Elevated Nitrogen Fertilization Compromises Lodging Resistance in High-Quality, Late-Season Indica Rice Grown in Southern China

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Design

2.2. Sampling and Measurements

2.2.1. Yield and Yield Components

2.2.2. Mechanical Properties

2.2.3. Morphological Traits

2.2.4. Carbohydrate and Dry Matter Determination

2.2.5. Anatomical Traits

2.3. Data Processing

3. Results

3.1. Effects of Nitrogen Application Rate on Yield and Yield Components of High-Quality Late-Season Indica Rice

3.2. Effects of Nitrogen Application on Mechanical Properties

3.3. Effects of Nitrogen Application on Morphological Traits

3.4. Effects of Nitrogen on Dry Matter Accumulation and Allocation

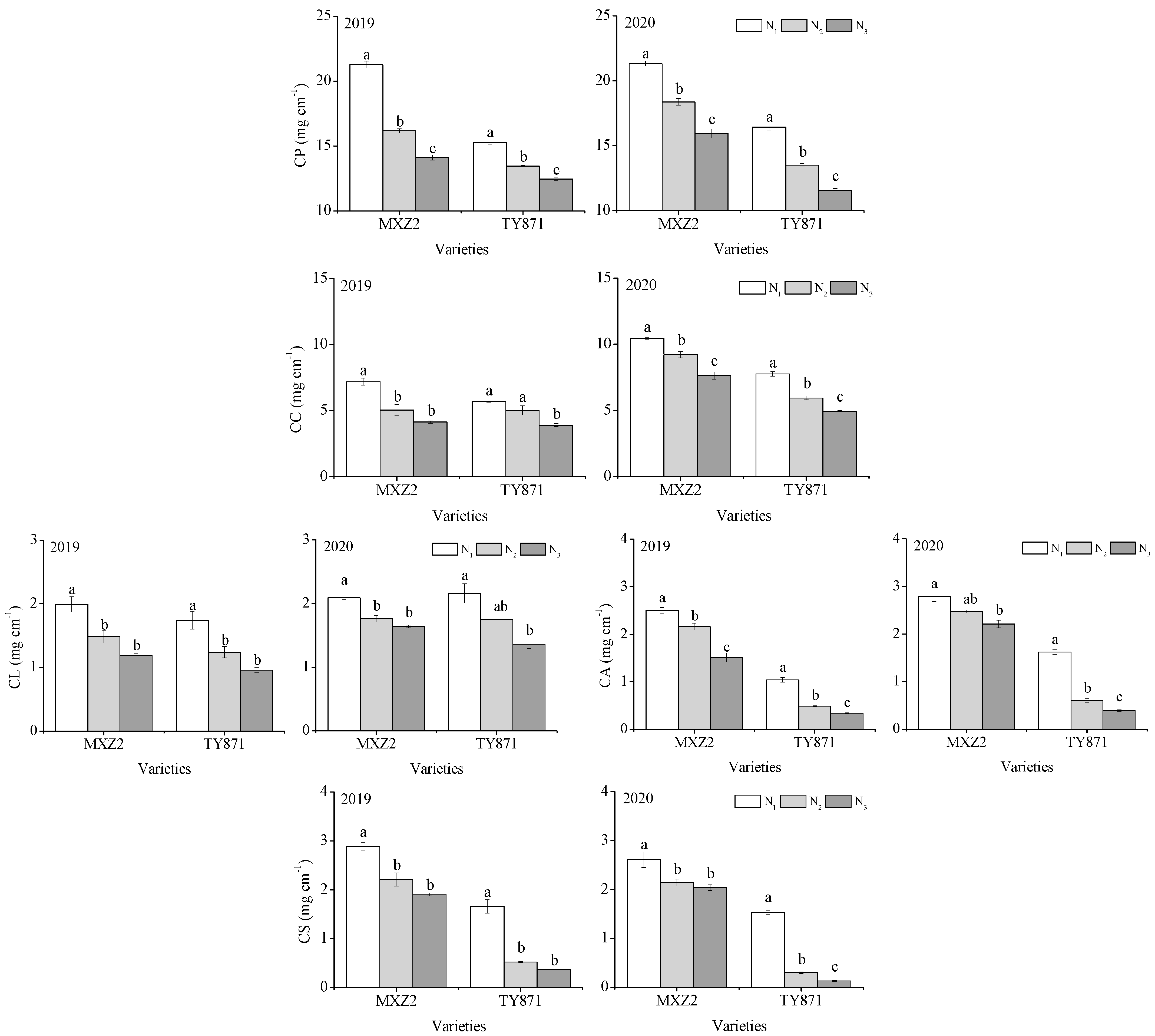

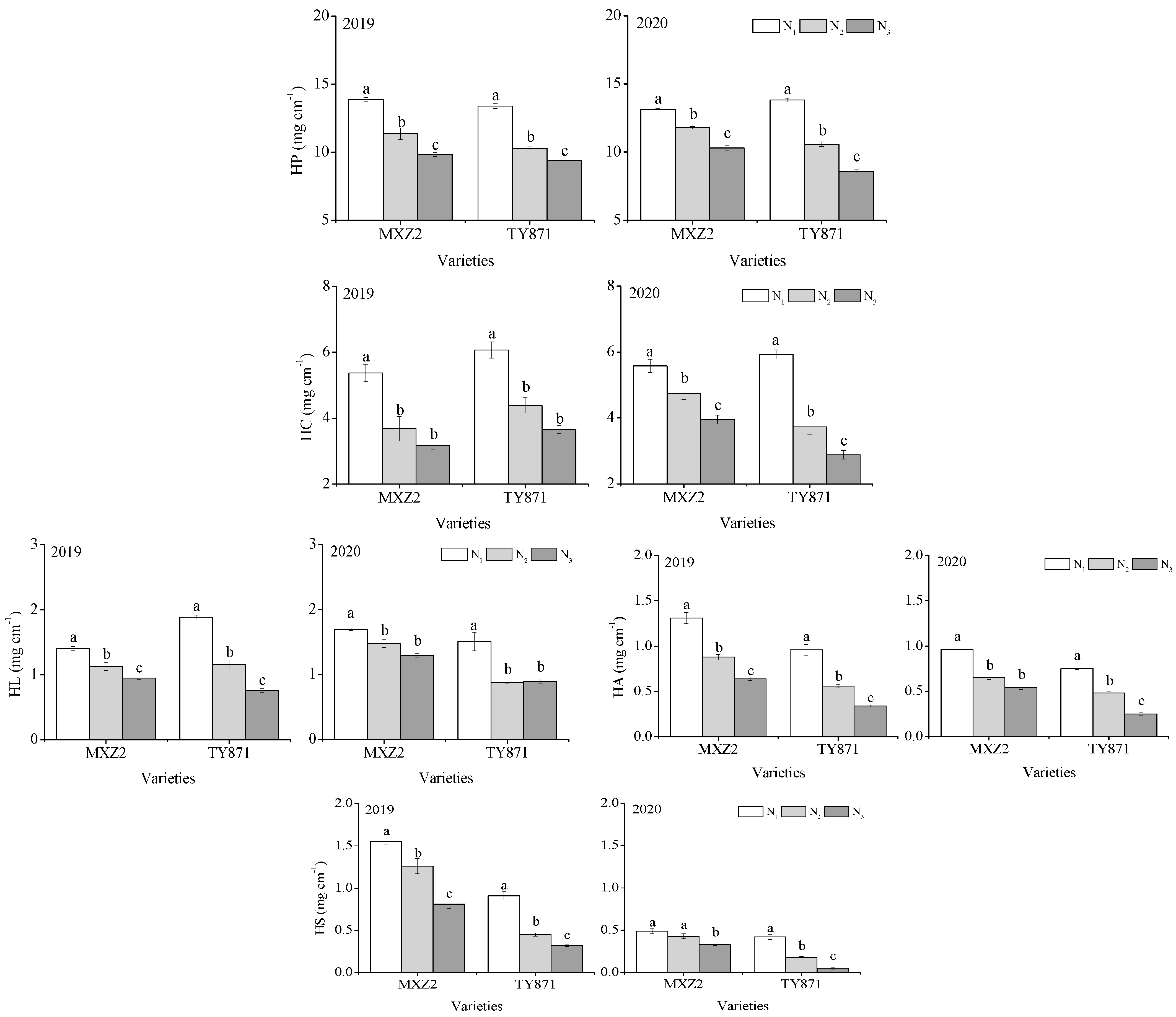

3.5. Effects of Nitrogen on Culm and Sheath Carbohydrates

3.6. Effects of Nitrogen on Anatomical Traits

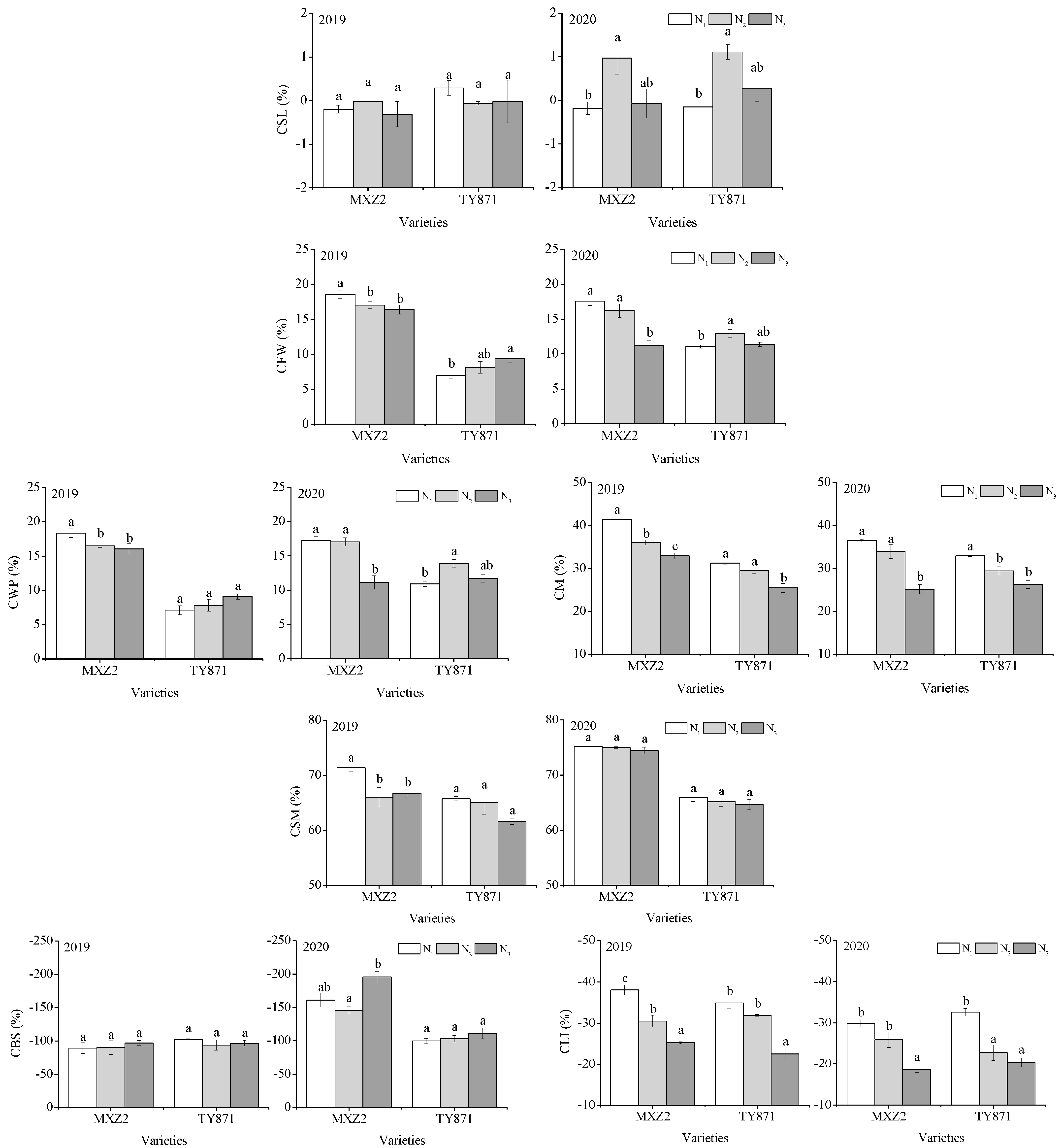

3.7. Effects of Nitrogen on Sheath Contribution Rate

4. Discussion

4.1. Elevated Nitrogen Increased Yield with a Slight Penalty in Lodging Resistance

