Modeling Airflow and Temperature in a Sealed Cold Storage System for Medicinal Plant Cultivation Using Computational Fluid Dynamics (CFD)

Abstract

1. Introduction

2. Materials and Methods

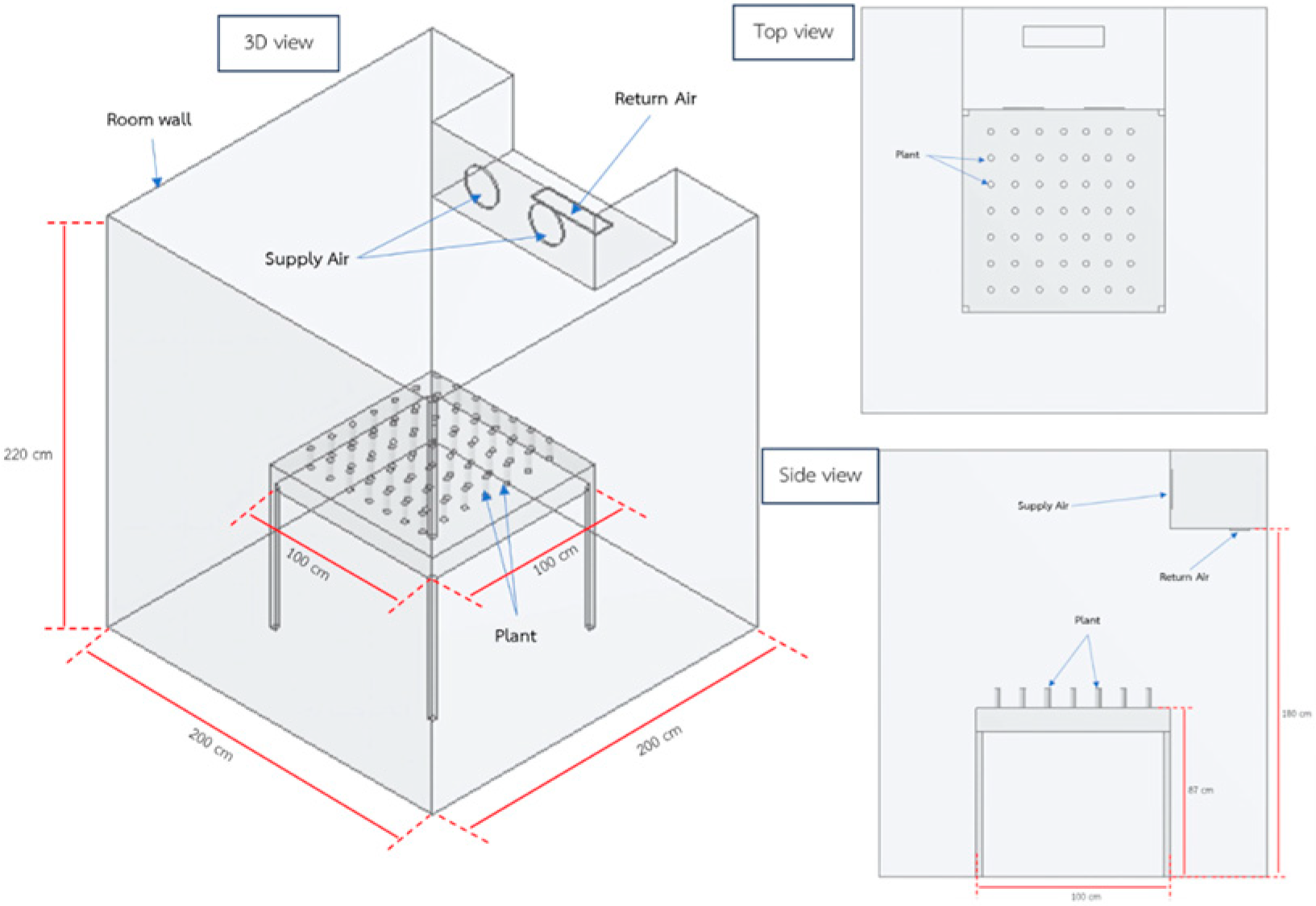

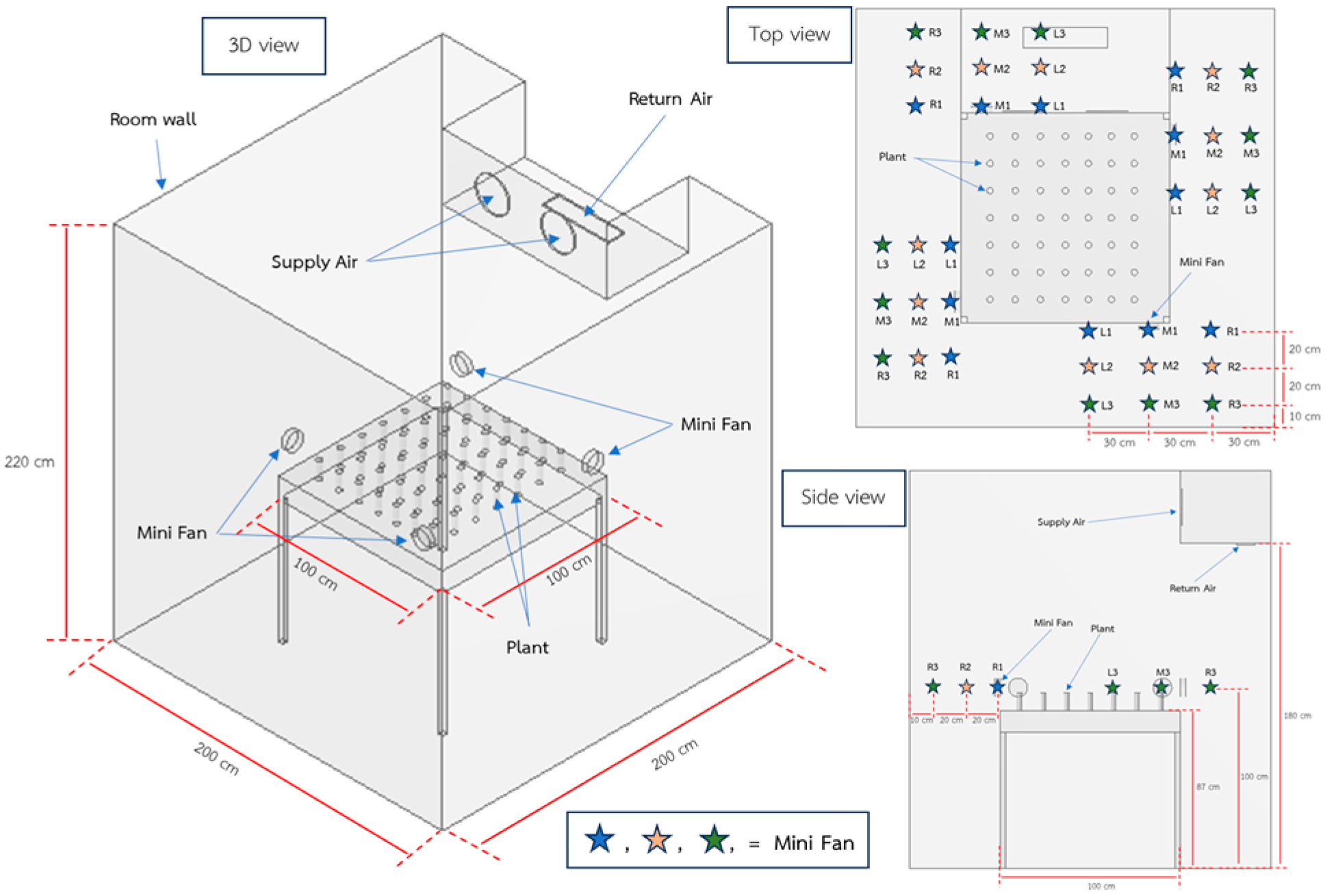

2.1. Case Description

2.2. CFD Simulation

2.2.1. Computational Fluid Dynamics Model

2.2.2. Regulatory Equation

2.3. Establishment of Experimental Parameters for Computational Fluid Dynamics Simulation

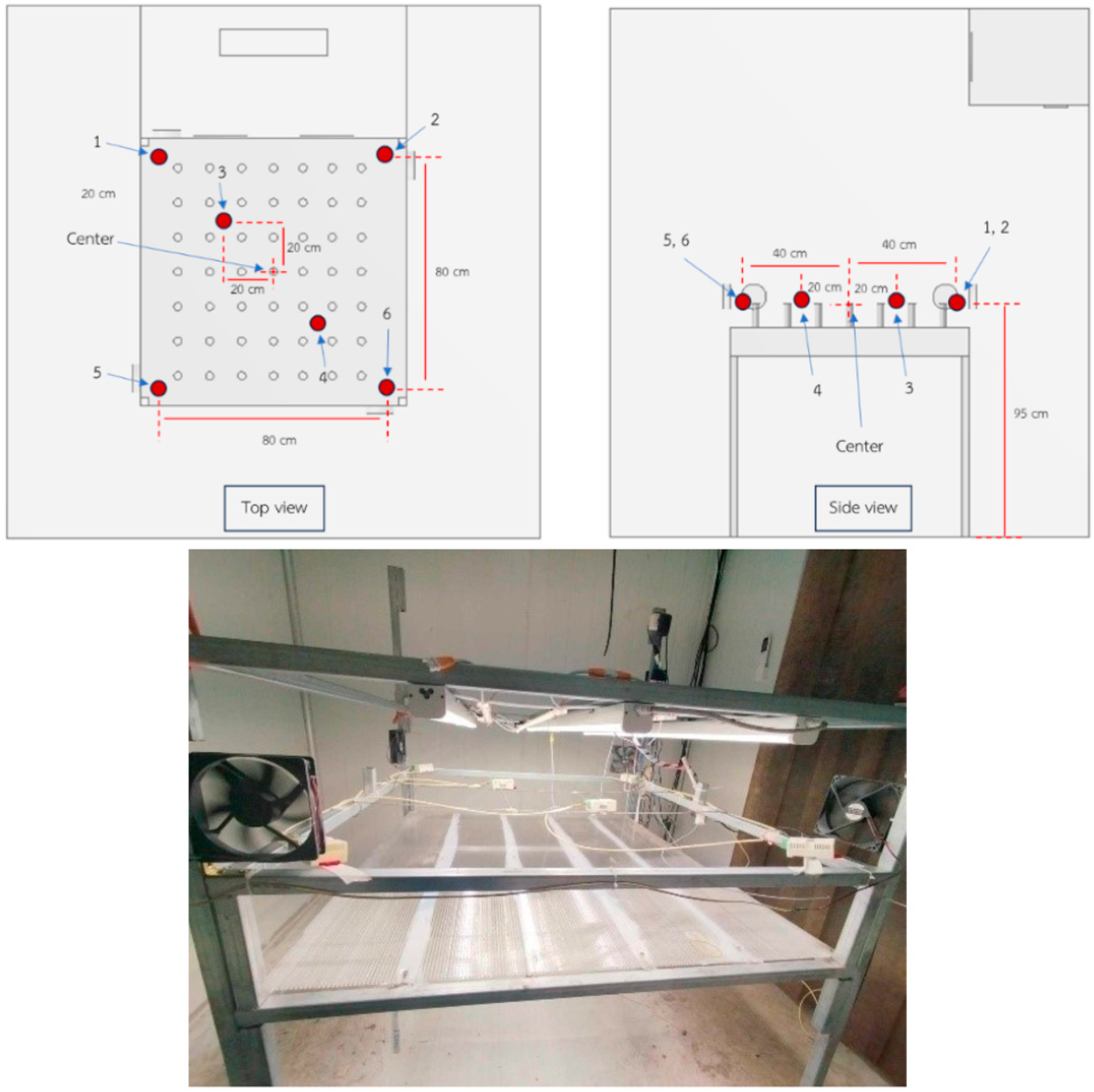

2.4. Verification of the Computational Fluid Dynamics Model

2.5. Quality of the Grid

2.6. Statistical Assessment

- yi is the observed value.

- ŷi is the predicted value from the model.

- ȳ is the mean of observed values.

- Oi represents observed values.

- Pi represents predicted values.

- Ōi represents the mean of observed values.

- NSE = 1 indicates perfect model performance.

- NSE > 0.8 indicates very good model performance.

- NSE < 0 indicates unsatisfactory model performance.

