Abstract

To demonstrate the feasibility and improve the implementation of laser weeding, a static movable lift-adjustable closed fiber laser weeding device and system have been developed, followed by experiments and performance evaluations. Physical experiments were conducted on the energy required for laser cutting of weed stems, targeting four common larger weeds (Chenopodium album, Amaranthus spinosus, Setaria viridis, and Eleusine indica) in farmland and orchards. At the same irradiation distances, the energy required to cut the same type of large weed generally increases with increasing distances and stem diameters but decreases with increasing irradiation time. The variance of stems’ power density after irradiation was larger and the values were more dispersed for Chenopodium album and Setaria viridis weeds, and the values were relatively scattered, while the power density values of Amaranthus spinosus and Eleusine indica weeds were more concentrated. When the irradiation time was 10 s, the 3.892 W/mm2 laser was sufficient to eliminate weeds and plants with the irradiation distances of 2 m. The 2.47 W/mm2 laser was more effective, as it killed weeds within a distance of 1 m in less than 1 s. This work demonstrates the feasibility of the laser weeding device and system that can completely cut off the stems of large weeds, and this technology has the potential to promote sustainable agriculture.

1. Introduction

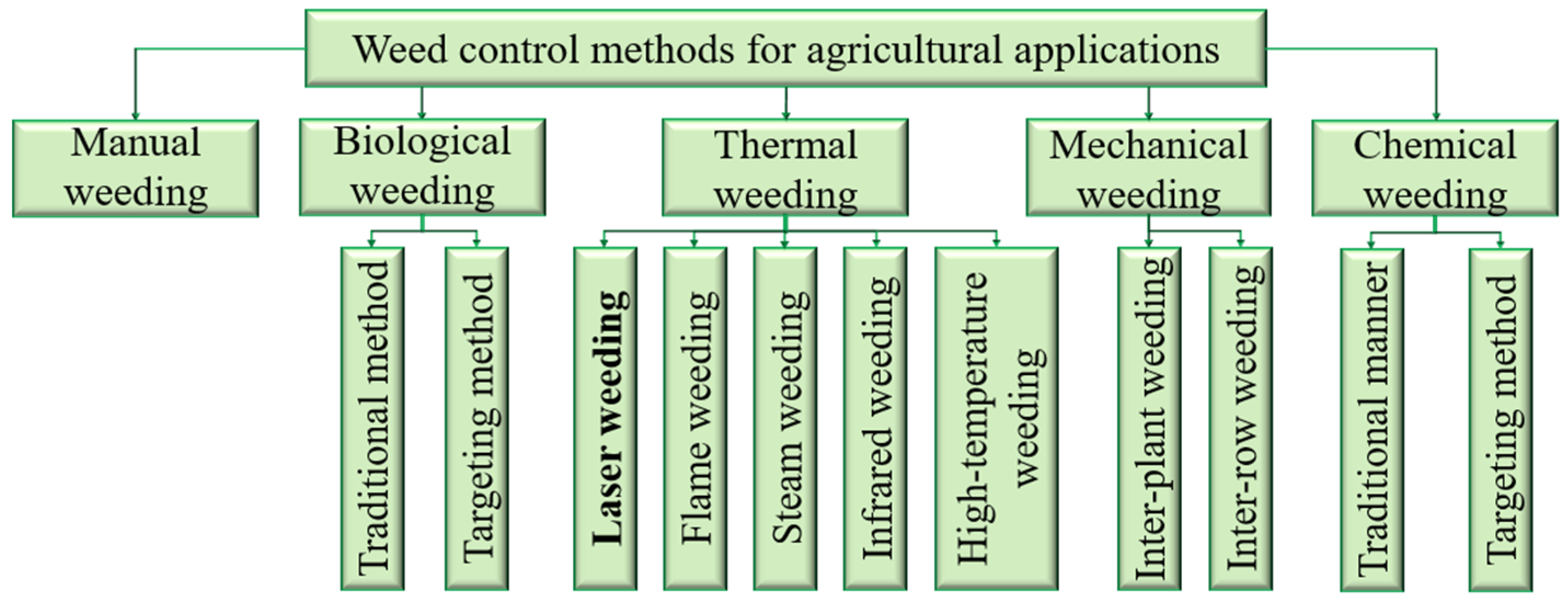

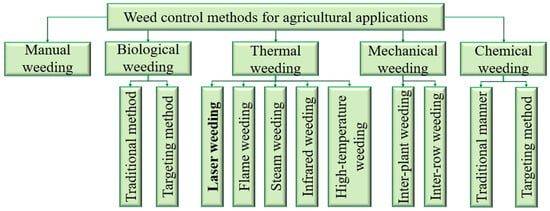

Weeds in farmland are a component of agricultural ecosystems, which directly or indirectly affect agricultural production. Weeds are one of the most significant yield-reducing factors for crop production worldwide, and they are an important factor affecting the orchards and farmland crops, limiting yield and quality by competing for nutrients, sunlight, and space [1]. At present, the main methods of weed control in farmland and orchards are manual weeding, currently biological control, thermal weed control, mechanical weed control, and chemical weed control [2,3,4], as shown in Figure 1. Among them, mechanical weeding and chemical weeding are the most common, while thermal weeding is a high-tech method developed in recent years, especially laser weeding technology [5]. Unlike chemical and mechanical weed control, laser weeding only exposes a small area of the field to treatment. Laser weeding leaves no chemicals in the field after the treatment and does not move the soil, which effectively protects the ecological environment in the field.

Figure 1.

Classification of weeding methods.

Laser weeding is a new low-cost and low environmental pollution weed control method. It delays re-growth and weakens and kills weeds [6,7]. At present, the widespread application of chemical pesticides in weed control has attracted great public attention to their negative impacts on the environment and human health [8]. Herbicides, as the most commonly used pesticides, can threaten agricultural safety and influence the water and soil resources, human and animal health, non-target plants, and ecosystem function and structure [9]. Laser weeding is recognized as an alternative thermal method for nonchemical weeding, and it has been considered as an efficient method of physical weeding in selective weed control strategies [10]. The principle of using laser weeding is to assume that the laser beam can directly transfer heat energy to the weeds, heating and killing the organs or cells inside the weeds, thereby inhibiting the growth of the weed. In addition, considering energy density and biological effects, it is possible to aim the laser beam directly at the tips or stalks of weeds, thus cutting them off to achieve a direct weed-killing effect.

Laser weeding holds great promise, as it uses a highly mobile focused beam of infrared light to thermally disrupt cell membranes in the weed leaves and shoots. The beam can be controlled easily by computer and can significantly reduce the energy needed for thermal weed control. To precisely control the laser beam and perform efficient and effective laser weeding, various manipulation approaches have been investigated by domestic and foreign experts. In terms of laser weeding equipment and systems, Xiong et al. designed and tested a novel dual-gimbal laser weeding robot prototype capable of detecting weeds in indoor environments, carrying lasers to target weeds, and also controlling the platform in real time realizing weeding continuously [11]. H. Zhu et al. verified the feasibility of blue light laser weed control and the optimal weed control laser dose for this experiment, a YOLOX-based blue light laser weed control robot was designed, and the YOLOX neural network was used to identify small targets with significant effect and improve the outdoor weed identification rate [12]. M. Wang et al. proposed a novel laser weeding gimbal based on a two-degrees-of-freedom 5-revolute rotational parallel manipulator to perform a dynamic interrow laser weeding operation, and the effectiveness of the proposed dynamic interrow weeding mechanism was evaluated in a real field trial [10]. E. S. Nadimi et al. successfully designed and developed a test setup to simulate the dynamic field conditions where a vehicle can be employed; this project aimed to accurately estimate and reconstruct the growth point of the weed using a stereo vision system, and it concluded that a laser weeding system can be a potential replacement for the traditional herbicide weeding system [13]. Second, in experimental research on laser cutting weeds, Mwitta et al. conducted three reaction experiments on weeds exposed to diode laser treatment and found that diode lasers have the potential to be an effective weed-controlling tool, and the weed stem diameter, laser power, treatment duration, and distances between laser and weed were all statistically significant in weed mortality [14]. Heisel et al. used the He–Ne laser as a novel non-destructive technique to measure weed stems, and the relationship between plant dry weight and laser energy was analyzed using two different non-linear dose–response regression models, indicating that it would be possible to optimize laser cutting by measuring stem thickness before cutting [15]. Wöltjen et al. carried out a study on the interaction of laser light and dicotyledonous plants represented by Echinochloa crus-galli and Nicotiana tabacum, in which the application of lasers as an alternative thermal method for the nonchemical control of weeds was investigated [16]. Overall, the application of laser radiation as a weed control method showed promising results, especially in the area of effectiveness and energy efficiency for non-chemical weed control.

