Effects of Ensiling Density on the Fermentation Profile and Aerobic Stability of Wilted Alfalfa Silage

Abstract

1. Introduction

2. Materials and Methods

2.1. Preparation of Alfalfa Silage

2.2. Chemical Component and Microbial Population Analysis

2.3. Aerobic Stability Test

2.4. Statistical Analysis

3. Results

3.1. Fermentation Quality of Alfalfa

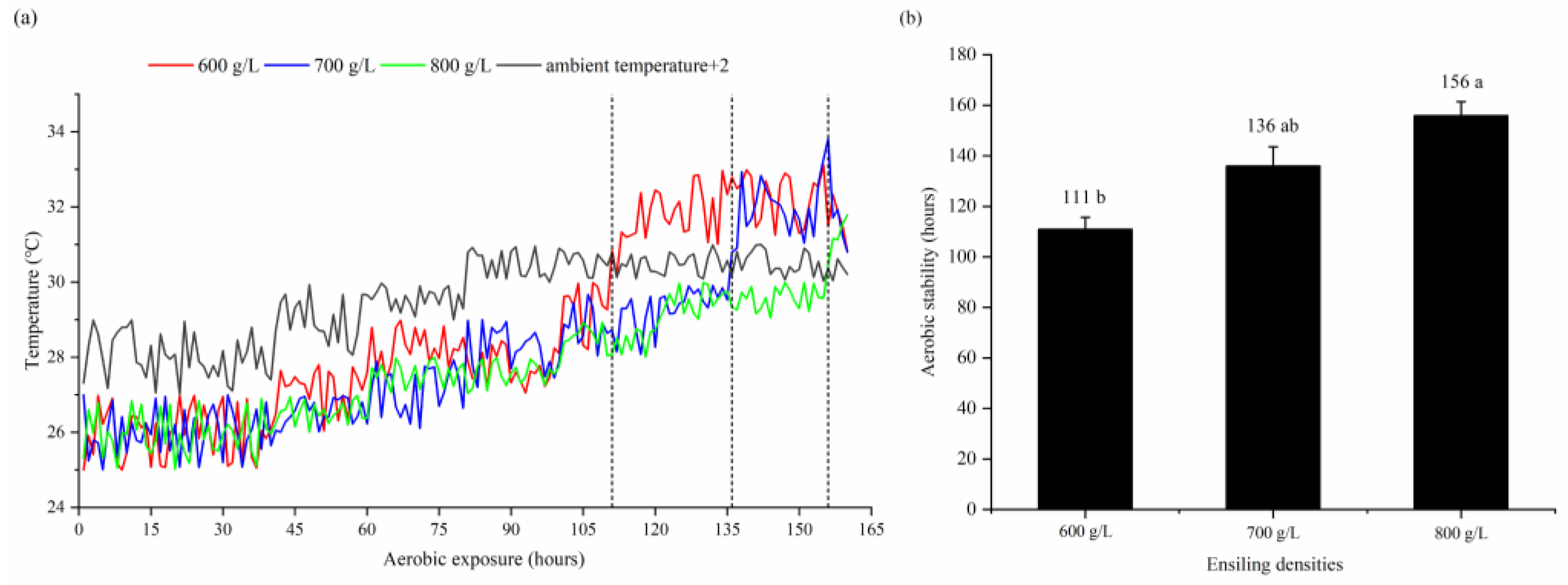

3.2. Aerobic Stability of Alfalfa Silage

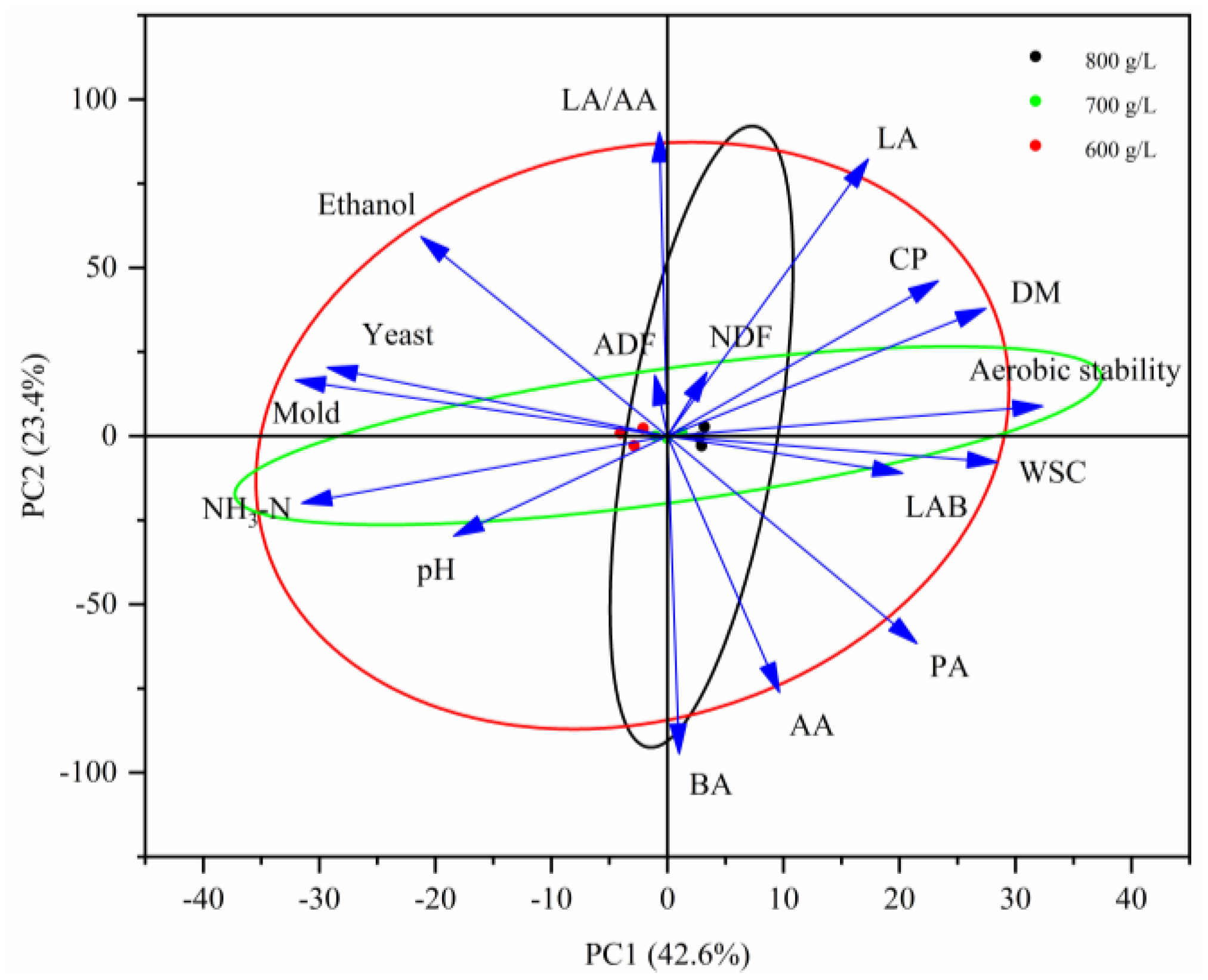

3.3. Dimension Reduction Analyses

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- McDonald, P.; Henderson, A.R.; Heron, S.J.E. The Biochemistry of Silage; Chalcomble Publications: Marlow, UK, 1991. [Google Scholar]

- Woolford, M.K. The detrimental effects of air on silage. J. Appl. Bacteriol. 1990, 68, 101–116. [Google Scholar] [CrossRef] [PubMed]

- Su, R.N.; Ke, W.C.; Usman, S.; Bai, J.; Kharazian, Z.A.; Guo, X.S. Dry matter content and inoculant alter the metabolome and bacterial community of alfalfa ensiled at high temperature. Appl. Microbiol. Biotechnol. 2023, 107, 3443–3457. [Google Scholar] [CrossRef] [PubMed]

- Gerlach, K.; Ross, F.; Weiss, K.; Büscher, W.; Südekum, K.H. Changes in maize silage fermentation products during aerobic deterioration and effects on dry matter intake by goats. Agric. Food Sci. 2013, 22, 168–181. [Google Scholar] [CrossRef]