2.7. The Creation of the Computational Domain and Boundary Conditions

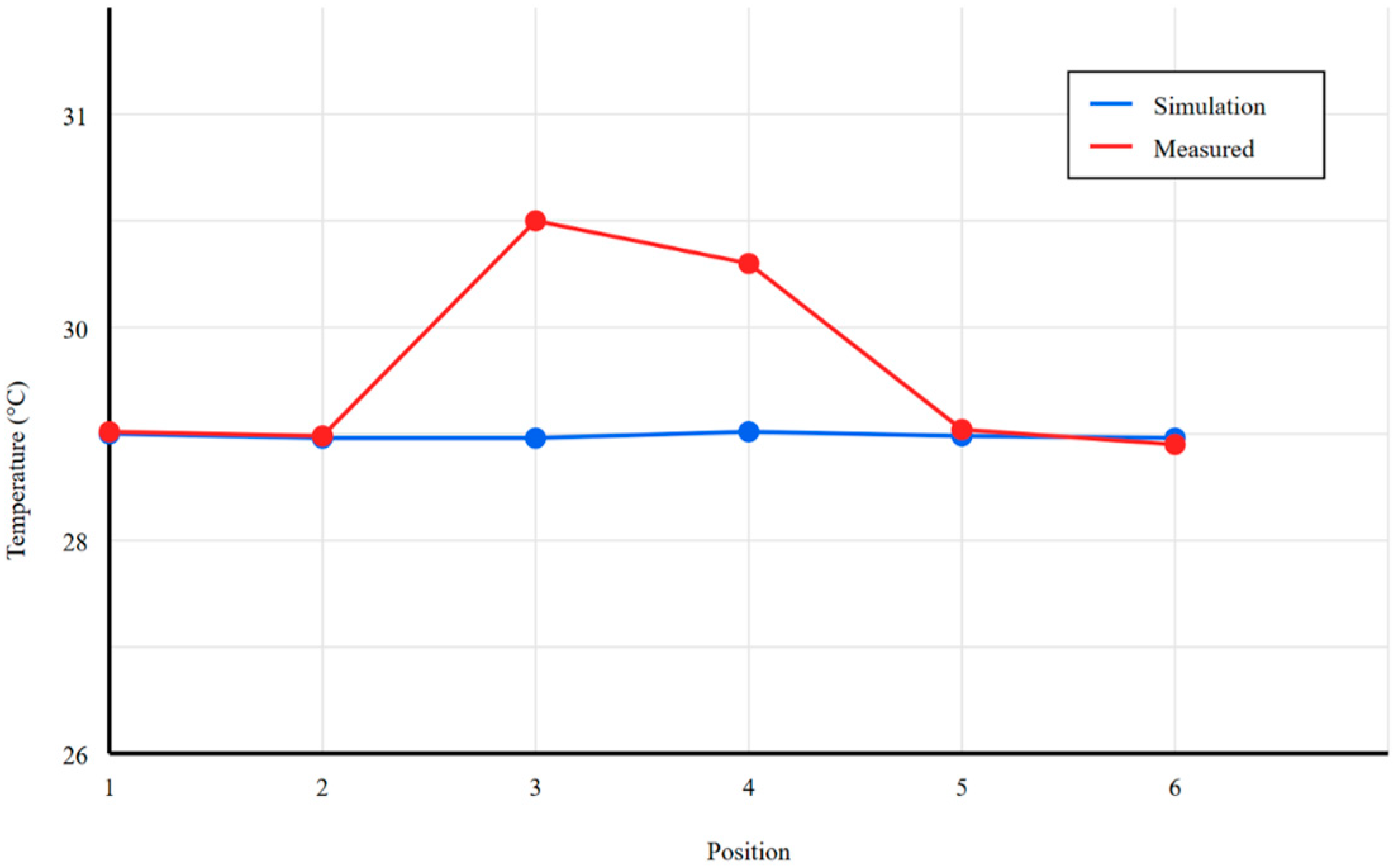

2.8. CFD Model Validation

3. Results

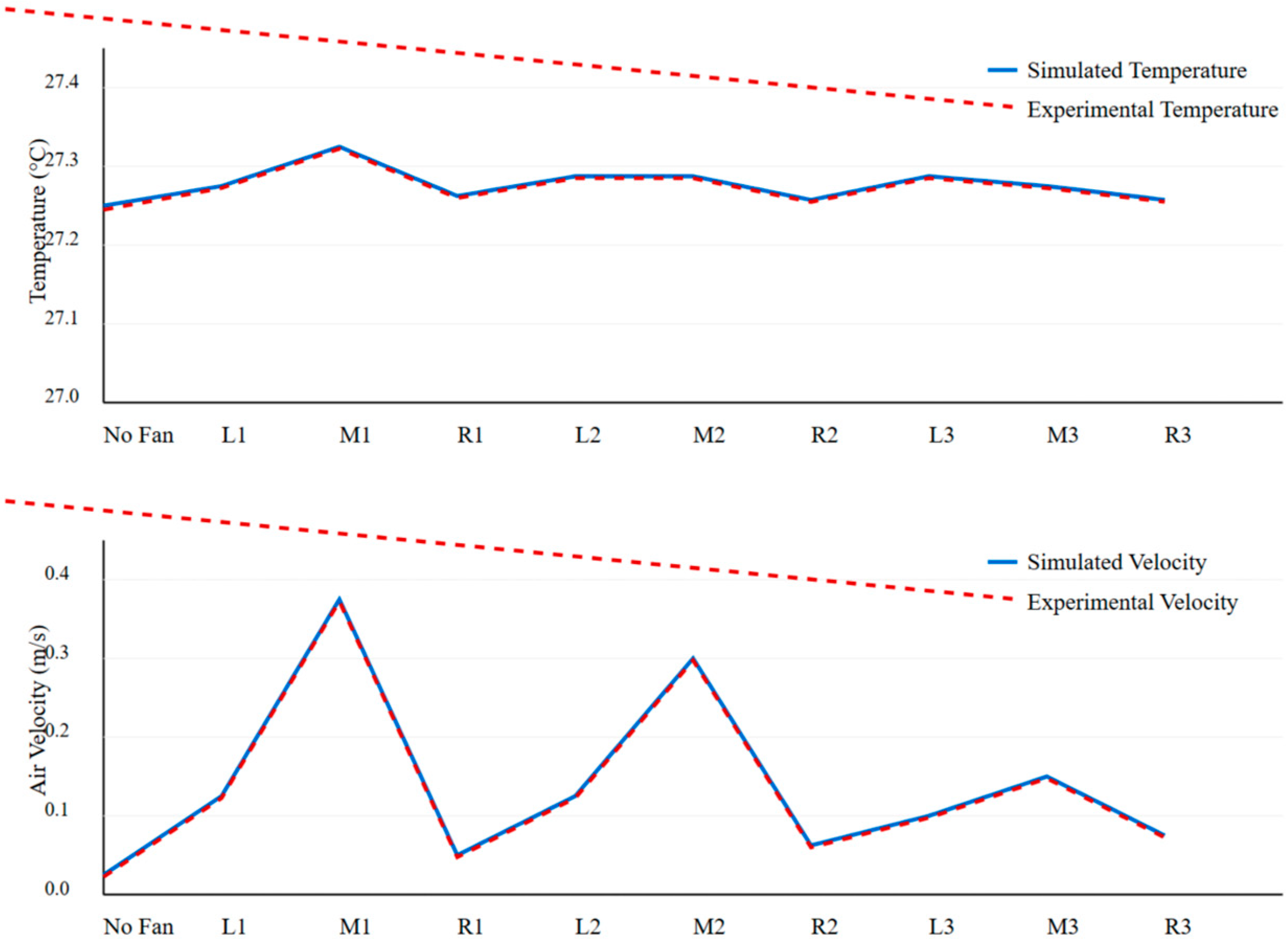

3.1. Results of CFD Model Validation

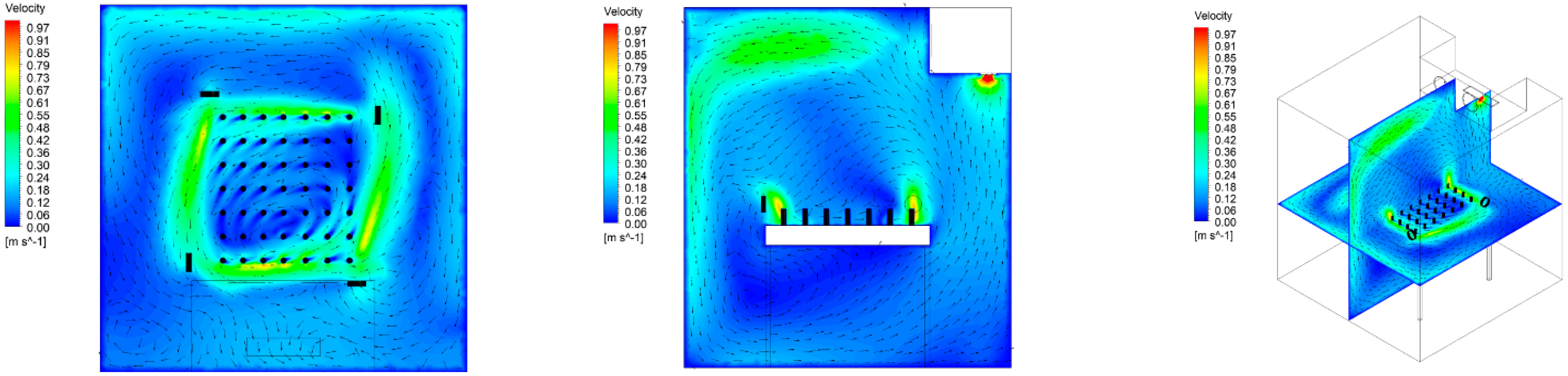

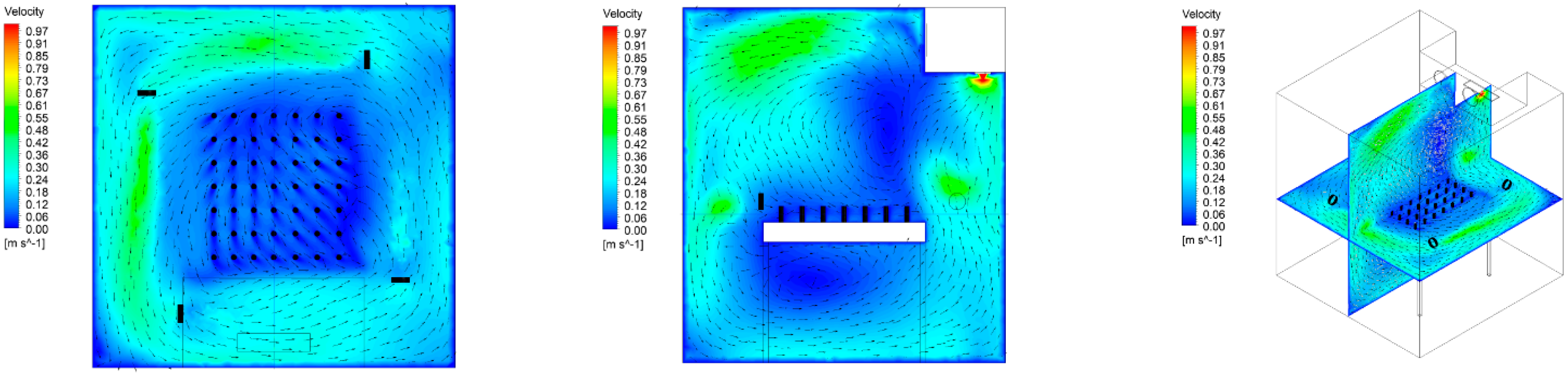

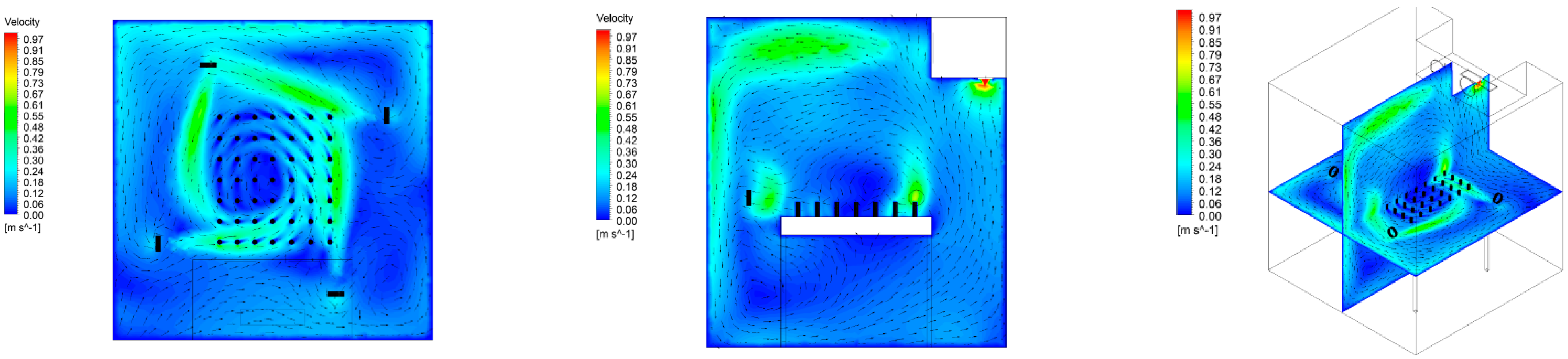

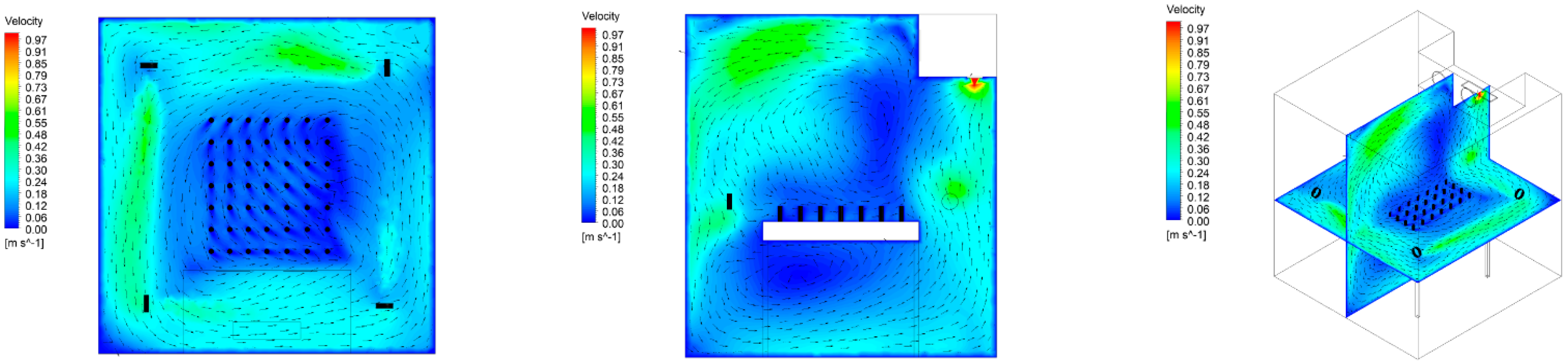

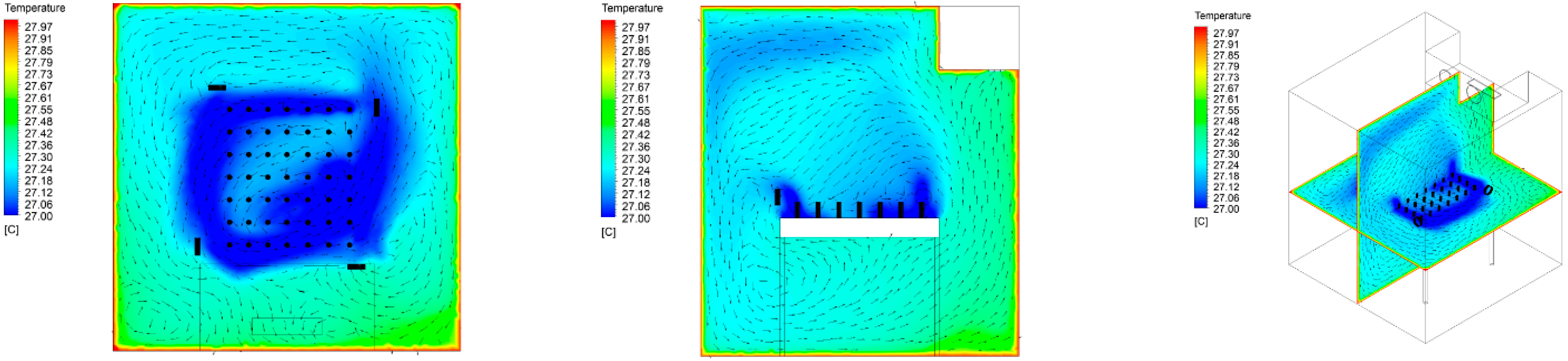

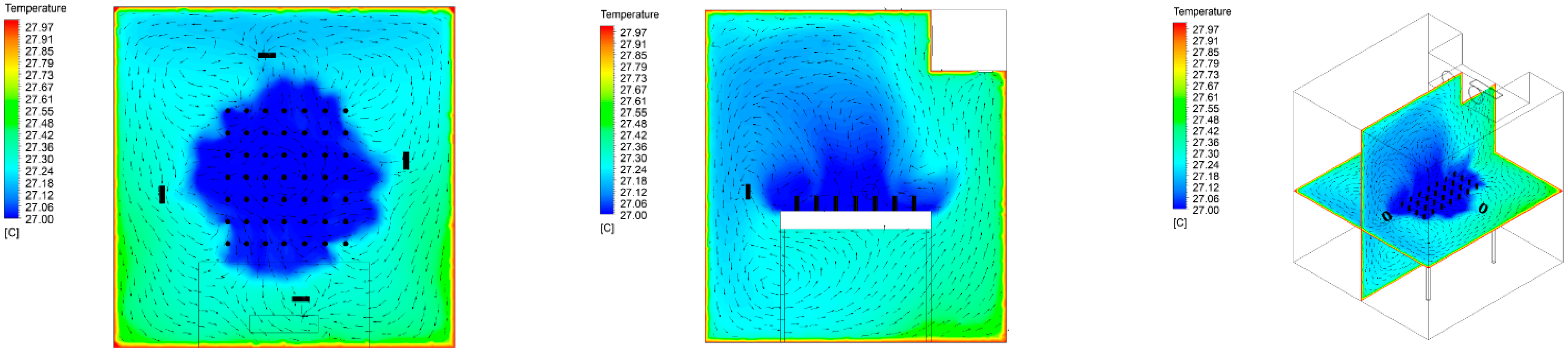

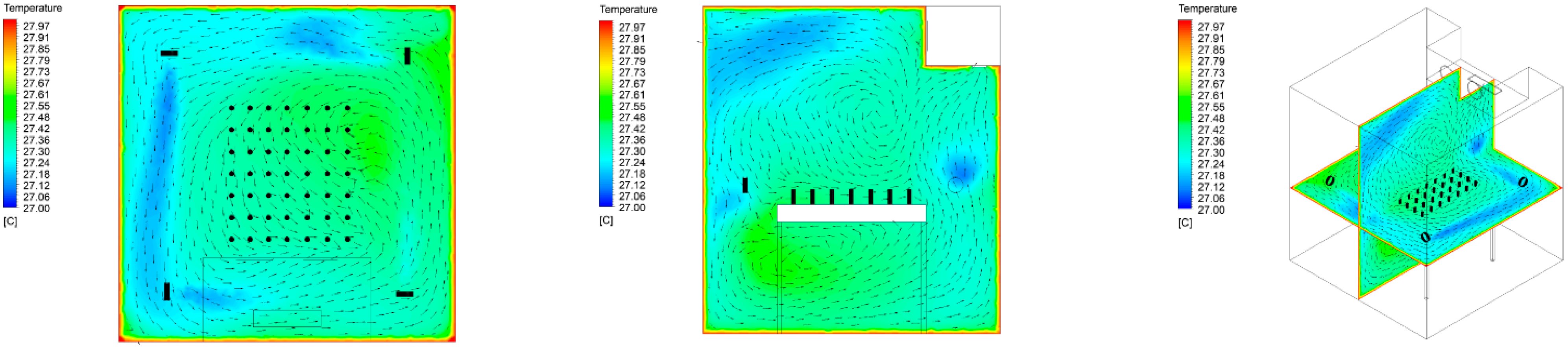

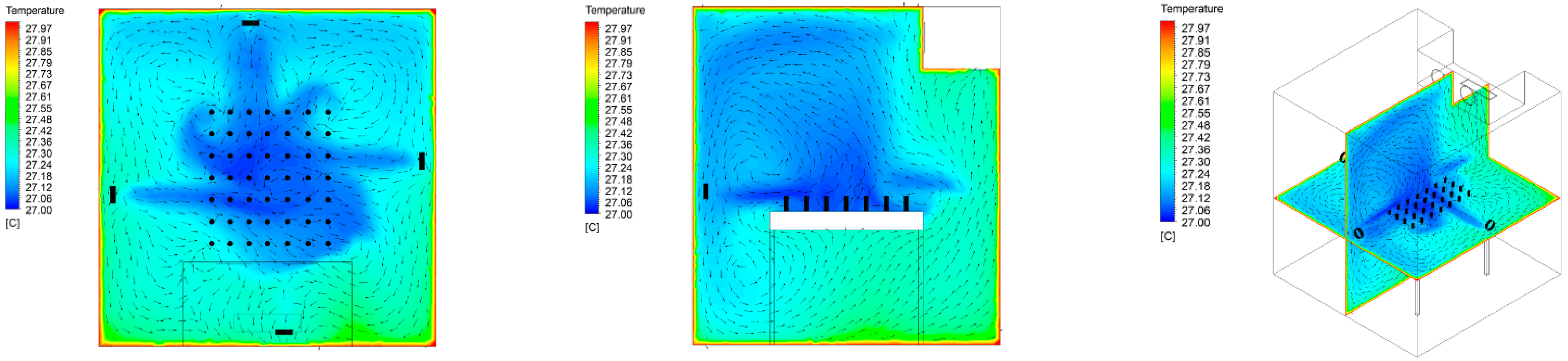

3.2. Results of the CFD Simulation on the Aerodynamic Environment

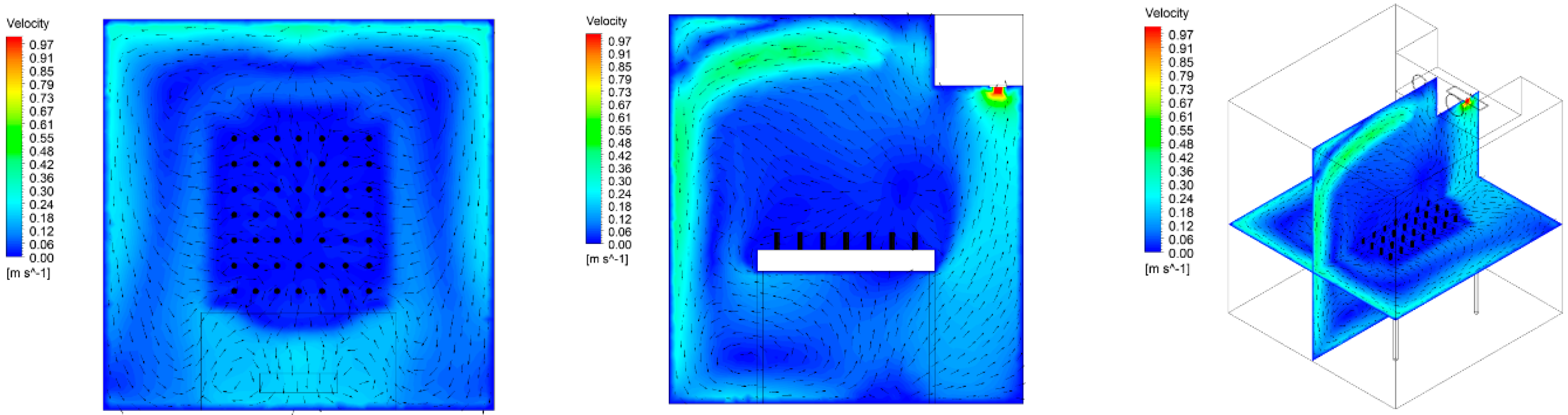

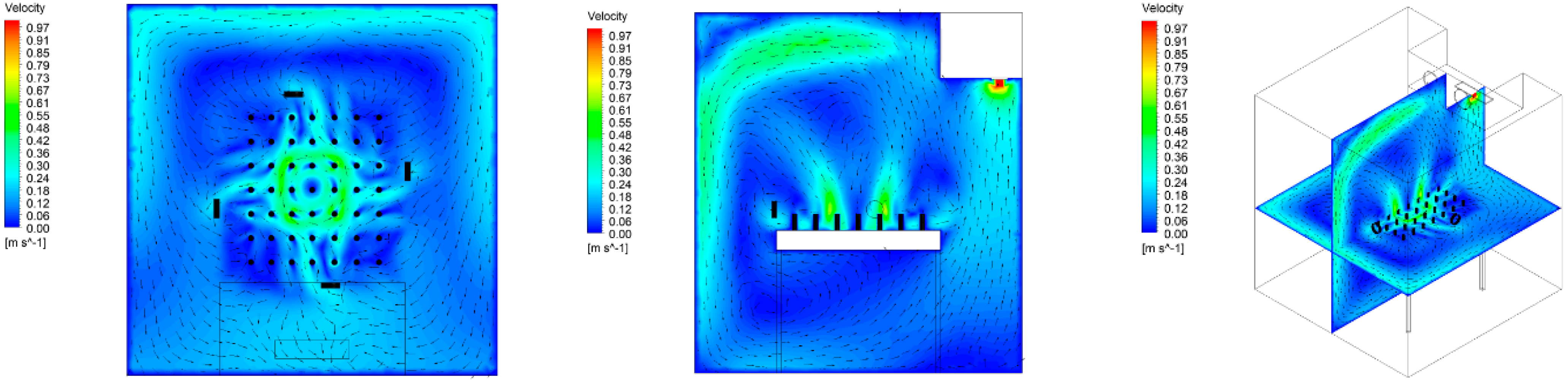

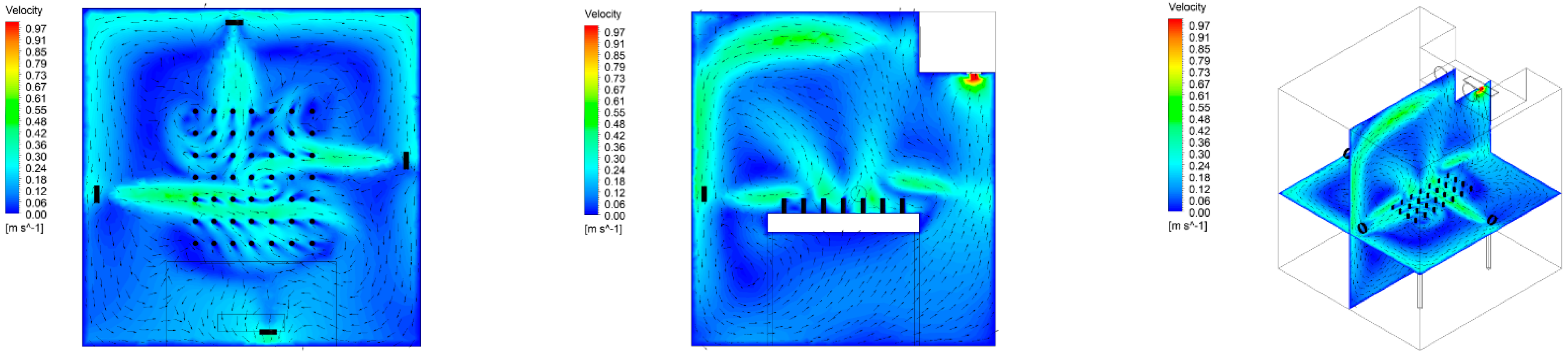

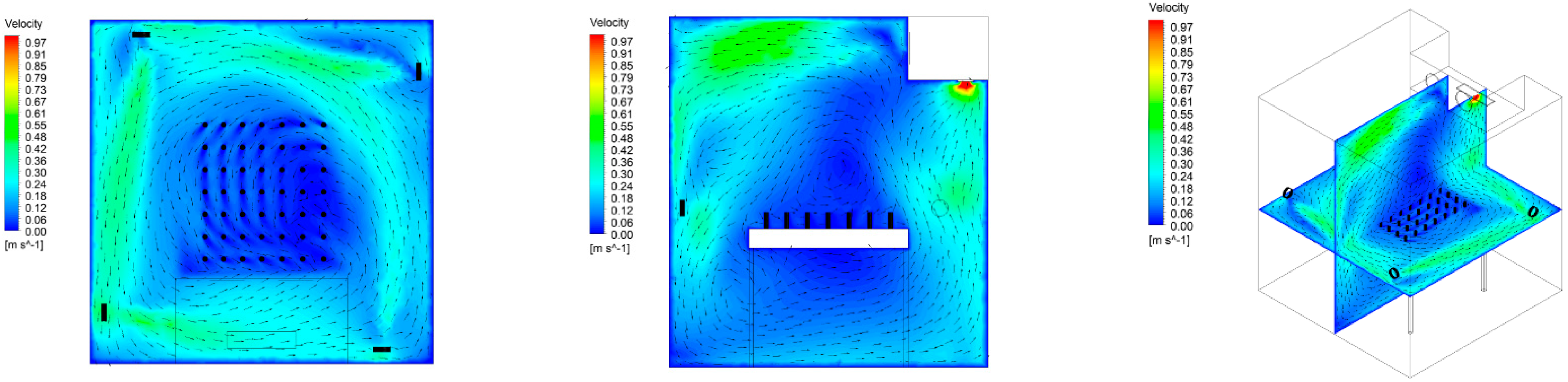

3.2.1. Results of the Wind Velocity Assessment in the Refrigeration Chamber

