1. Introduction

Conservation tillage, an advanced agricultural tillage method, including less tillage and no-tillage, aims to reduce soil and water erosion, increase soil organic matter, improve soil structure, save production costs, and achieve sustainability of crop production [

1,

2,

3,

4]. Over the past decades, conservation tillage, thus, has been developed rapidly and adopted widely for many crops all over the world. However, challenges in dealing with excessive residue remain, especially for the intensive rice–wheat rotation system.

In the intensive rice–wheat rotation system conducted in East-China, high-yield agriculture leads to a larger number of residues left in the field after harvesting, which is detrimental to seeding operations, seed germination, and early plant growth [

5,

6]. The time for seedbed preparation in the transition period between crops is also very short, and it is based on the limited annual sunshine duration in the intensive rice–wheat rotation area [

7]. Excessive residues in the field cause poor performance of soil-engaging tools, which affects the timely planting of the next crop [

8]. Therefore, agricultural producers have been seeking well adapted and high-performance tillage tools to deal with the problems of excessive crop residues for no-tillage seeding operations [

9].

Numerous types of soil-engaging tools are in use for conservation tillage, such as disc, hoe, chisel, and sweep for developing seed furrow and handling crop residues [

10,

11]. For dense residues cover conditions, the conventional soil-engaging tools for conservation tillage are various rotary tools (e.g., vertical discs and disc coulters) [

