultural electric tractors. Agriculture 2022, 12, 1373. [Google Scholar] [CrossRef]

- Han, L.; Mao, H.; Kumi, F. Development of a multi-task robotic transplanting workcell for greenhouse seedlings. Appl. Eng. Agric. 2018, 34, 335–342. [Google Scholar] [CrossRef]

- Zhu, C.; Hao, S.; Liu, C. An efficient computer vision-based Dual-Face target precision variable spraying robotic system for foliar fertilisers. Agronomy 2024, 14, 2770. [Google Scholar] [CrossRef]

- Xu, L.; Chai, X.; Gao, Z. Experimental study on driver seat vibration characteristics of crawler-type combine harvester. Int. J. Agric. Biol. Eng. 2019, 12, 90–97. [Google Scholar] [CrossRef]

- Yu, Y.; Wang, G.; Tang, Z. Structural form and field operation effect of crawler type broccoli harvester. Eng. Agric. 2023, 43, e20230132. [Google Scholar] [CrossRef]

- Zhu, X.; Xu, Y.; Han, C. Design and experiment of in-situ bionic harvesting device for edible sunflower. Agriculture 2024, 14, 1169. [Google Scholar] [CrossRef]

- Ji, W.; Wang, J.; Xu, B. Apple grading based on multi-dimensional view processing and deep learning. Foods 2023, 12, 2117. [Google Scholar] [CrossRef]

- Xu, B.; Cui, X.; Ji, W. Apple grading method design and implementation for automatic grader based on improved YOLOv5. Agriculture 2023, 13, 124. [Google Scholar] [CrossRef]

- Moseley, K.R.; House, L.; Roka, F.M. Adoption of mechanical harvesting for sweet orange trees in Florida: Addressing grower concerns on long-term impacts. Int. Food Agribus. Manag. Rev. 2012, 15, 83–98. [Google Scholar]

- Zhou, H.; Wang, X.; Au, W. Intelligent robots for fruit harvesting: Recent developments and future challenges. Precis. Agric. 2022, 23, 1856–1907. [Google Scholar] [CrossRef]

- Wang, Z.; Xun, Y.; Wang, Y.; Yang, Q. Review of smart robots for fruit and vegetable picking in agriculture. Int. J. Agric. Biol. Eng. 2022, 15, 33–54. [Google Scholar] [CrossRef]

- Jin, T.; Han, X. Robotic arms in precision agriculture: A comprehensive review of the technologies, applications, challenges, and future prospects. Comput. Electron. Agric. 2024, 221, 108938. [Google Scholar] [CrossRef]

- Ye, W.; Zhao, L.; Luo, X. Perceptual soft end-effectors for future unmanned agriculture. Sensors 2023, 23, 7905. [Google Scholar] [CrossRef]

- Peres, R.S.; Jia, X.; Lee, J.; Sun, K.; Colombo, A.W.; Barata, J. Industrial Artificial Intelligence in Industry 4.0-Systematic Review, Challenges and Outlook. IEEE Access 2020, 8, 220121–220139. [Google Scholar] [CrossRef]

- Zhao, Y.; Wan, X.; Duo, H. Review of rigid fruit and vegetable picking robots. Int. J. Agric. Biol. Eng. 2023, 16, 1–11. [Google Scholar] [CrossRef]

- Wang, C.; Pan, W.; Zou, T.; Li, C.; Han, Q.; Wang, H.; Zou, X. A review of perception technologies for berry fruit-picking robots: Advantages, disadvantages, challenges, and prospects. Agriculture 2024, 14, 1346. [Google Scholar] [CrossRef]

- Luo, Y.; Li, J.; Yao, B.; Luo, Q.; Zhu, Z.; Wu, W. Research progress and development trend of bionic harvesting technology. Comput. Electron. Agric. 2024, 222, 109013. [Google Scholar] [CrossRef]

- Lu, R.; Dickinson, N.; Lammers, K. Design and evaluation of end effectors for a vacuum-based robotic apple harvester. J. ASABE 2022, 65, 963–974. [Google Scholar] [CrossRef]

- Jo, Y.; Park, Y.; Son, H.I. A suction cup-based soft robotic gripper for cucumber harvesting: Design and validation. Biosyst. Eng. 2024, 238, 143–156. [Google Scholar] [CrossRef]

- Jun, J.; Kim, J.; Seol, J. Towards an efficient tomato harvesting robot: 3D perception, manipulation, and end-effector. IEEE Access 2021, 9, 17631–17640. [Google Scholar] [CrossRef]

- Hu, G.; Chen, C.; Chen, J. Simplified 4-DOF manipulator for rapid robotic apple harvesting. Comput. Electron. Agric. 2022, 199, 107177. [Google Scholar] [CrossRef]

- Baeten, J.; Donné, K.; Boedrij, S. Autonomous fruit picking machine: A robotic apple harvester. In Field and Service Robotics, Proceedings of the 6th International Conference on Field and Service Robotics, Chamonix, France 9–12 July 2007; Springer: Berlin/Heidelberg, Germany, 2008; pp. 531–539. [Google Scholar]

- Park, Y.; Seol, J.; Pak, J. A novel end-effector for a fruit and vegetable harvesting robot: Mechanism and field experiment. Precis. Agric. 2023, 24, 948–970. [Google Scholar] [CrossRef]

- Zhou, J.; Song, X.A.; Karydis, K. Design of an end-effector with application to avocado harvesting. In Proceedings of the 2024 IEEE International Conference on Advanced Intelligent Mechatronics (AIM), Boston, MA, USA, 15–19 July 2024; IEEE: Piscataway, NJ, USA, 2024; pp. 1241–1246. [Google Scholar]

- Zhang, K.; Lammers, K.; Chu, P. System design and control of an apple harvesting robot. Mechatronics 2021, 79, 102644. [Google Scholar] [CrossRef]

- Jangali, R.; McGuinness, B.; Lim, H. Development of a novel multipurpose robotic end effector for fruitlet thinning and fruit harvesting of apples. In Proceedings of the 2024 IEEE 20th International Conference on Automation Science and Engineering (CASE), Bari, Italy, 28 August–1 September 2024; IEEE: Piscataway, NJ, USA, 2024; pp. 2073–2078. [Google Scholar]