4.2. Mechanism of Nitrogen Regulation on Lodging Resistance in Rice via Modulating Dry Matter Partitioning and Sheath Structural Properties

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fu, J.; Jian, Y.; Wang, X.; Li, L.; Ciais, P.; Zscheischler, J.; Wang, Y.; Tang, Y.; Müller, C.; Webber, H. Extreme rainfall reduces one-twelfth of China’s rice yield over the last two decades. Nat. Food 2023, 4, 416–426. [Google Scholar] [CrossRef] [PubMed]

- Alam, M.; Lou, G.; Abbas, W.; Osti, R.; Ahmad, A.; Bista, S.; Ahiakpa, J.K.; He, Y. Improving rice grain quality through ecotype breeding for enhancing food and nutritional security in Asia–Pacific region. Rice 2024, 17, 47. [Google Scholar] [CrossRef]

- Chen, X.; Cai, Y.; Yue, D. The research progress on floating rice cultivation and frontier topics: Technological evolution, ecological adaptation, and sustainable development pathways. Adv. Resour. Res. 2025, 5, 1757–1783. [Google Scholar]

- Li, Q.; Fu, C.; Liang, C.; Ni, X.; Zhao, X.; Chen, M.; Ou, L. Crop lodging and the roles of lignin, cellulose, and hemicellulose in lodging resistance. Agronomy 2022, 12, 1795. [Google Scholar] [CrossRef]