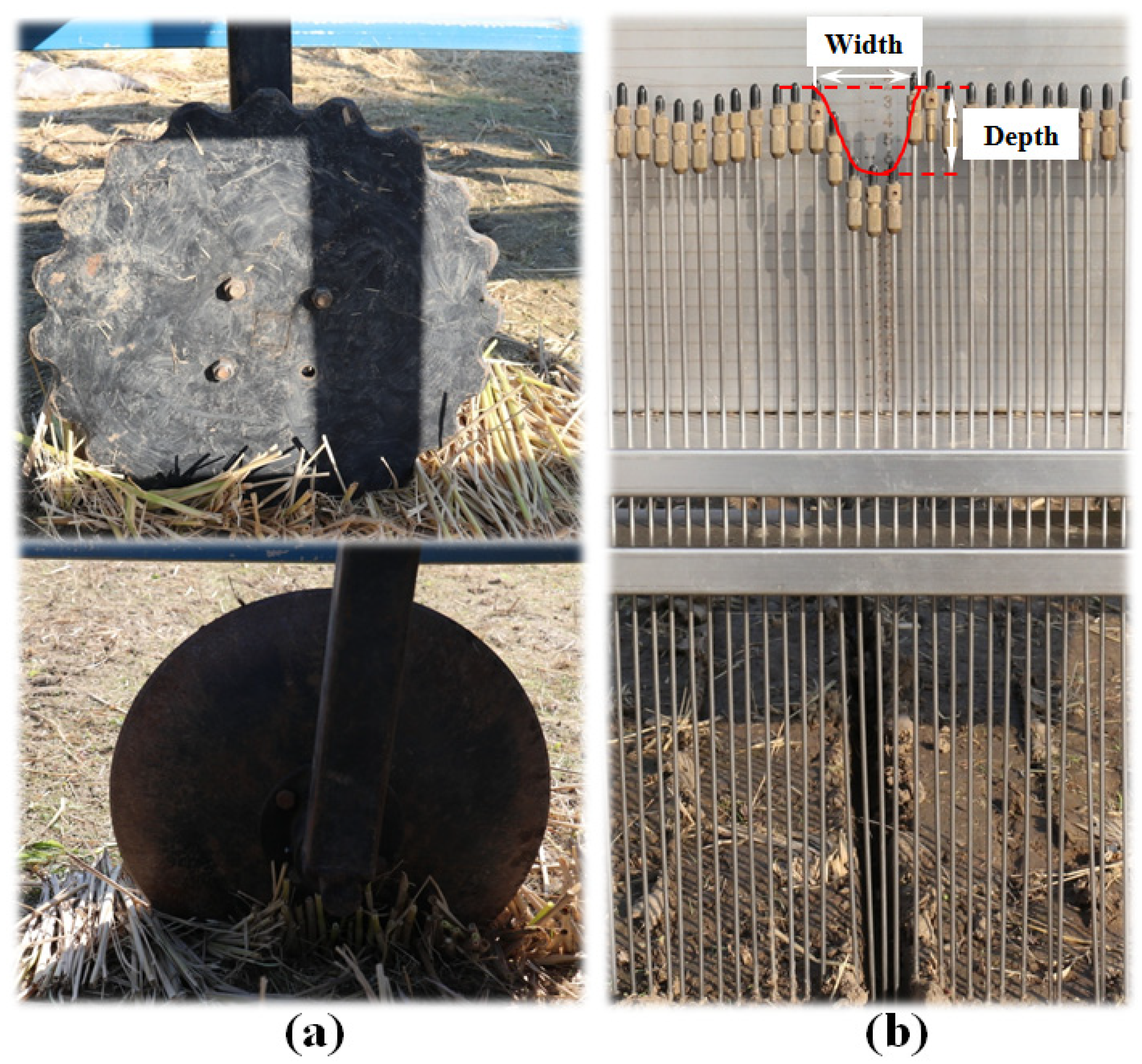

9]. Each rotary tool can be classified by its geometry, such as plain-type, notched-type, and rippled-type [

12]. Traditionally, vertical discs and disc coulters were on no-tillage planters as seed openers and straw-cutting tools [

12]. During the operation of the planter, the rotary tools were used to cut the crop residue on the ground and develop furrow for seed placement [

12]. The ultimate goal is to provide favorable field conditions for sowing operation and crop growth in an efficient manner [

9]. However, tillage performances may be affected by different geometries of rotary tools and their operational parameters.

In the past few decades, numerous studies have been carried out to evaluate the effects of the geometrical and operational parameters of the rotary tools used for conservation tillage on tillage performance [

13,

14,

15,

16]. For example, soil tillage forces and straw cutting efficiency were significantly affected by the double disc diameter and working depth [

8]; soil disturbance area and soil cutting force increased with the increase in disc diameter from 457 to 559 mm [

9]. Compared with the eight-wave coulter, the soil disturbance width of the 13-wave coulter decreased by 17% [

17]. A biomimetic disc, mimicking the mole rat’s claw, can achieve 21.4% reduction in vertical resistance and 28.7% reduction in draught forces, as compared with the notched disc [

18]. The working depth had a significant impact on the performance of the disc, and the deep tillage depth resulted in 5.1% higher residue mixing, 53.4% greater soil cutting forces, and 34.9% larger soil displacements, as compared to the shallow tillage depth [

19]. Overall, previous studies have shown that the tillage performance was affected by the geometrical parameters (disc diameter, tool shape, cutting edge design, etc.), as well as operational parameters (working depth, working speed, residue conditions, etc.). Several indicators, including soil cutting forces [

20], soil disturbance [

21], straw cutting efficiency [

8], residue incorporation [

22,

23], as well as fuel consumption efficiency [

24], have also been suggested to assess the tillage performance.

Despite a large number of previous studies, a better understanding of the relationships existing between tillage performance and soil-engaging tools has not been elucidated, especially when excessive residues are left in the field after harvesting in intensive rice–wheat rotation systems. Most studies to date have been based on a single type of tool to explore its performance, and the comparison between different types of tools (such as vertical discs and disc coulters) was lacking. Earlier studies of residue cutting evaluation focused on the planting mode of one crop per-year, which is different from the intensive rice–wheat rotation system with excessive crop residues left of two crops per-year [

9,

17]. Thus, more tests on different types of rotary tools for conservation tillage in this area are still need to be carried out. Moreover, previous studies were mostly conducted in an indoor soil bin. Although the use of soil bin test could significantly save time and cost, it is still different from the actual field conditions. Indoor remolded soil significantly differs from the field soil, and the indoor straw conditions are different from the real field environment. Thus, more detailed field test data of performance evaluation of rotary tools for conservation tillage are also required.

The accurate field test data on the tillage performance and its affecting factors of rotary tools for conservation tillage are lacking in intensive rice–wheat rotation system. Therefore, our study investigated the tillage performance of rotary tools for conservation tillage in intensive rice–wheat rotation system under actual field conditions using a specific field test rig. The specific objectives include: (i) to evaluate the performance of five typical rotary tools for conservation tillage in terms of soil tillage forces, soil disturbance, and straw cutting, as well as (ii) to investigate the effects of working depth of vertical discs and disc coulters on tillage performance.