- Li, Z.; Yuan, X.; Yang, Z. Design, simulation, and experiment for the end effector of a spherical fruit picking robot. Int. J. Adv. Robot. Syst. 2023, 20, 17298806231213442. [Google Scholar] [CrossRef]

- Sofla, M.S.; Golshanian, H.; Sklar, E.I. Development of a soft gripper for replicating human grasps in forest nursery tasks. Robot. Auton. Syst. 2025, 189, 104987. [Google Scholar] [CrossRef]

- An, B.; Choi, T.; Kim, U. Linkage integrated fin ray gripper capable of safe adaptive grasping for tomato harvesting. Comput. Electron. Agric. 2025, 232, 110118. [Google Scholar] [CrossRef]

- Zhao, X.; He, L.; Li, Y. Kinetostatic modeling of clamping force in a tendon-driven soft robotic gripper for tea shoot plucking. Comput. Electron. Agric. 2025, 236, 110441. [Google Scholar] [CrossRef]

- Zhang, B.; Zhou, J.; Meng, Y. Comparative study of mechanical damage caused by a two-finger tomato gripper with different robotic grasping patterns for harvesting robots. Biosyst. Eng. 2018, 171, 245–257. [Google Scholar] [CrossRef]

- Fang, J.; Dai, N.; Xin, Z. Design and interaction dynamics analysis of a novel hybrid bending-twisting-pulling end-effector for robotic tomato picking. Comput. Electron. Agric. 2025, 231, 110011. [Google Scholar] [CrossRef]

- Yu, Y.; Xie, H.; Zhang, K. Design, development, integration, and field evaluation of a ridge-planting strawberry harvesting robot. Agriculture 2024, 14, 2126. [Google Scholar] [CrossRef]

- Kang, S.; Long, S.; Li, D. Design, integration, and field evaluation of a selective harvesting robot for broccoli. Comput. Electron. Agric. 2024, 227, 109654. [Google Scholar] [CrossRef]

- Gao, J.; Zhang, F.; Zhang, J. Development and evaluation of a pneumatic finger-like end-effector for cherry tomato harvesting robot in greenhouse. Comput. Electron. Agric. 2022, 197, 106879. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, X.; Yu, X. Magnetic actuation bionic robotic gripper with bistable morphing structure. Compos. Struct. 2019, 229, 111422. [Google Scholar] [CrossRef]

- Zhao, Y.; Jin, Y.; Jian, Y. Kinematic design of new robot end-effectors for harvesting using deployable scissor mechanisms. Comput. Electron. Agric. 2024, 222, 109039. [Google Scholar] [CrossRef]

- Al Mashagbeh, M.; Tamimi, M.; Al-Adwan, R. Design of a Light-Weight, Low-Cost Three-Finger End Effector. Int. J. Mech. Eng. Robot. Res. 2025, 14, 105–112. [Google Scholar]

- Koirala, B.; Kafle, A.; Nguyen, H.C. A hybrid three-finger gripper for automated harvesting of button mushrooms. Actuators 2024, 13, 287. [Google Scholar] [CrossRef]

- Fan, P.; Yan, B.; Wang, M. Three-finger grasp planning and experimental analysis of picking patterns for robotic apple harvesting. Comput. Electron. Agric. 2021, 188, 106353. [Google Scholar] [CrossRef]

- Silwal, A.; Davidson, J.R.; Karkee, M. Design, integration, and field evaluation of a robotic apple harvester. J. Field Robot. 2017, 34, 1140–1159. [Google Scholar] [CrossRef]

- Shi, Y.; Zhu, K.; Zhai, S. Design of an apple-picking end effector. J. Mech. Eng. 2018, 64, 216–224. [Google Scholar]

- Davidson, J.R.; Hohimer, C.J.; Mo, C. Preliminary design of a robotic system for catching and storing fresh market apples. IFAC-PapersOnLine 2016, 49, 149–154. [Google Scholar] [CrossRef]

- Dischinger, L.M.; Cravetz, M.; Dawes, J. Towards intelligent fruit picking with in-hand sensing. In Proceedings of the 2021 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Prague, Czech Republic, 27 September–1 October 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 3285–3291. [Google Scholar]

- Pawikhum, K.; He, L.; Heinemann, P. Design of end-effectors for thinning apple in the green fruit stage. J. ASABE 2025, 68, 465–476. [Google Scholar] [CrossRef]

- Goulart, R.; Jarvis, D.; Walsh, K.B. Evaluation of end effectors for robotic harvesting of mango fruit. Sustainability 2023, 15, 6769. [Google Scholar] [CrossRef]

- Roshanianfard, A.; Noguchi, N. Pumpkin harvesting robotic end-effector. Comput. Electron. Agric. 2020, 174, 105503. [Google Scholar] [CrossRef]

- Wang, X.; Kang, H.; Zhou, H. Development and evaluation of a robust soft robotic gripper for apple harvesting. Comput. Electron. Agric. 2023, 204, 107552. [Google Scholar] [CrossRef]

- Yang, L.; Noguchi, T.; Hoshino, Y. Development of a pumpkin fruits pick-and-place robot using an RGB-D camera and a YOLO based object detection AI model. Comput. Electron. Agric. 2024, 227, 109625. [Google Scholar] [CrossRef]

- Choi, D.W.; Park, J.H.; Yoo, J.H. AI-driven adaptive grasping and precise detaching robot for efficient citrus harvesting. Comput. Electron. Agric. 2025, 232, 110131. [Google Scholar] [CrossRef]

- Gao, J.; Zhang, F.; Zhang, J. Picking patterns evaluation for cherry tomato robotic harvesting end-effector design. Biosyst. Eng. 2024, 239, 1–12. [Google Scholar] [CrossRef]

- Wang, Q.; Bai, K.; Zhang, L. Towards reliable and damage-less robotic fragile fruit grasping: An enveloping gripper with multimodal strategy inspired by Asian elephant trunk. Comput. Electron. Agric. 2025, 234, 110198. [Google Scholar] [CrossRef]

- Jiang, Y.; Liu, J.; Wang, J. Development of a dual-arm rapid grape-harvesting robot for horizontal trellis cultivation. Front. Plant Sci. 2022, 13, 881904. [Google Scholar] [CrossRef]