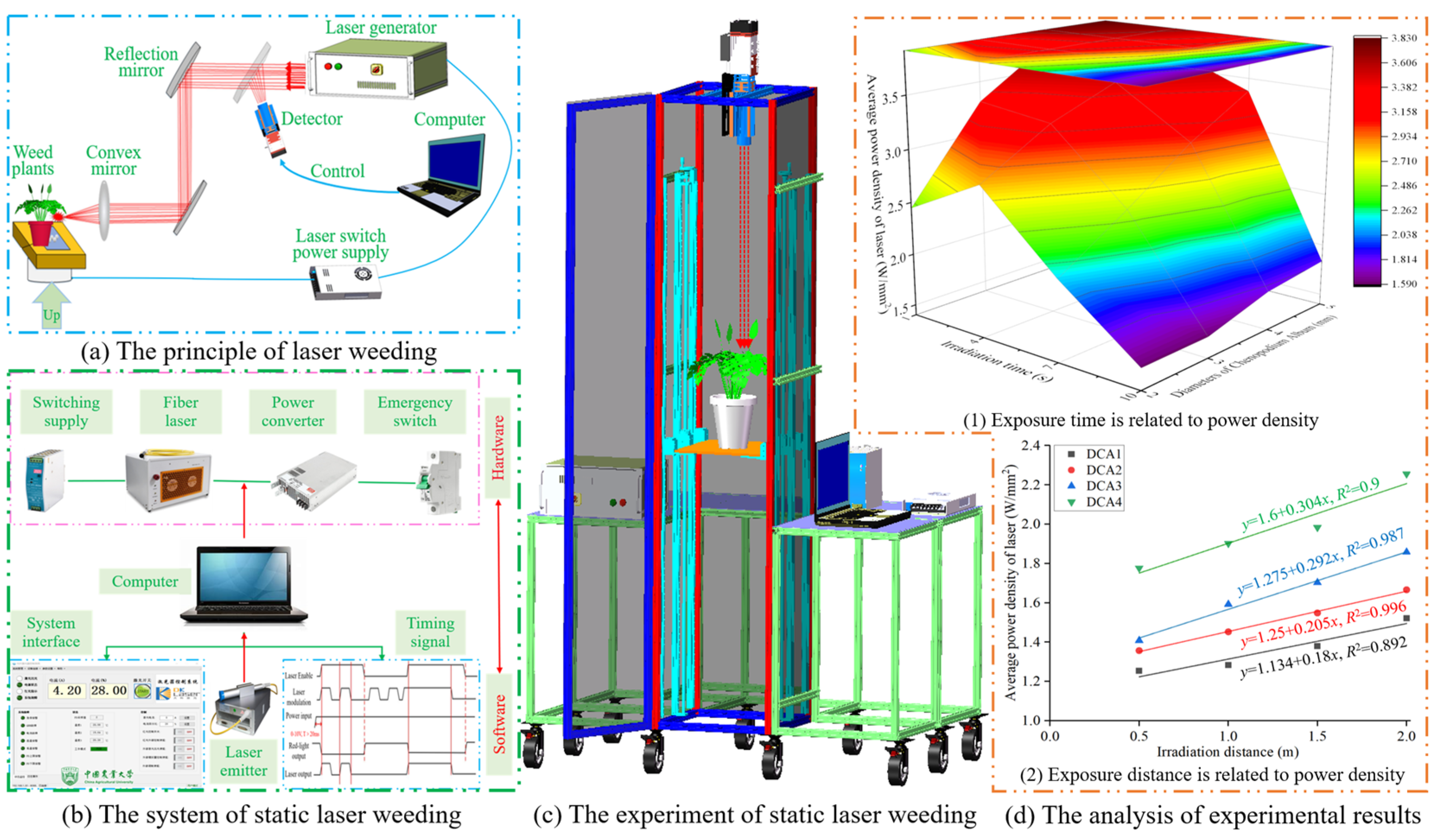

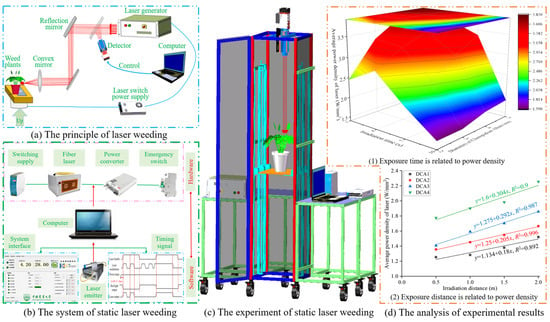

A robust method has been developed for evaluating the effectiveness of using laser patterns over green biomass that deliver preliminary results on pattern and speed effect. Research on laser weeding to date has primarily focused on early growth stage weeds and the ability of this approach to control larger weeds remains unknown. This article investigates the impact of a 500 W, 1080 nm fiber laser as a non-contact tool for the control of larger weeds in farmland and orchards. As shown in Figure 2, the study specifically designed a static laser weeding device and its system and explored the energy required to cut four common larger weeds (Chenopodium album, Amaranthus spinosus, Setaria viridis, and Eleusine indica).

Figure 2.

Overview.

2. Materials and Methods

2.1. The Device and System for Laser Weeding

2.1.1. Overview

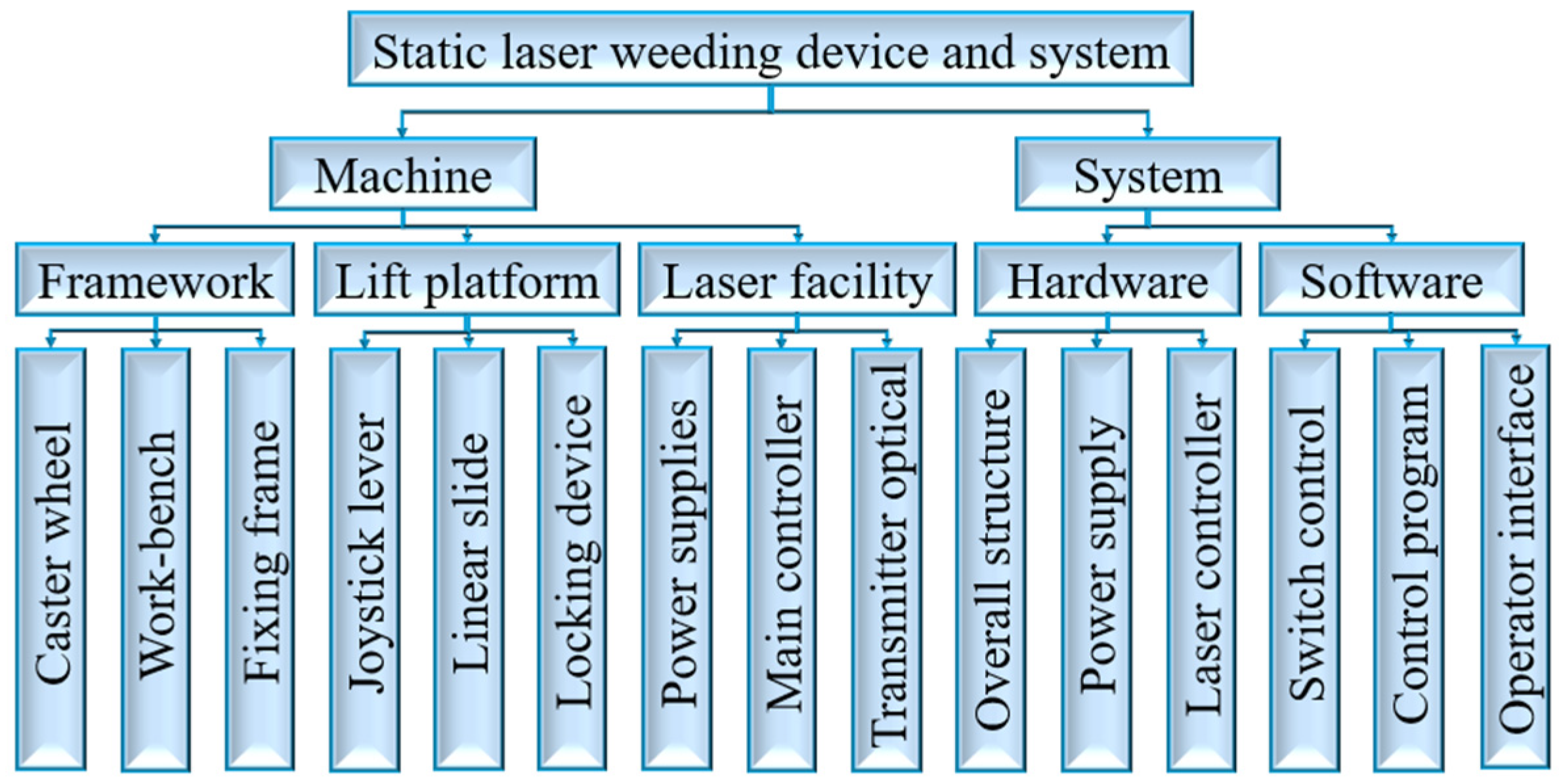

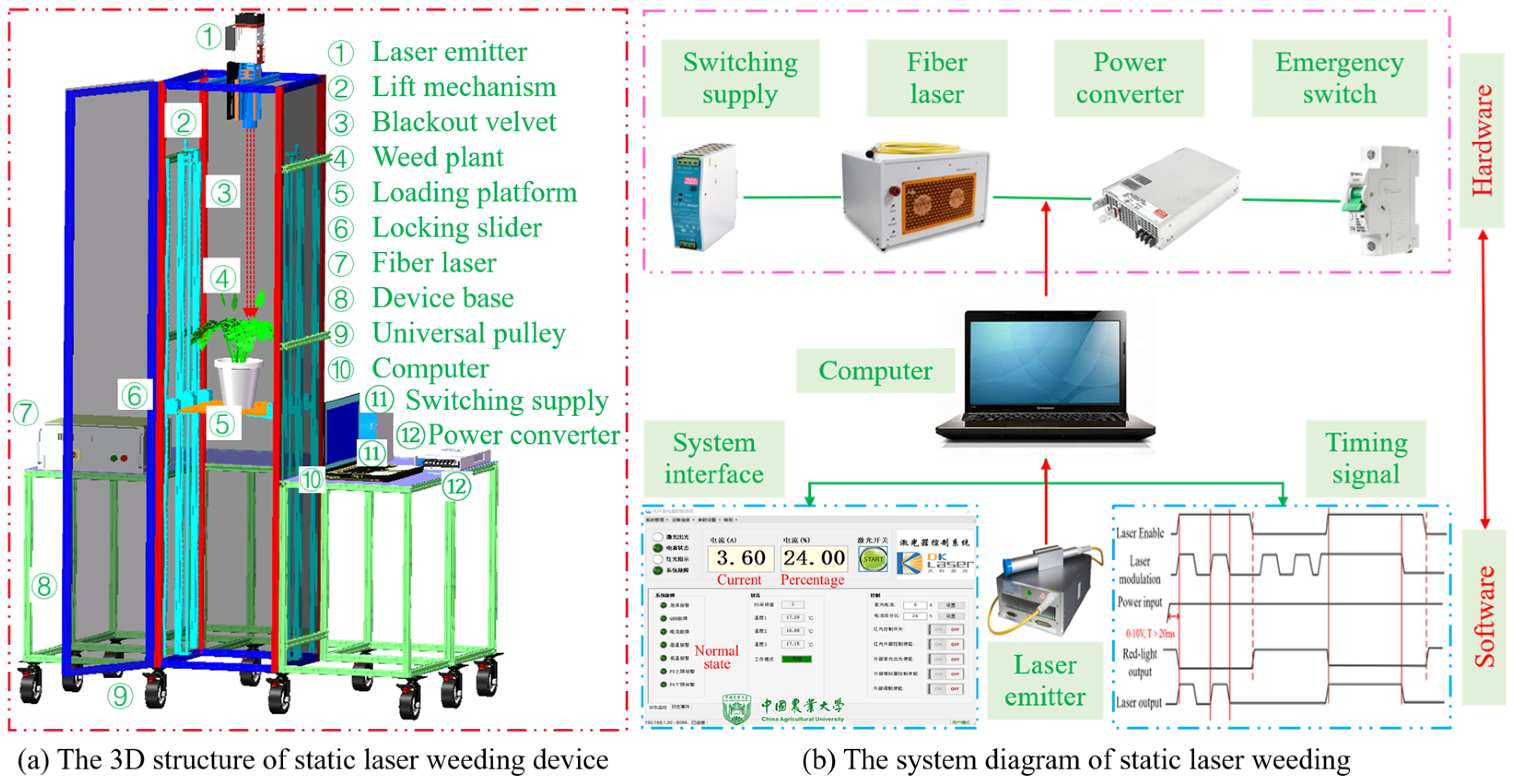

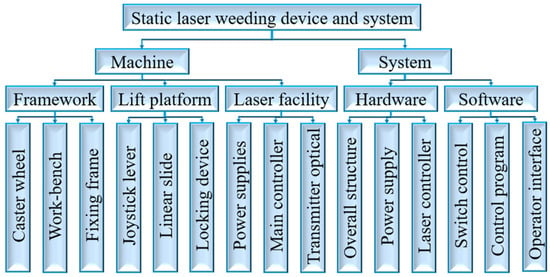

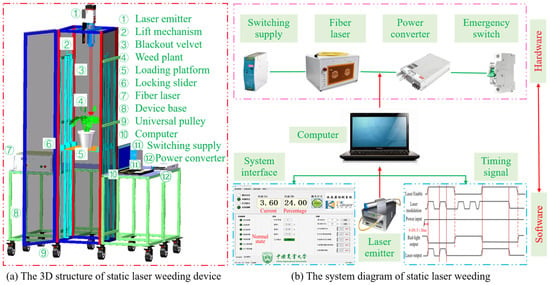

The effect of the laser beam on the weed plants depends on physical parameters (e.g., laser wavelengths, beam diameters, and doses) [17,18] and biological factors (e.g., plant species, plant size, and developmental stage) [15,19,20]. These factors may also be crucial for the effect of laser beams on non-target organisms and should be investigated. It is possible to quantify the cutting of plant stems by a laser beam in contrast to mechanical cutting. Therefore, this study aimed to design and test in the laboratory a novel prototype laser weeding device and system, along with its possibility and feasibility. Firstly, a static movable lift-adjustable closed laser weeding device and system have been constructed using the principles of fiber laser and mechanical modular design theory. The core working components were mainly divided into two parts: machine and system. The structure of the static laser weeding device and system is shown in Figure 3. The mechanical structure comprised three substructures, a framework, a lift platform, and a laser facility system, and the laser weeding system comprised mainly hardware and software.