4. Discussion

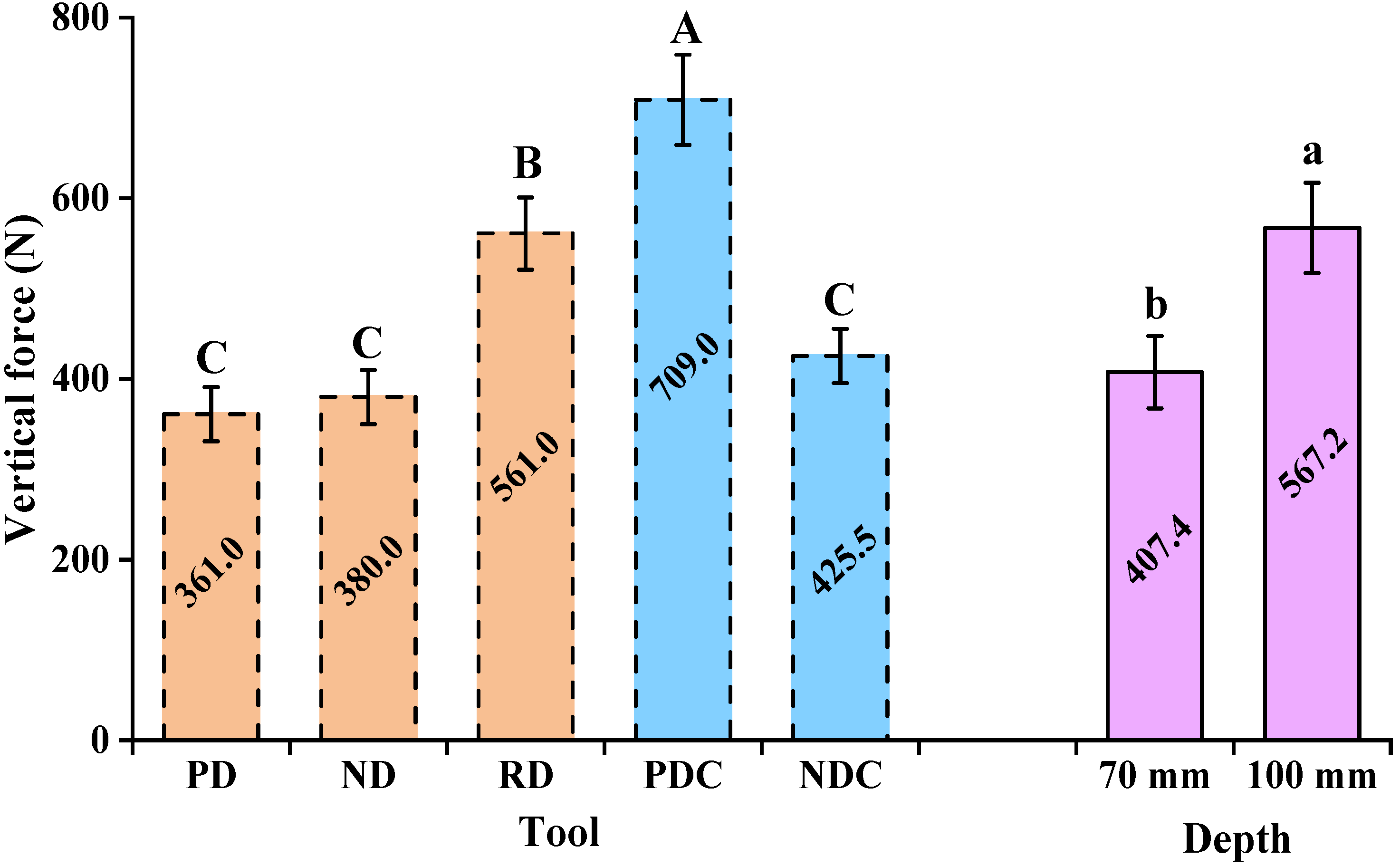

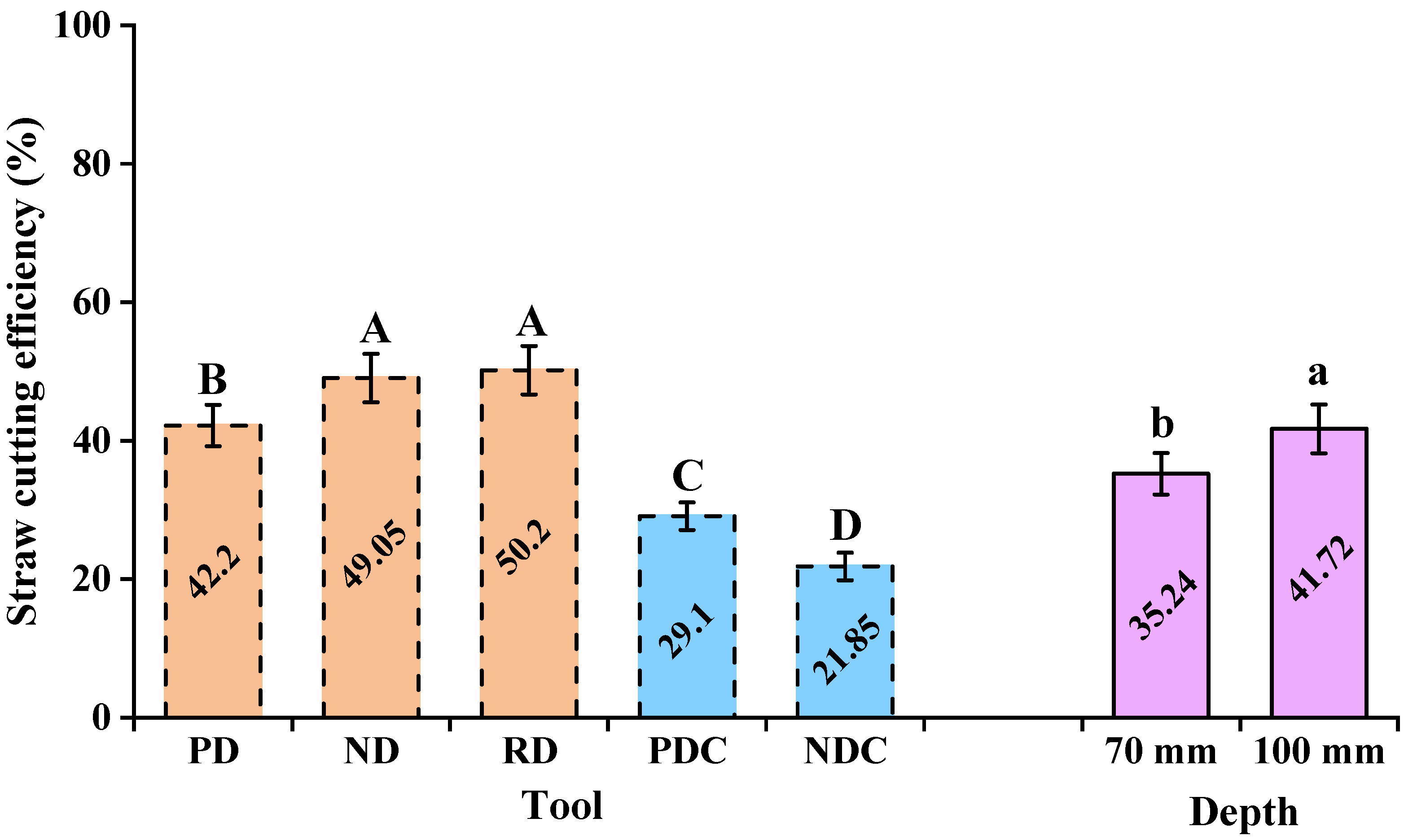

Although not all performance evaluation indicators of five tillage tools had significant differences, the overall results showed that the geometrical parameters (such as number of teeth and width) and operational parameters (such as working depth) of disc tools for conservation tillage have an essential impact on tillage forces, straw cutting efficiency, soil disturbance width, and soil cutting depth. The vertical disc performed with a higher straw cutting efficiency, as well as lower tillage forces and soil disturbance width, than the disc coulter. The effect of working depth also performed an essential role in the tillage performance.

