Research Status, Methods and Prospects of Air-Assisted Spray Technology

Abstract

1. Introduction

2. Research Status of Air-Assisted Sprayer

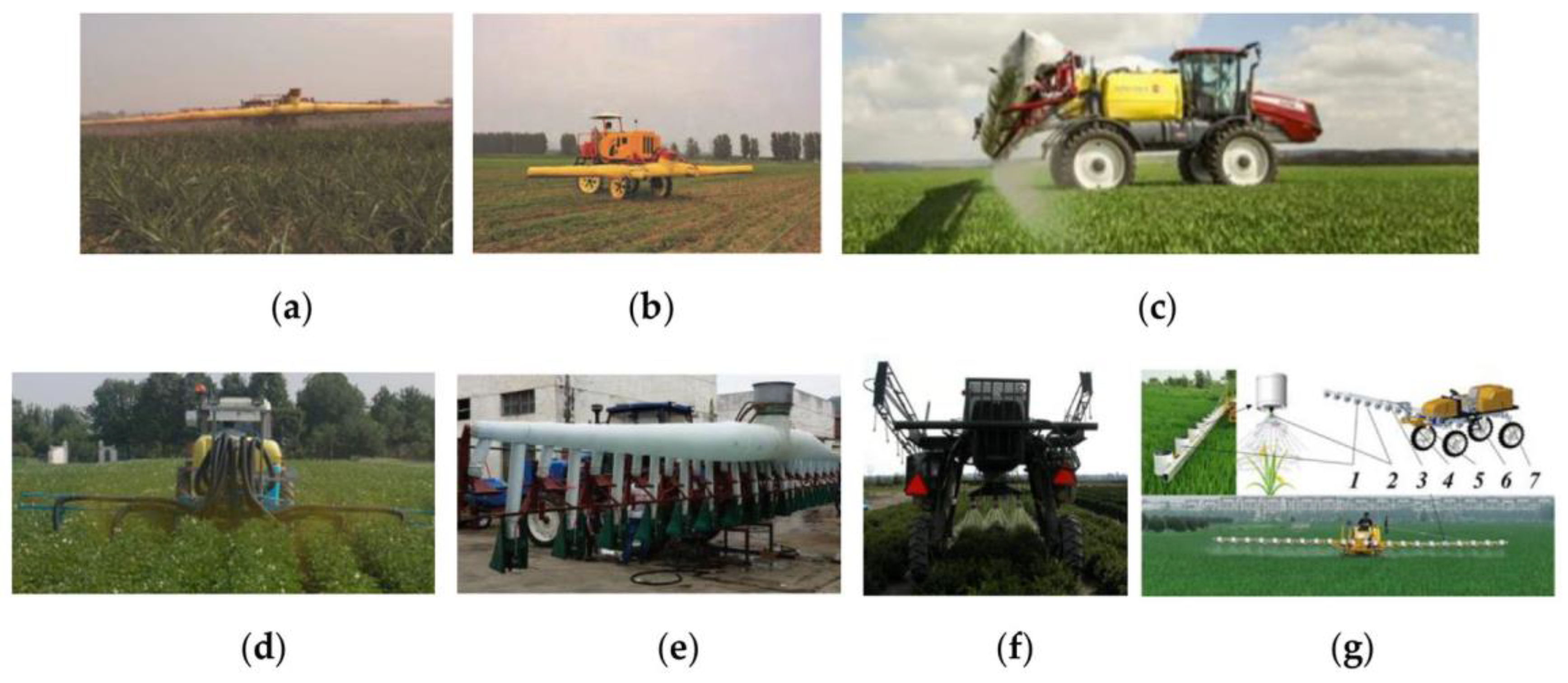

2.1. Air-Assisted Field Sprayer

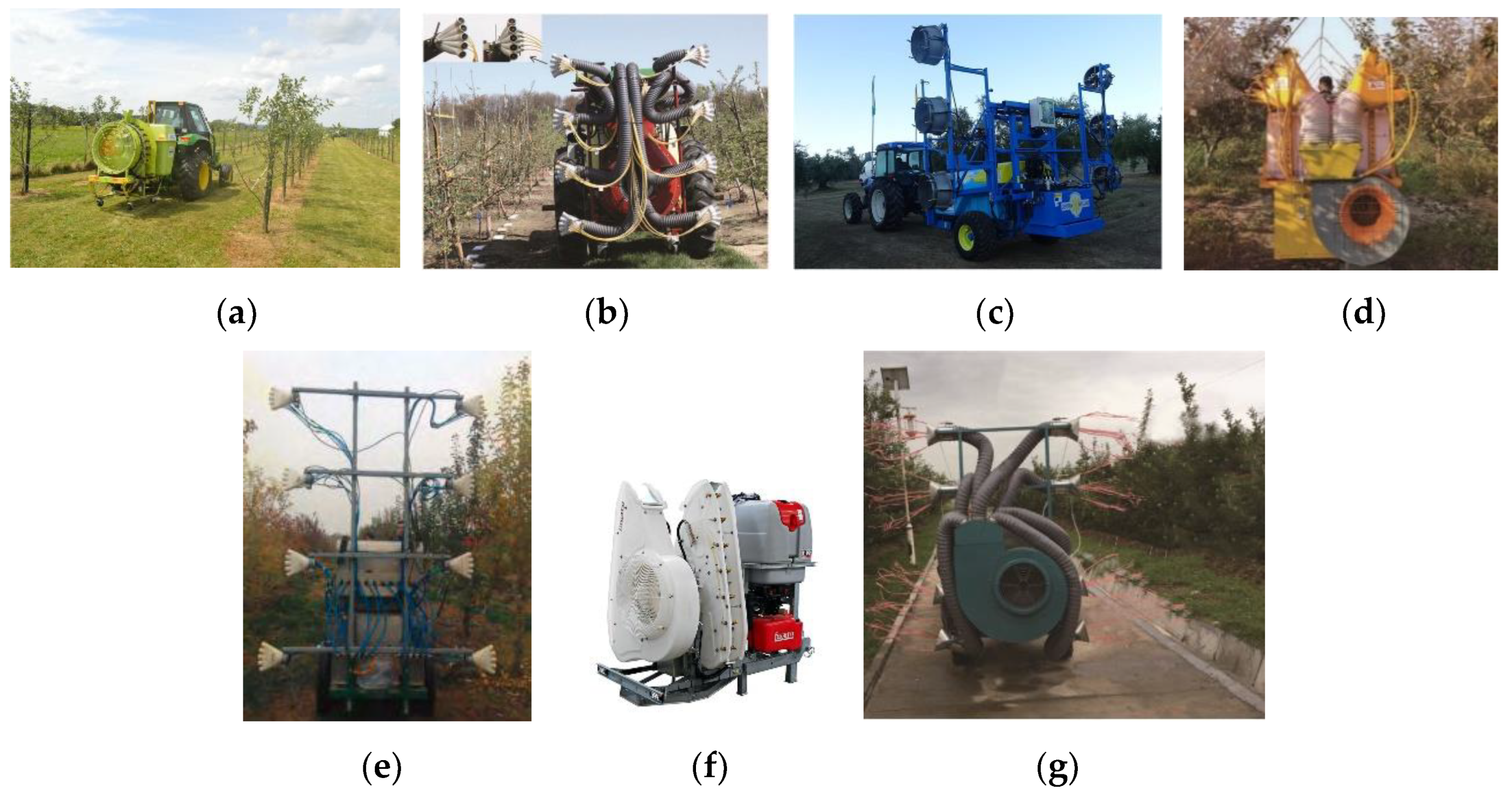

2.2. Orchard Sprayer

3. Research Methods of Air-Assisted Sprayer

3.1. Experimental Verification

- (1)

- Lower adaptability of test results. Field pesticide application tests are usually performed only for specific crops or canopy morphology in a specific growth stage under the uncontrollable pesticide application environment with the specific pesticide spraying equipment. Therefore, the test results obtained therein are not sufficiently adaptable. The test conclusions may vary significantly and even contradict each other when differences are found in target crop parameters, pesticide spraying equipment parameters and operation environments.

- (2)

- Restriction of test results. Only the relevant test data, such as spray operation parameters, environmental parameters, limited target crop parameters, droplet deposition amounts and drifts, can be obtained through field tests. It is difficult to obtain the relevant intermediate state data, such as the velocity field, spatial distribution and motion trajectory of droplets in the canopy. It is unable to reveal the deposition process and mechanism of droplets and the law of air flow attenuation in the crop canopy.

- (3)

- Heavy workload of data collection for field tests [66]. A typical field test involves water-sensitive paper, stainless steel mesh and nylon mesh to measure droplet deposition and drift, resulting in a heavy workload to set up the testing site and acquire the relevant data.

- (4)