Figure 3.

Overall scheme design of the static laser weeding device and system.

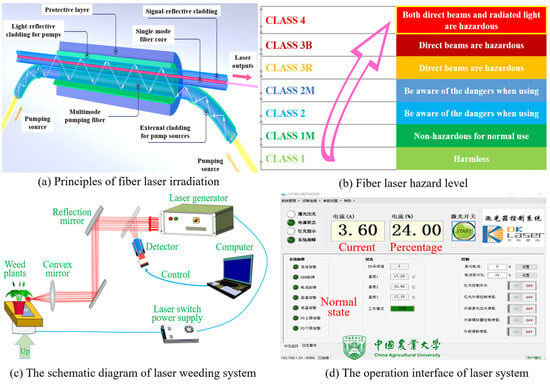

2.1.2. Laser Weeding System

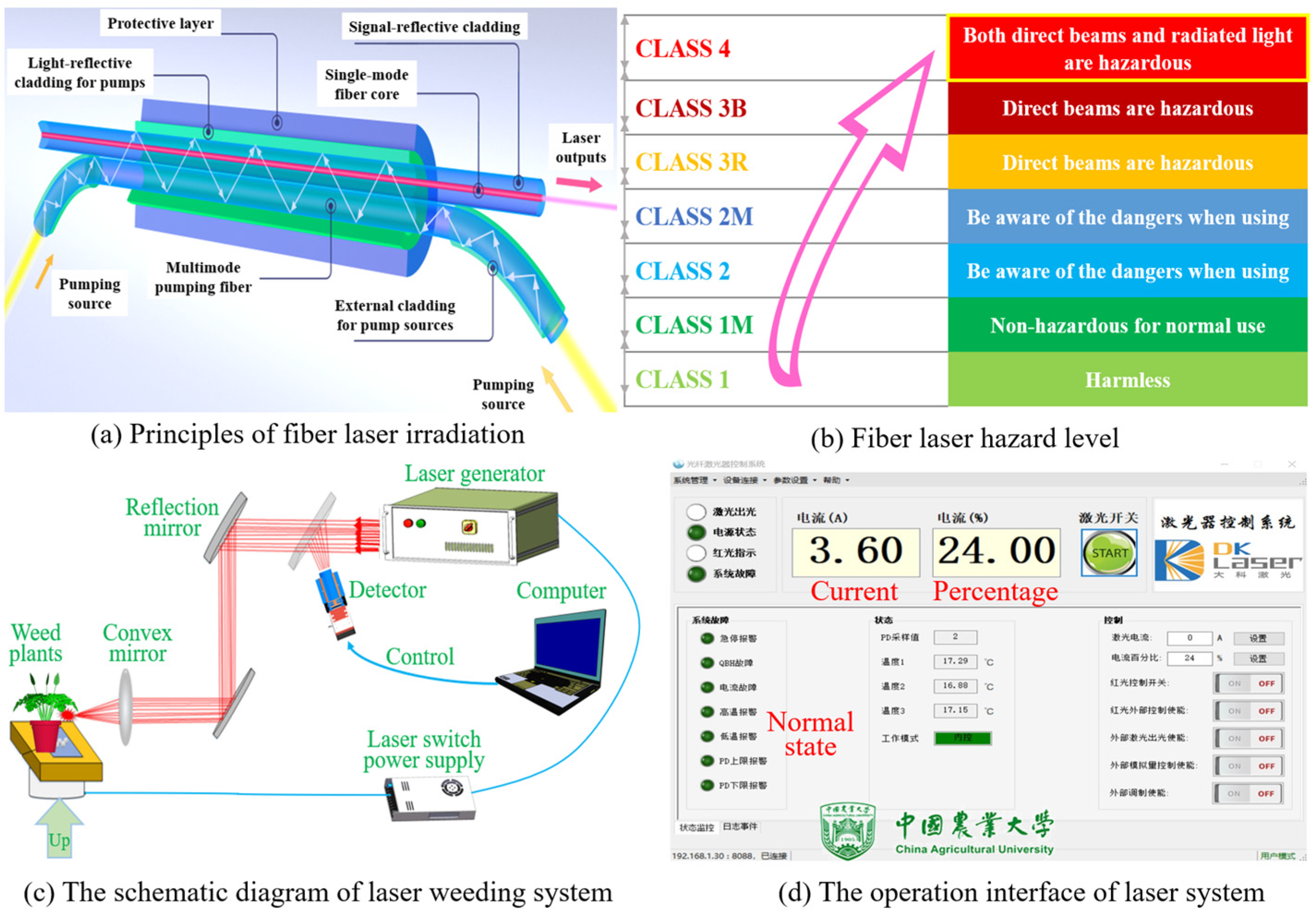

The laser is an optical instrument that can provide monochromatic coherent light via optical amplification using the stimulated emission of electromagnetic radiation [21]. The laser is powered by electricity and can reduce CO2 emissions compared to commonly used thermal weed control methods. The common practice of chemical and mechanical weed control can alter the soil structure or properties of most farmland, with the risk of affecting non-target organisms and the environment negatively [22,23]. In most cases, fiber lasers with a wavelength of 1080 nm are used. Their spectral characteristics are more suitable for plant crops and can be configured for high-power applications. As shown in Figure 4a, the fiber laser usually consists of an energy source, a protective layer, a pumping fiber, and a single-mode fiber core. From preliminary studies on laser weeding doses [24,25], a single-mode continuous fiber laser (DK-YSM 500, HUNAN DK LASER CO., LTD., Yueyang, China) was chosen, and the fiber laser system properties are listed in Table 1. The laser output power was varied via pulse modulation; the laser was more stable in the middle of its performance range rather than towards the limits of its range.

Figure 4.

The structural principle and performance of laser weeding system.

Table 1.

Parameters and variables of the fiber laser system.

Figure 4 shows the whole hardware and software assembly of the laser weeding system architecture. The laser source is a red laser pointer with a wavelength of 1080 nm, and the red laser pointer is rotated to aim the target. The laser system consists of a switch power supply, a laser generator, a detector, a computer, a reflection, and a convex mirror. It should be noted that a red diode pilot laser was installed on the fiber laser system to provide the double-checked aiming point [26]. The working principle is mainly powered by a power supply to the laser generator. The electrical signal is transmitted to the detector and the laser is irradiated onto the weeds through a reflector. The opening and closing of the laser and the output size are controlled by the computer’s system software.

2.1.3. Laser Weeding Device

As shown in Figure 5, the frame for the laser housing and supports is constructed out of 30 × 30 mm t-slot extruded aluminum tubing, the dimensions of the device frame are 500 × 500 × 2500 mm, and there is a workbench with a width of 500 mm below it. The device is mainly composed of a lift mechanism, a loading platform, and a device base, and the three-dimensional structure is completed by the software SOLIDWORKS 2023. The laser emitter is fixed directly above the frame, and the emitted laser directly irradiates the weed plants on the loading platform directly below. The height of the loading is adjusted by the lift mechanism on both sides to complete the irradiation distance setting. To reduce the adverse damage and effects caused by the laser in the experiment, the entire frame is covered with blackout velvet.

Figure 5.

The 3D structure of static laser weeding device and system.

2.2. The Static Laser Weeding Experiment

Laser weeding is a potentially environmentally friendly weed control method, mainly succeeding by focusing high-energy laser beams to kill weeds or cutting off stems to hinder growth [27,28,29]. Some studies have shown that the dose–response effects depend on the weed species being treated [15,30]. The technology was used to conduct cutting experiments on the stems of weeds, to achieve the research goal of killing weeds and efficient weed control. Technically, laser-based weeding depends on the amount of laser energy doses, which are necessary for the lethal damage of detected larger weeds. Hence, the objective of the study was to investigate the structural parameters (i.e., stem diameter) of laser cutting in four different weed plants, as well as the energy or power doses required for operational parameters (irradiation distances and time), and to design a laser weed damage model. With this model, laser-weeding applications could be controlled and steered in the future.

2.2.1. Weed Plants

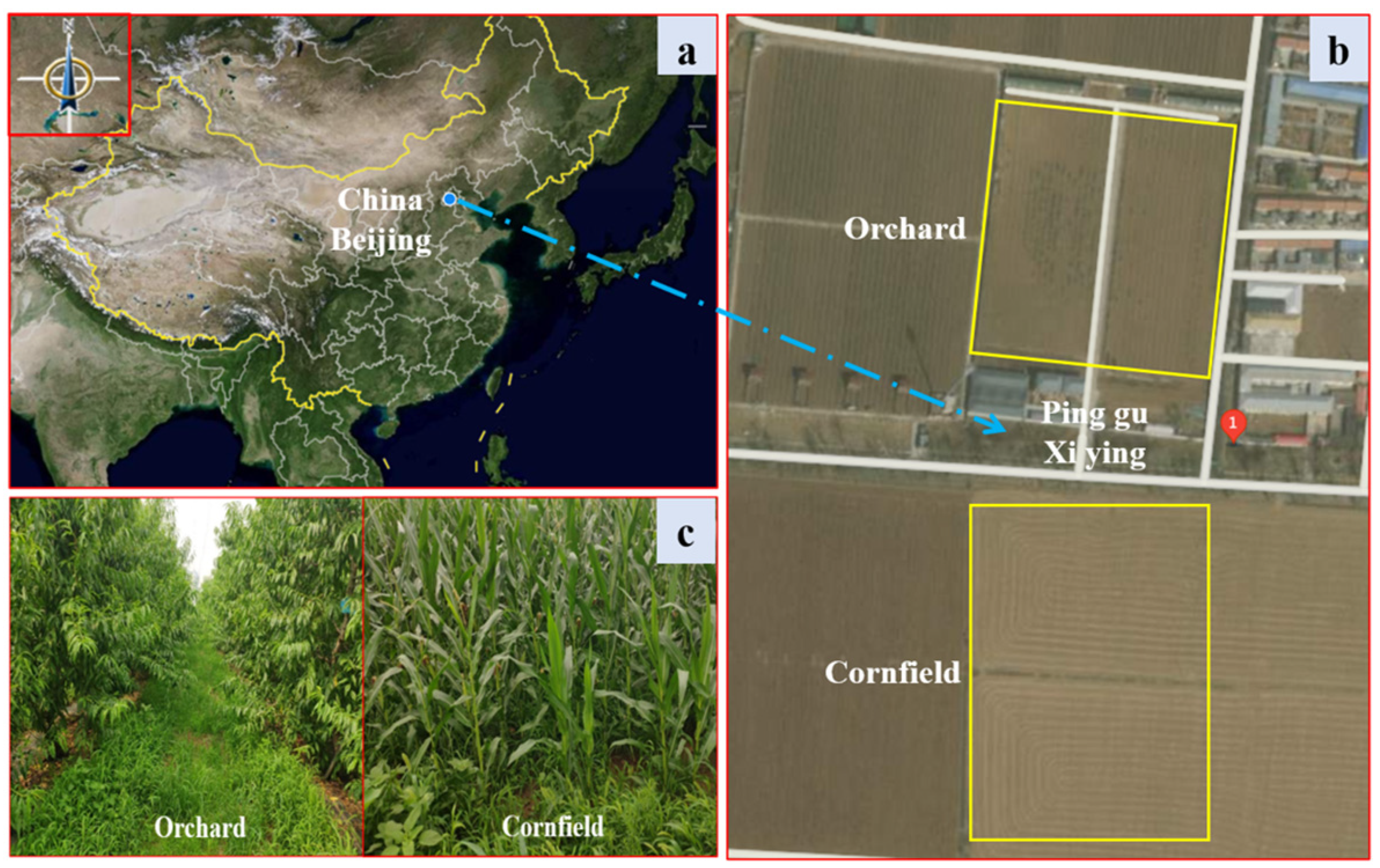

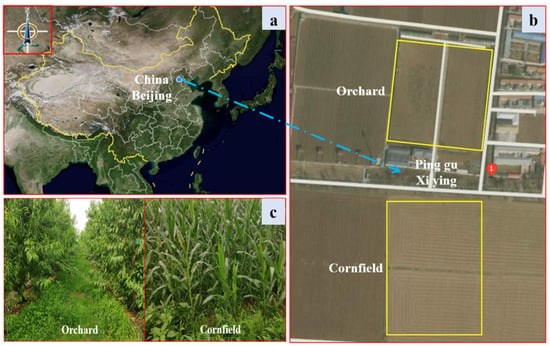

This article conducted a series of experiments carried out in the laboratory of the College of Agricultural Unmanned System, China Agricultural University. The weed samples were all selected from the Xiying Smart Orchard and farmland in Beijing, China, as shown in Figure 6.