- Yadav, K.; Kumar, M.; Gulaiya, S.; Singh, N.; Singh, S.; Salar, A.; Joshi, M.; Pal, S.S.; Singh, P.P. Adverse impacts of lodging and strategies for management in cereal crops: A comprehensive review. Plant Arch. 2024, 24, 495–503. [Google Scholar] [CrossRef]

- Guha, P.K.; Magar, N.D.; Kommana, M.; Barbadikar, K.M.; Suneel, B.; Gokulan, C.; Lakshmi, D.V.; Patel, H.K.; Sonti, R.V.; Sundaram, R. Strong culm: A crucial trait for developing next-generation climate-resilient rice lines. Physiol. Mol. Biol. Plants 2024, 30, 665–686. [Google Scholar] [CrossRef]

- Mullangie, D.P.; Thiyagarajan, K.; Swaminathan, M.; Ramalingam, J.; Natarajan, S.; Govindan, S. Breeding resilience: Exploring lodging resistance mechanisms in rice. Rice Sci. 2024, 31, 659–672. [Google Scholar] [CrossRef]

- Rehman, M.; Luo, D.; Mubeen, S.; Pan, J.; Cao, S.; Saeed, W.; Chen, P. Progress in agronomic crops lodging resistance and prevention: A review. J. Agron. Crop Sci. 2024, 210, e12785. [Google Scholar] [CrossRef]

- Wu, J.; Liao, Q.; Shah, F.; Li, Z.; Tao, Y.; Wang, P.; Xiong, L.; Yuan, Q.; Wu, W. The potential role of nitrogen management in enhancing grain yield and lodging resistance of shanlan upland rice (Oryza sativa L.). Agronomy 2025, 15, 614. [Google Scholar] [CrossRef]

- Fan, G.; Li, J.; Wang, X.; Zheng, T.; Guo, X.; Chen, Y.; Wu, Z.; Yang, W. Lodging Resistance of Winter Wheat in Response to Nitrogen and Planting Density and Border Effect under Relay Intercropping Condition. Crop J. 2012, 38, 1307–1317. [Google Scholar] [CrossRef]

- Pan, J.; Zhao, J.; Liu, Y.; Huang, N.; Tian, K.; Shah, F.; Liang, K.; Zhong, X.; Liu, B. Optimized nitrogen management enhances lodging resistance of rice and its morpho-anatomical, mechanical, and molecular mechanisms. Sci. Rep. 2019, 9, 20274. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Z.; Wu, M.; Wang, Z.; Yao, L.; Wang, D.; Ma, X.; Zhao, G.; Wei, X.; Wu, Z. Regulation of Nitrogen Utilization and Lodging Resistance of Rice in Northeast China Through Continuous Straw Return and Nitrogen Fertilizer Application. Agronomy 2025, 15, 2043. [Google Scholar] [CrossRef]

- Wu, M.; Jiang, H.; Wei, Z.; Li, W.; Gao, K.; Wang, D.; Wei, X.; Tian, P.; Cui, J.; Di, Y. Influence of nitrogen application rate on stem lodging resistance rice under dry cultivation. Agronomy 2023, 13, 426. [Google Scholar] [CrossRef]

- Liu, F.; Zhou, F.; Wang, X.; Zhan, X.; Guo, Z.; Liu, Q.; Wei, G.; Lan, T.; Feng, D.; Kong, F. Optimizing nitrogen management enhances stalk lodging resistance and grain yield in dense planting maize by improving canopy light distribution. Eur. J. Agron. 2023, 148, 126871. [Google Scholar] [CrossRef]

- Gong, D.; Wang, Y.; Chen, Y.; Liu, X.; Yu, G. Effects of increased planting density and reduced nitrogen application on rice lodging resistance yield and quality. Sci. Rep. 2025, 15, 25524. [Google Scholar] [CrossRef]

- Mu, H.; Wang, Z.; Sun, L.; Huang, Y.; Song, Y.; Zhang, R.; Wu, Z.; Fu, K.; Duan, J.; Kang, G. Optimizing nitrogen fertilization and planting density management enhances lodging resistance and wheat yield by promoting carbohydrate accumulation and single spike development. Crop Sci. 2024, 64, 3461–3479. [Google Scholar] [CrossRef]

- Li, G.; Chen, X.; Zhou, C.; Yang, Z.; Zhang, C.; Huang, Z.; Pan, W.; Xu, K. Vascular bundle characteristics of different rice variety treated with nitrogen fertilizers and its relation to stem assimilates allocation and grain yield. Agriculture 2022, 12, 779. [Google Scholar] [CrossRef]

- Li, Y.; Huang, G.; Guo, Y.; Zhou, Y.; Duan, L. Coronatine enhances stalk bending resistance of maize, thickens the cell wall and decreases the area of the vascular bundles. Agronomy 2020, 10, 807. [Google Scholar] [CrossRef]

- Ou, X.; Cui, X.; Zhu, D.; Guo, L.; Liu, D.; Yang, Y. Lowering nitrogen and increasing potassium application level can improve the yield and quality of Panax notoginseng. Front. Plant Sci. 2020, 11, 595095. [Google Scholar] [CrossRef]

- Ookawa, T.; Hobo, T.; Yano, M.; Murata, K.; Ando, T.; Miura, H.; Asano, K.; Ochiai, Y.; Ikeda, M.; Nishitani, R. New approach for rice improvement using a pleiotropic QTL gene for lodging resistance and yield. Nat. Commun. 2010, 1, 132. [Google Scholar] [CrossRef]

- Wu, L.; Zhang, W.; Ding, Y.; Zhang, J.; Cambula, E.D.; Weng, F.; Liu, Z.; Ding, C.; Tang, S.; Chen, L. Shading contributes to the reduction of stem mechanical strength by decreasing cell wall synthesis in japonica rice (Oryza sativa L.). Front. Plant Sci. 2017, 8, 881. [Google Scholar] [CrossRef] [PubMed]

- Kamran, M.; Ahmad, I.; Wang, H.; Wu, X.; Xu, J.; Liu, T.; Ding, R.; Han, Q. Mepiquat chloride application increases lodging resistance of maize by enhancing stem physical strength and lignin biosynthesis. Field Crops Res. 2018, 224, 148–159. [Google Scholar] [CrossRef]

- Xu, H.; Wang, Z.; Xiao, F.; Yang, L.; Li, G.; Ding, Y.; Paul, M.J.; Li, W.; Liu, Z. Dynamics of dry matter accumulation in internodes indicates source and sink relations during grain-filling stage of japonica rice. Field Crops Res. 2021, 263, 108009. [Google Scholar] [CrossRef]

- Yang, J.; Zhang, J.; Wang, Z.; Zhu, Q.; Wang, W. Remobilization of carbon reserves in response to water deficit during grain filling of rice. Field Crops Res. 2001, 71, 47–55. [Google Scholar] [CrossRef]

- Liu, C.; Zheng, S.; Gui, J.; Fu, C.; Yu, H.; Song, D.; Shen, J.; Qin, P.; Liu, X.; Han, B. Shortened basal internodes encodes a gibberellin 2-oxidase and contributes to lodging resistance in rice. Mol. Plant 2018, 11, 288–299. [Google Scholar] [CrossRef]