- Poor Immediacy of test feedback. At present, field test data analysis is mostly completed using special analysis software Deposit Scan in the laboratory, which is full of trivial details and requires a long time. The analysis cannot be finished in the fields. Therefore, the current air-assisted sprayers cannot realize instant adaptive feedback and adjustment according to the result of test data analysis.

3.2. Theoretical Analysis

3.3. Simulation

3.4. Structural Optimization

4. Conclusions and Prospect

- (1)

- The air-assisted spray technology should be improved.

- (2)

- The research methods should be enhanced.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- An, Q.; Li, D.; Wu, Y.; Pan, C. Deposition and distribution of myclobutanil and tebuconazole in a semidwarf apple orchard by hand-held gun and air-assisted sprayer application. Pest Manag. Sci. 2020, 76, 4123–4130. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Liu, X.; Cui, H.; Yuan, J. Research Progress and Trend Analysis of Crop Canopy Droplet Deposition. Trans. Chin. Soc. Agric. Mach. 2021, 52, 1–20. [Google Scholar]

- Lan, Y.; Yan, Y.; Wang, B.; Song, C.; Wang, G. Current status and future development of the key technologies for intelligent pesticide spraying robots. Trans. Chin. Soc. Agric. Eng. 2022, 38, 30–40. [Google Scholar]

- Jiang, Y.; He, X.; Song, J.; Liu, Y.; Wang, C.; Li, T.; Qi, P.; Yu, C.; Chen, F. Comprehensive assessment of intelligent unmanned vehicle techniques in pesticide application: A case study in pear orchard. Front. Plant Sci. 2022, 13, 959429. [Google Scholar] [CrossRef]

- Gu, C.; Wang, X.; Wang, X.; Yang, F.; Zhai, C. Research progress on variable-rate spraying technology in orchards. Appl. Eng. Agric. 2020, 36, 927–942. [Google Scholar] [CrossRef]

- Salcedo, R.; Zhu, H.; Ozkan, E.; Falchieri, D.; Zhang, Z.; Wei, Z. Reducing ground and airborne drift losses in young apple orchards with PWM-controlled spray systems. Comput. Electron. Agric. 2021, 189, 106389. [Google Scholar] [CrossRef]