- Shi, H.; Xu, G.; Lu, W. An electric gripper for picking brown mushrooms with flexible force and in situ measurement. Agriculture 2024, 14, 1181. [Google Scholar] [CrossRef]

- Zhao, X.; Liang, H.; Liu, Z. Research on design and experiment of rear-drive apple harvesting robotic arm based on obstacle avoidance posture conditions. Smart Agric. Technol. 2025, 11, 101028. [Google Scholar] [CrossRef]

- Visentin, F.; Castellini, F.; Muradore, R. A soft, sensorized gripper for delicate harvesting of small fruits. Comput. Electron. Agric. 2023, 213, 108202. [Google Scholar] [CrossRef]

- Zhao, K.; Li, H.; Ji, J. Pressure-stabilized flexible end-effector for selective picking of agaricus bisporus. Agriculture 2023, 13, 2256. [Google Scholar] [CrossRef]

- Arad, B.; Balendonck, J.; Barth, R.; Ben-Shahar, O.; Edan, Y.; Hellström, T.; Hemming, J.; Kurtser, P.; Ringdahl, O.; Tielen, Y.; et al. Development of a sweet pepper harvesting robot. J. Field Robot. 2020, 37, 1027–1039. [Google Scholar] [CrossRef]

- Bachche, S.; Oka, K. Performance testing of thermal cutting systems for sweet pepper harvesting robot in greenhouse horticulture. J. Syst. Des. Dyn. 2013, 7, 36–51. [Google Scholar] [CrossRef]

- Yoon, J.; Jeong, H.; Park, J.H.; Gong, Y.J.; Shin, D.; Seo, H.W.; Choi, H.R. A Three-Finger Adaptive Gripper with Finger-Embedded Suction Cups for Enhanced Object Grasping Mechanism. IEEE Robot. Autom. Lett. 2024, 9, 6875–6882. [Google Scholar] [CrossRef]

- Navas, E.; Fernández, R.; Sepúlveda, D. Soft grippers for automatic crop harvesting: A review. Sensors 2021, 21, 2689. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.; Song, Z.; Li, X. Research status of apple picking robotic arm picking strategy and end-effector. Comput. Electron. Agric. 2025, 235, 110349. [Google Scholar] [CrossRef]

- Yao, Z.; Xiong, J.; Yang, J. Design and verification of a litchi combing and cutting end-effector based on visual-tactile fusion. Comput. Electron. Agric. 2025, 232, 110077. [Google Scholar] [CrossRef]

- Yeshmukhametov, A.; Koganezawa, K.; Yamamoto, Y. Development of continuum robot arm and gripper for harvesting cherry tomatoes. Appl. Sci. 2022, 12, 6922. [Google Scholar] [CrossRef]

- Sorour, M.; From, P.L.J.; Elgeneidy, K. Compact strawberry harvesting tube employing laser cutter. In Proceedings of the 2022 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Kyoto, Japan, 23–27 October 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 8956–8962. [Google Scholar]

- Xu, Y.; Lv, M.; Xu, Q. Design and analysis of a robotic gripper mechanism for fruit picking. Actuators 2024, 13, 338. [Google Scholar] [CrossRef]

- Pan, Q.; Wang, D.; Lian, J.; Dong, Y.; Qiu, C. Development of an automatic sweet pepper harvesting robot and experimental evaluation. In Proceedings of the 2024 IEEE International Conference on Robotics and Automation (ICRA), Yokohama, Japan, 13–17 May 2024; IEEE: Piscataway, NJ, USA, 2024; pp. 15811–15817. [Google Scholar]

- Lehnert, C.; McCool, C.; Sa, I. Performance improvements of a sweet pepper harvesting robot in protected cropping environments. J. Field Robot. 2020, 37, 1197–1223. [Google Scholar] [CrossRef]

- Hua, W.; Zhang, W.; Zhang, Z. Vacuum suction end-effector development for robotic harvesters of fresh market apples. Biosyst. Eng. 2025, 249, 28–40. [Google Scholar] [CrossRef]

- Liu, X.; Wang, Z.; Qiu, Z.; Jiao, Z.; Chen, X.; Nie, R. Cascade control method for hydraulic secondary regulation drive system based on adaptive robust control. ISA Trans. 2025, 156, 479–489. [Google Scholar] [CrossRef] [PubMed]

- Chen, T.; Zhang, S.; Chen, J. Development, integration, and field experiment optimization of an autonomous Banana-Picking robot. Agriculture 2024, 14, 1389. [Google Scholar] [CrossRef]

- Mori, S.; Yamashina, K.; Funatsu, T. Pneumatic-Electric hybrid drive robot hand for both powerful grasping and dexterous manipulation using passive clutch mechanism. In Proceedings of the 2023 IEEE/SICE International Symposium on System Integration (SII), Atlanta, GA, USA, 17–20 January 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 1–8. [Google Scholar]

- Han, D.; Zhang, H.; Li, G. Development of a bionic picking device for high harvest and low loss rate pod pepper harvesting and related working parameter optimization details. Agriculture 2024, 14, 859. [Google Scholar] [CrossRef]

- Pi, J.; Liu, J.; Zhou, K. An octopus-inspired bionic flexible gripper for apple grasping. Agriculture 2021, 11, 1014. [Google Scholar] [CrossRef]

- Du, C.; Fang, W.; Han, D. Design and experimental study of a biomimetic pod-pepper-picking drum based on multi-finger collaboration. Agriculture 2024, 14, 314. [Google Scholar] [CrossRef]

- Cui, H.; Du, L.; Xie, Z.; Zhong, W.; Xu, D.; Bian, W.; Wu, L. Design and Experimental of the Soil Removal Device for Root-Soil Complex of Gentian Imitating the Percussion of Woodpeckers. Biomimetics 2024, 9, 479. [Google Scholar] [CrossRef]

- Chen, H.; Li, Y.; Xu, P. Octopus-inspired soft gripper with embedded triboelectric tactile sensor for underwater target recognition and grasp. Nano Energy 2025, 140, 111007. [Google Scholar] [CrossRef]

- Deng, L.; Liu, T.; Jiang, P. Design and testing of bionic-feature-based 3D-printed flexible end-effectors for picking horn peppers. Agronomy 2023, 13, 2231. [Google Scholar] [CrossRef]