Comparing the force data with the vertical discs, the disc coulters required a higher draught force and vertical force. The average draught and vertical forces of the disc coulters were 44% and 31% higher than that of the vertical discs, respectively. This study results agreed with previous studies. Zeng and Chen [

9] also found that that the fluted coulters had a 73% higher draft force than the rippled discs, on average. Typically, a wider tool creates a larger furrow, which would cause more soil disturbance, and this results in requiring a greater tillage force [

9]. Apart from the RD, the two other vertical discs produced less draught and vertical forces than the disc coulters, and they should be a better choice for conservation practices requiring less soil disturbance. It was interesting to note that tools with higher draught forces also had high vertical forces, which was also found in a previous study [

31]. The draught force and vertical force were associated with the contact area between the soil and tools, and the resistance increased with the increase in the contact area. The concavity of disc coulters and the waves of RD lead to a larger contact area, which resulted in higher tillage forces. The average vertical and draught forces required by one single tool range from 361 to 709 N and 261.5 to 531 N, respectively, which can be represented by the fact that vertical force was greater than draught force. This difference between vertical force and draught force may be related to contact area, soil conditions, straw status, as well as working parameters. This study also found that the tillage forces averaged across all five tools increased with the increase in working depth, which was similar to a previous study [

19].

In terms of the rice residue handling, the rotary tools for conservation tillage were considered effective because the average straw cutting efficiency after tillage ranged from 21.85% to 50.2%. Similar residue cutting findings have been illustrated for conservation tillage in other crop residues, such as corn straw [

32,

33]. These results supported vertical discs, and disc coulters were effective residue cutting tools for conservation tillage. However, the straw cutting efficiency of different tools was significantly different, and the RD had the highest straw cutting efficiency. Zeng et al. [

19] also found that the rippled disc was very aggressive in cutting residues, which resulted in less residue on the surface. Therefore, in terms of excessive residue, this phenomenon can result in poor seed placement, and it can slow seed germination [

5,

6]. The RD may be the most effective tool for conservation tillage practice in the intensive rice–wheat rotation system.

It was easy to conclude that the soil disturbance width increased with the working width of the tools. According to the ASABE standard, S477.1 [

12], the disc coulters were regarded as wide tools, which indicated that they had wider soil disturbance than that of the vertical discs. In narrow disc tools, the RD had a significantly larger soil disturbance width as compared to PD and ND, which was attributed to its wider rippled cutting edge. Therefore, RD may be a compromise solution for no-tillage planters that require a certain furrow width for seed placement and less soil disturbance. The soil cutting depth results indicated that, under a working depth of 70 and 100 mm, the actual soil cutting depth of all five tillage tools was close to the working depth. However, the soil cutting depth of disc coulters was lower than that of vertical discs. This may be due to the lower straw cutting efficiency of disc coulters, resulting in excessive residue blocking the tool edge from cutting the soil downward. A controllable soil cutting depth would lead to a seedbed with consistent depth, which could be conducive to seeding operation and crop growth. In addition, a 100 mm working depth created a deeper soil cultivation layer, which can also reduce soil bulk density, improve water storage capacity, promote crop root growth, and increase crop yield [

25].

For all five tools, compared to 70 mm depth, the 100 mm depth resulted in 40% higher draught force, 39% greater vertical force, and 18% higher straw cutting efficiency on average. Increasing the working depth from 70 mm to 100 mm resulted in a significantly increased portion of the tool in contact with soil, regardless of the disc type. The draught force increased with the increase in the contact area between the soil and the tool, according to the soil dynamics theory [

34]. A deeper operation also requires greater vertical force to favor penetration into the soil. For all discs and coulters, the deeper working depth had a higher straw cutting efficiency than the shallow depth. This may be attributed to the fact that higher tillage forces from a deeper working depth are more conducive to cutting the straw.

The information obtained in this study is of great significance to the design and use of disc tools for conservation tillage in intensive rice–wheat rotary systems. The results not only strengthen the universal view on the purpose of different rotary tools, but they also quantify the differences in the performance of the vertical discs and disc coulters based on a paddy field with plenty of crop residues. In terms of straw cutting, RD was the most aggressive for residue handling among five tools. As a rotary tool with a larger working width, the disc coulters achieved greater soil disturbance. Similar to varying the geometrical parameters of rotary tools, varying working depth for conservation tillage will also have an essential impact on tillage performance. Therefore, it is necessary to select appropriate tillage tools and their operational parameters according to the specific requirements for conservation tillage practice in intensive rice–wheat rotary systems.