- Boatwright, H.; Zhu, H.; Clark, A.; Schnabel, G. Evaluation of the Intelligent Sprayer System in peach production. Plant Dis. 2020, 104, 3207–3212. [Google Scholar] [CrossRef]

- Petrović, D.; Banaj, D.; Banaj, A.; Barač, Ž.; Vidaković, I.; Tadić, V. The impact of conventional and sensor spraying on drift and deposit in cherry orchard. Teh. Vjesn. 2019, 26, 1211–1217. [Google Scholar] [CrossRef]

- Tadić, V.; Marković, M.; Plaščak, I.; Stošić, M.; Lukinac-Čačić, J.; Vujčić, B. Impact of technical spraying factors on leaf area coverage in an apple orchard. Teh. Vjesn. 2014, 21, 1117–1124. [Google Scholar]

- Chen, Y.; Ozkan, H.E.; Zhu, H.; Derksen, R.C.; Krause, C.R. Spray deposition inside tree canopies from a newly developed variable-rate air-assisted sprayer. Trans. ASABE 2013, 56, 1263–1272. [Google Scholar] [CrossRef]

- Chen, Y.; Zhu, H.; Ozkan, H.E.; Derksen, R.C.; Krause, C.R. Spray drift and off-target loss reductions with a precision air-assisted sprayer. Trans. ASABE 2013, 56, 1273–1281. [Google Scholar] [CrossRef]

- Salcedo, R.; Pons, P.; Llop, J.; Zaragoza, T.; Campos, J.; Ortega, P.; Gallart, M.; Gil, E. Dynamic evaluation of airflow stream generated by a reverse system of an axial fan sprayer using 3D-ultrasonic anemometers. Effect of canopy structure. Comput. Electron. Agric. 2019, 163, 104851. [Google Scholar] [CrossRef]

- Xun, L.; Garcia-Ruiz, F.; Fabregas, F.X.; Gil, E. Pesticide dose based on canopy characteristics in apple trees: Reducing environmental risk by reducing the amount of pesticide while maintaining pest and disease control efficacy. Sci. Total Environ. 2022, 826, 154204. [Google Scholar] [CrossRef] [PubMed]

- Derksen, R.C.; Ozkan, H.E.; Paul, P.A.; Zhu, H. Plant canopy characteristics effect on spray deposition. Asp. Appl. Biol. 2014, 122, 227–235. [Google Scholar]

- Duga, A.T.; Ruysen, K.; Dekeyser, D.; Nuyttens, D.; Bylemans, D.; Nicolai, B.M.; Verboven, P. Spray deposition profiles in pome fruit trees: Effects of sprayer design, training system and tree canopy characteristics. Crop Prot. 2015, 67, 200–213. [Google Scholar] [CrossRef]

- Qiu, W.; Zhao, S.; Ding, W.; Sun, C.; Lu, J.; Li, Y.; Gu, J. Effects of fan speed on spray deposition and drift for targeting air-assisted sprayer in pear orchard. Int. J. Agric. Biol. Eng. 2016, 9, 53–62. [Google Scholar]

- Miranda-Fuentes, A.; Rodríguez-Lizana, A.; Gil, E.; Agüera-Vega, J.; Gil-Ribes, J.A. Influence of liquid-volume and airflow rates on spray application quality and homogeneity in super-intensive olive tree canopies. Sci. Total Environ. 2015, 537, 250–259. [Google Scholar] [CrossRef]

- Pascuzzi, S. The effects of the forward speed and air volume of an air-assisted sprayer on spray deposition in tendone trained vineyards. J. Agric. Eng. 2013, 44, 125–132. [Google Scholar] [CrossRef]

- Derksen, R.C.; Paul, P.A.; Ozkan, H.E.; Zhu, H. Field evaluation of application techniques for fungicide spray deposition on wheat and artificial targets. Appl. Eng. Agric. 2012, 28, 325–331. [Google Scholar] [CrossRef]

- Wang, J.; Dong, X.; Yan, H.; Wang, J.; Zhang, T.; Zeng, Y. Experiment on spraying performance of air-assisted boom sprayer in corn field. Trans. Chin. Soc. Agric. Mach. 2015, 46, 79–84. [Google Scholar]

- Ozkan, H.E.; Zhu, H.; Derksen, R.C. Evaluation of spraying equipment for effective application of fungicides to control Asian Soybean Rust. In Proceedings of the 2006 ASAE Annual Meeting, Portland, OR, USA, 9–12 July 2006. [Google Scholar] [CrossRef]

- Derksen, R.C.; Zhu, H.; Ozkan, H.E.; Hammond, R.B.; Dorrance, A.E.; Spongberg, A.L. Determining the influence of spray quality, nozzle type, spray volume, and air-assisted application strategies on deposition of pesticides in soybean canopy. Trans. ASABE 2008, 51, 1529–1537. [Google Scholar] [CrossRef]

- Liu, X.; Liu, X.; Li, Y.; Yuan, J.; Li, H. Predicting spray deposit distribution within a cotton plant canopy based on canopy stratification porosity and Gaussian process models. Biosyst. Eng. 2021, 204, 1–14. [Google Scholar] [CrossRef]

- Womac, A.R.; Mulrooney, J.E.; Scott, W.P. Characteristics of air-assisted and drop-nozzle sprays in cotton. Trans. ASAE 1992, 35, 1369–1376. [Google Scholar] [CrossRef]