- Vaudelle, F.; L’Huillier, J.P. Influence of the size and skin thickness of apple varieties on the retrieval of internal optical properties using Vis/NIR spectroscopy: A Monte Carlo-based study. Comput. Electron. Agric. 2015, 116, 137–149. [Google Scholar] [CrossRef]

- Ma, F.; Li, L.; Wang, Y. Biomechanical properties of wolfberry plant organs. Eng. Agric. 2020, 40, 162–176. [Google Scholar] [CrossRef]

- Ghonimy, M.; Alayouni, R.; Alshehry, G. Assessing the Physico-Mechanical properties of three date fruit varieties for conserving the keeping and appearance qualities. Foods 2025, 14, 1838. [Google Scholar] [CrossRef] [PubMed]

- Ji, W.; Qian, Z.; Xu, B. Apple viscoelastic complex model for bruise damage analysis in constant velocity grasping by gripper. Comput. Electron. Agric. 2019, 162, 907–920. [Google Scholar] [CrossRef]

- Chen, H.; Guo, T.; Jin, L. Prediction of damage characteristics of apple fruit based on test and finite element method. J. Stored Prod. Res. 2025, 111, 102543. [Google Scholar] [CrossRef]

- Song, R.; He, Y.; Li, Z. Blood orange clamping damage mechanism based on finite element method. J. Food Meas. Charact. 2025, 19, 453–466. [Google Scholar] [CrossRef]

- Zhang, F.; Chen, Z.; Ali, S. Multi-class detection of cherry tomatoes using improved Yolov4-tiny model. Int. J. Agric. Biol. Eng. 2023, 16, 225–231. [Google Scholar]

- Ji, W.; Pan, Y.; Xu, B. A real-time apple targets detection method for picking robot based on ShufflenetV2-YOLOX. Agriculture 2022, 12, 856. [Google Scholar] [CrossRef]

- Xu, Z.; Liu, J.; Wang, J. Realtime picking point decision algorithm of trellis grape for high-speed robotic cut-and-catch harvesting. Agronomy 2023, 13, 1618. [Google Scholar] [CrossRef]

- Ji, W.; Zhai, K.; Xu, B. Green apple detection method based on multidimensional feature extraction network model and transformer module. J. Food Prot. 2025, 88, 100397. [Google Scholar] [CrossRef]

- Ji, W.; Zhang, T.; Xu, B. Apple recognition and picking sequence planning for harvesting robot in a complex environment. J. Agric. Eng. 2024, 55, 1549. [Google Scholar]

- Dai, N.; Fang, J.; Yuan, J. 3MSP2: Sequential picking planning for multi-fruit congregated tomato harvesting in multi-clusters environment based on multi-views. Comput. Electron. Agric. 2024, 225, 109303. [Google Scholar] [CrossRef]

- Ye, L.; Duan, J.; Yang, Z. Collision-free motion planning for the litchi-picking robot. Comput. Electron. Agric. 2021, 185, 106151. [Google Scholar] [CrossRef]

- Suo, R.; Gao, F.; Zhou, Z. Improved multi-classes kiwifruit detection in orchard to avoid collisions during robotic picking. Comput. Electron. Agric. 2021, 182, 106052. [Google Scholar] [CrossRef]

- Xie, F.; Guo, Z.; Li, T. Dynamic task planning for Multi-Arm harvesting robots under multiple constraints using deep reinforcement learning. Horticulturae 2025, 11, 88. [Google Scholar] [CrossRef]

- Rana, S.; Gerbino, S.; Carillo, P. Study of spectral overlap and heterogeneity in agriculture based on soft classification techniques. MethodsX 2025, 14, 103114. [Google Scholar] [CrossRef]

- Ji, W.; He, G.; Xu, B. A new picking pattern of a flexible three-fingered end-effector for apple harvesting robot. Agriculture 2024, 14, 102. [Google Scholar] [CrossRef]

- Huang, H.; Wang, R.; Huang, F.; Chen, J. Analysis and realization of a self-adaptive grasper grasping for non-destructive picking of fruits and vegetables. Comput. Electron. Agric. 2025, 232, 110119. [Google Scholar] [CrossRef]

- Navas, E.; Fernández, R.; Armada, M. Diaphragm-type pneumatic-driven soft grippers for precision harvesting. Agronomy 2021, 11, 1727. [Google Scholar] [CrossRef]

- Fahui, Y.; Xiaochan, W.; Yinyan, S. Prediction of the viscoelastic parameters of asparagus and optimization of the harvesting robot gripping force based on a back-propagation neural network. Smart Agric. Technol. 2025, 12, 101177. [Google Scholar] [CrossRef]

- Zhang, H.; Ji, W.; Xu, B. Optimizing contact force on an apple picking robot end-effector. Agriculture 2024, 14, 996. [Google Scholar] [CrossRef]

- Varghese, F.; Cheein, F.A.; Koskinopoulou, M. Finite element optimization of a flexible fin-ray-based soft robotic gripper for scalable fruit harvesting and manipulation. Smart Agric. Technol. 2025, 11, 100899. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, Y.; Song, Y. Finding the lowest damage picking mode for tomatoes based on finite element analysis. Comput. Electron. Agric. 2023, 204, 107536. [Google Scholar] [CrossRef]

- Zhou, K.; Xia, L.; Liu, J. Design of a flexible end-effector based on characteristics of tomatoes. Int. J. Agric. Biol. Eng. 2022, 15, 13–24. [Google Scholar] [CrossRef]

- Waseem, S.; Adnan, M.; Iqbal, M.S. From classical to intelligent control: Evolving trends in robotic manipulator technology. Comput. Electr. Eng. 2025, 127, 110559. [Google Scholar] [CrossRef]

- Huang, A.; Yu, C.; Feng, J. A motion planning method for winter jujube harvesting robotic arm based on optimized Informed-RRT* algorithm. Smart Agric. Technol. 2025, 10, 100732. [Google Scholar] [CrossRef]

- Yin, X.; Yang, L.; Yao, D. Improved DeepLabV3+ and GR-ConvNet for shiitake mushroom harvest robots flexible grasping of mimicry. Comput. Electron. Agric. 2025, 236, 110449. [Google Scholar] [CrossRef]