- Liao, P.; Bell, S.M.; Chen, L.; Huang, S.; Wang, H.; Miao, J.; Qi, Y.; Sun, Y.; Liao, B.; Zeng, Y. Improving rice grain yield and reducing lodging risk simultaneously: A meta-analysis. Eur. J. Agron. 2023, 143, 126709. [Google Scholar] [CrossRef]

- Ju, C.; Liu, T.; Sun, C. Panicle nitrogen strategies for nitrogen-efficient rice varieties at a moderate nitrogen application rate in the lower reaches of the Yangtze River, China. Agronomy 2021, 11, 192. [Google Scholar] [CrossRef]

- Qin, L.; Wang, C.; Zhao, H.; Zhou, S.; Liu, K.; Liu, L. Impact of incorporating wheat straw together with basal nitrogen ratio on panicle formation and grain yield in rice. Sci. Rep. 2025, 15, 4093. [Google Scholar] [CrossRef]

- Li, Z.; Liu, F.; Wu, W. Optimising nitrogen management strategies to minimise lodging risk while sustaining high seed yield in rapeseed. Eur. J. Agron. 2023, 142, 126671. [Google Scholar] [CrossRef]

- Gai, D.; Wang, Y.; Li, H.; Shi, B.; Liu, Y.; Zhang, Q.; Geng, Y.; Guo, L.; Shao, X. Appropriate seeding rate facilitates the simultaneous enhancement of population yield and lodging resistance in direct-seeded rice. Front. Plant Sci. 2025, 16, 1622993. [Google Scholar] [CrossRef] [PubMed]

- Zhong, X.-H.; Liang, K.-M.; Huang, N.-R. Improving grain yield, nitrogen use efficiency and radiation use efficiency by dense planting, with delayed and reduced nitrogen application, in double cropping rice in South China. J. Integr. Agric. 2021, 20, 565–580. [Google Scholar] [CrossRef]

- Fu, Z. Study on the Physiological Basis of Efficient Nitrogen Utilization and Green Fertilization Strategy of Rice. Biosci. Methods 2025, 16, 202–215. [Google Scholar] [CrossRef]

- Chawla, R.; Sharma, S.K. Nitrogen fertilization of stone fruits: A comprehensive review. J. Plant Nutr. 2025, 48, 445–485. [Google Scholar] [CrossRef]

- Bacelar, E.; Pinto, T.; Anjos, R.; Morais, M.C.; Oliveira, I.; Vilela, A.; Cosme, F. Impacts of climate change and mitigation strategies for some abiotic and biotic constraints influencing fruit growth and quality. Plants 2024, 13, 1942. [Google Scholar] [CrossRef]

- Mehdi, F.; Galani, S.; Wickramasinghe, K.P.; Zhao, P.; Lu, X.; Lin, X.; Xu, C.; Liu, H.; Li, X.; Liu, X. Current perspectives on the regulatory mechanisms of sucrose accumulation in sugarcane. Heliyon 2024, 10, e27277. [Google Scholar] [CrossRef]

- Wang, Q.; Hu, J.; Yu, W.; Gu, L.; Liu, P.; Zhao, B.; Zhen, W.; Zhang, J.; Ren, B. Shading and waterlogging interactions exacerbate summer maize yield losses by reducing assimilate accumulation and remobilization processes. J. Integr. Agric. 2024; in press. [Google Scholar] [CrossRef]

- Yang, L.; Zhang, Y.-W.; Zhang, Y.-H. In situ measurements of winter wheat diurnal changes in photosynthesis and environmental factors reveal new insight into photosynthesis improvement by super-high-yield cultivation. J. Integr. Agric. 2021, 20, 527–539. [Google Scholar]

- Li, R.; Hu, D.; Ren, H.; Yang, Q.; Dong, S.; Zhang, J.; Zhao, B.; Liu, P. How delaying post-silking senescence in lower leaves of maize plants increases carbon and nitrogen accumulation and grain yield. Crop J. 2022, 10, 853–863. [Google Scholar] [CrossRef]

| Year | Variety | Nitrogen | Productive Panicles (No. m2) | Grains per Panicle (No.) | Percentage of Filled Grains (%) | 1000-Grain Weight (g) | Yield (t hm−2) |

|---|---|---|---|---|---|---|---|

| 2019 | MXZ2 | N1 | 335 ± 7.01 c | 125 ± 2.73 d | 83.3 ± 0.50 a | 18.3 ± 0.28 d | 7.96 ± 0.16 de |

| N2 | 383 ± 9.77 b | 117 ± 1.75 de | 82.9 ± 2.92 a | 17.8 ± 0.26 de | 8.84 ± 0.32 bc | ||

| N3 | 435 ± 6.27 a | 108 ± 1.92 ef | 79.2 ± 3.79 ab | 17.7 ± 0.12 e | 9.19 ± 0.12 ab | ||

| TY871 | N1 | 237 ± 6.44 f | 180 ± 2.49 b | 73.5 ± 2.14 bc | 23.1 ± 0.09 a | 8.28 ± 0.29 cd | |

| N2 | 256 ± 2.48 ef | 162 ± 4.25 c | 69.8 ± 0.42 c | 23.0 ± 0.14 ab | 9.52 ± 0.32 a | ||

| N3 | 301 ± 9.37 d | 156 ± 4.05 c | 69.0 ± 1.79 c | 22.8 ± 0.13 abc | 9.74 ± 0.10 a | ||

| 2020 | MXZ2 | N1 | 421 ± 12.4 a | 119 ± 6.19 de | 62.5 ± 0.51 d | 16.6 ± 0.07 f | 6.64 ± 0.11 g |

| N2 | 440 ± 11.1 a | 122 ± 3.16 d | 58.5 ± 3.07 de | 16.9 ± 0.24 f | 7.19 ± 0.08 fg | ||

| N3 | 448 ± 16.5 a | 103 ± 1.90 f | 50.9 ± 1.76 f | 15.9 ± 0.06 g | 5.27 ± 0.26 h | ||

| TY871 | N1 | 281 ± 8.25 de | 201 ± 3.50 a | 58.2 ± 2.01 de | 22.3 ± 0.14 c | 6.93 ± 0.14 fg | |

| N2 | 287 ± 5.72 d | 198 ± 4.20 a | 54.3 ± 1.98 ef | 22.5 ± 0.18 bc | 7.54 ± 0.19 ef | ||

| N3 | 298 ± 6.92 d | 177 ± 7.41 b | 43.7 ± 0.60 g | 22.6 ± 0.19 abc | 7.08 ± 0.25 fg | ||