- Ade, G.; Rondelli, V. Performance of an air-assisted boom sprayer in the control of Colorado beetle infestation in potato crops. Biosyst. Eng. 2007, 97, 181–187. [Google Scholar] [CrossRef]

- Womac, A.R.; Ozkan, E.; Zhu, H.; Kochendorfer, J.; Jeon, H. Status of spray penetration and deposition in dense field crop canopies. Trans. ASABE 2022, 65, 1107–1117. [Google Scholar] [CrossRef]

- Vujčić, B.; Tadić, V.; Marković, M.; Lukinac-Čačić, J.; Stošić, M.; Plaščak, I. Impact of technical spraying factors on vertical liquid distribution with Agromehanika AGP 440 axial fan sprayer. Teh. Vjesn. 2015, 22, 367–373. [Google Scholar] [CrossRef]

- Gu, J.; Zhu, H.; Ding, W.; Wang, X. Characterization of air profiles impeded by plant canopies for a variable-rate air assisted sprayer. Trans. ASABE 2014, 57, 1307–1315. [Google Scholar] [CrossRef]

- Piché, M.; Panneton, B.; Thériault, R. Field evaluation of air-assisted boom spraying on broccoli and potato. Trans. ASAE 2000, 43, 793–799. [Google Scholar] [CrossRef]

- Salcedo, R.; Sánchez, E.; Zhu, H.; Fàbregas, X.; García-Ruiz, F.; Gil, E. Evaluation of an electrostatic spray charge system implemented in three conventional orchard sprayers used on a commercial apple trees plantation. Crop Prot. 2023, 167, 106212. [Google Scholar] [CrossRef]

- Nan, Y.; Zhang, H.; Zheng, J.; Yang, K.; Yang, W.; Zhang, M. Research on profiling tracking control optimization of orchard sprayer based on the phenotypic characteristics of tree crown. Comput. Electron. Agric. 2022, 192, 106455. [Google Scholar] [CrossRef]

- Jeon, H.Y.; Zhu, H. Development of a variable-rate sprayer for nursery liner applications. Trans. ASABE 2012, 55, 303–312. [Google Scholar] [CrossRef]

- Zhu, H.; Brazee, R.D.; Fox, R.D.; Derksen, R.C.; Ozkan, H.E. Development of a canopy opener to improve spray deposition and coverage inside soybean canopies: Part 1. mathematical models to assist opener development. Trans. ASABE 2008, 51, 1905–1912. [Google Scholar] [CrossRef]

- Zhu, H.; Derksen, R.C.; Ozkan, H.E.; Reding, M.E.; Krause, C.R. Development of a canopy opener to improve spray deposition and coverage inside soybean canopies: Part 2. opener design with field experiments. Trans. ASABE 2008, 51, 1913–1922. [Google Scholar] [CrossRef]

- Warneke, B.W.; Zhu, H.; Pscheidt, J.W.; Nackley, L.L. Canopy spray application technology in specialty crops: A slowly evolving landscape. Pest Manag. Sci. 2020, 77, 2157–2164. [Google Scholar] [CrossRef] [PubMed]

- Asaei, H.; Jafari, A.; Loghavi, M. Site-specific orchard sprayer equipped with machine vision for chemical usage management. Comput. Electron. Agric. 2019, 162, 431–439. [Google Scholar] [CrossRef]

- Czaczyk, Z. Influence of air flow dynamics on droplet size in conditions of air-assisted sprayers. At. Sprays 2012, 22, 275–282. [Google Scholar] [CrossRef]

- Xiahou, B.; Sun, D.; Song, S.; Xue, X.; Dai, Q. Simulation and experimental research on droplet flow characteristics and deposition in airflow field. Int. J. Agric. Biol. Eng. 2020, 13, 16–24. [Google Scholar] [CrossRef]

- Rocamora, M.C.; Val, L.; Pérez, M. Modelling the performance of air-assisted spraying on artichoke. Biosyst. Eng. 2002, 81, 385–393. [Google Scholar] [CrossRef]

- Grella, M.; Gil, E.; Balsari, P.; Marucco, P.; Gallart, M. Advances in developing a new test method to assess spray drift potential from air blast sprayers. Span. J. Agric. Res. 2017, 15, e0207. [Google Scholar] [CrossRef]

- Zhu, H.; Rowland, D.L.; Dorner, J.W.; Derksen, R.C.; Sorensen, R.B. Influence of plant structure, orifice size, and nozzle inclination on spray penetration into peanut canopy. Trans. ASAE 2002, 45, 1295–1301. [Google Scholar] [CrossRef]

- Zhang, T.; Yang, X.; Dong, X.; Liu, S.; Wang, J.; Dou, L. Experiment on spraying performance of super-high clearance boom sprayer with air-assisted system. Trans. Chin. Soc. Agric. Mach. 2012, 43, 66–71. [Google Scholar]

- Zhang, T.; Yang, X.; Yan, H.; Wang, J.; Dong, X. Anti-drift technology of super-high clearance boom sprayer with air-assisted system. Trans. Chin. Soc. Agric. Mach. 2012, 43, 77–86. [Google Scholar]

- Garcerá, C.; Moltó, E.; Chueca, P. Spray pesticide applications in Mediterranean citrus orchards: Canopy deposition and off-target losses. Sci. Total Environ. 2017, 599, 1344–1362. [Google Scholar] [CrossRef] [PubMed]

- Zhang, T.; Dong, X.; Yin, S.; Yang, X.; Yan, H.; Gong, Q. Spraying performance of lightweight high clearance boom sprayer in soybean field. Trans. Chin. Soc. Agric. Mach. 2016, 47, 182–188. [Google Scholar]

- Hardi International A/S. Twin Air Assistence. 2022. Available online: https://www.hardichina.com/sprayers/selfpropelled/contact/booms#nav (accessed on 10 March 2023).