- Borreani, G.; Tabacco, E. Quantifying the extent of aerobic deterioration in corn bunker and pile silages at a farm level. In Proceedings of the 15th International Silage Conference, Madison, WI, USA, 27–29 July 2009; pp. 321–322. [Google Scholar]

- Liu, H.; Li, X.; Hu, J.; Zhao, J.; Xu, G.; Dong, D.; Jia, Y.; Shao, T. Fermentation Quality and Aerobic Stability Evaluation of Rice Straw Silage with Different Ensiling Densities. Fermentation 2024, 10, 20. [Google Scholar] [CrossRef]

- Ruppel, K.A.; Pitt, R.E.; Chase, L.E.; Galton, D.M. Bunker Silo Management and Its Relationship to Forage Preservation on Dairy Farms. J. Dairy Sci. 1995, 78, 141–153. [Google Scholar] [CrossRef]

- Yang, L.L.; Yuan, X.J.; Li, J.F.; Dong, Z.H.; Shao, T. Dynamics of microbial community and fermentation quality during ensiling of sterile and nonsterile alfalfa with or without Lactobacillus plantarum inoculant. Bioresour. Technol. 2019, 275, 280–287. [Google Scholar] [CrossRef] [PubMed]

- Nkosi, B.D.; Meeske, R.; Langa, T.; Motiang, M.D.; Modiba, S.; Mkhize, N.R.; Groenewald, I.B. Effects of ensiling forage soybean (Glycine max (L.) Merr.) with or without bacterial inoculants on the fermentation characteristics, aerobic stability and nutrient digestion of the silage by Damara rams. Small Rumin. Res. 2016, 134, 90–96. [Google Scholar] [CrossRef]

- Sucu, E.; Kalkan, H.; Canbolat, O.; Filya, I. Effects of ensiling density on nutritive value of maize and sorghum silages. Rev. Bras. Zootec.-Braz. J. Anim. Sci. 2016, 45, 596–603. [Google Scholar] [CrossRef]

- Catchpoole, V.R. Silage and silage-making from tropical herbage species. Herb. Abstr. 1971, 41, 213–219. [Google Scholar]

- Kung, L.; Savage, R.M.; da Silva, E.B.; Polukis, S.A.; Smith, M.L.; Johnson, A.C.B.; Miller, M.A. The effects of air stress during storage and low packing density on the fermentation and aerobic stability of corn silage inoculated with Lactobacillus buchneri 40788. J. Dairy Sci. 2021, 104, 4206–4222. [Google Scholar] [CrossRef]

- Zhao, J.; Dong, Z.H.; Li, J.F.; Chen, L.; Bai, Y.F.; Jia, Y.S.; Shao, T. Ensiling as pretreatment of rice straw: The effect of hemicellulase and Lactobacillus plantarum on hemicellulose degradation and cellulose conversion. Bioresour. Technol. 2018, 266, 158–165. [Google Scholar] [CrossRef] [PubMed]

- Abo-Donia, F.M.; Ahmed El-Shora, M.; Abd-Elaziz Riad, W.; Basuony Elgamal, N.; Abdel-Menaem El-Hamady, W. Improve the nutritional value and utilization of rice straw via an ensiling process with different sources of energy and nitrogen enrichment. J. Appl. Anim. Res. 2022, 50, 333–341. [Google Scholar] [CrossRef]

- Zhao, J.; Yin, X.J.; Wang, S.R.; Li, J.F.; Dong, Z.H.; Shao, T. Changes in the fermentation products, taxonomic and functional profiles of microbiota during high-moisture sweet sorghum silage fermentation. Front. Microbiol 2022, 13, 967624. [Google Scholar] [CrossRef] [PubMed]

- Wilkinson, J.M.; Davies, D.R. The aerobic stability of silage: Key findings and recent developments. Grass Forage Sci. 2013, 68, 1–19. [Google Scholar] [CrossRef]