Figure 6.

Geographic location of the experimental orchard and cornfield in this study. (a) Location of Beijing, China; (b) Location of Orchard and farmland; (c) The state of Orchard and farmland.

The effectiveness of laser weeding treatment depends on the wavelength, laser power, exposure time, and spot size [31,32]. Four common and uniformly sized weeds were selected as experimental subjects, including Chenopodium album plants, Amaranthus spinosus plants, Setaria viridis plants, and Eleusine indica plants. They were transplanted with soil into plastic pots filled with moist soil and grown in a natural environment (temperature = 18–22 °C, relative air humidity = 46–50%). In this study, all weed samples were labeled with plant labels, as shown in Table 2.

Table 2.

The four weed species and parameters.

2.2.2. Laser Weed Cutting Experiment

Laser treatment to kill weeds requires cutting off the stems to be effective [25,32]. For the experimental setup, individually grown weeds in pots were positioned manually in the beam path center below the laser emitter, and we used laser lateral irradiation to cut the weed stems. The laser systems were driven at different output powers to determine the minimum effective laser doses needed to cut the irradiated weed stems. The spot size of the fiber laser can fully irradiate the designated position of the transverse stems’ center of the weeds. Further research on these parameters is necessary to investigate the effect of the weed growth stage, the laser irradiation distances, and time on the degree of plant damage; two experiments were conducted in this paper. To evaluate the laser weeding device and system performance, two sets of weeding experiments were performed. Each treatment was repeated six times, and the average value was taken as the result. Experiment 1: The four types of weed stems were irradiated by a 500 W fiber laser at distances of 0.5, 1, 1.5, and 2 m. The cutting time was 10 s, and a total of 96 experiments were conducted. The diameter of the laser beam was about 12 mm, and simultaneous monitoring ensured that the laser beam could completely cut off the stems of the weeds. After laser illuminating, we observed a cross-section of the irradiation area after laser cutting the stems. Experiment 2: The operation method is the same as Experiment 1, with the irradiation time of 1, 4, 7, and 10 s. The laser irradiation distance was 1 m, and the number of experiments was also 96. All valid experiments were conducted a total of 192 times, and the parameters and abbreviations associated with the experiments are shown in Table 3.

Table 3.

Experimental parameters and variables.

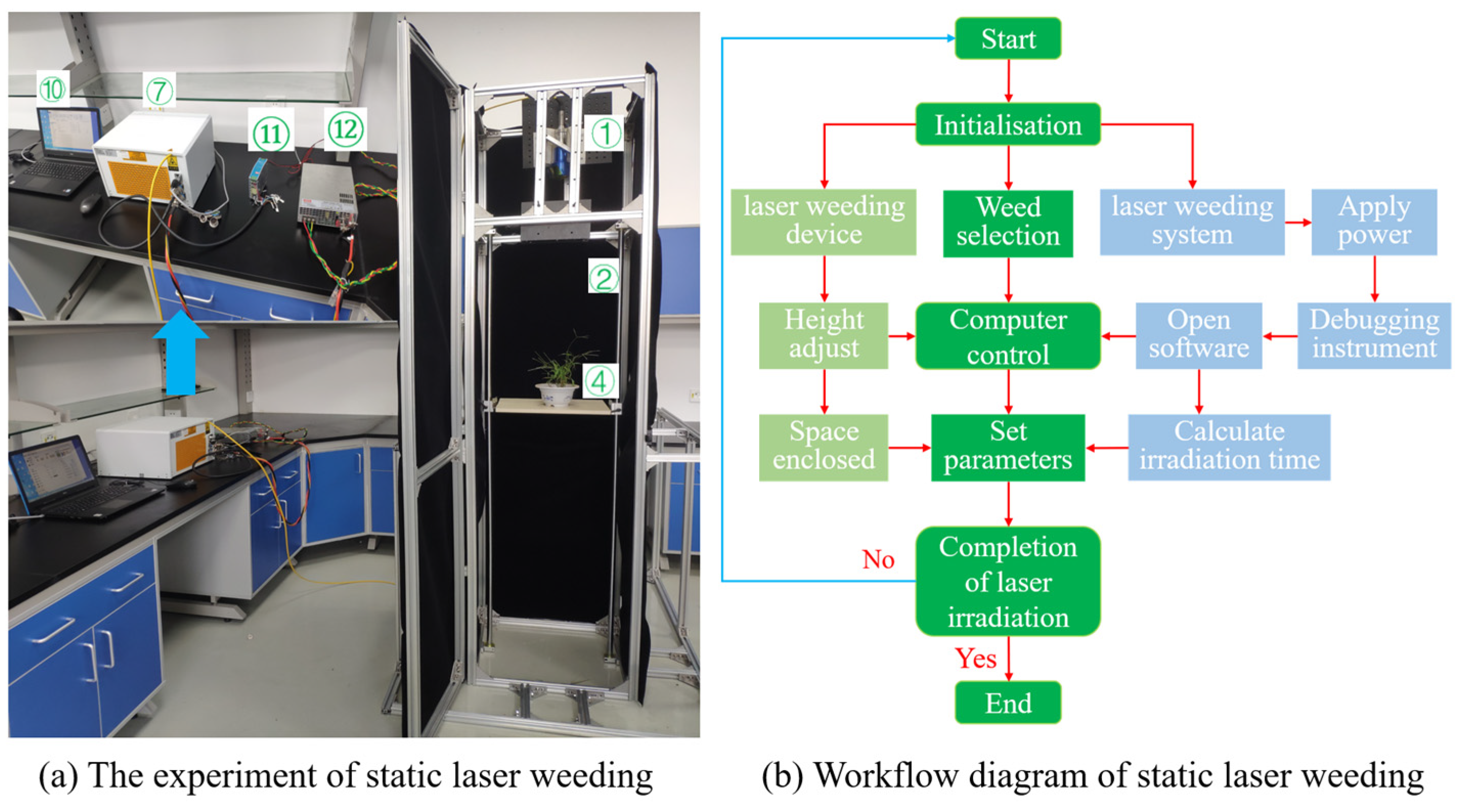

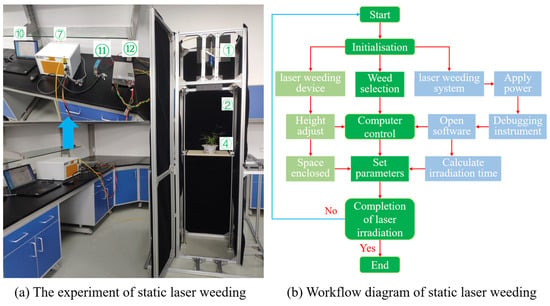

Figure 7b shows the operation process of irradiating weed stems in the laser weeding experiment. First, a sample of weed stems was selected for the experiment and the device and system were checked for initialization. After that, the laser irradiation distance was adjusted and the operating space was sealed. Next, we turned on various power supplies of the system and debugged the instrument. Then, the laser control software on the computer was opened to set relevant parameters, and the irradiation power level was adjusted. Laser irradiation experiments were conducted, and the laser irradiation time was calculated. Finally, the cutting results of the stems were observed. If the stems did not break completely or broke too much, the experiment was repeated to obtain the precise energy required for laser cutting.

Figure 7.

Completion of static laser weeding experiment. (The explanation for numbers with circles is shown in Figure 5).

2.2.3. Evaluation of Statistical Analysis

The power of the laser beam for cutting each weed stem was obtained to determine the amount of energy required to shear four types of weeds in the field and to investigate the impact of local or systemic irradiation on plant damage. The energy data obtained from the described parameter study was used to establish a statistical damage model. We proposed assessing the energy or power required for the fiber laser cutting of weed stems to have damaging effects using such a quantitative indicator as its lesion level [33]. In addition to the laser power, the laser beam area is also an essential parameter for inhibiting the growth of weeds. The laser power divided by the laser beam area is the intensity of the laser (referred to as laser power density in this article), as shown in Equations (1) and (2).

where E is the cutting power density, which refers to the ratio of the power required to cut stems to the diameter laser beam, W/mm2; P is the power required for the laser beam to just cut through the weed stems, W; S is the area of the laser beam with a diameter, which is about 113.04, mm2; E is the average power density of cutting, which refers to the average power density of 6 laser cutting stem experiments, W/mm2; x is the number of experimental repetitions, which is 6. Each laser treatment (Figure 7) was performed using 6 replicates (see experimental parameters, Table 3) with about 192 treatments overall. All statistical analyses were performed using IBM SPSS Statistics for Windows, and the figure drawing was completed using the software Origin 2022. A two-way analysis of variance (ANOVA) was adopted to explore the effects of the irradiation distances and time on the laser cutting of the stems. In all trials, the mean values of distribution uniformity at the different parameters together with those of percentage were compared using a one-way ANOVA via the Duncan test (α = 0.05).

3. Results

3.1. Experimental Effect of Laser Irradiation Distances and Time

In this study, the preliminary results indicate that under the same irradiation time, the energy required to cut the same type of weed generally increases with the increase in stem diameter and the increase in irradiation distance. The setting of cutting performance inspection is due to changes in the laser irradiation distance. The burning area was observed. The energy required for cutting is directly proportional to the distances emitted by the laser, which is simply explained by the beam divergence effect. To increase the cutting efficiency, it can be suggested to reduce the diameter of the laser beam at the cutting distance or to shorten the laser irradiation distance.