- Wei, X.; Shao, J.; Xie, L.; Lv, X. Design and experiment of air-assisted cotton boom sprayer with separating row and spraying in inside and upper canopy. Trans. Chin. Soc. Agric. Mach. 2016, 47, 101–107. [Google Scholar]

- Zhu, H.; Brazee, R.D.; Derksen, R.C.; Fox, R.D.; Krause, C.R.; Ozkan, H.E.; Losely, K. A specially designed air-assisted sprayer to improve spray penetration and air jet velocity distribution inside dense nursery crops. Trans. ASABE 2006, 49, 1285–1294. [Google Scholar] [CrossRef]

- Qiu, W.; Guo, H.; Cao, Y.; Li, X.; Wu, J.; Chen, Y.; Yu, H.; Zhang, Z. An electrical vortex air-assisted spraying system for improving droplet deposition on rice. Pest Manag. Sci. 2022, 78, 4037–4047. [Google Scholar] [CrossRef]

- Salcedo, R.; Zhu, H.; Zhang, Z.; Wei, Z.; Chen, L.; Ozkana, E.; Falchierie, D. Foliar deposition and coverage on young apple trees with PWM-controlled spray systems. Comput. Electron. Agric. 2020, 178, 105794. [Google Scholar] [CrossRef]

- Ortega, P.; Salas, B.; Balsari, P.; Polder, G.; Fountas, S.; Nuyttens, D.; Jesus, J.; Balafoutis, T.; Gil, E. H2020–OPTIMA–Optimised pest integrated management to precisely detect and control plant diseases in perennial crops and open-field vegetables. Asp. Appl. Biol. 2020, 144, 221–227. [Google Scholar]

- Gil, E.; Ortega, P.; Salas, B.; Andreu, F.; Berger, L.T.; Fountas, S.; Nuyttens, D. Development of a methodology to select the optimal application technologies in apple crop–EU project OPTIMA H2020. Asp. Appl. Biol. 2020, 144, 67–75. [Google Scholar]

- Miranda-Fuentes, A.; Rodríguez-Lizana, A.; Cuenca, A.; González-Sánchez, E.J.; Blanco-Roldán, G.L.; Gil-Ribes, J.A. Improving plant protection product applications in traditional and intensive olive orchards through the development of new prototype air-assisted sprayers. Crop Prot. 2017, 94, 44–58. [Google Scholar] [CrossRef]

- Wang, J.; Qiu, W.; Ding, W.; Zhang, Z.; Wen, Z.; Su, Y. Design and experiment of 3WZ-300 type air-assisted sprayer for orchard with Y-typed trellis. J. S. Chin. Agric. Univ. 2021, 42, 60–70. [Google Scholar]

- Li, L.; He, X.; Song, J.; Wang, X.; Jia, X.; Liu, C. Design and experiment of automatic profiling orchard sprayer based on variable air volume and flow rate. Trans. Chin. Soc. Agric. Eng. 2017, 33, 70–76. [Google Scholar]

- Jiang, H.; Niu, C.; Liu, L.; Wang, D.; Wang, J.; Mao, W. Design and experiment of air volume control system of orchard multi-pipe air sprayer. Trans. Chin. Soc. Agric. Mach. 2020, 51, 298–307. [Google Scholar]

- Grella, M.; Gallart, M.; Marucco, P.; Balsari, P.; Gil, E. Ground deposition and airborne spray drift assessment in vineyard and orchard: The influence of environmental variables and sprayer settings. Sustainability 2017, 9, 728. [Google Scholar] [CrossRef]

- Grella, M.; Marucco, P.; Zwertvaegher, I.; Gioelli, F.; Bozzer, C.; Biglia, A.; Manzone, M.; Caffini, A.; Fountas, S.; Nuyttens, D.; et al. The effect of fan setting, air-conveyor orientation and nozzle configuration on airblast sprayer efficiency: Insights relevant to trellised vineyards. Crop Prot. 2022, 155, 105921. [Google Scholar] [CrossRef]

- Gu, C.; Liu, Z.; Pan, G.; Pu, Y.; Yang, F. Optimization of working parameters for 3MGY-200 axial air-assisted sprayer in kiwifruit orchards. Int. J. Agric. Biol. Eng. 2020, 13, 81–91. [Google Scholar] [CrossRef]

- Fu, J.; Chen, C.; Zhao, R.; Ren, L. Accurate variable control system for boom sprayer based on auxiliary antidrift system. J. Sensors 2020, 2020, 8037046. [Google Scholar] [CrossRef]

- Panneton, B.; Philion, H.; Theriault, R.; Khelifi, M. Spray chamber evaluation of air-assisted spraying on Broccoli. Crop Sci. 2000, 40, 444–448. [Google Scholar] [CrossRef]

- Jia, W.; Li, X.; Zhou, H.; Gong, C.; Ou, M. Research on the calculation method of droplet drift in air curtain boom sprayer. J. Agric. Mech. Res. 2018, 8, 10–15. [Google Scholar] [CrossRef]