| Three-way ANOVA | |||||||

| Year (Y) | 52.8 ** | 24.7 ** | 303 ** | 94.0 ** | 278 ** | ||

| Variety (V) | 654 ** | 697 ** | 42.7 ** | 2956 ** | 26.7 ** | ||

| Nitrogen (N) | 33.6 ** | 23.8 ** | 16.8 ** | 4.16 * | 13.4 ** | ||

| Y × V | 7.08 * | 32.3 ** | 5.43 * | 23.0 ** | 1.38 | ||

| Y × N | 11.6 ** | 3.47 * | 4.55 * | 2.10 | 20.8 ** | ||

| V × N | 1.87 | 1.22 | 0.20 | 3.99 * | 4.13 * | ||

| Y × V × N | 0.58 | 0.15 | 0.47 | 2.72 | 3.55 * | ||

| Year | Variety | Nitrogen | SL | FW | WP | M | SM | BS | LI |

|---|---|---|---|---|---|---|---|---|---|

| 2019 | MXZ2 | N1 | 89.3 ± 1.12 g | 14.0 ± 0.15 g | 1251 ± 3.26 f | 2552 ± 80.8 a | 23.0 ± 0.46 g | 1228 ± 84.0 a | 50.2 ± 1.73 i |

| N2 | 94.3 ± 0.48 f | 13.4 ± 0.10 h | 1265 ± 13.9 f | 2060 ± 8.74 d | 18.4 ± 1.29 hi | 1156 ± 84.8 a | 62.2 ± 0.63 h | ||

| N3 | 96.1 ± 0.82 f | 13.3 ± 0.10 h | 1278 ± 6.30 f | 1619 ± 40.5 g | 16.7 ± 0.45 i | 1021 ± 51.3 b | 79.6 ± 1.58 f | ||

| TY871 | N1 | 101 ± 0.08 e | 19.1 ± 0.25 a | 1938 ± 25.2 ab | 2539 ± 39.4 ab | 48.9 ± 0.08 a | 524 ± 10.1 de | 77.2 ± 1.15 f | |

| N2 | 104 ± 0.11 d | 18.6 ± 0.27 b | 1930 ± 27.9 ab | 2205 ± 20.3 c | 47.1 ± 2.18 a | 493 ± 14.7 e | 87.8 ± 0.48 e | ||

| N3 | 107 ± 0.63 c | 18.1 ± 0.06 c | 1938 ± 14.9 ab | 1891 ± 49.0 e | 36.6 ± 0.57 c | 528 ± 9.5 de | 103.5 ± 3.02 b | ||

| 2020 | MXZ2 | N1 | 102 ± 0.76 de | 14.9 ± 0.02 f | 1520 ± 11.0 e | 2131 ± 43.2 cd | 25.4 ± 0.95 f | 853 ± 26.4 c | 72.0 ± 1.98 g |

| N2 | 108 ± 0.59 c | 14.5 ± 0.27 f | 1568 ± 20.0 d | 1861 ± 12.7 ef | 22.3 ± 0.16 g | 903 ± 9.50 c | 84.8 ± 0.58 e | ||

| N3 | 109 ± 0.55 bc | 13.9 ± 0.09 g | 1519 ± 16.4 e | 1561 ± 33.4 g | 19.5 ± 0.32 h | 817 ± 31.6 c | 98.4 ± 3.00 c | ||

| TY871 | N1 | 107 ± 0.53 c | 17.7 ± 0.33 cd | 1894 ± 28.6 bc | 2429 ± 40.9 b | 41.0 ± 0.11 b | 597 ± 10.8 de | 79.1 ± 1.79 f | |

| N2 | 111 ± 0.75 b | 16.7 ± 0.07 e | 1854 ± 17.7 c | 2022 ± 12.0 d | 34.0 ± 0.43 d | 604 ± 11.9 de | 92.4 ± 0.47 d | ||

| N3 | 113 ± 0.44 a | 17.5 ± 0.15 d | 1973 ± 13.7 a | 1761 ± 42.5 f | 28.5 ± 0.50 e | 624 ± 25.6 d | 113 ± 2.46 a | ||

| Three-way ANOVA | |||||||||

| Year (Y) | 669 ** | 5.82 * | 170 ** | 67.8 ** | 49.2 ** | 16.3 ** | 222 ** | ||

| Variety (V) | 391 ** | 1797 ** | 3135 ** | 63.1 ** | 1517 ** | 363 ** | 399 ** | ||

| Nitrogen (N) | 98.7 ** | 23.3 ** | 3.125 | 333 ** | 127 ** | 1.99 | 363 ** | ||

| Y × V | 87.7 ** | 136 ** | 260 ** | 3.62 | 179 ** | 66.0 ** | 81.8 ** | ||

| Y × N | 1.16 | 2.10 | 0.83 | 4.98 * | 1.80 | 1.71 | 0.50 | ||

| V × N | 3.94 * | 1.80 | 6.68 ** | 1.73 | 17.7 ** | 4.07 * | 0.73 | ||

| Y × V × N | 0.04 | 7.16 ** | 7.29 ** | 6.79 ** | 4.81 * | 0.87 | 3.16 | ||

| Year | Variety | Nitrogen | Flag Leaf Angle (°) | Second Top Leaf Angle (°) | Third Top Leaf Angle (°) | Plant Height (cm) | Height of Gravity Center (cm) | Culm Diameter (mm) | Wall Thickness (mm) | Upper Internode Length (cm) | Lower Internode Length (cm) | Proportion of Upper Internode Length (%) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2019 | MXZ2 | N1 | 6.63 ± 0.45 e | 11.3 ± 1.00 g | 17.7 ± 0.89 de | 94.7 ± 0.61 f | 41.5 ± 0.62 h | 6.64 ± 0.03 g | 1.24 ± 0.01 e | 62.3 ± 0.55 h | 8.11 ± 0.63 bcd | 88.5 ± 0.87 cd |

| N2 | 7.70 ± 0.23 e | 13.4 ± 1.39 fg | 16.0 ± 0.45 ef | 100 ± 1.40 e | 45.4 ± 1.06 g | 6.22 ± 0.15 h | 1.07 ± 0.04 fg | 64.7 ± 0.86 g | 8.98 ± 0.49 bc | 87.8 ± 0.51 de | ||

| N3 | 8.63 ± 0.22 e | 14.1 ± 0.37 f | 13.8 ± 0.94 f | 102 ± 0.30 e | 47.2 ± 0.18 f | 6.10 ± 0.00 h | 1.03 ± 0.01 g | 67.6 ± 0.64 f | 8.54 ± 0.60 bcd | 88.8 ± 0.79 bcd | ||

| TY871 | N1 | 6.30 ± 0.68 e | 12.6 ± 1.05 fg | 14.5 ± 0.95 f | 106 ± 0.32 d | 45.2 ± 0.36 g | 7.68 ± 0.02 b | 2.07 ± 0.02 a | 73.3 ± 0.66 e | 7.33 ± 0.17 d | 91.0 ± 0.25 a | |

| N2 | 8.43 ± 1.20 e | 16.8 ± 0.42 e | 19.3 ± 0.87 d | 111 ± 1.17 c | 48.2 ± 0.90 ef | 7.26 ± 0.09 de | 1.76 ± 0.05 b | 76.0 ± 0.85 d | 7.59 ± 0.29 cd | 91.0 ± 0.30 a | ||