- Huynh, T.N.; Nguyen, K.D. Integrative AI framework for robotics: LLM-enabled reinforcement learning in object manipulation and task planning. Robot. Auton. Syst. 2025, 181, 105197. [Google Scholar] [CrossRef]

- Papavasileiou, A.; Georgiadis, C.; Glykos, C.; Michalos, G.; Makris, S. Towards AI-driven task and motion planning of robotic assembly operations. Procedia CIRP 2025, 134, 783–788. [Google Scholar] [CrossRef]

- Sun, J.; Sun, L.; Zhao, G. Triboelectric force feedback-based fully actuated adaptive apple-picking gripper for optimized stability and non-destructive harvesting. Comput. Electron. Agric. 2025, 237, 110725. [Google Scholar] [CrossRef]

- Yu, X.; Ji, W.; Zhang, H. Grasping force optimization and DDPG impedance control for apple picking robot end-effector. Agriculture 2025, 15, 1018. [Google Scholar] [CrossRef]

- Hogan, N.; Buerger, S.P. Impedance and interaction control. In Robotics and Automation Handbook; CRC Press: Boca Raton, FL, USA, 2018; pp. 375–398. [Google Scholar]

- Li, Z.; He, Z.; Hao, W. Kiwifruit harvesting impedance control and optimisation. Biosyst. Eng. 2025, 251, 101–116. [Google Scholar] [CrossRef]

- Ji, W.; Tang, C.; Xu, B. Contact force modeling and variable damping impedance control of apple harvesting robot. Comput. Electron. Agric. 2022, 198, 107026. [Google Scholar] [CrossRef]

- Wang, Z.; Lou, K.; Zhang, B. Compliant picking control of dragon fruit picking robot based on adaptive variable impedance. Biosyst. Eng. 2025, 252, 126–143. [Google Scholar] [CrossRef]

- Sun, T.; Sun, J.; Lian, B.; Li, Q. Sensorless admittance control of 6-DoF parallel robot in human-robot collaborative assembly. Robot. Comput.-Integr. Manuf. 2024, 88, 102742. [Google Scholar] [CrossRef]

- Zhou, Q.; Feng, B.; Li, B.; Liu, C.; Chen, Y.; Bi, Y. Enhancing Human-Robot Collaborative Transportation of Deformable Objects using Multi-modal Reinforcement Learning and Adaptive Admittance Control. Adv. Eng. Inform. 2026, 69, 103905. [Google Scholar] [CrossRef]

- Hu, X.; Ye, Y. Tactile-based Reinforcement Learning for Adaptive Grasping under Observation Uncertainties. arXiv 2025, arXiv:2505.16167. [Google Scholar] [CrossRef]

- Yang, X.; Liu, Y.; Chu, G.; Wu, J.; Man, Z.; Cao, X.; Zhao, J. GBAGC-RL: Goal-based arm-gripper coordination reinforcement learning approach for robotic manipulation skills. Robot. Auton. Syst. 2025, 181, 105239. [Google Scholar] [CrossRef]

- Xiao, Y.; Li, Y.; Cui, G.; Zhang, H.; Zhang, W. A systematic review of multimodal fusion technologies for food quality and safety assessment: Recent advances and future trends. Trends Food Sci. Technol. 2025, 158, 105277. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, J.; Lou, Y. Soft bionic gripper with tactile sensing and slip detection for damage-free grasping of fragile fruits and vegetables. Comput. Electron. Agric. 2024, 220, 108904. [Google Scholar] [CrossRef]

- Chen, K.; Li, T.; Yan, T. A soft gripper design for apple harvesting with force feedback and fruit slip detection. Agriculture 2022, 12, 1802. [Google Scholar] [CrossRef]

- Ma, C.; Ying, Y.; Xie, L. Development of a visuo-tactile sensor for non-destructive peach firmness and contact force measurement suitable for robotic arm applications. Food Chem. 2025, 467, 142282. [Google Scholar] [CrossRef]

- Kosanovic, N.; Vaz, J.C.; Oh, P.Y. Biomimetic real-time multimodal tactile perception and haptics for telepresence humanoids. In Proceedings of the 2023 21st International Conference on Advanced Robotics (ICAR), Abu Dhabi, United Arab Emirates, 5–8 December 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 613–620. [Google Scholar]

- He, L.; Sun, Y.; Chen, L. Advance on agricultural robot Hand–Eye coordination for agronomic task: A review. Engineering 2025, 51, 263–279. [Google Scholar] [CrossRef]

- Zhang, P.; Dai, N.; Wang, Z. A parallel dual-arm robotic control method of white asparagus based on moving-looking-harvesting coordination and asynchronous harvest cooperation. Comput. Electron. Agric. 2025, 232, 110046. [Google Scholar] [CrossRef]

- Mehta, S.S.; MacKunis, W.; Burks, T.F. Robust visual servo control in the presence of fruit motion for robotic citrus harvesting. Comput. Electron. Agric. 2016, 123, 362–375. [Google Scholar] [CrossRef]

- Li, T.; Yu, J.; Qiu, Q. Hybrid uncalibrated visual servoing control of harvesting robots with RGB-D cameras. IEEE Trans. Ind. Electron. 2022, 70, 2729–2738. [Google Scholar] [CrossRef]

- Vrochidou, E.; Tsakalidou, V.N.; Kalathas, I. An overview of end effectors in agricultural robotic harvesting systems. Agriculture 2022, 12, 1240. [Google Scholar] [CrossRef]

- Bhuvana, J.; Barve, A.; Kumar, S.P.; Dikshit, S. Image sensor fusion for multimodal biometric recognition in mobile devices. Meas. Sens. 2024, 36, 101309. [Google Scholar] [CrossRef]

- Lang, Y.; Zhang, Y.; Sun, T. Digital twin-driven system for efficient tomato harvesting in greenhouses. Comput. Electron. Agric. 2025, 236, 110451. [Google Scholar] [CrossRef]

- Liu, J.; Liang, J.; Zhao, S. Design of a virtual multi-interaction operation system for hand-eye coordination of grape harvesting robots. Agronomy 2023, 13, 829. [Google Scholar] [CrossRef]