- Li, T.; Qi, P.; Wang, Z.; Xu, S.; Huang, Z.; Han, L.; He, X. Evaluation of the effects of airflow distribution patterns on deposit coverage and spray penetration in multi-unit air-assisted sprayer. Agronomy 2022, 12, 944. [Google Scholar] [CrossRef]

- Shi, R.; Sun, H.; Qiu, W.; Lv, X.; Ahmad, F.; Gu, J.; Yu, H. Analysing airflow velocity in the canopy to improve droplet deposition for air-assisted spraying: A case study on pears. Agronomy 2022, 12, 2424. [Google Scholar] [CrossRef]

- Salas, B.; Salcedo, R.; Ortega, P.; Grella, M.; Gil, E. Use of ultrasound anemometers to study the influence of air currents generated by a sprayer with an electronic control airflow system on foliar coverage. Effect of droplet size. Comput. Electron. Agric. 2022, 202, 107381. [Google Scholar] [CrossRef]

- Badules, J.; Vidal, M.; Boné, A.; Llop, J.; Salcedo, R.; Gil, E.; García-Ramos, F.J. Comparative study of CFD models of the air flow produced by an air-assisted sprayer adapted to the crop geometry. Comput. Electron. Agric. 2018, 149, 166–174. [Google Scholar] [CrossRef]

- Dai, F. Selection and calculation of the blowing rate of air assisted sprayers. Plant Protect. 2008, 34, 124–127. [Google Scholar]

- Panneton, B.; Lacasse, B.; Thériault, R. Penetration of spray in apple trees as a function of airspeed, airflow, and power for tower sprayers. Can. Bisyst. Eng. 2005, 47, 2.13–2.20. [Google Scholar]

- Endalew, A.M.; Debaer, C.; Rutten, N.; Vercammen, J.; Delele, M.A.; Ramon, H.; Nicolaï, B.M.; Verboven, P. A new integrated CFD modelling approach towards air-assisted orchard spraying. Part I. Model development and effect of wind speed and direction on sprayer airflow. Comput. Electron. Agric. 2010, 71, 128–136. [Google Scholar] [CrossRef]

- Endalew, A.M.; Debaer, C.; Rutten, N.; Vercammen, J.; Delele, M.A.; Ramon, H.; Nicolaï, B.M.; Verboven, P. A new integrated CFD modelling approach towards air-assisted orchard spraying—Part II: Validation for different sprayer types. Comput. Electron. Agric. 2010, 71, 137–147. [Google Scholar] [CrossRef]

- Hong, S.; Zhao, L.; Zhu, H. CFD simulation of airflow inside tree canopies discharged from air-assisted sprayers. Comput. Electron. Agric. 2018, 149, 121–132. [Google Scholar] [CrossRef]

- Xu, T.; Zhou, H.; Lv, X.; Lei, X.; Tao, S. Study of the distribution characteristics of the airflow field in tree canopies based on the CFD model. Agronomy 2022, 12, 3072. [Google Scholar] [CrossRef]

- Cui, H.; Wang, C.; Liu, X.; Yuan, J.; Liu, Y.; Song, L. Cotton canopy airflow simulation and velocity attenuation model based upon 3D phenotype and stratified sub-regional porous medium. Comput. Electron. Agric. 2022, 201, 107282. [Google Scholar] [CrossRef]

- Liu, X. Study on Air-Assisted Droplets Penetration in Dense Canopy Based on Stratification Porosity. Master’s Thesis, Shandong Agricultural University, Taian, China, 2021. [Google Scholar]

- Hong, S.; Zhao, L.; Zhu, H. CFD simulation of pesticide spray from air-assisted sprayers in an apple orchard: Tree deposition and off-target losses. Atmos. Environ. 2018, 175, 109–119. [Google Scholar] [CrossRef]

- Hong, S.; Zhao, L.; Zhu, H. SAAS, a computer program for estimating pesticide spray efficiency and drift of air-assisted pesticide applications. Comput. Electron. Agric. 2018, 155, 58–68. [Google Scholar] [CrossRef]

- Li, J.; Li, Z.; Ma, Y.; Cui, H.; Yang, Z.; Lu, H. Effects of leaf response velocity on spray deposition with an air-assisted orchard sprayer. Int. J. Agric. Biol. Eng. 2021, 14, 123–131. [Google Scholar] [CrossRef]

- Yan, C.; Niu, C.; Ma, S.; Tan, H.; Xu, L. CFD models as a tool to analyze the deformation behavior of grape leaves under an air-assisted sprayer. Comput. Electron. Agric. 2022, 198, 107112. [Google Scholar] [CrossRef]

- Zhang, T. Experimental Study and CFD Simulation of Air-Assisted System on Super-High Clearance Boom Sprayer. Ph.D. Thesis, China Academy of Agricultural Mechanization, Beijing, China, 2012. [Google Scholar]

- Liang, Z. Research on Parameter Optimization and Intelligent Control Strategy of Wind Curtain Anti-Drift System Based on Bimodal Distributed Drift Deposition Model. Master’s Thesis, Shandong Agricultural University, Taian, China, 2020. [Google Scholar]

- Hočevar, M.; Širok, B.; Jejčič, V.; Godeša, T.; Lešnika, M.; Stajnko, D. Design and testing of an automated system for targeted spraying in orchards. J. Plant Dis. Protect. 2010, 117, 71–79. [Google Scholar] [CrossRef]

- Osterman, A.; Godeša, T.; Hočevar, M.; Širok, B.; Stopar, M. Real-time positioning algorithm for variable-geometry air-assisted orchard sprayer. Comput. Electron. Agric. 2013, 98, 175–182. [Google Scholar] [CrossRef]