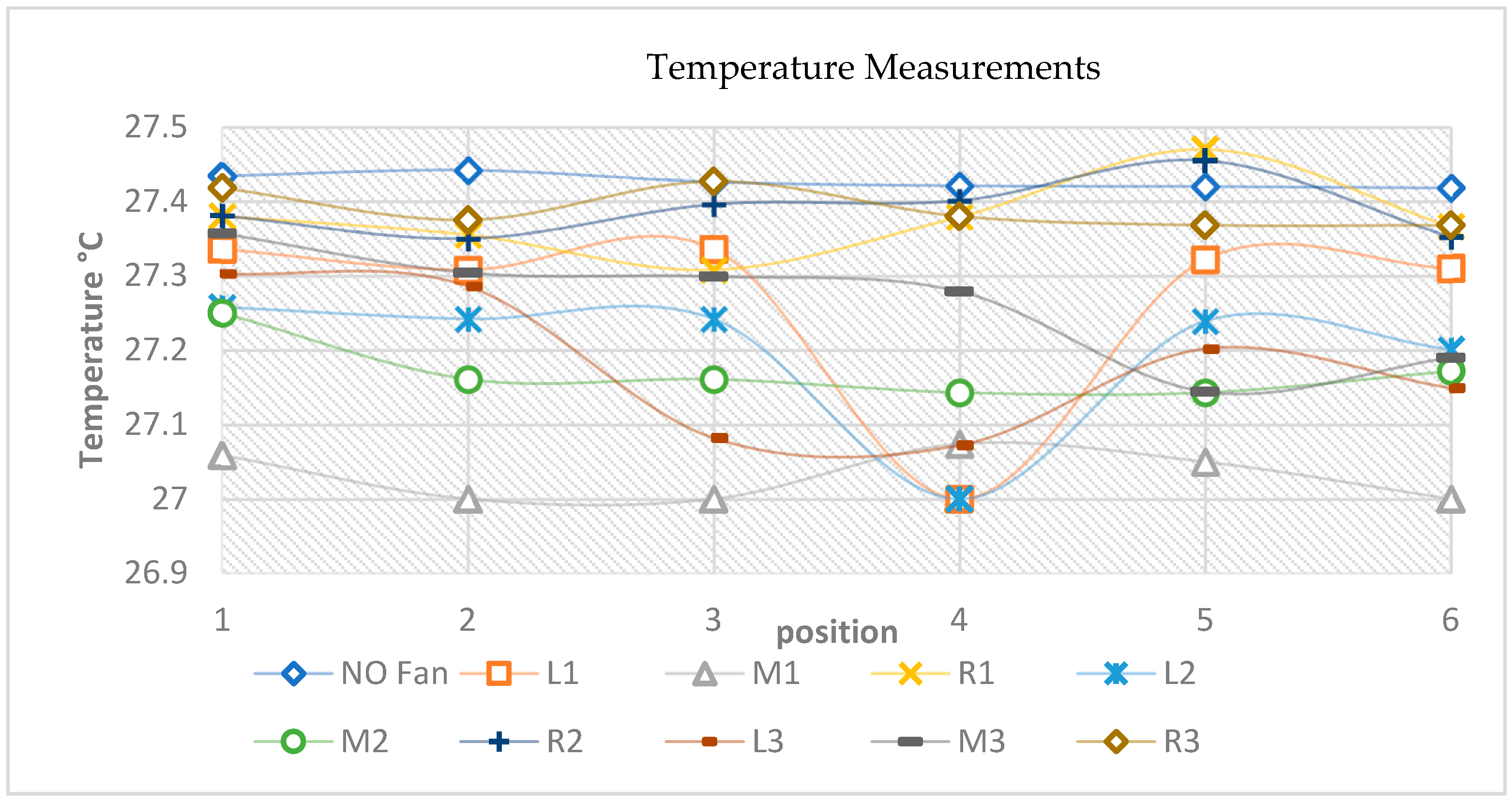

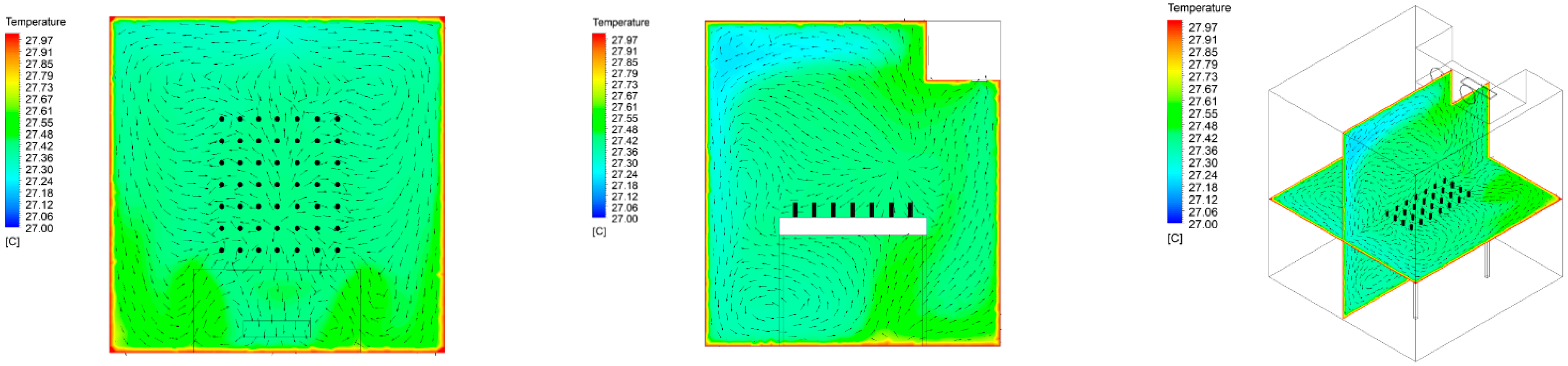

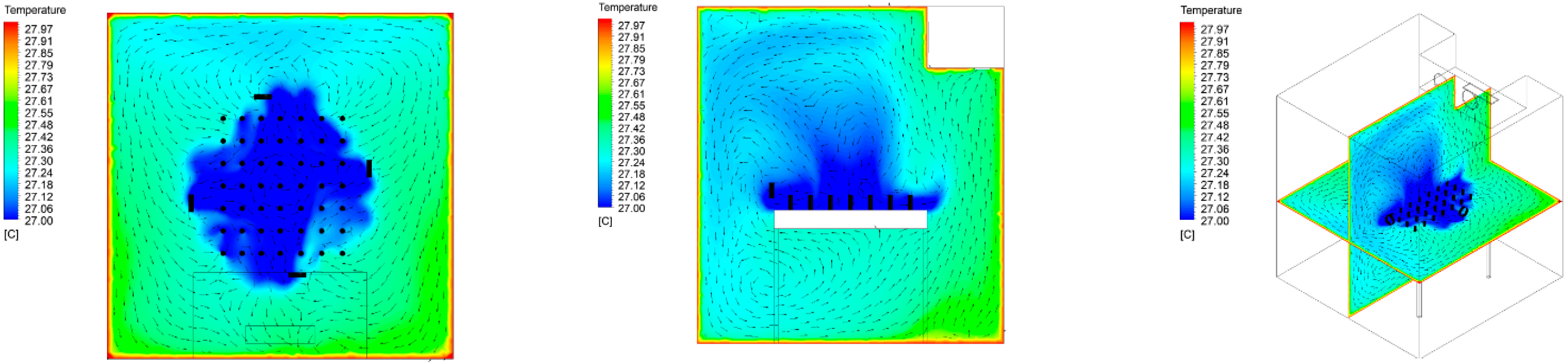

3.2.2. Results of Air Temperature Measurements in the Refrigerator

- (1)

- The substantial distance between the fan and planting table.

- (2)

- Fan orientation that directs airflow toward peripheral areas rather than the central zone.

- (3)

- Physical obstruction created by the table structure.

- (1)

- Repositioning the fan in closer proximity to the table.

- (2)

- Modifying the fan’s orientation to direct airflow toward the central area.

- (3)

- Installing air guidance systems.

- (4)

- Implementing a multiple-fan configuration.

4. Discussion

5. Conclusions

- (1)

- Enhanced air circulation may improve photosynthetic rates through better CO2 distribution.

- (2)