| N3 | 6.47 ± 1.00 e | 17.2 ± 0.50 e | 17.8 ± 0.38 de | 112 ± 0.13 c | 50.3 ± 0.25 cd | 7.07 ± 0.01 f | 1.65 ± 0.03 c | 79.0 ± 0.48 c | 7.99 ± 0.24 bcd | 90.9 ± 0.26 a | ||

| 2020 | MXZ2 | N1 | 13.5 ± 0.29 cd | 29.2 ± 0.35 b | 34.6 ± 0.53 a | 111 ± 0.89 c | 49.4 ± 0.35 de | 7.64 ± 0.06 b | 1.29 ± 0.02 e | 74.4 ± 0.59 de | 11.7 ± 0.45 a | 86.5 ± 0.35 e |

| N2 | 17.5 ± 1.63 b | 29.6 ± 1.00 ab | 34.2 ± 1.31 a | 116 ± 0.59 b | 52.5 ± 0.06 ab | 7.44 ± 0.01 cd | 1.23 ± 0.03 e | 79.2 ± 0.81 bc | 12.1 ± 0.10 a | 86.8 ± 0.19 e | ||

| N3 | 21.2 ± 0.49 a | 31.7 ± 0.52 a | 34.9 ± 2.90 a | 118 ± 0.59 ab | 53.9 ± 0.33 a | 7.15 ± 0.01 ef | 1.12 ± 0.02 f | 80.5 ± 0.93 bc | 11.6 ± 0.65 a | 87.4 ± 0.66 de | ||

| TY871 | N1 | 15.7 ± 1.84 bc | 19.8 ± 1.04 cd | 23.7 ± 0.87 b | 113 ± 0.14 c | 49.5 ± 0.33 de | 8.01 ± 0.01 a | 1.59 ± 0.02 c | 78.4 ± 0.25 c | 9.07 ± 0.62 b | 89.7 ± 0.64 abc | |

| N2 | 15.2 ± 1.53 bc | 21.8 ± 0.77 c | 23.1 ± 0.36 bc | 116 ± 0.28 b | 51.6 ± 0.38 bc | 7.66 ± 0.02 b | 1.41 ± 0.01 d | 81.5 ± 1.31 ab | 8.29 ± 0.56 bcd | 90.8 ± 0.70 a | ||

| N3 | 12.4 ± 1.19 d | 18.8 ± 0.88 de | 20.5 ± 1.16 cd | 119 ± 0.63 a | 53.6 ± 0.30 a | 7.45 ± 0.07 c | 1.29 ± 0.04 e | 83.2 ± 0.50 a | 9.17 ± 0.77 b | 90.1 ± 0.77 ab | ||

| Three-way ANOVA | ||||||||||||

| Year (Y) | 249 ** | 523 ** | 373 ** | 764 ** | 337 ** | 428 ** | 84.8 ** | 412 ** | 63.2 ** | 12.7 ** | ||

| Variety (V) | 10.7 ** | 61.3 ** | 75.6 ** | 214 ** | 23.3 ** | 347 ** | 833 ** | 254 ** | 47.2 ** | 88.2 ** | ||

| Nitrogen (N) | 4.28 * | 9.41 ** | 1.71 | 96.4 ** | 91.6 ** | 83.5 ** | 98.5 ** | 50.9 ** | 0.36 | 0.55 | ||

| Y × V | 4.78 * | 177 ** | 118 ** | 134 ** | 35.0 ** | 105 ** | 235 ** | 84.9 ** | 13.1 ** | 1.40 | ||

| Y × N | 0.43 | 3.39 | 0.90 | 0.63 | 1.26 | 1.32 | 4.07 * | 1.23 | 0.64 | 0.96 | ||

| V × N | 12.6 ** | 2.69 | 2.18 | 0.50 | 0.91 | 0.57 | 10.2 ** | 0.25 | 1.48 | 1.25 | ||

| Y × V × N | 6.06 ** | 3.18 | 6.32 ** | 0.39 | 0.03 | 0.45 | 0.43 | 0.53 | 0.11 | 0.01 | ||

| Year | Variety | Nitrogen | Culm-Sheath Dry Weight (g No.−1) | Leaf Dry Weight (g No.−1) | Panicle Dry Weight (g No.−1) | Culm-Sheath Dry Weight Proportion (%) | Leaf Dry Weight Proportion (%) | Panicle Dry Weight Proportion (%) | Panicle-Culm Diameter Ratio (g cm−1) | Panicle Weight Per Unit Culm Diameter and Plant Height (×10−2 g cm−2) |

|---|---|---|---|---|---|---|---|---|---|---|

| 2019 | MXZ2 | N1 | 1.75 ± 0.03 cd | 0.68 ± 0.01 h | 1.94 ± 0.02 fg | 40.1 ± 0.32 d | 15.6 ± 0.18 e | 44.3 ± 0.48 d | 2.93 ± 0.03 d | 3.10 ± 0.04 d |

| N2 | 1.61 ± 0.01 e | 0.73 ± 0.00 g | 2.09 ± 0.03 de | 36.3 ± 0.23 e | 16.5 ± 0.18 cd | 47.2 ± 0.41 c | 3.37 ± 0.13 c | 3.36 ± 0.18 c | ||

| N3 | 1.44 ± 0.01 f | 0.79 ± 0.01 cde | 2.07 ± 0.02 ef | 33.5 ± 0.26 g | 18.4 ± 0.20 ab | 48.2 ± 0.07 c | 3.39 ± 0.03 c | 3.33 ± 0.04 c | ||

| TY871 | N1 | 1.90 ± 0.02 ab | 0.80 ± 0.01 bcde | 3.11 ± 0.07 b | 32.9 ± 0.49 g | 13.8 ± 0.29 g | 53.4 ± 0.64 b | 4.04 ± 0.08 b | 3.82 ± 0.09 b | |

| N2 | 1.77 ± 0.02 cd | 0.83 ± 0.01 ab | 3.37 ± 0.09 a | 29.8 ± 0.39 h | 14.0 ± 0.36 fg | 56.2 ± 0.63 a | 4.64 ± 0.08 a | 4.18 ± 0.07 a | ||

| N3 | 1.61 ± 0.01 e | 0.85 ± 0.02 a | 3.38 ± 0.08 a | 27.7 ± 0.40 i | 14.7 ± 0.17 f | 57.6 ± 0.45 a | 4.76 ± 0.12 a | 4.24 ± 0.11 a | ||

| 2020 | MXZ2 | N1 | 1.92 ± 0.02 a | 0.71 ± 0.01 gh | 1.52 ± 0.02 i | 46.3 ± 0.19 a | 17.2 ± 0.23 c | 36.5 ± 0.11 g | 2.00 ± 0.02 f | 1.80 ± 0.03 g |

| N2 | 1.85 ± 0.01 b | 0.77 ± 0.00 ef | 1.68 ± 0.04 h | 43.1 ± 0.29 b | 18.1 ± 0.25 b | 38.9 ± 0.54 f | 2.27 ± 0.06 e | 1.96 ± 0.06 fg | ||