- Khot, L.R.; Ehsani, R.; Albrigo, G.; Landers, A.J.; Larbi, P.A. Spray pattern investigation of an axial-fan airblast precision sprayer using a modified vertical patternator. Appl. Eng. Agric. 2012, 28, 647–654. [Google Scholar] [CrossRef]

- Zhai, C.; Zhao, C.; Ning, W.; John, L.; Wang, X.; Paul, W.; Zhang, H. Research progress on precision control methods of air-assisted spraying in orchards. Trans. Chin. Soc. Agric. Eng. 2018, 34, 1–15. [Google Scholar]

- Wei, Z.; Xue, X.; Salcedo, R.; Zhang, Z.; Gil, E.; Sun, Y.; Li, Q.; Shen, J.; He, Q.; Dou, Q.; et al. Key technologies for an orchard variable-rate sprayer: Current status and future prospects. Agronomy 2023, 13, 59. [Google Scholar] [CrossRef]

- Zhou, L.; Fu, X.; Ding, W.; Ding, S.; Chen, J.; Chen, Z. Design and experiment of combined disc air-assisted orchard sprayer. Trans. Chin. Soc. Agric. Eng. 2015, 31, 64–71. [Google Scholar]

| Country | R&D Organization | Sprayer Name | Test Crop | Indicator | Year | Remarks |

|---|---|---|---|---|---|---|

| Denmark | Hardi | Alpha air curtain boom sprayer | / | With adjustable air flow velocity and air flow spray angle, it can save pesticides by 30% | 2004 | Industrialized |

| United States | United States Department of Agriculture | Air-assisted sprayer with five-port nozzles | Taxus chinensis | / | 2006 | Test prototype |

| Italy | University of Bologna | Air-assisted under-leaf sprayer | Potato | Reduce ground loss by 42% | 2007 | Test prototype |

| China | Chinese Academy of Agricultural Mechanization Sciences | Large-sized air curtain boom sprayer | Corn | Increase the average utilization rate of pesticides by 144.17% | 2015 | Test prototype |

| Country | R&D Organization | Sprayer Name | Air Flow Rate Mode | Testing Site | Indicator | Year | Remarks |

|---|---|---|---|---|---|---|---|

| United States | Ohio State University/United States Department of Agriculture | Air-assisted variable rate sprayer | Constant air volume | Apple orchard | Save pesticide by 27% to 53% | 2013 [10] | Test prototype |

| Spain | Universidad de Córdoba | Orchard sprayer | Constant air volume | Olive orchard | Increase droplet coverage by 61% | 2017 [53] | Test prototype |

| China | Nanjing Agricultural University | 3WZ-300 air-assisted sprayer | Constant air volume | Y-shaped umbrella-type fruit trees | The effective adhesive rate of pesticide solution on target is 60.1% | 2021 [54] | Test prototype |

| Italy | Favaro | OVS tower sprayer | Variable air volume | / | / | / | Industrialized |

| China | China Agricultural University | Automatic profile modeling orchard sprayer | Variable air volume | Apple orchard | Average deposition amount 1.92 μL cm−2 | 2017 [55] | Test prototype |

| China | Shandong Agricultural University | Orchard sprayer with multiple air ducts | Variable air volume | Apple orchard | Increase canopy deposition amount by 17.3% | 2020 [56] | Test prototype |

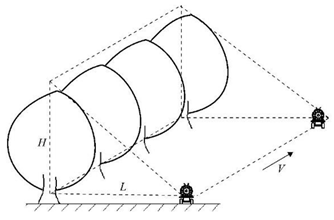

| No. | Demand Theory | Principle | Schematic Diagram | Calculation Formula | Advantages and Disadvantages |

|---|---|---|---|---|---|

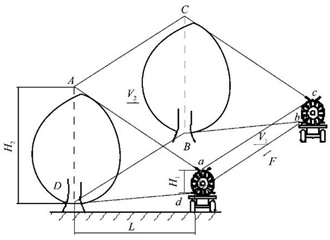

| 1 | “Displacement principle” of air flow volume for orchard sprayer | Air flows blown out by the fan of sprayer with droplets should repel and completely replace all the air contained from the front of the fan to the orchard sprayer operation space. |  | where (m3 s−1) is the air flow volume required for air-assisted spraying; is the operating velocity (m s−1) of the sprayer; H is the tree height (m); (m) is the distance between the sprayer and trees; and is a parameter determined after taking into account the attenuation of air flow and the loss along the way. The selection of value is related to air temperature, natural wind speed and natural wind direction. | Advantages: guide the research and development of sprayers and provide parameter estimation methods.Disadvantages: too many factors affect the K value, and the law of affecting this value by each factor needs to be further explored. |