- More uniform temperature distribution could reduce heat stress on plants.

- (3)

- Improved ventilation may help prevent fungal diseases by reducing humidity pockets.

- (4)

- Better air mixing could contribute to stronger stem development through mechanical stimulation.

- (1)

- Positioning fans at optimal M1 locations in similar greenhouse layouts.

- (2)

- Considering multiple fan installations for larger cultivation areas.

- (3)

- Adjusting fan speeds based on specific crop requirements.

- (4)

- Regular monitoring of airflow patterns and temperature distribution.

- (1)

- Results are specific to the tested room configuration and size.

- (2)

- Further validation needed under varying environmental conditions.

- (3)

- Long-term effects on plant growth and development require investigation.

- (4)

- Cost–benefit analysis of different ventilation strategies recommended.

- (5)

- Impact on different plant species should be evaluated.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, Y.; Kacira, M. Analysis of climate uniformity in indoor plant factory system with computational fluid dynamics (CFD). Biosyst. Eng. 2022, 220, 73–86. [Google Scholar] [CrossRef]

- He, R.; Ju, J.; Liu, K.; Song, J.; Zhang, S.; Zhang, M.; Hu, Y.; Liu, X.; Li, Y.; Liu, H. Technology of plant factory for vegetable crop speed breeding. Front. Plant Sci. 2024, 15, 1414860. [Google Scholar] [CrossRef] [PubMed]

- Shang, Y.; Hasan, M.K.; Ahammed, G.J.; Li, M.; Yin, H.; Zhou, J. Applications of Nanotechnology in Plant Growth and Crop Protection: A Review. Molecules 2019, 24, 2558. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Guo, Y.; Zhao, H.; Wang, Y.; Chow, D. Towards automated greenhouse: A state of the art review on greenhouse monitoring methods and technologies based on internet of things. Comput. Electron. Agric. 2021, 191, 106558. [Google Scholar] [CrossRef]

- Si, C.; Qi, F.; Ding, X.; He, F.; Gao, Z.; Feng, Q.; Zheng, L. CFD Analysis of Solar Greenhouse Thermal and Humidity Environment Considering Soil–Crop–Back Wall Interactions. Energies 2023, 16, 2305. [Google Scholar] [CrossRef]

- Li, K.; Mi, Y.; Zheng, W. An Optimal Control Method for Greenhouse Climate Management Considering Crop Growth’s Spatial Distribution and Energy Consumption. Energies 2023, 16, 3925. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, W.; Yang, Y.; Hu, G.; Ge, D.; Liu, H.; Cao, H. A cloud computing-based approach using the visible near-infrared spectrum to classify greenhouse tomato plants under water stress. Comput. Electron. Agric. 2021, 181, 105966. [Google Scholar]