- Sen, N.A.; Kulić, D.; Carreno-Medrano, P. Domain Randomization for Learning to Navigate in Human Environments. IEEE Robot. Autom. Lett. 2024, 9, 10234–10241. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, X.; Zhang, H. UAV-Based multispectral winter wheat growth monitoring with adaptive weight allocation. Agriculture 2024, 14, 1900. [Google Scholar] [CrossRef]

- Zhang, L.; Song, X.; Niu, Y. Estimating winter wheat plant nitrogen content by combining spectral and texture features based on a low-cost UAV RGB system throughout the growing season. Agriculture 2024, 14, 456. [Google Scholar] [CrossRef]

- Xu, S.; Xu, X.; Zhu, Q. Monitoring leaf nitrogen content in rice based on information fusion of multi-sensor imagery from UAV. Precis. Agric. 2023, 24, 2327–2349. [Google Scholar] [CrossRef]

- Hnida, Y.; Mahraz, M.A.; Riffi, J. Transfer learning-enhanced deep learning for tree crown geometric analysis and crop yield estimation using UAV imagery. Remote Sens. Appl. Soc. Environ. 2025, 39, 101663. [Google Scholar] [CrossRef]

- Wei, L.; Yang, H.; Niu, Y. Wheat biomass, yield, and straw-grain ratio estimation from multi-temporal UAV-based RGB and multispectral images. Biosyst. Eng. 2023, 234, 187–205. [Google Scholar] [CrossRef]

- Zhu, W.; Feng, Z.; Dai, S. Using UAV multispectral remote sensing with appropriate spatial resolution and machine learning to monitor wheat scab. Agronomy 2022, 12, 1785. [Google Scholar] [CrossRef]

- Amarasingam, N.; Powell, K.; Sandino, J. Mapping of insect pest infestation for precision agriculture: A UAV-based multispectral imaging and deep learning techniques. Int. J. Appl. Earth Obs. Geoinf. 2025, 137, 104413. [Google Scholar] [CrossRef]

- Ahmed, S.; Qiu, B.; Ahmad, F. A state-of-the-art analysis of obstacle avoidance methods from the perspective of an agricultural sprayer UAV’s operation scenario. Agronomy 2021, 11, 1069. [Google Scholar] [CrossRef]

- Kong, F.; Qiu, B.; Dong, X. Design and development of a side spray device for UAVs to improve spray coverage in obstacle neighborhoods. Agronomy 2024, 14, 2002. [Google Scholar] [CrossRef]

- Awais, M.; Li, W.; Hussain, S. Comparative evaluation of land surface temperature images from unmanned aerial vehicle and satellite observation for agricultural areas using in situ data. Agriculture 2022, 12, 184. [Google Scholar] [CrossRef]

- Pei, H.; Sun, Y.; Huang, H. Weed detection in maize fields by UAV images based on crop row preprocessing and improved YOLOv4. Agriculture 2022, 12, 975. [Google Scholar] [CrossRef]

- Wu, P.; Lei, X.; Zeng, J. Research progress in mechanized and intelligentized pollination technologies for fruit and vegetable crops. Int. J. Agric. Biol. Eng. 2024, 17, 11–21. [Google Scholar] [CrossRef]

- Zhang, S.; Xue, X.; Chen, C. Development of a low-cost quadrotor UAV based on ADRC for agricultural remote sensing. Int. J. Agric. Biol. Eng. 2019, 12, 82–87. [Google Scholar] [CrossRef]

- Guan, X.; Shi, L.; Yang, W. Multi-Feature fusion recognition and localization method for unmanned harvesting of aquatic vegetables. Agriculture 2024, 14, 971. [Google Scholar] [CrossRef]

- Wang, D.; Zhao, M.; Li, Z. A survey of unmanned aerial vehicles and deep learning in precision agriculture. Eur. J. Agron. 2025, 164, 127477. [Google Scholar] [CrossRef]

- Lin, S.; Lynch, A.; Liarokapis, M. An Ultra-Light, Ultra-Fast, passive closing aerial gripping system capable of grasping, perching, and aerial manipulation. In Proceedings of the 2024 IEEE International Symposium on Safety Security Rescue Robotics (SSRR), New York, NY, USA, 12–14 November 2024; IEEE: Piscataway, NJ, USA, 2024; pp. 12–17. [Google Scholar]

- Jagadeeswaran, P. A smart coconut and palm cutting drone. Inf. Technol. Ind. 2021, 9, 204–208. [Google Scholar]

- Park, H.; Kang, H.; Hwang, B. A fruit harvesting mechanism capable of multidimensional movements: A preliminary study on the integrated mechanism with a hexacopter. Aerospace 2024, 11, 203. [Google Scholar] [CrossRef]

- Davidson, J.R.; Silwal, A.; Hohimer, C.J. Proof-of-concept of a robotic apple harvester. In Proceedings of the 2016 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Daejeon, Republic of Korea, 9–14 October 2016; IEEE: Piscataway, NJ, USA, 2016; pp. 634–639. [Google Scholar]

- Ohkura, S.; Shinohira, D.; Yoshida, T. Development of three-fingered end-effector using pneumatic soft actuators. In Proceedings of the 2019 IEEE/SICE International Symposium on System Integration (SII), Paris, France, 14–16 January 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 701–706. [Google Scholar]

- Mapes, J.; Dai, A.; Xu, Y. Harvesting end-effector design and picking control. In Proceedings of the 2021 IEEE Symposium Series on Computational Intelligence (SSCI), Orlando, FL, USA, 5–7 December 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 1–6. [Google Scholar]

- Cao, M.; Sun, Y.; Zhang, J. A novel pneumatic gripper driven by combination of soft fingers and bellows actuator for flexible grasping. Sens. Actuators A Phys. 2023, 355, 114335. [Google Scholar] [CrossRef]

- Zhang, F.; Chen, Z.; Wang, Y.; Bao, R.; Chen, X.; Fu, S.; Tian, M.; Zhang, Y. Research on flexible end-effectors with humanoid grasp function for small spherical fruit picking. Agriculture 2023, 13, 123. [Google Scholar] [CrossRef]

- Wang, G.; Yu, Y.; Feng, Q. Design of end-effector for tomato robotic harvesting. IFAC-PapersOnLine 2016, 49, 190–193. [Google Scholar] [CrossRef]