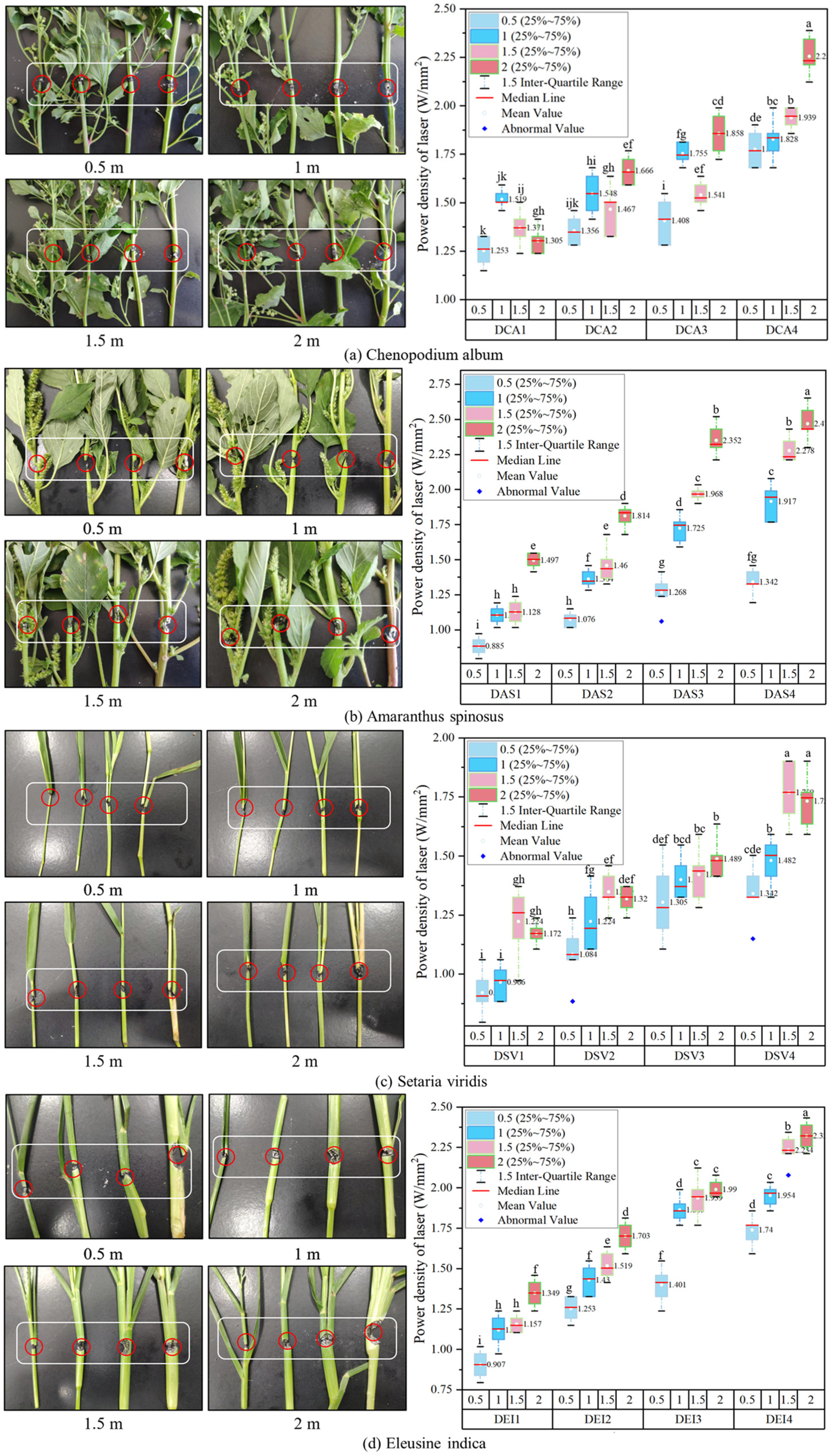

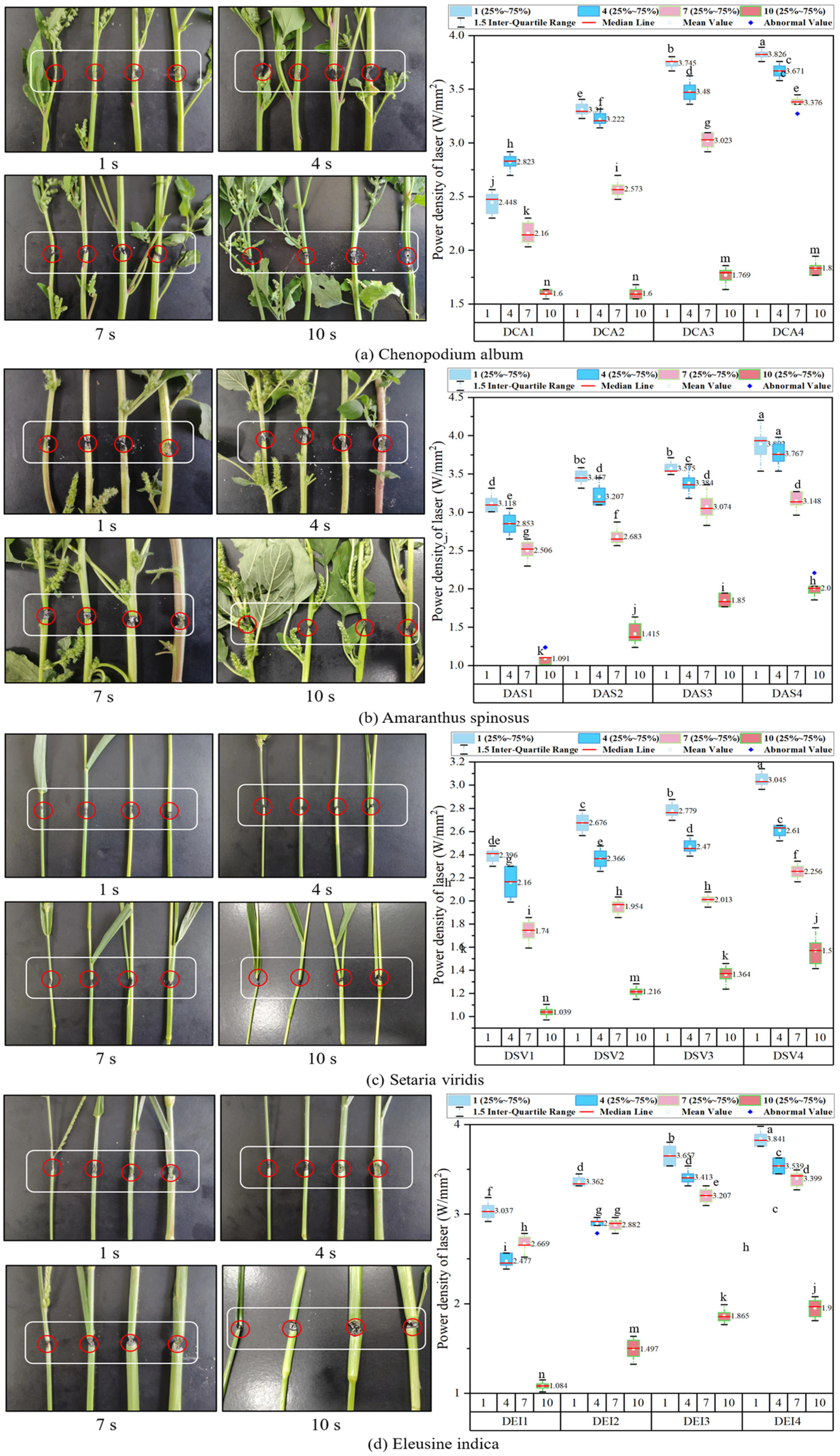

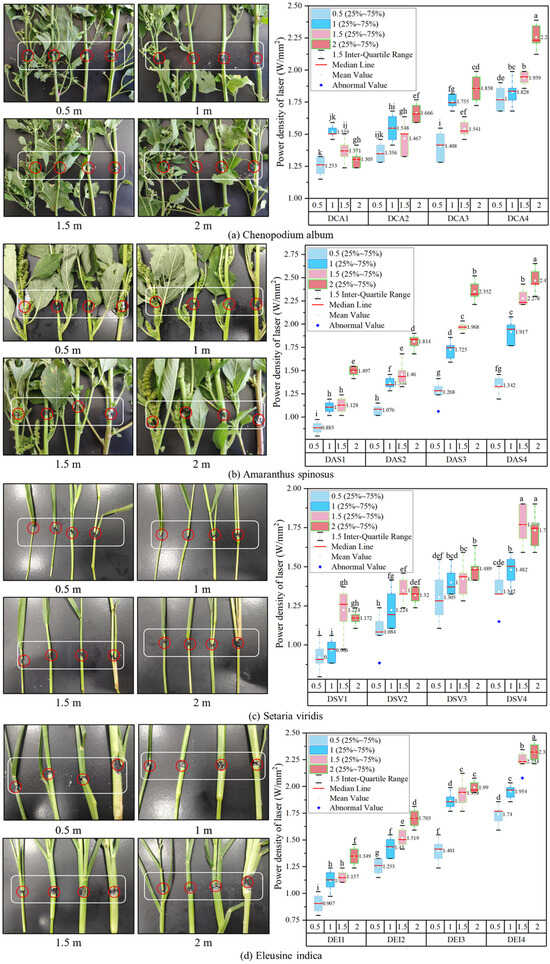

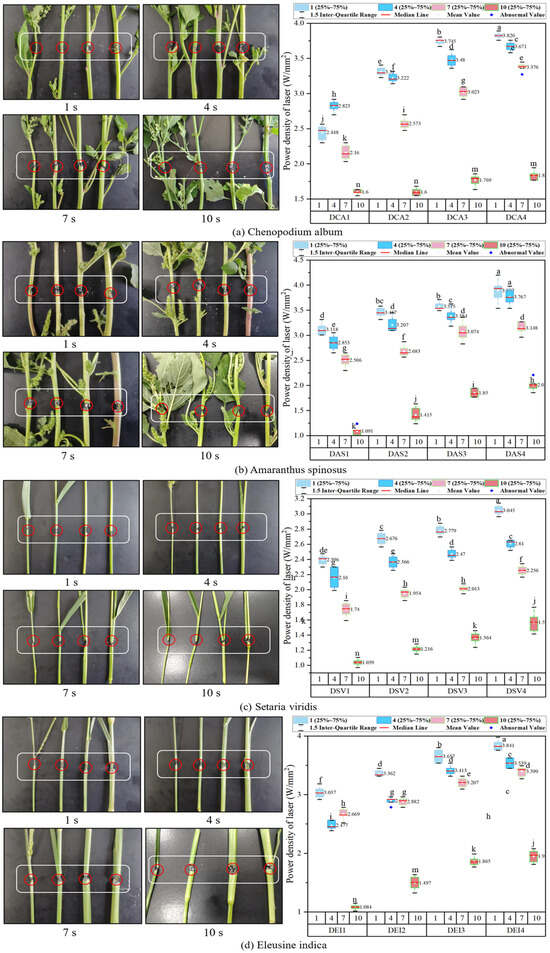

As shown in Figure 8, the stem diameters of the four weeds Chenopodium album, Amaranthus spinosus, Setaria viridis, and Eleusine indica were cut off under the laser irradiation of 10 s, and there were still burning marks in the combustion area. According to the experimental results under different irradiation distances and diameters of stems, the variance in the stem power density after irradiation was larger and the values were more dispersed for Chenopodium album and Setaria viridis weeds, and the values were relatively scattered, while the power density values of Amaranthus spinosus and Eleusine indica weeds were more concentrated.

Figure 8.

The results of four types of weeds under different irradiation distances with an irradiation time of 10 s. The left figure clearly illustrates the state of four types of weeds after laser irradiation at different distances; The figure on the right illustrates the correlation between the energy consumption and factors involved in cutting at different distances. Different letters indicate significant differences (Duncan test, a = 0.05). The X-axis represents the irradiation distances of 0.5, 1, 1.5, and 2 m for each weed species at different stem diameters.