- Farooq, M.S.; Javid, R.; Riaz, S.; Atal, Z. IoT based smart greenhouse framework and control strategies for sustainable agriculture. IEEE Access 2022, 10, 99394–99420. [Google Scholar] [CrossRef]

- Contreras-Castillo, J.; Guerrero-Ibañez, J.A.; Santana-Mancilla, P.C.; Anido-Rifón, L. SAgric-IoT: An IoT-based platform and deep learning for greenhouse monitoring. Appl. Sci. 2023, 13, 1961. [Google Scholar] [CrossRef]

- Liu, R.; Li, M.; Guzmán, J.L.; Rodríguez, F. A fast and practical one-dimensional transient model for greenhouse temperature and humidity. Comput. Electron. Agric. 2021, 186, 106186. [Google Scholar] [CrossRef]

- Noh, K.; Jeong, B.R. Optimizing temperature and photoperiod in a home cultivation system to program normal, delayed, and hastened growth and development modes for leafy Oak-leaf and Romaine lettuces. Sustainability 2021, 13, 10879. [Google Scholar] [CrossRef]

- Dutta, D.; Sharma, V.; Guria, S.; Chakraborty, S.; Sarveswaran, S.; Harshavardhan, D.; Roy, P.; Nandi, S.; Thakur, A.; Kumar, S.; et al. Optimizing plant growth and crop productivity through hydroponics technique for sustainable agriculture: A review. Int. J. Environ. Clim. Change 2023, 13, 933–940. [Google Scholar] [CrossRef]

- Ma, X.K.; Liu, Y. Supramolecular purely organic room-temperature phosphorescence. Acc. Chem. Res. 2021, 54, 3403–3414. [Google Scholar] [CrossRef]

- Yan, X.; Peng, H.; Xiang, Y.; Wang, J.; Yu, L.; Tao, Y.; Chen, R. Recent advances on host–guest material systems toward organic room temperature phosphorescence. Small 2022, 18, 2104073. [Google Scholar] [CrossRef]

- Chen, M.T.; Zhang, R.L.; Feng, J.J.; Mei, L.P.; Jiao, Y.; Zhang, L.; Wang, A.J. A facile one-pot room-temperature growth of self-supported ultrathin rhodium-iridium nanosheets as high-efficiency electrocatalysts for hydrogen evolution reaction. J. Colloid Interface Sci. 2022, 606, 1707–1714. [Google Scholar] [CrossRef]

- Zhang, S.; Zhuo, Y.; Ezugwu, C.I.; Wang, C.C.; Li, C.; Liu, S. Synergetic molecular oxygen activation and catalytic oxidation of formaldehyde over defective MIL-88B (Fe) nanorods at room temperature. Environ. Sci. Technol. 2021, 55, 8341–8350. [Google Scholar] [CrossRef]

- Jagadish, S.K.; Way, D.A.; Sharkey, T.D. Plant heat stress: Concepts directing future research. Plant Cell Environ. 2021, 44, 1992–2005. [Google Scholar] [CrossRef] [PubMed]

- Rajiv; Kumari, M. Protected Cultivation of High-Value Vegetable Crops Under Changing Climate. In Advances in Research on Vegetable Production Under a Changing Climate; Springer International Publishing: Cham, Switzerland, 2023; Volume 2, pp. 229–266. [Google Scholar]

- Chimankare, R.V.; Das, S.; Kaur, K.; Magare, D. A review study on the design and control of optimised greenhouse environments. J. Trop. Ecol. 2023, 39, e26. [Google Scholar] [CrossRef]

- Kumar, S.; Bairwa, D.S.; Kumar, K.; Yadav, R.K.; Yadav, L.P. Climate regulation in protected structures: A review. J. Agric. Ecol. 2022, 13, 20–34. [Google Scholar] [CrossRef]

- Galieni, A.; D′Ascenzo, N.; Stagnari, F.; Pagnani, G.; Xie, Q.; Pisante, M. Past and future of plant stress detection: An overview from remote sensing to positron emission tomography. Front. Plant Sci. 2021, 11, 609155. [Google Scholar] [CrossRef]

- Kaur, R.; Kumar, S.; Ali, S.A.; Kumar, S.; Ezing, U.M.; Bana, R.; Meena, S.; Dass, A.; Singh, T. Impacts of climate change on crop-weed dynamics: Challenges and strategies for weed management in a changing climate. Open J. Environ. Biol. 2024, 9, 015–021. [Google Scholar]

- Kolupaev, Y.E.; Blume, Y.B. Plant Adaptation to Changing Environment and its Enhancement. Open Agric. J. 2022, 16, e187433152208251. [Google Scholar] [CrossRef]

- de Wit, H.A.; Stoddard, J.L.; Monteith, D.T.; Sample, J.E.; Austnes, K.; Couture, S.; Evans, C.D. Cleaner air reveals growing influence of climate on dissolved organic carbon trends in northern headwaters. Environ. Res. Lett. 2021, 16, 104009. [Google Scholar] [CrossRef] [PubMed]

- Yang, X.; Baskin, C.C.; Baskin, J.M.; Pakeman, R.J.; Huang, Z.; Gao, R.; Cornelissen, J.H. Global patterns of potential future plant diversity hidden in soil seed banks. Nat. Commun. 2021, 12, 7023. [Google Scholar] [CrossRef]

- Norton, T.; Sun, D. Computational fluid dynamics (CFD)—An effective and efficient design and analysis tool for the food industry: A review. Trends Food Sci. Technol. 2006, 17, 600–620. [Google Scholar] [CrossRef]

- Zhang, G.; Choi, C.; Bartzanas, T.; Lee, I.-B.; Kacira, M. Computational Fluid Dynamics (CFD) research and application in Agricultural and Biological Engineering. Comput. Electron. Agric. 2018, 149, 1–2. [Google Scholar] [CrossRef]

- Rocha, G.A.O.; Pichimata, M.A.; Villagran, E. Research on the Microclimate of Protected Agriculture Structures Using Numerical Simulation Tools: A Technical and Bibliometric Analysis as a Contribution to the Sustainability of Under-Cover Cropping in Tropical and Subtropical Countries. Sustainability 2021, 13, 10433. [Google Scholar] [CrossRef]

- Patankar, S. Numerical Heat Transfer and Fluid Flow; CRC Press: Boca Raton, FL, USA, 2018. [Google Scholar]

- Piscia, D.; Muñoz, P.; Panadès, C.; Montero, J.I. A method of coupling CFD and energy balance simulations to study humidity control in unheated greenhouses. Comput. Electron. Agric. 2015, 115, 129–141. [Google Scholar] [CrossRef]

- He, X.; Wang, J.; Guo, S.; Zhang, J.; Wei, B.; Sun, J.; Shu, S. Ventilation optimization of solar greenhouse with removable back walls based on CFD. Comput. Electron. Agric. 2018, 149, 16–25. [Google Scholar] [CrossRef]

- Piscia, D.; Montero, J.I.; Baeza, E.; Bailey, B.J. A CFD greenhouse night-time condensation model. Biosyst. Eng. 2012, 111, 141–154. [Google Scholar] [CrossRef]

- Akrami, M.; Mutlum, C.D.; Javadi, A.A.; Salah, A.H.; Fath, H.E.; Dibaj, M.; Negm, A. Analysis of inlet configurations on the microclimate conditions of a novel standalone agricultural greenhouse for Egypt using computational fluid dynamics. Sustainability 2021, 13, 1446. [Google Scholar] [CrossRef]

- López-Martínez, A.; Granados-Ortiz, F.J.; Molina-Aiz, F.D.; Lai, C.H.; Moreno-Teruel, M.D.L.Á.; Valera-Martínez, D.L. Analysis of Turbulent Air Flow Characteristics Due to the Presence of a 13 × 30 Threads·cm−2 Insect Proof Screen on the Side Windows of a Mediterranean Greenhouse. Agronomy 2022, 12, 586. [Google Scholar] [CrossRef]

- Tianning, Y.; Ma, X. Cost-effectiveness analysis of greenhouse dehumidification and integrated pest management using air′s water holding capacity—A case study of the Trella Greenhouse in Taizhou, China. In E3S Web of Conferences 2021; EDP Sciences: Les Ulis, France, 2021; Volume 251, p. 02063. [Google Scholar]

- Friman-Peretz, M.; Ozer, S.; Levi, A.; Magadley, E.; Yehia, I.; Geoola, F.; Teitel, M. Energy partitioning and spatial variability of air temperature, VPD and radiation in a greenhouse tunnel shaded by semitransparent organic PV modules. Sol. Energy 2021, 220, 578–589. [Google Scholar] [CrossRef]

- El Jazouli, M.; Lekouch, K.; Wifaya, A.; Gourdo, L.; Bouirden, L. CFD Study of Airflow and Microclimate Patterns Inside a Multispan Greenhouse. WSEAS Trans. Fluid Mech. 2021, 16, 102–108. [Google Scholar] [CrossRef]