- Yin, Z.; Li, H.; Zuo, Z. Key technologies of tomato-picking robots based on machine vision. Int. J. Agric. Biol. Eng. 2025, 18, 247–256. [Google Scholar] [CrossRef]

- Wang, T.; Du, W.; Zeng, L. Design and testing of an end-effector for tomato picking. Agronomy 2023, 13, 947. [Google Scholar] [CrossRef]

- He, Z.; Liu, Z.; Zhou, Z. Improving picking efficiency under occlusion: Design, development, and field evaluation of an innovative robotic strawberry harvester. Comput. Electron. Agric. 2025, 237, 110684. [Google Scholar] [CrossRef]

- Tituaña, L.; Gholami, A.; He, Z. A small autonomous field robot for strawberry harvesting. Smart Agric. Technol. 2024, 8, 100454. [Google Scholar] [CrossRef]

- Parsa, S.; Parsons, S.; Ghalamzan, A. Peduncle gripping and cutting force for strawberry harvesting robotic end-effector design. In Proceedings of the 2022 4th International Conference on Control and Robotics (ICCR), Guangzhou, China, 2–4 December 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 59–64. [Google Scholar]

- Ochoa, E.; Mo, C. Design and field evaluation of an end effector for robotic strawberry harvesting. Actuators 2025, 14, 42. [Google Scholar] [CrossRef]

- Wang, M.; Zhou, Z.; Wang, Y. Design and experiment of facility elevated planting strawberry continuous picking manipulator. Comput. Electron. Agric. 2025, 228, 109703. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, K.; Yang, L. Design and simulation experiment of ridge planting strawberry picking manipulator. Comput. Electron. Agric. 2023, 208, 107690. [Google Scholar] [CrossRef]

- Zhong, M.; Han, R.; Liu, Y. Development, integration, and field evaluation of an autonomous Agaricus bisporus picking robot. Comput. Electron. Agric. 2024, 220, 108871. [Google Scholar] [CrossRef]

- Yang, S.; Ji, J.; Cai, H. Modeling and force analysis of a harvesting robot for button mushrooms. IEEE Access 2022, 10, 78519–78526. [Google Scholar] [CrossRef]

- Rong, J.; Wang, P.; Yang, Q. A field-tested harvesting robot for oyster mushroom in greenhouse. Agronomy 2021, 11, 1210. [Google Scholar] [CrossRef]

- Huang, M.; Jiang, X.; He, L. Development of a robotic harvesting mechanism for button mushrooms. Trans. ASABE 2021, 64, 565–575. [Google Scholar] [CrossRef]

- Xie, H. Optimization and experimental study of structural parameters of compliant end-effector for robotic cherry tomato harvesting. Appl. Eng. Agric. 2022, 38, 617–625. [Google Scholar] [CrossRef]

- Gunderman, A.L.; Collins, J.A.; Myers, A.L. Tendon-driven soft robotic gripper for blackberry harvesting. IEEE Robot. Autom. Lett. 2022, 7, 2652–2659. [Google Scholar] [CrossRef]

- Elfferich, J.F.; Shahabi, E.; Della Santina, C. Berrytwist: A twisting-tube soft robotic gripper for blackberry harvesting. IEEE Robot. Autom. Lett. 2024, 10, 429–435. [Google Scholar] [CrossRef]

- Qiu, A.; Young, C.; Gunderman, A. Tendon-driven soft robotic gripper with integrated ripeness sensing for blackberry harvesting. arXiv 2023, arXiv:2302.03099. [Google Scholar] [CrossRef]

- Li, Y.; Wu, S.; He, L. Development and field evaluation of a robotic harvesting system for plucking high-quality tea. Comput. Electron. Agric. 2023, 206, 107659. [Google Scholar] [CrossRef]

- Xiao, X.; Wang, Y.; Zhou, B. Flexible hand claw picking method for citrus-picking robot based on target fruit recognition. Agriculture 2024, 14, 1227. [Google Scholar] [CrossRef]

- Jin, L.; Wang, Z.; Tian, S. Grasping perception and prediction model of kiwifruit firmness based on flexible sensing claw. Comput. Electron. Agric. 2023, 215, 108389. [Google Scholar] [CrossRef]

- Mu, L.; Cui, G.; Liu, Y. Design and simulation of an integrated end-effector for picking kiwifruit by robot. Inf. Process. Agric. 2020, 7, 58–71. [Google Scholar] [CrossRef]

- Ye, Y.; Han, C.; Kang, S. Development of a novel variable-curvature soft gripper used for orientating broccoli in the trimming line. Comput. Electron. Agric. 2024, 225, 109267. [Google Scholar] [CrossRef]

- Park, Y.; Seol, J.; Pak, J. Human-centered approach for an efficient cucumber harvesting robot system: Harvest ordering, visual servoing, and end-effector. Comput. Electron. Agric. 2023, 212, 108116. [Google Scholar] [CrossRef]

- Gharakhani, H.; Thomasson, J.A.; Lu, Y. An end-effector for robotic cotton harvesting. Smart Agric. Technol. 2022, 2, 100043. [Google Scholar] [CrossRef]

- Li, M.; Liu, P. A bionic adaptive end-effector with rope-driven fingers for pear fruit harvesting. Comput. Electron. Agric. 2023, 211, 107952. [Google Scholar] [CrossRef]

- Blanes, C.; Ortiz, C.; Mellado, M. Assessment of eggplant firmness with accelerometers on a pneumatic robot gripper. Comput. Electron. Agric. 2015, 113, 44–50. [Google Scholar] [CrossRef]