Moreover, the stems at the largest diameter of the four weeds require the highest power density to be burned off at the farthest distance of 2 m, with average values of 2.256, 2.47, 1.732, and 2.322 W/mm2, respectively. The smallest diameter of the stems at the nearest distance of 0.5 m was burned off with the least power density, with average values of 1.253, 0.885, 0.922, and 0.907 W/mm2, respectively. After comparison, it was found that at the same irradiation distances, the power density of the stems is more significant than the basic significant difference (p < 0.05), indicating that changes in the stem diameters have an impact on the power density of laser irradiation, and the increase in the irradiation power density becomes more pronounced with the increase in the stem diameter. Compared with the same stem diameters of weeds, there were no significant differences (p > 0.05) between the laser irradiation distances and power density, indicating that the change in laser irradiation distances has a relatively small impact on the power density; and with the increase in the irradiation distance, the irradiation power density increase is not obvious. However, the difference in irradiation distances is not very significant when the stem diameters are small. This may be due to the slender stems, which consume less laser energy, and the adjustment accuracy range of laser power and irradiation distance not being precise enough; the difference in the laser irradiation distance is not very obvious. Finally, the overall view of the laser irradiation experiment results shows that under the same irradiation time, there is not much difference in energy consumption among the four weeds with smaller stem diameters. As the stem diameters increase, the power density between them also increases.

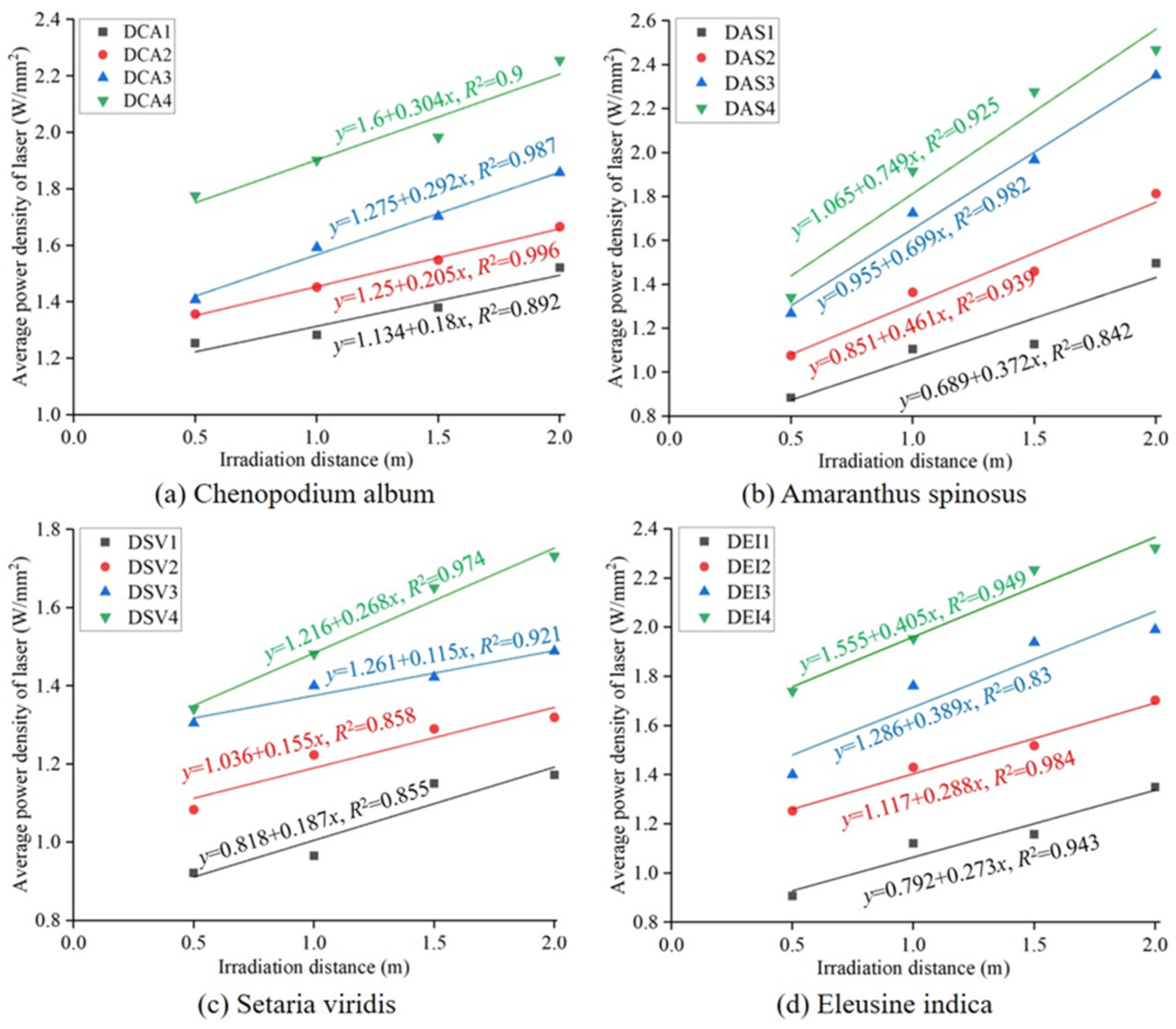

As shown in Figure 9, under the same irradiation distances, the energy required to cut the same type of weed generally increases with the increase in stem diameter and the decrease in irradiation time, which is inversely proportional to the time emitted by the laser. The variance in the power density after the irradiation of the four weeds was relatively small, and the values were more concentrated. The largest diameter of the stems was burned in the shortest time of 1 s and required the most power density, with average values of 3.826, 3.892, 3.045, and 3.841 W/mm2, respectively. The smallest diameter of the stems was burned in the longest irradiation time of 10 s and required the least power density, with average values of 1.6, 1.091, 1.039, and 1.084 W/mm2, respectively. After comparison, it was found that at the same irradiation time, the power density of the stems between the existence of significant differences (p < 0.05), indicating that changes in the diameter of stems have an impact on the power density of laser irradiation, and the power density increases significantly with the increase in stem diameters. There was no significant difference between the overall laser irradiation time and power density (p > 0.05), indicating that the changes in laser irradiation time have a relatively small impact on the power density of laser irradiation, and the power density increases insignificantly with the increase in irradiation time. However, the difference in the laser irradiation time is not very significant when the stem diameters are very small, possibly due to the slender stems, which consume less laser energy. The adjustment accuracy and range of laser power and irradiation time are not precise enough, and the difference in irradiation time is not very obvious. Finally, under the same irradiation distances, the four weeds consumed the least energy at the irradiation time of 10 s, and the difference between them was not significant, with a significant difference from the results at irradiation times of 1, 4, and 7 s.

Figure 9.

The results of the four types of weeds under different irradiation times with an irradiation distance of 1 m. The left figure clearly illustrates the state of the four types of weeds after laser irradiation at different times; The figure on the right illustrates the correlation between the energy consumption and factors involved in cutting at different times. Different letters indicate significant differences (Duncan test, a = 0.05). The X-axis represents the irradiation times of 1, 4, 7, and 10 s for each weed species at different stem diameters.

3.2. Analysis of Evaluation Factors Affecting Laser Weeding

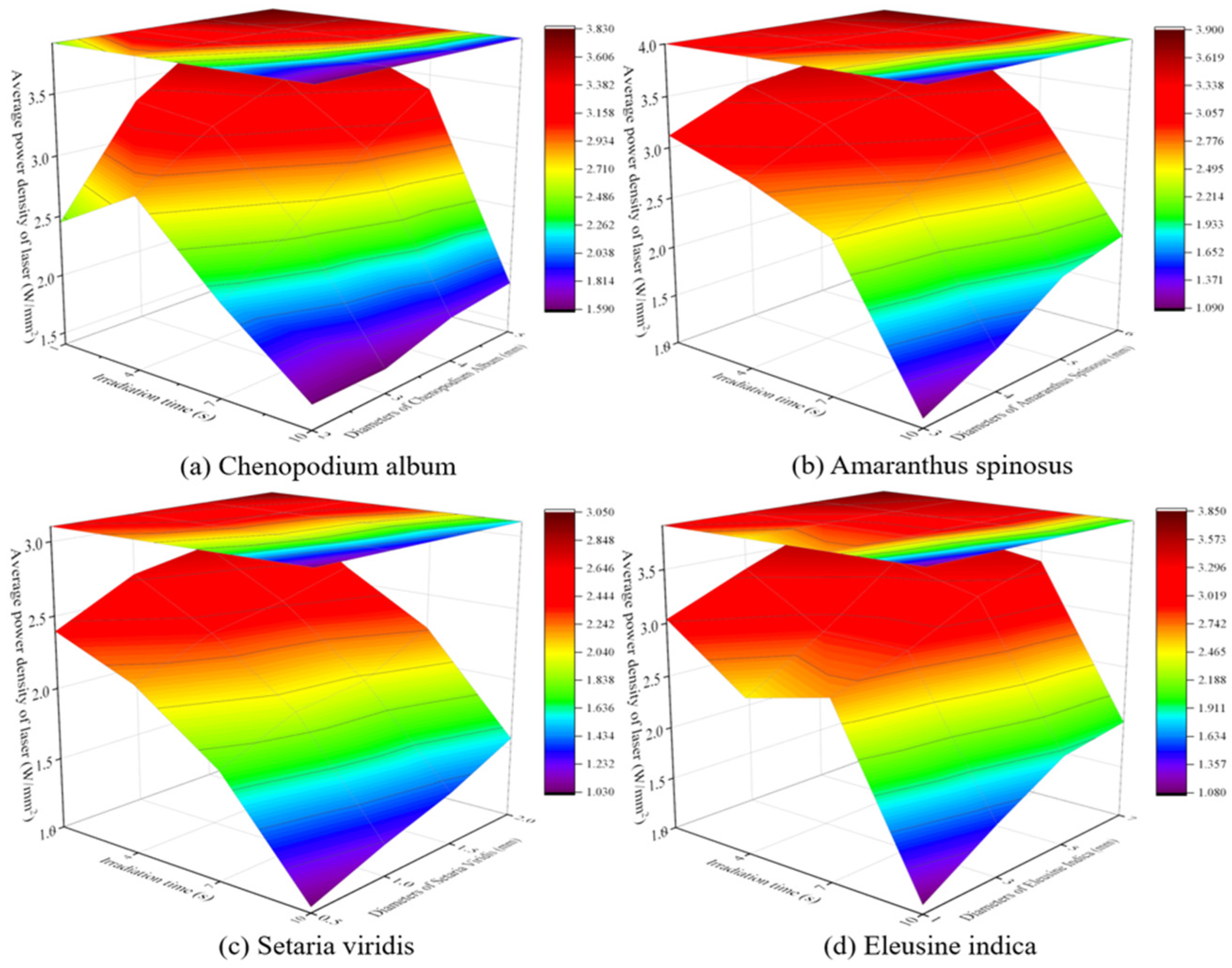

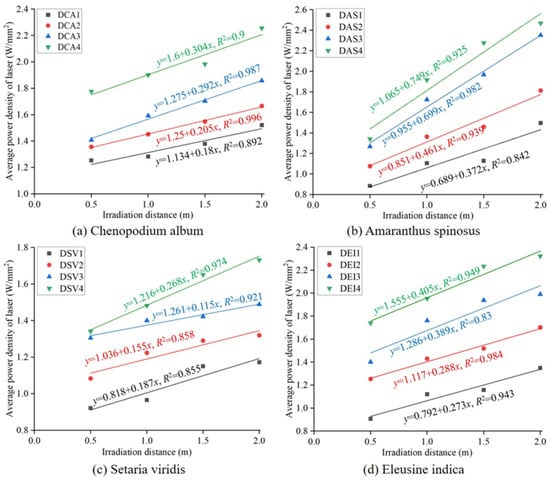

To better study the static operation rules of laser weeding devices indoors, comprehensive comparison experiments were applied at different stems using the laser with different irradiation distances and time. The linear function relationship between the different stem parts of the four weed species under different irradiation distances was obtained, as well as the change tendency of the energy required for weed stems under different irradiation times. As shown in Figure 10, there is a linear relationship between the irradiation distance and the power density for the four weeds with stems of the same diameter. Actually, it is similar to the dose–response curve proposed in this article [14,34]. As shown in Figure 10a–d, the larger the diameter of the weed stem, the steeper the curve, indicating that laser energy consumption is also increasing [35,36].