- Sun, L.; Na, N.; Li, X.M.; Li, Z.Q.; Wang, C.; Wu, X.G.; Xiao, Y.Z.; Yin, G.M.; Liu, S.B.; Liu, Z.P.; et al. Impact of Packing Density on the Bacterial Community, Fermentation, and In Vitro Digestibility of Whole-Crop Barley Silage. Agriculture 2021, 11, 672. [Google Scholar] [CrossRef]

- Tian, J.; Xu, N.; Liu, B.; Huan, H.; Gu, H.; Dong, C.; Ding, C. Interaction effect of silo density and additives on the fermentation quality, microbial counts, chemical composition and in vitro degradability of rice straw silage. Bioresour. Technol. 2020, 297, 122412. [Google Scholar] [CrossRef] [PubMed]

- Xu, H.W.; Wu, N.; Na, N.; Sun, L.; Zhao, Y.; Ding, H.J.; Fang, Y.Y.; Wang, T.W.; Xue, Y.L.; Zhong, J. Fermentation weight loss, fermentation quality, and bacterial community of ensiling of sweet sorghum with lactic acid bacteria at different silo densities. Front. Microbiol. 2022, 13, 1013913. [Google Scholar] [CrossRef]

- Ni, K.K.; Wang, F.F.; Zhu, B.G.; Yang, J.X.; Zhou, G.A.; Pan, Y.; Tao, Y.; Zhong, J. Effects of lactic acid bacteria and molasses additives on the microbial community and fermentation quality of soybean silage. Bioresour. Technol. 2017, 238, 706–715. [Google Scholar] [CrossRef] [PubMed]

- Shao, T.; Oba, N.; Shimojo, M.; Masuda, Y. Changes in Mono-and Disaccharides Compositions of Guineagrass (Panicum maximum Jacq.) Silage During Early Stages of Ensiling. J. Fac. Agric. Kyushu Univ. 2003, 47, 333–339. [Google Scholar] [CrossRef]

- Krüger, A.M.; Lima, P.d.M.T.; Abdalla Filho, A.L.; Moro, J.D.G.; De Carvalho, I.Q.; Abdalla, A.L.; Jobim, C.C. Dry matter concentration and corn silage density: Effects on forage quality. Trop. Grassl.-Forrajes Trop. 2020, 8, 20–27. [Google Scholar] [CrossRef]

- Kung, L., Jr. Aerobic stability of silage. In Proceedings of the 2010 California Alfalfa and Forage Symposium and Corn/Cereal Silage Conference, Visalia, CA, USA, 1–2 December 2010. [Google Scholar]

- Xie, Y.X.; Wang, L.; Li, W.Q.; Xu, S.Y.; Bao, J.Z.; Deng, J.J.; Wu, Z.; Yu, Z. Fermentation Quality, In Vitro Digestibility, and Aerobic Stability of Total Mixed Ration Silage in Response to Varying Proportion Alfalfa Silage. Animals 2022, 12, 1039. [Google Scholar] [CrossRef] [PubMed]

- Moselhy, M.A.; Borba, J.P.; Borba, A.E.S. Improving the nutritive value, in vitro digestibility and aerobic stability of Hedychium gardnerianum silage through application of additives at ensiling time. Anim. Feed Sci. Technol. 2015, 206, 8–18. [Google Scholar] [CrossRef]

- Bayat, J. Effects of microbial inoculant on composition, aerobic stability, in situ ruminal degradability and in vitro gas production of corn silage. Int. J. Agrisci. 2012, 2, 774–786. [Google Scholar]

- Tabacco, E.; Piano, S.; Cavallarin, L.; Bernardes, T.F.; Borreani, G. Clostridia spore formation during aerobic deterioration of maize and sorghum silages as influenced by Lactobacillus buchneri and Lactobacillus plantarum inoculants. J. Appl. Microbiol. 2009, 107, 1632–1641. [Google Scholar] [CrossRef] [PubMed]

- Kleinschmit, D.H.; Schmidt, R.J.; Kung, L. The effects of various antifungal additives on the fermentation and aerobic stability of corn silage. J. Dairy Sci. 2005, 88, 2130–2139. [Google Scholar] [CrossRef]