- Rong, J.; Fu, J.; Zhang, Z. Development and evaluation of a watermelon-harvesting robot prototype: Vision system and end-effector. Agronomy 2022, 12, 2836. [Google Scholar] [CrossRef]

| Criteria | Description |

|---|---|

| Search period | From January 2015 to June 2025, inclusive |

| Digital repositories | Web of Science, Google Scholar, ScienceDirect, IEEE Xplore |

| Records Screening | Must include the title, year, source, abstract and DOI |

| Document types | Article, conference paper, book chapter, early access |

| Language | English |

| Types | Advantages | Disadvantages | Harvest Rate | Time | Damage Rate | References |

|---|---|---|---|---|---|---|

| Fingerless | Simple structure, Easy control | Poor adaptability | 83.5% | 10.3 s | 4.8% | [28,29,30,31,32,33,34] |

| Two-finger | Cost-effective, reliable | Limited stability | 82.3% | 7.8 s | NULL | [35,36,37,38,39,40,41,42,43,44,45] |

| Three-finger | Superior stability, Diverse grasps | Highly complex structure, Challenging to control | 84.2% | 6.5 s | 2.9% | [46,47,48,49,50,51,52] |

| Multiple fingers | Highly flexible, adaptable | Presents control challenges | 68.9% | 9.2 s | 4.6% | [53,54,55,56,57,58,59,60] |

| Types | Materials | Advantages | Disadvantages | Harvest Rate | Time | Damage Rate | References |

|---|---|---|---|---|---|---|---|

| Hard end-effector | steel, aluminum, hard plastics | High rigidity, precision, durable, stable | Heavy, Rigid, Damaging | 79.6% | 13.4 s | 9% | [29,35,36,37,41,42,50,51,53] [55,57] |

| Soft end-effector | silicone, elastic plastics | Deformable, lightweight, safe | Low rigidity, Weak endurance, Limited lifespan | 80.6% | 9.6 s | 3% | [26,37,40,41,44,48,52,54] [56,62] |

| Hard end-effector with elastic membrane | Inner rigid, soft outer membrane | Gentle on products, minimizes damage | Insensitive, Difficult production | 82.3% | 5.9 s | NULL | [39,42,46,47,49,58,59] |

| Types | Theory | Advantages | Disadvantages | Harvest Rate | Time | Damage Rate | References |

|---|---|---|---|---|---|---|---|

| Negative pressure | Utilizing the low-pressure difference in a vacuum environment to achieve the adsorption of objects. | Low damage | Low applicability: Suitable for objects with smooth surfaces and light weight. | 81 | 6.5 s | 5% | [26,45,46,47,58] |

| Clamping | Uses finger-generated friction to grasp. | Strong grasping force, Reliable Performance, Wide adaptability | Prone to damage, poor versatility | 82.6% | 5.9 s | 3.06% | [36,37,39,41,43,44,48,49,50,51] [52,56,59,66] |

| Cutting | Severs material by mechanical or thermal means | Wide adaptability and low manufacturing difficulty | Prone to damage, requiring regular maintenance | 77.43% | 12 s | NULL | [35,41,42,53,54,56,58] |

| Clamping and Cutting simultaneously | Severs material by mechanical or thermal means | Low damage and high efficiency | Low flexibility, cost high | 86.77% | 33.2 s | NULL | [30,42,55,57,67] |

| Types | Major Component | Advantages | Disadvantages | References |

|---|---|---|---|---|

| Electric | Motor | Flexible, easy to maintain, highly adaptable | High cost, Complex control | [29,37,39,41,42,46,50,51,52,54,55] [57,58,59,61] |

| Pneumatic | Air cylinder | Low damage, simple structure | Low applicability, low gripping force, and inability to perform precise operations. | [26,29,37,53,59] |

| Vacuum | Vacuum pump | Low damage, simple structure | Control complexity | [27,31,35,43,48,54,56,66] |

| Magnetic | Magnet | Non-contact, low maintenance | High fever, High cost, Complex control | [44] |

| Hydraulic | Hydraulic cylinder | High stability | Poor flexibility, low efficiency | [67] |

| Hybrid | Motor, cylinder | High accuracy, high flexibility | High control difficulty, high cost, complex system | [47,57,73,74] |

| Types | Cost | Maintenance | Response Speed | Precision | Applicability | References |

|---|---|---|---|---|---|---|

| Electric | high (700$~2000$) | low (10,000 h–20,000 h) | High and controllable Direct Current Motor (1000–10,000 RPM), Alternating Current Motor (750~3600 RPM), Stepping Motor (100~1000 RPM) | ±0.01 mm~±0.05 mm | high | [29,37,39,41,42,46,50,51,52,54,55] [57,58,59,61] |

| Pneumatic | low (40$~50$) | middle (4000 h~8000 h | High (0.1~1.5 m/s) | ±0.005 mm~±5 mm | middle | [26,29,37,53,59] |

| Vacuum | low (10$~30$) | low (10,000 h–20,000 h) | High and difficult to control (1.32 m3/h~80 m3/h) | 0.03 mbar~2 mbar | low | [27,31,35,43,48,54,56,66] |

| Magnetic | Low(40$~50$) | low (30,000 h~50,000 h) | High and controllable (0.1 ms~6 ms) | ±0.01 mm~±0.1 mm | middle | [44] |

| Hydraulic | Moderate to high (1000$~3000$) | high (NAS7~9) | 0.1 m/s~2 m/s | Displacement ±0.1 mm~±0.5 mm Speed (±0.5%~±1%) | low | [67] |

| Hybrid | The highest (3000$~5000$) | mid-to-high (5000 h~10,000 h) | 0.1~1.5 m/s | ±0.01 mm | high | [47,57,73,74] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ao, J.; Ji, W.; Yu, X.; Ruan, C.; Xu, B. End-Effectors for Fruit and Vegetable Harvesting Robots: A Review of Key Technologies, Challenges, and Future Prospects. Agronomy 2025, 15, 2650. https://doi.org/10.3390/agronomy15112650

Ao J, Ji W, Yu X, Ruan C, Xu B. End-Effectors for Fruit and Vegetable Harvesting Robots: A Review of Key Technologies, Challenges, and Future Prospects. Agronomy. 2025; 15(11):2650. https://doi.org/10.3390/agronomy15112650

Chicago/Turabian StyleAo, Jiaxin, Wei Ji, Xiaowei Yu, Chengzhi Ruan, and Bo Xu. 2025. "End-Effectors for Fruit and Vegetable Harvesting Robots: A Review of Key Technologies, Challenges, and Future Prospects" Agronomy 15, no. 11: 2650. https://doi.org/10.3390/agronomy15112650

APA StyleAo, J., Ji, W., Yu, X., Ruan, C., & Xu, B. (2025). End-Effectors for Fruit and Vegetable Harvesting Robots: A Review of Key Technologies, Challenges, and Future Prospects. Agronomy, 15(11), 2650. https://doi.org/10.3390/agronomy15112650