- Moghaddam, J.J. The effect of turbulence on natural ventilation of a proposed octagonal greenhouse in a transient flow. Int. J. Environ. Sci. Technol. 2021, 18, 2181–2196. [Google Scholar] [CrossRef]

- Shojaei, M.H.; Mortezapour, H.; Jafarinaeimi, K.; Maharlooei, M.M. An Estimation Method for Greenhouse Temperature under the Influence of Evaporative Cooling System. J. Therm. Eng. 2021, 7, 918–933. [Google Scholar] [CrossRef]

- Omer, A.M. Analysis of Development in Solar Greenhouses. Indian J. Eng. 2019, 17, 15–52. [Google Scholar]

- Villagran, E. Implementation of ventilation towers in a greenhouse established in low altitude tropical climate conditions: Numerical approach to the behavior of the natural ventilation. Rev. Ceres 2021, 68, 10–22. [Google Scholar] [CrossRef]

- Mandal, C.; Ganguly, A. Thermal model development of a biomass regenerated desiccant supported greenhouse cooling for orchid cultivation. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2021; Volume 1080, p. 012044. [Google Scholar]

- Rasheed, A.; Lee, J.W.; Kim, H.T.; Lee, H.W. Study on Heating and Cooling Performance of Air-to-Water Heat Pump System for Protected Horticulture. Energies 2022, 15, 5467. [Google Scholar] [CrossRef]

- Munoz-Liesa, J.; Royapoor, M.; Cuerva, E.; Gassó-Domingo, S.; Gabarrell, X.; Josa, A. Building-integrated greenhouses raise energy co-benefits through active ventilation systems. Build. Environ. 2022, 208, 108585. [Google Scholar] [CrossRef]

- Mahmood, F.; Govindan, R.; Yang, D.; Bermak, A.; Al-Ansari, T. Forecasting cooling load and water demand of a semi-closed greenhouse using a hybrid modelling approach. Int. J. Ambient Energy 2022, 43, 8046–8066. [Google Scholar] [CrossRef]

- Larochelle Martin, G.; Monfet, D. High-density controlled environment agriculture (CEA-HD) air distribution optimization using computational fluid dynamics (CFD). Eng. Appl. Comput. Fluid Mech. 2024, 18, 2297027. [Google Scholar] [CrossRef]

- Doumbia, E.M.; Janke, D.; Yi, Q.; Amon, T.; Kriegel, M.; Hempel, S. CFD modelling of an animal occupied zone using an anisotropic porous medium model with velocity depended resistance parameters. Comput. Electron. Agric. 2021, 181, 105950. [Google Scholar] [CrossRef]

- Park, J.Y.; Yoo, Y.J.; Kim, Y.C. Optimization of the Outlet Shape of an Air Circulation System for Reduction of Indoor Temperature Difference. Sensors 2023, 23, 2570. [Google Scholar] [CrossRef]

| Order | Assumption |

|---|---|

| 1 | The analysis is static (steady state). |

| 2 | Use the properties of air as flow characteristics in the analysis. |

| 3 | Three-dimensional analysis. |

| 4 | An analysis of the gravitational aggregation of the Earth. |

| 5 | The viscosity model employs the standard k-epsilon equation |

| 6 | The model represents a refrigerator, and the walls of the chamber are insulated. |

| No | Parameter | Condition |

|---|---|---|

| 1 | No Fan | The input temperature of the supply air is 27 °C, and the wind speed is 1 m/s. |

| 2 | L1 | |

| 3 | M1 | The input temperature of the supply air is 27 °C, with a wind speed of 1 m/s. The fan speed is low, also set at 1 m/s. |

| 4 | R1 | |

| 5 | L2 | |

| 6 | M2 | |

| 7 | R2 | |

| 8 | L3 | |

| 9 | M3 | |

| 10 | R3 |

| Fan Installation Location | Multiple Comparisons | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| NO Fan | L1 | M1 | R1 | L2 | M2 | R2 | L3 | M3 | R3 | |

| NO Fan | 1 | −0.11617 | −0.29500 * | −0.04417 | −0.11433 | −0.23317 * | −0.05000 | −0.09950 | −0.14283 * | −0.05733 |

| L1 | 1 | −0.17883 * | 0.07200 | 0.00183 | −0.11700 | 0.06617 | 0.01667 | −0.02667 | 0.05883 | |

| M1 | 1 | 0.05883 * | 0.18067 * | 0.06183 | 0.24500 * | 0.19550 * | 0.15217 * | 0.23767 * | ||

| R1 | 1 | −0.07017 | −0.18900 * | −0.00583 | −0.05533 | −0.09867 | −0.01317 | |||

| L2 | 1 | −0.11883 | 0.06433 | 0.01483 | −0.02850 | 0.05700 | ||||

| M2 | 1 | 0.18317 * | 0.13367 * | 0.09033 | 0.17583 * | |||||

| R2 | 1 | −0.04950 | −0.09283 | −0.00733 | ||||||

| L3 | 1 | −0.04333 | 0.04217 | |||||||

| M3 | 1 | 0.08550 | ||||||||

| R3 | 1 | |||||||||

| Mean (m/s) | 0.0215 | 0.1377 | 0.3165 | 0.0657 | 0.1358 | 0.2547 | 0.0715 | 0.121 | 0.1643 | 0.0788 |

| ANOVA | Sum of Squares | df | Mean Square | F | Sig. | |||||

| Between Groups | 0.439 | 9 | 0.049 | 4.287 | 0.000 | |||||

| Within Groups | 0.569 | 50 | 0.011 | |||||||

| Total | 1.008 | 59 | ||||||||

| Fan Installation Location | Multiple Comparisons | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| NO Fan | L1 | M1 | R1 | L2 | M2 | R2 | L3 | M3 | R3 | |

| NO Fan | 1 | 0.15817 * | 0.39633 * | 0.05050 | 0.22983 * | 0.25517 | 0.03767 | 0.24450 * | 0.16467 * | 0.03750 |

| L1 | 1 | 0.23817 * | −0.10767 * | 0.07167 | 0.09700 * | −0.12050 * | 0.08633 * | 0.00650 | −0.12067 * | |

| M1 | 1 | −0.34583 * | −0.16650 * | −0.14117 * | −0.35867 * | −0.15183 * | −0.23167 * | −0.35883 * | ||

| R1 | 1 | 0.17933 * | 0.20467 * | −0.01283 | 0.19400 * | 0.11417 * | −0.01300 | |||

| L2 | 1 | 0.02533 | −0.19217 * | 0.01467 | −0.06517 | −0.19233 * | ||||

| M2 | 1 | −0.21750 * | −0.01067 | −0.09050 * | −0.21767 * | |||||

| R2 | 1 | 0.20683 * | 0.12700 * | −0.00017 | ||||||

| L3 | 1 | −0.07983 | −0.20700 * | |||||||

| M3 | 1 | −0.12717 * | ||||||||

| R3 | 1 | |||||||||

| Mean (°C) | 27.4268 | 27.2687 | 270.0305 | 27.3763 | 27.1970 | 27.1717 | 27.3892 | 27.1823 | 27.2622 | 27.3893 |

| ANOVA | Sum of Squares | df | Mean Square | F | Sig. | |||||

| Between Groups | 0.867 | 9 | 0.096 | 18.837 | 0.000 | |||||

| Within Groups | 0.256 | 50 | 0.005 | |||||||

| Total | 1.122 | 59 | ||||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wangkahart, S.; Junsiri, C.; Srichat, A.; Laloon, K.; Hongtong, K.; Boupha, P.; Katekaew, S.; Poojeera, S. Modeling Airflow and Temperature in a Sealed Cold Storage System for Medicinal Plant Cultivation Using Computational Fluid Dynamics (CFD). Agronomy 2024, 14, 2808. https://doi.org/10.3390/agronomy14122808

Wangkahart S, Junsiri C, Srichat A, Laloon K, Hongtong K, Boupha P, Katekaew S, Poojeera S. Modeling Airflow and Temperature in a Sealed Cold Storage System for Medicinal Plant Cultivation Using Computational Fluid Dynamics (CFD). Agronomy. 2024; 14(12):2808. https://doi.org/10.3390/agronomy14122808

Chicago/Turabian StyleWangkahart, Sakkarin, Chaiyan Junsiri, Aphichat Srichat, Kittipong Laloon, Kaweepong Hongtong, Phaiboon Boupha, Somporn Katekaew, and Sahassawas Poojeera. 2024. "Modeling Airflow and Temperature in a Sealed Cold Storage System for Medicinal Plant Cultivation Using Computational Fluid Dynamics (CFD)" Agronomy 14, no. 12: 2808. https://doi.org/10.3390/agronomy14122808

APA StyleWangkahart, S., Junsiri, C., Srichat, A., Laloon, K., Hongtong, K., Boupha, P., Katekaew, S., & Poojeera, S. (2024). Modeling Airflow and Temperature in a Sealed Cold Storage System for Medicinal Plant Cultivation Using Computational Fluid Dynamics (CFD). Agronomy, 14(12), 2808. https://doi.org/10.3390/agronomy14122808