- Holmes, B.J.; Muck, R.E. Packing Bunkers and Piles to Maximize Forage Preservation. In Proceedings of the American Society of Agricultural and Biological Engineers Sixth International Dairy Housing Conference Proceeding, Minneapolis, MN, USA, 16–18 June 2007. [Google Scholar]

- Samarasinghe, M.B.; Larsen, M.; Johansen, M.; Waldemar, P.; Weisbjerg, M.R. Effects of shredding on silage density and fermentation quality. Grass Forage Sci. 2019, 74, 244–253. [Google Scholar] [CrossRef]

| Items | Value ± SD |

|---|---|

| pH value | 6.42 ± 0.13 |

| Dry matter (g/kg FW) | 256 ± 1.16 |

| Crude protein (g/kg DM) | 255 ± 8.47 |

| Neutral detergent fiber (g/kg DM) | 404 ± 5.88 |

| Acid detergent fiber (g/kg DM) | 279 ± 6.92 |

| Buffering capacity (mEq/kg DM) | 271 ± 7.03 |

| Water-soluble carbohydrates (g/kg DM) | 79.0 ± 3.60 |

| Lactic acid bacteria (log10 cfu/g FW) | 6.73 ± 0.12 |

| Yeast (log10 cfu/g FW) | 6.24 ± 0.09 |

| Aerobic bacteria (log10 cfu/g FW) | 9.36 ± 0.07 |

| Items | Ensiling Density | SEM | p-Value | ||

|---|---|---|---|---|---|

| 600 g/L | 700 g/L | 800 g/L | |||

| Fermentation profile (g/kg DM) | |||||

| Dry matter (g/kg FW) | 207 | 212 | 221 | 2.772 | 0.193 |

| Water-soluble carbohydrates | 12.9 b | 20.1 ab | 23.4 a | 2.009 | 0.071 |

| NH3-N (g/kg TN) | 116 a | 85.6 b | 73.2 b | 7.072 | 0.005 |

| Crude protein | 53.4 b | 61.0 ab | 85.3 a | 6.333 | 0.076 |

| Neutral detergent fiber | 318 | 308 | 305 | 8.003 | 0.882 |

| Acid detergent fiber | 226 | 221 | 220 | 7.666 | 0.927 |

| pH | 4.89 | 4.52 | 4.30 | 0.051 | 0.136 |

| Lactic acid | 71.6 | 75.8 | 78.5 | 2.044 | 0.449 |

| Acetic acid | 26.6 | 23.8 | 21.0 | 1.882 | 0.547 |

| Propionic acid | 3.42 | 4.17 | 4.97 | 0.346 | 0.199 |

| Butyric acid | 4.46 | 3.75 | 3.01 | 0.584 | 0.802 |

| Ethanol | 14.8 | 12.7 | 9.45 | 1.357 | 0.310 |

| Lactic acid/acetic acid | 3.26 | 3.22 | 3.63 | 0.342 | 0.894 |

| Flieg Score | 50.8 b | 66.6 ab | 77.2 a | 1.725 | <0.001 |

| Microbial numbers (log10 cfu/g FW) | |||||

| Lactic acid bacteria | 11.6 | 13.8 | 16.4 | 1.148 | 0.249 |

| Yeasts | 3.84 a | 2.49 ab | 0.98 b | 0.517 | 0.047 |

| Molds | 1.99 a | 1.09 b | - | 0.299 | <0.001 |

| Items | Ensiling Density | Exposure Day | SEM | p-Value | |||||

|---|---|---|---|---|---|---|---|---|---|

| 0 | 2 | 4 | 6 | T | D | T × D | |||

| pH | 600 g/L | 4.89 c | 5.06 bc | 5.23 b | 6.82 a | 0.882 | <0.001 | <0.001 | <0.001 |

| 700 g/L | 4.52 | 4.85 | 5.04 | 5.65 | |||||

| 800 g/L | 4.30 | 4.52 | 4.84 | 5.14 | |||||

| NH3-N (g/kg TN) | 600 g/L | 116 | 114 | 129 | 153 | 5.821 | 0.006 | <0.001 | 0.862 |