| N3 | 1.80 ± 0.01 c | 0.82 ± 0.01 abc | 1.70 ± 0.01 h | 41.4 ± 0.02 c | 19.1 ± 0.18 a | 39.5 ± 0.18 f | 2.38 ± 0.02 e | 2.02 ± 0.03 fg | ||

| TY871 | N1 | 1.93 ± 0.04 a | 0.73 ± 0.02 fg | 1.92 ± 0.05 g | 42.3 ± 0.89 bc | 16.1 ± 0.26 de | 41.6 ± 1.03 e | 2.39 ± 0.06 e | 2.12 ± 0.06 f | |

| N2 | 1.74 ± 0.02 d | 0.78 ± 0.03 de | 2.23 ± 0.04 cd | 36.8 ± 0.59 e | 16.5 ± 0.68 cd | 46.8 ± 0.99 c | 2.92 ± 0.04 d | 2.50 ± 0.03 e | ||

| N3 | 1.64 ± 0.02 e | 0.81 ± 0.01 bcd | 2.26 ± 0.04 c | 34.8 ± 0.10 f | 17.2 ± 0.05 c | 48.0 ± 0.14 c | 3.05 ± 0.06 d | 2.56 ± 0.04 e | ||

| Three-way ANOVA | ||||||||||

| Year (Y) | 177 ** | 0.85 | 789 ** | 1058 ** | 123 ** | 836 ** | 1135 ** | 1196 ** | ||

| Variety (V) | 13.4 ** | 37.8 ** | 1005 ** | 713 ** | 158 ** | 651 ** | 510 ** | 214 ** | ||

| Nitrogen (N) | 212 ** | 40.6 ** | 29.8 ** | 242 ** | 34.3 ** | 67.6 ** | 72.0 ** | 22.1 ** | ||

| Y × V | 154 ** | 31.2 ** | 183 ** | 4.05 | 11.5 ** | 10.3 ** | 72.6 ** | 16.7 ** | ||

| Y × N | 8.73 ** | 0.26 | 0.40 | 1.57 | 0.66 | 0.67 | 0.76 | 0.11 | ||

| V × N | 4.810 * | 2.58 | 2.78 | 1.11 | 5.02 * | 3.12 | 3.97 * | 2.03 | ||

| Y × V × N | 7.25 ** | 0.14 | 0.02 | 7.47 ** | 0.96 | 2.34 | 0.12 | 0.24 | ||

| Culm | Sheath | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| CP | CC | CL | CA | CS | HP | HC | HL | HA | HS | |

| Year (Y) | 47.8 ** | 359 ** | 50.3 ** | 99.7 ** | 7.76 * | 0.01 | 0.48 | 6.18 * | 69.5 ** | 621 ** |

| Variety (V) | 1446 ** | 174 ** | 9.37 ** | 1991 ** | 1022 ** | 60.7 ** | 0.05 | 21.7 ** | 171 ** | 350 ** |

| Nitrogen (N) | 756 ** | 132 ** | 65.1 ** | 225 ** | 182 ** | 655 ** | 130 ** | 147 ** | 233 ** | 141 ** |

| Y × V | 34.8 ** | 76.2 ** | 2.64 | 7.29 * | 1.74 | 0.18 | 25.0 ** | 63.7 ** | 5.24 * | 101 ** |

| Y × N | 3.46 * | 0.79 | 0.93 | 3.55 * | 0.80 | 3.60 * | 0.27 | 7.04 ** | 6.60 ** | 25.4 ** |

| V × N | 44.1 ** | 1.96 | 0.93 | 15.5 ** | 16.2 ** | 19.0 ** | 4.35 * | 21.5 ** | 0.51 | 6.00 ** |

| Y × V × N | 31.1 ** | 5.28 * | 1.18 | 16.0 ** | 2.45 | 14.7 ** | 3.24 | 5.03 * | 1.14 | 7.11 ** |

| Year | Variety | Nitrogen | Culm | Sheath | Culm Area (×104 μm2) | Sheath Area (×104 μm2) | Pith Cavity Area (×104 μm2) | Pith Cavity Area Ratio (%) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Number of Large Vascular Bundles | Number of Small Vascular Bundles | Large Vascular Bundle Area (×104 μm2) | Small Vascular Bundle Area (×104 μm2) | Number of Large Vascular Bundles | Number of Small Vascular Bundles | Large Vascular Bundle Area (×104 μm2) | Small Vascular Bundle Area (×104 μm2) | |||||||

| 2019 | MXZ2 | N1 | 30.8 ± 0.73 cde | 30.3 ± 0.73 cd | 1.60 ± 0.05 ab | 0.40 ± 0.02 e | 21.3 ± 0.67 abc | 21.7 ± 1.09 ab | 1.10 ± 0.07 cd | 0.34 ± 0.00 g | 1013 ± 27.6 cde | 1127 ± 47.2 def | 738 ± 4.80 j | 23.9 ± 0.76 f |

| N2 | 29.5 ± 0.58 e | 29.2 ± 0.44 d | 1.59 ± 0.05 ab | 0.45 ± 0.02 de | 20.2 ± 0.60 c | 20.8 ± 0.73 b | 1.06 ± 0.08 d | 0.37 ± 0.02 fg | 962 ± 30.0 defg | 1076 ± 16.0 ef | 823 ± 8.60 i | 25.3 ± 0.42 ef | ||

| N3 | 31.8 ± 0.33 bcd | 31.0 ± 0.29 bcd | 1.43 ± 0.05 b | 0.48 ± 0.02 cd | 21.3 ± 0.44 abc | 21.3 ± 0.17 ab | 1.15 ± 0.05 bcd | 0.35 ± 0.02 g | 866 ± 24.4 fg | 1015 ± 46.8 f | 928 ± 35.5 gh | 29.4 ± 0.54 bc | ||

| TY871 | N1 | 33.7 ± 0.44 a | 33.3 ± 0.44 a | 1.49 ± 0.09 ab | 0.57 ± 0.02 b | 22.3 ± 1.01 ab | 22.2 ± 1.09 ab | 1.27 ± 0.04 abcd | 0.43 ± 0.01 cdef | 1208 ± 25.4 ab | 1822 ± 30.2 a | 1224 ± 5.59 e | 26.9 ± 0.60 de | |

| N2 | 32.3 ± 0.17 abcd | 31.8 ± 0.44 abc | 1.53 ± 0.07 ab | 0.61 ± 0.03 b | 20.8 ± 0.60 bc | 21.0 ± 0.87 ab | 1.40 ± 0.05 a | 0.44 ± 0.02 bcde | 1138 ± 71.3 bc | 1758 ± 29.2 ab | 1330 ± 28.5 d | 29.5 ± 0.36 bc | ||

| N3 | 33.5 ± 0.76 ab | 33.0 ± 0.58 ab | 1.59 ± 0.05 ab | 0.75 ± 0.01 a | 22.2 ± 0.60 abc | 22.2 ± 0.73 ab | 1.43 ± 0.03 a | 0.46 ± 0.01 bcd | 1060 ± 34.8 cd | 1703 ± 12.2 abc | 1446 ± 32.2 c | 32.5 ± 0.67 a | ||