Figure 10.

The power density relationship of four weeds under different irradiation distances.

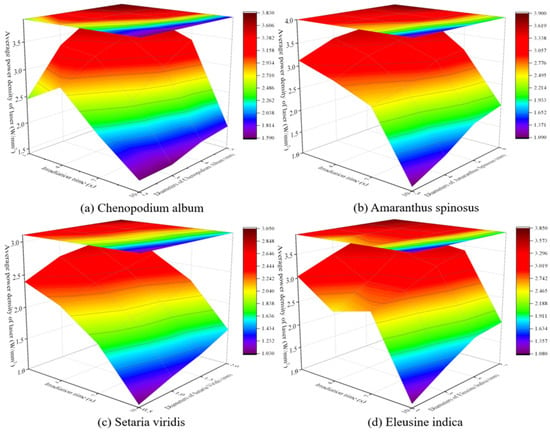

To analyze more clearly the effect of laser irradiation time on burning the weed stems, it was found that the linear relationship between laser irradiation time and power density is insignificant. Therefore, the 3D curved surfaces were used to analyze the variation pattern between laser irradiation time and power density. Under the same irradiation time, as the diameter of weed stems increases, the power density consumed also increases, but the increase is insignificant and there are slight fluctuations in the values. Compared with the same diameter stems, the power density consumed decreases sharply with increase in irradiation time, and there are more drastic fluctuations. With the increase in stem diameter, the surface becomes steeper, and the difference in power density gradually increases.

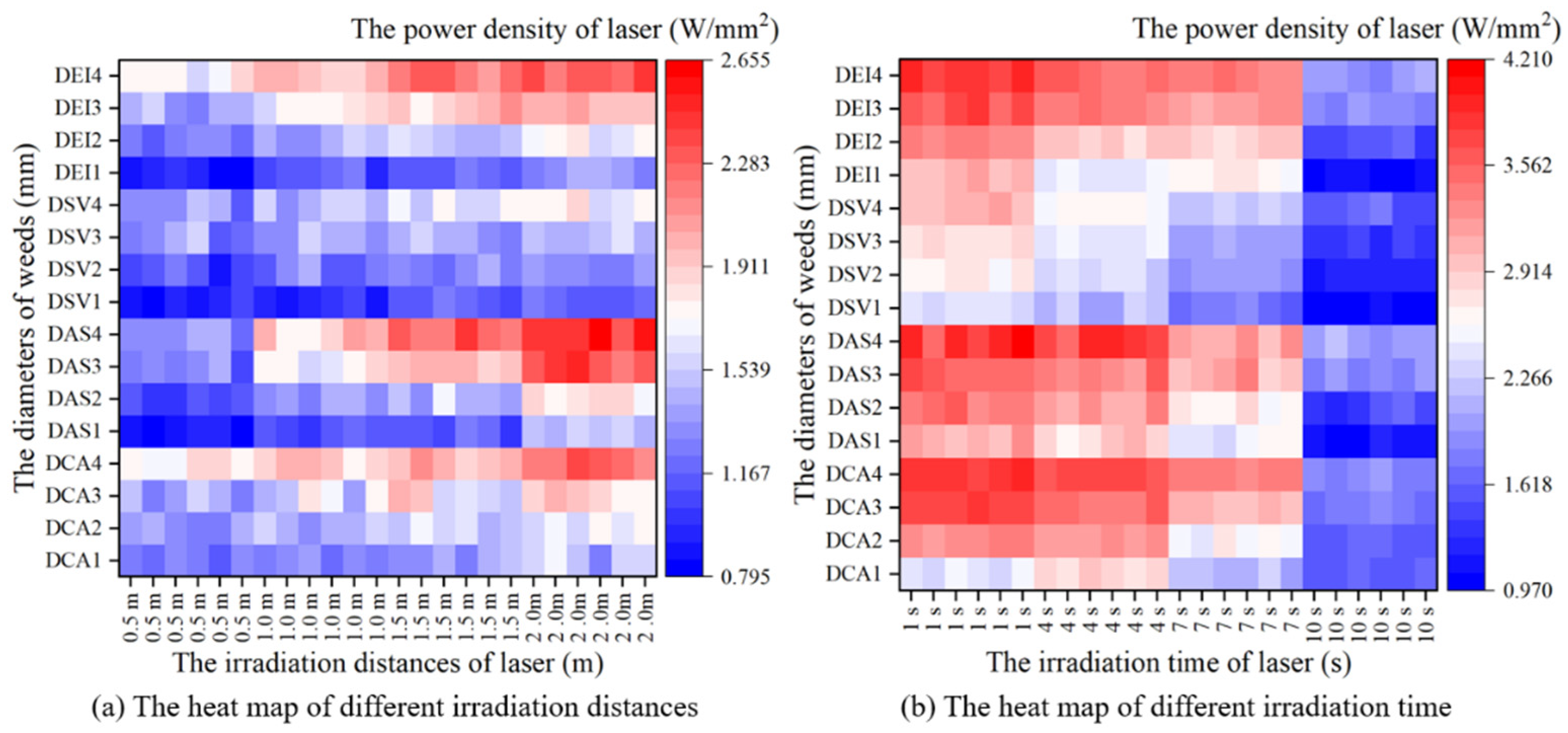

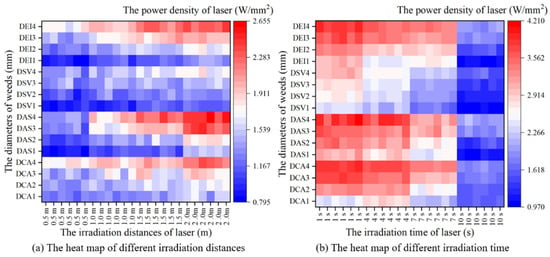

From the analysis results in Figure 10, Figure 11 and Figure 12, the Amaranthus spinosus consumed the least amount of energy for the shortest irradiation distances and stem diameters, and the most for the farthest irradiation distances and stem diameters at the same irradiation time. When Amaranthus spinosus was treated with the laser at different distances and stem diameters, the difference in energy required was the greatest, and the most significant changes were also observed. After comparison, under the same irradiation distances, the energy consumption of Setaria viridis at the longest irradiation time and stem diameter was the least among the four weeds, which may be related to it having the smallest stem diameter.

Figure 11.

The power density relationship of four weeds under different irradiation times.

Figure 12.

The heat map between irradiation distances/times and laser power density.

4. Discussion

In this study, we have made progress in the attempt of laser cutting for weed control application. Figure 8 shows the thinnest stem with the shortest irradiation distance of 0.5 m consumed the least energy. When the laser intensity increased to 0.885 W/mm2, the stems of Amaranthus spinosus began to be penetrated. When the laser intensity increased to 1.253 W/mm2, the stems of Chenopodium album were finally penetrated; the thickest stem with the farthest irradiation distance of 2 m consumed the largest energy. When the laser intensity increased to 1.732 W/mm2, the stems of Setaria viridis began to be penetrated. When the laser intensity increased to 2.47 W/mm2, the stems of Amaranthus spinosus were finally penetrated. In Figure 9, the thinnest stem with the longest irradiation time of 10 s consumed the least energy. When the laser intensity increased to 1.039 W/mm2, the stems of Setaria viridis began to be penetrated. When the laser intensity increased to 1.6 W/mm2, the stems of Chenopodium album were finally penetrated. The thickest stem with the longest irradiation time of 1 s consumed the largest energy. When the laser intensity increased to 3.045 W/mm2, the stems of Setaria viridis began to be penetrated. When the laser intensity increased to 3.892 W/mm2, the stems of Amaranthus spinosus were finally penetrated. It is noteworthy that the difference in energy consumed by the laser passing through the shortest stem diameters was not significant, although the stems of the weed vary in thickness. It causes the tissue around the laser path to burn, and the laser passes through the stem leaving clear lines. Although a higher laser intensity could easily penetrate the stems, the damage region was relatively small [25]. Therefore, this paper conducts further analysis on the most resistant weeds that require more energy consumption, to apply in subsequent field weed control. When the irradiation time is 10 s, the 3.892 W/mm2 laser is sufficient to eliminate weeds and plants with irradiation distances of 2 m, and it requires too long an exposure time. The 2.47 W/mm2 laser is more effective, as it can kill weeds within a distance of 1 m in less than 1 s. However, excessive energy can cause waste and also harm crops. Still, the research showed that it is possible to develop a concept for laser weeding using relatively cheap equipment, which can work in complicated situations where weeds and crops are mixed. This requires the popularization of laser weeding in the field, especially for weed identification. Based on the interaction between the fiber laser and weed stem’s tissue, the surface temperature of the stem’s tissue will increase because it absorbs light [36,37]. Continuous high temperatures can increase the rate of chemical reactions in weeds, reducing or depleting the concentration of dry matter. This sustained high temperature can burn the weed stems and even cut them off completely.

Furthermore, the damaging influence of weed species is dependent on the cultivar produced. The weeds with different irradiation distances have varying degrees of dispersion in the results, possibly due to the hard texture of the stems of Amaranthus spinosus and Eleusine indica weeds, resulting in large dispersion deviations. Hence, laser applications based on the energy consumption model must be adapted to incorporate the variables of output power and application time as detected weed species, weed densities, and weed growth stages may vary. This is because the heat coupling, driven by the laser irradiation and its beam-profile-dependent energy distribution, is systemic, and a critical burning temperature level is only achieved in limited stem areas [16,30,38]. Shortening the laser irradiation distances could decrease the required energy dose but requires a higher accuracy considering the laser beam positioning and irradiation time for crops in orchards and farmlands. Decreasing the laser irradiation time as well as increasing the stems of weeds’ growth stages shifted all effective doses to higher levels. With the combination of an intelligent fiber laser weeding system and device, and the deep level damage weeds detection work can be performed in the future. Therefore, based on the findings and data of this study, in the future, a mainly autonomous field robot should be preferred, which can be improved by tracking the laser beams along the direction of travel. For the recognition aspect of weeds, the use of selective plant recognition algorithms can be borrowed from chemical and mechanical weed control. When dealing with weeds in multiple plant rows at the same time, the laser can aim to only remove weeds around the crop to reduce crop yield loss.

5. Conclusions and Outlook

This contribution discusses the technical and mechanical relevant aspects of using laser techniques for large weed control, which can provide experimental data and equipment development experience for the emerging field of laser weeding technology. Firstly, based on the principle of fiber laser and the theory of mechanical modular design, a static movable lift-adjustable closed laser weed control device and system were constructed, and the main mechanical and system components corresponding to different functions were designed. Secondly, physical experiments were conducted on the energy required for the laser cutting of weed stems under different irradiation distances and response times, targeting four common weed species in farmland and orchards, and a significant relationship between energy consumption and various factors was obtained. Once again, the experimental results were further fitted and analyzed, and the linear function relationship between the different stem parts of four weed species under different irradiation distances was obtained, as well as the change tendency of the energy required for weed stems under different irradiation time. Finally, based on the experimental results, a discussion and summary were conducted on the mechanism of laser cutting of stems. In summary, the conclusion and main innovations of this article are as follows: (1) A static movable lift-adjustable closed laser weeding device and system have been developed, which can effectively cut off the stems of weeds, verifying the feasibility of using a laser for weed control. (2) A significant relationship model between energy consumption and various factors was obtained. Under different irradiation distances and diameters of stems, the variance in the stems’ power density after irradiation was larger and the values were more dispersed for Chenopodium album and Setaria viridis weeds, and the values are relatively scattered, while the power density of Amaranthus spinosus and Eleusine indica weeds were more concentrated. (3) The results of a laser cutting the stems of four fresh weeds show that the irradiation time is 10 s, a 3.892 W/mm2 laser is sufficient to eliminate weeds and plants with irradiation distances of 2 m, and the process requires too long an exposure time. The 2.47 W/mm2 laser is more effective, as it can kill weeds within a distance of 1 m in less than 1 s. (4) The mechanism and feasibility of laser weeding were discussed based on the experimental results, providing basic data and technical guidance for the subsequent field applications of laser weed control.