| 700 g/L | 85.6 | 104 | 107 | 135 | |||||

| 800 g/L | 73.2 | 108 | 106 | 129 | |||||

| Lactic acid (g/kg DM) | 600 g/L | 71.6 | 62.1 | 54.8 | 39.2 | 1.570 | <0.001 | <0.001 | 0.022 |

| 700 g/L | 75.8 | 70.8 | 68.9 | 51.6 | |||||

| 800 g/L | 78.5 | 73.9 | 69.5 | 57.5 | |||||

| Acetic acid (g/kg DM) | 600 g/L | 26.6 | 20.4 | 24.3 | 20.7 | 1.966 | 0.009 | 0.010 | 0.882 |

| 700 g/L | 23.8 | 15.3 | 15.9 | 16.1 | |||||

| 800 g/L | 21.0 | 15.2 | 12.4 | 11.4 | |||||

| Propionic acid (g/kg DM) | 600 g/L | 3.42 | 4.47 | 5.48 | 7.00 | 0.201 | 0.001 | <0.001 | 0.337 |

| 700 g/L | 4.17 | 5.77 | 5.80 | 6.59 | |||||

| 800 g/L | 4.97 | 6.52 | 6.75 | 6.18 | |||||

| Butyric acid (g/kg DM) | 600 g/L | 4.46 | 3.76 | 3.87 | 4.27 | 0.184 | 0.001 | 0.001 | 0.083 |

| 700 g/L | 3.75 | 3.46 | 3.21 | 4.04 | |||||

| 800 g/L | 4.81 | 3.50 | 3.45 | 2.57 | |||||

| Items | Ensiling Density | Exposure Day | SEM | p-Value | |||||

|---|---|---|---|---|---|---|---|---|---|

| 0 | 2 | 4 | 6 | T | D | T × D | |||

| LAB (log10 cfu/g FW) | 600 g/L | 11.6 | 13.9 | 9.54 | 7.31 | 0.746 | <0.001 | <0.001 | 0.879 |

| 700 g/L | 13.8 | 15.2 | 10.5 | 9.64 | |||||

| 800 g/L | 16.4 | 18.1 | 12.1 | 10.7 | |||||

| AB (log10 cfu/g FW) | 600 g/L | 7.93 b | 9.17 ab | 10.5 a | 11.7 a | 0.234 | <0.001 | <0.001 | 0.520 |

| 700 g/L | 7.27 b | 8.62 ab | 9.81 ab | 10.6 a | |||||

| 800 g/L | 7.24 c | 8.48 b | 9.58 b | 10.1 a | |||||

| Yeast (log10 cfu/g FW) | 600 g/L | 5.58 c | 6.07 b | 6.87 ab | 7.93 a | 0.192 | <0.001 | <0.001 | 0.638 |

| 700 g/L | 5.42 c | 5.25 c | 5.84 b | 6.82 a | |||||

| 800 g/L | 4.64 c | 5.31 b | 5.59 b | 6.32 a | |||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, H.; Li, X.; Yang, F.; Hu, J.; Jia, Y.; Shao, T. Effects of Ensiling Density on the Fermentation Profile and Aerobic Stability of Wilted Alfalfa Silage. Agronomy 2024, 14, 1143. https://doi.org/10.3390/agronomy14061143

Liu H, Li X, Yang F, Hu J, Jia Y, Shao T. Effects of Ensiling Density on the Fermentation Profile and Aerobic Stability of Wilted Alfalfa Silage. Agronomy. 2024; 14(6):1143. https://doi.org/10.3390/agronomy14061143

Chicago/Turabian StyleLiu, Haopeng, Xinbao Li, Feifei Yang, Junfeng Hu, Yushan Jia, and Tao Shao. 2024. "Effects of Ensiling Density on the Fermentation Profile and Aerobic Stability of Wilted Alfalfa Silage" Agronomy 14, no. 6: 1143. https://doi.org/10.3390/agronomy14061143

APA StyleLiu, H., Li, X., Yang, F., Hu, J., Jia, Y., & Shao, T. (2024). Effects of Ensiling Density on the Fermentation Profile and Aerobic Stability of Wilted Alfalfa Silage. Agronomy, 14(6), 1143. https://doi.org/10.3390/agronomy14061143