| 2020 | MXZ2 | N1 | 31.0 ± 0.76 cde | 30.2 ± 1.09 cd | 1.65 ± 0.04 ab | 0.40 ± 0.03 e | 21.5 ± 0.29 abc | 21.3 ± 0.44 ab | 1.14 ± 0.09 bcd | 0.36 ± 0.02 g | 994 ± 52.5 cdef | 1241 ± 16.4 d | 864 ± 8.40 hi | 24.5 ± 0.17 f |

| N2 | 30.7 ± 0.73 de | 30.3 ± 0.60 cd | 1.56 ± 0.05 ab | 0.46 ± 0.00 de | 21.0 ± 0.50 bc | 20.8 ± 0.60 b | 1.26 ± 0.03 abcd | 0.38 ± 0.01 efg | 906 ± 58.7 efg | 1188 ± 56.2 de | 962 ± 3.74 g | 28.4 ± 0.87 cd | ||

| N3 | 29.5 ± 0.76 e | 29.8 ± 0.73 cd | 1.58 ± 0.07 ab | 0.42 ± 0.04 de | 21.3 ± 0.33 abc | 21.3 ± 0.33 ab | 1.21 ± 0.06 abcd | 0.41 ± 0.04 defg | 820 ± 30.0 g | 1076 ± 71.9 ef | 1055 ± 35.4 f | 32.4 ± 0.22 a | ||

| TY871 | N1 | 33.2 ± 0.33 ab | 33.3 ± 0.33 a | 1.71 ± 0.15 a | 0.54 ± 0.04 bc | 21.0 ± 0.76 bc | 20.7 ± 0.73 b | 1.36 ± 0.13 ab | 0.51 ± 0.03 ab | 1304 ± 34.7 a | 1769 ± 59.5 ab | 1502 ± 20.8 c | 26.7 ± 0.27 e | |

| N2 | 32.5 ± 0.58 abc | 31.7 ± 1.01 abc | 1.51 ± 0.14 ab | 0.70 ± 0.05 a | 20.7 ± 0.67 bc | 20.3 ± 0.44 b | 1.31 ± 0.08 abc | 0.49 ± 0.02 abc | 1212 ± 84.6 ab | 1688 ± 42.4 bc | 1622 ± 34.0 b | 30.5 ± 0.83 b | ||

| N3 | 33.5 ± 0.29 ab | 32.7 ± 0.88 ab | 1.72 ± 0.06 a | 0.49 ± 0.02 cd | 23.2 ± 1.30 a | 23.2 ± 1.20 a | 1.40 ± 0.16 a | 0.54 ± 0.04 a | 1129 ± 46.8 bc | 1624 ± 30.4 c | 1778 ± 33.2 a | 32.6 ± 0.33 a | ||

| Three-way ANOVA | ||||||||||||||

| Year (Y) | 0.41 | 0.08 | 2.82 | 7.07 * | 0.04 | 0.33 | 1.02 | 11.6 ** | 0.47 | 0.37 | 213 ** | 15.9 ** | ||

| Variety (V) | 54.7 ** | 39.5 ** | 0.25 | 133 ** | 2.11 | 0.68 | 19.4 ** | 68.2 ** | 75.8 ** | 636 ** | 1586 ** | 57.9 ** | ||

| Nitrogen (N) | 2.87 | 2.64 | 0.55 | 9.12 ** | 3.80 * | 2.73 | 1.01 | 2.19 | 10.7 ** | 10.5 ** | 73.7 ** | 121 ** | ||

| Y × V | 0.10 | 0.02 | 0.27 | 2.93 | 0.39 | 0.10 | 1.43 | 2.31 | 4.41 * | 11.4 ** | 33.1 ** | 8.65 ** | ||

| Y × N | 2.35 | 0.82 | 1.24 | 16.3 ** | 0.70 | 0.88 | 0.08 | 0.61 | 0.11 | 0.25 | 0.30 | 2.80 | ||

| V × N | 0.18 | 0.63 | 1.72 | 0.50 | 0.88 | 1.24 | 0.08 | 0.55 | 0.02 | 0.12 | 1.34 | 1.65 | ||

| Y × V × N | 2.35 | 0.65 | 0.38 | 6.62 ** | 0.91 | 0.56 | 1.11 | 0.09 | 0.01 | 0.07 | 0.35 | 0.92 | ||

| Treatment | CSL | CFW | CWP | CM | CSM | CBS | CLI |

|---|---|---|---|---|---|---|---|

| Year (Y) | 5.62 * | 3.50 | 9.85 ** | 18.4 ** | 52.7 ** | 120 ** | 58.1 ** |

| Variety (V) | 1.69 | 302 ** | 260 ** | 107 ** | 152 ** | 58.4 ** | 0.56 |

| Nitrogen (N) | 5.11 * | 7.50 ** | 8.87 ** | 87.6 ** | 8.17 ** | 7.21 ** | 95.8 ** |

| Y × V | 0.04 | 69.9 ** | 65.3 ** | 32.9 ** | 27.5 ** | 82.8 ** | 1.84 |

| Y × N | 5.53 * | 9.77 ** | 12.4 ** | 2.1 | 3.51 * | 4.36 * | 1.05 |

| V × N | 0.27 | 20.2 ** | 19.2 ** | 4.64 * | 1.52 | 3.501 * | 0.07 |

| Y × V × N | 0.38 | 0.79 | 1.12 | 3.81 * | 2.06 | 2.28 | 5.08 * |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, L.; Lv, R.; Zhang, Y.; Fang, Y.; Yi, S.; Pan, X.; Zeng, Y.; Shang, Q. Elevated Nitrogen Fertilization Compromises Lodging Resistance in High-Quality, Late-Season Indica Rice Grown in Southern China. Agronomy 2025, 15, 2451. https://doi.org/10.3390/agronomy15112451

Guo L, Lv R, Zhang Y, Fang Y, Yi S, Pan X, Zeng Y, Shang Q. Elevated Nitrogen Fertilization Compromises Lodging Resistance in High-Quality, Late-Season Indica Rice Grown in Southern China. Agronomy. 2025; 15(11):2451. https://doi.org/10.3390/agronomy15112451

Chicago/Turabian StyleGuo, Lin, Rujie Lv, Yunhan Zhang, Yuan Fang, Simin Yi, Xiaohua Pan, Yongjun Zeng, and Qingyin Shang. 2025. "Elevated Nitrogen Fertilization Compromises Lodging Resistance in High-Quality, Late-Season Indica Rice Grown in Southern China" Agronomy 15, no. 11: 2451. https://doi.org/10.3390/agronomy15112451

APA StyleGuo, L., Lv, R., Zhang, Y., Fang, Y., Yi, S., Pan, X., Zeng, Y., & Shang, Q. (2025). Elevated Nitrogen Fertilization Compromises Lodging Resistance in High-Quality, Late-Season Indica Rice Grown in Southern China. Agronomy, 15(11), 2451. https://doi.org/10.3390/agronomy15112451