This work demonstrates the feasibility of the laser weeding device and system that can completely cut off the stems of large weeds, and even eliminate individual weeds. Further specifications of the required system, as well as of the investment and operating costs, will be possible after the analysis of the laws of application in terms of laser irradiation distances and time. The future work will focus on collecting more data for the given crops and weed species and treating the weeds with multiple laser beams at once. Future testing will investigate the field performance on a small autonomous robot using machine vision for laser aiming and control in addition to observing the laser effect on weeds and crop growth, and the image processing and laser positioning have to be taken into account. This technology has the potential to promote sustainable agriculture and underscores the significance of innovation in this area.

Author Contributions

Conceptualization, X.H. and C.W.; methodology, P.Q. and Z.Y.; analysis, Z.W. and Z.Y.; investigation, Z.W., L.L. and Z.Y.; resources, X.H., C.W., L.H. and Z.Y.; data curation, Z.H. and Z.Y.; writing—original draft preparation, Z.Y.; writing—review and editing, X.H. and Z.Y.; visualization, Z.Y.; supervision, X.H. and C.W.; project administration, X.H.; funding acquisition, X.H. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the 2115 talent development program of China Agricultural University, the earmarked fund for China Agriculture Research System (No. CARS-28), and the Sanya Institute of China Agricultural University Guiding Fund Project, Grant (No. SYND-2021-06).

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

Acknowledgments

The authors would like to thank all other staff of CCAT and CAUS, China Agricultural University, for their great contributions to this work.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Westwood, J.H.; Charudattan, R.; Duke, S.O.; Fennimore, S.A.; Marrone, P.; Slaughter, D.C.; Swanton, C.; Zollinger, R. Weed Management in 2050: Perspectives on the Future of Weed Science. Weed Sci. 2018, 66, 275–285. [Google Scholar] [CrossRef]

- Abouziena, H.; Haggag, W. Métodos alternativos de controle não químicos de plantas daninhas: Uma revisão. Planta Daninha 2016, 34, 377–392. [Google Scholar] [CrossRef]

- Barratt, B.I.P.; Moran, V.C.; Bigler, F.; van Lenteren, J.C. The status of biological control and recommendations for improving uptake for the future. BioControl 2017, 63, 155–167. [Google Scholar] [CrossRef]

- Oerke, E.-C. Crop losses to pests. J. Agric. Sci. 2005, 144, 31–43. [Google Scholar] [CrossRef]

- Sartorato, I.; Zanin, G.; Baldoin, C.; DE Zanche, C. Observations on the potential of microwaves for weed control. Weed Res. 2006, 46, 1–9. [Google Scholar] [CrossRef]

- Wang, X.; Huang, J.; Zhao, D.; Guo, H.; Li, C.; Zhang, B. Kinematics and statics analysis of a novle 4-dof parallel mechanism for laser weeding robot. INMATEH Agric. Eng. 2016, 50, 29–38. [Google Scholar]

- Sahin, H. A Review on Parameters Affecting the Choice of Alternative (Non-Chemical) Weed Control Methods. Eur. J. Eng. Technol. Res. 2019, 4, 16–19. [Google Scholar] [CrossRef]

- Boutin, C.; Strandberg, B.; Carpenter, D.; Mathiassen, S.; Thomas, P. Herbicide impact on non-target plant reproduction: What are the toxicological and ecological implications? Environ. Pollut. 2014, 185, 295–306. [Google Scholar] [CrossRef]

- Peillex, C.; Pelletier, M. The impact and toxicity of glyphosate and glyphosate-based herbicides on health and immunity. J. Immunotoxicol. 2020, 17, 163–174. [Google Scholar] [CrossRef]

- Wang, M.; Leal-Naranjo, J.-A.; Ceccarelli, M.; Blackmore, S. A Novel Two-Degree-of-Freedom Gimbal for Dynamic Laser Weeding: Design, Analysis, and Experimentation. IEEE/ASME Trans. Mechatron. 2022, 27, 5016–5026. [Google Scholar] [CrossRef]

- Xiong, Y.; Ge, Y.; Liang, Y.; Blackmore, S. Development of a prototype robot and fast path-planning algorithm for static laser weeding. Comput. Electron. Agric. 2017, 142, 494–503. [Google Scholar] [CrossRef]

- Zhu, H.; Zhang, Y.; Mu, D.; Bai, L.; Zhuang, H.; Li, H. YOLOX-based blue laser weeding robot in corn field. Front. Plant Sci. 2022, 13, 1017803. [Google Scholar] [CrossRef]

- Nadimi, E.S.; Andersson, K.J.; Jørgensen, R.N.; Maagaard, J.; Mathiassen, S.; Christensen, S. Designing, modeling and controlling a novel autonomous laser weeding system. In Proceedings of the 7th World Congress on Computers in Agriculture Conference Proceedings, Reno, Nevada, 22–24 June 2009. [Google Scholar]

- Mwitta, C.; Rains, G.C.; Prostko, E. Evaluation of Diode Laser Treatments to Manage Weeds in Row Crops. Agronomy 2022, 12, 2681. [Google Scholar] [CrossRef]

- Heisel, T.; Schou, J.; Andreasen, C.; Christensen, S. Using laser to measure stem thickness and cut weed stems. Weed Res. 2002, 42, 242–248. [Google Scholar] [CrossRef]

- Wöltjen, C.; Haferkamp, H.; Rath, T.; Herzog, D. Plant growth depression by selective irradiation of the meristem with CO2 and diode lasers. Biosyst. Eng. 2008, 101, 316–324. [Google Scholar] [CrossRef]

- Rakhmatulin, I.; Andreasen, C. A Concept of a Compact and Inexpensive Device for Controlling Weeds with Laser Beams. Agronomy 2020, 10, 1616. [Google Scholar] [CrossRef]

- Schou, J.; Heisel, T.; Nordskov, A.; Christensen, S.; Jensen, P.S.; Thestrup, B.; Toftmann, B. Quantitative laser cutting of plants. In International Symposium on High-Power Laser Ablation; 2002; pp. 734–743. [Google Scholar] [CrossRef]

- Andreasen, C.; Hansen, L.; Streibig, J.C. The Effect of Ultraviolet Radiation on the Fresh Weight of Some Weeds and Crops. Weed Technol. 1999, 13, 554–560. [Google Scholar] [CrossRef]

- Couch, R.; Gangstad, E.O. Response of Waterhyacinth to Laser Radiation. Weed Sci. 1974, 22, 450–453. [Google Scholar] [CrossRef]

- Nadimi, M.; Sun, D.-W.; Paliwal, J. Recent applications of novel laser techniques for enhancing agricultural production. Laser Phys. 2021, 31, 053001. [Google Scholar] [CrossRef]

- Noble, S.D.; Brown, R.B.; Crowe, T.G. The use of spectral proplerties for weed detection and identification—A review. In Proceedings of the AIC 2002 Meeting CSAE/SCGR Program, Saskatoon, Saskatchewan, 14–17 July 2002. [Google Scholar]

- Pannacci, E.; Lattanzi, B.; Tei, F. Non-chemical weed management strategies in minor crops: A review. Crop Prot. 2017, 96, 44–58. [Google Scholar] [CrossRef]

- Shah, R.; Lee, W.S. An approach to a laser weeding system for elimination of in-row Weeds. In Precision Agriculture’15; Wageningen Academic: Wageningen, the Netherlands, 2015; pp. 307–312. [Google Scholar] [CrossRef]

- Andreasen, C.; Scholle, K.; Saberi, M. Laser Weeding With Small Autonomous Vehicles: Friends or Foes? Front. Agron. 2022, 4, 841086. [Google Scholar] [CrossRef]

- Li, J.-L.; Su, W.-H.; Zhang, H.-Y.; Peng, Y. A real-time smart sensing system for automatic localization and recognition of vegetable plants for weed control. Front. Plant Sci. 2023, 14, 1133969. [Google Scholar] [CrossRef] [PubMed]

- Osadčuks, V.; Kostromins, A.; Pecka, A.; Koteļeņecs, V.; Jaško, J. Experimental efficiency evaluation of 445 nm semicon-ductor laser for robotized weed control applications. Agron. Res. 2020, 18, 1380–1387. [Google Scholar]

- Arsa, D.M.S.; Ilyas, T.; Park, S.-H.; Won, O.; Kim, H. Eco-friendly weeding through precise detection of growing points via efficient multi-branch convolutional neural networks. Comput. Electron. Agric. 2023, 209, 107830. [Google Scholar] [CrossRef]

- Andreasen, C.; Vlassi, E.; Johannsen, K.S.; Jensen, S.M. Side-effects of laser weeding: Quantifying off-target risks to earthworms (Enchytraeids) and insects (Tenebrio molitor and Adalia bipunctata). Front. Agron. 2023, 5, 1198840. [Google Scholar] [CrossRef]

- Heisel, T.; Schou, J.; Christensen, S.; Andreasen, C. Cutting weeds with a CO2 laser. Weed Res. 2001, 41, 19–29. [Google Scholar] [CrossRef]

- Kaierle, S.; Marx, C.; Rath, T.; Hustedt, M. Find and Irradiate—Lasers Used for Weed Control. PhotonicsViews 2013, 10, 44–47. [Google Scholar] [CrossRef]

- Mathiassen, S.K.; Bak, T.; Christensen, S.; Kudsk, P. The Effect of Laser Treatment as a Weed Control Method. Biosyst. Eng. 2006, 95, 497–505. [Google Scholar] [CrossRef]

- Sorour, M.; From, P.J.; Elgeneidy, K.; Kanarachos, S.; Sallam, M. Compact Strawberry Harvesting Tube Employing Laser Cutter. In Proceedings of the 2022 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Kyoto, Japan, 23–27 October 2022; pp. 8956–8962. [Google Scholar]

- Shaner, D.L.; Beckie, H.J. The future for weed control and technology. Pest Manag. Sci. 2014, 70, 1329–1339. [Google Scholar] [CrossRef]

- Madić, M.; Radovanović, M.; Nedić, B.; Gostimirović, M. CO2 Laser Cutting Cost Estimation: Mathematical Model and Application. Int. J. Laser Sci. 2020, 1, 169–183. [Google Scholar]

- Morales-Orellana, R.J.; Winkelmann, T.; Bettin, A.; Rath, T. Stimulation of adventitious root formation by laser wounding in rose cuttings: A matter of energy and pattern. Front. Plant Sci. 2022, 13, 1009085. [Google Scholar] [CrossRef] [PubMed]

- Lan, Y.-P. Laser-optics-based method to suppress Mikania micrantha growth. Sci. Rep. 2022, 12, 19864. [Google Scholar] [CrossRef] [PubMed]

- Sorour, M.; From, P.J.; Elgeneidy, K.; Kanarachos, S.; Sallam, M. Produce Harvesting by Laser Stem-Cutting. In Proceedings of the 2022 IEEE 18th International Conference on Automation Science and Engineering (CASE), Mexico City, Mexico, 20–24 August 2022; pp. 487–492. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).