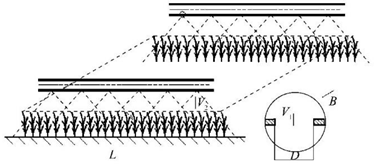

| 2 | “Displacement principle” of air flow volume demand for air curtain boom sprayer | Air flows blown out from the air duct of sprayer with droplets should repel and completely replace all the air contained below the air duct to the sprayer operation space at the bottom surface of the crop. |  | where (m3 s−1) is the air flow volume required for air curtain spraying; (m) is the height of the nozzle above the ground; L (m) is the spraying swath; is the operating velocity (m s−1) of the sprayer; and is a parameter determined after taking into account the attenuation of air flow and the loss along the way. The selection of value is related to air temperature, natural wind speed and natural wind direction. | |

| 3 | “Terminal velocity principle” of air flow velocity demand for orchard sprayer | The terminal velocity of the sprayer air flow through fruit tree canopy cannot be lower than a certain value, and an abnormally high value is unacceptable. |  | In the formula, is the terminal velocity (m s−1) of air flow through the canopy; is the air flow velocity (m s−1) at the fan outlet; is the vertical height (m) of the fan; is the tree height (m); and is the parameter determined after taking into account the attenuation of air flow and the loss of air flow along the way. The value of is selected according to meteorological condi-tions, crop varieties and branch and leaf den-sities. | Advantages: this principle specifies the basic requirements for the terminal velocity of air flow through the canopy (for orchard sprayer) and the head velocity of air flow at the crop and provides the estimation method. Disadvantages: the terminal velocity is affected by many factors. We need to further study the characteristics and calculation methods of air flow losses in the air and fruit tree canopy. |

| 4 | “Terminal velocity principle” of air flow velocity demand for air curtain boom sprayer | It refers to the air flow velocity when the sprayer air flow reaches the crop top. |  | In the formula, (m s−1) is air flow velocity at the crop top; is the air outlet number of air duct; is the area (m2) of a single air outlet of air duct; is the air flow velocity (m s−1) at the air outlet of air duct; (m) is the spraying swath; and (m s−1) is the operating velocity of the sprayer. |

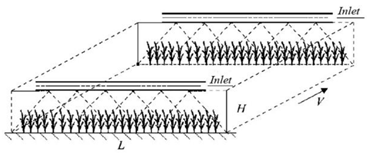

| No. | Name of Crop Canopy Model | Principle | Schematic Diagram of Model | Advantages and Disadvantages | Model Indicator |

|---|---|---|---|---|---|

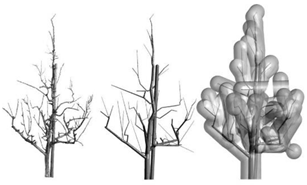

| 1 | Equivalent model with the real main canopy body and porous media as the branches and leaves in some parts [69,70] | The main canopy body Is constructed using the measured test data and the branches and leaves in some parts are simplified and characterized by porous media. |  | Advantages: ensure a high similarity with the actual canopy. Disadvantages: complex model, difficult modeling, complex simulation and calculation process, and low simulation efficiency. | The average relative error of peak air flow velocity predicted by the model is less than 11.04%. |

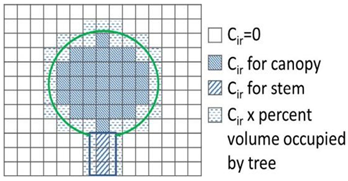

| 2 | Equivalent simplified model with porous media as the whole canopy [71,72] | The whole canopy is simplified and characterized using porous media, leaves and branches are simulated using a sphere and the stem is simulated using a cylinder. |  | Advantages: reduced the difficulty of modeling, simplified the simulation and calculation process and improved the efficiency of simulation. Disadvantages: ignored the reality of uneven distribution of branches and leaves in the canopy and resulted in a big difference with the actual crop canopy. | The average relative error of peak air flow velocity predicted by the model is 29.2%. |

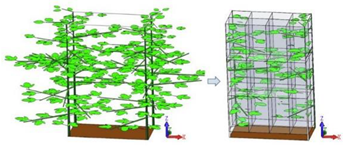

| 3 | Layered and partitioned equivalent model of adjacent canopies [73,74] | Based on the characteristics of crop growth and the spatial distribution of branches and leaves, a canopy 3D model containing canopy structure parameters such as leaf area, density and porosity is quantitatively constructed, and the target area surrounded by adjacent canopy is characterized by porous media after being layered and partitioned. |  | Advantages: it can provide quantitative canopy structure data, such as leaf area, density and porosity. Disadvantages: crop growth and distribution of branches and leaves are affected by many factors, and the model precision needs to be improved. | The mean normalized mean absolute errors (NMAEs) of the lower, middle, and upper layers are 17.38%, 21.35% and 9.75%, respectively. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wei, Z.; Li, R.; Xue, X.; Sun, Y.; Zhang, S.; Li, Q.; Chang, C.; Zhang, Z.; Sun, Y.; Dou, Q. Research Status, Methods and Prospects of Air-Assisted Spray Technology. Agronomy 2023, 13, 1407. https://doi.org/10.3390/agronomy13051407

Wei Z, Li R, Xue X, Sun Y, Zhang S, Li Q, Chang C, Zhang Z, Sun Y, Dou Q. Research Status, Methods and Prospects of Air-Assisted Spray Technology. Agronomy. 2023; 13(5):1407. https://doi.org/10.3390/agronomy13051407

Chicago/Turabian StyleWei, Zhiming, Rui Li, Xinyu Xue, Yitian Sun, Songchao Zhang, Qinglong Li, Chun Chang, Zhihong Zhang, Yongjia Sun, and Qingqing Dou. 2023. "Research Status, Methods and Prospects of Air-Assisted Spray Technology" Agronomy 13, no. 5: 1407. https://doi.org/10.3390/agronomy13051407

APA StyleWei, Z., Li, R., Xue, X., Sun, Y., Zhang, S., Li, Q., Chang, C., Zhang, Z., Sun, Y., & Dou, Q. (2023). Research Status, Methods and Prospects of Air-Assisted Spray Technology. Agronomy, 13(5), 1407. https://doi.org/10.3390/agronomy13051407